Energy Management System and Control Strategy of Intelligent Connected New Energy Vehicle in Line with the Dual-Carbon Strategy

Abstract

This thesis studies the development of the energy management system and control strategy of intelligent connected new energy vehicles and discusses the core techniques of the energy management system and control strategy of the vehicles. The energy management control strategy holds the key for the development of the new vehicles. It is designed to use its energy-saving principles and technologies to give full play to the energy-saving potential of the design scheme, thus optimizing the energy efficiency of the entire vehicle while meeting the driving needs of vehicles according to the performance characteristics of key components and the driving conditions of the vehicle. This thesis not only analyzes the V2X standards to be met in the application of ICV technology and briefly describes the CD/CS strategy and Blended strategy of plug-in hybrid vehicles and the energy management control strategy based on rules and optimization but also studies the control and strategy of information management system in practical circumstances.

1. Introduction

In 2021, the goals, “carbon emission peak and carbon neutrality” are listed into the Report on the Work of the Government for the first time in the two sessions (the National People’s Congress, NPC and the Chinese People’s Political Consultative Conference, CPPCC). It is mentioned that in the future, the government will continue to optimize the industrial structure and the mix of energy and take robust measures to develop new energy. Actively promoting the development of the new energy vehicle industry can not only effectively reduce China’s overall carbon emissions, but also serve as an important strategic measure to promote the sustainable development of China’s green economy [1].

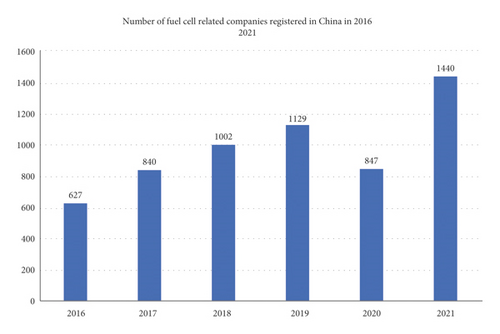

Under the background of double carbon, fuel cell technology is a strategic choice for China’s future energy technology. Fuel cell has been listed as one of the “three horizontal and three vertical” for electric vehicles by the Ministry of Science and Technology since the “10th Five-Year Plan,” and it has been listed as a key R&D target from the “11th Five-Year Plan” to the “14th Five-Year Plan.” During the period from the 11th Five-Year Plan to the 14th Five-Year Plan, fuel cells have been listed as a key R&D target. According to statistics, there will be 1,440 fuel cell companies registered in China in 2021, an increase of 70% year-on-year [2] (Figure 1).

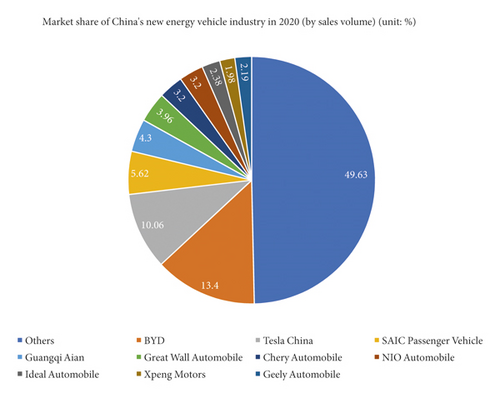

In terms of the market share of China’s new energy vehicle industry, BYD has taken the lead, accounting for 13.4% of the market share. The second is Tesla Motors, which accounts for 10.06% of the market (see Figure 2).

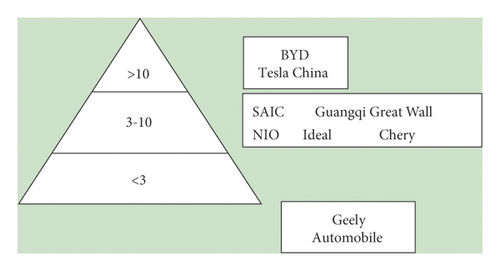

Moreover, in terms of sales volume alone, BYD and Tesla China can be said to have exceeded 10 W vehicles (see Figure 3).

From the data, China is vigorously developing the new energy vehicle industry and has considerable support for new energy vehicles. It can be said that new energy vehicles will develop faster in the future. For China’s new energy automobile enterprises, BYD, Weilai automobile, Zhidong automobile, and chehejia have the highest degree of relevance in this regard, followed by Geely holdings, JAC, Great Wall Motors, BAIC bluevale, GAC group, and SAIC Group, which can be said to have great pressure on market competition [3] (see Table 1).

| Brief introduction | Established time | Business scope | Correlation to the industry |

|---|---|---|---|

| BYD | 1995/2/10 | New energy vehicles, pure electric buses, pure electric taxis, lithium iron phosphate batteries | ∗∗∗∗∗ |

| SIAC | 1984/4/16 | Complete vehicles and parts of new energy vehicles (including power drive systems, interior and exterior trim systems) | ∗∗∗∗ |

| Guangqi | 1997/6/6 | New energy vehicles and its spare parts | ∗∗∗∗ |

| Beingqi | 1992/10/6 | New energy vehicles and its core parts | ∗∗∗∗ |

| Changan | 1996/10/31 | IICVs, charging and replacing operation, time-sharing leasing | ∗∗∗ |

| Great wall | 2001/6/12 | Small-sized new energy vehicle | ∗∗∗∗ |

| JAC | 1999/9/30 | IEV pure electric passenger car | ∗∗∗∗ |

| Xiaokang | 2007/5/11 | New energy vehicles, powertrains and key components | ∗∗∗ |

| NIO | 2015/5/7 | A global smart electric vehicle brand, focusing on pure electric vehicles | ∗∗∗∗∗ |

| Intelligent automobile | 2015/1/9 | A focus on pure electric vehicle models | ∗∗∗∗∗ |

| Autohome | 2015/4/10 | Manufacture and maintenance of pure electric vehicles | ∗∗∗∗∗ |

| Geely | 2003/3/24 | Design, R&D, and production of complete vehicles, powertrains, and key components | ∗∗∗∗ |

| Chery | 1997/1/8 | R&D and manufacture of new energy vehicle | ∗∗∗ |

| Tesla China | 2019/5/22 | New energy vehicle R&D and manufacturing, and charging pile services | ∗∗∗∗∗ |

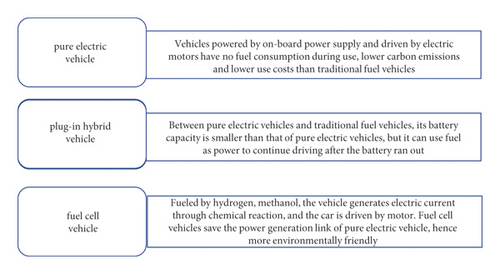

For March 2022, China’s new energy vehicle production and sales completed 465,000 and 484,000 units, respectively, of which the production and sales of pure electric vehicles completed 376,000 and 396,000 units, respectively, plug-in hybrid vehicle production and sales completed 89,000 and 88,000 units, respectively, and fuel cell vehicle production and sales completed 500 and 367 units, respectively (as shown in Table 2).

| Production and sales volumes | Pure electric vehicle | Plug-in hybrid vehicle | Fuel sell vehicle |

|---|---|---|---|

| Production | 37.6 | 8.9 | 500 |

| Sales volume | 39.6 | 8.8 | 367 |

Meanwhile, the year-on-year growth rate is shown in Table 3.

| Growth of production volume | Pure electric vehicle (multiplayer) | Plug in hybrid vehicle (multiplayer) | Full cell vehicle |

|---|---|---|---|

| Growth of production | 1.1 | 1.6 | 10.1 |

| Growth in sales | 1.1 | 1.4 | 5.2 |

In terms of new energy vehicle batteries, they can be divided into two main categories, namely, batteries and fuel cells. The battery is applicable to pure new energy vehicles and the fuel cell is dedicated to fuel cell new energy vehicles [4].

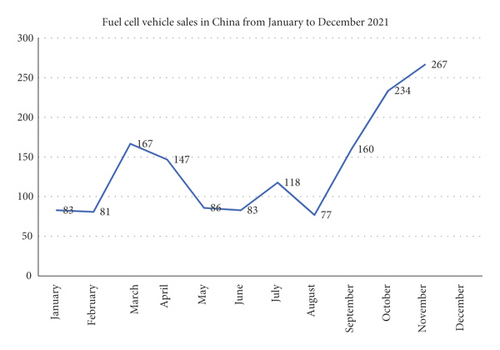

For fuel cells 2021, China’s hydrogen fuel cell vehicle sales were 1,881 units, up 25.7% year-on-year, with sales by month as shown in Figure 4.

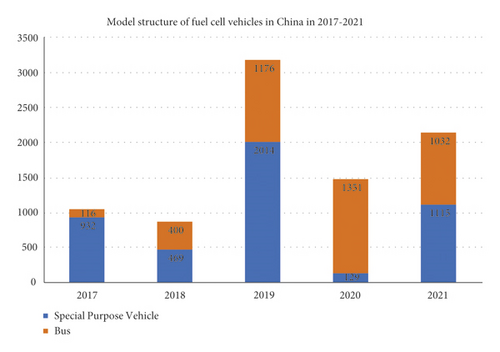

In terms of model structure, fuel cell bus sales reached 1,032 units in 2021, although down 23.6% year-on-year, fuel cell buses are still the most dominant model of fuel cell vehicles as shown in Figure 5.

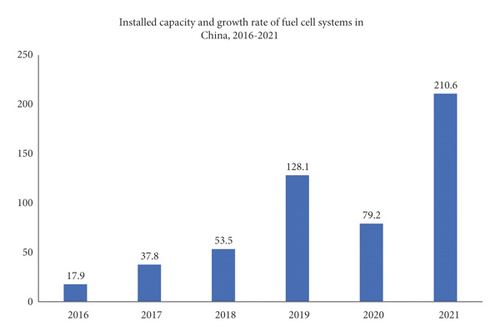

In terms of installed capacity, according to statistics, the installed capacity of fuel cell systems in China is 210.6 MW in 2021, an increase of 165.9% year-on-year (As shown in Figure 6).

ICVs can effectively reduce air pollution and are of great significance to improve people’s living standards and enhance national development. Despite recent development in ICV technology, much remains to be done immediately, for example, how to efficiently use the energy of the power battery and prolong the life of the power battery. Boasting the combination of 5G technology and intelligent network technology, ICVs stand a great chance of becoming the most promising vehicle for future development. As the new-energy-based vehicle is a new type of ICV, the most important issue is how to effectively use the energy management system of the vehicle to manage power consumption because it is pivotal to the performance of the vehicle. Therefore, it is crucial to study the energy management system and control strategy of ICVs.

2. State of the Art

New-energy-based ICVs are equipped with intelligent mobile space and a new generation of “intelligent connected” terminals. These new types of vehicles utilize new techniques such as intelligence and carry with advanced equipment like sensors and actuators. At the same time, by applying electrification and intelligent connected technology, the vehicles are intelligent and connected. At the same time, through the application of electrification and intelligent connected technology to new energy vehicles, the vehicles can be intelligent and connected. Improving and optimizing the motor efficiency is the intelligent use of the cooperation of the battery system drive system, which greatly improves the economy and comfort of the vehicle [5]. Today, many cars developed by car companies are equipped with intelligent platforms with highly flexible technology openness and future-oriented intelligent attributes, and the safety of power batteries will be greatly improved. At the same time, some vehicles adopt upgradable and replaceable battery modules to carry out flexible cell design solutions, which can easily upgrade functions and optimize cell formulas according to consumers’ needs. It is worth noting that some car companies have developed and put into production the electric platform of the wireless energy management system (WBMS), which greatly improves the development space and technical flexibility, and the battery development and testing are above the national standard. Thanks to the three advantages of flexibility, intelligence, and safety of the intelligent platform, the electrification products of intelligent and connected new energy vehicles will soon be available to consumer groups as shown in Figure 7.

Intelligent connected vehicles are the intersection of the Internet of vehicles, intelligent transportation, and intelligent vehicles, which can realize the information interaction between vehicles and X (vehicles, people, roads, backstage) and have the ability of intelligent decision-making.

The traditional automobile network architecture is mainly composed of CAN bus. The distributed electronic control unit ECU in the vehicle is divided into powertrain, body control, auxiliary driving, and other bus areas according to its functions; Windows, lights, skylights, etc., are connected to the can network through the LIN bus. This also benefits from the advantages of CAN bus communication, such as high real time, long transmission distance, and strong anti-electromagnetic interference ability. Under the wave of the new generation of intelligent network-connected vehicles, with the multiplication of on-board ECU and the rapid development of processor computing power and hardware, the network connecting ECU needs more bandwidth, which is far beyond the capacity limit of traditional on-board networks such as can.

For automotive network architectures, the clearer trend is the transition to CAN FD, which offers 64 bytes of data throughput and transmission rates of up to 5 Mbps. In addition, in-vehicle Ethernet technology seems to have become the darling of this wave. Because of its high bandwidth, low latency, and low cost, in-vehicle Ethernet will replace CAN bus as the preferred network architecture in the new generation of vehicle architecture. In-vehicle Ethernet is used as the backbone network to connect the core domain controllers (powertrain, body, entertainment, ADAS) together. Each domain controller provides a powerful gateway function along with dedicated control functions. Underneath each domain controller, the communication between components is basically through CANFD for data sharing, which is similar to the traditional in-vehicle network architecture (except in the entertainment subnet, where the communication between the entertainment domain controller and its subcomponents will be realized through Ethernet). In addition, when a domain needs to exchange information with other domains, it needs to be realized through gateway and Ethernet routing. This domain controller-based architecture changes the traditional point-to-point communication from ECU to ECU in the in-vehicle network.

The advent of the new vehicles is attributable to the achievements of core technologies such as intelligent networked technology, new energy vehicles, battery power, intelligent control, etc. Some problems that severely inhibit the development of core technologies need to be addressed in R&D and product industrialization of these ICVs [6]. In order to ensure the high safety of the discharge of intelligent networked new energy vehicles in use, the power battery energy consumption of intelligent networked new energy vehicles is slightly different from that of ordinary electric vehicles, and the battery discharge rate and efficiency are higher. The power battery must have high energy density and high-power density to provide large peak power during acceleration and hill climbing. The performance and life of the power battery are closely related to the charging and discharging time, temperature, and other factors of the power battery as shown in Figure 8. Overcharge, excessive discharge, and undervoltage will seriously affect the performance of the power battery and even cause damage to the internal modules. Therefore, a power management system is needed to monitor the working process and environment in real time and accurately predict the remaining battery power [7]. This is especially important for efficient use and improved energy efficiency, extending battery life. Increasing the research and development of large-capacity batteries and high-efficiency energy management systems is a useful technical challenge for the development of intelligent and connected new energy vehicles, and it marks a milestone in solving key technical problems [8].

s is the distance and t is the time.

P: represents the electrical power. U: represents the voltage between the terminals of the appliance. I: indicates the current.

This parameter is defined as 15 minutes. For example, if the 1221 W battery is 12 V (6 CELL), each CELL provides 21 W power for 15 minutes.

3. Methodology

3.1. V2X Application Standards for ICVs

- (1)

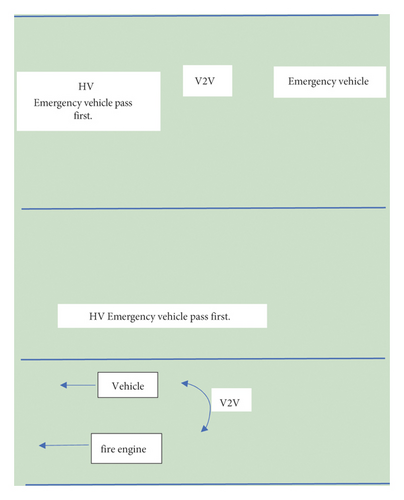

VIP vehicle avoidance reminder based on V2V: The hybrid vehicle (HV) and the emergency vehicle are equipped with V2X on-board terminals. As shown in Figure 8, the emergency vehicle is driving in the direction behind the simulated hybrid vehicle (HV), and the two vehicles exchange positions and status information through V2V during driving. When the V2X vehicle terminal of the hybrid vehicle (HV) receives the approaching information of the rear vehicle, the hybrid vehicle (HV) issues an early warning, prompting the hybrid vehicle (HV) driver to stop quickly to the right to avoid, and let the emergency vehicle pass first, as shown in Figure 9.

- (2)

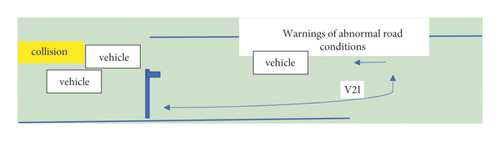

Vehicle warnings based on V2V for abnormal road conditions: The vehicle (HV) is equipped with a V2X on-board terminal. When the vehicle (HV) V2X roadside terminal obtains the abnormal road conditions ahead, the vehicle (HV) V2X roadside terminal publishes information to the surrounding vehicles through V2I communication and the driver of the vehicle (HV) appropriately adjusts the route to leave the abnormal road section, as seen in Figure 10.

3.2. Performance Requirements for the Energy Management System

Data acquisition sensor module, management control unit MCU, monitoring control module, output actuator module, high-voltage safety system and current balance module, data display, state estimation, fault diagnosis, etc., are all the battery energy management systems of new-energy-based ICVs [9]. The extremely difficult operating conditions of the car in real time and the major changes in the real-time working environment will affect the power management system, and the noise and electric waves accompanying the operation of the vehicle will paralyze the function of the system and lose its normal functions.

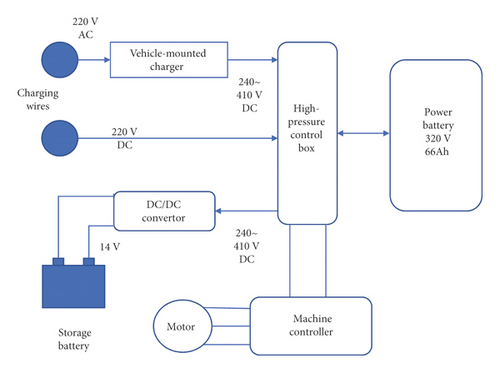

3.3. Structural Features of the Energy Management System

The energy management system detects the voltage, current, and temperature of the power battery in real time, manages leakage detection, thermal management, and battery balance in real time, and controls the maximum output power through an algorithm, so that the car can obtain the maximum cruising range [10]. It can be seen that the reliability, versatility, and economy of the power battery energy management system of the intelligent network-connected new energy vehicle should be possessed. Because it is equipped with advanced sensors and other devices, it is necessary to ensure that the power supply is normal when the device is running. Otherwise, it cannot be intelligently controlled, and the electrification and intelligent network connection of the vehicle cannot be realized. The key technologies of energy management system are: SOC evaluation method of BMS, balanced management of BMS, and thermal management system of BMS. Balance management includes: automatic balance between single cells after charging, automatic balance between single cells during charging, and the use of auxiliary management devices [11]. The energy management system of intelligent and connected new energy vehicles is very important. After meeting the performance of the vehicle, the energy management system must be able to meet the characteristics of the vehicle’s electrical system and driving operating conditions in a timely manner in reality.

3.4. Control Principles of the Battery Energy Management System

The discharge performance of the power battery interacts and affects the remaining power (SOC) of the power battery. If the SOC value is lower than the set value, the vehicle will display a fault and cannot drive normally, and the high-power equipment (air conditioning system, etc.) will be forced to be turned off, and the warning light on the meter is always on; when the SOC value is higher than the set range value, the overcharge of the battery will reduce the service life of the battery pack [12]. When calculating the SOC value, according to the ampere-hour integration method, the remaining power (SOC) value of the power battery is calculated and corrected according to its initial value and open circuit voltage [13]. Among the influencing factors of the total capacity of the battery, the ambient temperature, the number of battery cycles, and the average discharge current are the key factors, and the correction factor of the influencing factors is set to ensure the total capacity of the single battery. When the driver starts the vehicle, the power battery is discharged, and the drive motor and body equipment are self-diagnosed [14]. When the vehicle is in a normal driving state, the vehicle speed is at a normal speed, and the motor is working in a high-load area. At the same time, through the DC-DC converter, the high-voltage electricity is converted into low-voltage electricity to supply power to the electrical system and to charge the auxiliary battery.

3.5. The Purpose of Setting the Energy Management Control Strategy

Due to the matching of the multipower source energy coupling system, new energy vehicles are more flexible than traditional internal combustion engine vehicles in meeting the power requirements of the entire vehicle. In order to manage the energy coupling system of multiple power sources reasonably, the power or torque of multiple power sources is distributed by setting the energy management control strategy, and the mechanical braking and electric energy recovery are coordinated, so as to ensure the power and safety of the vehicle. On the basis of improving the system efficiency and comfort, it can improve the energy-saving and emission-reduction performance of the vehicle. Usually, the energy management control strategy will use related algorithms to achieve the above goals [15].

Traditional HEVs have limited charge and discharge capabilities and low battery capacity and power and can operate within a small battery state-of-charge (SOC) window. When the vehicle is running, the energy management control strategy smooths the engine operating point by optimizing the charging and discharging process of the battery, thereby reducing vehicle fuel consumption [16]. The SOC of traditional HEVs has a certain degree of convergence. During a period of operation, the initial value and final value of the SOC are the same, in other words, Charge Sustaining (CS) mode. Similarly, for the plug-in hybrid electric vehicle, since it can be charged through the external grid, its energy management control strategy increases the power consumption mode (Charge Depleting, CD) [17]. The “Power Consumption-Power Sustain” (CD-CS) control strategy is simple and easy to apply, but the optimization space for energy consumption is very limited once the power maintenance mode is entered. In addition, the “Power Consumption-Power Sustain” (CD-CS) control strategy usually matches the electric drive system with a larger capacity and power level, so that the battery discharge capacity can be used in CD mode to achieve full coverage of the power performance. Therefore, vehicle costs are more affected by the electric drive system. Another strategy adopted by plug-in hybrid vehicles is the hybrid control strategy (Blended Mode), which gradually consumes battery power by rationally distributing the power of the battery and the engine in real time throughout the cycle [18]. The hybrid control strategy must be adjusted according to the mileage length. In the absence of travel mileage related information, the hybrid control strategy (Blended Mode) may consume more fuel than the established power consumption-power maintenance (CD-CS) strategy, which is one of the main reasons hindering the practical application of the hybrid control strategy (Blended Mode). However, if the required mileage information is known to us, the blended control strategy (Blended Mode) has a more significant optimized improvement in fuel economy than the power consumption-power maintenance (CD-CS) strategy and fully utilizes the characteristics of the PHEV.

3.6. Brief Description of the Rule-Based Energy Management Control Strategy

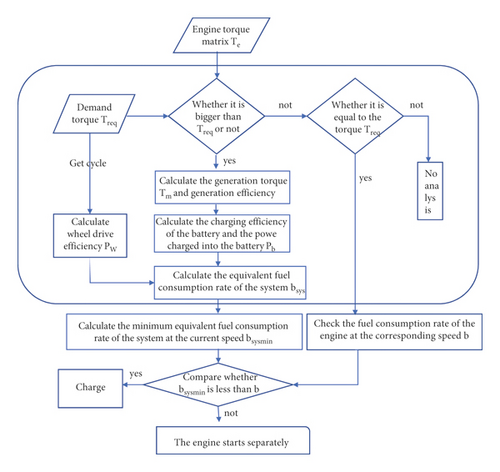

That is, the engine torque matrix is used to make a determination as to whether a line charge or a separate engine start is being performed. Energy management control strategies are divided into rule-based (RB) and optimization-based control strategies (see Figure 11). Among them, the former includes deterministic strategies and fuzzy logic (FL) control strategies, both of which are preset rules, and control signals are calculated on the basis of preset thresholds of control variables, which are usually based on the selected driving calculated by looping through optimal control analysis. These rules define vehicle operating modes for ease of implementation and understanding. The rule-based (RB) control strategy is widely used in HEVs [19]. There are also studies that combine fuzzy logic (FL) with optimal control to improve the performance of fuzzy logic (FL) without increasing the computational load, such as combining neuro-fuzzy logic (FL) and fuzzy logic (FL) with genetic algorithm or evolution algorithm [20].

3.7. Brief Introduction of the Optimization-Based Energy Management Control Strategy

The rule-based (RB) control strategy is more suitable for low electrification levels, while the optimization-based (OB) control strategy is better than the rule-based strategy. However, there are still some problems in practical applications, such as algorithmic complexity, excessive computation, stability, sensitivity to operating condition information and features, and slow integration with industry. At present, a large number of optimization algorithms are used in the energy management of PHEVs, mainly in the simulation research stage, which can be divided into all-time optimization and real-time optimization. The two types of optimization have no stark differences because they are both confined by algorithms and affected by sampling time, model accuracy, parameter definitions, and other factors. The main optimization algorithms include dynamic programming (Dynamic Programming, DP), equivalent fuel consumption minimization (equivalent consumption minimization, ECMS), simulated annealing (simulated annealing, SA), genetic algorithm (genetic algorithm, GA), particle swarm algorithm (particle swarm optimization (PSO), DIRECT algorithm, neural networks (NN), game theory (GT), sliding mode control (SMC), convex programming (CP) and related Algorithms Simplified Algorithms, and Model Predictive Control (MPC).

3.8. Control Strategy of the Information-Based Energy Management System

In the management of the power battery energy system of new-energy-driven ICVS, it is necessary to make a comprehensive data analysis on the flow of information and formulate an appropriate control strategy of energy management system for the specific data of the motor’s instantaneous start, smooth running, and control feedback. However, in the process of driving, the car will stop, start, and meet the car and the work change of electrical equipment. It is necessary to analyze and study different working conditions of the vehicle according to the actual situation so as to formulate the information energy system control strategy under different working conditions [21]. In the actual control, by sampling and analyzing the information of parameters such as the vehicle accelerator pedal position signal and the working condition of the driving vehicle, the control system distributes the motor torque to it according to the actual working condition parameters to ensure that the distribution is scientific and reasonable so that the driving motor is in a high-efficiency rotation state, and the information exchange control of related electrical equipment ensures optimal control of information energy.

In the intelligent network control system, an important information control technology during driving is the alternating change of high and low beam lights and automatic deceleration control in foggy days, rainy days, and when meeting cars [22]. However, to realize the functions of information control technology, a variety of sensors are required to collect and execute information for control simultaneously.

During the automatic control process of the car, the information energy management of the car will make corresponding control strategies when it meets the vehicle ahead or encounters the foggy weather. For example, in foggy days, due to insufficient visibility, there will be potential safety hazards for vehicles to drive automatically and quickly, especially at intersections for it is difficult for vehicle sensors to quickly check the communication situation at the intersection. If the speed is not controlled, it may cause traffic accidents. Another is that in foggy weather, the signal received by the sensor will be affected in such humid weather [23]. Therefore, in this environment, it is necessary to control the speed. At this time, the sensor responsible for controlling the high beam and low beam will obtain the environmental information and feedback to the control unit. If the vehicle speed is low, the high beam cannot be illuminated, and the low beam can only be automatically controlled.

When the car encounters rainy days and runs fast, then the car information control system will perform systematic deceleration control in order to ensure driving safety. For example, in rainy days, due to the slippery road surface, the car will be automatically switched and controlled to restrict high driving speed. At this time, the information received by the sensor responsible for controlling the speed of the vehicle will be fed back to the control system and changed to ensure driving safety and use accurate data to control the motor speed and recover the energy.

4. Result Analysis and Discussion

4.1. Innovation of Relevant Laws and Policies

At the legal level, the state should issue relevant laws and regulations and clarify legal responsibilities and legal roles. It should focus on clarifying the responsibility distribution of property owner and user in legal liability. Each region can independently formulate its own relevant laws and regulations on intelligent connected vehicles according to the actual situation.

4.2. Expected Benefits

With the development of the automobile industry, China’s intelligent networked vehicles can be put into large-scale production in the near future. Moreover, as a comprehensive product, more than 90% of the scientific and technological innovation in the automotive industry in the future will be concentrated in the intelligent networked automotive industry. In 2035, about 20 million vehicles in the world will have some automatic driving functions, and 12 million vehicles will have all automatic driving functions.

4.3. Multi-Industry Joint Development and Industrial Integration

Intelligent connected vehicle is the integration of traditional automobile industry and artificial intelligence industry. The intelligent connected automobile industry integrates cloud computing, new energy, artificial intelligence, and other industries. Most of them are products of the nonindustrial age. Through multi-industry development and joint intelligent networking, the automobile industry will bring Earth shaking changes to the transportation industry.

5. Conclusions

As a new type of vehicle equipped with advanced sensors and new technologies such as artificial intelligence, new-energy-driven ICVs have become a new transportation for intelligent mobile spaces and application terminals, which is indispensable to the energy management strategy of performance power batteries. That means we need to extend the service life of the power battery, ensure the continuous efficiency and safety of the power battery, and strengthen the energy management of intelligent vehicle batteries. At present, the power battery energy management system of intelligent and connected new energy vehicles still needs in-depth research and testing and needs to be further improved. To this end, it is imperative for us to build a reasonable energy management strategy for ICVs and ensures effective testing and assessment of the vehicle’s performance so as to provide a strong boost to the ICV industry.

In a word, compared with foreign developed countries, China still has a long way to go in the development of numerical control technology. Only by comprehensively understanding and mastering the development direction of intelligent manufacturing and numerical control technology in foreign countries can we provide guidance for the integrated development of intelligent manufacturing and numerical control technology in China, which is of great significance to promote the development and innovation of high and new technology in China. By studying the difficulties encountered in the integration of intelligent manufacturing and numerical control technology in China, it can help relevant enterprises better apply advanced numerical control technology to intelligent numerical control equipment. In the industrial 40 era, China’s industrial enterprises need to continuously carry out technological improvement and innovation, so as to speed up the integration between intelligent manufacturing and numerical control technology, improve their competitiveness in the market, and play a key role in the industrial revolution, so as to comprehensively promote the development of intelligent manufacturing numerical control technology.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This work was supported by the City College of Huizhou.

Open Research

Data Availability

The labeled data set used to support the findings of this study is available from the corresponding author upon request.