[Retracted] Optimization of Flash Extraction of Akebia trifoliata Seed Oil by the Box-Behnken Response Surface Methodology and Comparison of Oil Yields from Different Origins

Abstract

The aim was to optimize the extraction process of Akebia trifoliata seed oil. Using Akebia trifoliata seed as raw material, the oil extraction rate was used as index. The effect of flash extraction on the yield of Akebia trifoliata seed oil was investigated. Taking the liquid-material ratio, extraction voltage, and extraction time as the investigation factors and the oil extraction rate of Akebia trifoliata seed as the response value and on the basis of the single-factor test, the extraction process of Akebia trifoliata seed oil was optimized by the Box-Behnken response surface method. The oil yields of Akebia trifoliata seeds from different origins in China were compared. The experimental results showed that the optimum technological conditions for flash extraction of Akebia trifoliata seed oil were as follows: liquid-material ratio, 12 : 1; extraction voltage, 150 V; extraction time, 90 s; and oil yield of Akebia trifoliata seed, 19.83%. For comparison, it is found that the oil yield of Akebia trifoliata seed produced in Qujing of Yunnan is relatively the highest, followed by Tongren of Guizhou and Zhangjiajie of Hunan; the oil yield of Akebia trifoliata seed produced in Shimian of Sichuan is the lowest. The flash extraction process of Akebia trifoliata seed oil is reasonable, and the oil yield of Akebia trifoliata seed produced in Qujing of Yunnan, China, is relatively the highest. It provides a theoretical and experimental reference for the research and development of Akebia trifoliata seed oil.

1. Introduction

Akebia trifoliata is the fruit of Akebia (Thunb.), also known as Akebia fruit, August fried melon, Beef rolling melon, and Wild banana in China. Due to its strict requirements on the growth environment, there are relatively few artificially cultivated Akebia trifoliata and mainly wild resources, which are widely distributed in China and are mostly found in higher altitude areas such as Yunnan, Guizhou, Sichuan, Hunan, and Southeast Tibet. Akebia trifoliata is delicious and nutritious with high edible and medicinal value. However, it is easy to deteriorate and rot; therefore, the deep processing of Akebia trifoliata is very necessary [1]. Some experimental studies have found that Akebia trifoliata seeds are rich in unsaturated fatty acids such as oleic acid, linoleic acid, and linolenic acid, as well as amino acids and minerals such as potassium, iron, magnesium, and copper, which are high-quality edible oil sources with nutrition and health care effects. Therefore, the research on Akebia trifoliata has attracted extensive attention of scholars [2–10]. Modern medical studies show that Akebia trifoliata has good pharmacological effects such as antioxidant, hypoglycemic, and tumor prevention. In particular, Akebia trifoliata seed oil also has the effects of lowering blood pressure, regulating blood lipids, antioxidation, and so on, which could effectively prevent the occurrence of cardiovascular and cerebrovascular accidents, so it has a high market development value [11–16]. However, there are few research reports on the extraction process of Akebia trifoliata seed oil.

Response Surface Methodology, also known as RSM, is a method commonly used in scientific research to optimize extraction conditions. It is also a statistical method to solve multivariable problems by obtaining certain data through reasonable experimental design and experiments, using multiple quadratic regression equation to fit the functional relationship between various factors and response values, and finding the optimal extraction parameters through the analysis of regression equation. Among them, the Box-Behnken response surface methodology is the most commonly used. Compared with the orthogonal test method, the experimental results are more reasonable and reliable because it can continuously analyze all levels of the experiment, and this method has the advantages of short periods and high accuracy [17–21].

There are three traditional technologies of oil extraction: pressing method, leaching method and the combination of pressing and leaching method. However, these methods have disadvantages of complicated operation process, high cost, many consumables, long extraction time, and a large amount of water and electricity consumption. Therefore, the application of new seed oil extraction techniques such as hydroenzymatic extraction, ultrasonic extraction, supercritical CO2 extraction and flash extraction is an important way to improve the extraction efficiency of seed oil [22–25]. Flash extraction technology relies on high-speed mechanical shear force and ultradynamic molecular penetration technology to break the vegetable oil into fine particles in a few seconds, so that the solvent is more easily permeated into the tissue, and the active ingredients can be quickly dissolved and diffused, so as to achieve internal and external balance and complete the extraction process. Compared with other methods, flash extraction has advantages of easy operation, short time consuming, environmental protection, and high extraction rate. Application of flash extraction has been widely reported in oilseed crops such as rape and Camellia oleifera, but it was not used in the extraction of Akebia trifoliata seed oil [26–29]. In this experiment, the seeds of Akebia trifoliata were used as raw material to study the effects of liquid-solid ratio, extraction voltage, and extraction time on the yield of Akebia trifoliata seed oil. The Box-Behnken response surface method was used to optimize the extraction process of Akebia trifoliata seed oil, and the oil yields of Akebia trifoliata seeds from 4 representative regions in China were compared. The results could not only provide theoretical and experimental basis for the development and utilization of Akebia trifoliata but also have certain reference value for the oil extraction of other oilseed crops.

2. Materials and Methods

2.1. Materials

2.1.1. Materials and Reagents

Four varieties of fresh Akebia trifoliata fruits were purchased from Qujing of Yunnan Province, Tongren of Guizhou Province, Shimian of Sichuan Province, and Zhangjiajie of Hunan Province in China; they were all identified by Professor Dai yi of Anhui Xinhua University. And the fruits were shelled to take seeds, dried at 60°C to constant weight, crushed, and sieved for use. Petroleum ether (60-90°C) and other experimental reagents were all analytically pure and purchased from Shanghai Hansi Chemical Co., Ltd.

2.1.2. Experimental Instruments and Equipment

Multifunction grinder JP-800C, flash extractor JHBE-20A, electronic balance AUW220, rotary evaporator ZT-52A, constant-temperature incubator LP/DHS-225, electric thermostatic water bath JHH-4, electric heating constant temperature drying oven DHG-9023A, and UV-visible spectrophotometer Fe-260 were used.

2.2. Experimental Methods

2.2.1. Extraction Process of Akebia trifoliata Seed Oil

The 100 g of 80 mesh Akebia trifoliata seed powder was accurately weighed and put into a beaker, and the amount of petroleum ether, extraction voltage, and extraction time were set to be extracted by a flash extraction method at 60°C. Finally, the extracted seed oil was filtered, concentrated, and dried at 105°C to constant weight, and the oil extraction rate was calculated according to the following formula.

2.2.2. Calculation of Akebia trifoliata Seed Oil Extraction Rate

where A is the weight of the extracted Akebia trifoliata seed oil and W is the weight of Akebia trifoliata seed powder.

3. Results and Discussion

3.1. Single-Factor Experiment

3.1.1. The Effect of Extraction Voltage on Oil Extraction Rate of Akebia trifoliata Seed

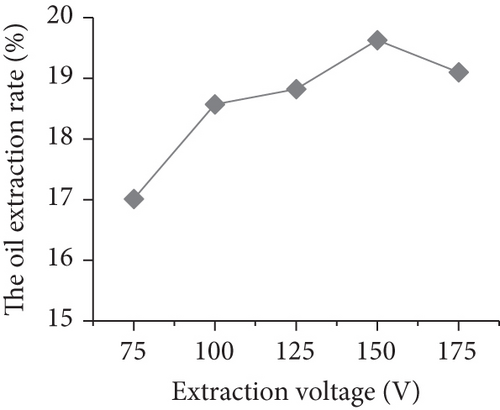

An appropriate amount of dried Akebia trifoliata seeds in the same batch were used as raw materials. According to the method of 1.2.1, under the conditions of the liquid-solid ratio of 10 : 1, extraction time of 90 s, and extraction voltage of 75 V, 100 V, 125 V, 150 V, and 175 V, respectively, the influence of extraction voltage on oil extraction rate of Akebia trifoliata seeds was investigated. The results are shown in Figure 1.

It can be seen from Figure 1 that the oil extraction rate of Akebia trifoliata seeds increased gradually when the extraction voltage was between 75 and 150 V and reached the peak value when the voltage was 150 V, while the oil yield showed a downward trend after 150 V. The reason may be related to the initial voltage rise which will accelerate the blade speed of the flash extractor, which will increase the penetration of petroleum ether and be more conducive to oil production. However, if the extraction voltage exceeds a certain limit, the heat energy generated by the rapid operation of the cutter head will accelerate the volatilization of petroleum ether, which will lead to the decline of oil extraction rate. Therefore, the selected extraction voltage is about 150 V [30].

3.1.2. Effect of the Liquid-Solid Ratio on Oil Extraction Rate of Akebia trifoliata Seeds

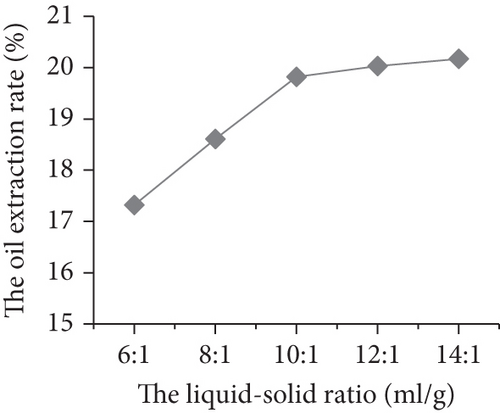

An appropriate amount of dried Akebia trifoliata seeds in the same batch were used as raw materials. According to the method of 1.2.1, under the conditions of extraction voltage of 150 V, extraction time of 90 s, and the liquid-solid ratio of 6 : 1, 8 : 1, 10 : 1, 12 : 1, and 14 : 1, respectively, the influence of the liquid-solid ratio on the oil extraction rate of Akebia trifoliata seeds was investigated. The results are shown in Figure 2.

As can be seen from Figure 2, the oil extraction rate of Akebia trifoliata seeds increased with the increase in liquid-to-material ratio, but when the liquid-to-material ratio exceeded 10 : 1, the increased amplitude of oil extraction rate gradually decreased. The reason may be that the concentration difference between petroleum ether and Akebia trifoliata seed oil in the early stage of extraction is large, so the diffusion rate of seed oil is faster, and the increase in oil extraction rate is more obvious. When the ratio of liquid to solid exceeds 10 : 1, the increase in petroleum ether usage will lead to more heat loss, and the recovery of solvent may also lead to increased oil loss. Therefore, the ratio of liquid-to-material is about 10 : 1 [31].

3.1.3. Effect of Extraction Time on Oil Extraction Rate of Akebia trifoliata Seeds

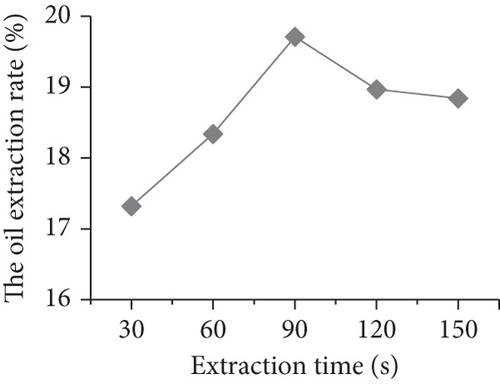

An appropriate amount of dried Akebia trifoliata seeds in the same batch were used as raw materials. According to the method of 1.2.1, under the conditions of extraction voltage of 150 V, liquid-solid ratio of 10 : 1, and extraction time of 30 s, 60 s, 90 s, 120 s, and 150 s, respectively, the influence of extraction time on oil extraction rate of Akebia trifoliata seeds was investigated. The results are shown in Figure 3.

Figure 3 shows that the oil extraction rate of Akebia trifoliata seeds will gradually increase with the extension of extraction time between 30 and 90 s and reach the peak value of oil extraction rate at 90 s and then show a gradual downward trend after 90 s, and the oil yield drops to 18.84% when the extraction time is 150 s. The reason may be that the seed powder of Akebia trifoliata was not completely infiltrated by petroleum ether in the early stage. With the extension of extraction time, when seed powder was completely soaked by solvent, the oil yield increased significantly. However, if the extraction time continues to extend, it will increase the energy consumption and reduce the oil yield. Therefore, the extraction time selected in the experiment is about 90 s [32].

3.2. Optimization Experiment of the Response Surface Method

3.2.1. Box-Behnken Response Surface Experiment Design and Results

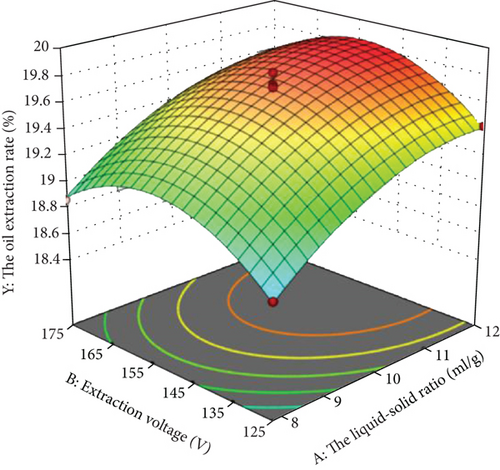

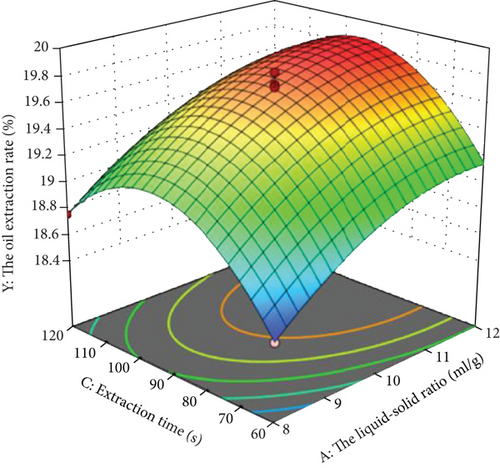

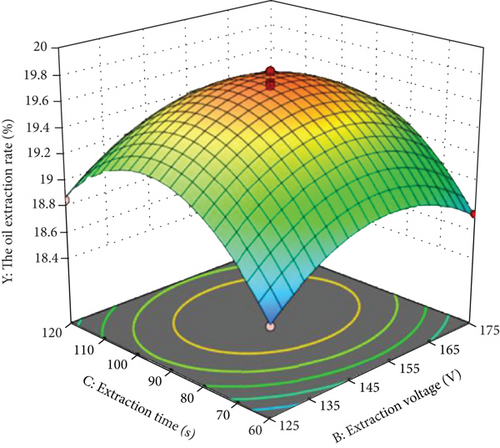

According to the results of single-factor experiment, the Box-Behnken response surface experiment was designed by Design-Expert 8.0.6 software with three factors of liquid-material ratio (A), extraction voltage (B), and extraction time (C) as independent variables and oil yield of Akebia trifoliata seeds (Y) as response value. Related data were analyzed. The level of the response surface experimental factors is shown in Table 1, the experimental design and results of the response surface method are shown in Table 2, the analysis of variance is shown in Table 3, and the three-dimensional interaction diagram of the response surface is shown in Figures 4–6 [33].

| Horizontal | Factors | ||

|---|---|---|---|

| Liquid-solid ratio A (ml/g) | Extraction voltage B (V) | Extraction time C (s) | |

| -1 | 8 : 1 | 125 | 60 |

| 0 | 10 : 1 | 150 | 90 |

| 1 | 12 : 1 | 175 | 120 |

| Test no. | Liquid-solid ratio A (ml/g) | Extraction voltage B (V) | Extraction time C (s) | Oil yield Y (%) |

|---|---|---|---|---|

| 1 | 1 | 0 | -1 | 19.14 |

| 2 | 0 | 0 | 0 | 19.74 |

| 3 | 1 | 1 | 0 | 19.55 |

| 4 | -1 | 0 | -1 | 18.45 |

| 5 | 0 | -1 | 1 | 18.85 |

| 6 | 1 | 0 | 1 | 19.45 |

| 7 | 0 | 0 | 0 | 19.83 |

| 8 | 0 | 0 | 0 | 19.57 |

| 9 | 0 | 0 | 0 | 19.66 |

| 10 | 0 | 1 | -1 | 18.74 |

| 11 | 0 | -1 | -1 | 18.54 |

| 12 | 0 | 0 | 0 | 19.72 |

| 13 | 1 | -1 | 0 | 19.43 |

| 14 | 0 | 1 | 1 | 19.02 |

| 15 | -1 | 1 | 0 | 18.87 |

| 16 | -1 | -1 | 0 | 18.73 |

| 17 | -1 | 0 | 1 | 18.76 |

| Variance source | Sum of square | Degree of freedom | Mean square | F value | P value | Significance |

|---|---|---|---|---|---|---|

| Model | 3.39 | 9 | 0.38 | 67.72 | <0.0001 | Highly significant |

| A | 0.95 | 1 | 0.95 | 171.15 | <0.0001 | Highly significant |

| B | 0.050 | 1 | 0.050 | 8.92 | 0.0203 | Significant |

| C | 0.18 | 1 | 0.18 | 32.89 | 0.0007 | Significant |

| AB | 0.0001 | 1 | 0.0001 | 0.018 | 0.8971 | |

| AC | 0.000 | 1 | 0.000 | 0.000 | 1.0000 | |

| BC | 0.000225 | 1 | 0.000225 | 0.040 | 0.8463 | |

| A2 | 0.17 | 1 | 0.17 | 29.74 | 0.0010 | Significant |

| B2 | 0.55 | 1 | 0.55 | 98.49 | <0.0001 | Highly significant |

| C2 | 1.3 | 1 | 1.3 | 233.74 | <0.0001 | Highly significant |

| Residual | 0.039 | 7 | 0.000556 | |||

| Lack of fit | 0.00163 | 3 | 0.000542 | 0.058 | 0.9792 | |

| Pure error | 0.037 | 4 | 0.00933 | |||

| The sum | 3.43 | 16 |

Response surface regression analysis was conducted on the data in Table 2 by Design-Expert software, and the quadratic multiple regression equation was obtained as follows: Y = 19.70 + 0.35A + 0.079B + 0.15C + 0.005AB + 0.000 AC − 0.008 BC − 0.20A2 − 0.36B2 − 0.56C2.

As can be seen from Table 3, the regression model is highly significant (P < 0.0001), while the missing term is not significant (P > 0.05), which shows that the experimental results have a good fit with the predicted value, indicating that the method is feasible for the prediction and analysis of the extraction process of Akebia trifoliata seed oil. The primary term A is highly significant, B and C are significant, the secondary terms B2 and C2 are highly significant, and A2 is significant. The effects of three factors on the extraction process were A > C > B.

It can be seen from Figure 5 that the liquid-solid ratio has high significance with voltage and time. Although the extraction time and voltage interacted, they are not significant.

3.2.2. Validation Test

The optimal extraction conditions were as follows: liquid-solid ratio, 11.7 : 1; extraction voltage, 152.55 V; and extraction time, 94.05 s. The highest predicted value of oil extraction rate of Akebia trifoliata seed oil was 19.8681%. In order to test the effectiveness of the regression model and consider the convenience of operation, the optimal conditions obtained by response surface quadratic regression were modified. The optimal process conditions were determined as liquid-material ratio of 12 : 1, extraction voltage of 150 V, and extraction time of 90 s. The average oil yield of Akebia trifoliata seeds was 19.83%, which was close to the predicted value, indicating that the method fitted well with the actual situation and verified the effectiveness of the regression model. Therefore, the flash extraction process of Akebia trifoliata seed oil optimized by the response surface method is stable, reliable, and practical [34].

3.2.3. Comparison of Oil Yields of Akebia trifoliata Seeds from Different Origins

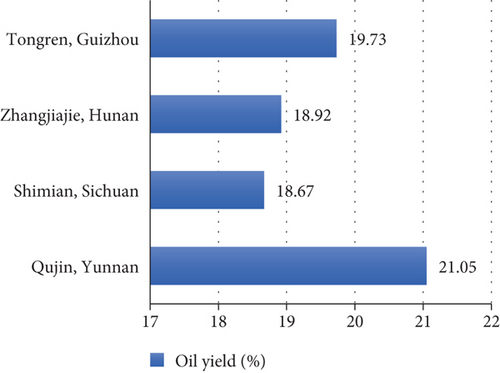

The Akebia trifoliata seeds from four different origins (Qujing of Yunnan, Shimian of Sichuan, Zhangjiajie of Hunan, and Tongren of Guizhou) were taken in equal quantities, cleaned and dried, crushed and screened, and extracted at 60°C according to the optimal flash extraction process conditions optimized in the above experiments. The oil yield of each origin was compared, and the results are shown in Figure 7.

By comparing the oil yields of Akebia trifoliata seeds from four different origins in Figure 7, it can be seen that the oil yield of Akebia trifoliata seeds produced in Qujing of Yunnan is relatively the highest, followed by Tongren of Guizhou and Zhangjiajie of Hunan; the oil yield of Akebia trifoliata seeds produced in Shimian of Sichuan is relatively the lowest.

4. Conclusion

In this study, the oil extraction rate of Akebia trifoliata seed was used as the index to extract Akebia trifoliata seed oil by the flash extraction method. On the basis of the single-factor experiment, the extraction conditions were optimized by the Box-Behnken response surface method. The optimal extraction conditions were as follows: liquid-solid ratio, 12 : 1; extraction voltage, 150 V; and extraction time, 90 s. Under the optimal extraction conditions, the average oil extraction rate of Akebia trifoliata seed was 19.83%. By comparing the oil yields of Akebia trifoliata seeds from four major producing areas in China, it was found that the oil yield of Akebia trifoliata seeds from Qujing of Yunnan province was relatively the highest, and the oil yield of Shimian, Sichuan Province, was the lowest. The research will provide a basis and reference for the development and deep processing of Akebia trifoliata.

Conflicts of Interest

The authors of this paper declare that they have no conflicts of interest regarding the publication of this paper.

Authors’ Contributions

All authors have equally contributed to this paper.

Acknowledgments

This study was supported by the Outstanding Young Talents Program of Anhui Province (Grant no. Gxyq2020075), the Quality Engineering Project of Anhui Province (Grant nos. 2018MOOC438, 2020WYXM099, and 2020SXZX12), the Natural Science Foundation of Anhui Province (Grant no. KJ2021A1169), the Quality Engineering Project of Anhui Xinhua University (Grant nos. 2021JY007 and 2021KCSZX03), and the Innovation and Entrepreneurship Education Training Program for College Students (Grant nos. 202012216049 and 201912216197).

Open Research

Data Availability

The data used to support the findings of this study are included within the article.