A New Unsteady Flow Control Technology of Centrifugal Compressor Based on Negative Circulation Concept

Abstract

The tip leakage vortex (TLV) induced by the tip clearance flow has a significant impact on the performance of centrifugal compressors, causing impeller flow losses and reducing the stall margin. To solve this problem, an unsteady flow control technology called the NCFC method is proposed based on the concept of negative circulation control, realized by a vortex generator placed in a tube connected with the shroud through a hole. The approach is derived from a theoretical study of the compressor TLV by introducing a two-dimensional vortex model. A numerical simulation is then performed to verify the effectiveness of the NCFC method. The result shows that the NCFC method can greatly stabilize the flow field at the blade tip and improve the stall margin and efficiency of the compressor without reducing the total pressure ratio of the compressor, which has the characteristics of both unsteadiness and negative circulation effect. In addition, a HC method with only unsteady excitation effect is also studied for comparison, which only slightly stabilizes the blade tip flow and increases the stall margin of the compressor, suggesting that the NCFC is more effective than the HC. Finally, it is highly recommended to improve the efficiency of any unsteady jet/suction and separation flow interaction.

1. Introduction

Since the invention of the centrifugal compressor, it has been widely used in military and civil fields, such as auxiliary power unit for aircraft [1], propulsion system for unmanned aerial vehicle or missile [2, 3], turbocharger for vehicle [4], and fuel cell for automobile [5, 6]. With the development of modern industrial system and the improvement of technical requirements, people’s demand for compressor performance is gradually increasing. At present, centrifugal compressors are developing towards high advanced pressure ratio, high efficiency, and high stability. The design technique of compressor has already evolved from the one-dimensional empirical formula to the full three-dimensional flow field analysis [7–9]. In addition, some blade optimization measures are also widely used, such as leading edge sweep blade [10, 11], split blade [12, 13], tandem blade [14, 15], and back-swept blade [16]. In recent years, artificial intelligence has further optimized the compressor structure and blade profile. Ma et al. [17] used NSGA-III algorithms to optimize a centrifugal compressor in a fuel cell system, significantly improving the pressure ratio and efficiency of the compressor. Based on blade profile optimization, flow control technology is beginning to attract people’s attention to further improve the performance of the compressor.

Most of the flow control techniques currently applied to centrifugal compressors at present are concentrated in the tip region, mainly for two reasons: one is that some devices installed in the blade or wheel hub are usually limited by space due to the compact structure of centrifugal compressors; the other is that the flow field structure of the centrifugal compressor tip is extremely complex due to the effects of meridian curvature and centrifugal force, and it has a great influence on the compressor performance [18–23]. It is precisely for these two reasons that our subsequent research and application of flow control will also be established at the blade tip. At present, the applications applied to the tip area of centrifugal compressor are various, among which the most widely used is casing treatment, including self-recirculation casing treatment (SRCT) [24], circumferential grooves [25], bleed slots [26], axial groove [27], nonaxisymmetric casing treatment [28], and ported shroud [29]. Except for casing treatment, the application of some other control methods, such as air injection [30], suction [31], and blade tip winglet [32], is relatively less. Although the compressor performance can be improved to some extent by these flow control techniques, the results obtained when applying these techniques are often inconsistent. Taking SRCT as an example, Wang et al. [33] can improve the operating efficiency of 1.5% while increasing the stable operating range of the compressor by 20% by applying SRCT. However, in Jung and Pelton’s research [34], he used SRCT to increase the stable working area of the compressor by 25%, but the efficiency decreased by 0.4%. Taking the circumferential grooves as an example, Bareiß et al. [25] found that the circumferential groove method would not affect the compressor efficiency while improving the compressor pressure ratio under any circumstances after applying this flow control technology to a centrifugal compressor. The circumferential groove method is also used by Park et al. [35], whose research found that this technology can increase the stall margin of the compressor, but the efficiency will decrease. Similar conclusions can be drawn from the review article [36]. Therefore, when these flow control technologies are applied in practice, many questions will arise, such as which control method is the most suitable? What is the essential difference between different control methods? Will the effect of the same flow control method change when applied to different compressors? How should the control parameters of the same flow control method applied to different compressors be optimized?

The basic reason for the above questions is the lack of sufficient understanding of the flow theory and flow control mechanism of the centrifugal compressor. To solve this problem, some researchers have carried out modeling research on the compressor based on the mathematical model and theoretical analysis [37–43]. Although these theories have made some achievements, the following problems still exist: (1) Some theories take the compressor as an integral unit, which lacks the details of the flow field and the complicated physical phenomena; (2) many models are based on cascade research, which may not be applicable to centrifugal compressors; (3) these one-dimensional models lack further support in describing complex flow structures; (4) part of the theories only predict the simple actions of vortices and cannot describe their complex motions; (5) the most important point is how to guide the flow control technology based on these models.

Due to the complex internal flow structure of the compressor, it is difficult to give a detailed and complete theoretical description, so we focus on the flow structure that plays a key role in the performance of the compressor. As mentioned above, the flow field in the tip region of the impeller is particularly important in the centrifugal compressor. In particular, the TLV (tip leakage vortex) often has a decisive influence on the performance of the centrifugal compressor [21–23, 44]. Tomita et al. [45] found that the blockage of the TLV breakdown is a major cause of compressor stall which may occur even at low flow rates. Schleer et al. [46] believe that a large TLV will cause the compressor stall and affect the performance of the compressor throughout the operating range. Cao et al. [22] found a Kelvin–Helmholtz-type instability of the shear layer formed between the mainstream flow and the tip leakage flow, which will form TLV with strong unsteadiness and pressure fluctuations causing the reduction of the blade loading. Kaneko and Tsujita [47] found that TLVs formed by the main blade and split blade reduce the blade loading and compressor efficiency. Therefore, considering the important influences of TLV on the performance of centrifugal compressors, our research focus is based on TLV. Our approach is to optimize the flow at the compressor blade tip by suppressing the TLV, thereby improving the compressor performance. The specific steps are as follows: First, in order to obtain regular and generalised conclusions, we conducted theoretical research on TLV by introducing a two-dimensional vortex model. Secondly, we investigated the behaviour of the TLV vortex model under some external factors to provide a reference for our subsequent flow control technology. Then, following the theoretical research results, we proposed a flow control technology applicable to centrifugal compressors, which we call the negative circulation flow control (NCFC) method. Finally, we used unsteady numerical simulation to compare the performance of the centrifugal compressor with and without flow control.

2. Introduction of a Two-Dimensional TLV Model

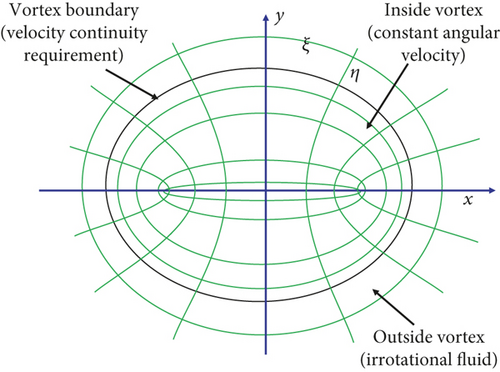

Through many numerical simulations and experimental studies, it is found that the cross-sectional profile of the compressor TLV has an obvious elliptical structure [48–50], so we use an elliptical vortex model to describe the TLV rather than a circular model often adopted by many researchers. The region where vorticity is concentrated in a two-dimensional inviscid flow field is called the vortex patch. For example, the vortex core of a Rankine vortex is the simplest circular vortex patch often used by researchers to analyze vortex structures. In general, the boundary shape of a vortex patch of any shape should change continuously as the vortex patch moves. There is a special case: an elliptical vortex patch with uniform vorticity will rotate on itself at a constant angular velocity and remain unchanged; this type of vortex is called a Kirchhoff elliptical vortex, as shown in Figure 1.

2.1. Outside the Elliptical Vortex

2.2. Inside the Elliptical Vortex

3. Modeling Analysis of TLV under Imposed Strain

The flow field structures inside the compressor are complex, even a certain simple dynamic behaviour of the TLV may be the result of some combined effects of many different factors. Therefore, our approach is to use a theoretical expression to describe the overall performance of the TLV. Although a particular state of motion may also be a combination of many factors, the theory used to describe this phenomenon should be concise and clear. Our specific approach is to employ some typical external loads, which can be expressed by mathematical models, to the above TLV model. In addition, the specific performance of the model with external loads applied is also discussed. We expect that this approach will help us to understand the effect of the TLV and to find out what factors affect the TLV behaviour, such as other flow field structures or the configuration of the compressor itself, thereby guiding us to take appropriate flow control measures to improve the performance of the compressor.

Four external strain effects are considered in this paper. They are the “Flow Passage Constriction Effect,” “Passage Vortex Squeeze Effect,” “Leakage Flow Translation Effect,” and “Additional Circulation Effect.” As we have given detailed introductions to the first three in our previous research [48], this paper only briefly describes them and mainly introduces the “Additional Circulation Effect.”

3.1. Flow Passage Constriction Effect

3.2. Passage Vortex Squeeze Effect

3.3. Leakage Flow Translation Effect

The above formula also only gives the minimum value of ab/2(2b + a). As the leakage flow is a necessary condition for producing the TLV, it is easy to understand that the ratio of its strength to the TLV strength is only the minimum value.

3.4. Additional Circulation Effect

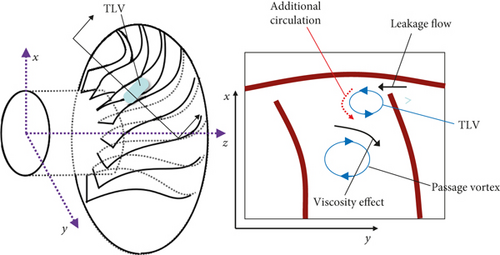

As mentioned above, the behaviour of the TLV may be a combination of several factors, including the additional circulation effect. Figure 2 illustrates the generation mechanism of the “Additional Circulation Effect.” As shown in the figure, the direction of the leakage flow and the viscosity effect caused by the passage vortex are the same as the direction of rotation of the TLV. Therefore, the leakage flow and passage vortex will strengthen the TLV, as if an additional circulation is imposed around the TLV, so we call it the “Additional Circulation Effect.”

The above expression gives the range of Γ0/ω. It can be seen that the “Additional Circulation Effect” depends on the long and short axis of the elliptical vortex. By analyzing the minimum value of Γ0/ω, we can find that the minimum value of Γ0/ω is always greater than 1 as long as b/a is not extremely small (corresponding to an extremely elongated ellipse). We can therefore conclude that in most cases, the value of Γ0/ω is greater than 1. This means that in most cases, when the “Additional Circulation Effect” acts on the TLV, its influence will even exceed that of the TLV itself. As for the extremely narrow elliptical vortex, it can be generated at a very small tip clearance. Of course, in this case, the leakage flow generated by the small gap will also be small, and the corresponding “Additional Circulation Effect” may also be weakened at the same time. For most centrifugal compressors, the clearance may not reach this situation, so we will not discuss this extreme case.

4. A Negative Circulation Flow Control (NCFC) Method

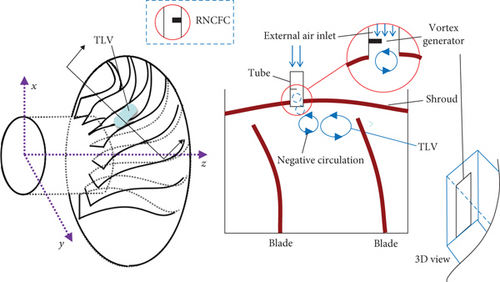

From Equations (28) and (32), it can be seen that the intensity ratio of the “Flow Passage Constriction Effect” to the TLV and the ratio of the “Leakage Flow Translation Effect” to the TLV have only minimum values, which means that the two effects are the necessary conditions to affect the TLV. Therefore, from a flow control point of view, we are not willing to spend much energy on controlling these two effects. For the “Passage Vortex Squeeze Effect,” if we take a conventional ellipse with axis ratio ε = 2, the maximum intensity ratio of the “Passage Vortex Squeeze Effect” to TLV can be gotten from Equation (30) as 1/3. Comparing this value with the minimum value of Γ0/ω (Equation (38)), which is greater than 1 in most cases, we can conclude that the effect of the “Additional Circulation Effect” on the TLV will be much greater than that of “Passage Vortex Squeeze Effect” on the TLV. Therefore, a proper flow control method that we adopt should be to weaken or better inhibit the “Additional Circulation Effect.” This is why we propose the negative circulation flow control (NCFC) method. Its essence is to create an effect opposite to the “Additional Circulation Effect” to weaken the TLV.

Figure 3 shows an NCFC device mounted on the shroud. A vortex generator to create negative circulation in the opposite direction to the TLV is located in a tube that connects to the hole near the starting position of the TLV on the shroud. A certain number of such devices can be placed around the circumference of the casing, depending on the structure of the compressor.

Because this article mainly focuses on the feasibility of the NCFC method, we choose fc ≈ fBPF here for simplification, which means Nc = Nb. In the similar way, other frequencies can also be studied.

5. The Numerical Simulation Methods

The investigated microcentrifugal compressor is used in a 30 kW distribution power generation system. The impeller consists of 10 pairs of main and split back-swept blades (Nb = 10). The meridional channel shape is determined by a cubic Bezier curve. Table 1 shows the main geometric and aerodynamic parameters of the compressor.

| Parameter | Value | |

|---|---|---|

| Overall performance | Mass flow rate | 0.36 kg/s |

| Rotation speed | 80,000 RPM | |

| Total pressure ratio | 3.2 | |

| Impeller inlet | Inlet tip diameter | 59.5 mm |

| Outlet tip diameter | 19.5 mm | |

| Relative Mach’s number of inlet blade tip | 0.87 | |

| Relative flow angle of inlet blade tip | 30.6° | |

| Relative flow angle of inlet blade root | 59.3° | |

| Impeller outlet | Outlet diameter | 98.5 mm |

| Outlet blade width | 4.08 mm | |

| Outlet absolute airflow angle | 30.0 | |

| Outlet relative airflow angle | 71.7 | |

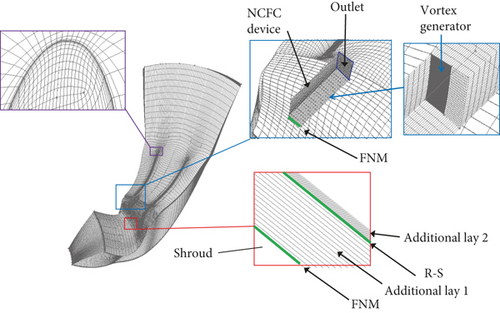

To simulate the effect of the relative positioning of the NCFC devices and the blades changing due to the rotation of the impeller, two very thin transition layers (layer 1 and layer 2 in Figure 4) are added between the NCFC device computational domain and the shroud. Figure 4 shows the computational grid of the compressor and the data exchange settings between the different computational domains. The total thickness of the additional layer is 0.075 mm, which is 1/8 of the tip clearance height of 0.3 mm. A full nonmatching (FNM) connection is used between the shroud and layer 1. The calculation domain of the impeller and layer 1 is performed in the rotating coordinate system. This is because FNM requires the coordinate system solved on both sides to be consistent but does not need to consider mesh matching. FNM is also set for data exchange between the NCFC device and layer 2, and the two domains are calculated in the static coordinate system. Therefore, a rotor-stator (R-S) interaction is used to link layer 1 and layer 2.

Considering the relative motion between the NCFC device and the impeller, we adopt an unsteady numerical simulation to study a single blade passage with Numeca/Fine. Since we use the same unsteady control frequency as BPF, the number of NCFC devices is the same as the number of blades Nb, so one blade passage corresponds to one NCFC device. The total number of grids in the compressor calculation domain without flow control is approximately 900,000. The total number of additional meshes for layer 1, layer 2, and NCFC devices for the controlled compressor calculation is approximately 30,000. The thickness of the first layer of mesh near the wall surface is set to 0.001 mm. The Reynolds number is approximately 3.1 × 105, and the dimensionless wall distance y+ varies from 1 − 3.

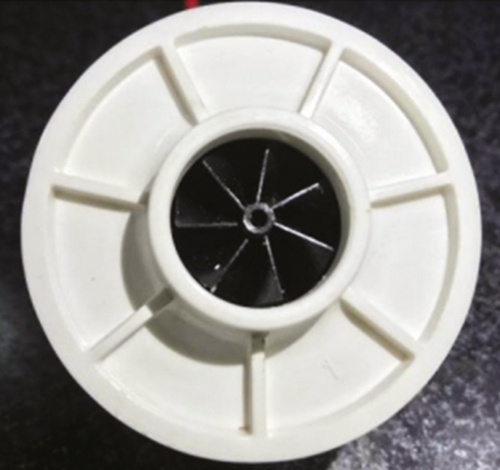

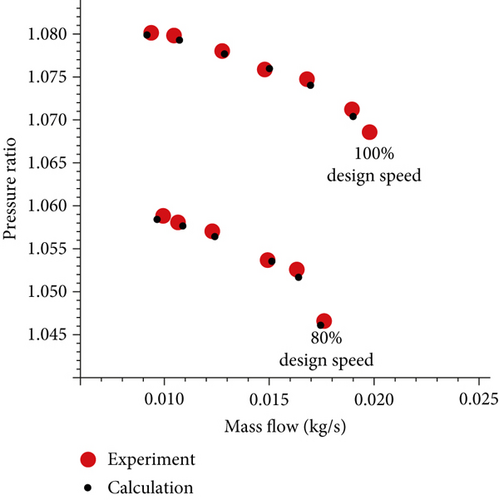

The time step is determined by the number of angular positions, which is set to be 30 points. Therefore, according to the rotational speed, the time step is 2.5 × 10−6 s with 30 inner iterations. The domain scaling method is used for rotor/stator interface. The impeller inlet is set to at a rotational speed of 80,000 RPM, a total pressure of 101,325 Pa, and a total temperature of 293 K. The given static pressure at the outlet of the NCFC device is 101,325 Pa. The solid wall is set to adiabatic no-slip condition. The Spalart-Allmaras (S-A) model is employed for the turbulent model. If the compressor performance parameters change periodically, we assume that the calculation is convergent. By continuously increasing the static pressure at the impeller outlet, the calculation becomes divergent. A state before divergence is defined as a near-stall condition. We have validated the effectiveness of the numerical simulation method on a low-speed commercial centrifugal compressor as shown in Figure 5. Figure 6 shows the comparison of experimental and calculated results of the centrifugal compressor at 100% and 80% design speed (the red circle corresponding to the experimental point is large, reflecting the error band). From the characteristic diagram, it can be seen that the numerical calculation results are in good agreement with the experimental results. Therefore, it is believed that the numerical simulation method used in this article has a certain degree of credibility. More detailed experimental information can be found in references [53, 57].

6. Compressor Performance with and without NCFC Devices

6.1. Overall Performance

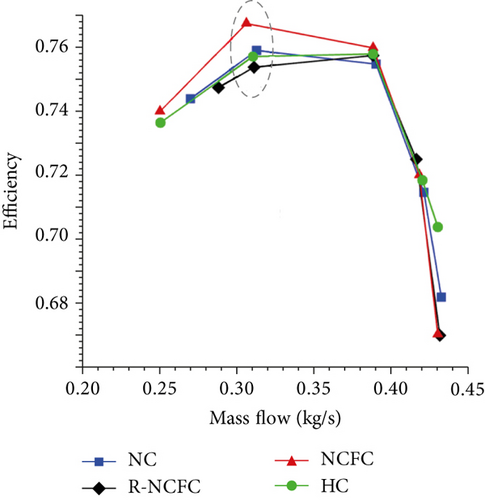

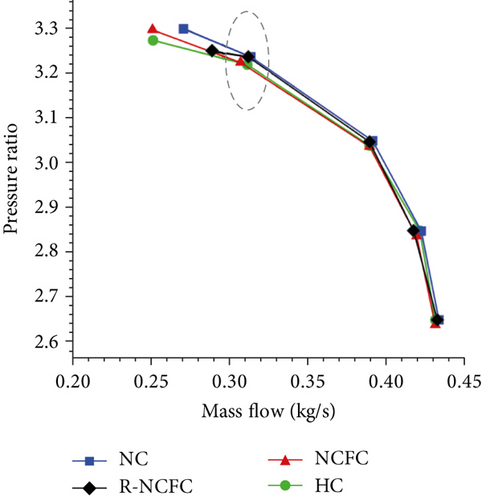

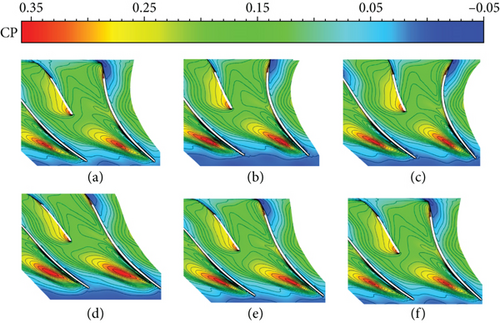

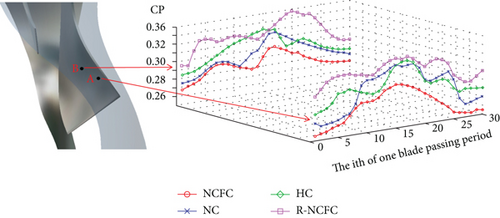

In order to have a comparative analysis, we have simulated the cases of the compressor with noncontrolled (NC), hole control (HC, holes are placed on the shroud with the same size and number with NCFC devices), NCFC, and reverse NCFC (R-NCFC, generating vortex opposite with NCFC as shown in Figure 4). The flow field in one blade passage period after calculation convergence is selected for analysis. The performance of the time-averaged flow field of the compressor in this period is shown in Figure 7. The figure shows that for high flow conditions, these control methods have little effect on compressor efficiency. For conditions spanning a wide range of flow rates, including the design point (the mass flow is 0.36 kg/s), these control methods have a significant impact on compressor efficiency. In particular, the NCFC method can significantly improve the efficiency of the compressor among these flow control technologies, with a maximum efficiency increase of 0.95%. Compared to the uncontrolled compressor, the efficiency of the compressor with the HC method hardly changes. However, the R-NCFC method reduces the efficiency of the compressor by about 0.05%. Therefore, it is obvious that the NCFC method is optimal among these methods. As mentioned above, the NCFC method has the advantages of both unsteadiness and negative circulation effect. The HC method has only the unsteadiness characteristic.

6.2. Flow Field Analysis of the Centrifugal Compressor

| Location | NC | NCFC | HC | R-NCFC |

|---|---|---|---|---|

| A | 0.0277 | 0.0275 | 0.0421 | 0.0232 |

| B | 0.0247 | 0.0182 | 0.0238 | 0.0249 |

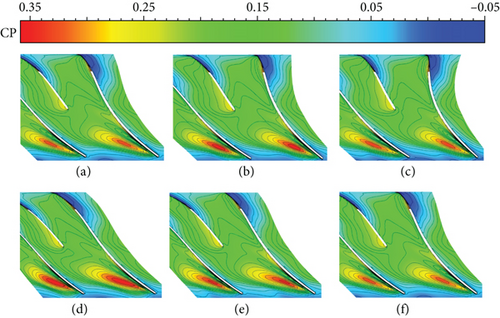

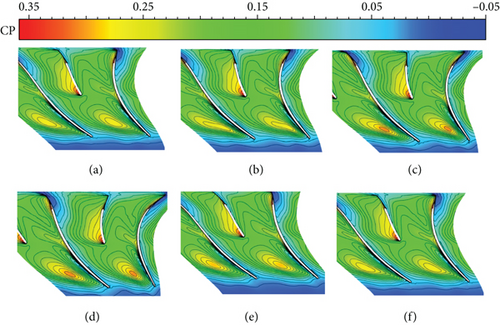

Figure 10 shows the case of the compressor using the HC method. It can be seen that only a small area of the high-pressure zone appears at T2-T4. In addition, a comparison of the HC method with the NCFC and NC methods shows that the HC method is less stable to pressure fluctuations. The use of the R-NCFC method gives the worst flow field (Figure 11). In this operation, the overall characteristics of the flow field are similar to those of the NC case, but the area of the high-pressure zone is larger than that of the NC, which means that the clogging effect will increase.

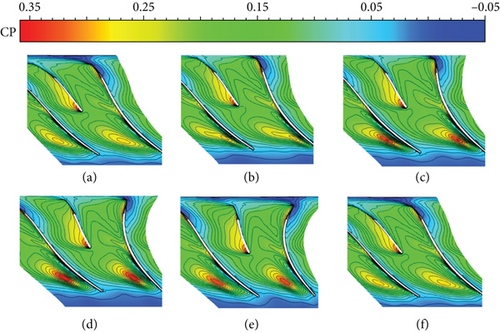

Based on the above results, we can see that the NCFC method can effectively stabilize the blade tip flow field of the compressor, thus improving the stable operating range and efficiency of the compressor, without affecting the total pressure ratio. The HC method can also give good results, which is very useful for increasing the stall margin of the compressor. However, the excitation that is opposite to the mode of action of the NCFC, namely, R-NCFC, will deteriorate the flow field at the compressor blade tip and will cause the performance of the compressor to decrease.

The HC method uses the unsteady effect created by the relative motion of the impeller and hole to realize periodic excitation. However, the efficiency of each excitation is not taken into account. The NCFC method not only takes advantage of the same unsteady property as HC but also considers the efficiency of each excitation. Here, we use the concept of negative circulation to force the momentum to exchange in the original flow field. Therefore, from the perspective of flow control, we propose to strengthen the efficiency of each unsteady incentive, which is very beneficial to improve the overall effect of unsteady control.

7. Conclusions

- (1)

The Kirchhoff elliptical vortex is introduced to represent the compressor TLV. A point vortex model is drawn into the two-dimensional model to reveal an additional circulation effect caused by leakage flow and passage vortex viscous effect. The result shows that the additional circulation effect will exceed the TLV itself in most cases, which is also larger than the passage vortex squeeze effect

- (2)

A negative circulation flow control device is designed and verified by numerical simulation. It is found that the NCFC method can greatly stabilize the flow field at the blade tip and improve the stall margin and efficiency of the compressor without affecting the total pressure ratio of the compressor

- (3)

The effect of NCFC is better than that of the HC. The former utilizes both unsteady excitation and injection of negative circulation to improve momentum exchange. The latter only uses the unsteady effect. Therefore, it is highly recommended to improve the efficiency of each unsteady jet/suction and separation flow interaction

Nomenclature

-

- A:

-

- Undetermined constant

-

- a:

-

- Long axis

-

- B:

-

- Undetermined constant

-

- b:

-

- Short axis

-

- C:

-

- Undetermined constant

-

- CP:

-

- Dimensionless static pressure coefficient

-

- :

-

- Average static pressure coefficient

-

- CPi:

-

- Instantaneous static pressure coefficient

-

- c:

-

- Elliptic focus

-

- e:

-

- Strain rate strength

-

- ex:

-

- Unit vector in the x direction

-

- ey:

-

- Unit vector in the y direction

-

- ez:

-

- Unit vector in the z direction

-

- F:

-

- Genetic function

-

- fBPF:

-

- Blade passing frequency

-

- fc:

-

- Unsteady control frequency

-

- fT:

-

- Unsteady fluctuation frequency of the TLV

-

- :

-

- Mass flow rate of the compressor near stall condition with control

-

- :

-

- Mass flow rate of the compressor near stall condition without control

-

- Nb:

-

- The number of blades

-

- Nc:

-

- The number of NCFC devices

-

- n:

-

- Unit outer normal vector

-

- nx:

-

- X component of the unit outer normal vector

-

- ny:

-

- Y component of the unit outer normal vector

-

- p(t):

-

- Transient static pressure

-

- pinlet:

-

- Average static pressure at inlet

-

- r:

-

- Vector distance from origin

-

- r:

-

- Distance from origin

-

- SMrel:

-

- Relative stall margin

-

- s:

-

- Surface arc length

-

- U:

-

- Main flow velocity

-

- V:

-

- Strain rate matrix

-

- Vb:

-

- Velocity of a point on the vortex border

-

- x:

-

- x coordinate

-

- y:

-

- y coordinate

-

- Γ:

-

- Circulation of the ellipse vortex

-

- Γo:

-

- Circulation of the point vortex

-

- ε:

-

- Axis ratio of the ellipse

-

- η:

-

- Elliptic coordinate in η direction

-

- ξ:

-

- Elliptic coordinate in ξ direction

-

- ξ0:

-

- Elliptic coordinate on the ellipse border

-

- πcs:

-

- Total pressure ratio of the compressor near stall condition with control

-

- πocs:

-

- Total pressure ratio of the compressor near stall condition without control

-

- σcp:

-

- Static pressure coefficient variance

-

- Ψ:

-

- Stream function

-

- Ψb:

-

- Stream function on the ellipse border

-

- Ψ(i):

-

- Internal flow function

-

- Ψ(o):

-

- External flow function

-

- :

-

- External flow function with additional circulation effect

-

- Ω:

-

- Angular velocity

-

- ω:

-

- Vorticity

-

- ωr:

-

- Impeller rotational speed.

Conflicts of Interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Acknowledgments

This research was funded by the Zhejiang Provincial Natural Science Foundation of China under grant number LQ20E060004. This research was also supported by the Fundamental Research Funds for the Ningbo University of Technology. We are also grateful to Fuxin (NUAA) and Huang Guoping (NUAA) for the technical aspects.

Open Research

Data Availability

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.