Effect of Coral Aggregates of Blended Cement Concrete Subjected to Different Water Immersion Condition

Abstract

The increasing use of concrete in construction has caused an increase in the need for resources for concrete mixtures and driving wide-scale mining. One alternate material that can be used for aggregates replacement is coral. Coral aggregates (CA) have similar chemical characteristics to cement. The compressive strength and tensile splitting strength tests of concrete coral aggregates were performed based on the ASTM and ACI standards. This study aims are to investigate the usage of CA as a partial replacement of cement and fine aggregate to increase the strength of concrete at substitution percentages of 0, 5, 10, and 15%. Two different water submerged scenarios of distilled water and salt sea water immersion were applied. The concrete strength test was carried out after 28 days of curing time, with the specified concrete quality of 17 MPa. The results showed that immersion in distilled water has a higher concrete strength than immersion in sea water. The maximum compressive strength of concrete for distilled and sea water immersion is for 0% CA content of 18.47 and 14.89 MPa, respectively. Moreover, the highest value of the split tensile strength of concrete with distilled and sea water immersion is for CA substitution of 5% of 2.52 and 2.5 MPa, respectively. The addition of 5% coral aggregates to cement and fine sand is the optimum combination since it increases the maximum split tensile strength of concrete.

1. Introduction

Global production of cement is over 12 billion tons per year, which equals nearly 1 m3 per person per year, making it one of the world’s major consumers of natural resources [1–3]. By 2025, concrete consumption is expected to exceed 7.5 billion m3 (approximately 18 billion tons) per year [4, 5]. Concrete is a fundamental component that is regularly utilized in the construction of buildings [6–8]. Concrete is made up of cement, aggregates, chemical and mineral admixtures, and water and contains a large proportion of artificial components [9, 10]. The amount of concrete consumed on our entire Planet is measured in billions of tons [1, 11, 12]. The extensive use of concrete in the building has increased the demand for concrete materials, resulting in large-scale mining for raw materials [13–15]. The consequences of this condition include a decline in the availability of materials such as cement for concrete production, which is directly proportionate to the increase in costs and material shortages [16, 17].

With the marine industry rapid development, marine engineering infrastructure projects such as island construction, reclamation, and massive floating structures are rising [18]. Due to the remoteness of the island from the near mainland and accompanying transportation challenges, materials like aggregates and water supplies are scarce on-site [19]. Coral debris is a unique organic sedimentary rock that contains more than 96% calcium carbonate and is abundant on the sea island [20]. Coral debris is primarily formed of coral reef alga and marine species bone debris [21]. It is the result of channel digging and harbor dredging, as well as natural weathering, which take up valuable island space and have a detrimental effect on ecological systems [20]. As a result, maximizing the utilization of this coral debris is necessary to meet the marine industry’s material requirements. Additionally, Aceh-Indonesia has one of the highest rates of seismic activity in the world [22, 23]. Notably in the aftermath of multiple historic big earthquakes in Aceh, such as the 8.9 Mw earthquake-tsunami of 2004 that caused death and destroyed numerous structures [24], it is critical to conduct a comprehensive analysis of the concrete used in construction [25].

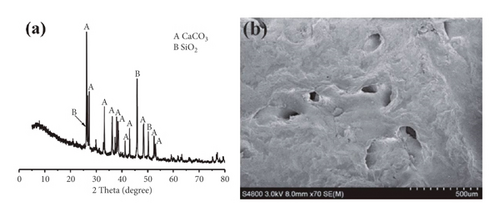

Coral aggregates (CA) are a type of undersea environment comprised of coral invertebrates that produce a calcium carbonate structure, a form of limestone. CA is typically composed of limestone, which means that the aggregates formed from coral have the most chemical content in the form of CaCO3, which is classified as limestone [26]. CA may be used in the replacement of fine aggregate in concrete as a substitute ingredient [18, 19, 27, 28]. By and large, CA is composed of limestone. This is because these rocks contain a high concentration of CaO [29]. Geologically defined, limestone-containing rock is also referred to as crystalline limestone. Meanwhile, coral reefs degrade when they are damaged. As a result, this form of rock is known as coral limestone [26]. CA is formed when coral reef-building organisms deposit vast amounts of calcium carbonate (CaCO3). Calcium carbonate (CaCO3), which contains a similar chemical composition to cement, can be used in place of some of the cements in concrete [30–32].

The extensive usage of rock fragments as a cement substitute will affect the chemical composition of cement [33]. When used with cement, CA can enhance the binding capacity by acting as a more homogenous binder throughout the hydration process. CA can be used as a common aggregate; however, it is light and porous, with a rough surface, lack of adhesion, and high sea salt concentrations. These parameters affect the resulting workability, mechanical capabilities, volume stability, and durability of concrete [34, 35]. Numerous researcher findings indicate that the CA used to replace a portion of the conventional aggregates has physical qualities similar to river aggregates [21, 36–39].

There are several external forces of concrete failure such as weathering, high-temperature variation, wetting-drying cycles, abrasion, and exposure to extreme environments [40]. The effect of pozzolanic materials added to concrete when exposed to highly humid marine environments or the tropical climate has yet to be fully investigated [41]. As a consequence, it is essential to investigate the effect of strength and workability of CA on the durability characteristics of concrete exposed to an extreme sea water environment. Thus, it is vital to determine the extent to which the CaCO3 content of CA affects the ability of CA to react homogeneously with cement and fine sand in concrete.

Recent research on the usage of CA has included the use of coral as a partial alternative for cement and gravel. This study employs a higher percentage of CA as a partial alternative for cement and fine sand, to lower CO2 emissions caused by increased cement production and also reduce cement scarcity. The previous study has shown that immersion with solely distilled water is effective. Other novel immersion methods were evaluated in this study, specifically with sea water and in comparison to distilled water. CA was used in place of conventional aggregates and sands for concrete production subjected to two different water conditions. Following casting, the concrete specimens were submerged for 28 days in distilled and sea water conditions. Furthermore, the compressive strength and tensile splitting strength tests of concrete CA were investigated. The results of an experimental inquiry into the strength and workability of concrete including CA substitution subjected to different water immersion conditions are reported in this article.

2. Material and Methods

2.1. Materials

For this investigation, ordinary Portland cement (OPC) was obtained from an Andalas cement factory, Aceh, with a specific gravity of 3.15 according to ASTM C595 [42]. When coupled with water, Portland cement is made of calcium silicates and calcium aluminates that hydrate to generate the cementing components calcium silicate hydrate (CSH) and calcium aluminate hydrate (CAH), along with excess calcium hydroxide [7].

The processing of CA into granular and ash is depicted in Figure 1. The CA are cleaned and immersed in distilled water for one day after they are collected from the coast. Then, it is dried in the sun until it is ready to be used.

The used natural CA was obtained in Lamreh beach. The white sand beach region of Lamreh village, Aceh Besar, Aceh Province, is abundant life, with coral reefs on the seafloor. Some dead coral reefs are washed away by the waves and end up as a pile of boulders on the beach. These coral fragments come in a variety of sizes, with some being comparable to sand. CA is often constituted of limestone, which implies that coral aggregates have the highest chemical composition in the form of CaCO3 and SiO2, as illustrated in Figure 2. In addition, CA is utilized in place of cement and fine sand in the concrete.

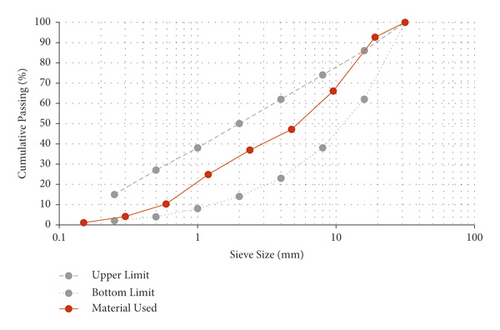

The study incorporated fine and coarse aggregate from Jantho, Aceh Besar District. The fine sand passed through a 4.76-mm sieve, coarse sand passed through a 9.52-mm sieve, and gravel passed through a sieve size of 31.5 and remained in a sieve size of 4.76 mm. In this study, the test object was treated with distilled water and sea water. The typical tropical sea water chemical composition can be seen in Table 1. Each treatment involves the use of twenty concrete cylinder specimens. The distilled water used is safe for drinking. Furthermore, sea water was taken from Cermin Beach, Banda Aceh of Ulee Lheue Sea.

| Chemical constituent | Value |

|---|---|

| Sodium, Na+: ppm | 2000–2400 |

| Potassium, K+: ppm | 375 |

| Calcium, Ca2+: ppm | 285 |

| Magnesium, Mg2+: ppm | 1055 |

| Chloride, Cl−: ppm | 16 618–18 020 |

| Sulfate, SO42−: ppm | 1098 |

| Specific gravity: G/ml | 1.025 |

| pH | 7.9–8.2 |

| Temperature range: °C | 26.5–32.0 |

2.2. Mix Proportion and Specimen Preparation

The ASTM [43] and ACI 211.1-91 [44] standards were used to design concrete mixes. The concrete is mixed using a forced mixer in the order of cement, sand, coarse aggregates, and water. The whole time required for mixing was 15 minutes. The substitution material is fine sand that passes through a number 200 sieve and is used to replace a portion of the fine sand that passes through a 4.75-mm sieve [45]. The concrete compressive strength machine was applied in this study.

Coral from the white sand coast of Lamreh, Aceh Besar District in Aceh Province, was used as a substitute material in this investigation. The CA were substituted for cement and fine sand at rates of 0%, 5%, 10%, and 15%. The ratio of substitute materials to cement and fine sand in concrete is 1 : 1 [46]. The CA was separated into two sections: the first section was utilized as a substitute for cement, while the second section was used in place of fine sand. The ratio of CA substituted in cement and fine sand was equal.

CA collected along the coast are transported to the laboratory and washed to remove any clinging sand. The CA are then submerged in distilled water for 24 hours. After 24 hours of saturation with water, CA is dried in the sun and then crushed. It produces 5 kg of coarse grain-sized rock powder from the Los Angeles machine. The rock powder was sieved using a 4.75-mm sieve and utilized in place of fine sand. According to the sieve results, it can obtain coarse grains for sand up to 3 kg. The remaining rock powder on a 4.75-mm sieve was then crushed with an iron stick until it formed fine grains that went through the No. 200 sieve. By using sieve number 200, it got a total of up to 2 kg of fine coral grains. The fine grains are next roasted until they take on an almost blackish color. The color shift occurs at a temperature of 200°C for ten to fifteen minutes. CA possess the chemical properties of CaCO3 in high quantities and, when burned, changes this substance which behaves as a binder in concrete and can behave like cement.

2.3. Testing Details

Compressive strength and split tensile strength of concrete tests were used for predicting concrete cracks and maximum tensile strength. A compressive strength test was conducted with a 15 cm × 30 cm cylindrical test object. The cylinder compression experiment was performed by gradually applying a force vertically or parallel to the cylinder height until the sample reaches its maximum compressive strength. The split tensile strength of concrete with a cylindrical test object is the value of the test object’s indirect splitting tensile strength as determined by loading the test object horizontally parallel to the compression testing machine’s surface [47]. The tensile strength of concrete is quite modest, representing around 9% to 15% of the compressive strength. This strength is more difficult to measure and the findings vary depending on the experimental material used.

The designing of the concrete mix begins with determining the compressive strength of concrete, which is 17 MPa with a slump design of (75–150) mm. The amount of water used for each 1 m3 of concrete is based on the ACI standard, which indicates that the maximum diameter of aggregate is 31.5 mm. The amount of cement used was derived using the water F02D cement ratio value from the ACI standard. The normal weight of concrete is determined using the ACI, with cement, fine sand, coarse sand, and water being the projected normal arrangement of concrete. The results of the concrete mix design calculation are shown in Table 2. Figure 3 illustrates the gradation curve of the mixed materials.

| Material | Required amount | Unit |

|---|---|---|

| Water | 193.00 | kg/m3 |

| Cement | 288.06 | |

| Gravel | 1201.31 | |

| Coarse sand | 184.72 | |

| Fine sand | 512.91 | |

| Total | 2380.00 | kg/m3 |

The preparation for the concrete mix starts with the preparation of cement, fine sand, sifted coarse sand and gravel, water, and rock that has been processed to perform as a substitute for cement and fine sand. Then, before the start of the mold, each material is weighed following the mixture ratio determined by the concrete mix design. The test specimen mold is covered with oil to assist in its removal once the concrete has hardened. The mixer utilized has a capacity of 50 liters/mix and is propelled by an electric dynamo. Before casting, the concrete mix machine and mortar storage container are saturated with water. This prevents the concrete mortar from sticking to the container, making it easy to remove. After the preparations are complete, the concrete mortar was mixed by sequentially incorporating the concrete-forming ingredients, including coarse aggregate, fine aggregate, fine and coarse grains of rock, cement, and water. The stirring duration is around 15 minutes with the concrete mix machine axis tilted approximately 45°. After thoroughly mixing the materials, the mortar is placed into a steel mortar storage container. After the mixing process is complete, the mortar mixture is slump tested to determine the workability and viscosity parameters.

Concrete cylindrical specimens are made by filling the cylindrical mold with mortar in three layers. Each layer was compacted by dropping a steel rod with a diameter of 16 mm and a length of 60 cm from a height of 30 cm, with 25 compactions per layer. After filling the mold to the maximum, tap the side of the mold with a rubber mallet to densify the mortar. As in Figure 4(a), after 24 hours, the test object is removed from the mold and each is assigned a number/code accordingly.

For compressive and split tensile strength tests, fresh concrete is poured into cylindrical molds. The samples consisted of 80 cylindrical specimens measuring 15 cm × 30 cm. 40 of which were immersed in distilled water and 40 of which were immersed in sea water (Table 3). Cement usage was replaced by 5%, 10%, and 15% of CA, respectively. The fine sand was also replaced by 5%, 10%, and 15% fine CA. The purpose of reducing the cement concentration is to determine if the chemical composition of CaCO3 in the CA has an effect, primarily as a binder for concrete. Furthermore, assess whether an extra additive is still required to ensure that the bonding power created during the hydration process is more consistent. The influences of a marine ecosystem on cement and CA-blended concrete were investigated in a field study and compared with the neutral ecosystem. The treatment of test specimens with distilled water begins with the specimens being immersed in a shielded immersion tube in the laboratory for 28 days as in Figure 4(b). The distilled water used is completely safe to drink. Furthermore, sea water immersion begins with the direct immersion of a concrete cylinder test object for 28 days in sea water at the Cermin beach, Aceh, as in Figure 4(c).

| Test | Mixes | OPC (%) | CA-OPC (%) | CA-FS (%) | Submerged distilled | Submerged sea water |

|---|---|---|---|---|---|---|

| Compressive strength | Control | 100 | — | — | 5 | 5 |

| CA5FS5 | 90 | 5 | 5 | 5 | 5 | |

| CA10FS10 | 80 | 10 | 10 | 5 | 5 | |

| CA15FS15 | 70 | 15 | 15 | 5 | 5 | |

| Splitting tensile strength | Control | 100 | — | — | 5 | 5 |

| CA5FS5 | 90 | 5 | 5 | 5 | 5 | |

| CA10FS10 | 80 | 10 | 10 | 5 | 5 | |

| CA15FS15 | 70 | 15 | 15 | 5 | 5 | |

| Total specimens | 40 | 40 | ||||

- Note. CA = coarse aggregates, FS = fine sand, OPC = ordinary Portland cement.

The concrete specimen was tested for compressive and split tensile strength after 28 days of immersion. The laboratory-scale test was used to measure and record the dimensions and weight of the test object. The test object is then positioned vertically on a compressive strength tester machine to determine the compressive and split tensile strength of concrete, and the machine speed was gradually increased until the test object reaches the maximum strength, at which point the test object becomes cracked or broken.

3. Results and Discussion

3.1. Slump Test

The slump test is the most often used method for determining the workability of concrete. It can be performed in the laboratory or on-site. It is not appropriate for either wet or extremely dry concrete. Indonesia standard of SNI 1972 : 2008 was used for slump test procedures. Sea water was employed in this study for immersion of the samples only. While the water used to fabricate concrete test items for each scenario was distilled. Slump is a term that refers to the ability of fresh concrete to work or is one of the properties. Slump is determined after the concrete mixture has been thoroughly mixed. The amount of the slump is the fall in the value of the concrete mixture poured into the test cone. The results indicated that the slump varied, as it was evaluated on each of the test objects. The test findings indicate that the slump obtained in the laboratory remains within the ideal range of 75 to 100 mm.

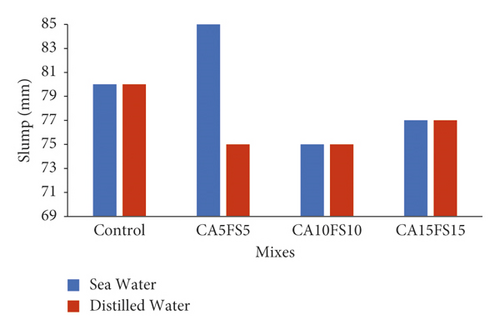

The workability of CA-concrete was tested utilizing a variety of replacement levels. Figure 5 illustrates the workability values in terms of the slump test. As illustrated in Figure 5, the slump test result varies between 75 and 85 mm. This is consistent with the proposed slump of (75–100) mm. The results indicate that, except for 5% sea water submerged, the workability of concrete built with CA as fine aggregate and cement declined as the proportion of substitution and water F02D cement ratio increased even though the slump test results obtained are still within the acceptable range.

Similarly, Althoey et al. [48] reported that the slump values appear to decrease linearly as the fine aggregate content of the concrete is increased. Furthermore, the reduced slump could be a result of the roughness and heterogeneity of the CA particles, which contribute to the mixtures’ fluidity. Additionally, the slump test results correspond to the finding of Mangi et al. [49], which workability declines as the proportion of substitute material in the concrete mix increases. This could be because of the fineness of the particles, which increases surface area; as a result, the concrete mix absorbed more water.

3.2. Compressive Strength

The compressive strength test was conducted on cylindrical specimens of 150 mm in diameter and 300 mm in length. This test was used to determine the compressive strength of CA concrete samples. SNI 1974 : 2011 was used for compressive strength test procedures. A 28-day-old concrete cylinder specimen was subjected to the test. Concrete’s compressive strength was measured under two different conditions, namely sea water immersion and distilled water immersion.

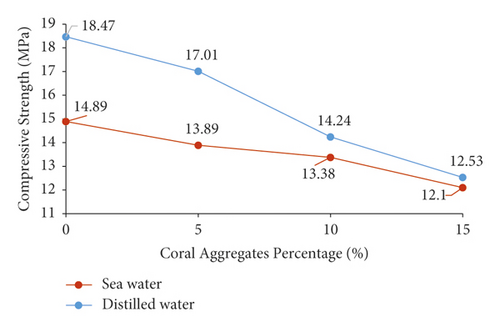

Figure 6 displays the compressive strength test results of concrete after 28 days of curing. The compressive strength curve of concrete when immersed in distilled water and sea water exhibits the same pattern, specifically, the greater CA added to the concrete, the lower the compressive strength. It demonstrates that the salt content of sea water has a negative effect on the overall strength of concrete. Additionally, by immersing the concrete in sea water, it was demonstrated that the maximum strength of concrete with 0% variation in CA provided a compressive strength of 14.89 MPa. Additionally, the result of concrete testing using the distilled water immersion method indicated that the maximum compressive strength of concrete is 18.47 MPa at 0% CA. The results indicated that the addition of CA resulted in a decrease in compressive strength when compared to 0% CA. This demonstrates that when the CA content of the concrete increased, the compressive strength of the concrete decreased. The possible reason for the loss in compressive strength of CA concrete is that a significant percentage of cement was replaced with CA, lowering the cement content of the concrete and thereby limiting cement hydration processes [50]. Additionally, this is because the chemical content of the CaCO3 of CA does not contribute much to the production of cement and fine sand. There may be too saturated lime in the cement F02D CA mixture, reducing the homogeneity of the bonding power. Thus, when the force is applied vertically, parallel to the test object, the upper surface area of the concrete is insufficiently strong to sustain the strain. Apart from the increased CA content, this resulted in a higher water need, resulting in water being unavailable for cement hydration [49].

3.3. Splitting Tensile Strength

The strength of tensile for CA-concrete samples was determined in this test. Cylindrical specimens with a diameter of 150 mm and a length of 300 mm were used for the split tensile test. SNI 03-2491-2002 was used for splitting tensile strength test procedures. The splitting tensile strength test was performed on a 28-day-old concrete cylinder specimen. The splitting tensile strength of concrete was determined for two scenarios namely sea water immersion concrete and distilled water immersion scenarios. Based on the findings, it is confirmed that distilled water immersion has a higher splitting tensile strength than sea water immersion.

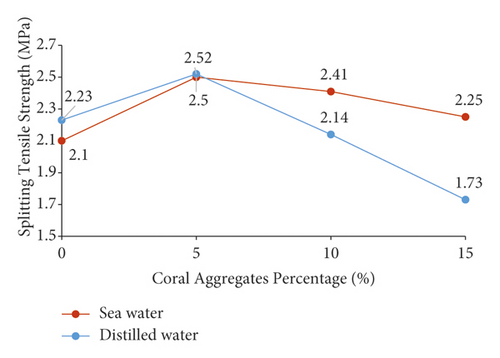

The results indicate that substituting CA for a portion of the cement and fine sand can boost the split tensile strength of the concrete. From Figure 7, the split tensile strength of concrete for CA substitution using a sea water immersion method of 0%, 5%, 10%, and 15% is 2.10 MPa, 2.50 MPa, 2.41 MPa, and 2.25 MPa, respectively. Moreover, the split tensile strength of concrete at 0%, 5%, 10%, and 15% CA using the distilled water immersion was 2.23 MPa, 2.52 MPa, 2.14 MPa, and 1.73 MPa, respectively.

The maximum split tensile strength of concrete is obtained when 5% CA was substituted and the least split tensile strength of concrete occurs when regular concrete. The immersion method with sea water and distilled water at a difference of 5% generates the same value of concrete’s split tensile strength, which is around 2.50 MPa. This is because CA released moisture continually during cement hydration, which enhanced cement hydration and the reaction of pozzolanic for CA [20].

Additionally, the split tensile strength of concrete increased by 5% due to the perpendicular loading of the test specimen for cylinders. As a result, the surface area that may be retained is increased by 30 cm. When loading occurs, the CA that has been substituted for cement and fine sand is capable of maintaining a 15-cm broad bond on the horizontal side. The tensile strength declined further when the CA substitute was increased to 10% and 15%. This is because the chemical composition of the concrete has saturated to the point where it can no longer maintain its binding capacity on the horizontal side of the test object.

The specimens immersed in sea water, on the other hand, showed a higher average split tensile strength than those immersed in distilled water. This may be because the rock contains CaCO3 (lime substance), which triggers a chemical reaction in the test object during immersion in sea water, which is the rock’s natural habitat/environment. The concrete mix contains 5% CA develops strength at a rate of approximately 8% higher than the control mix. This could be an indication of the production of C-S-H gel in the concrete mix as a result of the presence of CA [49]. As a result, a higher split tensile strength value was achieved than when the specimen is soaked in distilled water.

3.4. Volume Weight of Concrete

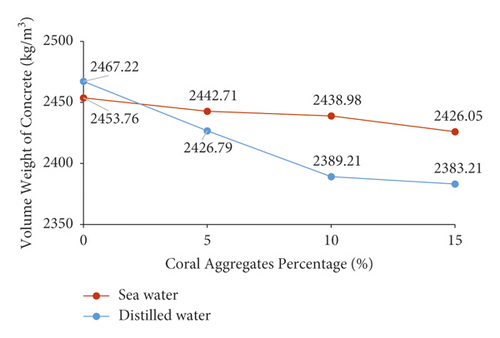

After the concrete cylinder specimen had been treated for 28 days, the volume weight of the concrete was determined utilizing the dimensions and weight of the concrete cylinder. As illustrated in Figure 8, the weight of the concrete volume was determined for the sea water immersion scenario. The weight values of concrete volume for rock substitution for the sea water immersion scenario are 2453.76 kg/m3, 2442.71 kg/m3, 2438.98 kg/m3, and 2426.05 kg/m3. Furthermore, the volume of concrete measured using the distilled water immersion with substitutions of 0%, 5%, 10%, and 15% results in 2467.22 kg/m3, 2426.79 kg/m3, 2389.21 kg/m3, and 2383.21 kg/m3, respectively.

The results of the weight testing of the concrete volume utilizing the sea water and distilled water immersion indicate that normal concrete has the maximum volume weight. Moreover, specimens with 5%, 10%, and 15% substitution experienced a considerable drop in the weight of the concrete volume. The more CA substituted for cement and fine sand, the lighter the concrete [51]. This is because the amount of water (workability) in the concrete mixture is reduced by up to 2%–5% when rock substitution was used. The workability specification attempts to achieve a design slump of 75–100 mm in conformity with ACI standards [52].

According to Figure 8, the weight of the concrete volume fluctuated between 2383.21 kg/m3 and 2467.22 kg/m3. This indicates that the weight of the concrete volume obtained is still within the range of 2200 kg/m3 to 2500 kg/m3. The volume weight of regular concrete treated with distilled water immersion is somewhat greater than that of sea water-treated concrete. This is owing to the excellent absorption of the test object of distilled water. Meanwhile, sea water is not completely absorbed by other test objects, resulting in the formation of pores. Meanwhile, the weight of the concrete volume when CA was substituted for 5% to 15% of the saltwater immersion test object is more than the weight of the distilled water immersion test object. This is because sea water has higher specific gravity than distilled water and also contains CA that reacts well when dissolved in sea water, hence reducing pores during hydration.

4. Conclusion

Several conclusions can be drawn from this study, including the following: reducing the amount of rock in cement and fine sand by 0%, 5%, 10%, and 15% has a significant effect on the compressive and splitting tensile strength of concrete and the weight of the concrete volume, both when using the sea water distilled water immersion scenario. The compressive strength of concrete results shows that 0% of CA as the optimum percentage. Moreover, the splitting tensile strength results indicated that the strength increased at 5% CA and subsequently fell significantly at 10% and 15% CA substitution. In terms of volumetric weight, the more CA substituted for cement and fine sand, the lower the volumetric weight of the concrete. Moreover, CA incorporation into concrete has several additional environmental and technological benefits for all associated businesses. Additionally, partial substitution of CA lowers the cost of concrete production.

Immersion of the samples in sea water may affect the quality of the cement-water heat hydration process in concrete. During cement hydration, concrete requires high-quality water to achieve maximum hardness and avoid cracking, swelling, and shrinking. In this investigation, the CA was partially exchanged for cement and fine sand. Even though crushed CA processed as a substitute material does not react properly with cement and water, when submerged in sea water, the volume of the concrete changes, i.e., the weight of the concrete is larger, in comparison to concrete immersed in fresh water. For further research, curing days of concrete after mixing, such as 7 and 90 days, are considered to determine the rate of strength development in the concrete samples. Moreover, a different type of sea water immersion is considered, namely immersing the test object in sea water, with the test object floating and sheltered from the sun to determine the effect of water depth and direct sun exposure.

In brief, distilled water immersion provides a stronger concrete bond than immersion in sea water. Moreover, CA possess excellent pozzolanic abilities, and it has been proven experimentally that concrete comprising 5% cement substitution with CA exhibits reasonable strength performance and is thus designated as the optimum replacement ratio. Thus, the substitution of modified cement concrete for conventional cement has two advantages namely reducing carbon dioxide (CO2) emissions and may reduce construction costs. As a result, it may be seen as a cost-effective and long-term strategy.

Substituting a portion of the CA for cement and fine sand might decrease the compressive strength of concrete, as the chemical composition of CaCO3 is too high and saturated and is unable to sustain its binding ability with cement and fine sand in the vertical direction. On the other hand, it can improve the split tensile strength of concrete. This is because the chemical composition of CaCO3 in the CA allows it to retain a horizontal direction with cement and fine sand.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This study was supported by the Universitas Syiah Kuala, Banda Aceh, Indonesia, and Universiti Malaysia Pahang under the research grant (RDU/UMP) vote number RDU190339. Furthermore, the authors wish to extend their gratitude to Mr. Bagus and Mr. Siddiqul for assisting in the experimental and data collections.

Open Research

Data Availability

The data used to support the findings of this study are included within the article.