Energy and Exergy Evaluation of the Integrated Waste Energy Recovery System (IWERS) and the Solar-Powered Integrated Waste Energy Recovery System (SPIWERS) in Various Climates

Abstract

The integrated waste energy recovery system (IWERS) is a thermal system that recovers waste heat from steam generated in bakery ovens to produce hot water. This reduces energy and water consumption in shopping centers. This article analyzes the technical improvement of incorporating renewable solar thermal energy into the system. It introduces the new solar-powered IWERS (SPIWERS) for the first time. The exergetic efficiency of IWERS and SPIWERS was measured over 1 year in real supermarkets located in different climatic zones to determine their performance variables. This paper presents precise data for future improvements in the energy efficiency of waste heat recovery systems, making it an innovative contribution to the field. The exergetic efficiency of IWERS was found to be lower in subtropical climates, but no significant variation was observed in other climates studied. Additionally, the exergetic efficiency of IWERS components decreases with ambient temperature, particularly in warm months. Regarding SPIWERS, the highest exergetic efficiency values were obtained in oceanic climates. IWERS employs electric boilers, whereas SPIWERS system utilizes solar collectors. Although IWERS exhibited superior overall exergy efficiency, particularly in cold climates, SPIWERS distinguished itself with a reduced environmental impact, wholly supplanting electric power with solar thermal energy and a swift economic return on investment within a period of less than 4 years, a duration that is half that of IWERS. A detailed examination of the individual components of each system will facilitate the identification of potential avenues for enhancement, ensuring the system’s capacity for adaptation to specific climatic conditions and seasonal variations. Thus, the exergy efficiency of the DWH tank in IWERS remains constant across all climatic zones and throughout the year. This exergy efficiency is approximately 65%. In contrast, a notable variation is observed in the case of SPIWERS, which is more pronounced in more favorable weather conditions. On the other hand, the exergy efficiency of electric water boilers is greater in colder climates and times of the year, with a range of 30%–40%. Additionally, the exergy efficiency of the solar collector is greater in months and areas with cool ambient temperatures, optimal solar radiation, and moderate fluid temperatures within the collector, with a range of 5%–11%.

1. Introduction

Rising energy costs are affecting businesses around the world, including small retailers such as supermarkets [1, 2]. This negative impact on economic activity has increased in recent years due to the negative influence of the COVID-19 pandemic and the international political situation [3]. In addition, the increase in the operating costs of supermarkets has increased the cost of the shopping basket, which has had a negative impact on the CPI of states and on the purchasing capacity of families [4, 5]. On the other hand, in 2021, the Conference of the Parties (COP 26), where almost 200 countries signed the Glasgow Climate Pact [6], with the aim of maintaining the objectives celebrated in the Paris Agreement [7]. In particular, to limit global warming to 1.5°C above preindustrial levels. Its implementation would mean phasing out fossil fuels (coal, oil, and gas), promoting the use of renewable energies, and reversing the traditional trend of growth at the expense of more pollution. The Paris Agreement also recognized the importance of science for effective climate action [7].

On the other hand, in 2015, 193 member states of the United Nations approved a resolution aimed at achieving a more sustainable development that would achieve the eradication of poverty. This goal was called 2030 Agenda for Sustainable Development [8, 9] and among its 17 improvement actions called Goals is included Goal 2: End hunger, achieve food security, and improved nutrition and promote sustainable agriculture; Goal 6: Ensure availability and sustainable management of water and sanitation for all; Goal 9: Build resilient infrastructure, promote inclusive and sustainable industrialization, and foster innovation; Goal 11: Make cities and human settlements inclusive, safe, resilient, and sustainable; Goal 12: Ensure sustainable consumption and production. In an attempt to comply with these actions aimed at achieving a more sustainable development, this research was carried out.

In the literature, we find different research aimed at improving energy efficiency in the commercial sector and in supermarkets. For example, some research is based on the adoption of broad and targeted sets of energy efficiency measures and policies to achieve efficiency gains in buildings and commercial industries [10, 11]. Thus, several energy-efficient technologies are being developed and implemented to reduce energy demand and increase energy reliability in the commercial sector [12, 13]. But most efforts to decrease electricity usage concentrate on upgrading the lighting, air conditioning, and refrigeration systems in these enterprises [14–18]. In other cases, the analysis of the building envelope is focused on the cost savings resulting from the implementation of thermal insulation [19–21]. And there is research that examines the impact of materials that prevent commercial buildings from overheating from solar radiation. This has been demonstrated in cool roof studies [22, 23].

Exergy analysis has been widely employed as a thermodynamic technique to assess energy quality and identify the sources and magnitudes of thermodynamic inefficiencies in a system. Consequently, there are articles that did not analyze bakery ovens but did perform these analyses on annealing ovens, which are used to heat metal parts to relieve internal stress. The researchers analyzed the efficiencies, losses, and energy and exergy savings in these ovens following the same thermodynamic procedures that have been used in our methodology [24, 25]. Exergy analyses were also performed on electric arc furnaces used to melt and refine metals [26]. The objective was to obtain optimal design parameters and operating conditions to improve efficiency. The exergy losses were caused by chemical reactions, heat transfer, and other reasons. Another article performed an exergy and optimization analysis of a ladle furnace refining process with the objective of reducing energy consumption in this type of furnace [27]. In this case, exergy losses induced by unavailable electric energy were the largest contributor to overall losses. Another investigation analyzed the exergy efficiency and influencing factors in a tube heating furnace system and found that the largest proportion of exergy losses were due to heat transfer [28]. The excess air coefficient, exhaust gas temperature, and external surface temperature of the furnace exhibited a negative correlation with exergy efficiency.

In conclusion, numerous studies have demonstrated the efficacy of rigorous exergy analysis techniques in evaluating thermodynamic performance and identifying efficiency improvements across a diverse range of industrial furnace systems. However, no analysis has been conducted on our systems, which exhibit unique characteristics due to the equipment comprising the systems and which, as will be demonstrated, are influenced by the climates where the systems are installed. There is currently no research that analyzes the improvement of energy efficiency in businesses by calculating the exergy performance of the integrated waste energy recovery system (IWERS) [29].

IWERS technology is a system for recovering waste heat from the steam generated during baking processes in electric and gas ovens used in both supermarket bakeries and other companies that bake frozen dough [29]. This type of bread production has gained great popularity and consists of fermenting and baking the previously prepared and frozen dough in commercial ovens. The ovens have a drinking water inlet, which is necessary for the different hydration processes of the bread dough. Some of this water becomes part of the finished product, while some evaporate and must be removed from the oven before the doors are opened. Traditionally, these ovens removed the steam through a condenser located at the top of the oven. In this steel tank, the steam was mixed with cold water from the company’s general water network, condensing the steam generated in the oven, and then draining all the water through the general sanitary network. This process resulted in high consumption of potable water, about 2000 liters per day in each oven [29], and wasted thermal energy from the steam. The energy recovered with IWERS is used to heat the hot water used in the shop, resulting in significant energy savings. IWERS technology is currently being developed in commercial facilities, mainly supermarkets in Southern Europe [30].

- a.

Energy efficiency: Studies show that IWERS technology has the potential to significantly improve energy efficiency in commercial facilities using bakery ovens [29].

- b.

Thermoeconomic analysis: Research has been conducted to evaluate the performance of IWERS systems using thermoeconomic analysis, which combines thermodynamic principles with economic analysis to optimize the design and operation of the systems [31] to achieve optimal results.

- c.

Environmental impact: The use of IWERS technology has been shown to reduce energy consumption and greenhouse gas emissions, contributing to environmental sustainability [13].

- d.

System optimization: Research and efforts are underway to optimize IWERS system components, such as the steam condenser, to further improve overall efficiency and performance [31].

- e.

Future applications: IWERS technology has the potential to be applied in a variety of commercial and industrial settings where waste heat is generated [32]. In addition, the current study includes enhancements, such as the use of renewable energy, that may increase the feasibility and applicability in future commercial installations.

This study analyzes for the first time IWERS [29] from an exergetic point of view and presents a novel technical improvement in the way solar energy is used in the system, called solar-powered IWERS (SPIWERS). SPIWERS replace the electric water heaters previously used to heat water with solar thermal installations, as described in the methodology section.

The novelty of this article lies in its presentation of SPIWERS and the fact that, for the first time, an exergy study has been performed on IWERS and SPIWERS for the purpose of calculating their efficiency in the context of thermal energy usage in bakery ovens. The objective was to quantify and contrast the exergy efficiencies of the two systems. Both systems were developed by the author of the article and have been validated in numerous installations. They have been utilized to reduce the consumption of energy destined for the supply of hot water to commercial establishments. The data was collected over a period of 1 year in supermarkets situated in a variety of climatic zones. The objective was to compare the operation of both systems in different climates. Exergy efficiency was analyzed for each component and for the entire system. This is the inaugural analysis of its kind, providing the requisite exergetic equations to establish an analysis methodology for future improvements applied to IWERS.

This information allows for the selection of the most appropriate system and the identification of the component within the installation that requires the most improvement, thus, enabling the optimization of the processes.

Therefore, this article describes and analyzes the engineering improvements applied to IWERS to: 1. Reduce the power consumption of the system; 2. use renewable energy in its operation; 3. minimize consumption of associated potable water; 4. reduce the economic costs of food production in the stores and of baking frozen dough in supermarkets and other bakery outlets.

2. Methodology

The concept of exergy is typically associated with the notion of energy quality, which refers to the maximum useful work or work potential of energy in each system [33]. Exergy is typically associated with the concept of energy quality, which refers to the maximum useful work or work potential of energy in any system. Consequently, the paper employed exergy to ascertain the optimal efficiency of energy utilization by IWERS and SPIWERS. In this way, the most convenient operation of the system as a whole and in each component was evaluated. The analysis was carried out over a period of 1 year, considering the characteristics of the different climatic zones present in Spain.

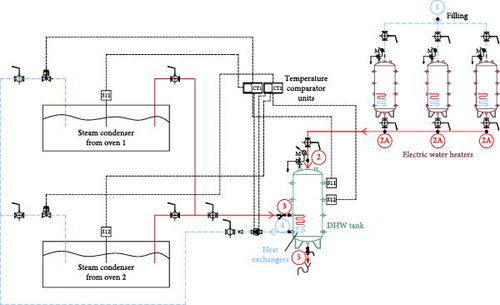

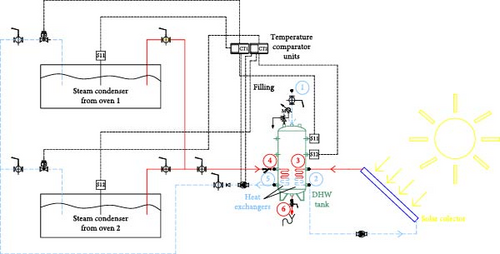

Spain is a country with a great variety of climatic zones, which makes it possible to extend the results obtained to a large part of the world. Both IWERS and SPIWERS consist of several technical components, as shown in Figures 1 and 2. This made it necessary to base the research on previous works that exergetically analyzed some of these components individually.

Table 1 details the studies considered for the calculation of exergy and IWERS component that it implies.

2.1. IWERS Description

The most common supermarket in Europe is the medium-sized supermarket with a sales area of 400–1000 m2 [47–50]. In these medium-sized supermarkets, there are at least two baking ovens [1]. Therefore, each supermarket can have two IWERS, and the potential use of this system is very large. The use of this innovative system, which exploits the residual heat from the condensation water of bread ovens and avoids the consumption of potable water, has shown excellent results in supermarkets and retail stores [13]. Figure 1 shows the traditional IWERS and its different elements.

IWERS recovers steam from the baking process. A wet rotor pump transfers steam from the steam condensers to a heat recovery unit located in the hot water tank. Several temperature sensors placed in the steam condensers and in the hot water tank allow the water temperature to be measured to prevent the water in the condensers from cooling the water in the tank. Thus, when the temperature difference between the two tanks is less than 2°C, solenoid valves close the water flow. It also prevents water circulation from the condenser of ovens that are not operating. In addition, a safety feature prevents the wet rotor circulation pump from operating when the solenoid valves are closed. Finally, three 50-l electric water heaters are available to meet the hot water needs of the different areas of the supermarket (butcher shop, delicatessen, fish shop, fruit shop, changing rooms, toilets, storage, and sales room). Table 2 shows the thermal properties at analyzed IWERS points. The mains water temperature (TW) in each city is detailed in Table 3.

| Point | T (°C) |

P (bar) |

Point | T (°C) |

P (bar) |

||

|---|---|---|---|---|---|---|---|

| 1 | TW | 3 | 0.01 | 3 | 90 | 3 | 0.01 |

| 2 | 50 | 4 | 0.01 | 4 | 75 | 3 | 0.01 |

| 2A | 50 | 4 | 0.01 | 5 | 60 | 5 | 0.01 |

| Month | Las Palmas | Madrid | Oviedo | Valencia | ||||

|---|---|---|---|---|---|---|---|---|

Ta |

TW [53] |

Ta |

TW [53] |

Ta |

TW [53] |

Ta |

TW [53] |

|

| January | 17.6 | 15.0 | 6.3 | 8.0 | 8.3 | 9.0 | 11.8 | 10.0 |

| February | 17.9 | 15.0 | 7.9 | 8.0 | 8.7 | 9.0 | 12.5 | 11.0 |

| March | 18.6 | 16.0 | 11.2 | 10.0 | 10.5 | 10.0 | 14.4 | 12.0 |

| April | 18.9 | 16.0 | 12.0 | 12.0 | 11.3 | 10.0 | 16.2 | 13.0 |

| May | 20.0 | 17.0 | 14.0 | 14.0 | 13.9 | 12.0 | 19.0 | 15.0 |

| June | 21.7 | 18.0 | 17.0 | 17.0 | 16.7 | 14.0 | 22.9 | 17.0 |

| July | 23.5 | 19.0 | 20.0 | 20.0 | 18.7 | 15.0 | 25.6 | 19.0 |

| August | 24.2 | 19.0 | 19.0 | 19.0 | 19.1 | 16.0 | 26.1 | 20.0 |

| September | 24.1 | 19.0 | 20.9 | 17.0 | 17.6 | 15.0 | 23.5 | 18.0 |

| October | 22.8 | 18.0 | 17.0 | 13.0 | 14.6 | 13.0 | 19.7 | 16.0 |

| November | 20.9 | 17.0 | 13.0 | 10.0 | 10.9 | 10.0 | 15.3 | 13.0 |

| December | 18.7 | 16.0 | 6.9 | 8.0 | 8.9 | 9.0 | 12.6 | 11.0 |

| Annual average | 20.7 | 17.0 | 15.0 | 13.0 | 13.3 | 12.0 | 18.3 | 15.0 |

| P0 | P0 | P0 | P0 | |||||

| Average ambient pressure | 1.019 | 1.025 | 1.018 | 1.016 | ||||

2.2. SPIWERS Description

As a technical innovation, IWERS has developed a system for recovering waste heat from the vapors coming from the bakery ovens using renewable energy. The system was named SPIWERS. Renewable energy is solar thermal energy from solar collectors that provide the thermal energy needed to heat the hot water to the required temperature. The domestic hot water (DHW) tank is equipped with a heat exchanger connected to a solar thermal panel that can supply the necessary thermal energy to supplement that of the steam from the condensers, if necessary. This solar panel is located on the roof of the supermarket or commercial building. In this way, SPIWERS replaces the electric water heaters with a renewable installation, increasing the exergy efficiency of the facility. Figure 2 shows the components of SPIWERS. The system replaces electric water heaters with a solar collector connected to the water tank. The system uses steam from ovens with the same components as IWERS.

Table 4 shows the thermal properties at analyzed SPIWERS points. The mains water temperature (TW) in each city is detailed in Table 3.

| Point | T (°C) |

P (bar) |

Point | T (°C) |

P (bar) |

||

|---|---|---|---|---|---|---|---|

| 1 | TW | 3 | 0.01 | 4 | 90 | 3 | 0.01 |

| 2 |

|

3 | 0.4 | 5 | 80 | 3 | 0.01 |

| 3 |

|

3 | 0.4 | 6 | 60 | 5 | 0.01 |

2.3. Exergetic Analysis

The energetic (quantity) and exergetic (quality) potentials of IWERS and SPIWERS were obtained through numerical modeling and with real energy consumption results. For this purpose, results were obtained from the operation of the two systems for 12 months in four Spanish cities with different climates [54]. The climates and cities were: oceanic (city of Oviedo); Mediterranean (city of Valencia); continental (city of Madrid); Subtropical (city of Las Palmas de Gran Canaria). Table 3 shows the characteristics of meteorological data in selected cities, including average monthly/yearly temperature (T0) and average monthly/yearly tap water temperature (TW).

Calculations were performed using Engineering Equation Solver (EES) software, using the equations for solar collectors according to the research detailed in Table 1. In particular, the exergy of solar radiation, which is detailed below and represented by Equation 14, was employed. Furthermore, the energy and exergy balances were conducted for each component of the system and for the entire system.

The input and output exergy values include both the exergy associated with energy and material transfers in each element of the system.

The terms associated with potential exergy () and kinetic () are neglected due to their minimal influence. Chemical exergy was also ignored , since the chemical composition of the fluids involved in the different systems remained unchanged.

The ambient temperature (T0) and the ambient pressure (P0) are the temperature and pressure of the system boundaries outside the device. Therefore, there is no heat transfer to the environment and the exergy losses are only related to material waste. Thus, the destruction of exergy within each component of the system was due to the irreversibility of heat transfer within the control volume and friction [56].

The next step was to apply the exergy balance and exergy efficiency equation to each of the components, both IWERS and SPIWERS.

2.3.1. IWERS Evaluation

For the entire system:

2.3.2. SPIWERS Evaluation

In SPIWERS there is only heat and mass transfer. The analysis is then performed for each element of the system.

For the DHW tank:

Temperature exchange occurred between three fluid streams. Thus, the water in the tank increased in temperature with the heat released by the heat exchangers, as shown in Figure 2.

Points 2–3 represent the primary circuit. In this circuit the fluid was water with 20% ethylene glycol. Points 1 and 4–5 correspond to the secondary circuit. In this secondary circuit, the fluid was water.

3. Results

3.1. Achievements in the IWERS

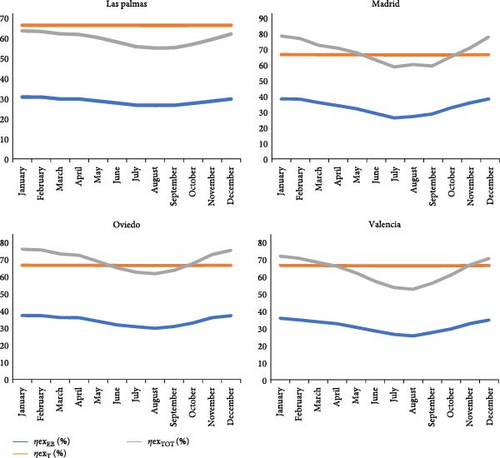

Figure 3 illustrates the exergy efficiency attained with the IWERS in the four urban centers/climates under investigation. The exergy efficiency values were calculated for the domestic hot water tank (ηexT), the electric water heaters (ηexEB), the solar collector (ηexSC), and the complete system (ηexTot). Therefore, the exergy efficiency of the IWERS was found to be inferior in Las Palmas in comparison to the other cities, where it reached analogous values. Therefore, the system demonstrated a diminished exergy efficiency in subtropical climates, though it exhibited minimal variation in the other climates under investigation (oceanic, Mediterranean, and continental). The system exhibited its highest performance during the winter months in cities with oceanic and continental Mediterranean climates. These findings can be attributed to the observation that enhanced efficiency was associated with climates characterized by cold winters and consequently, lower network water temperatures. This made it more viable to capitalize on the steam enthalpy within the heat exchanger.

The exergy efficiency of the DHW tanks remained largely consistent across a range of climates and times of the year, due to the absence of fluctuations in the temperatures of the fluid streams within the tanks. Nevertheless, the exergy efficiency of the electric water heaters declines with rising ambient temperature, exhibiting a more pronounced decline during the warmer months of the year. The decrease was more pronounced in Mediterranean and continental climates. This discrepancy can be attributed to two factors: the temperature differential between the cold and warm months is more pronounced in these climates than in the other two and it is also more difficult to take advantage of the steam enthalpy in the heat exchangers when the two water inlet flows have closer temperatures.

It is also noteworthy that the exergy efficiency of the DHW tank was approximately double that of electric water heaters, exhibiting a consistently high exergy efficiency of between 53% and 78%. This can be attributed to the low efficiency of electric energy in the production of heat.

Furthermore, it was observed that the elevated temperatures characteristic of the summer months resulted in a reduction in the exergy efficiency of both electric boilers and the system in general. This decline was more pronounced in Mediterranean and continental Mediterranean climates. However, the DHW accumulator demonstrated a relatively limited impact from this variation. This can be attributed to the lower temperature differential between the hot water and the tap water temperature, necessitating less thermal energy to achieve the desired domestic hot water temperature. Consequently, the thermal utilization was found to be reduced.

3.2. Achievements in SPIWERS

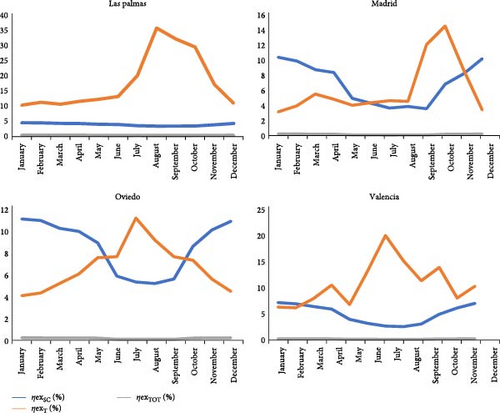

Figure 4 illustrates the exergy efficiency attained by the SPIWERS in the four urban centers/climates under investigation. The exergy efficiency of the SPIWERS array was observed to exhibit slight increases in colder meteorological conditions, with minimal and nearly undetectable variations between climatic zones. This can be attributed to the influence of solar radiation exergy. It is possible that this value could have been increased by adjusting the collector size. However, this adjustment was not made in the present study because it was postulated that high thermal power might be necessary at certain times in the supermarket when high hot water consumption was required due to the simultaneous use in several areas of commercial establishment. Therefore, the highest exergy efficiency values were observed in the city with an oceanic climate.

The exergy efficiency values of the solar circuit were notably high (11%) during the winter months in the city with a continental climate, due to the combination of sunny weather and a lower ambient temperature. These values remained constant throughout the year, at approximately 5%, in the city with a subtropical climate. The exergy efficiency exhibited a range of values between 3.6% and 11%, contingent on the prevailing climatic conditions and the specific period under consideration.

The exergy efficiency of the DWH tank exhibited a considerable range, spanning from 3.1% to 35.6%. It was observed that the values were higher during the summer months, except for the city with an oceanic climate, where the exergy efficiency was higher during the autumn months. The highest recorded value (35.6%) was observed in the month of August, which is characteristic of a subtropical climate. These variations were attributable to the disparate temperature gradients between the tap water flows and those from the condensers and the solar collector. The efficiency was found to increase in proportion to the gradient. It is noteworthy that in oceanic climates, solar irrigation is prevalent during the autumn season, and the temperature of tap water is significantly lower than that of the collectors. Moreover, during periods of markedly elevated solar irrigation in the summer months, the thermal gradient is observed to increase in the remaining climates under analysis.

Additionally, it was observed that the elevated temperatures during the summer months resulted in a reduction in the exergy efficiency of both the electric boilers and the system in general, although this was only discernible for a brief period. This decline is particularly evident in continental Mediterranean climates and primarily in continental climates. In climates with more stable temperatures throughout the year, such as Las Palmas or Valencia, the variation in the electric boilers is almost negligible. Conversely, the summer months, with elevated temperatures and solar irrigation, enhance the functionality of the DHW tank in all climates, with a markedly pronounced effect observed in Mediterranean and subtropical climates. This is also attributable to the variation in thermal gradients between the different flows in the various components of the system. The efficiency is greater when the gradient is greater.

3.3. Economic Analysis

A reduction in electricity consumption of 2700 kW h per year and a decrease in water usage of 56 m3 per year were observed in a supermarket with two bakery ovens where the IWERS system was installed, as reported in the study [29]. In a supermarket of the same type where the SPIWERS system is installed, the energy savings would increase by completely avoiding the electrical consumption of the three electric water heaters, which could be estimated at an average value of 4050 kW h per year (1.5 kW for each of the three heaters, operating for 3 h per day for 300 days per year). The consumption of drinking water would be identical with IWERS and SPIWERS. In both cases, the savings are determined by comparing the results with those of a similar supermarket that has not been equipped with either IWERS or SPIWERS.

The cost of IWERS is approximately 5500 €, which encompasses the following components: electric water heaters, an electronic control unit and sensors, a storage tank, motorized two-way valves, a high-efficiency motor pump unit, rigid copper pipe, and electrical, electronic, and mechanical connections. The cost of SPIWERS is approximately 6600 €, which includes IWERS elements without electric water heaters and the solar collector.

Thus, assuming an electricity price of 0.25 € per kW h [58], the payback period for the investment made with the installation of IWERS, considering the energy savings achieved in comparison to the same supermarket without IWERS, is a mere 8 years. The payback period for the investment made with the installation of SPIWERS is less than 4 years.

4. Conclusions

The overall exergy efficiency of the IWERS is higher in climates with lower temperatures. A similar phenomenon is observed in the SPIWERS, though with less pronounced variation. Thus, no significant alterations were noted in either climatic zones or seasonal fluctuations. This may be attributed to the fact that in both systems, the primary component is the heat exchanger utilized to harness the residual heat from the steam generated by the furnaces. Furthermore, exergy efficiency is enhanced in a heat exchanger at lower ambient temperatures due to the increased potential for energy conversion into useful work, resulting from a greater temperature differential and reduced losses to the environment. This indicates an improved utilization of the quality of the energy transferred within the exchanger.

A detailed examination of the exergy efficiency of the various components within the system revealed the following:

The exergy efficiency of the DWH tank in the IWERS remains constant across all climatic zones and times of the year. This is due to the absence of fluctuations in the thermal gradient of the water flows from the steam condensers and the electric water heaters. This exergy efficiency is approximately 65%. In contrast, in the case of SPIWERS, there is a notable variation, which is more pronounced in more favorable weather conditions. This results in reduced thermal losses and a more optimal utilization of solar energy. Moreover, in the case of SPIWERS, efficiency never exceeds 40%.

The exergy efficiency of electric water boilers is greater in colder climates and times of the year, due to the inverse relationship between ambient temperature and exergy efficiency. This is since the useful work potential of the heated water (its exergy) increases in direct proportion to the temperature gradient with the environment. This indicates that a greater proportion of the electrical energy supplied is utilized effectively from the perspective of exergy. The exergy efficiency of the solar collector is greater in months and areas with cool ambient temperatures, optimal solar radiation, and moderate fluid temperatures within the collector. This is since solar collectors exhibit a higher exergy efficiency under conditions of low ambient temperature (higher thermal gradient), high incident solar radiation (more available energy), low wind speed (less convective losses), low relative humidity (less radiative and convective losses), and optimized operating fluid temperatures to maximize heat utilization with respect to the environment.

This analysis of the individual components of the systems, rather than a global assessment, will facilitate the future implementation of optimal technical improvements to IWERS and SPIWERS, ensuring greater adaptation to specific climatic zones and seasonal variations.

While the overall exergy efficiency of SPIWERS was inferior to that of IWERS, the substitution of electric boilers with a solar collector was notable from an environmental perspective, as the boilers’ electrical consumption was supplanted by renewable thermal energy. Solar collectors typically exhibit low exergy efficiency due to the relatively low quality of solar energy, which is characterized by high energy availability but low exergy due to its high entropy. In contrast, electric heaters possess a relatively high exergy efficiency due to the high-quality nature of electricity, which is characterized by low entropy and high exergy. This is the reason why the overall exergy efficiency of SPIWERS was found to be inferior to that of IWERS.

From an economic standpoint, while the exergy efficiency of IWERS is superior to that of SPIWERS, the recovery period for the economic investment made with SPIWERS is reduced by half compared to IWERS. This period can be further reduced if, as anticipated, electricity prices continue to rise.

Nomenclature

-

- Ac:

-

- Solar collector area (m2)

-

- cp:

-

- Heat capacity at constant pressure (kJ kg−1 K−1)

-

- Ex:

-

- Exergy (kJ)

-

- :

-

- Exergy flow rate (kW)

-

- e:

-

- Specific exergy (kJ kg−1)

-

- h:

-

- Specific enthalpy (kJ kg−1)

-

- I:

-

- Solar radiation (W m−2)

-

- m:

-

- Mass (kg)

-

- :

-

- Mass flow rate (kg s−1)

-

- Q:

-

- Heat transfer (kJ)

-

- :

-

- Heat transfer flow rate (kW)

-

- P:

-

- Pressure (bar)

-

- S:

-

- Entropy (kJ K−1)

-

- s:

-

- Specific entropy (kJ K−1 kg−1)

-

- T:

-

- Temperature (K or °C)

-

- T0:

-

- Average monthly/yearly temperature (°C)

-

- Tw:

-

- Monthly/yearly tap water temperature (°C)

Abbreviations

-

- BTC:

-

- Spanish building technical code

-

- COP 26:

-

- the 26 conference of the parties

-

- COVID-19:

-

- Coronavirus disease

-

- DHW:

-

- domestic hot water

-

- EES:

-

- engineering equation solver

-

- IWERS:

-

- integrated waste energy recovery systems

-

- SPIWERS:

-

- solar-powered integrated waste energy recovery system

-

- °C:

-

- degrees celsius

Greek letters

-

- Σ:

-

- sum

-

- η:

-

- efficiency

Subscripts

-

- D:

-

- destruction

-

- ex:

-

- exergetic

-

- i:

-

- i-th material stream

-

- in:

-

- inlet

-

- j:

-

- j-th instant

-

- L:

-

- loss

-

- out:

-

- outlet

-

- Q:

-

- associated with heat losses

-

- s:

-

- sun surface

-

- SC:

-

- solar collector

-

- sr:

-

- solar radiation

-

- tot:

-

- total

-

- WT:

-

- water tank

-

- 0:

-

- ambient o surrounding value

Superscripts

-

- CH:

-

- chemical

-

- EB:

-

- electric boiler

-

- HX:

-

- heat exchanger

-

- KN:

-

- kinetic

-

- PH:

-

- physical

-

- PT:

-

- potential

-

- Q:

-

- associated with heat transfer

-

- T:

-

- DHW tank

-

- .:

-

- flow rate.

Conflicts of Interest

The author declares no conflicts of interest.

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Open Research

Data Availability Statement

The data supporting the findings of this study are reflected in the text.