Model-Free Robust Backstepping Adaptive Cruise Control

Abstract

This paper studies the model-free robust adaptive cruise control problem of a vehicle with unknown nonlinear dynamics and disturbances. First, under backstepping control framework, the position tracking errors with different spacing strategies are used to design a virtual control law, which provides a velocity reference. Then, a novel data-driven sliding surface whose parameters are updated by designing estimation algorithm is developed to handle the unknown uncertainties and disturbances. Finally, the model-free robust backstepping adaptive cruise control (MFRB-ACC) method including PI control, model-free control, and robust control is designed. The novelty of the proposed control technique lies in its strong robustness, which is not based on the precise vehicle model. The designed data-driven sliding surface releases the necessity for the accurate mathematical model of the vehicle and guarantees the inherent robustness of the controller, in particular to uncertainties, modelling error, or external disturbance. Moreover, the designed controller contains three terms such that it has an effective decoupling ability and strong robustness. The effectiveness and superiority of the designed MFRB-ACC method are validated on MATLAB, and the simulation results show that compared to the PID algorithm, the designed MFRB-ACC algorithm can track its preceding vehicle with lower tracking error under different spacing strategies, different operating conditions, and low sampling frequencies. Especially at a sampling frequency of 0.1 s, the error under the PID-ACC increases from 0.2 m at a sampling frequency of 0.01 s to 2 m, and the error under MFRB-ACC has little change compared to the error at a sampling frequency of 0.01 s.

1. Introduction

Adaptive cruise control (ACC), which is an advanced driver assistance system (ADAS), has been attractively studied and equipped in some brands’ high-end vehicles [1]. Unlike the widely used cruise control (CC) which aims to maintain a constant velocity, ACC mainly focuses on tracking predecessor vehicle with a desired distance by adjusting its velocity adaptively [2]. As a consequence, ACC has unique advantages in driver desired response and fuel economy [3]. From the control theory perspective, previous researches about ACC mainly focused on the controller designation with different models, different spacing strategies, different control methods, and their tracking performance, stability, and robustness.

1.1. ACC from Vehicle Model Perspective

At present, ACC mainly adopts one- or two-layer control structure. For the one-layer control structure, a three-order vehicle model is established, where the accelerator and brake pedal of the engine are taken as the inputs, and the position and velocity of the vehicle are taken as the outputs. California PATH Program uses this type of model to develop its controller [4]. For the two-layer control structure, the upper layer determines the desired longitudinal acceleration according to the driving environment, and the lower layer controls the accelerator and brake pedal of the engine such that the vehicle can move with the desired longitudinal acceleration of the upper layer. The lower-layer control can be well achieved using existing control methods. So, the researchers mainly focus on the controller designation of the upper-layer vehicle model. For instance, [5] proposed a model predictive control (MPC) structure to solve the ACC problem with nonlinear vehicle model, where MPC is placed in the upper layer. [6] designed a multiobjective upper-layer controller for ACC under MPC theory, and the designed ACC can solve the problems of fuel economy, tracking capability, and driver desired response. It should be pointed out that the above methods require the accurate vehicle model for controller designation. However, it is impossible to establish the accuracy vehicle model due to uncertainties, disturbances of the mechanism (actuator, sensors, etc.), and interference of the complex external environment (time-varying driving resistance caused by different weather, road, etc.) [7, 8].

In order to avoid the necessity for the accurate vehicle model, neural network and fuzzy logic were used to approximate the nonlinear terms of a vehicle in many kinds of researches. For example, [9] used radial basis function neural networks (RBF NNs) to approximate the unknown driving resistance of a vehicle, and a neural cooperative ACC was designed. [10] adopted a fuzzy model to approximate the preceding vehicle model so that the unknown tracking target was predicted. However, the approximate ability is related to the high-frequency adaptive law and the number of neurons. Besides, PI/PID approaches were applied in various fields without any model knowledge to achieve complex tasks [11]. [12] proposed an intelligent PI feedback/feedforward control scheme to design the ACC system. In the Grand Cooperative Driving Challenge (GCDC), [13] used PID control to design ACC for production vehicles. However, nonlinearities and disturbances of vehicle dynamics are still intractable problems for PID control. So, in practice, PID controller adopts a high-frequency control strategy (usually 0.01 s) to reduce the disturbances of nonlinearities and disturbances. It is clear that both neural ACC and PID ACC require high-frequency sampling and control, which cause great requirements for sensors and actuators. So, it is necessary to design ACC which can release the necessary high-frequency time steps and accurate vehicle model.

1.2. ACC from Spacing Strategy Perspective

Spacing strategy provides reference distance for ACC algorithm; it can be seen as the basic control objective of the ACC. Too small spacing strategy may cause traffic collision. Too large spacing strategy will not only lose the traffic capacity of the road but also can be easily inserted by vehicles in adjacent lanes. So, the spacing strategy has important influence for the tracking performance. There are two main spacing strategies: constant spacing strategy and variable spacing strategy [14]. The constant spacing strategy means that the vehicle moves at a constant distance. This strategy is simple, less computation, and has no interference with the controller designation. But the constant spacing strategy cannot adapt to the complex and changeable driving environment. To solve this problem, variable spacing strategies were widely studied. Representative strategies include time headway-based spacing strategy and human factor distance strategy.

The time headway spacing strategy means that the desired space keeps a linear relationship with the vehicle’s velocity. The greater the velocity, the greater the desired space, and vice versa. Headway is another factor that affects the desired space. If the headway is constant, the spacing strategy is called constant time headway (CTH) [15]. [16] studied the driving performance and traffic flow of the ACC with different values of time headway according to a large number of simulations, and the results shown that different driving environments should adopt different time headway. [17] pointed out that CTH is too conservative in the complex driving environment due to it does not consider the velocity of its preceding vehicle. If the headway is a variable, the spacing strategy is called variable time headway (VTH) [18]. Different from CTH, the time headway of VTH changes with the driving environment [19]. It should be pointed out that the variable space will lead to the variable control objectives and increase the difficulty of controller design. The existing ACC is mainly designed for the specific spacing strategy, which cannot achieve other space requirements. So, it is necessary to design ACC which can achieve the tracking control for different spacing strategies.

1.3. ACC from Control Method Perspective

ACC designation mainly relies on the model-based and approximation-based approaches. Due to the vehicle having complex hydrodynamics with uncertainties and interferences induced by internal equipment and the external environment, accurate vehicle modelling is difficult and even impossible [20]. Thus, the model-based ACC approaches mostly adopt the nominal vehicle model. Specifically, the ACC is designed using nonlinear model predictive control for the nominal vehicle model [21]. Then, to make the ACC system more robust, sensor failure, actuator failure, energy efficiency, and other problems are considered and solved based on the MPC framework [22]. In addition, by linearizing the nonlinear model of the longitudinal vehicle equation of motion, proportional integral (PI), and proportional integral derivative (PID), H∞, sliding mode-based ACC structures are designed. However, the above results rely on the accurate vehicle model. To improve the control performance for the vehicle with uncertain parameters, the adaptive control approach is used to design the ACC structure [22]. Furthermore, to design the ACC for the vehicle with unknown nonlinear driving resistances and disturbances, approximation-based approaches are used to design ACC by developing fuzzy logic or neural network techniques [23]. For example, [24] used a fuzzy model to approximate the model of the preceding car, and a predictive control scheme was developed by neural network technique for the ACC system. Although many methods have been proposed, there still exist open issues. Specifically, nominal model and system order are required in the above approximation-based and model-based methods.

During the past decades, PI/PID approaches were applied in various fields without any model knowledge to achieve complex tasks. Recently, model-free control was paid more attention due to its advantages in handling nonlinearities with input and output data only [25, 26]. Although the nonlinearities and uncertainties can be handled using model-free control, the robustness of the control system is hardly guaranteed, and it is aimed at being the first-order nonlinear system. Backstepping technique decomposes the high-order system into several first-order systems. The variables of the next level are regarded as virtual inputs, which act on the first-level system. At the same time, the Lyapunov function is established according to the upper-level system to achieve system stability, until the last system realizes control and gets the input [27, 28]. Backstepping technique provides a complete controller design framework for high-order nonlinear systems to study different problems, such as state constraints [29–31], fixed-time stabilization [32], event-triggered control [33], and prescribed performance control [34]. A combination of backstepping technique and model-free control can provide a research line for model-free ACC design. Sliding mode control is usually used to guarantee robustness and has been well applied [35–37]. In [38], a robust fractional-order fast power-reaching guidance scheme was proposed by introducing the fractional-order operator into the sliding surface. In [39], a new robust fixed-time sliding mode control was proposed by using a fixed-time sliding mode observer for the trajectory tracking problem of the flexible joint robot attached to the drone system. To achieve high performance for the flexible joint robot control, [40] developed an adaptive integral sliding mode controller based on a singular perturbation method and two state observers. [41] developed a robust terminal sliding mode control for underactuated flexible joint robot. [42] proposed a cascaded-extended-state-observer-based sliding mode control for underactuated flexible joint robot. [43] proposed a robust fuzzy sliding mode controller for a skid-steered vehicle subjected to friction variations. [44] proposed a model-based chattering-free sliding mode control algorithm to maintain a desired heating value trajectory of the syngas mixture. [45] proposed a mass adaptive control method combined with robust sliding mode control and linear active disturbance rejection control. However, the superiority of traditional sliding mode control methods is based on the prior knowledge of the plant’s accurate model or nominal model, and the plant-model mismatch may determine the magnitude of the discontinuous term in the discrete sliding mode control law.

- (i)

Compared with the existing ACC method using accurate vehicle model, the model-free approach for the actual vehicle dynamics is investigated, where only the input and output data are used to design the controller

- (ii)

Compared with the existing ACC method for specific spacing strategy, the designed controller can achieve the tracking control for different spacing strategies

- (iii)

Compared with the existing ACC method needing high-frequency sample, the designed controller can achieve the tracking control with low sampling frequency

The rest of this paper is organized as follows: Section 2 presents the problem formulation. Section 3 proposes the ACC method. Illustrative examples are given in Section 4. Section 5 concludes this paper.

2. Problem Formulation

2.1. Vehicle Motion with Disturbances

The model (3) has the following properties: the mass of vehicle M(t) is time-varying and unknown. The model disturbance w(t) also is time-varying. Thereby, the nonlinear function H(⋅) is time-varying. Thus, the available neural network approaches cannot be simply applied to achieve the vehicle adaptive control.

Property 1. The vehicle (3) satisfies the Lipschitz condition for Δp(k), ΔF(k), and Δw(k), that is, |Δv(k + 1)| ≤ β|Δp(k)ΔF(k)Δw(k)|, where Δv(k + 1) = v(k + 1) − v(k), Δp(k + 1) = p(k + 1) − p(k), ΔF(k + 1) = F(k + 1) − F(k), Δw(k + 1) = w(k + 1) − w(k), and β is a small constant.

2.2. The Adaptive Cruise Objective

- (i)

Constant space (CS)

- (ii)

Constant time headway (CTH)

- (iii)

Varying time headway (VTH)

3. Adaptive Cruise Control Design

- (i)

The backstepping error is defined, and the virtual control law is designed using backstepping technique for converting distance control to velocity control in Section 3.1

- (ii)

The data-driven sliding mode surface is constructed, and the data-driven estimation algorithm is designed to update the parameters of the designed data-driven sliding mode surface in Section 3.2

- (iii)

The MFRB-ACC controller, which contains PI control term, feedback control term, and discontinuous control term, is designed to achieve high precision vehicle tracking performance with strong robustness in Section 3.3

- (iv)

The stability of the closed-loop vehicle system is analysed using two steps in Section 3.4: (1) the boundedness of the parameters of the designed data-driven sliding mode surface; (2) the reachability of the sliding mode and the convergence of the tracking error

In this procedure, the construction of data-driven sliding-mode surface and the stability analysis are two key points, and we give four theorems to show the main results.

3.1. Backstepping Error

It is known that (14) results in the convergence of e(k).

Remark 2. The sampling time and the spacing strategies both have influence for the controller designation. The designed ACC should fully consider these factors.

3.2. Model-Free Vehicle System Description: Data-Driven Sliding Surface

Due to the accurate mathematical model of the vehicle, (1) is unavailable for the controller, and the tradition sliding surface (15) cannot be used directly to design the controller. Considering property 1 of the discrete form of vehicle dynamic (3), the data-driven sliding surface is given in the following theorem.

Theorem 3. For the vehicle (3) with unknown dynamics with property 1, there exists pseudopartial-derivative (PPD) Π(k), Φ(k), and Ψ(k), such that when ΔF(k) ≠ 0, the designed sliding mode surface (15) can be transformed as

In some cases, the nonlinear functions G1(⋅), G2(⋅), and G3(⋅) are not differentiable. For example, the mass of sprinkler-car, bus, and some other vehicles change discontinuously.

Case 1: M is smooth, the nonlinear functions G1(⋅), G2(⋅), and G3(⋅) can be differentiated.

Case 2: M is not smooth, and the nonlinear functions G1(⋅), G2(⋅), G3(⋅) cannot be differentiated.

In this way, (19) still can be obtained regardless of the differentiability of H(⋅).

Let Φ(k) = ∂G∗/∂pλ(k), Ψ(k) = ∂G∗/∂wλ(k), and Π(k) = (∂G∗/∂Fλ(k)) + (o(k)/ΔF(k)); then, (16) is obtained from (17). Moreover, the defined variables satisfy the inequalities |Φ(k)| ≤ β, |Ψ(k)| ≤ β, and |Π(k)| ≤ β according to Property 1.

The proof of Theorem 3 is completed.

There are three unknown terms in (21), Φ(k), Π(k), and . These terms affect the cruising effectiveness of the vehicle. Thus, the following data-based estimation algorithm is given.

Lemma 4 (see [26].)For the simplified data-driven sliding mode surface (21) of vehicle (1), the unknown terms Φ(k), Π(k), and could be updated by the following data-driven adaptive laws

3.3. Robust Controller

Remark 5. The designed controller contains three terms: PI control, feedback control, and discontinuous control. PI control term ΔFPI(k) is designed to stabilize the vehicle dynamic (3); feedback control term ΔFFEE(k) is designed to compensate the unmeasurable, measurable, and unmodelled disturbances; the discontinuous term ΔFDIS(k) is designed to guarantee the robustness. Thus, the designed hybrid controller has effective decoupling ability and strong robustness.

3.4. Stability Analysis

The stability of the closed-loop system of the vehicle (3) via MFRB-ACC contains two steps. (1) The boundedness of , , and ; (2) the reachability of the sliding mode and the convergence of the tracking error.

Theorem 6. Let the sliding-mode surface be

Proof. The mathematical induction is used to prove Theorem 6.

Step 1: it is reasonable that the initial conditions satisfy Theorem 6.

Step 2: suppose Theorem 6 holds at instant k − 1, which means , , , and are bounded and for j ∈ 1, 2, ⋯, k − 1, where and .

For the instant k, we have

- (1)

For |Π(k)| ≤ φ1, is bounded according to (24).

- (2)

For |Π(k)| > φ1, by subtracting Π(k) on the both sides of (22), it yields

Leveraging the work of [26], we have

Then, we have

Thus, the boundedness of is proved. Using the similar method, the boundedness of can be proved.

In order to analyse the boundedness of , (21) is written as

Defining and and combining (26) and (36), it yields

Since and are bounded, it can derive that and are bounded according to (36). Thus, there exists a constant such that , where . And it can further yield

Finally, it can be derived that , , and are bounded using the above discussion and mathematical induction.

The proof of Theorem 6 is completed.

Proposition 7. Define . The term is bounded with the help of Theorem 6, i.e.,

Theorem 8. Considering the vehicle (3) under Proposition 7, control law (28), adaptive laws (22)–(26), and virtual control law (11). If ρ is chosen as

Proof. Defining the following Lyapunov candidate function as follows:

Substituting (28) into (39) yields

Similarly, we can derive

Combining (45) and (46), we have

Then, it can derive

For any , it can derive V(k + 1) < 0. Thus, the quasisliding mode is obtained, and s(k + 1) satisfies s(k + 1)⟶0. Furthermore, by combining (15), we have

Defining , the solution of (49) can be obtained as follows.

Since KP, KI, σ, and θ are chosen as (2KP + KI)(−β + (σ/θ)) < 2, so it can derive

The proof of Theorem 8 is completed.

4. Simulation Studies

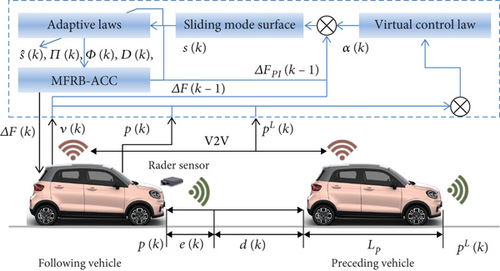

In this section, the MATLAB simulations, running on Windows 10 platform with Intel Core i7-11700, 16 G memory, are shown to demonstrate the effectiveness of the designed MFRB-ACC considering three factors: spacing strategies (CTH and VTH), sampling time (Ts = 0.1 and Ts = 0.01), and vehicle moving conditions (cut-out and cut-in). In addition, to illustrate the advantages of the designed MFRB-ACC, the PID-ACC is also used in the examples.

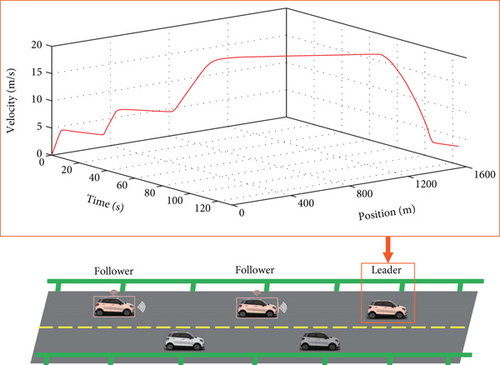

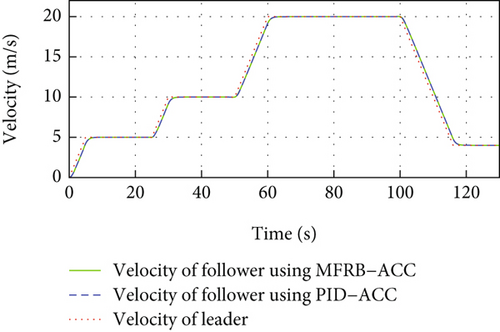

The time-velocity-position profile of the lead vehicle is shown in Figure 2. The parameters of the vehicle are given as follows: M = 3250 + 5000∗sin(0.01t)kg, Lp = 5m, g = 9.8m/s2, Af = 2.2m2, cr = 0.018 + 0.002∗sin(t), cf = 0.35 + 0.005∗sin(t), ρa = 1.2258, γ = 30, and δ = 1. These parameters can only be used to update the vehicle states and cannot be used in the controller.

4.1. Validation of Control Performance for the Spacing Strategy

In order to illustrate the advantages of the proposed controller for the different spacing strategies, the CTH and VTH are set as control objectives for the designed MFRB-ACC and PID-ACC.

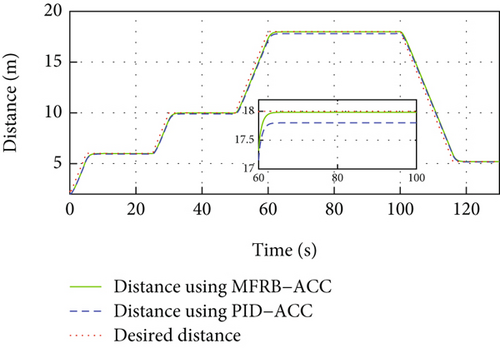

4.1.1. Control Performance for CTH

In this example, the spacing strategy is CTH, and the sampling time is Ts = 0.01. The desired distance parameters are set as follows: ds = 2 and h = 0.8. The designed MFRB-ACC scheme and the traditional PID-ACC method are used to perform the comparison analysis. The initial conditions of vehicle and system states are chosen as follows: p(1) = 0, v(1) = 0, pL(1) = 2, , , , F(1) = 3, and α(1) = −0.455. The control parameters of MFRB-ACC are chosen as follows: k1 = 0.1, θ = 0.9, σ = 1, KP = 2, KI = 0.1, , , , , ρ = 0.05, and . The control parameters of PID-ACC are chosen as follows: KP = 50, KI = 100, and KD = 50.

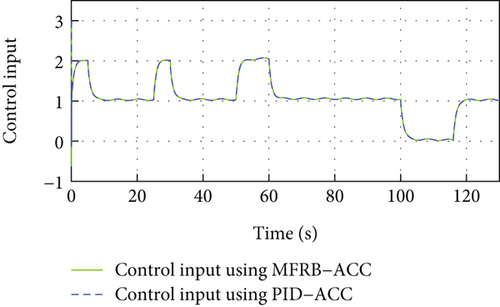

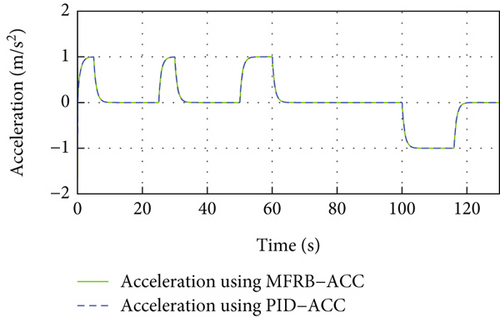

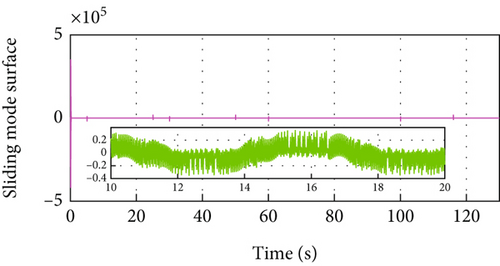

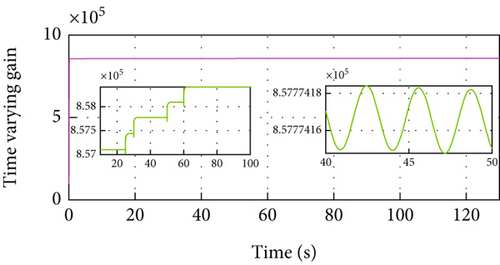

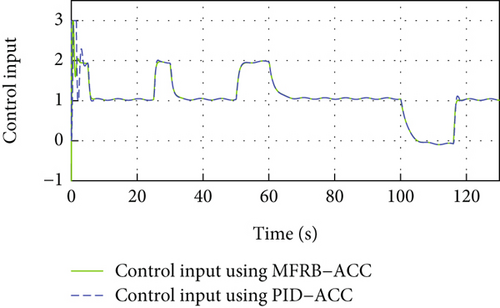

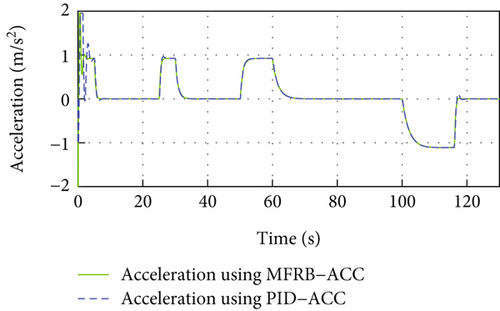

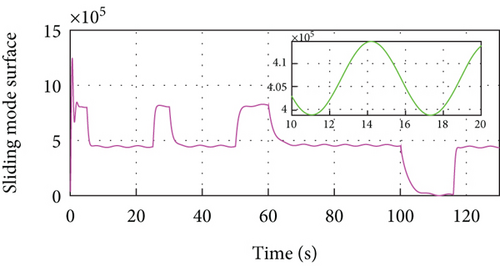

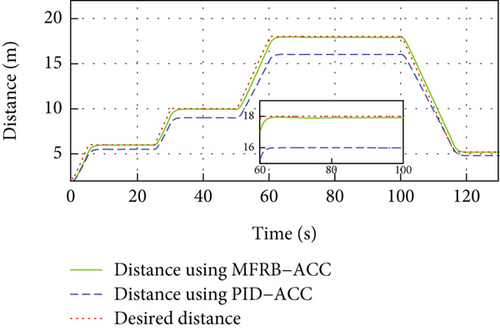

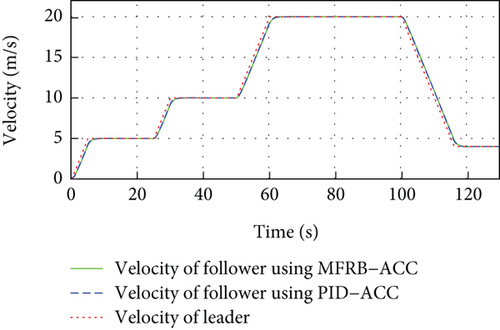

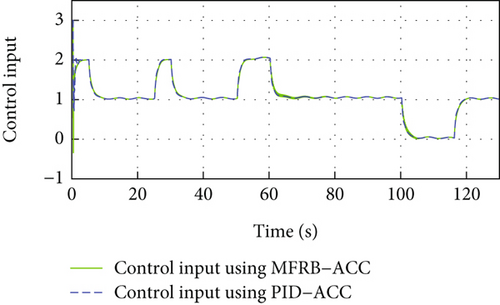

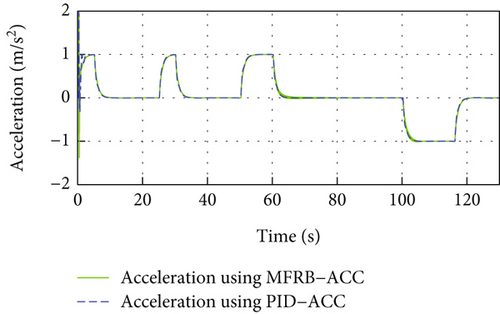

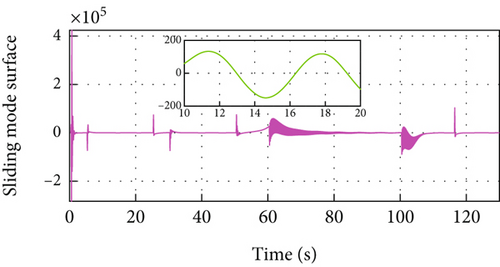

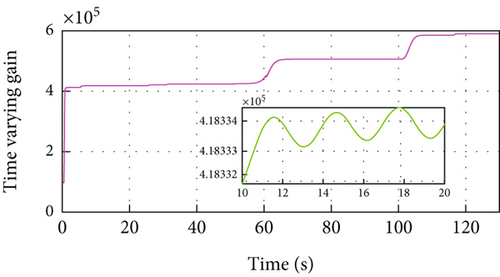

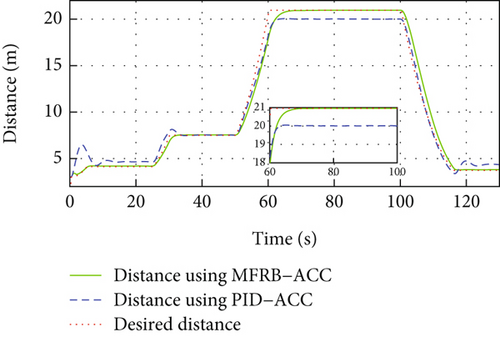

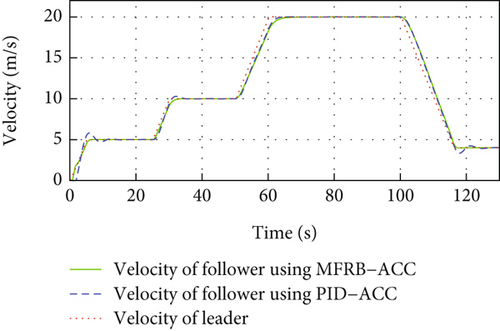

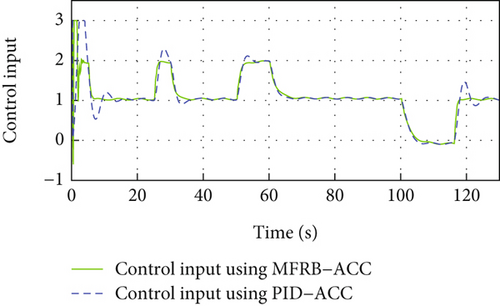

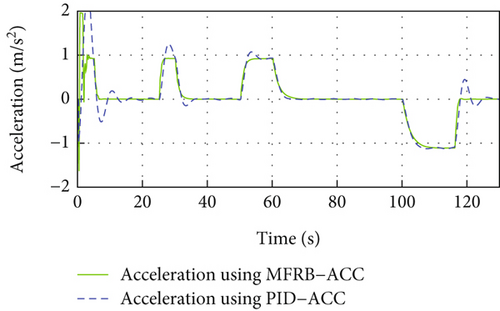

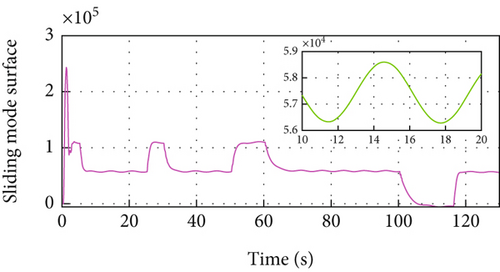

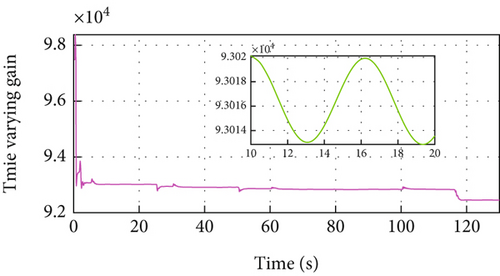

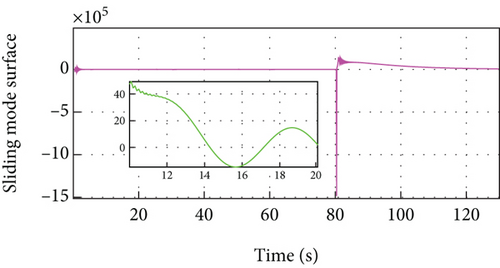

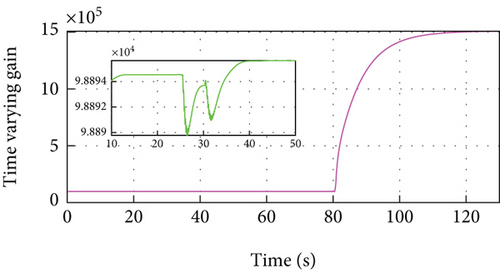

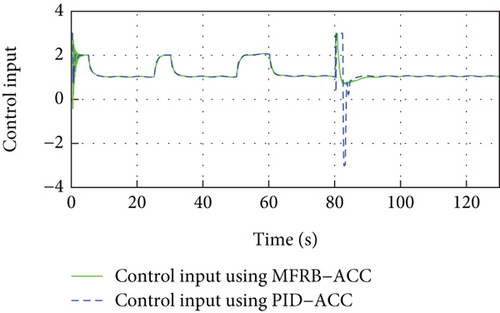

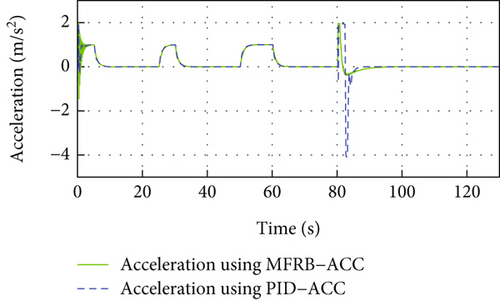

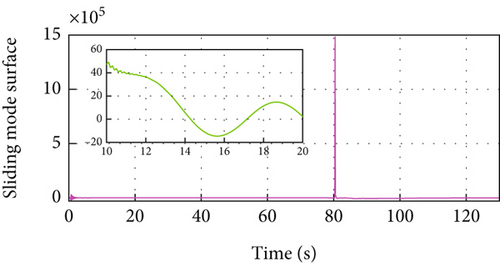

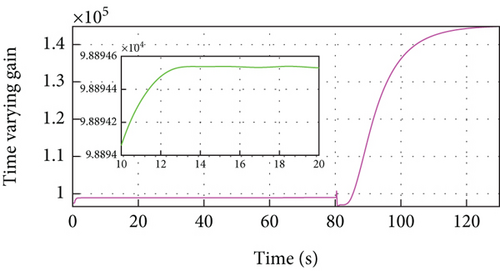

Figure 3 gives the distance, velocity, control input, and acceleration of the controlled vehicle, respectively. The vehicle can security track its preceding vehicle with the desired distance, even if the distance is varying with its velocity. Specifically, the MFRB-ACC exhibits better cruising performance than PID-ACC in terms of tracking precision during 60 s-100 s. In Figure 3(b), when the leader vehicle moves with constant velocity, the follower can track it asymptotically. When the reference trajectory changes, the controller provides corresponding force to accelerate the vehicle; moreover, the control input has no saturation in Figures 3(c) and 3(d). Figures 3(e) and 3(f) show the sliding mode surface and time-varying gain. All of these show that the designed MFRB-ACC can security track its preceding vehicle with good tracking performance and good ride comfort.

4.1.2. Control Performance for VTH

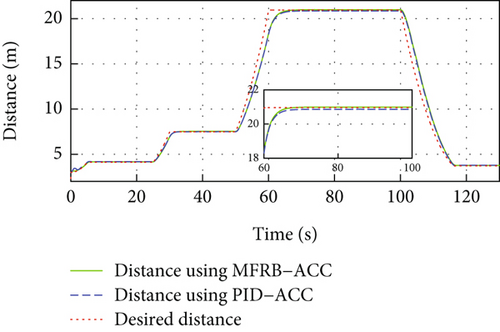

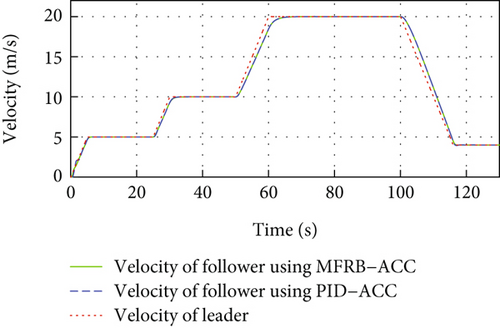

In this example, the spacing strategy is VTH, and the sampling time is Ts = 0.01. The desired distance parameters are set as follows: a = 3, b = 0.0019, and c = 0.0488. The initial conditions of vehicle and system states are chosen as the above example. The control parameters of MFRB-ACC are chosen as follows: k1 = 0.1, θ = 0.9, σ = 1, KP = 1, KI = 0.2, , , , , ρ = 0.005, and . The control parameters of PID-ACC are chosen as follows: KP = 5, KI = 10, and KD = 5.

In Figure 4, same as Figure 3, the developed MFRB-ACC exhibits better cruising performance than PID-ACC in terms of tracking precision during 60 s-100 s. Specifically, the position tracking error using PID-ACC scheme is larger than using MFRB-ACC. The main reason is the influence of unknown disturbances, unknown driving resistances, discretization errors, and backstepping errors. The MFRB-ACC scheme can achieve the full-velocity cruising with the desired distance. The main reason is that the designed decoupled PI-type sliding surface can deal with the disturbances and couplings, and the designed MFRB-ACC can compensate for the unknown nonlinearities. The simulation results demonstrate the decoupling ability and strong robustness of the developed MFRB-ACC scheme. Figure 4(b) shows that the velocity trajectory can track the leader. The control input is smooth, and there is no saturation in Figures 4(c) and 4(d). Figures 4(e) and 4(f) show the sliding mode surface and time-varying gain.

To evaluate the advantages of the proposed MFRB-ACC, Table 1 shows the position tracking error when using MFRB-ACC and PID-ACC, respectively. It is clear that the proposed MFRB-ACC has better control accuracy than PID-ACC.

| Sample time | 20 s | 40 s | 80 s | |

|---|---|---|---|---|

| CTH | MFRB-ACC | 0.005 m | 0.010 m | 0.018 m |

| PID-ACC | 0.050 m | 0.100 m | 0.200 m | |

| VTH | MFRB-ACC | 0.045 m | 0.040 m | 0.030 m |

| PID-ACC | 0.055 m | 0.050 m | 0.100 m | |

4.2. Validation of Control Performance for the Sampling Time

4.2.1. Control Performance for CTH

In this example, the spacing strategy is CTH, and the sampling time is selected as Ts = 0.1. The desired distance parameters, initial conditions of the vehicle, and system states are set as Example 1. The control parameters of MFRB-ACC are chosen as follows: k1 = 0.05, θ = 0.8, σ = 1, KP = 2, KI = 0.1, , , , , ρ = 0.005, and . The control parameters of PID-ACC are chosen as follows: KP = 5, KI = 5, and KD = 5.

Figure 5 gives the distance, velocity, control input, and acceleration of the controlled vehicle. The PID-ACC cannot guarantee the desired distance. Especially, if the velocity is larger, the tracking error is larger when using PID-ACC. Figure 5(b) gives the velocity trajectory of the vehicle and it can track the leader. The control input is smooth with a small jerk, and there is no saturation in Figures 5(c) and 5(d). Figures 5(e) and 5(f) show the sliding mode surface and time-varying gain.

In Figure 5(a) and Figure 3(a), PID-ACC causes errors to increase as sampling time increases, and the developed MFRB-ACC scheme shows better robustness. On the other hand, the relatively small sample time would cost large lots of computing resources. Thus, the sample time in practice should make a compromise between tracking accuracy and cost.

4.2.2. Control Performance for VTH

In this example, the spacing strategy is VTH, and the sampling time is selected as Ts = 0.1. The desired distance parameters, initial conditions of the vehicle, and system states are set as Example 2. The control parameters of MFRB-ACC are chosen as follows: k1 = 0.05, θ = 0.6, σ = 1, KP = 0.05, KI = 1, , , , , ρ = 0.05, and . The control parameters of PID-ACC are chosen as follows: KP = 2, KI = 1, and KD = 10.

In Figure 6(a), the PID-ACC cannot guarantee the desired distance. Same as Figure 5(a), the vehicle cannot track its preceding vehicle with the desired distance, and the tracking error is related with its velocity. Different velocity leads to different position tracking error. The developed MFRB-ACC can security track its preceding vehicle with the desired distance, even if the distance varies with its velocity. It illustrates that the developed MFRB-ACC exhibits the better cruising performance than PID-ACC in terms of tracking precision. Figure 6(b) gives the velocity trajectory of the vehicle. The control input is smooth with a small jerk, and there is no saturation in Figures 6(c) and 6(d). Figures 6(e) and 6(f) show the sliding mode surface and time-varying gain.

To evaluate the advantages of the proposed MFRB-ACC in low-frequency sample, Table 2 shows the tracking error of vehicle when Ts = 0.1. The results show that the proposed MFRB-ACC has better control accuracy than PID-ACC.

| Sample time | 20 s | 40 s | 80 s | |

|---|---|---|---|---|

| CTH | MFRB-ACC | 0.020 m | 0.050 m | 0.090 m |

| PID-ACC | 0.500 m | 1.000 m | 2.000 m | |

| VTH | MFRB-ACC | 0.075 m | 0.050 m | 0.004 m |

| PID-ACC | 0.525 m | 0.050 m | 0.900 m | |

4.3. Validation of Control Performance for Typical Condition

Above simulations verify the advantages of MFRB-ACC for the unknown vehicle nonlinear running resistances, spacing strategies disturbances, and sampling time errors. This section will test the control performance of MFRB-ACC in different work conditions, such as cut-in and cut-out.

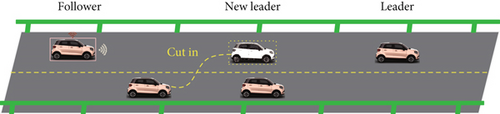

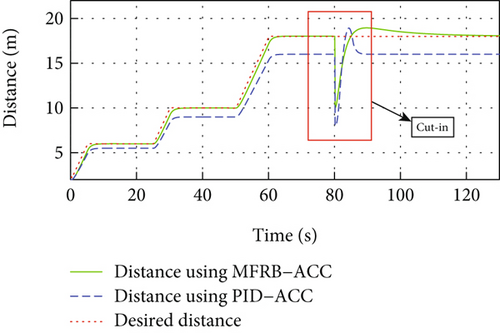

4.3.1. Cut-In Condition

As is shown in Figure 7(a), in this condition, a vehicle cuts between the follower vehicle and the leader vehicle, and the cut-in vehicle will be the new leader vehicle. As a result, the distance between the follower vehicle and the new leader vehicle is smaller than the desired distance. If the MFRB-ACC can make the two vehicles guarantee the desired distance, the robustness of MFRB-ACC can be demonstrated. In this condition, based on the example in Section 4.2.1, when the vehicle runs to 80 s, a vehicle cuts between the follower vehicle and the leader vehicle, and the distance between the follower vehicle and the new leader vehicle decreased by 8 m.

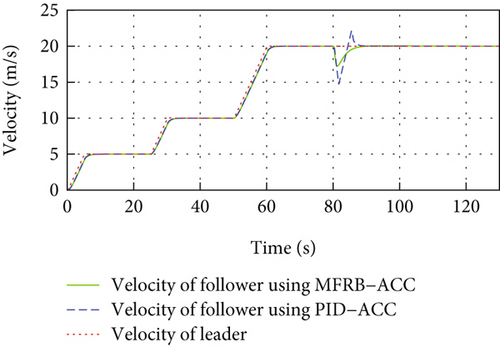

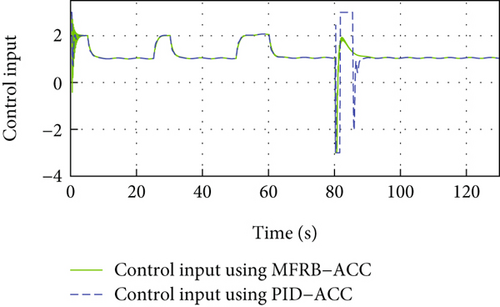

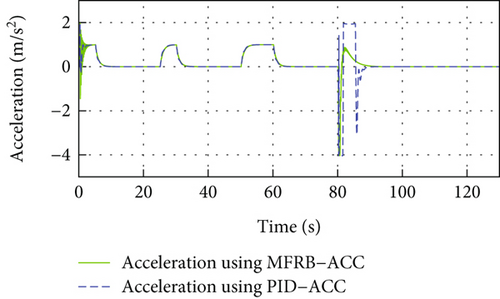

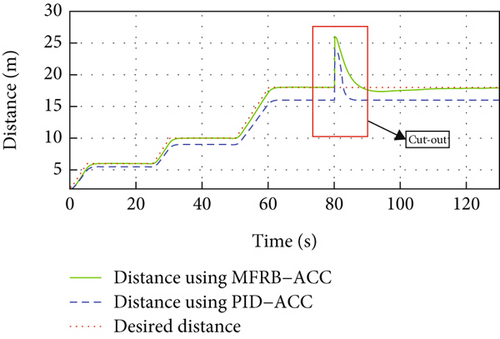

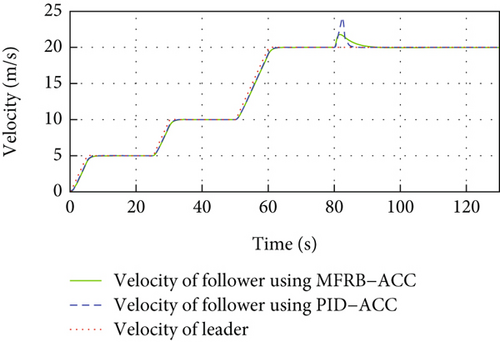

In Figure 8(a), a vehicle cuts between the follower vehicle and the leader vehicle at 80 s, and the developed MFRB-ACC adjusts the distance to the desired distance within 5 s and converges to the desired distance with a small position tracking error within 40 s. However, as shown in Figure 5(a), PID-ACC scheme tracks its preceding vehicle with a larger position tracking error even if it can rapidly adjust the distance to the desired distance. In Figure 8(b), the deviation of speed using PID-ACC is larger than using MFRB-ACC. The velocity curve has overshoot using PID-ACC. The change of speed is smooth using MFRB-ACC. All of these illustrate that MFRB-ACC leads to better ride comfort than PID-ACC. In addition, it can also demonstrate that the MFRB-ACC has strong robustness in different work conditions. These results can be also demonstrated in Figures 8(c) and 8(d). The PID-ACC leads to input saturation and leads to the vehicle moving with maximum acceleration and deceleration. However, the control input and acceleration using MFRB-ACC are smooth. Figures 8(e) and 8(f) show the sliding mode surface and time-varying gain.

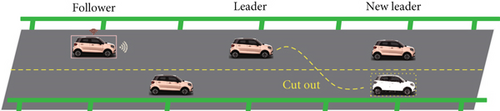

4.3.2. Cut-Out Condition

As shown in Figure 7(b), in this condition, the leader vehicle cuts out the current lane, and the follower vehicle remarks the leader vehicle. As a result, the distance between the follower vehicle and the new leader vehicle is larger than the desired distance. Same as Section 4.3.1, this simulation is based on the example in Section 4.2.1, and we assume that the leader vehicle cuts out the current lane at 80 s, and the distance between the follower vehicle and the new leader vehicle increased by 8 m.

In Figure 9(a), PID-ACC scheme tracks its preceding vehicle with a larger position tracking error even if it can rapidly adjust the distance to the desired distance. MFRB-ACC adjusts the distance to the desired distance asymptotically. As shown in Figure 8(b) and Figure 9(b), the deviation of speed using PID-ACC is also larger than using MFRB-ACC. In Figures 9(c) and 9(d), PID-ACC leads to input saturation and leads to the vehicle moving with maximum acceleration and deceleration. However, the control input and acceleration using MFRB-ACC are smooth. Figures 9(e) and 9(f) show the sliding mode surface and time-varying gain. All of these show the advantages of MFRB-ACC in tracking performance and robustness.

5. Conclusion

- (i)

This paper has studied the ACC problem of the nonlinear vehicle with disturbances. A novel MFRB-ACC method including PI control, feedback control, and robust control was designed. The model information was completely removed, and robust cruising control was ensured for the vehicle only using position and velocity data

- (ii)

The designed MFRB-ACC algorithm can accurately achieve different spacing targets such as CTH and VTH. Theoretically, this algorithm can accurately achieve any spacing policy

- (iii)

The designed MFRB-ACC can effectively compensate the discrete error caused by the low sampling frequency. Whether the sampling time is 0.01 s or 0.1 s, the designed MFRB-ACC algorithm can accurately track the leader vehicle with the desired distance

- (iv)

The designed MFRB-ACC has strong robustness. It can achieve stable and safe distance adjustment in different conditions, such as cut-in and cut-out

The designed MFRB-ACC can be applied to many nonlinear systems that are difficult to accurately model, such as robots, UAVs, and unmanned ships. Like many existing robust control methods, the designed controller has discontinuous robust term causing chatting phenomena, cannot be applied to or cannot be directly used on hardware platforms, and needs to be matched with other power electronics technologies. In the future, under the control framework of this paper, research on ACC control such as chatting-free will be carried out, and a comprehensive physical platform will be established.

Conflicts of Interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Acknowledgments

This work was supported by the Fundamental Research Funds for the Central University of China, Grant/Award number: Z1090122053.

Open Research

Data Availability

The data used to support the findings of this study are included within the article.