Enhancing Interpretability of Data-Driven Fault Detection and Diagnosis Methodology with Maintainability Rules in Smart Building Management

Abstract

Data-driven fault detection and diagnosis (FDD) methods, referring to the newer generation of artificial intelligence (AI) empowered classification methods, such as data science analysis, big data, Internet of things (IoT), industry 4.0, etc., become increasingly important for facility management in the smart building design and smart city construction. While data-driven FDD methods nowadays outperform the majority of traditional FDD approaches, such as the physically based models and mathematically based models, in terms of both efficiency and accuracy, the interpretability of those methods does not grow significantly. Instead, according to the literature survey, the interpretability of the data-driven FDD methods becomes the main concern and creates barriers for those methods to be adopted in real-world industrial applications. In this study, we reviewed the existing data-driven FDD approaches for building mechanical & electrical engineering (M&E) services faults and discussed the interpretability of the modern data-driven FDD methods. Two data-driven FDD strategies integrating the expert reasoning of the faults were proposed. Lists of expert rules, knowledge of maintainability, international/local standards were concluded for various M&E services, including heating, ventilation air-conditioning (HVAC), plumbing, fire safety, electrical and elevator systems based on surveys of 110 buildings in Singapore. The surveyed results significantly enhance the interpretability of data-driven FDD methods for M&E services, potentially enhance the FDD performance in terms of accuracy and promote the data-driven FDD approaches to real-world facility management practices.

1. Introduction

1.1. Motivation

Aligning with the fast development of artificial intelligence (AI) technology, data-driven fault detection and diagnosis (FDD) plays an essential role in modern smart building maintenance and management systems [1]. However, while the data-driven FDD models are often viewed as black-box models, the interpretability of FDD models hinders the methods to be widely applied to real-world applications [2, 3]. Expert rules and standards are helpful for data-driven FDD methods to be adapted to real-world scenarios. The expert rules and standards not only increase the interpretability level of the data-driven FDD methods but also improve the FDD performance in terms of diagnosis accuracy rates. According to our literature survey, the relevant expert knowledge is considered as a research gap in the field and is highly demanded to detect and diagnose possible faults in building equipment and services [4–6]. In this study, we are interested to concretize the expert knowledge, using maintainability rules and standards for FDD, both regionally and globally, of different building mechanical & electrical engineering (M&E) services, including HVAC systems, plumbing & sanitary, fire safety, electrical and elevators & escalators systems, and their critical components.

1.2. Background

Building fault detection and diagnosis (FDD) methods automatically recognize potential and existing building facility faults based on existing standards, expert knowledge and sensor information, which are important techniques ensuring the safety, efficiency and quality services of building infrastructure and development [7, 8]. According to the different approaches replying to different types of evident information, FDD methods are categorized into data-driven FDD, physical model based FDD and mathematical model based FDD methods [9]. Data-driven FDD builds computational models based on historical sensor data, while different types of building faults are recognized as classes [10]. A physical model based FDD understands the whole building system using physics-based models and usually requires a significant amount of prior knowledge for faults identifications [11, 12]. A mathematical model based FDD methods also requires prior physics knowledge to define a rule space for an inferencing method searching for the corresponding faults [13, 14].

Data-driven fault detection and diagnosis methods represent the next-generation facility management and maintenance techniques adopting modern AI techniques, such as sensor networks [15, 16], data analytics [17], big data [18, 19], machine learning (ML) [20, 21], cybernetic intelligence (CI) [22, 23] and Internet of things (IoT) [24, 25] and etc. For different building infrastructures, such as heating, ventilation air-conditioning (HVAC), plumbing, fire safety, electrical and elevator systems. In the era of big data, smart building and smart city, data-driven FDD usually serves as one of the most important applications utilizing big data and one of the hottest research topics in the fields of smart city and industry 4.0 [26–28].

Compared with traditional physical model based and mathematical model based methods, data-driven FDD methods are usually more efficient, robust and accurate in detecting and diagnosing various building faults, while the machine learning (ML) techniques, such as the neural networks, are constructed for predictive analysis. The ML techniques are generally much more efficient and effective than traditional PM-FDD, MM-FDD and manual classification methods. For example, for HVAC FDD, the existing works showed FDD accuracy rates over 99% for typical chiller faults and 93% for air handling unit (AHU) faults [29–32]. Traditional approaches, such as the sensitivity test, can only achieve accuracy rates close to 83% for chiller faults and around 80% for AHU faults [33–37]. The 10% to 15% improvement on different FDD approaches saves the energy wasted in buildings significantly, enhances the overall building performance and maintains a sustainable environment for building infrastructure maintenance.

However, the interpretability of the data-driven FDD method has always been the problem for data-driven FDD methods and hinders the data-driven FDD techniques to be widely adopted in real-world applications. While the prediction accuracy and efficiency of the data-driven FDD methods improved significantly in recent years, the internal structures of the AI approaches become more complex, resulting in more challenges for model interpretation [38–41]. The data-driven FDD models were also tentatively called black-box models in many existing publications [42–44], which we believe is not accurate. Many data-driven FDD models are indeed interpretable. For example, Yan et al. [45] presented a decision tree model for FDD of air handling units (AHUs). The decision tree structure is interpretable with if-else rules. However, the if-else rules were not easily recognizable for experts deriving standards for AHU maintenance.

It is evident that the expert knowledge, experience, rules, ISO standards and maintenance guidelines are valuable information and can deeply influence the performance of data-driven FDD methods. Zhao et al. [46] demonstrated that the additional expert knowledge inputs can greatly enhance a Bayesian belief network (BBN) data-driven FDD model’s performance by increasing the FDD accuracy for various chiller faults. Li et al. [47] improved [46] by integrated expert knowledge into a diagnostic Bayesian network (DBN) for AHU fault FDD. The reasonings of the AHU FDD were plotted by local casual graphs. The main shortcoming of the works [46, 47] is that the expert knowledge inputs were generally generated based on the authors’ hypotheses.

1.3. Approach

In this study, we reviewed the recent publications on data-driven FDD for building mechanical & electrical engineering (M&E) services, including HVAC, plumbing, fire safety, electrical and elevator systems. Different M&E faults were surveyed over 110 buildings in Singapore, including commercial, hotels, industrial, institutional, clinical and residential buildings, for all three stages of infrastructure management life-cycles, in all design, construction and management stages. The expert knowledge of M&E FDD is converted into maintainability rules and international/local standards in Singapore. It is evident that the conveyed maintainability rules greatly enhance the interpretability of the data-driven FDD approach and potentially improve the diagnosis accuracy.

We propose two data-driven FDD methods integrating the maintainability rules for general facility management in buildings, particularly focusing on FDD. The two specific data-driven FDD methods integrating maintainability rules are 1. data-driven expert rules for decision making in smart building facility FDD; and 2. maintainability rules as inputs for data-driven FDD systems. The actual implementations of the two proposed approaches were omitted, while there were existing implementations such as [46, 47]. The main aim of this study is to specify the expert knowledge pool of M&E FDD using maintainability rules shown in Section 4. The specification greatly enhances the interpretability of the existing M&E FDD methods.

1.4. Contributions

- (i)

Extending the existing data-driven FDD from HVAC systems to the infrastructure of the whole building. The majority of the existing work of data-driven FDD integrating expert knowledge, e.g., maintainability rules, focuses on HVAC FDD. In this study, we extend the above-mentioned data-driven FDD framework to the whole building system. The targeted facilities include almost all M&E services for smart building design

- (ii)

Identifying expert rules and standards for various M&E faults in buildings. A total of 110 buildings in Singapore, including commercial, hotels, industrial, institutional, clinical and residential buildings were surveyed, over all three stages of infrastructure management life-cycles, in all design, construction and management stages, collecting necessary FDD information based on experts’ knowledge and international/local standards in Singapore. In this way, typical faults for the major M&E equipment are surveyed with detailed experts’ rules and standards stated in tables. This main contribution impacts the literature for data-driven FDD approaches targeting building M&E services significantly

- (iii)

Enhancing the interpretability of the existing data-driven FDD methods for building infrastructure faults. The interpretability of the data-driven FDD methods has been a bottleneck problem for a long time. The surveyed expert rules and standards bridge the gap between theoretical FDD strategy and real-world practices. The interpretability enhancement greatly improves the practicality of the data-driven methods in Industry 4.0 [48] and Construction 4.0 [49].

- (iv)

Potentially improving the diagnosis accuracy of the existing data-driven FDD methods for building infrastructure faults. According to the literature study, such as the works of [46, 47], expert knowledge, e.g., the maintainability rules enhance the FDD performance significantly in terms of accuracy. The diagnosis accuracy improvements are justified by various publications [46, 47, 50–52].

2. Literature Review for Interpretability Study of the Existing M&E Services FDD Methods

Intelligent facilities management is one of the important topics for smart city design, smart building maintenance system development, Industry 4.0 and Construction 4.0. Techniques based on AI and data-driven approaches attract increasing attention from various perspectives. Besides the effectiveness and robustness of the data-driven approaches for data-driven FDD, the shortcomings and issues, such as the interpretability of the data-driven model and the efficiency for data-driven FDD algorithms, were raised in recent years.

Yan et al. [45] introduced a decision tree induction (DTI) based FDD method for detecting and diagnosing AHU faults. The proposed method is data-driven, and interpretable with a post-pruned binary tree structure. The main concern of [45] is that the derived rules do not explicitly map to expert reasoning available in the HVAC system design. Most of the DTI rules were still unreadable from the perspective of HVAC engineers. Mulumba et al. [50] worked on a Kalman filter-based FDD reasonings for AHU faults. The method works for various AHU faults and is also considered a data-driven approach. The shortcoming is again that the Kalman filter rules do not map correspondingly to HVAC experts. Srinivasan et al. [51] showed the importance of explainable AI (XAI) for chiller fault detection systems to gain human trust. Li et al. [52] developed an explainable one-dimensional convolutional neural networks (CNN)-based fault diagnosis method for building HVAC systems.

Besides the interpretability study of FDD for HVAC systems, there are existing data-driven FDD approaches proposed for other M&E service systems. Kumar et al. [53] developed a deep learning detecting defects in sewerage systems. The deep learning structure relies on the CNN for object detection in images. The image processing technology using CNN is more interpretable using expert knowledge compared to other ML techniques. Gonzalez-Jimenez et al. [54] surveyed the existing fault diagnostic methods to examine faults for electric drives and revisited the general workflow using ML techniques for electric drive FDD. The main drawback of the data-driven FDD method as concluded in [54] is the lack of interpretability and the lack of explanations for specific phenomena in every particular electric drive. Gavan et al. [55] proposed to integrate expert rules and data-driven FDD methods to develop a positive energy building in France. The project has a nice workflow chart utilizing expert rules for building data analysis and FDD practices. However, it is an ongoing project and the performance of the proposed workflow is yet to be verified.

All the above-surveyed existing works showed that there are already quite many efforts on integrating expert rules and reasonings into the existing data-driven FDD methods to enhance the interpretability of the methods as well as improve the FDD performance on the classification accuracy for building maintenance problems. However, there still exist gaps between expert rules and data-driven methods, such as neural networks. The gap is mainly from the reasoning of AI and the ordinary reasoning of human beings. The most appropriate matching and fitting using the expert rules with the modern data-driven FDD methods remain unknown and desired further explorations, such as the current study. The current study expands the scope of the FDD methods and greatly enhances the applicable area of data-driven FDD methods in building services.

3. Integrating the Maintainability Rules into Data-Driven FDD for M&E Services

Two types of data-driven FDD strategies are available in general for the concept of next-generation AI-technology integrated smart buildings for facility management and maintenance. The first strategy is named post-caution maintenance. This strategy is widely adopted for modern buildings when expert knowledge of precautions is lacking. Without sufficient rules and guidance in the stages of design and construction, the only option left is monitoring the facilities regularly using physical, mathematical or AI-driven models and detecting potential errors with frequent data analysis. The expert knowledge and rules are added as an additional layer of the ML model for performance enhancement. Existing examples of post-caution maintenance include [46, 47].

The second type of the data-driven FDD strategy is to involve the expert knowledge in the FDD monitoring of the entire life-cycle of all facilities, or precaution maintenance. With the experts in the fields of, e.g., project management, construction, interior design and quantity survey, relevant regional and global standards, such as SS, BS, ISO, EN, AS and ASTM (Table 1) can be adopted in the precaution of potential risks in the early stage of the FDD. However, there are generally gaps between those standards and the real-world maintenance strategy, i.e., lacking clear guidance of different maintenance rules for different elements of the M&E system. The main contribution of this study is providing systematic and comprehensive maintainability rules for all kinds of M&E elements.

| Normative references/standards referred to for mechanical and electrical systems | |

|---|---|

| AHRI 260 | Sound rating of ducted air moving and conditioning equipment |

| ANSI/ASHRAE 188-2018 | Legionellosis: Risk management for building water systems |

| ANSI/ASHRAE/ACCA standard 180-2018 | Standard practice for inspection and maintenance of commercial building HVAC systems |

| ANSI/ASHRAE/IES standard 90.1-2016 | Energy standard for buildings except low- rise residential buildings |

| ANSI/ASHRAE/IES/USGBC standard 189.1-2014 | Standard for the Design of High- Performance Green Buildings |

| AS 1668.2-2012 | The use of ventilation and airconditioning in buildings — Mechanical ventilation in buildings |

| AS 1735.1 : 2016 | Lifts, escalators and moving walks. General requirements |

| AS 2293 SET:2005 | Emergency escape lighting and exit signs set |

| AS HB 197 : 1999 | An introductory guide to the slip resistance of pedestrian surface materials |

| AS/NZS 2293.2 : 2019 | Emergency escape lighting and exit signs for buildings inspection and maintenance |

| AS/NZS 4663 : 2004 | Slip resistance measurement of existing pedestrian surfaces |

| ASHRAE guideline 12-2020 | Managing the risk of Legionellosis associated with building water systems |

| ASME A17.1/CSA B44:2019 | Safety code for elevators and escalators |

| ASME A17.3 : 2020 | Safety code for existing elevators and escalators |

| ASME A17.6 : 2017 | Standard for elevator suspension, compensation, and governor systems |

| BS 1363-4 : 2016 | 13 A plugs, socket-outlets, adaptors and connection units. Specification for 13 A fused connection units switched and unswitched |

| BS 5266-1 : 2016 | Emergency lighting. Code of practice for the emergency lighting of premises |

| BS 5306-3 : 2017 | Fire extinguishing installations and equipment on premises. Commissioning and maintenance of portable fire extinguishers. Code of practice |

| BS 5306-8 : 2012 | Fire extinguishing installations and equipment on premises. Selection and positioning of portable fire extinguishers. Code of practice |

| BS 5306-9 : 2015 | Fire extinguishing installations and equipment on premises. Recharging of portable fire extinguishers. Code of practice |

| BS 5655-11 : 2005 | Lifts and service lifts. Code of practice for the undertaking of modifications to existing electric lifts |

| BS 5655-6 : 2011 | Lifts and service lifts. Code of practice for the selection, installation and location of new lifts |

| BS 5839-1 : 2017 | Fire detection and fire alarm systems for buildings. Code of practice for design, in-stallation, commissioning and maintenance of systems in non-domestic premises |

| BS 5839-3 : 1988 | Fire detection and alarm systems for buildings. Specification for automatic release mechanisms for certain fire protection equipment |

| BS 5839-6 : 2019 | Fire detection and fire alarm systems for buildings. Code of practice for the design, installation, commissioning and maintenance of fire detection and fire alarm systems in domestic premises |

| BS 5839-9 : 2011 | Fire detection and fire alarm systems for buildings. Code of practice for the design, installation, commissioning and maintenance of emergency voice communication systems |

| BS 5908-1 : 2012 | Fire and explosion precautions at premises handling flammable gases, liquids and dusts. Code of practice for precautions against fire and explosion in chemical plants, chemical storage and similar premises |

| BS 6391 : 2009 | Specification for non-percolating lay flat delivery hoses and hose assemblies for fire-fighting purposes |

| BS 6423 : 2014 | Code of practice for maintenance of low-voltage switchgear and control gear |

| BS 6626 : 2010 | Maintenance of electrical switchgear and control gear for voltages above 1 kV and up to and including 36 kV. Code of practice |

| BS 7255 : 2012 | Code of practice for safe working on lifts |

| BS 7291-1 : 2010 | Thermoplastics pipe and fitting systems for hot and cold water for domestic purpos-es and heating installations in buildings. General requirements |

| BS 7430 : 2011 + A1 : 2015 | Code of practice for protective earthing of electrical installations |

| BS 7671 : 2018 | Requirements for electrical installations. IET wiring regulations |

| BS 7698-7 : 1996, ISO 8528-7 : 1994 | Reciprocating internal combustion engine driven alternating current generating sets. Technical declarations for specification and design |

| BS 8486-1 : 2007 + A1 : 2011 | Examination and test of new lifts before putting into service. Specification for means of determining compliance with BS EN 81. Electric lifts |

| BS 8512 : 2008 | Electric cables. Code of practice for the storage, handling, installation and disposal of cables on wooden drums |

| BS 8554 : 2015 | Code of practice for the sampling and monitoring of hot and cold water services in buildings |

| BS 8558 : 2015 | Guide to the design, installation, testing and maintenance of services supplying water for domestic use within buildings and their curtilages. Complementary guidance to BS EN 806 |

| BS 8899 : 2016 | Improvement of fire-fighting and evacuation provisions in existing lifts. Code of practice |

| BS 9990 : 2015 | Non automatic fire-fighting systems in buildings. Code of practice |

| BS EN 1004 : 2020 | Mobile access and working towers made of prefabricated elements. Materials, di-mensions, design loads, safety and performance requirements |

| BS EN 10088-2 : 2014 | Stainless steels. Technical delivery conditions for sheet/plate and strip of corro-Sion resisting steels for general purposes |

| BS EN 1057 : 2006 + A1 : 2010 | Copper and copper alloys. Seamless, round copper tubes for water and gas in sanitary and heating applications |

| BS EN 115-1 : 2008 + A1:2017 | Safety of escalators and moving walks. Construction and installation |

| BS EN 13015 : 2001 + A1:2008 | Maintenance for lifts and escalators. Rules for maintenance instructions |

| BS EN 13121-3 : 2016 | GRP tanks and vessels for use above ground. Design and workmanship |

| BS EN 1402 : 2009 | Rubber and plastics hoses and hose assemblies. Hydrostatic testing |

| BS EN 1567 : 1999 | Building valves. Water pressure reducing valves and combination water reducing valves. Requirements and tests. |

| BS EN 16767 : 2016 | Industrial valves. Steel and cast iron check valves |

| BS EN 1796 : 2013 | Plastics piping systems for water supply with or without pressure. Glass-reinforced thermosetting plastics (GRP) based on unsaturated polyester resin (UP) |

| BS EN 1838 : 2013 | Lighting applications. Emergency lighting |

| BS EN 1947 : 2014 | Fire-fighting hoses. Semi-rigid delivery hoses and hose assemblies for pumps and vehicles |

| BS EN 1982 : 2017 | Copper and copper alloys. Ingots and castings |

| BS EN 1992-1-1 : 2004 + A1 : 2014 | Eurocode 2: Design of concrete structures. General rules and rules for buildings |

| BS EN 3 series | Portable fire extinguishers |

| BS EN 50172 : 2004, BS 5266-8 : 2004 | Emergency escape lighting systems |

| BS EN 545 : 2010 | Ductile iron pipes, fittings, accessories and their joints for water pipe- lines. Require-ments and test methods |

| BS EN 598 : 2007 + A1 : 2009 | Ductile iron pipes, fittings, accessories and their joints for sewerage applications. Requirements and test methods |

| BS EN 61009-2-1 : 1995 | Specification for residual current operated circuit-breakers with integral overcur-rent protection for household and similar uses (RCBOs). Applicability of the general rules to RCBOs functionally independent of line voltage |

| BS EN 62305-1 : 2011 | Protection against lightning. General principles |

| BS EN 694 : 2014 | Fire-fighting hoses. Semi-rigid hoses for fixed systems |

| BS EN 805 : 2000 | Water supply. Requirements for systems and components outside buildings |

| BS EN 806-5 : 2012 | Specifications for installations inside buildings conveying water for human con-sumption. Operation and maintenance |

| BS EN 81-20 : 2020 | Safety rules for the construction and installation of lifts. Lifts for the transport of persons and goods. Passenger and goods passenger lifts |

| BS EN 81-50 : 2020 | Safety rules for the construction and installation of lifts. Examinations and tests. Design rules, calculations, examinations and tests of lift components |

| BS EN ISO 16841 : 2014 | Steel wire ropes. Pulling eyes for rope installation. Types and minimum re-quirements |

| BS EN ISO 21003-2 : 2008 + A1 : 2011 | Multilayer piping systems for hot and cold water installations in-side buildings. Pipes |

| BS EN ISO 21003-3 : 2008 | Multilayer piping systems for hot and cold water installations inside build-ings. Fittings |

| BS EN ISO 21003-5 : 2008 | Multilayer piping systems for hot and cold water installations inside build-ings. Fitness for purpose of the system |

| BS ISO 10916 : 2014 | Calculation of the impact of daylight utilization on the net and final energy de-mand for lighting |

| BS ISO 18738 : 2012 | Measurement of lift ride quality. Lift (elevators) |

| BS ISO 18738-2 : 2012 | Measurement of ride quality — Part 2: Escalators and moving walks |

| CSA Z412-2000 (R2016) | Guideline on office ergonomics |

| IEC 60079: 2021 | Explosive atmosphere standards |

| IEC 61009-1 : 2010 + AMD1 : 2012 + AMD2:2013 CSV (Consolidated version) | Residual current operated circuit-breakers with integral overcurrent protection for household and similar uses (RCBOs) — Part 1: General rules |

| IEC 62305-3 : 2010 | Protection against lightning — Part 3: Physical damage to structures and life hazard |

| IEC 62305-4 : 2010 | Protection against lightning — Part 4: Electrical and electronic systems within struc-tures |

| ISO 10816-3 : 2009 | Mechanical vibration — Evaluation of machine vibration by measurements on non-rotating parts — Part 3: Industrial machines with nominal power above 15 kW and nominal speeds be-tween 120 r/min and 15 000 r/min when measured in situ |

| ISO 12242 : 2012 | Measurement of fluid flow in closed conduits — Ultrasonic transit- time meters for liquid |

| IISO 13612-1 : 2014 | Heating and cooling systems in buildings — Method for calculation of the system performance and system design for heat pump systems — Part 1: Design and dimensioning |

| ISO 1452-1 : 2009 | Plastics piping systems for water supply and for buried and aboveground drainage and sewerage under pressure – Unplaticized poly(vinyl chloride)(PVC-U) – Part 1: General |

| ISO 14798 : 2009 | Lifts (elevators), escalators and moving walks — Risk assessment and reduction methodology |

| ISO 16814 : 2008 | Building environment design — Indoor air quality — Methods of expressing the quality of indoor air for human occupancy |

| ISO 2017-1 : 2005 | Mechanical vibration and shock — Resilient mounting systems — Part 1: Technical information to be exchanged for the application of isolation systems |

| ISO 2230 : 2002 | Rubber products — Guidelines for storage |

| IISO 2408 : 2017 | Steel wire ropes for general purposes — Minimum requirements |

| ISO 25745-1 : 2012 | Energy performance of lifts, escalators and moving walks — Part 1: Energy measurement and verification |

| ISO 25745-2 : 2015 | Energy performance of lifts, escalators and moving walks — Part 2: Energy calcula-tion and classification for lifts (elevators) |

| ISO 25745-3 : 2015 | Energy performance of lifts, escalators and moving walks — Part 3: Energy calculation and classification of escalators and moving walks |

| ISO 29463-1 : 2011 | High-efficiency filters and filter media for removing particles in air — Part 1: Classi-fication, performance testing and marking |

| ISO 29463-5 : 2011 | High-efficiency filters and filter media for removing particles in air — Part 5: Test method for filter elements |

| ISO 3864-1 : 2011 | Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety signs and safety markings |

| ISO 4344 : 2004 | Steel wire ropes for lifts — Minimum requirements |

| ISO 5149-1 : 2014/Amd 1 : 2015 | Refrigerating systems and heat pumps - safety and environmental requirements - part 1: Definitions, classification and selection criteria AMENDMENT 1: Correction of QLAV, QLMV |

| ISO 6182 series | Fire protection - automatic sprinkler systems |

|

|

| ISO 8995-1 : 2002/Cor 1 : 2005 | Lighting of work places — Part 1: Indoor |

| ISO9996:1996 | Mechanical vibration and shock — Disturbance to human activity and performance -classification |

| IISO/CD 8100-30 : 2019 | Lifts for the transport of persons and goods - part 30: Class I, II, III and VI lifts in-stallation |

| ISO/DIS 22559-1 : 2014 | Safety requirements for lifts (elevators) - part 1: Global essential safety requirements (GESRs) |

| ISO/DTS 8100-21 : 2018 | Lifts for the transport of persons and goods - part 21: Global safety parameters (GSPs) meeting the global essential safety requirements (GESRs) |

| ISO/FDIS 13253 : 2017 | Ducted air-conditioners and air-to-air heat pumps - testing and rating for performance |

| ISO/NP TR 16765 : 2003 | Comparison of worldwide safety standards on lifts for firefighters |

| ISO/PRF 7165 : 2017 | Firefighting - portable fire extinguishers - performance and construction |

| ISO/TR 11071-2 : 2006 | Comparison of worldwide lift safety standards -part 2: Hydraulic lifts (elevators) |

| ISO/TR 25743 : 2010 | Lifts (elevators) - study of the use of lifts for evacuation during an emergency |

| JIS A 4302 : 2006 | Inspection standard of elevator, escalator and dumbwaiter |

| JIS A 4422 : 2020 | Toilet seat with shower unit |

| NFPA 10 : 2013 | Standard for portable fire extinguishers |

| NFPA 101 – 2018 | Life safety code |

| NFPA 110 - 2019 | Standard for emergency and standby power systems |

| NFPA 13 - 2019 | Standard for the installation of sprinkler systems |

| NFPA 14 – 2016 | Standard for the installation of standpipe and hose systems |

| NFPA 25 – 2017 | Standard for the inspection, testing, and maintenance of water-based fire protection systems |

| NFPA 72 – 2019 | National Fire Alarm and signaling code |

| NFPA 780 – 2020 | Standard for the installation of lightning protection systems |

| NFPA 80 – 2019 | Standard for fire doors and other opening protectives |

| SS 141 : 2013 | Specification for unplasticised PVC pipe for cold water services and industrial uses |

| SS 245 : 2014 | Specification for glass reinforced polyester sectional water tanks |

| SS 332 : 2018 | Specification for fire doors |

| SS 375-1 : 2015 | Suitability of non-metallic products for use in contact with water intended for human consumption with regard to their effect on the quality of the water - part 1: Specification |

| SS 403 : 2013 | Specification for 13A fused connection units switched and unswitched |

| SS 480 : 2016 | Residual current operated circuit-breakers with integral overcurrent protec- tion for house-hold and similar uses (RCBOs) - general rules |

| SS 485 : 2011 | Specification for slip resistance classification of pedestrian surface materials |

| SS 508-3 : 2013 | Graphical symbols — Safety colours and safety signs — Design princi- ples for graph-ical symbols for use in safety signs |

| SS 514 : 2016 | Code of practice for office ergonomics |

| SS 530 : 2014 | Code of practice for energy efficiency standard for building services and equipment |

| SS 531-1 : 2006 (2019) | Code of practice for lighting of work places — Indoor |

| SS 532 : 2016 | Code of practice for the storage of flammable liquids |

| SS 535 : 2018 | Code of practice for installation, operation, maintenance, performance and construction requirements of mains failure standby generating systems |

| SS 538 : 2008 | Code of practice for maintenance of electrical equipment of electrical installations |

| SS 546 : 2009 | Code of practice for emergency voice communication systems in buildings |

| SS 550 : 2020 | Code of practice for installation, operation and maintenance of electric passenger and goods lifts |

| SS 551 : 2009 | Code of practice for earthing |

| SS 553 : 2016 | Code of practice for air-conditioning and mechanical ventilation in buildings |

| SS 554 : 2016 | Code of practice for indoor air quality for air-conditioned buildings |

| SS 555-1 : 2018 | Code of practice for protection against lightning — Part 1: General principles |

| SS 555-3 : 2018 | Code of practice for protection against lightning — Part 3: Physical damage to struc-tures and life hazard |

| SS 555-4 : 2018 | Code of practice for protection against lightning — Part 4: Electrical and electronic systems within structures |

| SS 563-1 : 2010 (2017) | Code of practice for the design, installation and maintenance of emergency lighting and power supply systems in buildings — Part 1: Emergency lighting |

| SS 563-2 : 2010 (2017) | Code of practice for the design, installation and maintenance of emer- gency lighting and power supply systems in buildings — Part 2: Installation requirements and maintenance procedures |

| SS 564-1 : 2020 | Green data centres - part 1: Energy and environmental management systems |

| SS 564-2 : 2020 | Singapore standard for green data centres — Part 2: Guidance for energy and envi-ronmental management systems |

| SS 575 : 2012 | Code of practice for fire hydrant, rising mains and hose reel systems |

| SS 578 : 2019 | Code of practice for use and maintenance of portable fire extinguishers |

| SS 591 : 2013 | Code of practice for long term measurement of central chilled water system energy efficiency |

| SS 626 : 2017 | Code of practice for design, installation and maintenance of escalators and moving walks |

| SS CP 10 : 2005 | Code of practice for the installation and servicing of electrical fire alarm systems |

| SS CP 48 : 2005 | Code of practice for water services |

| SS CP 5 : 1998 | Code of practice for electrical installations |

| SS CP 52 : 2004 | Code of practice for automatic fire sprinkler system |

| SS CP 82 : 1999 | Code of practice for waterproofing of reinforced concrete buildings |

| SS CP 99 : 2003 | Code of practice for industrial noise control |

| SS EN 3–7 : 2012 (2020)) | Portable fire extinguishers — Characteristics, performance requirements and test methods |

| SS IEC 60598-1 : 2016 | Luminaires — Part 1: General requirements and tests |

| SS ISO 22301 : 2020 | Security and resilience - business continuity management systems — Requirements |

| SS ISO 22313 : 2020 | Security and Resilience - Business continuity management systems — Guidance on the use of ISO 22301 |

| V DI 4707 : 2007 | Lifts energy efficiency |

In this section, we demonstrate two data-driven FDD strategies with the maintainability rules for precaution and post-caution maintenance, which apply the maintainability rules as the inputs and the knowledge pool, respectively. These two strategies serve as examples of the usage of the maintainability rules listed in the Tables in Section 4.

3.1. Knowledge-Based Rule System Integrated Data-Driven FDD for M&E Faults

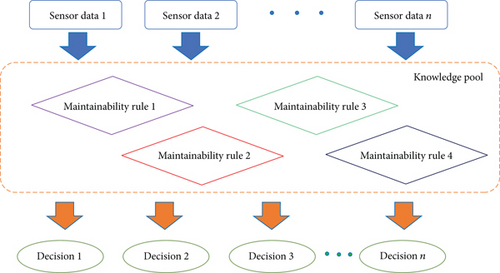

A knowledge-based system is a fundamental AI system that makes decisions purely based on rules. A traditional knowledge-based system comprises a large set of if-else rules that builds a decision tree and processes FDD queries efficiently. A semantic of a typical knowledge-based FDD system is shown in Figure 1. The collected sensor data is evaluated by maintainability rules. The evaluation results lead to the various maintenance decisions following a tree-alike structure.

For example, following the escalator maintainability rules stated in Table 2: ‘The landing area of escalators and passenger conveyors should have a surface that provides a secure foothold for a minimum distance of 0.85 m (measured from the root of the comb teeth)’, the measurement data collected from the sensor can be easily evaluated as ‘satisfactory’ or ‘unsatisfactory’. Different evaluation results will arrive to different decisions for automated maintenance.

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

A knowledge-based FDD system integrating traditional data-driven FDD framework treats the knowledge pool (Figure 1) as an expert system [9, 56]., where if-else rules are derived from maintainability rules. Following the existing rule-based system structures proposed in the related fields, such as [45, 57, 58], decisions for labeling various faults can be reached. The accuracy and performance of such FDD systems depend on the precision and reasonings of the rules. Compared with the existing rule-based systems, the maintainability rules proposed in this study are more precise and reasonable, consequently providing better results in terms of diagnostic accuracy.

3.2. Maintainability Rules as Inputs for Data-Driven FDD Systems

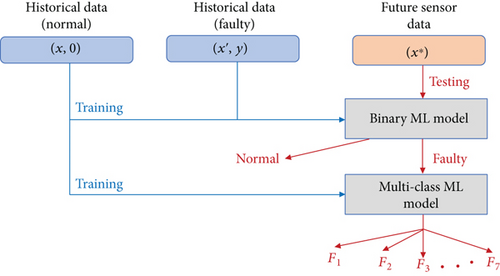

Data-driven FDD applied machine learning techniques to sensor data and performs automated classification with a pre-defined training process on the collected data. A typical data-driven FDD process is shown in Figure 2, where historical data containing both normal operational and faulty conditional data is received by the machine learning (ML) models. Two particular ML models are trained. The binary ML model handles the fault detection for facilities management, which classifies the future sensor data into normal or faulty classes. The multi-class ML model handles the fault diagnosis part, which classifies the faulty sensor data into different types of faults.

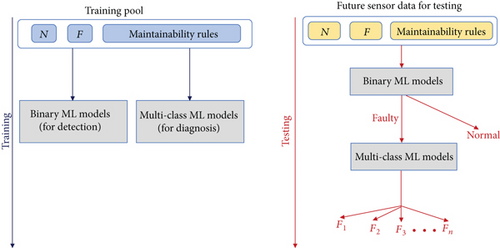

Traditional FDD methods, as shown in Figure 2, assume completely no background knowledge of the maintainability of the facilities. The maintainability rules that we proposed in this study provide a great opportunity to improve the existing FDD approaches. The simplest way of extending the current FDD framework with the maintainability rules is to treat them as inputs for the ML models. We formalize the proposed extension of the existing FDD framework in Figure 3.

In Figure 3, the traditional FDD framework has been improved by adding maintainability rules as inputs for both training and testing phases. Since ML models, in general, do not require background knowledge for classifications, the maintainability rules are served as additional inputs for both training and testing of the ML models. The maintainability rules have the potentials of enhancing the interpretation capability of the ML models as well as the prediction performance.

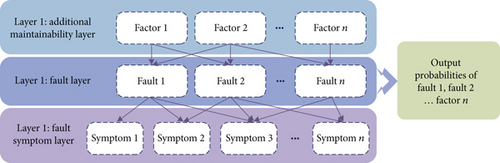

A concrete example of the proposed framework shown in Figure 3 is the three-layer Bayesian Belief Network (BBN) adapting the maintainability rules as an additional layer for FDD. The three-layer BBN is a three-layer neural network, calculating the probabilities of label assignment based on evidence and conditional probability. The details of the BBN construction can be found in [46, 47]. The internal structure of the BBN is illustrated in Figure 4, where expert knowledge is interpreted using maintainability rules as introduced in the Introduction Section (Section 1) and Section 4. For prediction probabilities calculated by neural networks, the maintainability rules provide evidence that influence the probability calculation. Therefore, the FDD accuracy will be improved significantly.

4. Maintainability Rules Study for Facility Management in M&E Services

In this section, we summarize the maintainability rules following the expert knowledge of typical components in M&E services, namely, HVAC system, plumbing and sanitary system, fire safety, electrical system and elevator & escalator system collected through survey and interview results over 110 buildings in Singapore, including commercial, hotels, industrial, institutional, clinical and residential buildings. The maintainability rules summarize the preventive checklist based on expert knowledge as well as standards regionally or globally in all design, construction and operational stages of buildings. The maintainability rules are useful serving as the knowledge pool for the post-caution FDD approach or as the additional maintainability layer for a precaution FDD approach, as explained in Section 3.

The maintainability rules for the chiller plant, the cooling tower, the air handling unit (AHU) and the air distribution, terminal system of the HVAC system are summarized in Tables 3–6, respectively. The maintainability guidance for general pumping issues, the water supply system and the water tank of the plumbing and sanitary system ae summarized in Tables 7–9, respectively. The maintainability issues for the fire detection, the fire hydrant system, the sprinkler system and the fire extinguishers of the fire safety (Table 10) are listed in Tables 11–13, respectively. The maintainability rules for the switchgear, the standby generator, the artificial lighting, the lightning protection system (LPS) and earthing are summarized in Tables 14–17, respectively. The general rules for the elevators and escalators, common faults for the elevators and escalators, the elevator safety, energy efficiency for the elevators and escalators and the maintenance for escalators, in general, are summarized in Tables 18–21, respectively.

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

| Water efficiency |

|

|

|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

Careful design is necessary to reduce vibration disturbances caused by impact force. Conform to noise control and elimination guidelines. Use principles of vibration control in determining noise control measures in accordance with SS CP 99, AHRI 260, ISO 9996 or equivalent. |

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

Adopt the construction and installation requirements for air duct systems and their fittings and accessories. Ensure that the ducts or duct linings (where glass fibre or mineral wool is exposed to the air stream) are suitably protected to prevent fibre erosion. The ducts should be sturdily supported - provide metal hangers and brackets for supporting ducts. Guarantee that the inner surfaces of the ducts for supply and return air are smooth and resistant to abrasion in order to reduce dust accumulation in accordance with SS 553, AS 1668.2 or equivalent. |

|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

Adopt the pipe sizing requirements based on hydraulic design and pump performance. Provide allowance for head loss, and frictional loss due to internal roughness, loss at fittings, turbidity, surge and pumping facility. Do not oversize piping as slow flow will cause stagnation. Specify standard fittings such as tees, elbows, etc. in accordance with BS 7291-1, BS EN 598, BS EN 545 or equivalent. |

|

Perform thorough investigation to check compliance with SS 636 and BS8554. Monthly inspection of water flow rate and pressure should be carried out, and position and functioning of valves. Maintenance inspections of the pipe installation should be carried out and identify/rectify physical defects such as broken pipe braces, dents, or leaks in accordance with BS 8558, BS EN 806-5 or equivalent. |

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

Pipework design should consider factors such as the choice of material, rate of flow, accessibility, protection against damage, corrosion, avoidance of airlocks, water hammers, noise transmission, unsightly arrangements, vibration and expansion of fluid, stress and strains, etc. in accordance with BS EN 1057, BS EN ISO 21003-2, BS EN ISO 21003-3, BS EN ISO 21003-5 or equivalent. Provide adequate longitudinal support to pipe installations below ground to cater for loads and traffic vibration. |

|

|

|

|

|

|

|

|

|

|

| Sensor self-closing delayed-action basin taps | To specify the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | To ensure the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | Carry out routine checks to ensure that sensor self-closing delayed-action tap can function properly and when the tap is activated, the water is automatically cut-off after a pre-set period of time. The tap should automatically stop functioning during power failure in accordance with SS 448. |

| Self-closing delayed-action basin taps | To specify the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | To ensure the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | Carry out routine checks to ensure that self-closing delayed-action tap can function properly and that the water is automatically cut-off after a pre-set time in accordance with SS448. |

| Dual-flush low-capacity flushing cisterns | To specify the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | To ensure the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | Ensure that flushing cistern can function properly in accordance with SS574 and check for signs of leakage, defect or damage (including any leakage, defect or damage at the outlet and inlet valves). |

| Sensor urinal flush valves | To specify the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | To ensure the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | Carry out routine checks to ensure that sensor urinal flush valves can function properly and discharge the flush volumes not exceeding those specified in SS 636. |

| Sensor WC flush valves | To specify the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | To ensure the display contact numbers of maintenance staff so that users can report any faulty, leakages or damaged taps to them for immediate rectification. | Carry out routine checks to ensure that sensor WC flush valves can function properly and discharge the flush volumes not exceeding 4.5 L per flush as specified in SS 636. |

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

|

|

|

|

The body of the water tank should be made of watertight and corrosion-resistant material, such as reinforced or pre-stressed concrete, steel, and glass fibre reinforced plastics in accordance with SS 245, BS EN 13121-3 or equivalent. | Structure of water tank should be constructed with adequate strength and be free from any deformation. Refer to BS EN 10088-2 for standards for a Stainless-Steel Sectional Water Storage Tank (Minimum Grade 316). |

|

|

|

The water storage tank’s installation should be certified by a professional engineer to ensure that it is structurally sound with regard to hydrostatic pressures, deflection and leakage. Use disinfectant to clean water tanks in accordance with BS EN 805 or equivalent. Once disinfectant has been sprayed on inner surfaces and pipes for the designated period, it should be thoroughly cleaned/removed. |

|

|

Decision on the size(s) of the tanks should be made based on water demand, supply, probability of pump failure, time needed for repairs, ratio of peak hours to average flow rate, provision of alternative supply or storage, etc. in accordance with BS 8558, SS 636 or equivalent. | Ensure that the tank is capable of handling various loads (as applicable) without showing cracks, stress or deformation in accordance with SS 245, BS EN 13121-3 or equivalent. |

|

| Potable water tanks | Cleaning and disinfection of potable water tanks should be adopted in accordance with SS 636 or equivalent. |

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

Construct lift lobby pedestrian flooring in accordance with recommended minimum pendulum ratings specified in SS 485, HB 197, AS/NZS 4663 or equivalent. |

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Problem | Design | Construction | Maintenance |

|---|---|---|---|

|

|

|

|

|

Lift car should be provided with permanently fixed electric lights (no less than two lighting fittings per car to be provided). Ensure lighting intensity of at least 50 lux at floor level in accordance with BS 5655-6, BS 5655-11, BS EN 81-20, SS 550 or equivalent. |

|

Ensure that luminaires are protected to prevent injury of passengers from breakage; and to prevent access to live parts by passengers in accordance with BS 5655-6, BS 5655-11, BS 7255, BS EN 13015, SS 550 or equivalent. |

The details of the regional (Singapore-based) and global standards, such as SS, BS, ISO, EN, AS and ASTM, are listed in Table 1.

5. Conclusions, Limitation & Future Works

Maintainability rules for M&E systems based on the survey and interview results of 110 buildings including commercial, hotels, industrial, institutional, healthcare and residential buildings are summarized. The maintainability rules are useful to be integrated into the existing data-driven FDD approaches for 1) an extension of the existing FDD algorithm to all M&E facilities in buildings, 2) enhancing the interpretability of the existing AI models and 3) improving the performances of the AI models. In Section 3, we demonstrate two data-driven FDD strategies integrating the maintainability rules, including 1) data-driven expert rules for decision making in smart building facility FDD; and 2) maintainability rules as inputs for data-driven FDD systems.

Based on the literature study, the surveyed maintainability rules will greatly enhance the interpretability of the existing data-driven FDD methods for M&E services and consequently promote the FDD methods to other building facilities and to other industrial areas, such as the Industry 4.0 evolution solutions. Furthermore, existing works show that the expert knowledge potentially improves the data-driven FDD results by adding the rules to the machine learning models, such as the decision trees.

The limitation of this study includes not showing the actual implementation of the maintainability rules integrated FDD framework, which we believe is a repetitive work to the existing publications. The main contribution of this study is first, to further extend the existing studies and concretize the maintainability rules that are used in existing interpretable data-driven FDD methods based on expert knowledge and existing standards. The second main contribution is to extend the existing FDD methods to a broader scope of facility management.

Future study of this work includes the experiments on the accuracy and efficiency improvement on existing BMS system adding the maintainability rules for additional supports as well as a wider the scope of applications for maintainability rules in smart city design.

Conflicts of Interest

The authors declare no conflict of interest.

Authors’ Contributions

Conceptualization, M.Y.L.C.; methodology, M.Y.L.C.; investigation, M.Y.L.C.; resources, M.Y.L.C.; data curation, K.Y.; writing—original draft preparation, M.Y.L.C.& K.Y.; writing—review and editing, M.Y.L.C.& K.Y.; visualization, M.Y.L.C.& K.Y.; supervision, M.Y.L.C.; project administration, M.Y.L.C.; funding acquisition, K.Y.

Acknowledgments

This work was supported by the faculty research grant of the National University of Singapore under grant number R-296-000-208-133 (K.Y.).

Open Research

Data Availability

The research data used in this study is confidential and only accessible internally for employees of National University of Singapore.