Doped Nanostructured Manganese Ferrites: Synthesis, Characterization, and Magnetic Properties

Abstract

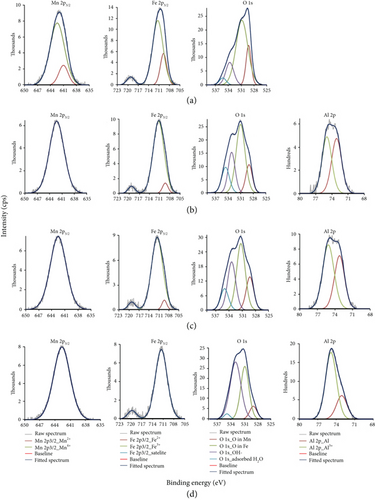

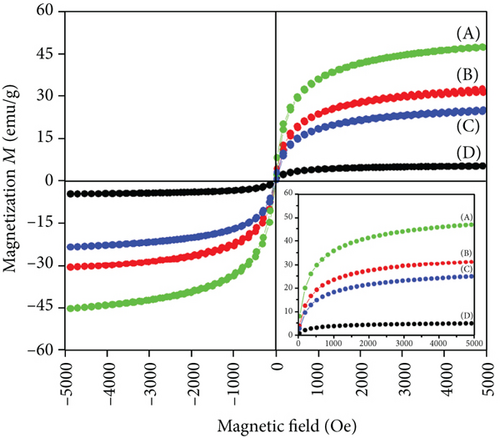

Nanocrystalline aluminum-doped manganese ferrite was synthesized by facile thermal treatment method. Nanostructure-doped ferrite with crystalline size that ranged between 3.71 and 6.35 nm was characterized via X-ray diffraction (XRD), scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), and vibrating-sample magnetometry (VSM). The Scherrer and Williamson-Hall hypothesis techniques were utilized to determine lattice constants and strain. Various types of structural properties including octahedral and tetrahedral site radius, bond lengths and angles, hopping parameter, oxygen positional parameters, site bonds, and edge lengths were determined from XRD spectrum analysis. Discrepancy in the hypothetically expected angle indicates improvement of A-B superexchange intercommunication. Furthermore, magnetic-hysteresis (M-H) and XPS analysis support the claim of enhancement. The presence of the ionic nature of iron and manganese in ferrite is FeII, FeIII, MnII, and MnIV as revealed by the results of XPS. Moreover, XPS assists in an excellent way to understand the properties such as configuration, chemical nature, and average inversion degree of doped ferrite samples. The spin noncollinearity and exquisite interaction amid the sublattice are responsible for the decrease in the saturation and remnant magnetization determined from the hysteresis loop at ambient temperature with maximum magnetic field of 1.8 T.

1. Introduction

The transition metal-oriented nanoferrites which consist of unique structural, electrical, thermal, and magnetic characteristics are utilized for various types of engineering and biomedical applications. Nanostructure ferrites are used in different types of biological applications such as X-ray diagnosis, drug delivery, hyperthermia, and magnetic resonance imaging (MRI) [1–4]. Moreover, nanocrystalline spinel ferrites possess a variety of characteristics which are applied in the field of electromagnetic interference (EMI), circuit-based electronic, pigments, sensors, radar systems, motors, and inductors [5–12]. Manganese ferrite (MnFe2O4) nanoparticles (NPs) with other ferrites are considered as a crucial tool for biomedical applications particularly for enhancing efficiency of magnetic resonance imaging, hyperthermia, and drug delivery [13]. The properties such as facile preparation, proper saturation magnetization, inflated Curie temperature, high coercivity, and redundant anisotropic constant make manganese NPs an exceptional contender for biological applications [14, 15].

Generally spinel-based ferrites are represented by the specification AB2O4, where A and B indicates divalent and trivalent cations. Ferrites exhibit different types of unit cell with eight formula units in each cell. The oxygen anions with larger size and metal cations with smaller size occupies face-centered cubic (fcc) and interstitial sites, respectively. The magnetite (Fe3O4), a form of iron oxide is the primary building block of most of the ferrites [16]. The (M2+1-δFe3+δ)[M2+δFe3+2-δ]O4 formula provides general information related to sites and degree of inversion (δ). The () and [] bracket represents tetrahedral and octahedral sections and “δ” furnishes ferrite nature in terms of whether the structure is normal, inverse or random. When δ = 0, the formula is expressed as (M2+)[Fe23+]O4, and the ferrite is called normal spinel ferrite. When δ = 1, the formula is expressed as (Fe3+)[M2+Fe3+]O4, and the ferrite is called inverse spinel ferrite. When 0 < δ < 1, such as δ = 0.3, 0.6, or 0.9, the ferrite is called as mixed spinel ferrite. When δ = 0.3, the formula is expressed as (M0.72+Fe0.33+)[M0.32+Fe1.73+]O42-[17]. Zinc ferrite (ZnFe2O4), a normal spinel, where Zn2+ cations represent as tetrahedral site and Fe3+ cations as octahedral sites leads to the formula as (Zn2+)[Fe23+]O4 [18]. Cobalt ferrite (CoFe2O4) is an inverse ferrite, where Co2+ prefers octahedral and Fe3+ prefers uniform placement in octahedral and tetrahedral sites [19]. Manganese ferrite (MnFe2O4) is a mixed ferrite, where Mn2+ and Fe3+ prefer both tetrahedral and octahedral bonding sites [20]. Structural, magnetic, and optical characteristics of ferrites depends upon tetrahedral and octahedral sites occupied by divalent and trivalent cations [21, 22]. Furthermore, particle size distribution (PSD) also affects optical and magnetic characteristics of spinel ferrites [23, 24].

Ferrite nanoparticles bearing new unique characteristics are prepared by different routes which include high-energy ball milling, solvothermal, coprecipitation, sol-gel method, thermal decomposition, hydrothermal, microemulsion, electrochemical, and laser ablation method [25–33]. It was reported that the crystal structure, size, and magnetic properties of ferrites including manganese ferrite are influenced by calcinations, reaction duration, capping reagent, and pH [34–36]. The preparation methods including thermal decomposition, microemulsion, and coprecipitation affect crystal structure and magnetic properties of ferrites as reported by Gyergyek et al. [37]. Furthermore, it was also reported that different types of the preparation method change cation distribution, composition, and crystallinity among tetrahedral and octahedral sites [37–39]. The lattice parameter and average strain of cobalt ferrites vary with doping of erbium. Furthermore, this variation is due to a large size of Er3+ cations as compared to Fe3+ ions [40]. Incorporation of Mg into ZnFe2O4 significantly affects the rearrangement of cation distribution at tetrahedral and octahedral sites [41]. The crystal size of nickel-cobalt spinel changes upon doping of rare-earth metals. Moreover, variation in crystal size is because of blocking of crystal expansion by large size metals. The crystal size and surface area of ferrite are influenced by changing the variation of different types of metals such as La, Zn, Cd, and Ni [27, 40–44].

In this research work, the preparation of mixed spinel ferrite MnFe2−xAlxO4 (0 ≤ x ≤ 0.9) with (x) = 0.0, 0.3, 0.6, and 0.9 via a thermal method in association with capping agent polyvinylpyrrolidone is presented in detail. For mixed doped manganese spinel ferrite preparation, thermal disintegration route was chosen because of distinct accomplishments such as environmental acceptance, cheap, and persistent reproducibility; however, this process has a few drawbacks which include shape discrepancy and cluster of particles. Detailed characterization analysis of crystal structural parameter, nanostructure morphology, and quantitative assessment and magnetization characteristics of purified and Al-doped manganese mixed ferrite were also reported in this research work.

2. Experimental

2.1. Synthesis

Analytical precursors were used for the synthesis of pure and Al-doped manganese ferrite MnFe2−xAlxO4 (x = 0.0, 0.3, 0.6, and 0.9) without repeating purification: polyvinylpyrrolidone (PVP) (Alfa Aesar), iron (III) nitrate nonahydrate [Fe(NO3)3·9H2O] (min. 98%, Sigma-Aldrich), manganese (II) nitrate hexahydrate [Mn(NO3)2·6H2O] (min. 98%, Sigma-Aldrich), and aluminum nitrate nonahydrate [Al(NO3)3·9H2O] (min. 98%, Sigma-Aldrich).

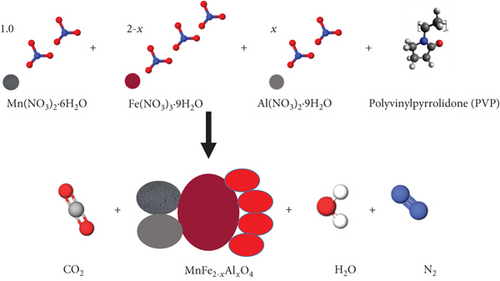

In a thermal synthesis process of MnFe2O4, a solution containing 0.2 mmol (0.0808 g) Fe(NO3)3·9H2O and 0.1 mmol (0.0179 g) Mn(NO3)2·6H2O was vigorously stirred for 2 h, followed by inclusion of capping agent (PVP) solution. The capping agent solution was synthesized by adding 0.1 g of PVP into 50 ml of deionized water (DI) at 90°C. The mixed solution was vigorously stirred for 2 h at room temperature (RT). The pH of the above solution was determined by litmus paper which was followed by drying at 80°C for 24 h. The dried orange-colored sample was converted into powder and calcinated at 500°C for 4 h to eliminated PVP in order to form pristine MnFe2O4. A similar method was executed for the preparation of MnFe2−xAlxO4 (x = 0.3, 0.6, and 0.9). For clarity, hereafter, the Al-doped MnFe2O4 are referred to as MnFe1.7Al0.3O4, MnFe1.4Al0.6O4, and MnFe1.1Al0.9O4. A graphic reaction design for the synthesis of MnFe2−xAlxO4 is presented in Figure 1.

2.2. Characterization

Structure of pristine and doped ferrite was determined by the XRD spectrum. The XRD spectrum was achieved using an INEL CPS 180 XRD Equinox 1000 diffractometer assembled with Co-Kα1 emission (λ = 1.789 Å) and regulated at 40 kV and 30 mA. The analysis was managed in the 2θ range of 10-80° at RT. The nanostructure behavior of samples was investigated by SEM. A wafer-delicate carbon film captivated inner side of a copper framework was used to install nanoparticles present in an ethanol solution. The XPS was operated by employing the SPEC GmbH (Germany) spectrometer at RT. The instrument is assembled with X-ray-bearing dual anode origin SPECS XR-50 Mg-Kα (hn = 1283.6 eV) in the presence of lift-off angle of photoelectrons of 90°. The ferrite samples were converted into pellets, before shifting to a high vacuum chamber. The vacuum was managed at 5 × 10−9 bar, during the operation. In order to perform surface quantification of the ferrite sample, a detailed operating method was employed containing high-resolution spectrum of O1s and C1s. To achieve a high quality XPS spectrum, calibration of the BE scale was performed by BE of C1s peak at 284.6 eV. The Lake Shore 7400 magnetometer VSM that was equipped with a 1.8 Tesla magnet was utilized to determine magnetic properties of ferrite samples at RT. The hysteresis loop of ferrite samples was obtained by plotting magnetization verses magnetic field. Furthermore, to measure remnant magnetization (Mr), saturation magnetization (Ms), and coercivity, magnetic hysteresis loops were utilized.

3. Results and Discussion

| Sample name | Lattice parameter a (Å) | Cell volume V (Å)3 | Bulk density ρm (gm/cm3) | X-ray density ρx−ray (gm/cm3) | Porosity (%) | Crystal size (nm) |

|---|---|---|---|---|---|---|

| MnFe2O4 | 8.515 | 617.380 | 2.998 | 4.962 | 39.580 | 6.35 |

| MnAl0.3Fe1.7O4 | 8.512 | 613.910 | 2.885 | 4.775 | 39.581 | 5.99 |

| MnAl0.6Fe1.4O4 | 8.499 | 605.170 | 2.772 | 4.589 | 39.583 | 4.47 |

| MnAl0.9Fe1.1O4 | 8.458 | 601.120 | 2.660 | 4.403 | 39.586 | 3.71 |

X-ray wavelength, FWHM in radians, and Bragg’s angle, respectively, refer to λ, β, and θ.

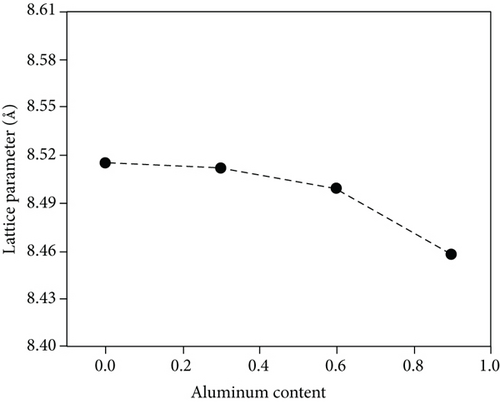

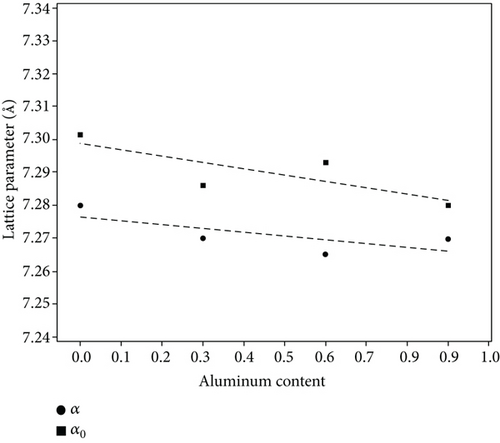

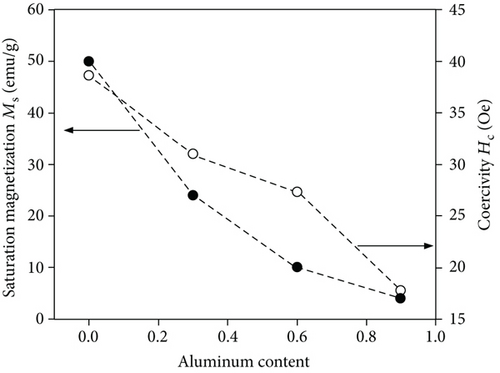

Table 1 shows average crystal size data calculated from Equation (1) and was found to be 6.35, 5.99, 4.47, and 3.71 nm. The capping agent PVP was employed during the synthesis process to avert agglomeration of ferrite particles. The absence of PVP creates aggregation of particles owing to high energy of small particles as reported in the Ostwald ripening process [45]. Table 1 confirms the variation in lattice parameter, X-ray density, bulk density, cell volume, and porosity as the content of nonmagnetic Al changes. Furthermore, increasing Al concentration decreases lattice constant parameters, density, and particle size as shown in Figure 3. Dessai et al. also observed that increasing nonmagnetic Al3+ content in manganese ferrite decreases lattice parameter and density [46].

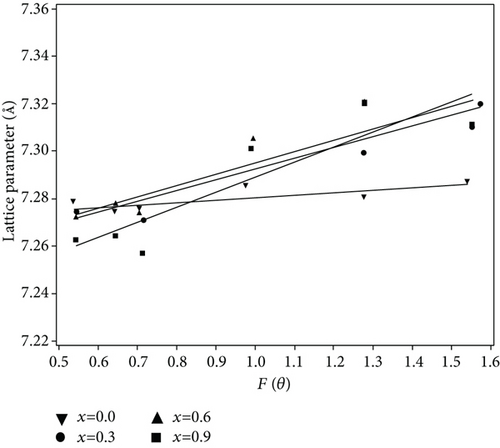

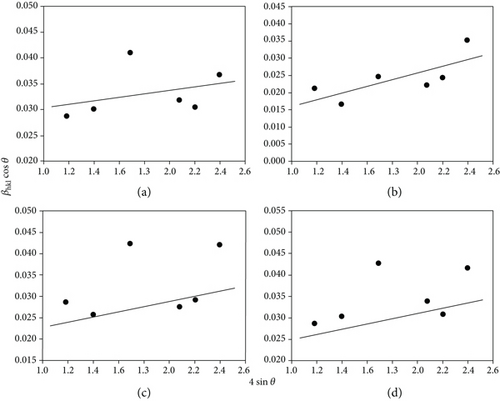

Williamson-Hall (W-H) calculations shown above in the form of Equations (9) and (10) were used to calculate crystallite size and average strain. The “βhklcosθ” verses “4sinθ” presented in Figure 5 is employed to calculate both the particle size and the strain. The linear fit of the crystal size and strain follows the uniform deformation process, where the strain is assumed as homogeneous in all directions, a property of isotropy. The W-H and Scherer formulas used for the calculation of the average strain were in complete harmony with each other as shown in Table 2.

| Sample name | Scherrer method | W-H method |

|---|---|---|

| 〈ε〉 × 10−3 | 〈ε〉 × 10−3 | |

| MnFe2O4 | 10.90 | 27.10 |

| MnFe1.7Al0.3O4 | 7.99 | 6.50 |

| MnFe1.4Al0.6O4 | 10.75 | 21.50 |

| MnFe1.1Al0.9O4 | 11.44 | 23.60 |

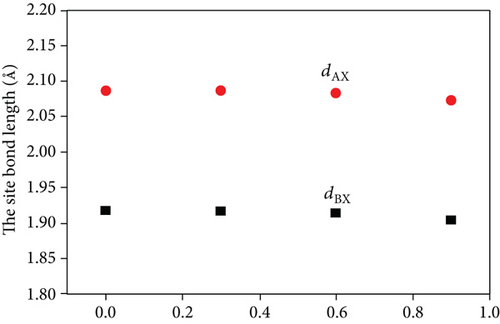

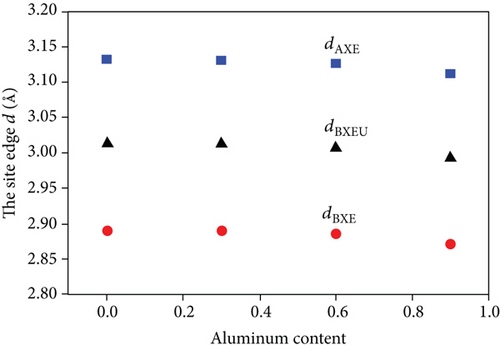

| Sample name | Bond length (Å) | Hopping length (Å) | dAx (Å) | dBx (Å) | dAxE (Å) | dBxE (Å) | dBxEU (Å) | ||

|---|---|---|---|---|---|---|---|---|---|

| RA | RB | LA | LB | ||||||

| MnFe2O4 | 1.9173 | 2.0871 | 2.0870 | 2.0870 | 1.9173 | 2.0870 | 3.1309 | 2.8901 | 3.0118 |

| MnFe1.7 Al0.3O4 | 1.9166 | 2.0863 | 2.0863 | 2.0863 | 1.9167 | 2.0863 | 3.1298 | 2.8890 | 3.0107 |

| MnFe1.4 Al0.6O4 | 1.9137 | 2.0831 | 2.0831 | 2.0831 | 1.9137 | 2.0831 | 3.1250 | 2.8846 | 3.0061 |

| MnFe1.1 Al0.9O4 | 1.9045 | 2.0731 | 2.0731 | 2.0731 | 1.9045 | 2.0730 | 3.1100 | 2.8707 | 2.9916 |

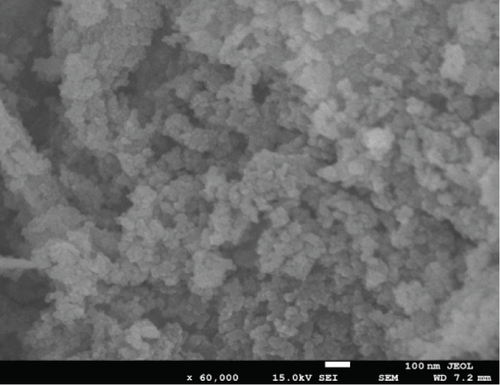

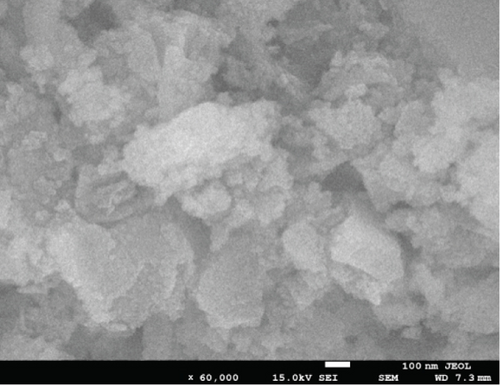

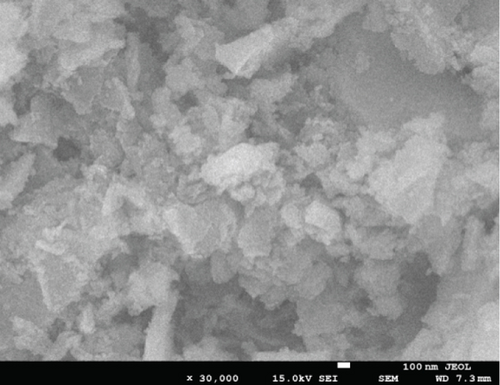

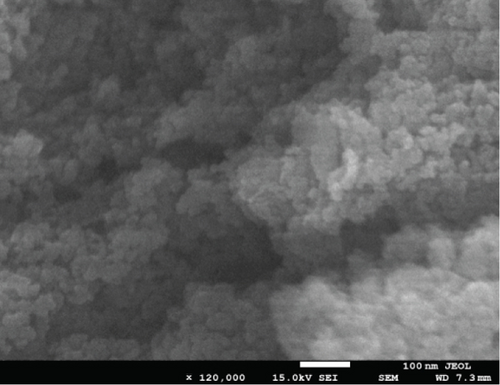

The nanostructure characterization of MnFe2−xAlxO4 performed by SEM is presented in Figure 7, where (a) corresponds to pure ferrite and (b–d) correlate to Al-doped manganese ferrites. The scale bar for all the samples is 100 nm. The agglomeration of smaller particles is visible in the nanostructured samples of ferrites. The EDX and elemental investigation averaged over different parts of the samples are presented in Table 4.

| Target composition | Composition by EDX | ||

|---|---|---|---|

| Mn | Fe | Al | |

| MnFe2O4 | 0.88 | 2.35 | |

| MnFe1.7Al0.3O4 | 0.98 | 2.20 | 0.42 |

| MnFe1.4Al0.6O4 | 0.99 | 1.80 | 0.71 |

| MnFe1.1Al0.9O4 | 1.03 | 1.20 | 1.06 |

With regard to the assessment of cations among octahedral and tetrahedral, Al3+ cations choose tetrahedral sites, which deals with chances that Al3+ cations would substitute Fe3+ cations. The substitution of Fe3+ cations by Al3+ cations is in good compliance with preparation, XRD calculation analysis, EDX spectrum analysis, and magnetic characteristics.

| Sample name | Hc (Oe) | Mr (emu/g) | Ms (emu/g) | ηexp | R = Mr/Ms |

|---|---|---|---|---|---|

| MnFe2O4 | 40 | 5.01 | 47.32 | 1.95 | 0.106 |

| MnFe1.7Al0.3O4 | 27 | 1.97 | 31.90 | 1.27 | 0.062 |

| MnFe1.4Al0.6O4 | 20 | 1.18 | 24.71 | 0.94 | 0.050 |

| MnFe1.1Al0.9O4 | 17 | 0.35 | 5.02 | 0.2 | 0.065 |

The Fe2+ and Fe3+ cation saturation magnetization and coercivity are changed by embedding Al3+ cations into manganese ferrite. As a result of integrated intensity of deconvoluted peaks, visible saturation magnetization and coercivity addiction to Mn2+ and Mn4+ ions were negligibly afflicted by the doping of Al3+ cations into manganese ferrite. The moderate saturation magnetization contraction and coercivity escalation as the Al content is elevated is shown in Figure 10. The decreased value of Ms and Mr of the doped ferrite sample may be associated to reduced particle size. The reduction in Ms after addition of nonmagnetic Al3+ in ferrite is also confirmed by the literature date reported by Dessai et al. [46]. Furthermore, there is a decrease in the average crystallite size control existence of spin inclination and spin canting, which appear by virtue of a defined size and surface-related effects. The reduction in Ms and Mr of doped samples as the Al content is elevated may be due to cation diffusion among the host and embedded groups. The substitution of Fe2+ and Fe3+ ions by Al3+ ions at the octahedral and tetrahedral decreases the bond stability of Fe3+-O-Fe3+. The decrease in the amount of Fe2+ and Fe3+ cations in the A- and B-sites decreases the magnetic dipole moment of the B-sublattice and consequently decreases the magnetic moment of ferrites. The exchange of Fe3+ cations bearing magnetic moment 5 μB with nonmagnetic Al3+ cations carrying magnetic moment 0 μB decreases the superexchange bonding that balances adjacent magnetic dipoles in an antiparallel form. Moreover, the decrease in overall magnetization is possible because of reinforced spin noncollinearity. The elevation of Al3+ ions which decreases the lattice parameter is due to smaller ionic radius (0.55 Å) of Al3+ cations as compared to Fe3+ cations (0.67 Å). The decrease in magnetization in embedded ferrite is also associated with exchange of cations in the A- and B-sites. The fact is that Ms builds upon the number and type of cation based at different sites in tetrahedral and octahedral bonding sites in the ferrite. The exchange influences the magnetization MA and MB of the A and B ferrite sublattices. The affiliation of MB – MA produces magnetization in spinel ferrites. In manganese-based ferrite, Mn4+ ions choose tetrahedral sites and are emphasized as the Al concentration is elevated. The Mn2+ ion location in the octahedral sites fades away as the Al content increases. Generally, tetrahedral and octahedral sites in ferrites engaged by Fe3+ cations are partially substituted by Al3+ cations. The substitution of Fe3+ by Al3+ cations in the B-sites decides magnetization of manganese ferrites. The reduction of magnetization of the Al-doped ferrite samples is due to substitution of Al3+ ions. The squareness ratio (R) less than 0.5 indicates a multidomain structure of ferrite materials while greater than 0.5 signifies a single-domain structure of manganese ferrite. According to the recent investigation carried out related to squareness ratio (R) revealed in several places in the literature, the squareness ratio (R) observed between 0.01 and 0.1 suggests a multidomain structure of ferrite materials [54–56].

4. Conclusions

The significance of Al3+ cations as a dopant in nanocrystalline manganese ferrite prepared through the thermal treatment method was discussed. The nanostructured samples were characterized by different methods to examine nanocrystallinity, thermal stability, chemical stability, distribution, and morphological properties. The representative Scherrer formula and Williamson-Hall extrapolation equations were employed to determine the crystallite size and lattice strain parameters. The parameters including ionic radii of tetrahedral and octahedral bonding sites, oxygen positional constants, hopping and bond lengths, bond angles and sites, and edge lengths were determined from the XRD spectrum. The characterization such as XPS and M-H analysis explains the inconsistency in the theoretically anticipated bond angles which implied beefing up of the A-B superexchange synergy. Distribution, chemical form, and degree of inversion were determined from the XPS spectrum. The characteristic magnetic hysteresis loop attained from VSM at RT displays that both Mr and Ms are reduced as the Al content is elevated. This contraction was associated with spin noncollinearity and delicate interactions between sublattices.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This project was funded by the Deanship of Scientific Research (DSR) at King Abdulaziz University, Jeddah, under grant no. (G: 191-135-1442). The authors, therefore, acknowledge with thanks the DSR for the technical and financial support.

Open Research

Data Availability

The data used to support the findings of this study are included within the article.