Improving Particle-Burning Efficiency of Pulverized Coal in New Inclined Jet Burners

Abstract

This paper shows an investigation of pulverized coal in new inclined jet burners for improving particle-burning efficiency through parameter adjustment. The research focuses on the interaction between two oblique jet methane (CH4)/air premixed flame burners and a coal particle jet feeder on an impinging burner. Various parameters such as CH4/air ratios, gas fuel flow rates, deflection angles, and coal dust feed speeds are systematically examined. The findings of the study reveal the establishment of distinct flow field structures, characterized by collision and recirculation zones, upon the interaction of jets. Momentum transfer in the upstream airflow creates a preheating zone, fostering fuel–air mixing. Within these recirculation zones, coal particles undergo pyrolysis facilitated by temperature gradients, resulting in increased volatile output that promotes downstream combustion. Additionally, coal particles traversing recirculation zones with higher vorticity and elevated temperature regions tend to undergo early fragmentation and combustion of volatile components upon exiting these zones. This study underscores the intricate interplay of parameters in optimizing coal combustion efficiency and highlights avenues for further research and practical application. Observations indicate enhanced burner performance with increased CH4/air ratios and central flow speeds. The study identifies a correlation between the deflection angle and particle reduction rate, which increases from 63.5% to 64.7% with an increase in the deflection angle. The reduction rate ranges from 59.7% to 67.8% with a transition from fuel-rich to fuel-lean conditions. As velocity increases from 0.6 to 1.2 m/s, the particle reduction rate escalates from 57.5% to 74.5%.

1. Introduction

Coal holds a prominent position in the energy landscape and climate discussions because it serves as the primary energy source for worldwide power generation, steel and cement production, while also being a major contributor to carbon dioxide (CO2) emissions. There have been numerous studies on coal particle combustion addressing various issues. Gvozdyakov, Zenkov, and Kuznetsov [1] aimed to evaluate the effectiveness of incorporating isopropyl alcohol into coal–water fuels by experimentally measuring the ignition delay times of single droplets across a wide temperature range. The combustion of coal releases substantial quantities of pollutants, including CO2, nitrogen oxides (NOx), sulfur dioxide, heavy metals, and particulate matter [2–4]. Jia et al. [5] investigated the co-combustion of carbon-rich fractions from coal gasification fine slag and corn straw char. Findings highlight enhanced combustibility of the carbon-rich fraction with corn straw char, mineral composition of the ash, and environmental implications of co-combustion processes. Li et al. [6] invesigated combustion behavior of coal pelletts blended with biochar, observing significant changes in the ignition delay and burnout temperature of the blended fuels. In addition, the combustion of coal with new fuel alternatives, such as iron particles [7] and ammonia [8], has also been studied recently to mitigate carbon emissions. Lei, Sun, and Zhang [9] examined how high-pressure conditions affect coal char’s properties during pyrolysis and the transformation of coal ash minerals during combustion with O2/N2 and O2/CO2 mixtures. Key findings include enhanced decomposition of aromatic structures under higher pressures and significant influence of temperature on ash mineral transformations compared to pressure effects. Li et al. [10] focused on establishing a numerical model for a tower boiler burning low calorific value and high-alkali coal. It investigates the impact of air velocity and air volume flow on combustion efficiency and NOx emissions, emphasizing the importance of separated overfire air (SOFA).

Pulverized coal refers to a fine powder fuel obtained by grinding, grading, and screening coal through various processes. Pulverized coal is commonly used as a boiler fuel in industrial and power generation industries and can be used on different combustion equipment such as gas boilers and oil boilers. During combustion, powdered coal can release high calorific value thermal energy and emit gases such as CO2, NOx, and sulfur oxides. The principle of powdered coal combustion technology is to mix coal powder with air to form a mixture of coal powder and air, which is then introduced into the combustion chamber for combustion. Lu et al. [11] studied the effect of the fineness range of powdered coal of 50–200 μm on its flow pattern and flow characteristics in pipes. The results showed that the fineness of pulverized coal had a significant impact on its flow pattern and flow characteristics in pipes, with small fineness pulverized coal more likely to form dense flow and large fineness powdered coal more likely to form sparse flow. Tsuda et al. [12] showed that the Reynolds number and Stokes number in fluid mechanics can be used to describe the motion of particles in fluid media, the effect of particle surface shape and particle size on their motion and sedimentation behavior in fluid media and discussed the particle motion behavior under different flow patterns and can be used to classify sedimentation behavior. Fine powders often behave more like fluids than coarse powders when subjected to forced flow. Hsu et al. [13] focused on the impact of pulverized coal injection (PCI) techniques in the blast furnace ironmaking process, emphasizing the reduction of energy consumption and CO2 emissions. It explores optimal solid–gas ratios (SGRs) and oxygen enrichment strategies using a lance–blowpipe–tuyere–raceway model. The research highlights improvements in coal burnout rates and furnace permeability, particularly under conditions of high SGR conveying during oxy-coal injection.

Three regions are displayed during the coal ignition: heterogeneous ignition, homogeneous ignition, and combined heterogeneous ignition, with the latter dominating in all particle sizes at sufficiently high heating rates (>103°C/s). Homogeneous and heterogeneous ignition are two different ways of ignition during coal particle combustion. Homogeneous ignition occurs when fuel and oxygen are fully mixed, while heterogeneous ignition occurs when fuel and oxygen are not fully mixed. Both types of ignitions can occur during coal particle combustion, and their interactions have important effects on the combustion process and products.

The particle combustion process is an important part of pulverized coal combustion. Therefore, the combustion stages of coal must be considered as an important step [14–17], which includes heating, devolatilization, volatile combustion, and char combustion. During combustion, the volatile matter (VM) in solid pulverized coal is released and burned. Coal particles undergo devolatilization first, with volatile substances reacting homogeneously with reaction gases [18], and char reacting heterogeneously with reaction gases. During coal devolatilization, organic substances are heated and vaporized into gases and liquid fuels such as water, methane (CH4), and ethane. When volatile substances are generated, the physical structure of the char also changes, with particles expanding to form a pore structure.

The structure of the char is highly complex, as it is highly heterogeneous not only within particles but also between particles. According to Kang et al. [19, 20] and Helble and Sarofim[21], the chemical properties of char are greatly influenced by coal characteristics such as pressure and heating rate, but temperature mainly affects its structure. Char fragmentation is an important phenomenon in the pulverized coal combustion process, which has a significant effect on ash formation and transformation efficiency [22–24]. Fragmentation can reduce the initial particle mass of coal dust by about 20%–30% [23, 25], thus reducing the burning time of coal particles. In addition, different mineral components can produce different types of char structures. Therefore, due to the different particle compositions of coal, the combustion and gasification behaviors of coal differ significantly in different coals. Understanding the structure of the char is very important, as it can strongly influence subsequent char reactions and ash formation [23, 25, 26].

During the high-temperature combustion of coal particles, pyrolysis takes place, necessitating the creation of a heated environment through the initial ignition process that burns other gaseous or liquid fuels to maintain the heat-release process [27]. Pyrolysis or carbonization is a primary way to convert low-grade coal into high-grade fuels and chemicals that are economically transportable and usable. Pyrolysis is a common stage in many coal utilization processes [14, 28, 29], such as carbonization, gasification, combustion, and liquefaction, which typically operate in close systems under inert, reducing, or oxidizing atmospheres at different pressures and residence times. The pyrolysis process is a critical step before the combustion of powdered coal, during which coal decomposes at high temperatures and releases many volatile molecules, including gases, liquids, and solids.

The pyrolysis process affects powdered coal in several ways, including the generation and release of volatile molecules [30], changes in porosity and surface area [31], and changes in the coal’s pyrolysis characteristics, such as pyrolysis rate [32], pyrolysis temperature, and pyrolysis products. The relationship between the functional groups attached to coal macromolecules and the production of volatile products such as CH4, hydrogen (H2), carbon monoxide (CO), and CO2 during coal pyrolysis is an important but perplexing issue in Solomon et al. [33] pointed out the relationship between the substituents on the aromatic ring and the volatile products, such as in the primary pyrolysis process, where methyl can not only be stripped off and terminated by H2 radicals to form CH4 at high temperatures.

Therefore, this study seeks to address the drawbacks of coal burning [34–37]. By investigating varying gas fuel flow rates, equivalence ratios, gas fuel inlet angles, and coal dust flow rates, we aim to modify the flow field structure upstream of the combustion chamber, thereby increasing the initial temperature of the coal dust before combustion and prolonging its residence time upstream.

As global energy demands escalate [38, 39], the imperative to enhance coal particle-burning efficiency intensifies, aiming for a reliable energy supply while mitigating environmental impact. Factors such as gas flow rate, burner angle, equivalence ratio, central flow channel feed rate, and recirculation zone properties significantly influence efficiency. However, uncertainties persist, particularly regarding the impact of vorticity strength on temperature distribution and coal volatility under high vorticity conditions. This research addresses these critical gaps, motivated by the overarching goal of improving coal particle-burning efficiency for sustainable energy production.

This study differs from previous research by (i) innovatively exploring the impact of upstream flow-field structure modifications on coal particle combustion efficiency, rather than focusing solely on combustion additives or high-pressure pyrolysis conditions. (ii) Additionally, unlike prior studies on coal powder flow characteristics or PCI in blast furnaces, this research introduces a novel approach that combines oblique CH4/air flames with a coal dust jet feeder. Using advanced experimental techniques, it analyzes flame-flow interactions to enhance combustion efficiency and reduce environmental impacts.

To achieve this, the research employs a multifaceted methodology, investigating the intricate relationship between combustion efficiency and key parameters such as premixed gas flow speed, burner angle, and temperature distribution. Emphasizing the need for cleaner combustion, the study proposes a novel method utilizing oblique CH4/air flames and a coal dust jet feeder. Through a comprehensive suite of experimental techniques, including particle image velocimetry (PIV) and gas analysis, the research scrutinizes burner design, gas composition, and flame-flow interactions. Critical metrics such as residual coal reduction and recirculation zone formation are used to assess efficiency. By optimizing flow-field structures to improve mixing, the study aims to provide empirical evidence for achieving cleaner and more efficient combustion, contributing to technological advancements and environmental sustainability in energy production.

2. Methodology

2.1. Description of Coal Properties and Inclined Jet Burner

In the coal combustion process, moisture in coal evaporates as it heats up, followed by pyrolytic reactions releasing volatile gases. These gases react with oxygen, forming a stable flame. We focus on the early, predominantly homogeneous combustion stages, leading to volatile gas release. Subsequently, heterogeneous chemical reactions dominate. Our study aims to promote early coal volatilization for enhanced combustion efficiency [40]. We used coal dust (particle size: 74–94 µm) for combustion experiments. Thermogravimetric analysis (TGA) and differential thermogravimetric (DTG) analysis were employed to analyze mass changes during heating.

TGA is a technique that measures the weight changes of a material as it is heated or cooled. TGA curves revealed moisture, volatiles, and fixed carbon (FC) losses. DTG is a derivative of TGA that measures the rate of weight change as a function of temperature. DTG curves indicated peak pyrolysis rates for volatile release and areas of FC oxidation. Huang et al. [41] performed proximate and elemental analyses of Australian coal, measuring heat energy with a calorimeter. Proximate analysis covered FC, volatiles, moisture, and ash, while elemental analysis assessed carbon, H2, oxygen, nitrogen, and sulfur content. These data contribute to understanding coal properties, including calorific value and temperature distribution [42, 43]. Table 1 shows the chemical and physical characteristics of the coal dust used in this study and the properties of pulverized coal.

| (a) Parameters | Australian coal | |

|---|---|---|

| Proximate analysis (wt.%) | ||

| Moisture (M) | 1.31 | |

| Volatile matter (VM) | 33.49 | |

| Fixed carbon (FC) | 46.32 | |

| Ash | 18.88 | |

| Ultimate analysis | ||

| C | 73.30 | |

| H | 4.17 | |

| O | 5.25 | |

| N | 1.14 | |

| S | 0.52 | |

| Atomic ratio | ||

| H/C | 0.057 | |

| O/C | 0.072 | |

| Calorific value (kcal/kg) | ||

| — | 6,253 | |

| (b) Material | Size (μm) | Shape |

| Pulverized coal | 74–94 | Irregular |

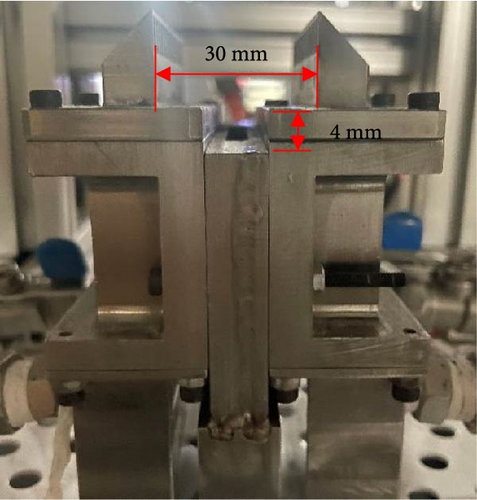

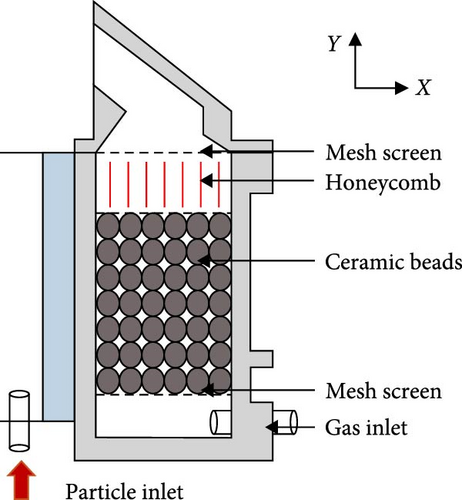

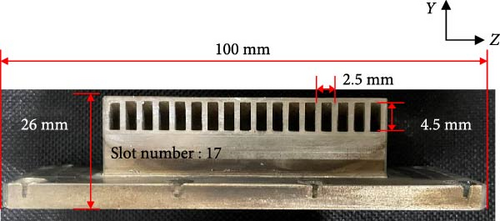

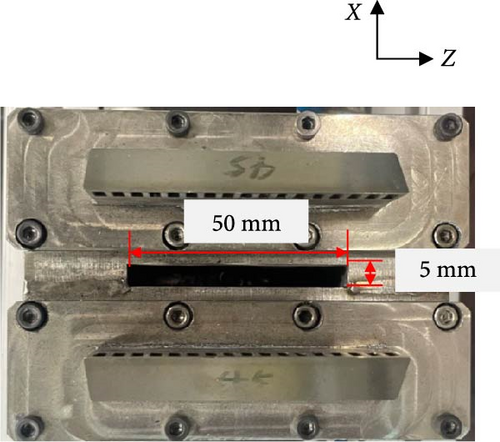

This research presents the design and key specifications of an oblique pressure flame burner. The burner comprises two independent slot components, each with a predetermined deflection angle (Figure 1a). Its internal structure is revealed in the cross-sectional diagram (Figure 1b). Within the oblique jet flame burner, there is a larger slot burner, measuring 10 mm in width, 100 mm in length, and 115 mm in height, providing ample space for efficient combustion. The burner outlet features 17 precisely drilled slot holes, each measuring 2.4 mm by 4.5 mm (Figure 1c), strategically designed to ensure uniform fuel distribution and effective flame propagation. The top view (Figure 1d) highlights an outlet size of 5 mm wide by 50 mm long for coal particle conveyance.

2.2. Experimental Apparatus and Measurement Systems

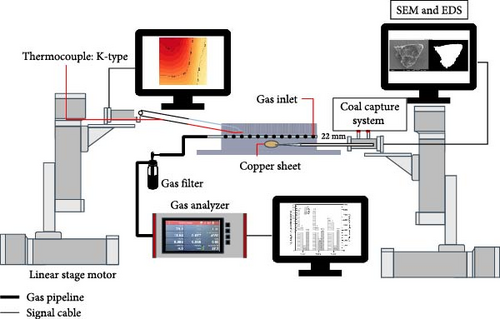

As shown in Figure 2a, the PIV experiment used a Nd-YAG laser, model Solo III. The laser beam generated by this laser forms a light sheet after passing through a cylindrical lens, then transmits the pulsed laser to the reaction zone in the burner. At the same time, we inject alumni (Al2O3) particles with a diameter of 10 µm into the flame. These tiny particles can scatter the passing laser light sheet, and this scattered light is collected on a charge-coupled device (CCD) camera. The bright light of the laser also illuminates these alumina particles, allowing them to be clearly captured by the camera. A dual-image mode was used in the CCD, obtaining paired images at short intervals of 610 μs. All setups are synchronized by a pulse generator. Finally, the data are analyzed by software from PIVview (PIVTEC GmbH, Germany) [44].

This research focuses on assessing the impact of particle size and distribution on the combustion efficiency of pulverized coal. A scanning electron microscope (SEM), model JSM-7001F by JEOL, Japan, as shown in Figure 2b, was employed for precise coal particle analysis and elemental identification. Additionally, a linear motion controller (EZ Limo, model PAB-S4S3R015, Oriental Moter Co., Ltd., Japan) played a crucial role in regulating gas and the spray device, enabling adjustments to flame heights during the experiments. To investigate the effects of pyrolysis in the recirculation zone on pulverized coal, four strategically placed sampling points within the burner and recirculation zones were used.

This study focuses on the combustion process of pulverized coal, particularly the initial pyrolysis stage that generates valuable volatiles like CO, H2, and CH4. A synthetic gas analyzer (Vario Luxx, MRU gas analyzer, USA) with a cotton filter at the intake was employed for emissions monitoring. As pulverized coal enters the recirculation zone upstream of the burner, it undergoes pyrolysis, releasing these volatiles, which serve dual purposes. First, they enhance combustion efficiency and flame stability by acting as premixed fuel and reducing environmental risks like flashover and explosion. Second, they aid emission control by utilizing pyrolysis-generated CO and other combustible gases for preliminary combustion, effectively reducing CO emissions from the burner, thus benefiting environmental protection. Understanding the gas distribution in the recirculation zone’s pyrolysis process is crucial for optimizing combustion efficiency, flame stability, and emission reduction.

In this study, precise temperature measurement in the upstream recirculation zone of the burner was achieved using a K-type thermocouple with a data logger (NI-USB-TC-01) known for its high-temperature accuracy and stability, with a maximum sampling rate of four samples per second. The measuring uncertainty of the K-type thermocouple is much less than 1%. A linear motion controller (EZ Limo, PAB-S4S3R015) was utilized to gather extensive temperature distribution data. This controller enabled multi-point temperature measurements every 2 mm within the burner area (x = 14 mm, y = 14 mm), totaling 64 measurement points. This approach yielded detailed temperature distribution information under varying parameters. Figure 2b illustrates the system layout and measurement process, providing essential data for a deeper comprehension and analysis of the combustion process.

3. Combustion Characteristics

3.1. Flame Appearance and Mechanism

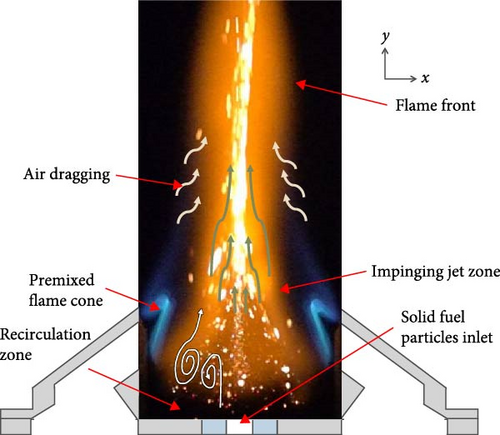

In this study, we investigated the flame mechanism of a specially designed slot burner, particularly focusing on the recirculation region upstream of the burner, a concept supported by various previous studies [45–47]. Figure 3 shows the flame mechanism for this study. This unique burner design incorporates specific deflection angles and nozzles with the primary aim of creating a preheating and mixing environment upstream of the burner. The objective is to enhance combustion efficiency while minimizing the production of incomplete combustion products. The burner design strategically ensures even distribution of combustion gas within the combustion chamber by utilizing the interaction of the jet with the surrounding air.

As combustion gases pass through the burner’s outlet nozzle, they form a robust recirculation zone upstream of the burner. This zone facilitates the mixing of combustion gases with surrounding air, effectively preheating the gases. The preheating and mixing processes in the upstream recirculation zone are crucial for efficient coal dust combustion. This zone facilitates heat transfer, thorough mixing with combustion gases, and ideal conditions for complete combustion, ensuring sufficient oxygen participation. The slot burner design enhances combustion efficiency and flame stability.

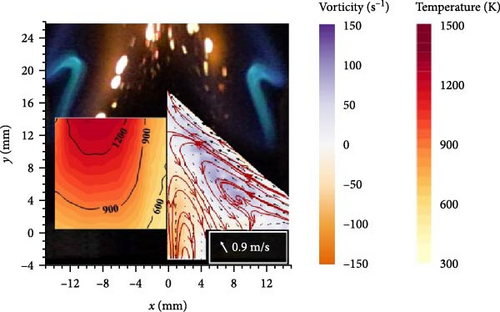

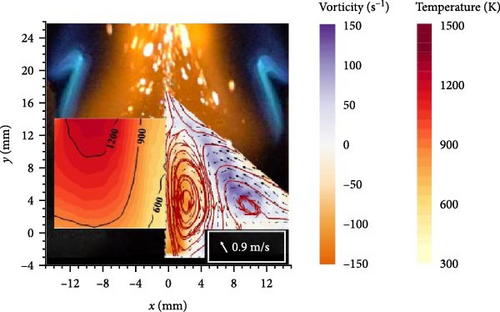

3.2. Flow Structure and Vorticity

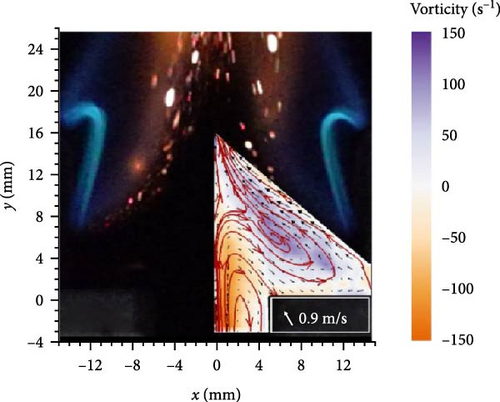

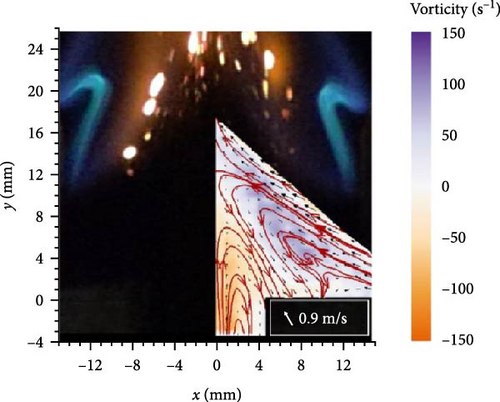

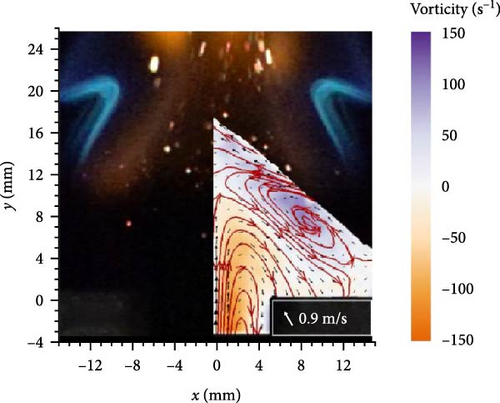

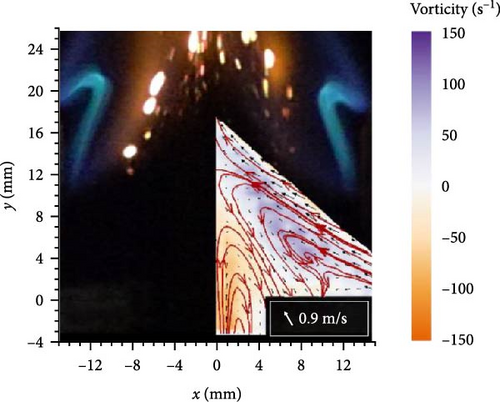

Vorticity encapsulates fluid rotation’s magnitude and direction. In these recirculation zones, we often encounter significant shear flows and large-scale vortices, influencing the mixing of coal and oxidant, and, subsequently, combustion reactions. This research employs PIV and vorticity map analysis to uncover flow characteristics, enhancing our understanding of combustion complexities. The study investigates various conditions, including different angles, equivalence ratios, coal/air feed flow rates, and gas fuel flow rates, yielding comprehensive flow visualizations for each flame configuration combination.

In this experiment, the PIV measurements were taken as the average of 200, 400, and 600 image pairs to obtain velocity vectors. The maximum averaged velocities obtained were 0.365 m/s for 200 image pairs, 0.343 m/s for 400 image pairs, and 0.346 m/s for 600 image pairs. The deviation between 200 pairs and 600 pairs velocities was approximately 5.5%, while the deviation between 400 pairs and 600 pairs was down to 0.87%. These findings suggested consistency in the measurement results while the image pairs number is more than 400 pairs, indicating a stable trend in the measured velocities. To determine the flow structure upstream of the proposed burner, PIV was used to gauge the vorticity field distribution at different angles, equivalence ratios, pulverized coal/air feed flow rates, and gas fuel flow rates. Each PIV result was taken as the average of 800 image pairs, showing flow visualization corresponding to the flame configuration combination.

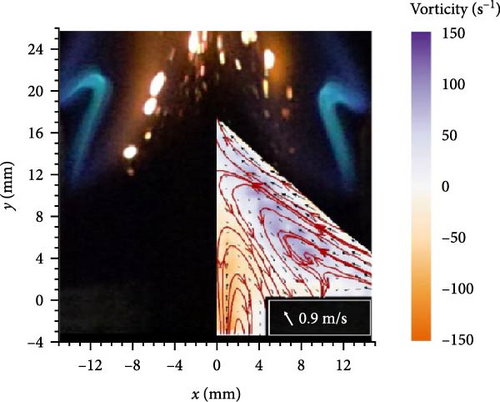

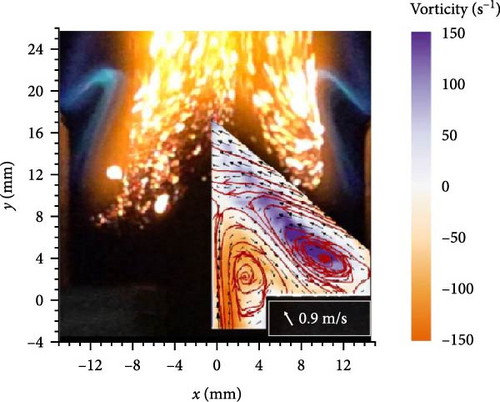

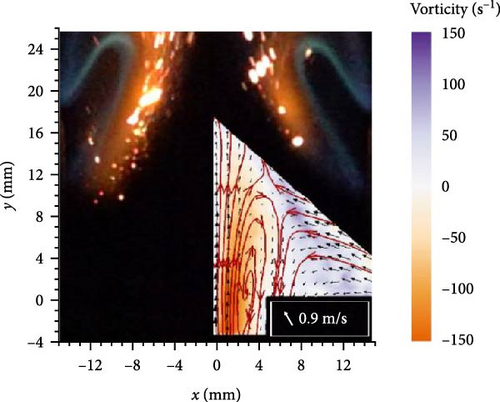

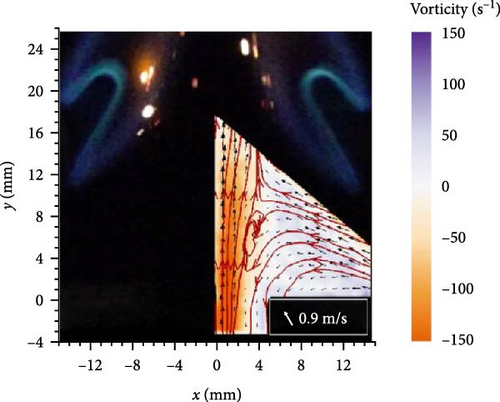

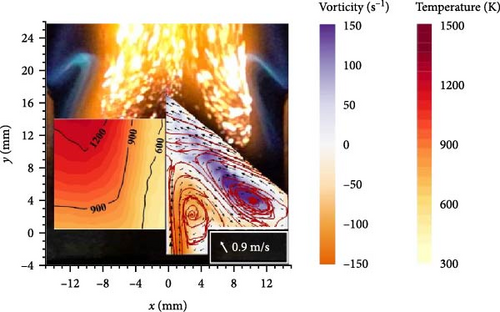

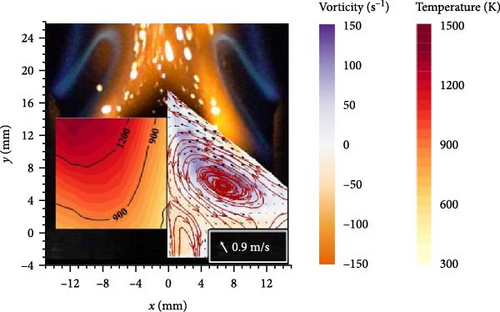

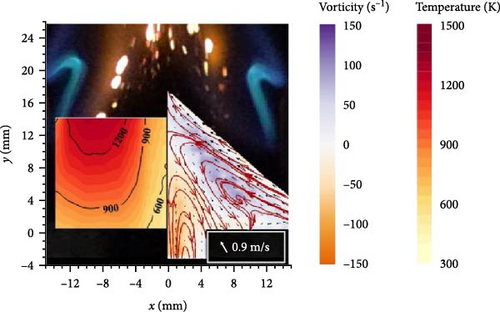

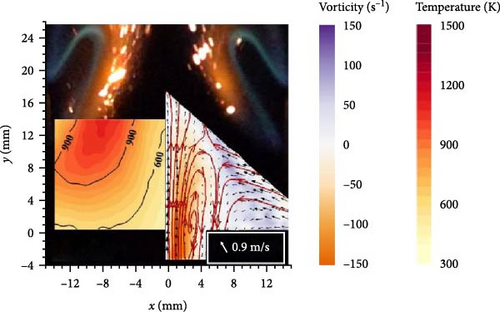

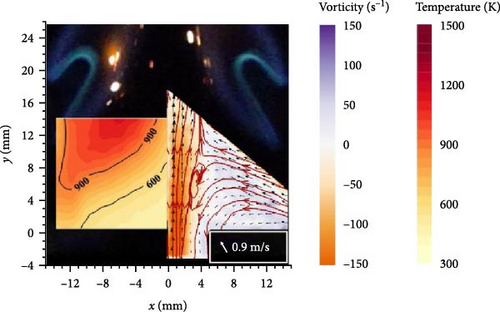

In Figure 4a,b, when the equivalence ratio (Φ) is 1, burner angle at 45°, and the gas fuel flow speed is 0.9 m/s, varying the pulverized coal/air feed flow rates (6.75 and 9.75 L/min) reveals notable insights. Increasing the pulverized coal/air feed rate enhances the visibility and size of primary recirculation zones upstream. This effect is linked to higher air velocity in the central channel and increased turbulence from the counterflow flame. Consequently, pulverized coal mixes more thoroughly in the upstream recirculation zone, especially evident at 9.75 L/min, where the recirculation zone extends, prolonging the residence time for crucial coal combustion processes like devolatilization and char combustion.

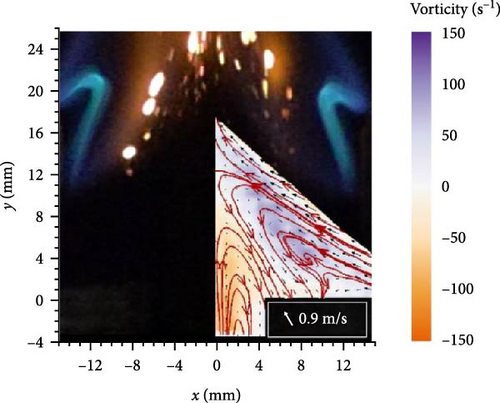

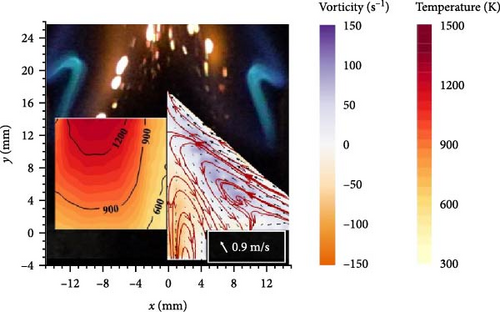

Figure 4c–e illustrates the impact of flame inclination under constant equivalence ratio of 1, fuel flow speed of 0.9 m/s, and the pulverized coal/air feed flow rates of 6.75 L/min. At 30°, the flame primarily progresses downstream, aligned with the central channel. However, at a 60° inclination, the flame exerts a strong lateral influence, inducing robust horizontal convective currents upon leaving the secondary recirculation zone. This lateral convective pattern indicates that with increased flame inclination, thermal energy tends to dissipate horizontally into the ambient airstream, influencing streamlines and flow dynamics. In summary, the flame’s deflection angle significantly affects its morphology, streamline distribution, and inherent flow dynamics, highlighting its crucial role in understanding and modulating the combustion process.

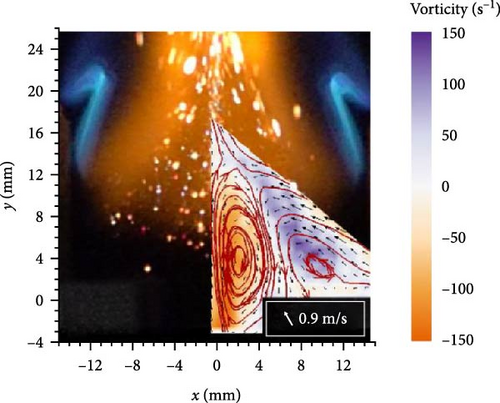

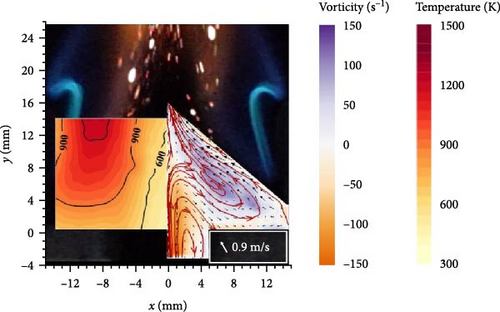

In Figure 5a,b, under an equivalence ratio of 0.8 with a constant burner angle of 45°, a fuel flow speed of 0.9 m/s, and pulverized coal/air feed flow rates of 6.75 L/min, a prominent second vortex in the flame is observed, more pronounced than scenarios with equivalence ratios of 1 and 1.5. This is likely due to the CH4-to-oxygen ratio, which generates significant heat, elevating the flame’s temperature and brightness. This increased thermal condition leads to gas volume expansion, creating a negative pressure zone that induces a powerful recirculation, referred to as the second vortex.

This vortex enhances fuel and oxygen mixing, amplifying combustion dynamics. Flames naturally gravitate toward fuel-rich areas, drawing the flame closer to PCI zones. The combustion of pulverized coal in this region releases heat, further expanding gas volume and diminishing pressure, and strengthening the localized combustion process. An equivalence ratio of 1.5, with a fuel surplus, leads to substantial unburned CH4 and pulverized coal due to an oxygen deficit, compromising combustion efficiency. The reduced flame temperature diminishes the second vortex’s prominence.

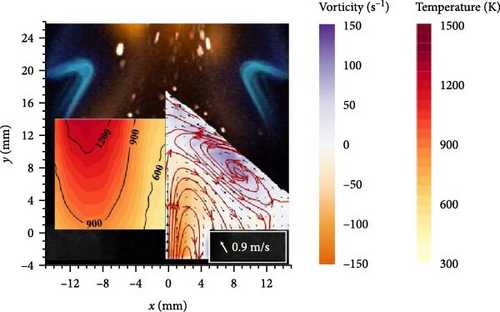

In Figure 5c–e, at a flow rate of 0.6 m/s with a constant burner angle of 45°, a constant equivalence ratio of 1, and pulverized coal/air feed flow rates of 6.75 L/min, insufficient velocity negates any discernible upstream recirculation, potentially indicating suboptimal pulverized coal combustion due to inadequate coal–oxygen mixture. Elevating the flow rate to 0.9 m/s results in two noticeable upstream recirculation zones, suggesting enhanced coal–oxygen mixing facilitated by gas-induced recirculation, improving combustion. Further increasing the flow rate to 1.2 m/s intensifies coal agitation, likely due to more vigorous gas flow inducing enhanced recirculation and vortices, optimizing coal–oxygen mixing and bolstering pulverized coal combustion.

3.2.1. Vorticity Profile Analysis

The spatial distribution of these vortices suggests that the upstream vortex arrangement of the burner provides insights into the combustion dynamics of pulverized coal. Furthermore, it elucidates the flow rate’s implications on flame stability, combustion efficiency, and fuel utility. This examination holds paramount significance in directing burner design and optimizing its performance.

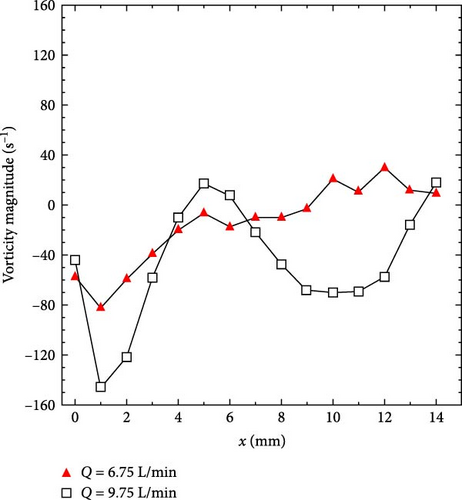

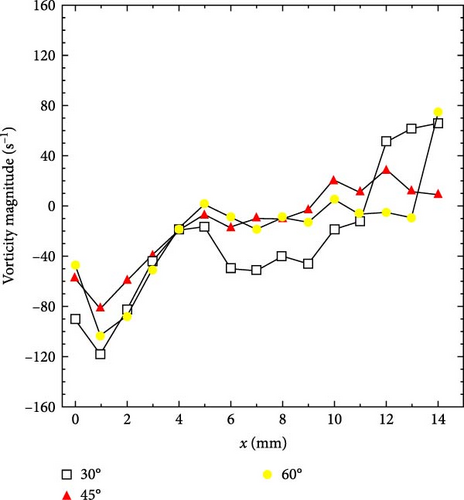

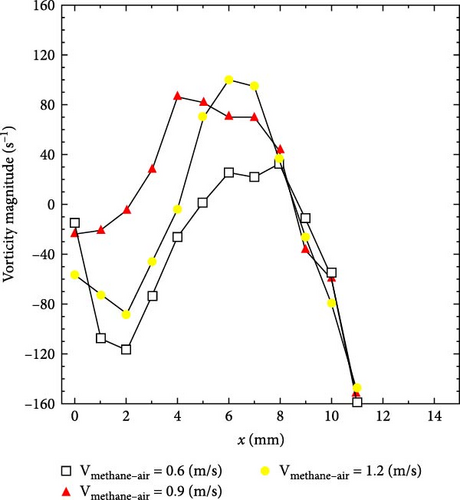

Figure 6 reveals significant insights into flow vorticity components at different heights along the centerline (y = 0 mm and y = 9 mm). From Figure 6a, a clear difference in vorticity distribution emerges between flow rates of 9.75 L/min and 6.75 L/min at y = 0 mm. The higher flow rate exhibits a broader clockwise vorticity distribution, spanning from x = 0 to 13 mm, with a peak vorticity of −145.8 (1/s), indicating more robust rotational movement. In contrast, the lower flow rate (6.75 L/min) registers a maximum vorticity of only −82.4 (1/s) over a shorter span (0–9 mm), signifying weaker rotational motion. Furthermore, at the higher flow rate, the initial vortex extends across the entire 0–13 mm x-range, while at the lower flow rate, it covers only approximately 0–9 mm. This extended influence of the initial vortex at higher flow rates could potentially impact flame shape and stability.

Shifting to y = 9 mm as shown in Figure 6b, the 9.75 L/min flow rate demonstrates the second vortex’s influence over a wider range (x = 3 to 11 mm) with a peak vorticity of 140.4 (1/s). This highlights pronounced rotational movement at higher flow rates. Conversely, the 6.75 L/min rate confines the second vortex’s impact to x = 2 to 9 mm, with a peak vorticity of 87.0 (1/s), indicating subdued rotational flow. In summary, the flow rate in the central channel significantly affects the upstream flow field, with higher flow rates expanding the vortex’s influence and intensifying its vorticity, potentially promoting more homogeneous fluid mixing in the recirculation zone.

Figure 6c,d presents flow vorticity component sections at different angles of the CH4-air premixed flame burner at heights y = 0 and y = 9 mm. At a 30° flame angle, the maximum clockwise vorticity at y = 0 mm is −117.8 (1/s). At a 45° angle, this value decreases to −82.4 (1/s), and at a 60° angle, the maximum vorticity is −103.7 (1/s). At y = 9 mm, the vorticity values are 103.7 (1/s) for 30°, 87.0 (1/s) for 45°, and 98.5 (1/s) for 60°. These data reveal that different flame angles have minimal impact on vorticity distribution, indicating that variations in flame angle do not significantly affect vortex strength or range under these conditions.

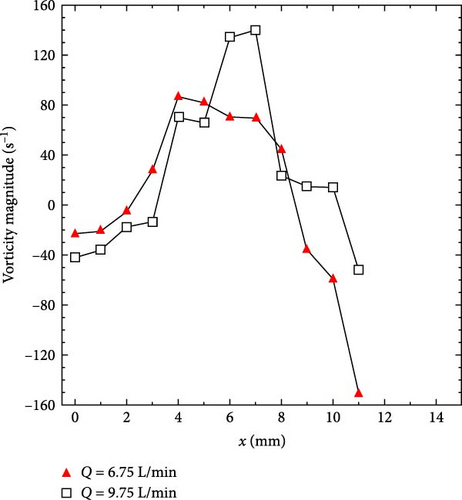

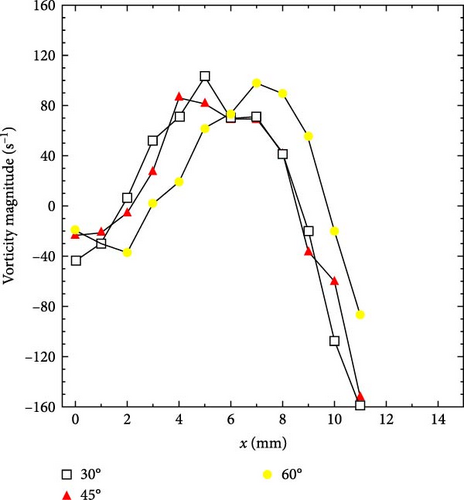

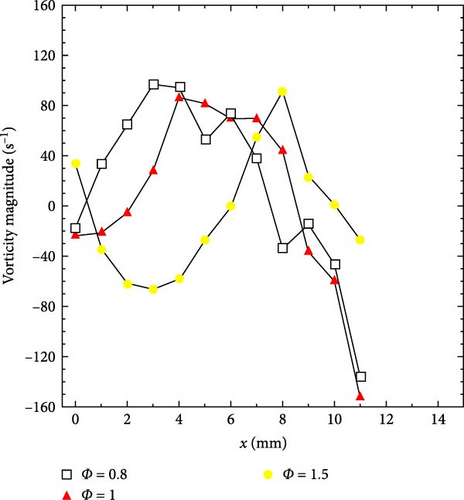

Figure 7a,b illustrates how adjustments in the equivalence ratio within counterflow flames result in noticeable differences in vorticity distribution. Our observations under various equivalence ratios revealed intriguing insights:

Starting with the position y = 0 mm, we noted that at an equivalence ratio of 1.5, the strength of the first vortex significantly increases, with vorticity reaching −146.4 (1/s). Conversely, at equivalence ratios of 1 and 0.8, the vorticity is lower, at −82.4 and −55.2 (1/s), respectively. This suggests that higher equivalence ratios generate stronger vorticity. However, at y = 9 mm, the maximum vorticity under an equivalence ratio of 1.5 is 81.1 (1/s), with a narrower vortex flow distribution range of 6–10 mm. In contrast, at equivalence ratios of 0.8 and 1, the vortex flow ranges are 0–8 mm and 2–9 mm, respectively, with the maximum vortex flow at 0.8 being 100.6 (1/s). In summary, reducing the equivalence ratio enlarges the second recirculation zone while shrinking the first recirculation zone. Additionally, different outlet flow speeds lead to corresponding changes in the vorticity distribution of counterflow flames.

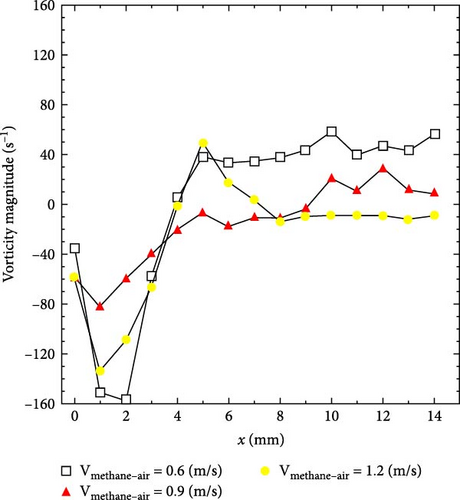

Figure 7c,d provides vorticity component sections at a height of y = 0 and y = 9 mm under different gaseous fuel speeds. At y = 0 mm, an inlet flow rate of 0.6 m/s results in a maximum vorticity of −157.4 (1/s), while at 1.2 m/s, it decreases to −133.2 (1/s). At y = 9 mm, the highest vorticity, 100.6 (1/s), occurs with an inlet flow rate of 1.2 m/s, compared to only 33.0 (1/s) at 0.6 m/s. Vorticity intensity is positively correlated with flow rate increase. Notably, an inlet flow rate of 1.2 m/s forms two large and intense recirculation zones upstream of the flame, while a rate of 0.6 m/s results in only one. These findings emphasize the significant impact of inlet flow rate on the flow field structure and vorticity distribution, particularly in the upstream flame region, where recirculation zone intensity increases with higher flow rates.

3.3. Temperature Distribution

The combustion efficiency of pulverized coal is profoundly influenced by preheating effects upstream. Effective preheating of coal dust accelerates pyrolysis and combustion, enhancing overall efficiency. Elevated temperatures expedite volatile release from coal, supplying ample fuel for combustion. Temperature distribution upstream correlates with combustion efficiency, offering insights into burner flow structure, thermodynamics, and combustion progress. Understanding this relationship is crucial for optimizing burner performance.

Figure 8a,b displays temperature distribution for different central flow rates (6.75 and 9.75 L/min with a constant angle of 45°, flow speed of 0.9 m/s, and equivalence ratio of 1). Higher central flow rates intensify mixing, promoting coal dust combustion. Elevated temperatures facilitate volatiles’ release. Although 9.75 L/min has a lower outlet temperature, intense turbulence broadens its 900K+ temperature region, possibly improving combustion efficiency. Figure 8c–e illustrates temperature distribution at varying flame inclinations under a constant flow rate of 6.75 L/min, flow speed of 0.9 m/s, and equivalence ratio of 1. At 30°, a smaller > 900 K area indicates uneven heating. At 60°, wider dispersion yields a larger > 900 K area, enhancing preheating.

Figure 9a–c explores equivalence ratio (Φ) effects with a constant angle of 45°, flow speed of 0.9 m/s, and a constant flow rate of 6.75 L/min. Φ = 0.8 creates a “lean” mixture; laminar flame speed is 0.25 m/s, with higher coal dust reactivity. Φ = 1 achieves “chemically equivalent” combustion, yielding 0.4 m/s laminar flame speed, highest temperature, and combustion rate. At Φ = 1.5, a “rich” mixture reduces speed to 0.1 m/s, as coal dust absorbs heat and increases the mixture equivalence ratio. Figure 9d–f demonstrates flow rate influence under a constant angle of 45°, an equivalence ratio of 1, and a constant flow rate of 6.75 L/min. At 0.6 m/s, the lower vertical central streamline counterflow flame component reduces the second recirculation zone’s formation, leading to uneven temperature distribution. At 1.2 m/s, counterflow flames impact the vertical central streamline, enhancing the second recirculation zone, and resulting in higher and more uniform temperatures.

Flow rate adjustment optimizes combustion processes by altering counterflow flame dynamics and enhancing recirculation zone temperature distribution.

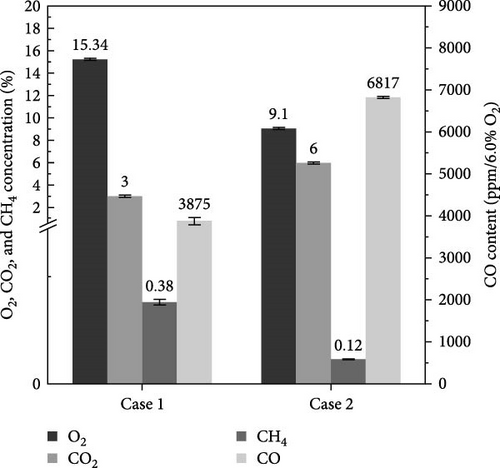

3.4. Gas Emission Analysis

This process can improve combustion efficiency because CO and H2 can release more heat in the subsequent combustion process. Therefore, even though the absolute concentration of CH4 decreases, the production of CO and H2 in the burner increases, indicating an improvement in combustion efficiency. Overall, these results demonstrate that regulating the air–coal flow in the central channel can effectively control the combustion efficiency and gas composition in the burner, thereby achieving optimization of the combustion process.

Figure 10a presents notable shifts in gas composition within the burner as the central channel’s air–coal flow rate increases from 6.75 to 9.75 L/min. First, the oxygen (O2) concentration exhibits a substantial decrease from 15.34% to 9.1%. This decline suggests that higher flow rates lead to a more efficient combustion process, signifying increased air–coal mixture sufficiency and greater oxygen consumption. This aligns with fundamental combustion theory, emphasizing optimal combustion efficacy near or slightly above the theoretical air volume. Second, there is a noteworthy increase in CO2 concentration, rising from 3% to 6%. This points to enhanced combustion efficiency because CO2 is the primary product of complete combustion.

When an ample oxygen supply is available, carbon combustion proceeds thoroughly, forming CO2 as the product. Third, CO concentration undergoes a significant rise, surging from 3875 to 6817 ppm with increased flow rates. This phenomenon can be attributed to several factors, including heightened mixing, elevated temperatures, and prolonged coal dust retention within the burner. These conditions promote increased devolatilization reactions, leading to elevated CO production. Lastly, CH4 concentration experiences a notable decline from 0.38% to 0.12% under the same conditions. This decrease is in line with the explanation for heightened CO production, indicating that distinct temperatures within the burner impact pyrolysis and partial oxidation reactions, thereby altering the gas composition.

These findings underscore the profound influence of temperature variations on gas composition within the burner. Such variations are driven by differences in pyrolysis and oxidation reactions, and they have significant implications for combustion efficiency and performance optimization. Figure 10b illustrates the impact of varying inclination angles (30°, 45°, and 60°) on the burner’s temperature and gas composition, shedding light on crucial findings. At a 30° angle, flames primarily collide parallel to the central channel, reducing direct interaction with coal dust. Consequently, heat transfer mainly occurs between flames, resulting in a smaller and uneven area with temperatures exceeding 900 K.

This limited contact between flames and coal dust leads to incomplete combustion and pyrolysis reactions, resulting in higher oxygen concentrations and lower CO and CO2 concentrations. Conversely, at a 60° angle, flame-coal dust collisions primarily occur perpendicularly to the central channel. This forces coal dust to remain in the upstream area, elevating temperatures, and rendering a more uniform temperature distribution. Enhanced contact between flames and coal dust facilitates thorough combustion and pyrolysis reactions, yielding lower oxygen and CH4 concentrations and higher CO and CO2 concentrations.

For instance, oxygen concentration varies from 15.98% at 30° to 8.62% at 60°, emphasizing the impact of flame angle on oxygen consumption. CO2 concentration remains at 3% at 30° and 45° but rises to 7% at 60° due to intensified pyrolysis and partial oxidation reactions at higher temperatures. CH4 concentration shifts from 0.12% at 30° to 0.38% at 45°, then drops to 0.11% at 60° as temperature changes affect CH4 production. CO concentration experiences a slight increase from 3723 ppm at 30° to 3930 ppm at 60°, attributable to intensified partial oxidation reactions with rising temperatures. Comparing these angles, it is evident that above 60° results in the highest CO production from coal dust pyrolysis, followed by 45° and 30°, although the degree of change is not significant. These findings underscore the profound influence of flame inclination on combustion reactions and resultant gas composition.

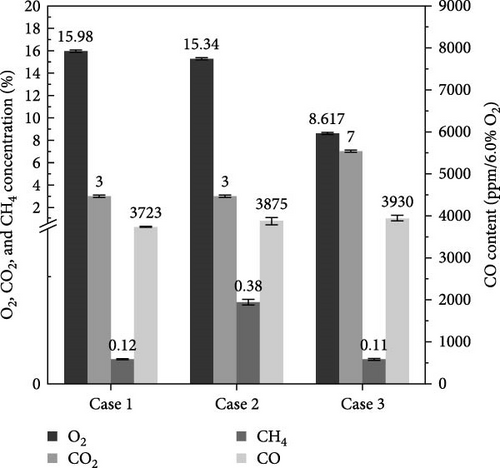

Figure 11a provides insights into the profound influence of varying equivalence ratios on gas composition and combustion efficiency. At an oxygen-deficient condition Φ = 0.8, O2 concentration decreases to 12.67%, signifying relatively high combustion efficiency. Simultaneously, CO concentration increases to 4306 ppm, indicating effective coal dust pyrolysis in the recirculation zone. CH4 concentration registers at 0.19%, and CO2 concentration rises to 4%, signifying partial combustion of coal dust. When the equivalence ratio reaches the stoichiometric point, O2 concentration rises to 15.34%, resulting in decreased combustion efficiency. CO concentration decreases to 3875 ppm, suggesting weakened coal dust pyrolysis in the recirculation zone. CH4 concentration increases to 0.38%, and CO2 concentration drops to 3%, indicating reduced complete combustion of coal dust.

Conversely, in an oxygen-rich condition Φ = 1.5, O2 concentration further increases to 17.4%, leading to a further reduction in combustion efficiency. CO concentration further decreases to 3,746 ppm, reflecting weakened coal dust pyrolysis. In this state, CH4 concentration rises to 0.52%, and CO2 concentration decreases to 2%, signifying a further reduction in the degree of complete coal dust combustion. These findings emphasize the direct impact of equivalence ratios on gas composition during combustion, which, in turn, significantly influences combustion efficiency.

Figure 11b underscores the substantial impact of varying CH4 premixed flame flow speeds on combustion reactions and gas composition, reflecting changes in combustion efficiency and coal dust pyrolysis. At a lower flame flow speed (0.6 m/s), O2 concentration is 15.7%, and CO concentration is 3519 ppm, indicating incipient coal dust pyrolysis. CH4 concentration is 0.29%, and CO2 concentration is 3%. When the flame flow speed increases to 0.9 m/s, O2 remains at 15.34%, CO concentration rises to 3875 ppm, indicating improved coal dust pyrolysis. CH4 concentration is 0.38%, and CO2 remains at 3%, suggesting relatively stable complete combustion of coal dust.

At a higher flame flow speed (1.2 m/s), O2 drops to 5.78%, implying improved combustion efficiency. CO concentration increases to 8204 ppm, indicating enhanced coal dust pyrolysis. CH4 concentration drops to 0.12%, and CO2 rises to 8%, signifying more complete combustion of coal dust. In summary, varying CH4 premixed flame flow speeds significantly impact gas composition during combustion. This influence extends to combustion efficiency and coal dust pyrolysis effects. Consequently, changes in flame flow speed hold significant potential for optimizing the combustion process and enhancing energy utilization.

4. Pulverized Coal Burning Rate Analysis

This study meticulously examines the distribution of coal dust particles throughout the combustion process with a focus on precise combustion analysis. It employs the median as a statistical measure, chosen over the mean for its resistance to outliers, to accurately depict combustion trends.

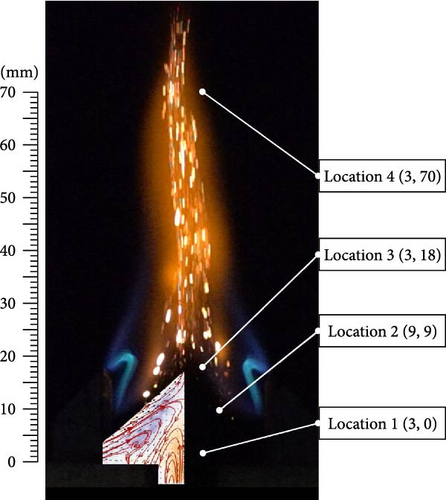

- 1.

Inlet of the burner (first point): Located at (x, y) = (3, 0) mm, this initial point captures the baseline particle size distribution of coal dust as it enters the upstream of the burner.

- 2.

Upper edge of the second recirculation zone (second point): Positioned at (x, y) = (9, 9) mm, this sampling point analyzes the impact of pyrolysis and combustion processes within the recirculation zone on coal dust particle size.

- 3.

Transition from recirculation zone to CH4 premixed air counterflow flame (third point): Located at (x, y) = (3, 18) mm, this point assesses the influence of flame and coal dust interactions on particle size distribution.

- 4.

Seventy milimeters above the burner (fourth point): Positioned at (x, y) = (3, 70) mm, this point captures the particle size distribution of coal dust downstream of the flame, providing an overview of the entire combustion process’s effect on particle size.

This study employs precise particle size analysis at specific points, offering a deep understanding of coal dust behavior during combustion. This knowledge is crucial for optimizing combustion efficiency and control. To achieve accurate coal dust particle size determination, advanced machine learning tools like the Weka plugin in ImageJ software are employed. These tools extract essential features from SEM images, such as color, texture, and morphology, to characterize coal dust particles effectively. A classifier, trained on these features, identifies coal dust particles pixel by pixel. This meticulous, automated approach reduces subjectivity and inaccuracies, enhancing our understanding of coal dust combustion dynamics and improving combustion efficiency.

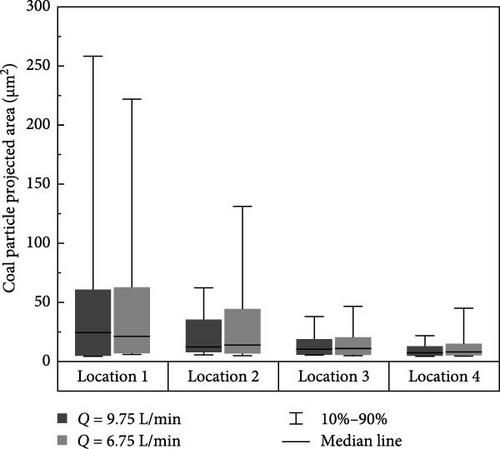

4.1. The Effect of Central Flow Channel Pulverized Coal Flow Rate

In an experiment altering the coal dust-air flow rate through the central flow channel, intriguing findings emerged (see Table 2 and Figure 13). When the coal dust-air flow rates were 9.75 (L/min) and 6.75 (L/min), the initial median particle sizes were 24.2 and 21.6 µm2, with similar interquartile ranges of 55.0 and 54.5 µm2, indicating minor differences in initial coal dust size distribution. However, upon entering the second recirculation zone, substantial changes occurred. The median sizes decreased to 12.2 and 13.8 µm2, with coal dust reduction rates of 49.6% and 36.3% at 9.75 (L/min) and 6.75 (L/min), respectively.

| Operating conditions | 9.75 (L/min) | 6.75 (L/min) |

|---|---|---|

| Median (µm2) | ||

| Location 1 | 24.2 | 21.6 |

| Location 2 | 12.2 | 13.8 |

| Location 3 | 9.9 | 10.5 |

| Location 4 | 7.1 | 7.8 |

| Interquartile range (µm2) | ||

| Location 1 | 55.0 | 54.5 |

| Location 2 | 25.1 | 36.9 |

| Location 3 | 12.1 | 13.6 |

| Location 4 | 6.8 | 9.1 |

| 10–90 percentile range (µm2) | ||

| Location 1 | 254.9 | 216.1 |

| Location 2 | 54.3 | 127.1 |

| Location 3 | 33.0 | 41.6 |

| Location 4 | 17.0 | 40.8 |

| Reduction rate (%) | ||

| Location 1 | — | — |

| Location 2 | 49.6 | 36.3 |

| Location 3 | 58.9 | 51.5 |

| Location 4 | 70.8 | 63.9 |

This suggests that, at 9.75 (L/min), the pyrolysis of coal dust intensified in the second recirculation zone, possibly due to enhanced mixing from the larger flow rate in the central channel. Upon entering the flame front, the median particle sizes further decreased to 9.9 and 10.5 µm2, with reduction rates of 58.9% and 51.5%. Finally, passing through the downstream of the burner, the median sizes reached 7.1 and 7.8 µm2, with interquartile ranges of 6.8 and 9.1 µm2, and substantial differences from the 10th to 90th percentile (17.0 and 40.8 µm2, respectively).

These findings highlight that a coal dust-air flow rate of 9.75 (L/min) intensifies the pyrolysis reaction, likely due to an enlarged central flow channel promoting thorough coal dust mixing upstream of the burner. Consequently, this leads to a significantly higher final combustion rate of coal dust at 70.8%, compared to 63.9% at 6.75 (L/min). These results offer critical insights into coal dust combustion processes, aiding in improved understanding and control of this vital process.

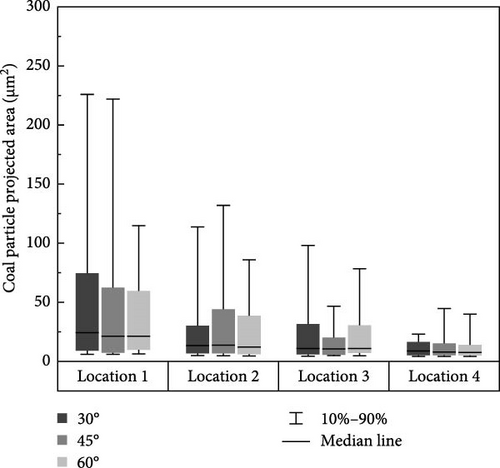

4.2. The Effect of Deflected Angle

In an experiment exploring variations in the counterflame angle (30°, 45°, and 60°), coal dust particle size distributions were observed and detailed in Table 3 and Figure 14. Initially, at these angles, medians of coal dust particle sizes were 23.9, 21.6, and 21.2 µm2, respectively, with corresponding interquartile ranges of 64.7, 54.5, and 49.1 µm2. When the flame entered the second recirculation zone, the medians changed to 13.5, 13.8, and 12.6 µm2, with varying interquartile ranges and differences between the 10th and 90th percentiles. Reduction rates were 43.5%, 36.3%, and 40.6%, respectively.

| Operating conditions | 30° | 45° | 60° |

|---|---|---|---|

| Median (µm2) | |||

| Location 1 | 23.9 | 21.6 | 21.2 |

| Location 2 | 13.5 | 13.8 | 12.6 |

| Location 3 | 10.9 | 10.5 | 10.6 |

| Location 4 | 8.7 | 7.8 | 7.5 |

| Interquartile range (µm2) | |||

| Location 1 | 64.7 | 54.5 | 49.1 |

| Location 2 | 22.4 | 36.9 | 31.8 |

| Location 3 | 24.8 | 13.6 | 22.7 |

| Location 4 | 10.6 | 9.1 | 8.1 |

| 10–90 percentile range (µm2) | |||

| Location 1 | 220.1 | 216.1 | 108.1 |

| Location 2 | 108.4 | 127.1 | 79.8 |

| Location 3 | 93.6 | 41.6 | 73.5 |

| Location 4 | 18.5 | 40.8 | 35.16 |

| Reduction rate (%) | |||

| Location 1 | — | — | — |

| Location 2 | 43.5 | 36.3 | 40.6 |

| Location 3 | 54.3 | 51.5 | 50.0 |

| Location 4 | 63.5 | 63.9 | 64.7 |

Notably, at 60°, although its reduction rate was not the highest, the particle size distribution was more concentrated, indicating that coal dust particle distribution was denser in the recirculation zone. Upon reaching the flame front, median sizes changed to 10.9, 10.5, and 10.6 µm2, with different interquartile ranges and differences between the 10th and 90th percentiles. Reduction rates were 54.3%, 51.5%, and 50%. At 60°, the coal dust size distribution was relatively concentrated, suggesting that the flame primarily interacted with coal dust in the direction perpendicular to the central flow channel, leading to denser distribution in the upstream area.

Finally, downstream of the burner, median particle sizes changed to 8.7, 7.8, and 7.5 µm2, with reduction rates of 63.5%, 63.9%, and 64.7%. Notably, at 60°, the coal burnout rate was the highest. Although 30° exhibited localized concentration, overall, a 60° flame angle contributed more to coal dust combustion efficiency.

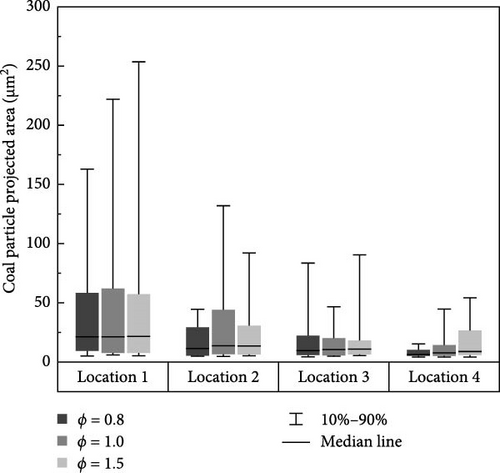

4.3. The Effect of Equivalent Ratio of Premixed Flames

In an experiment varying the counterflame equivalence ratio (0.8, 1, and 1.5), changes in coal dust particle size distribution were observed and are detailed in Table 4 and Figure 15. Initially, under each equivalence ratio, medians of coal dust particle sizes were 21.4, 21.6, and 21.3 µm2, with corresponding interquartile ranges of 48.0, 54.5, and 51.9 µm2. Upon entering the second recirculation zone, medians changed to 11.4, 13.8, and 13.1 µm2, with differences in interquartile ranges, percentiles, and reduction rates (46.7%, 36.3%, and 38.3%). Notably, at an equivalence ratio of 0.8, the coal dust size distribution was significantly more concentrated.

| Operating conditions | V = 1.2 m/s | V = 0.9 m/s | V = 0.6 m/s |

|---|---|---|---|

| Median (µm2) | |||

| Location 1 | 24.6 | 21.6 | 21.6 |

| Location 2 | 11.7 | 13.8 | 14.7 |

| Location 3 | 9.6 | 10.5 | 11.1 |

| Location 4 | 6.3 | 7.8 | 9.2 |

| Interquartile range (µm2) | |||

| Location 1 | 55.6 | 54.5 | 59.1 |

| Location 2 | 17.6 | 36.9 | 37.8 |

| Location 3 | 14.8 | 13.6 | 15.7 |

| Location 4 | 4.9 | 9.1 | 13.5 |

| 10–90 percentile range (µm2) | |||

| Location 1 | 231.2 | 216.1 | 263.2 |

| Location 2 | 43.3 | 127.1 | 175.6 |

| Location 3 | 43.1 | 41.6 | 52 |

| Location 4 | 10.6 | 40.8 | 39.8 |

| Reduction rate (%) | |||

| Location 1 | — | — | — |

| Location 2 | 52.6 | 36.3 | 31.8 |

| Location 3 | 61 | 51.5 | 48.6 |

| Location 4 | 74.5 | 63.9 | 57.5 |

As the flame reached the flame front, median sizes became 9.4, 10.5, and 10.7 µm2, with reduction rates of 55.8%, 51.5%, and 49.6%. Downstream of the burner, median sizes changed to 6.9, 7.8, and 8.6 µm2, with varying interquartile range differences, percentiles, and reduction rates (67.8%, 63.9%, and 59.7%).

Comparatively, at an equivalence ratio of 0.8, the coal dust particle size distribution in the second recirculation zone was significantly more concentrated. These findings suggest that, under these experimental conditions, an equivalence ratio of 0.8 may be more conducive to improving combustion efficiency.

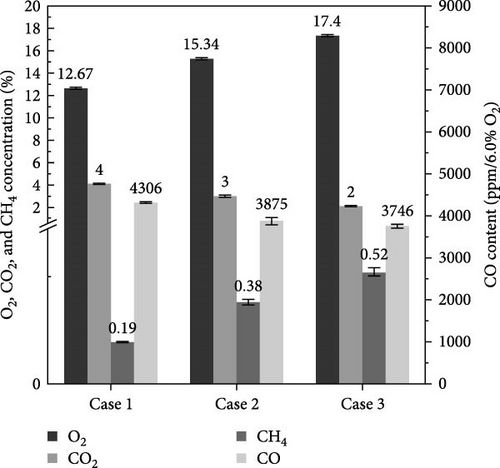

4.4. The Effect of Flow Rate of Premixed Flames

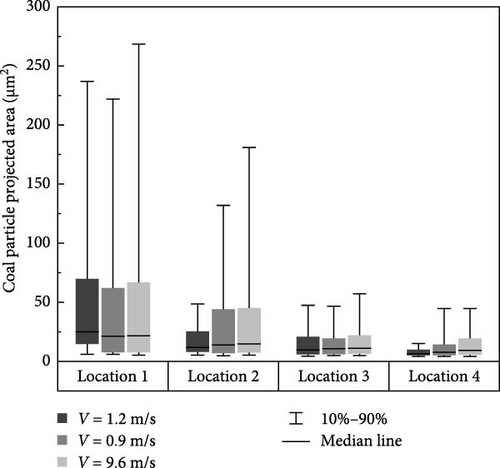

In an experiment investigating variations in counterflame flow velocity (1.2, 0.9, and 0.6 m/s), changes in coal dust particle size distribution were observed, detailed in Table 5 and Figure 16. Initially, median coal dust particle sizes at each flow rate were 24.6, 21.6, and 21.6 µm2. Upon entering the second recirculation zone, medians changed to 11.7, 13.8, and 14.7 µm2, with interquartile ranges of 17.6, 36.9, and 37.8 µm2. The range from the 10th to the 90th percentile was 43.3, 127.1, and 175.6 µm2, with reduction rates (52.6%, 36.3%, and 31.8%). Notably, at a flow velocity of 1.2 m/s, coal dust distribution was significantly more concentrated.

| Operating conditions | V = 1.2 m/s | V = 0.9 m/s | V = 0.6 m/s |

|---|---|---|---|

| Median (µm2) | |||

| Location 1 | 24.6 | 21.6 | 21.6 |

| Location 2 | 11.7 | 13.8 | 14.7 |

| Location 3 | 9.6 | 10.5 | 11.1 |

| Location 4 | 6.3 | 7.8 | 9.2 |

| Interquartile range (µm2) | |||

| Location 1 | 55.6 | 54.5 | 59.1 |

| Location 2 | 17.6 | 36.9 | 37.8 |

| Location 3 | 14.8 | 13.6 | 15.7 |

| Location 4 | 4.9 | 9.1 | 13.5 |

| 10–90 percentile range (µm2) | |||

| Location 1 | 231.2 | 216.1 | 263.2 |

| Location 2 | 43.3 | 127.1 | 175.6 |

| Location 3 | 43.1 | 41.6 | 52 |

| Location 4 | 10.6 | 40.8 | 39.8 |

| Reduction rate (%) | |||

| Location 1 | — | — | — |

| Location 2 | 52.6 | 36.3 | 31.8 |

| Location 3 | 61 | 51.5 | 48.6 |

| Location 4 | 74.5 | 63.9 | 57.5 |

As the flame reached the flame front, median sizes became 9.6, 10.5, and 11.1 µm2, with reduction rates of 61.0%, 51.5%, and 48.6%. Downstream of the burner, medians changed to 6.3, 7.8, and 9.2 µm2, with interquartile ranges of 4.9, 9.1, and 13.5 µm2, and ranges from the 10th to the 90th percentiles of 10.6, 40.8, and 39.8 µm2. Reduction rates were 74.5%, 65.9%, and 57.5%.

Comparatively, at a flow velocity of 1.2 m/s, coal dust exhibited better mixing and preheating effects, resulting in a significantly higher coal dust reduction rate downstream of the burner (74.5%), compared to the other two conditions. This suggests that increasing the flow velocity of the counterflame may enhance the combustion efficiency of coal dust under these experimental conditions.

5. Conclusions

- 1.

Flame angle: A 30° flame angle results in a smaller, uneven high-temperature zone with incomplete combustion, as shown by higher oxygen and CH4 levels. In contrast, a 60° flame angle enhances convective currents, producing a wider, more uniform high-temperature region that promotes better preheating and complete combustion. Vorticity distribution is minimally impacted by flame angle changes.

- 2.

Equivalence ratio: A lean mixture (Φ = 0.8) improves combustion efficiency by facilitating effective pyrolysis and partial combustion. A chemically equivalent mixture (Φ = 1) achieves the highest combustion efficiency and temperature but with slightly reduced pyrolysis effectiveness. A rich mixture (Φ = 1.5) lowers efficiency due to unburned fuel, indicated by higher oxygen and CH4 concentrations.

- 3.

Combustion velocity: Higher velocities (1.2 m/s) enhance fluid mixing and recirculation zones, improving combustion efficiency. At lower velocities (0.6 m/s), poor mixing leads to uneven temperature distribution and reduced efficiency. Increased velocity also results in higher vorticity, greater recirculation, and more complete combustion.

- 4.

Central channel flow rate: A higher flow rate (9.75 L/min) enhances turbulence and promotes better mixing in recirculation zones, resulting in more efficient combustion, lower oxygen and CH4 concentrations, and higher CO and CO2 levels. A lower flow rate (6.75 L/min) leads to reduced mixing, smaller high-temperature areas, and less efficient combustion.

Overall, the study highlights the importance of optimizing these parameters to improve preheating, pyrolysis, and combustion efficiency. However, it also acknowledges the simplified conditions of the experiment and recommends further research to better simulate real furnace combustion environments.

Nomenclature

Symbols

-

- C:

-

- Carbon

-

- FC:

-

- Fixed carbon

-

- H2:

-

- Hydrogen

-

- M:

-

- Moisture

-

- N:

-

- Nitrogen

-

- O:

-

- Oxygen

-

- S:

-

- Sulfur

-

- T:

-

- Temperature (K)

-

- V:

-

- Velocity vector V (u, v, w) (1/s)

-

- VM:

-

- Volatile matter

-

- HHV:

-

- High heating value (kcal/kg)

Greek

-

- α:

-

- Fuel conversion ratio

-

- Φ:

-

- Equivalence ratio

-

- Ω:

-

- Vorticity.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Yu-Ting Wu: methodology, software, validation. Chia-Wei Chang: writing–original draft, formal analysis, investigation, data curation, visualization. Po-Hung Lin: formal analysis, investigation, data curation, visualization. Yueh-Heng Li: conceptualization, writing-review and editing, supervision, project administration, funding acquisition. Janusz Lasek: supervision, project administration, funding acquisition. Hsiao-Kai Kan: formal analysis, investigation, data curation.

Funding

This study was supported by the National Science and Technology Council of Taiwan (NSTC 112-2923-E-006-002-MY3 and NSTC 112-2221-E-006-106) and the National Center for Research and Development in Poland (POLTAJ10/2022/49/MethaHydrAmmon).

Acknowledgments

This study was financially supported by the National Science and Technology Council of Taiwan (NSTC 112-2923-E-006-002-MY3 and NSTC 112-2221-E-006-106) and the National Center for Research and Development in Poland (POLTAJ10/2022/49/MethaHydrAmmon).

Open Research

Data Availability Statement

The data that support the findings of this study are available upon request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.