[Retracted] Design Method of Intelligent Touchpoint: Intelligent Auto-Loading Cargo Transport Vehicle for Automobile Passenger Transportation

Abstract

The integration of passenger and cargo transportation has become a new profit development point in the transformation of automotive passenger transport services, and cargo vehicles are a major service touchpoint for the integrated passenger and cargo transport system. This study presents a set of intelligent service touchpoint design principles with intelligent perception, connection, analysis, decision-making, and execution, to innovate the integrated intelligent service system of automobile passenger and cargo transportation, and intelligent self-loading and unloading cargo transport. Based on the field data of cargo transport services of five automobile passenger stations in China, the problems are analyzed and summarized from the aspects of service facilities, content, price, and process, and ultimately form an intelligent service system integrating automobile passenger and cargo transportation. Next, the proposed system is analyzed and compared with five existing intelligent consignment products, and target tasks and requirements of cargo transport vehicles are extracted. The system realizes the usability evaluation of the functional prototype through the combination of open-source hardware, Arduino platform, and mechanical transmission structure, and verifies the availability of the design principles of intelligent service touchpoints.

1. Introduction

Service touchpoints arise from the interactions between service providers and service recipients and are also important to influence the user experience in the service process which include Physical TouchPoint, Digital TouchPoint, and Personal Touchpoint [1]. Physical TouchPoint is the tangible, physical, and touchable touchpoint between service providers and service recipients, such as product and space environment [2]. Digital Touch Point comes from the interaction between smartphone applications or PC webs and a digital system. Personal TouchPoint arises from the direct or indirect interaction between people, such as information consultation with waiters. From the perspective of the intelligent development trend, the service touchpoints integrate with intelligent technology smoothly, which will improve the overall-service efficiency and user experience; intelligent service touchpoints can improve service efficiency and user experience without a doubt [3]. Unlike traditional physical touchpoints, digital touchpoints, and personal touch pint, intelligent touchpoints can assist environmental perception, senior identification, information reception, and behavioral decision-making. Currently, the focus of intelligent service touchpoints is primarily on locating specific intelligent service touchpoints in the service process using the method of service design; few people are interested in the intelligent service interaction ontology of intelligent service touchpoints, and the majority of them are primarily interested in discovering the basic functions of intelligent cargo transport vehicles [4].

In recent years, intelligent technologies such as intelligent hardware, robots, and 3D visual perception have assisted in the research and development of intelligent logistics and the integration of passenger and cargo transportation, while also assisting in the development of intelligent cargo transport vehicles [5]. The design and development of intelligent cargo transport vehicles have become a tool for increasing cargo transport service efficiency and improving customer experience. As a result, intelligent vehicles have a large market opportunity. Various manufacturers are pouring into the diverse new sectors of intelligent cargo sorting and intelligent handling of different sorts of goods using current technology and features of intelligent cargo transport vehicles [6]. In this case, the intelligent cargo transport vehicle is the most important service touchpoint in the transformation of the integrated intelligent system of passenger and cargo transportation in the automobile passenger station, and its design and research, and development are of great importance in solving the problem of the last kilometer between the goods and the automobile storage [7].

This study presents an integrated intelligent service system of automobile passenger and cargo transportation, as well as the new function of intelligent self-loading and unloading cargo transport vehicles in automobile passenger stations, to fill the gap in cross-platform transportation of intelligent transportation, which may be valuable guidance for other designers. The design elements and principles of intelligent service touchpoints are verified through the Arduino prototype. Considering the users’ needs for the same intelligent service touchpoints in different scenarios and products, the results can be applied to the operation and research of other relevant service touchpoints.

The rest of the manuscript is organized as: Section 2 is about related works. Section is about material and methods and provides a detailed description of the proposed method. Section 4 is about results and Section 5 provides discussion on the obtained results. Finally, the conclusion is presented in Section 6.

2. Related Works

Service touchpoint, also known as a customer contact point (customer touchpoint, CTP), is one of the three pillars of service design research. Touchpoints are the individual contacts or interactions between an organization and a person, which occur in interactions with places, people, products, or marketing initiatives. Intelligent touchpoints are mainly the products, facilities, or intelligent systems between service providers and service recipients [8]. Various models have been proposed to explore the requirements and design of intelligent products, services, or systems. For instance, Wang and He [9] proposed a design method model of smart home product touchpoints based on user behavior. Miao et al. [10] proposed a design strategy of service touchpoint of intelligent home product portfolio based on a scenario. The author in Ref. [11] proposed that intelligent products should have the ability to record data and information, learn and think. Zheng [12] presented a hexahedral component model of an intelligent product-service system. Only a few people began to explore intelligent service touchpoints directly but only put forward this statement: Wang et al. [13] directly apply customer touchpoints to the development of intelligent product touchpoints in service design. As a medium for users to interact directly with the enterprise, service touchpoints play an important role in the direct perception and evaluation of the whole service.

With the continuous development of intelligent transportation and intelligent transportation system and the increasing discussion on the service mode of integration of passenger and cargo transport, scholars have discussed the operation organization and the last mile of the integrated passenger and cargo transport system from the point of view of all modes of transport (air, sea, land) [14–16]. From the point of view of logistics management, some scholars have discussed the integrated warehousing management system based on RFID software and hardware, temperature monitoring and tracking system of frozen goods, intelligent logistics management model based on RFID technology and geographic fence algorithm, and iTape intelligent tape for cargo damage and theft monitoring [17, 18].

The research on self-loading and unloading cargo mainly focuses on lifting mechanisms, hydraulic systems, synchronous control systems, and cargo frames, and its application fields are bulk container logistics, waste transportation, and field transportation. Lee et al. [19] put forward the process of logistics equipment system research. Iwan and Stanissimaw [20] introduced the availability of cellular automata as a traffic simulation tool for urban freight transport systems to analyze the efficiency of this measure and its potential impact on the urban environment. Rahman and Nielsen [21] developed a method for scheduling automatic transport vehicles to ensure the integrated operation of multiple automatic transport vehicles in production and container station environments. Shen et al. [22] presented the framework of an intelligent logistics system for parallel loading and unloading. Although researchers and enterprises have made some exploration with different emphasis on intelligent self-loading and unloading cargo transport vehicles, in the context of automobile passenger stations, few researchers and enterprises study and explore the intelligent links between automobile warehouses, goods, and intelligent self-loading and unloading cargo transport vehicles.

As a result, greater research into the design and development of intelligent self-loading and unloading freight transport in the context of an automotive passenger station is required.

With the rise of the integration of passenger and cargo transportation, various advanced technologies such as artificial intelligence (AI) and digital twinning are integrated into the design and research of transportation and logistics, and the intelligence of automobile passenger transport service touchpoints is becoming a trend [23, 24]. However, there is little research on intelligent self-loading and unloading cargo transportation of automobile passenger transport. The research on the integration of passenger and cargo transportation and intelligent logistics transportation has some inspiration for the research and design of automobile intelligent self-loading and unloading cargo transportation service touchpoints.

Traditional bus stations gain commercial benefits by transporting passengers, luggage, and a small amount of private bulk cargo [25]. With the change in technology and demand, without the mode transformation of intelligent passenger and cargo transportation integration, the profit will continue to decline and bus stations may eventually be banned. Traditional intelligent transportation tools are used in warehouse logistics sorting and cargo handling, mainly to complete single-plane vertical lifting [26, 27]. However, in the service situation of the automobile passenger station, it will be impossible to transport goods to the automobile storage area, so cross-platform transportation tools are needed.

Handling technology is changing from labor-intensive to technology-intensive, but most of them are developed for specific areas, not for the unique environment of bus passenger stations [28–30]. Therefore, combined with the analysis results of field investigation, this study puts forward the intelligent service of automobile passenger and cargo integrated transportation and a kind of service touchpoint of intelligent self-loading and unloading transport, to solve the problems of low efficiency and high labor cost in the field of loading and unloading.

3. Methods

3.1. Field Data Collection of Automobile Passenger Station

In this study, the data are collected from a field survey of Beijing’s large-scale automobile passenger station, aiming to obtain the current situation of cargo service of the automobile passenger station. The information on automobile passenger stations in Beijing is selected from the Internet, and the appropriate stations are chosen according to the cargo transportation content, station level, station type, and station configuration to determine the final list. Next, in-depth field research is conducted one by one, and five automobile passenger stations were investigated, including Ba Wangfen automobile passenger station (PS1), Sihui long-distance passenger station (PS2), Liuliqiao long-distance passenger station (PS3), Zhao Hongkou long-distance passenger station (PS4), and Muxiyuan long-distance passenger station (ps5).

This study aims to complete two tasks. Firstly, an element analysis model of service touchpoint is established using service content, service facilities, service cost, and service process to understand the attitude and status of automobile passenger stations towards cargo transportation service, to put forward the design principles of intelligent service touchpoints. Next an intelligent cargo transportation service system is built using the design principles and cargo demand. During the field investigation, the service observation method and personal experience method were used to record the service process and service experience of cargo transportation in an automobile passenger station, and we get the typical scenes and factors affecting cargo transportation. The core content of the field research tried to answer the questions: (i) Does the existing automobile passenger station provide integrated passenger and cargo transport. (ii) If so, what specific types of goods are provided for transportation? (iii) What are the charges for transportation services? (iv) What is the service flow of existing goods transportation? (5) How is the experience of the service touchpoints in the service process?

3.2. Element Analysis Model of Intelligent Service Touchpoint

To understand the service status of cargo transportation in automobile passenger stations, the service provision, service facilities, and service process elements are used in the service design to record and add the price factors affecting the decision-making; explore the demand and touchpoint of intelligent cargo transportation to find the most appropriate solution and find out the core service touchpoint finally.

The data of five stations were collected and the basic information was input and sorted out the service content, service facilities, service cost, and service process according to on-site photos and on-site records of the station. The basic information of the five stations is shown in Table 1.

| Number | Coding | Station name | Photo | Introduction |

|---|---|---|---|---|

| 1 | Ps1 | Bawangfen bus station |  |

The Bawangfen long-distance bus station is a passenger joint venture jointly established by the Spanish Alsa Group and the Beijing Transportation Company. This station has its own logistics express center (subordinate to ALSA). |

| 2 | Ps2 | Sihui long-distance bus station |  |

The passenger transportation route of Sihui long-distance passenger station covers 9 provinces and one city, including Jilin, Liaoning, Hebei, Anhui, Henan, Inner Mongolia, and Tianjin, and is sent to the three northeastern provinces, Tangshan area of Hebei province, Tianjin area, and parts of the south. |

| 3 | Ps3 | Liuliqiao long-distance bus station |  |

There are 137 passenger lines in Liuliqiao Passenger Transport Station, reaching 17 provinces and autonomous regions including Jilin, Liaoning, Hebei, Henan, Inner Mongolia, Shandong, Shanxi, Jiangsu, Zhejiang, Anhui, Shaanxi, Chongqing, Gansu, Ningxia. Fujian, Hubei, Hunan, etc.; integrated passenger transport hubs integrating inter-provincial passenger transport, public transport, rental, social vehicles, subways, etc., the first to achieve a seamless connection mode in the station. This station has a package consignment service. |

| 4 | Ps4 | Zhaogongkou long-distance bus station |  |

Zhaogongkou long-distance passenger station line covers 13 provinces (cities) across the country, including Harbin, Longgang, Weihai, Jincheng, Qingdao, Yantai, Tai’an, Yiwu, etc.; it is a state-owned enterprise and belongs to Beijing Second Transportation Company; this station has the functions of luggage consignment and freight transportation. |

| 5 | Ps5 | Muxiyuan long-distance bus station |  |

The Muxiyuan long-distance passenger station line covers 11 provinces and cities in North China, including Zhejiang, Fujian, Jiangsu, Anhui, Hunan, Liaoning, Shandong, Henan, Ningxia, Inner Mongolia, Hebei, etc.; it is the passenger flow, logistics gathering area and transportation hub, and first-class station in the south of Beijing. |

Next, the duplicate data were eliminated according to the sorted documents to determine the cargo transportation of the automobile passenger station. Finally, the data were entered into the service status matrix list.

3.3. Data Qualitative Analysis

Based on the grounded theory and qualitative analysis of service design theory, an analysis model of service facilities, service content, service cost, and service process was constructed, analyzed, and recorded for the 5 stations one by one (as shown in Table 2), and the existing problems of each station were analyzed according to the analysis records (as shown in Table 3). Through the above demand analysis, it is found that there are four common problems in the existing consignment service system of automobile passenger transport: first, there are many private order shipments because there is no standardized and complete service system as the service part of the automobile passenger station; second, there is no whole process service system, only set process stages without corresponding products and equipment as support; third, there is no standardized service space to implement services and there is consignment space without pick-up, storage point; fourth, there is no platform-professional operation services to brand promotion.

| Coding | Station name | Service facilities | Service content | Service fee | Service process |

|---|---|---|---|---|---|

| Ps1 | Bawangfen bus station | Specialized logistics express center, baggage check-in desk, storage | Baggage check, item shipment, baggage storage | Pick-up service fee: 5 yuan/piece/day; the accumulation of goods reaches 50 or more by 4 yuan/piece | Inbound check-in-100% weighing-providing (shipping, consignee information) and payment-issuing-loading |

| Ps2 | Sihui long-distance bus station | Consignment center, cargo storage | Baggage check, object shipment | There is no public standard, the service staff will open the price | Inbound check-in-weighing-evaluation-filling the consignment order and paying the bill-issuing-loading |

| Ps3 | Liuliqiao long-distance bus station | Special line package express | Mainly based on commercial orders (shipping around the passenger station), a small number of small personal items | There is no open standard, the service staff asks for the price based on the weight of the item. | Inbound check-in-weighing-evaluation-filling in the consignment order and paying the fee-loading |

| Ps4 | Zhaogongkou long-distance bus station | Specialized package consignment, large weighing machine | Zero-single freight, vehicle freight, door-to-door delivery service, small storage | There are special price specifications, which are calculated based on weight and distance. | Inbound check-in/telephone reservation/on-site service-weighing-fill out the order (information specification is detailed) and pay the fee-issuing-loading |

| Ps5 | Muxiyuan long-distance bus station | Specialized package consignment, large weighing machine | Zero-single freight, vehicle freight, door-to-door delivery service | According to the shipping weight, distance, and item category, the bigger the order, the more favorable | Inbound check-in/telephone reservation/on-site service-weighing-fill out the order (information specification is detailed) and pay the fee-issuing-loading |

| Number | Coding | Conclusion |

|---|---|---|

| 1 | Ps1 | 1. Relative comprehensive service, but less publicity, fewer waybills, less customer awareness |

| 2. More expensive, should use their platform to expand its business | ||

| 2 | Ps2 | 1. The phenomenon of self-communication between waiter and driver occurs, rather than a standardized and complete service system, services are random |

| 2. Poor service attitude, random service price, each waiter has different opinion | ||

| 3 | Ps3 | 1. The passenger coach unloads the goods to the coach parking place, causing the goods to be placed in disorder, and the consignment service personnel are required to use manpower trailers to consign one by one to the pick-up place |

| 2. There is no special storage area if goods are not taken take immediately, or goods will be placed in the outdoor venue | ||

| 3. Customers bring their trailers to take goods away from the pick-up place | ||

| 4. Private order consignment, random operation, no complete specifications | ||

| 4 | Ps4 | 1. The package consignment is located next to the ticket office, but there is no storage place |

| 2. Passengers bring their transport cargo trailers, no consignment tools | ||

| 3. Only consignment shipping service, but no receiving storage area | ||

| 5 | Ps5 | 1. Only consignment shipping service, but no receiving storage area |

| 2. The passenger coach unloads the goods to the coach parking place, causing the goods to be placed in disorder, and the consignment service personnel are required to use manpower trailers to consign one by one to the pick-up place. | ||

| 3. Private order consignment, random operation, no complete specifications | ||

3.4. Design

3.4.1. Design Guidelines

Finally, by integrating the above sections, the design framework is obtained for intelligent service touchpoints:

D1: IntelliSense. Using the sensing technology, real-time information and data such as spatial environment, path lines, running status, and target recognition can be obtained.

D2: Intelliconnection. In the intelligent service system, different intelligent touchpoints are connected and interact with each other, such as the transmission of information and data.

D3: Intellianalysis. Through the intelligent service system, conduct a comprehensive analysis of the task requirements, spatial environment, and running status of different intelligent service touchpoints.

D4: Intelligent decision-making. Through the intelligent analysis of the data and information of the intelligent service system, the optimal service scheme is output, such as the best route, process, and resource allocation.

D5: Intelligent execution. According to the optimal decision-making scheme, the intelligent service touchpoint completes the automatic and intelligent process and task execution.

According to the field research of automobile passenger stations and the comprehensive analysis of similar cargo transport service tools, the demand for integrated services of bus passengers and cargo transportation is derived, and the solution of an intelligent cargo transportation service system is designed. The combination of cargo transport baskets and intelligent cargo transportation tools solves the most important problems, i.e., the problem of the last kilometer between goods and automobile storage.

3.4.2. Design of Intelligent Transportation System

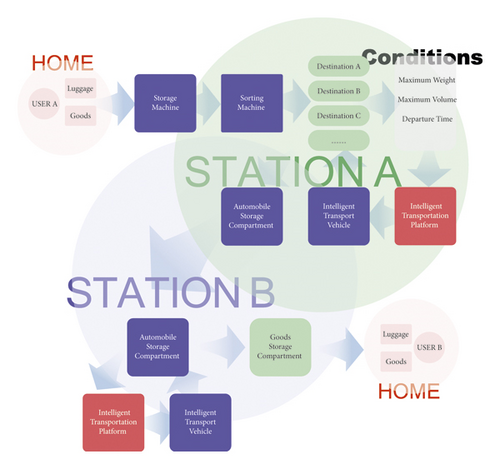

- (1)

The users take the goods to the automobile passenger station.

- (2)

The user goes to the intelligent service cargo transportation machine to fill in the mailing information and deliver the goods.

- (3)

The intelligent transport machine passes through the security check and sorting machine, sorts the target location, and throws the goods into the target transport basket

- (4)

When the goods in the transportation basket reach a certain weight, volume reaches a certain amount, or reaches the first 10 minutes of the car departure time, the intelligent cargo transport vehicle will execute the consignment luggage transport basket.

- (5)

The intelligent transport vehicle will transport along the path of the target vehicle and transport to the car storage area for loading and unloading.

- (6)

The intelligent cargo transport vehicle will exit.

- (7)

When the car reaches the destination, the intelligent cargo transport vehicle of the destination will transport the cargo transport basket to the cargo storage area again, waiting for the users to pick up the goods. In practice, this means that, in addition to logistics enterprises, companies and individuals in other industries can also use the system to deliver their goods (as shown in Figure 1).

3.4.3. Design of Cargo Transport Basket

The cargo transport basket is developed for organizing the cargo to facilitate the transportation of intelligent transport vehicles, which is mainly divided into four steps: automobile information data collection, baggage compartment size determination, transport basket size determination, and conceptual design of transport baskets.

Step 1: Automobile information data collection. Therefore, we need to understand the existing bus luggage compartment volume, cargo-carrying capacity, maximum cargo capacity, and maximum cargo weight. First, we researched the brands, models, and lengths of existing passenger vehicles on the Internet. The main brands are Yutong, Jinlong, Zhongtong, Ankai, Golden Travel, Hagrid higher, and JAC Jianghuai. Passenger car models are mainly limited by the number of seats, which are divided into 10–20 seats, 21–30 seats, 31–40 seats, 41–50 seats, and more than 50 seats. The vehicle length is mainly divided into 5000–6000 mm, 6000–7000 mm, 7000–8000 mm, 8000–9000 mm, 9000–10000 mm, 10000–11000 mm, 11000–12000 mm, 12000–13000, and 13000 or more models.

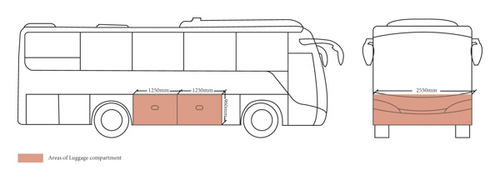

Step 2: Luggage compartment size determination. Then, due to the wide variety of vehicle types in the market, it was found that the 41–50-seat model is the main transport vehicle, so we selected a typical Yutong ZK6908H1Y model as the reference sample, which belongs to the neutral high class, length 8995 mm, width 2550 mm, height 3450 mm, vehicle weight 10200 kg, seat capacity 24–41 people (as shown in Figure 2). Then, the actual measurement of the baggage compartment of this model was carried out by field research, and it was found that it is divided into two cabins, the length of a single compartment is 1250 mm, and the width is 2550 mm, and the height is 1000 mm. Then, according to the measured data, the baggage compartment volume/lift volume is calculated, and it is concluded that the maximum volume is 6120000 mm3 (length width height). To ensure the feasibility of car baggage compartment sharing service, it is necessary to satisfy whether there is still idle space to ensure the execution and uninterrupted service when the automobile is full. Taking each passenger carrying a maximum 28-inch suitcase (450 mm × 280 mm × 680 mm) as the benchmark, it can be derived whether there are free space resources; that is, by dividing the volume of the baggage compartment by the volume of the largest suitcase, it is concluded that the maximum number of suitcases in the baggage compartment is 72 pieces (6375000000 mm3/87584000 mm3) of 28-inch suitcases, subtracting the maximum number of passengers 41 people with one piece of luggage; it comes out that there is still 31 free space of 28-inch luggage volume, which means that there is free space in the luggage compartment to provide cargo transportation service.

Step 3: Determine the size of transport baskets. To reduce the consignment times of intelligent cargo transport, it was divided into 4 storage areas according to the two-compartment luggage compartment, and 4 transport boxes were set according to the volume size of the storage area, which is divided into two categories, namely, consignment luggage transport boxes and consignment item luggage boxes, and distinguished by color; and the number of transport boxes can be intelligently allocated according to the number of luggage and consignment items, and the number and the quantity can be adjusted (1:3, 2:2, 3:1). Through the above measurements, the length, width, and height of the four storage areas are 1250 mm, 1275 mm, and 1000 mm, which are used to find the maximum size of the transport basket. In this study, owing to the intelligent operation, the psychological correction is the error correction, and the length of the transport box can be calculated by adding the functional correction to the psychological correction. The maximum number of suitcases that can be accommodated by the transport box length = luggage compartment length/luggage box length (take the maximum integer) 1250 mm/280 mm ≈ 4.6, that is, the maximum integer 4, and the transport box length is 4 × 280 mm = 1120 mm (functional correction amount), taking 80 mm (the isolation frame between the two cabin + error) as the error correction, that is, the size correction of the transport box length = function correction ± error correction = 1040 mm ∼ 1200 mm. Next, calculate the width of the transport box; first find out the width of the transport box can accommodate; the maximum number of suitcases multiplied by the width of the suitcase can be derived, the width of the transport box can accommodate the maximum number of suitcases = luggage compartment width/luggage width (take the largest integer) 1275 mm / 460 mm ≈ 2.8; take the largest integer 2, resulting in the transport box width of 2 × 460 mm = 920 mm (functional correction amount), and we can also accommodate a side put luggage that should be added to the length of its luggage 280 mm, resulting in a functional correction amount of 920 mm + 280 mm = 1200 mm; its error correction amount of 50 mm (luggage compartment for through type, so the actual error correction amount of two transport box error correction amount of 50 mm × 2 = 100 mm), that is, the resulting transport box width of the size correction amount = functional correction amount ± error correction amount = 1200 mm ∼ 1250 mm. Calculate the height of the transport box; first find out the maximum number of suitcases that can be accommodated in the transport box high multiplied by the luggage box high can be derived, the maximum number of suitcases that can be accommodated in the transport box high = luggage compartment high/luggage box high (take the largest integer) 1000 mm/680 mm ≈ 1.4, take the largest integer 1. The resulting transport box width is 1680 mm = 680 mm (it can also accommodate side luggage, that is, the luggage should be added to the length of 280 mm, resulting in a functional correction of 680 mm + 280 mm = 960 mm), the error correction of 30 mm, and the size of the transport box width correction = functional correction ± error correction = 930 mm ∼ 990 mm so that the transport box length and width of the height is 1040 mm ∼ 1200 mm, 1200 mm ∼ 1250 mm. 1200 mm, 1200 mm ∼ 1250 mm, and 930 mm ∼ 990 mm.

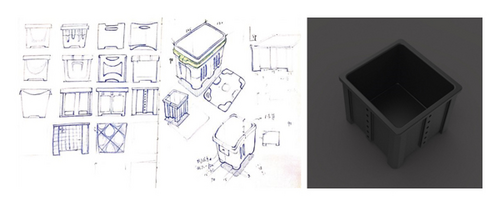

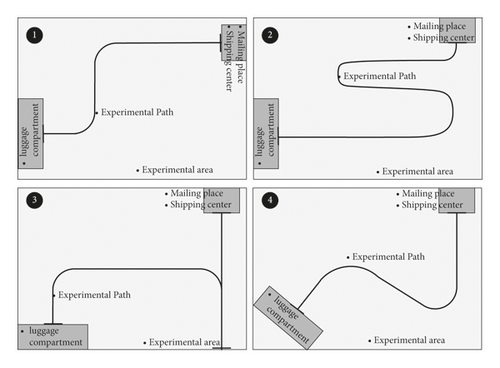

Step 4: Conceptual design of transport baskets. According to the reasoning of the above transport basket size, that is, the length, width, and height are 1040 mm 1200 mm, 1200 mm 1250 mm, and 930 mm – 990 mm. In addition, coupled with the demand analysis of the transport basket in the early stage, it is necessary to facilitate the insertion, lifting, and lowering of the lifting platform of the intelligent transport vehicle. Based on this pair, the modeling scheme of the transport basket was designed, as shown in Figure 3.

3.4.4. Intelligent Transport Vehicle Design

Through the previous analysis, it can be seen that the design of intelligent self-loading and unloading cargo transport is divided into four different parts, data collection and analysis of the same type of products, balance calculation, conceptual design, and process design.

Step 1: Data collection and analysis of similar products of intelligent cargo carriers: We analyzed the type of cargo, operation modes, route identification, and cargo acquisition of five existing intelligent transportation tools (such as Table 4). It is found that the existing means of cargo transport are mainly used in warehouse logistics sorting and cargo handling. From the point of view of the mode of operation, the existing products are mainly single-plane vertical lifting, a small amount of grasping cross-platform transportation, and there are immature heavy objects; from the way of route identification, it is mainly one-point, optics, image, inertial magneto-optic, and magnetic tape teaching coordinate path guidance, and so on. Based on the previous analysis and the analysis of similar products, for the intelligent service system, the intelligent cargo transportation of the automobile passenger station needs to meet the service behaviors such as cargo transportation, cargo loading and unloading truck, route identification, fast platform, and transportation.

| Coding | Product image | Service content | Operation method | Path recognition method | Way of obtaining goods |

|---|---|---|---|---|---|

| Sp1 |  |

Warehouse item sorting | Single-plane operation | White line and black line path identification fixed line | Manual goods placement |

| Sp2 |  |

Hospital item handling | Vertical elevation | AGV control system | Automatic identification of goods, location, handling |

| Sp3 |  |

Warehouse item sorting | Vertical elevation | Electromagnetic/Optical/Image/GPS/Inertial laser/Tape direct coordinate path guidance | Automatic identification of goods, location, handling |

| Sp4 |  |

Small items handling (books, etc.) | Cross-plane picking | Electromagnetic/Optical/Image/GPS/Inertial laser/Tape direct coordinate path guidance | Automatically identify the cargo rack, item location, and tick |

| Sp5 |  |

FCL handling | Single-plane operation | The information brought by the electromagnetic track moves and moves | Automatic identification of cargo racks, item locations, and gripping |

Step 2: Calculation of the balance of the intelligent cargo vehicle: To find out whether the intelligent auto-loading cargo transport vehicle can balance and carry the goods to complete the service, it is necessary to calculate the vehicle’s self-weight, maximum cargo weight, motor power, rechargeable battery capacity, and charging time. Suppose the self-weight of the vehicle is M, the self-weight of the mechanical arm carrying the luggage on it is M1, and the other parts of it are M2, which include the battery, motor, counterweight, housing, and other structural parts of the vehicle, M = M1 + M2.

To save cost and achieve the purpose of lightweight, M2 should be as small as possible while satisfying the function. The design should satisfy three functions:

Stability function: The center of gravity will change when the vehicle is moving and handling operations, so the horizontal projection of the center of gravity of trolleys should be under the car body to prevent the car body from overturning for maintaining stability.

Battery duration: The battery of the vehicle should meet the energy consumed by its continuous operation for a certain period.

Improve efficiency: The working time of the vehicle should maintain a good ratio with its charging time, to facilitate it to carry out reasonable operation time arrangements.

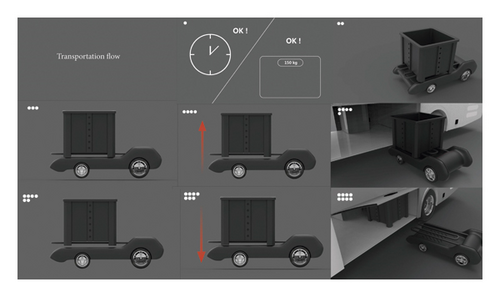

Step 3: Conceptual design of an intelligent cargo carrier. According to the previous demand analysis, it is concluded that the intelligent auto-loading cargo transport vehicle needs to be able to load a transport box with a length, width, and height of 1040 mm ∼ 1200 mm, 1200 mm ∼ 1250 mm and 930 mm ∼ 990 mm, respectively, and can automatically load and unload the transport box from the passenger transport station and the luggage compartment of the automobile, with the functions of tracking, loading, unloading, information receiving and identification, and infrared shielding, thus defining the form and structural design of the intelligent auto-loading cargo transport vehicle. After comprehensive thinking on structure and function, it was finally determined that the intelligent auto-loading cargo transport vehicle has three functions: information identification, battery placement, and cargo lifting. The first part is the front-end recognition function area, that is, infrared obstacle avoidance and path recognition; the second part is that the middle part places the battery; the third part is that the back-end meets the functions of auxiliary lifting, stable counterweight, and auxiliary positioning, to complete service provision and intelligent consignment. According to the three functional partitions obtained from the previous requirements analysis, the functional scheme comparison analysis is performed on the final scheme, as shown in Figure 4.

Step 4: Conceptual design of an intelligent cargo vehicle. When the departure time is up or the transport basket reaches the maximum weight, the basket will send a signal to the intelligent cargo transport vehicle; after receiving the signal, the vehicle moves to the corresponding position, and transports the basket along the path to the corresponding passenger luggage compartment; by identifying the height, the vehicle lifts the transport basket and uses the transport rack to transport the basket into the luggage compartment; then the transport rack descends and the vehicle falls back, which means the vehicle completes this task.

An intelligent auto-loading cargo transportation system uses the technology of tractor turbine vortex to realize the lifting of the handling platform and innovates in the lifting structure. The new lifting structure enables the chassis of the intelligent auto-loading cargo vehicle to partially penetrate under the luggage compartment of the passenger automobile, and the transport platform carrying the transport basket can be directly inserted into the luggage compartment; after the platform is slightly lowered, the intelligent auto-loading cargo vehicle is backed up, so that the platform can be withdrawn from the bottom of the transport box, leaving the transport box in the luggage compartment of the bus (as shown in Figure 5).

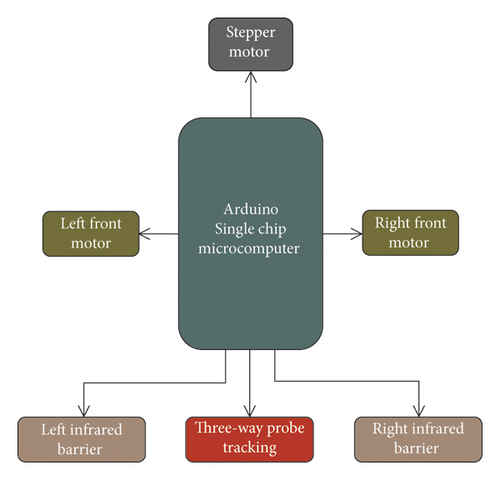

3.5. Evaluation

Arduino is an open-source software and hardware electronic prototyping design and development platform [28]. Its application field mainly focuses on the prototype test design of intelligent electronic products, including software and hardware [29]. The software part refers to the integrated development environment (IDE) and the hardware part is available for various types of Arduino programmable control circuit boards for circuit connection. The sensors suitable for this study can be selected for the intelligent hardware interaction design of intelligent self-loading and unloading trolleys. Their convenient, flexible, and easy-to-use operation characteristics have made them global leaders in the fields of maker prototype development, design prototype experiments, and electronic product research [30].

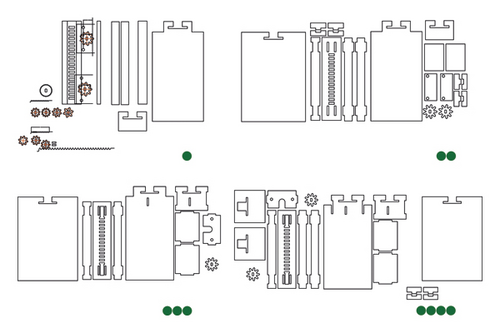

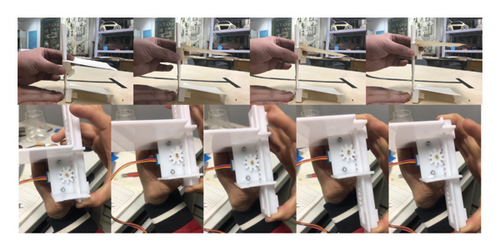

We used the Arduino open-source hardware to cooperate with the mechanical transmission structure, to complete the intelligent self-loading and unloading cargo transportation trolley experiment; then we use the tracking sensing technology to identify the transportation path in the whole service system, including the checked baggage transport path and the mailing logistics path of the mail item. Transportation baskets carry luggage to the pick-up path. It uses stepper motor drive technology and gear drive sliders. Based on the slide rod fixed auxiliary mechanical principle, transportation baskets can carry out services which include the loading and unloading of the transport baskets corresponding to the consignment center and transport baggage at the mailing station. Eventually, the transportation and the luggage compartment will be unloaded at the pick-up rack.

3.5.1. Experimental Method and Material

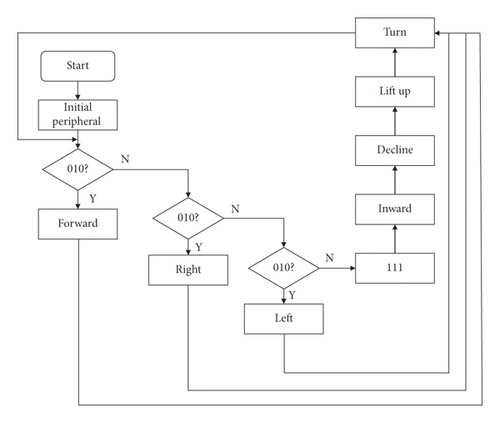

The experiment was performed on a flat wooden board with a size of 841 mm × 1189 mm in the model laboratory of the Beijing University of Technology. The model of the cargo loading and unloading platform was proportionally reduced according to the height of the chassis and luggage compartment of the passenger vehicle. The experiment stuck black tape on the wooden board to identify the experiment path, and the path is S-shaped since there will be straight lines and twisted lines in real-time application. Although high-precision sensing enables car right-angle turns; it was decided to avoid right-angle turns because of the sensitivity of sensors in this experiment. The experiment used a three-way tracking probe of Arduino to identify the path, stepper motor, and self-made flat lifting platform to complete the loading and unloading simulation, as shown in Figure 6.

3.5.2. Secondary Tasks

This experiment needs to complete two other experiments, namely, the path recognition experiment, and the loading and unloading lifting experiment, as shown in Figure 7. There are three cases in the path recognition task: the first task is straight path recognition; the second task is curved path recognition; the last is the recognition of path return after reaching the destination coordinates. The loading and unloading elevating experiment includes: the first one is determining the target coordinate A and then descending and then loading; the second is determining the target coordinate B and descending and unloading, exiting the route, and returning.

3.5.3. Experimental Design

Prototype experiments are performed on the Arduino open-source hardware platform to demonstrate the functions of tracking and plane lifting, as shown in Figure 8. This experiment uses three infrared lamps of the three-way tracking probe to identify the black line; the car turned left when the left probe recognized the black line, the car went straight when the middle probe recognized the black line, and the car turned right when the right probe recognized the black line, and the car stopped when the three probes recognized the black line at the same time. Next, when the three-way tracking probe stops at the same time as identifying the black line, it means starting the stepping motor, and the stepping motor rotates counter-clockwise upwards; similarly, when the three-way tracking probe stops identified the destination, the stepping motor closed down. The stepping motor rotates clockwise to descend and then exits.

4. Results

4.1. Path Recognition Experiment Performance

According to the requirements of the previous experimental design of path recognition, a total of four iterations of path recognition line iterations are shown in Figure 9 to meet the experiments of smart freight cars returning on straight, curved, and single-line paths return. In the first path experiment, the black line recognized by the middle probe meets the straight-line path recognition. In the second path experiment, the straight line and the curve are used for experimental purposes. The middle probe is used to realize the forward recognition, and the left and right probes identify the turning path. Straight-line plus curve plus single-line path return is used for the third experimental purpose. The three-way tracking probe is used to complete straight travel, direction determination, and stop; by controlling the left front motor to suspend operation, the inertia brought by the rotation of the front right, rear right, and left rear motors is realized. Plus the real-time identification of the three-way tracking probe to determine the direction to achieve a single-line path return experiment; path experiment four is a circular single-line path return experiment based on the single determination task performed in experiment three. The comparative analysis of the four rounds of experiments found that experiments 3 and 4 are to complete the overall objective of the experiment. Experiments 1 and 2 are mainly based on the completion of a single task, as shown in Table 5.

| Task 1: Straight path recognition | Task 2: Curved path recognition | Task 3: Same route return | |

|---|---|---|---|

| Path 1 | ✓ | ||

| Path 2 | ✓ | ✓ | |

| Path 3 | ✓ | ✓ | ✓ |

| Path 4 | ✓ | ✓ | ✓ |

4.2. Loading and Unloading Lifting Experiment Performance

The service prototype is updated according to the problems found in the actual prototype of the service prototype (as shown in Figure 10). The main update part is the part of the transport lifting platform, which changes the gear and rack drive into a ruler. The reason for the change is that the gear and the rack cannot completely fit, resulting in the drive jam, and inability to carry out plane lifting, as shown in Figure 11.

5. Discussion

This research demonstrates the feasibility of an intelligent service system for automobile passenger and cargo integrated transportation, as well as the feasibility of an intelligent cargo self-loading and unloading transport vehicle validated by open-source hardware. Compared with other studies, the transportation scenario of automobile passenger and cargo integrated transportation is expanded and developed from the single-platform transportation of intelligent cargo carriers to cross-platform transportation of cargo. It was estimated that the baggage compartment can accommodate up to 72 28-inch suitcases, minus 41 28-inch suitcases at full capacity, ((72–41)/72 ≈ 43%), increasing the utilization rate of idle space by at least 43%. At the same time, supporting tools were added to our field research to enhance our analysis and understanding of services, which helped us to be able to discuss future trends in smart service touchpoints.

This study is based on the service touchpoint of service design, in terms of consignment service of the automobile passenger station, where service content, service facilities, service cost, and service process were chosen to construct our sub-service analysis model. According to the vertical comprehensive analysis of the four dimensions, an intelligent cargo transport service system of automobile passenger and cargo integrated transportation is constructed, and the intelligent auto-loading cargo transport vehicle is designed to solve the problem of the last kilometer between the goods and the automobile storage warehouse. In terms of theory and method, based on an artificial intelligence system, this study presented a product size calculation method of dimension correction = function correction ± error correction. The analysis of the data and information of the field research by auxiliary tools helps us to record the service status of the real scenarios and ensure the authenticity of the data. On this basis, the problems and demand transformation of cargo transportation are analyzed to promote the five design principles and suggestions for intelligent service touchpoints. The biggest limitation of this study is that only the Yutong zk6908h1y model is selected as the data reference sample in the design stage; although there are various model numbers in the market, not all models are used as a data reference. In this case, we inevitably limit the adaptability and flexibility of different sizes of intelligent vehicles.

For the prospect of the intelligent service of automobile passenger and cargo integrated transportation, this study proposed the intelligent cargo transportation service system, and designed and verified the functional prototype of the cargo transport vehicle. However, for the system, there are still many design opportunities for service touchpoints, which can enrich the intelligent services of the system. For intelligent cargo transport tools, adaptability can be explored according to different models of vehicles in the future.

As future work, this study will assume that all service touchpoints exist independently based on a single existence. However, with the progress and development of the fifth-generation technology and using the continuous development of digital twinning and depth learning, the automobile passenger and cargo transportation service will become more intelligent and humanized.

6. Conclusion

With the revolution of automotive passenger transport services, the integration of passenger and cargo transportation has become a new profit development point, and cargo vehicles are a significant service contact point for the integrated passenger and cargo transport system. This study explored the intelligent service system of automobile passenger and cargo integrated transportation and the intelligent self-loading and unloading transportation tool. The cargo design process, pain points, and demand for cargo transportation are analyzed, and the characteristics of the solution for cargo transportation are summarized. The present status of cargo transportation from the aspects of service content, service facilities, service cost, and service process is examined and the design principles of intelligent cargo transport service touchpoints are presented. Although this study provided feasible recommendations and can be used for commercial purposes, there are still limitations. First, this study selected the Beijing station as the only sample and the spatial environment of each bus passenger station is different. Secondly, only one vehicle model is selected as the sample data for reasoning. Therefore, it is essential to construct a vehicle model sample database and improve the elasticity perception of vehicles.

- (1)

An intelligent cargo transport service system of automobile passenger and cargo integrated transportation is constructed.

- (2)

The intelligent auto-loading cargo transport vehicle is designed to solve the problem of the last kilometer between the goods and the automobile storage warehouse.

- (3)

The transportation scenario of automobile passenger and cargo integrated transportation is expanded and developed from the single-platform transportation of intelligent cargo carriers to cross-platform transportation of cargo.

- (4)

The five design principles and suggestions for intelligent service touchpoints are presented.

- (5)

A product size calculation method of dimension correction is presented based on an artificial intelligence system.

Conflicts of Interest

The authors declare no conflict of interest.

Acknowledgments

This project was supported by the China Service Design Development Research Center, the Design Department of the School of Art and Design of Beijing University of Technology, and the Research Foundation of Ministry of Education of the People’s Republic of China (12YJA760020).

Open Research

Data Availability

The data of vehicle dimensions, weight, and seating capacity of the Yutong ZK6908H1Y used to support the findings of this study can be obtained from the Yutong website (https://www.yutong.com/products/ZK6908H_ky.shtml).