Effect of Polymer Additives on Improvement of Concrete Properties

Abstract

This article presents a review of achievements in the research aimed at improving the main building material—concrete—along with its physical, mechanical, and operational properties. As is well known, in the near future, the role of concrete will continue to be primary in the construction of buildings and structures due to increasing demand. However, despite its advantages, this important building material is not without flaws. In particular, due to its porosity, concrete is highly permeable to liquids, making it insufficiently resistant to frost and corrosion and sometimes even brittle. At the same time, concrete mixtures used in modern construction must meet requirements such as good adhesive properties, improved waterproofing, high workability, retention of rheological characteristics over time, and the potential for increased strength. Today, the use of polymer additives as modifiers to improving concrete is particularly relevant. The purpose of this review is to examine recent advances in understanding the impact of polymer additives of both inorganic and organic nature on improving concrete properties. Continued research in the field of polymer modifiers and exploration of new research opportunities are for engineering advancements and the development of modern materials.

1. Introduction

Nowadays it is well-established that achieving concrete with specific characteristics is possible only through the addition of special chemical additives to the mixture. Every concrete production facility necessarily incorporates various additives into their mixtures, significantly enhancing the quality characteristics and influencing the processes of setting and hardening. Depending on the desired outcomes, experts identify six common types of concrete additives: superplasticizers, strength accelerators that reduce hardening time, sealants, mobility regulators, antifreeze agents, and modifiers [1–3].

Modern concrete production aims to produce materials that adhere to the Olympic principle of “faster, higher, stronger-together.” And there appears a natural question: do all of the above mentioned six types of supplements provide the Olympic principle? The answer is “not always.” While enhancing one characteristic, another important property of the concrete mixture may be adversely affected. This means that not every additive can guarantee the desired outcome in every context. In this regard, modifiers are of particular interest, as they possess the unique ability to alter multiple properties of concrete simultaneously. Modifiers are substances added to concrete mixtures to adjust one or more parameters while maintaining other characteristics unchanged [1, 4]. By origin, modifiers can be mineral, technogenic, or products of chemical industries. Today, there are approximately a thousand different modifiers, each designed for a specific function. These can be categorized into three main groups: additives that modify the properties of hardened concrete, modifiers that adjust the fundamental properties of concrete mixtures, and ligatures that impart special properties to concrete products [5, 6].

The study of polymer additives in concrete has gained significant attention in recent years due to their potential to enhance both the durability and overall performance of this critical building material. Concrete, widely used in construction for its strength and availability, faces challenges related to its natural porosity and brittleness, which can affect its resistance to frost, impermeability to water, and overall durability.

Plasticizers, which belong to the first group, include air-entraining and stabilizing additives.

Their main benefits lie in their liquefying and plasticizing effects. These additives are essential for preventing the segregation of ready-mix concrete, as well as improving the homogeneity and moisture resistance of the final product. Modifiers that alter the properties of concrete must be able to adjust the curing rate (both accelerators and retarders), endure low temperatures, and control shrinkage and expansion. Such additives are often used to achieve hydrophobic properties and biocidal resistance in concrete. From a theoretical perspective, water-repellent additives should provide concrete with enhanced water resistance, increased frost resistance, and improved resistance to corrosion. When these objectives are met, the hardening process is accelerated and cement consumption is reduced. To combat bacteria and fungi, which, when present in concrete, continuously release organic acids that accelerate degradation, biocidal additives are employed.

The incorporation of polymer additives—both inorganic and organic—offers promising solutions to these challenges, making this an essential area of research for the needs of modern construction.

2. Polymer Additives in Concrete: Organic and Inorganic Contributions

Recent advancements in the use of polymer additives have highlighted the distinct benefits provided by both organic and inorganic compounds. Organic polymer additives, such as latexes, epoxy resins, and superplasticizers, contribute significantly to the improvement of concrete’s workability, adhesion, and water resistance. These materials help in reducing the water–cement ratio, thereby, enhancing the density and overall strength of the concrete matrix. In [7], authors constructed an organic–inorganic network within the cement matrix by utilizing the synergy of in situ polymerization of monomers and cement hydration, which significantly enhances its flexural strength and toughness, while maintaining a comparable compressive strength with ordinary Portland cement (OPC). By tuning the proportions of acrylic acid (AA), methacrylic acid (MAA), and acrylamide (AM), the cement paste experienced an 86% increase in flexural strength with a similar compressive strength to OPC. The in situ formed organic–inorganic (polymer–cement) network provided both flexibility and stiffness, playing a pivotal role in the increased mechanical strength. Cement hydration was retarded with the incorporation of the AMA copolymer, which was supported by the offset of the maximum hydration temperature. In contrast, in situ polymerization of monomers proved more effective than directly adding polymer in improving the fluidity and mechanical strength.

In work [8], authors present a new method based on the use of two admixtures: a nanometric, amorphous, and silica SiO2 (for its reactivity with the cement paste), combined with a specific polysaccharide (for its suspending ability), both of them used under a liquid form. Authors show that one can formulate, at a reasonable cost, a highly fluid concrete, without bleeding or segregation. The setting kinetic is improved, which allows the reduction of the demoulding time; the surface of the hardened concrete is smooth and homogeneous; and the final strengths values achieved are in line with those attained with high strength concrete.

3. Mechanisms of Improvement: How Polymers Enhance Concrete Properties

The effectiveness of polymer additives in concrete can be attributed to their ability to modify the microstructure of the cement paste. Organic polymers form films that bridge the pores in the concrete, providing a barrier against water penetration and improving resistance to freeze–thaw cycles. Inorganic polymers, on the other hand, act as pozzolanic materials, reacting with calcium hydroxide (CH) to form additional calcium silicate hydrate (C─S─H), which fills the voids in the concrete and contributes to increased strength and reduced permeability [9].

Typical coatings incorporate organic groups as carrier of hydrophobicity and polar groups at the solid interface, which are weak points in the interaction with water. In contrast, REOs are shielded from interactions with the environment [9].

Superhydrophobic coatings are essential for self-cleaning and anti-icing applications in extreme conditions. In study [10], an eco-friendly and self-adhesive polydopamine coating was developed, inspired by mussel adhesion, and optimized for growth through precise formula control. Tests revealed an ideal contact angle of 162.7° and roll-off angle of 5.5°, achieved by creating a rough surface structure and reducing surface energy. Mechanical and wear resistance tests showed high robustness, attributed to strong metal-chelating interactions between polydopamine and steel.

4. Mineral Modifiers

Mineral modifiers, also known as supplementary cementitious materials (SCMs), are additives that enhance the properties of concrete, including strength, durability, and workability. These materials often replace a portion of the cement in a mixture, which not only improves concrete’s performance but also makes it more environmentally sustainable by reducing cement demand.

In numerous studies aimed at enhancing the operational characteristics of cement-based materials, inorganic mineral additives are employed, which bear a resemblance to the crystal-chemical structures of cement clinker minerals. These additives facilitate the formation of a high-density cement matrix by regulating the hydration process of clinker minerals, ultimately leading to the development of stable, high-strength, and dense cement stone composed of calcium hydrocyclates with a reduced base content in cement systems [11, 12]. Among these active mineral additives, amorphous microsilica (SiO2) is frequently utilized [13–15].

Research [16] indicates that the incorporation of nano-SiO2 (NS) into cement systems significantly decreases the setting time of concrete. The high reactivity and nucleation potential of NS during the mixing process result in an increased capacity for water absorption due to the presence of numerous unsaturated bonds, which subsequently diminishes concrete shrinkage. Ye et al. [17] conducted a comparative analysis of the effects of NS as an additive versus silica fume (SF) on the properties of hardened cement paste (hcp) by evaluating compressive and bond strength. Their findings reveal that the inclusion of 3% NS promotes the fragmentation of CH crystals, thereby, reducing their orientation and size at the interfacial region, thus, enhancing interfacial bonding more effectively than SF.

In another study [18], a series of concrete mixtures comprising nine different compositions was examined, incorporating mineral additives at levels of 0%, 2.5%, 5%, 7.5%, and 10% by weight of cement. The authors observed that the addition of mineral additives up to 10% increased the compressive strength of concrete by 0.99% in comparison to the control mixture. Furthermore, as the content of mineral additives approached 10%, a reduction in water absorption was noted, alongside an enhanced resistance to freezing and thawing.

A substantial body of literature supports the notion that the introduction of microsilica optimizes the production processes for various classes of concrete [19–22]. Research [23] focuses on the utilization of shungite waste generated from mining and processing operations, detailing the mechanisms occurring within the hardened silicate system of “cement-dispersed shungite particles.” This approach has been shown to enhance concrete strength, while reducing the duration required for heat and moisture treatment.

In addition to SiO2, other materials such as blast furnace slag [24], fly ash [25, 26], and rice husk ash (RHA) [27, 28] have also been investigated as additives. For instance, Li, Qiao, and Ni [24] explored the mechanical properties and hydration behaviors of green concrete formulated with ground granulated blast furnace slag (GGBS), desulfurizing gypsum (DG), and electric arc furnace reduction slag (EAFRS). Their findings indicated that an ecological concrete with a water-to-cement ratio of 0.32 achieved a compressive strength exceeding 50 MPa after 28 days.

The influence of fly ash particle size fractions on the hydration properties of Portland fly ash cement and its resultant characteristics is explored in [25]. The authors found that identical quantities of fly ash fractions of the same size can yield cements with variable initial strengths and differing degrees of strength development over time. Notably, the incorporation of 20 wt% of an ash fraction measuring 0–16 microns enables the production of Portland cement classified as CEM II/A-V with strength classes of 42.5R or 52.5N.

In the investigation of RHA, the physical and mechanical properties of concrete were assessed in the study [27]. The results indicated that the incorporation of RHA into concrete increases the water demand. However, when RHA was used to replace 10% of cement, a significant strength enhancement of 30.8% over the control mixture was observed. Furthermore, up to 20% of cement could be effectively substituted with RHA without adversely affecting strength. Similar beneficial outcomes were reported for partial replacements of 5%, 10%, and 15% cement with RHA in the study [28].

Additionally, there is substantial evidence supporting the positive effects of nanodispersed silica additives in cement compositions [29, 30]. Research in [29] utilized X-ray diffraction (XRD) and differential thermal analysis (DTA) techniques to demonstrate that SiO2 contributes to the formation of a denser microstructure in cement stone, thereby, enhancing the mechanical properties of modified cement concrete. Study [30] further revealed a 30% increase in the strength of hardened cement stone at 28 days compared to the control sample when modified with both microsilica and NS.

Despite the numerous advantages of microsilica—including its excellent adsorption capacity, enhanced thermal conductivity, and improved insulation properties—its application in the construction and concrete industries is accompanied by several significant disadvantages. One notable issue is the increased complexity of construction processes, as the introduction of SiO2 can complicate workability due to decreased compaction. Additionally, microsilica can contribute to dry shrinkage, which diminishes the moisture content of concrete and can result in the formation of drying shrinkage cracks.

Polymer additives are used in concrete production to reduce and prevent the negative effects of mineral modifiers in addition to them.

5. Polymer Modifiers

5.1. Polymer Resins and Rubbers

Based on the aforementioned discussion of mineral additives, it is evident that the high porosity and limited binding capability of mineral additives make cement concrete vulnerable to deterioration in aggressive environments. This brittleness and poor resistance to low temperatures further limit its applicability under certain conditions. To address these limitations, organic additives—specifically polymers—can be incorporated to enhance both strength [31] and durability [32], allowing concrete to better withstand harsh environmental impacts [33].

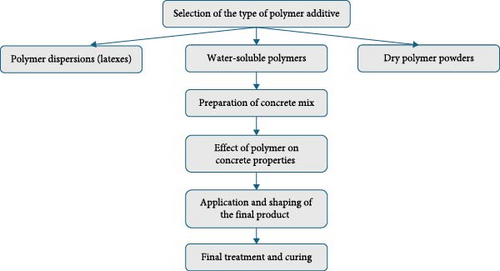

Commonly used polymers, such as polyester and epoxy resins [33], latex [34], and styrene–butadiene rubber [35], provide excellent binding properties and reduce water evaporation rates. This controlled evaporation supports continued crystalline growth and strengthening during the early curing phases, which contributes to more effective cement hardening. For instance, research [36] has analyzed the properties of polymer concrete containing polyester and epoxy resins as well as latex-modified concrete with styrene–butadiene rubber and epoxy latexes, demonstrating significant improvements in durability and resilience. Figure 1 presents a scheme of polymer application in concrete.

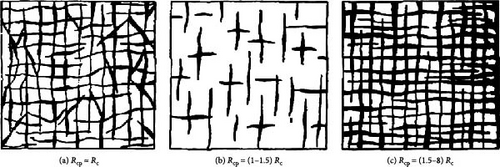

The strength of the concrete polymer largely depends on the polymer content in the concrete pores (Figure 2).

The authors determined that, in polymer-modified cement, polyester was incorporated at 10% and 20%, while epoxy resin was added at 10% by weight of the aggregate. In latex-modified concrete, 15% and 25% styrene–butadiene rubber and 25% epoxy resin, by weight of cement, were used. Their research demonstrated that these additions led to significantly higher compressive, tensile, and flexural strengths in comparison to conventional concrete. Additionally, these polymer modifications enhanced resistance to freeze–thaw cycles and abrasion, while also reducing shrinkage and permeability when polymers were added in optimal proportions.

Research on polymer additives became active in the 20s of last century. Essentially, polymer concrete is a type of concrete in which thermosetting polymers are used instead of mineral binders. Often, epoxy, polyester, and phenol–formaldehyde high-molecular substances are used. Also polymer cement mortars and concretes with the addition of aqueous polymer dispersions are most widely used.

For example, polyvinyl acetate [38], synthetic rubber latexes [39], styrene [40], and methyl methacrylate [41]. In work [41] was studied the effect of polyvinyl alcohol and polyvinyl acetate on polymer fibers to create a cement base. The authors used polymer fiber as a superplasticizer, which provides low water absorption, high water repellency, high strength, and excellent elasticity. In the experimental studies the optimal dosages of additives were determined and the effects of excessive dosage were studied. The polymer fiber was dissolved in water in five different proportions from 2% to 10% relative to the weight of cement in kilograms. On the 7th, 14th, and 28th days, the test sample was examined for curing and compressive strength. The results showed that the concrete mixture containing polymer fiber has greater strength than the standard mixture. Besides, there were found out of five different proportions, a 2% mixture of polyvinyl alcohol and polyvinyl acetate to give higher strength than the other higher proportions. The result can be even better if you use proportions from 0.5% to 2%.

Similarly, Cheng et al. [40] used styrene acrylate emulsion and vinyl acetate–ethylene copolymer emulsion to improve the toughness and abrasion resistance of cement-based materials used in residential precast floors. Improvement in strength and increase in wear resistance as well as change in porosity of mesopores were found to be dependent on polymer dosages. Additionally, study found that a water/cement ratio of 0.3 and polymer (PVA)/cement ratio of 0.016 yielded the highest flexural strength in Portland cement paste. Increasing the PVA/cement ratio leads to a decrease in the total volume of permeable pores and a decrease in water retention.

In general, it can be noted that polymer fibers reduce the formation of cracks in concrete and increase durability [32, 42], mechanical properties such as flexural and tensile strength are increased by 42% and 20%, respectively [42, 43]. In [44], there was studied the elastic property of polymer fiber (polyvinyl alcohol and polyvinyl acetate) reinforced in a cement–concrete mixture. Elastic polymer concrete can increase the seismic resistance of a building or structure (which is one of the most current issues in sustainable construction today), so far as during load is applied, it bends for a while and then returns to its original position when the load is removed.

Further research shows that concrete reinforced with polypropylene fibers yields higher Marshall strength while reducing fluidity, indicating enhanced stability and reduced deformation [45]. Similarly, sisal fiber, a natural alternative to synthetic fibers, has demonstrated comparable mechanical properties, making it a cost-effective and accessible option for enhancing concrete performance [43].

In pavement applications, studies by Singh and Gupta [46] have reviewed a range of polymer fibers, including PETE, HDPE, PVC, LDPE, PP, PS, PU, PC, and EVA. These fibers improve concrete pavement properties by increasing stiffness, rutting resistance, and fatigue life, with greater resistance to moisture, rutting, and fatigue than traditional aggregate replacements.

Polymer-based composites for steel structure coating are an effective strategy to improve tribological properties and service durability under hygrothermal aging conditions. The research [47] focuses on multifiller reinforced epoxy composites (MFREC) aimed at enhancing the tribological properties and durability of steel structure coatings under hygrothermal aging conditions. As detailed in [47], epoxy resin composites were improved through the incorporation of frictional fillers and mechanical reinforcements, leading to enhanced water uptake behavior, mechanical strength, thermal stability, and wear resistance. Degradation was primarily due to resin hydrolysis and filler/matrix debonding. Prior to aging, MFREC showed superior friction and wear resistance, with a 59.6% increase in anti-wear rate under water-lubricated conditions. In [48], further analysis indicated a 98.46% increase in tensile toughness attributed to multifiller reinforcement, which also improved tensile strength (9.56%), modulus (22.07%), and elongation at break (39.09%). Tribological sensitivity was greatest under load, with temperature, sliding speed, and water lubrication as additional factors affecting MFREC’s performance.

Based on the literature data, it can be noted that polymer fibers are materials that are characterized by elasticity, chemical resistance, high strength, and excellent wear resistance. In accordance with the given characteristics, cement-based materials containing polymer fibers are characterized by improved mechanical properties, impact strength, ductility, and resistance to cracking. Besides, it should be emphasized that the low melting temperature point of polymer fibers results in concrete-based composites with reduced delamination at higher temperatures.

Despite the above advantages of polymer resins, latexes, and rubbers, the main disadvantages of such additives are the high cost of their synthesis and the release of harmful substances at the end of their service life. In addition, it is known that almost all of them are unsafe for humans.

5.2. Polystyrene

Polystyrene is widely utilized in the creation of concrete with enhanced performance characteristics, valued for its efficiency as a thermal insulation material and relative cost-effectiveness. Numerous studies have focused on optimizing the composition of polystyrene concrete and investigating its physical [49], mechanical [50–52], thermal, and technological properties [53, 54]. Despite its popularity, there is a problem in the production of polystyrene–concrete mixture and the manufacture of products from it, which manifests itself in delamination due to the different weights of its components.

In [53], the authors proposed the way to overcome this disadvantage by adding various reinforcing materials, as well as plasticizing and air-entraining additives. Scientists have developed a reinforced polystyrene concrete mixture, which includes expanded polystyrene, crushed polystyrene, type I portland cement, gypsum, lime, chrysotile asbestos fiber, an aqueous solution of polyacrylamide plasticizer, carboxymethylcellulose, tartaric acid, saponified tree resin, and water for mixing. The developed composition makes it possible in a simple way to obtain a polystyrene concrete mixture with a uniform distribution of granules throughout the volume and with minimal shrinkage deformations, without delamination and setting within a predictable time, sufficient for transportation from the production site to the construction site. In [52], mathematical models were established to relate mechanical properties such as tensile and flexural strength, elasticity modulus, and energy absorption with time post-casting, showing a strong correlation with empirical data. Further studies [49, 54] indicate that polystyrene improves thermal insulation, reduces weight, and enhances soundproofing in prefabricated structures. In a study [55] with Rheomix 141, a butadiene–styrene copolymer latex, concrete grades M20–M60 demonstrated positive results in compressive and flexural strength and modulus of elasticity with up to 10% polymer content.

While polystyrene concrete provides enhanced insulation and weight reduction, its low structural strength, poor fastener retention, and susceptibility to aging limit its broader application.

5.3. Waste From Polymer Production

The recycling of organic and inorganic waste has emerged as an attractive alternative for substitution or integration with other materials across various industries, primarily aimed at enhancing the ecological state of the environment. This trend also extends to the waste generated during polymer production, which can be processed or reused in the modification of concrete mixtures. Such an approach offers promising solutions not only for waste disposal [56, 57], but also for improving sound and thermal insulation [58, 59], enhancing energy efficiency in buildings [59, 60], and augmenting mechanical properties such as strength, toughness [61], tensile resistance [62, 63], and resistance to compression and abrasion [64]. Additionally, it can improve the fragility and crack resistance of conventional cement, as well as the residual compressive strength [65, 66].

Research conducted by Basha et al. [60] focused on the utilization of waste polyester fibers in roofing applications, examining their impact on the indirect tensile strength (ITS) and moisture resistance of asphalt mixtures. The findings indicated that the incorporation of polyester fibers generally enhances the wet tensile strength and the tensile strength ratio (TSR) of the modified mixtures, while also improving toughness under both dry and wet conditions. Furthermore, the study noted increases in void content, asphalt content, specific gravity, and Marshall stability. The exploration of waste materials is not limited to light and heavy concrete mixtures; it also encompasses the rehabilitation of asphalt road mixtures, such as reclaimed asphalt pavement (RAP) [57, 66]. Research demonstrated that the addition of crumb rubber contributes to an increase in the voids in mineral aggregate (VMA) and enhances the rutting resistance of the mixture, irrespective of the size and type of rubber utilized [60]. The authors of [67] suggest that to optimize the performance of sprayed surfaces in high-traffic areas or regions with preexisting pavement cracks, it may be beneficial to incorporate shredded scrap rubber into the asphalt concrete prior to application.

However, it is important to acknowledge that some studies indicate unfavorable outcomes associated with the use of recycled materials in concrete. For instance, Oliver [68] reported a negative impact on the mechanical strength of aged materials resulting from the interaction between rubber and bitumen. Additionally, research in [69] highlighted the superior mechanical properties of concrete produced with natural aggregates compared to those containing recycled aggregates, as evidenced by experiments with three types of water used as conservation baths. Replacing natural aggregates with recycled alternatives has not consistently led to significant improvements in the durability of concrete mixtures [70] and may in fact increase porosity and susceptibility to aggressive environments [71], thereby, reducing service life [72] and overall durability [73], as well as increasing water absorption [74].

5.4. Silanes and Polysiloxanes

Silanes [75] and polysiloxanes (silicones) [76] are of particular interest as a polymer additive to concrete. While silane additives are often used to impregnate cement-based materials to give the surface water-repellent properties and in most cases are sprayed on the concrete surface [77], the latter can be applied both on the surface of the concrete [78] and mixed with the mortar to enhance the performance of the concrete mixture from the inside [79]. Polysiloxanes are widely used in coatings due to their hydrophobic properties [80], resistance to atmospheric influences, and long-term breathability [78]. But despite this, research on polysiloxanes as additives to concretes and concrete mixtures that improve their performance properties is not so great. Considering this fact and the fact that the main chain of polysiloxane molecules is Si─O─Si with high binding energy, the side chains of which are alkane chains with outstanding hydrophobicity and ─OH groups with high reactivity, there is a high probability of a condensation reaction between hydroxyl groups, which can form stable chemical bonds with cement the basis. Based on these assumptions, our research group, within the framework of a scientific project, began research on the synthesis of polysiloxanes (as the least studied and promising polymers as modifiers of concrete and concrete mixtures) with various functional groups and their further use as additives to create highly functional concretes.

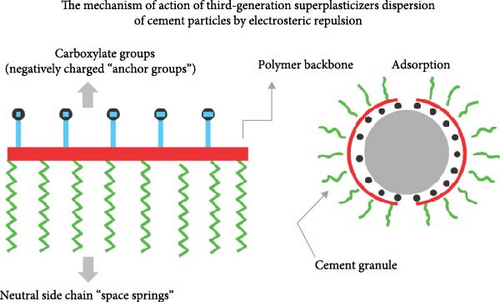

The mechanism of action of these additives (Figure 3) is based on the electrostatic and steric effect, due to the chemisorption of plasticizer molecules on the surface of cement clinker particles, which contributes to the dispersion of the system [81].

6. Conclusions

- 1.

Current focus of research: The literature reveals that research predominantly centers on the effects of polymer additives on cement binders, emphasizing their construction and technical properties. Although there are studies exploring the mechanisms of action for specific additives, these efforts are limited and do not provide a comprehensive framework for their selection and optimal use.

- 2.

Influencing factors: Enhancements in concrete characteristics depend on various factors, including the type and nature of polymers, dosage, mixing methods, curing techniques, and other parameters. While progress has been made in understanding the properties of cements modified with various additives, a systematic scientific framework for classifying and applying these additives is still lacking.

- 3.

Further research: Given the importance of polymer-based additives in overcoming concrete’s operational and esthetic limitations, there is an urgent need for more rigorous guidelines and methodologies to effectively incorporate these additives into concrete formulations. Establishing such frameworks would promote rational utilization and facilitate the integration of novel polymer additives into practical applications.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Neila Ye. Bekturganova: project administration, funding acquisition, methodology, writing–original draft, writing–review and editing. Inna V. Kolesnikova: methodology, writing–original draft, writing–review and editing.

Funding

This research was supported and funded by Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant 19679906).

Acknowledgments

This research was supported and funded by Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant 19679906).

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.