Photonic Crystal-Integrated Semitransparent Solar Cell for Solar Greenhouse Application

Abstract

Solar greenhouse technology emerges as a solution that intensifies crop yields and allows utilities to generate energy from photovoltaic cells. Here, we demonstrate a photonic crystal-integrated solar cell that selectively transmits photosynthetic light for plant cultivation and reflects the remaining light to the adjacent solar cells to generate electricity. The photonic crystal is fabricated using an e-beam evaporation method by nonperiodic stacking of TiO2 and SiO2 layers to transmit light at 400–500 nm (blue) and 600–700 nm (red) and reflect green (500–600 nm), ultraviolet, and infrared light. The photonic crystal-integrated solar cell is constructed with the vertically arranged copper indium gallium diselenide (CIGS) solar cell and the tilted photonic crystal with respect to the CIGS cell. By controlling the tilting angle of the photonic crystal film, it achieves the generated electric power of 40.2 W m-2 and the irradiance of 124.6 W m-2 for transmitted photosynthetic lights (400–500 and 600–700 nm). In contrast, a conventional horizontal CIGS cell shows a power generation of 55.6 W m-2 without any light transmission. This work provides a new optical strategy and design principle for the development of a wavelength-selective semitransparent solar cell.

1. Introduction

Controlled-environment agriculture, such as greenhouses and vertical farms, has been widely recognized as a primary solution for sustainable food production [1]. The crop yield can be maximized within the minimum space with efficient control of essential plant growing necessities, such as water, temperature, humidity, ventilation, light, and CO2 [2, 3]. With the increasing number of industries implementing this idea, much greater energy is required to drive these microclimate controls. In addition, with the current high demand for land for renewable energy production, there is a high risk of food scarcity due to converting land usage from food farming to renewable energy farming [4–6]. Therefore, a more sustainable system is needed to ensure the food and energy demand.

One of the most recent technologies developed to satisfy these conditions is integrating photovoltaic technology with greenhouse operation [3, 7, 8] (i.e., solar greenhouse technology). With this technology, solar light is converted to electricity using a solar cell directly to drive the photosynthetic reaction in plants, outperforming traditional greenhouses in terms of carbon footprint [9]. The generated electricity can be used directly for greenhouse operations or exported to a power grid or battery when surplus energy is generated [10]. In this system, the primary role of the greenhouse cover/cladding materials is to direct the light into the internal environment of the greenhouse and toward the solar cells, in addition to protecting the interior from damaging UV light. For this purpose, many transparent solar cells for invisible energy harvesters can be adopted. For example, a lightweight and flexible Ga2O3/Cu2O heterojunction can generate electric power with 1.66% power conversion efficiency (PCE) while delivering photovoltage of 900 mV with a power of 1.66 mW cm-2 [11]. This heterojunction allows for electric power generation while maintaining the UV and visible light-controlling properties of the material. In another work, a broadband energy harvester, integrated transparent photovoltaic-transparent heater (TPV-TH), simultaneously blocked ultraviolet (UV) rays and maintained 39% light transmittance, while generating 6 mW onsite power which corresponds to 3% PCE under AM1.5G condition [12]. Interestingly, this concept of electricity generation from a transparent material can be further evolved by incorporating a color-tuning scheme. For example, color-tunable photovoltaic cells were reported to deliver onsite power for indoor applications [13]. The color can be tuned by controlling the thickness of the ZnO back reflector (BR) layer, thus performing a high efficiency of 3.8% under indoor light.

Accounting for the photosynthetically active radiation (PAR) mainly comprised of 400–500 (blue) and 600–700 nm (red) wavelengths [14], a successful greenhouse cover material should transmit light within this wavelength range [15–18]. While excessive direct solar radiation results in crop damage, limited radiation may inhibit plant growth. In addition, an appropriate cover design excludes undesirable light that are harmful to the plant, such as ultraviolet (UV), green, or near-infrared light, which can increase the temperature inside the greenhouse [14, 19]. Therefore, engineering the cover materials requires highly fine-tuned efforts that satisfy plant needs, which are unique for each plant [9, 19, 20].

Among many developed materials, photonic crystals, with their unique ability to manipulate the flow of light, present a revolutionary solution as greenhouse cover materials [21], particularly in optimizing plant growth through precise control of transmitted radiation. The tunability of photonic crystals allows for the selective transmission of crucial photosynthetically active radiation (PAR) while efficiently reflecting detrimental lights. Especially, significant advancements have been made in the field of multilayer photonic crystals employing nonabsorbing and nondispersive titanium dioxide (TiO2) and silicon dioxide (SiO2) which are widely used for visible range transmission [22]. The work by Kanehira et al. laid foundational insights into the fabrication and optical characteristics of TiO2/SiO2 multilayer structures [23]. Subsequent contributions delved into the optimization of layer thicknesses [22, 24], temperature evolution [25], and porosity [26] to achieve specific optical functionalities. This collective progress underscores the versatility and promise of the manipulable photonic response of TiO2/SiO2 multilayer photonic crystals and its adaptability as cover materials in a greenhouse.

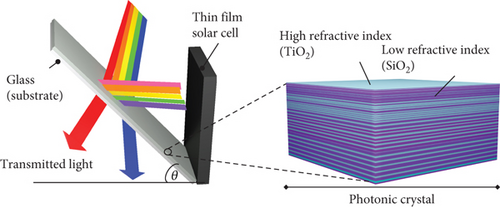

In this work, we demonstrate a photonic crystal-integrated solar cell (PCISC) that selectively transmits photosynthetically efficient light for plant cultivation and reflects the remaining wavelengths to the integrated solar cells to produce electricity (Figure 1). To prepare the photonic crystal, we simulated a nonperiodic multilayer comprising TiO2 and SiO2 to transmit specific wavelengths (400–500 nm and 600–700 nm) [27]. Then, we fabricated it using electron beam evaporation on a glass substrate. The photonic crystal was installed with an inclined angle relative to a vertical solar cell to direct reflected light into the solar cell. The effects of a tilting angle on power generation and light transmission were studied. By applying the photonic crystal-integrated solar cell onto the virtual greenhouse roof, the photosynthetically active light can be illuminated with high irradiance while assuring a significant amount of power generation comparable to a conventional horizontal solar cell.

2. Materials and Methods

2.1. Photonic Crystal Simulation and Fabrication

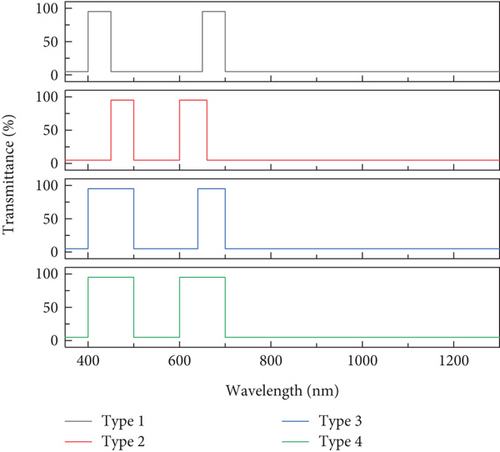

The photonic crystals were designed and fabricated considering the wavelength range of light for plant photosynthesis as in previous publications [28, 29]. Briefly, the photonic crystals were designed to transmit the blue (450 nm) and red (660 nm) light while reflecting the green (550 nm) and infrared (>1000 nm) lights using the Essential Macleod simulation program (Thin Film Center, Inc., USA). In the simulation process, TiO2 (with a high refractive index) and SiO2 (with a low refractive index) were adopted as materials for the photonic crystal. All photonic crystal types were initially designed with the optical thickness of (0.5SiO2/TiO2/0.5SiO2)n, and refinement processes were performed to minimize the ripple at the baseline. Four types of photonic crystal were designed according to the transmission bands, (1) type 1 with transmission bands of 400–450 and 650–700 nm, (2) type 2 with transmission bands of 450–500 and 600–650 nm, (3) type 3 with transmission bands of 400–500 and 640–700 nm, and (4) type 4 with transmission bands of 400–500 and 600–700 nm, to obtain the photonic crystal that gives the highest transmission and reflection in the desired wavelength region. The SiO2 and TiO2 were then deposited accordingly, following the calculated nonperiodic sequence at a temperature of 250°C using an e-beam evaporator on a 10 × 10 cm glass substrate. The cross-section of the fabricated photonic crystals was confirmed using field-emission scanning electron microscopy (JSM-7610F, JEOL Ltd., Japan), and the transmittance was confirmed using UV-visible spectroscopy (LAMBDA 365, PerkinElmer, Inc., USA). The detailed simulated and fabricated layer thicknesses are shown in Table S1.

2.2. Photonic Crystal-Integrated Solar Cell Performance Measurement

3. Results and Discussion

Figure 1 demonstrates a schematic of the photonic crystal-integrated solar cell for solar greenhouse application. The optical properties of the one-dimensional photonic crystals (1DPC) can be tuned by designing its stacking components to only reflect a specific wavelength range [27–32]. The lights reflected by the photonic crystal are absorbed by the thin-film solar cells to generate electrical power, which can be employed for greenhouse operation. The CIGS solar cell was used as the model solar cell because it allows for light absorption with a high-power conversion efficiency in a broader wavelength range [33].

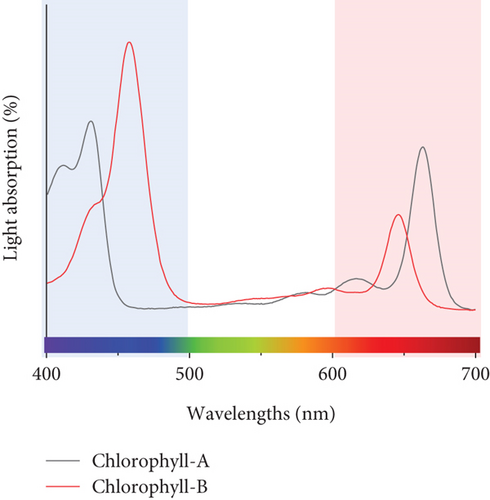

It is known that blue (400–500 nm) and red (600–700 nm) lights of the PAR constitute the light absorbed by plants to carry out photosynthetic reactions (Figure 2(a)) [14]. Photosynthetic reactions efficiently occur when important photosynthesis pigments such as chlorophyll a, chlorophyll b, and carotenoids absorb light under these blue and red regions [34, 35]. Additionally, in some cases, the illumination of green light (500-600 nm) hinders the growth of plants and lowers the photosynthates such as protein and starches [36]. Therefore, the structural design of photonic crystal thin films was simulated to selectively transmit the red and blue lights. Four types of photonic crystal were designed in this study: types 1, 2, 3, and 4. Each type was designed to transmit light with different center wavelengths and bandwidths at the wavelength regions of 400-500 nm (blue) and 600-700 nm (red) (Figure 2(b)). The simulation is based on the constructive and destructive optical interferences produced within a multilayer thin film comprising high and low refractive index materials [28, 29, 37, 38].

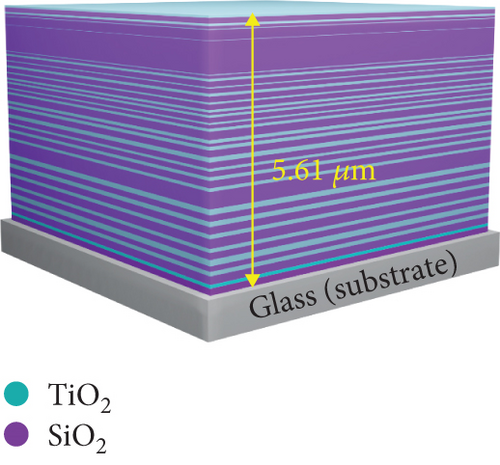

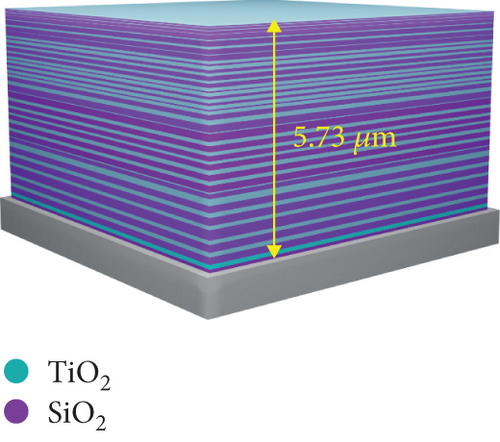

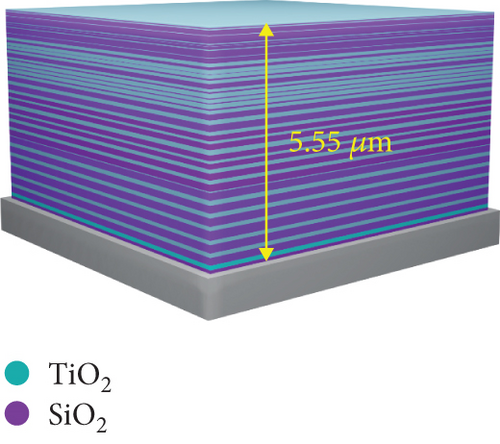

The photonic crystals were fabricated using an e-beam evaporator to deposit SiO2 (theoretical refractive index = 1.46) and TiO2 (theoretical refractive index = 2.31) layers nonperiodically on a 10 × 10 cm transparent glass substrate to maximize the light-transmitting property of the photonic crystal. The e-beam evaporator method is used because of its capability to create high resolution structures with intricate and precise features with direct writing and rapid prototyping capability [39]. For type 1 1DPC, a total of 52 layers consisting of TiO2 and SiO2 were deposited according to the simulated thickness (Figure 2(c)). Meanwhile, 62 layers for type 2 (Figure 2(d)) and 60 layers for type 3 and 4 1DPC (Figures 2(e) and 2(f), respectively) were deposited; the thicknesses of each layer is provided in Table S1, where layer #1 corresponds to the starting layer. The detailed analysis results of material characterization on the photonic crystal thin films can be found in Figure S2 (reproduced with permission from Ref. [32]). These deposited layers yield total thicknesses of 5.61, 5.62, 5.73, and 5.55 μm with an average per layer thickness error of 8.18, 10.72, 7.83, and 7.99 nm for type 1, 2, 3, and 4 1DPC, respectively (Figure S3). The significant contrast of refractive indices between SiO2 and TiO2 enables the production of narrowband and pure colors by combinatorically optimizing the layer structural parameters, such as the thickness, stacking order, number of stacking pairs, and periodicity of the high- and low-index layers [27]. The nonperiodic stacking layer photonic crystal yields enhanced color purity with the minimum baseline of ripple-shape patterns [27, 32], which is crucial for selectively transmitting photosynthetic active light.

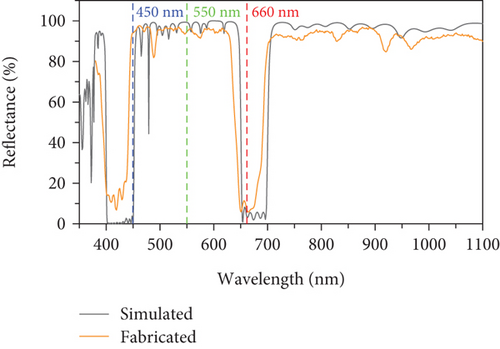

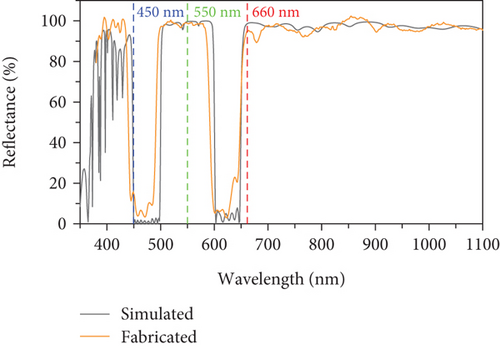

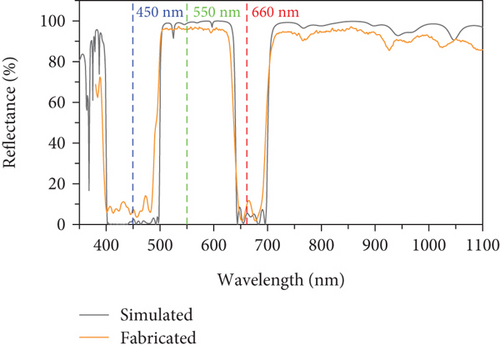

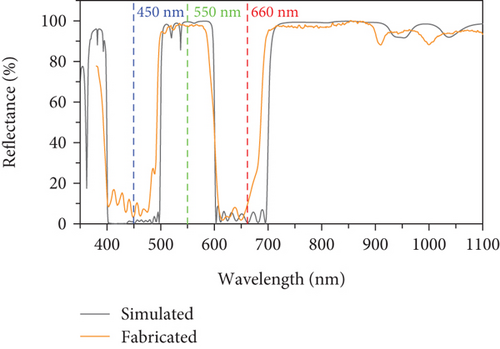

In Figure 3 and Figure S4, reflectance and transmittance spectra are presented for both simulated and fabricated photonic crystals. For type 1 1DPC, only 14.4% and 7.9% reflectances were measured under 400-450 nm and 650-700 nm spectral region, while the simulated reflectance values were 1.0% and 4.3%, respectively. Conversely, within the wavelength range of 450-650 nm, the 1DPC exhibited a reflectance of 94.8%, slightly below the simulated value of 97.3%. In type 2 1DPC, a comparatively lower reflectance value of 9.4% and 10.5% was obtained under 450-500 nm and 600-650 nm regions, which also substantially deviated from the simulated values of 1.3% and 3.8%. However, a notably high reflectance of 98.2% was achieved under 500-600 nm region, closely approaching the target reflectance of 98.8% in the same wavelength region. Meanwhile, under 400-500 nm region, type 3 and 4 1DPC reflect only 8 to 9% of light, while maintaining low reflectance of approximately 5.9% at 650-700 nm (type 3) and 600-700 nm (type 4). Furthermore, these filters demonstrated a high reflectance up to 97% under 500-600 nm region.

The reflectance spectra suggest that the fabricated photonic crystals successfully reflect the targeted wavelengths as simulated in all spectra, with only <4% shift from the target wavelength. Among all fabricated photonic crystals, the type 4 photonic crystal exhibited the appropriate bandwidths around the wavelengths of blue (450 nm) and red (660 nm) lights (Figure 3(d)), which are the primary target wavelengths for greenhouse operations. It can be identified that the band center is positioned at 450 and 650 nm with a bandwidth of approximately 100 nm for the transmission of blue and red light. Moreover, the band center for the reflection of green light is placed at 550 nm with a bandwidth of 100 nm. Furthermore, the high reflectance at wavelengths higher than 780 nm indicates that these photonic crystals successfully reflect near-infrared light, which can be used for CIGS solar cells with a narrow bandgap. The reflection of near-infrared light can also help to increase energy efficiency in greenhouse operation because infrared light could require excessive cooling [7, 42, 43].

The photonic crystal-integrated solar cell was constructed with a vertical solar cell and a tilted photonic crystal (type 4) as illustrated in Figure S1. Spectral irradiance of transmitted solar light, following its passage through the tilted photonic crystal, was measured using a spectrophotometer positioned beneath the crystal. Concurrently, the solar cells were linked to a portable multimeter to quantify generated power. The irradiation of the solar spectrum was performed using a solar simulator. The selection of a commercial CIGS solar cell was based on its capacity for light absorption across a wide wavelength range of 400 to 1100 nm [44, 45]. A summary of the reported cell efficiency and performance is provided in Table S2.

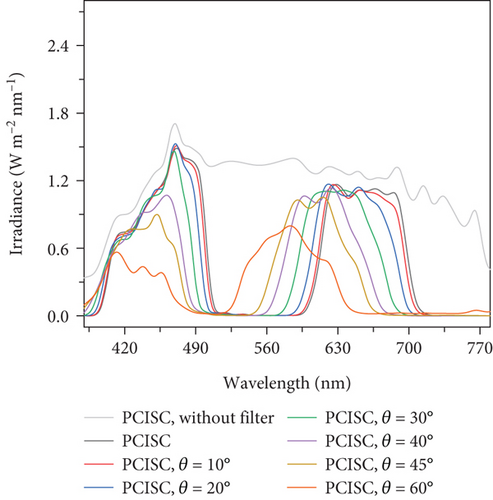

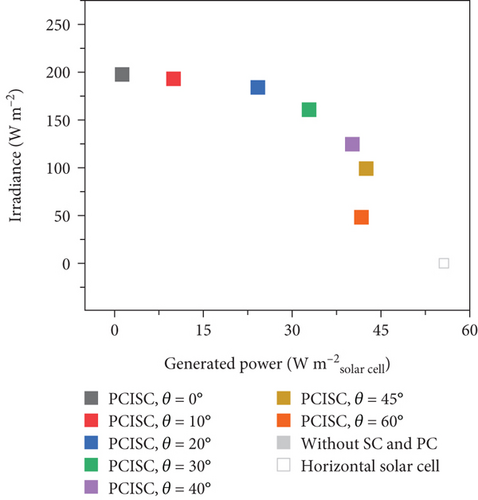

As presented in Figure 4(a), tilting the photonic crystal resulted in the wavelength shift and the intensity decrease of transmitted light. This phenomenon arises from variations in the incident light angle, causing different light reflection and refraction interference between the multilayer interfaces or Bragg stack within the photonic crystal coating [29, 37, 46]. Nevertheless, it is intriguing to note that the tilting of the photonic crystal facilitates the generation of electricity by the solar cell (Figure 4(b)). Systematic variation of the tilt angle from 0 to 45° resulted in an increase of the generated power from 1.46 to 44.35 W m-2. This improvement results from the capability of the inclined photonic crystal to redirect reflected solar irradiation toward the solar cell. Consequently, a greater proportion of residual light penetrates the light absorption region of the solar cell, thereby resulting in an elevation of the generated electricity [47, 48]. In summation, the photonic crystal-integrated solar cell generates electricity in the cost of transmittance.

By setting the tilting angle at 40°, PCISC achieves a generated electric power of 40.2 W m-2 and the irradiance of 124.6 W m-2 for transmitted photosynthetic lights (400–500 and 600–700 nm). In contrast, a conventional horizontal CIGS cell shows the power generation of 55.6 W m-2 without any light transmission. This power generation is equivalent to 6.55% power conversion efficiency (PCE) considering the lower nominal lamp power used which is 144 W. Without photonic crystals and solar cells (denoted as without SC and PC in Figure 4(b)), the irradiance for transmitted photosynthetic lights was measured to be 239.3 W m-2. Therefore, the photonic crystal-integrated solar cell enables about 72.3% of its maximum capability for electricity generation, which corresponds to 5.75% PCE, while still allowing the irradiation of blue and red lights. These results show that the light-guiding technology that utilizes photonic crystal is useful for solar greenhouse applications, as it exceeds the PCE records from present works about transparent photovoltaic (TPV) applications for self-sustain building [11–13]. However, for the harsh environment in the greenhouse applications, it is necessary to ensure the stability of the metal oxide layers composing the photonic crystal stability. Therefore, further study about the encapsulation process to ensure high permeability and chemical stability will be conducted in the future.

4. Conclusions

In summary, we simulated 1-D photonic crystals composed of a nonperiodic multilayer of SiO2 and TiO2 to design a photonic crystal that not only selectively transmits red and blue lights for photosynthesis and but also reflects UV, green, yellow, and infrared lights for electricity generation by CIGS solar cells. The photonic crystal was prepared with an e-beam evaporation method on a glass substrate. The developed photonic crystal can deliver high transmittance for solar light in the PAR (400–500 and 600–700 nm) into the greenhouse interior while reflecting the remaining wavelengths. When the tilted photonic crystal was integrated with vertically arranged CIGS solar cells under simulated solar light, it made up 72.3% of the electricity power generated from horizontally placed solar cells. It allowed the transmission of PAR light at moderate levels of 52.1% to promote crop cultivation. Especially, when tilting the type 4 filter at 40°, 40.2 W m-2 electric power can be generated while maintaining 124.6 W m-2 irradiance of PAR light, which corresponds to 5.75% PCE. This proof of concept proposes an alternative cover material for solar greenhouse to realize new possibilities to elevate crop yields with net-zero emissions in the agricultural field.

Conflicts of Interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Acknowledgments

This work was supported by the Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry (IPET) and Korea Smart Farm R&D Foundation (KosFarm) through Smart Farm Innovation Technology Development Program, funded by the Ministry of Agriculture, Food and Rural Affairs (MAFRA) and Ministry of Science and ICT (MSIT), Rural Development Administration (RDA) (No. RS-2024-00402759). This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean Government (MSIT) (RS-2023-00210114 and NRF-2022R1A4A1019296).

Open Research

Data Availability

The data used to support the findings of this study are included within the article.