Preparation and Assessment of Some Characteristics of Nanoparticles Based on Sodium Alginate, Chitosan, and Camellia chrysantha Polyphenols

Abstract

This paper presents the characteristics, morphology, and properties of alginate/chitosan/polyphenol nanoparticles, in which polyphenols were extracted from Camellia chrysantha leaves collected in Tam Dao district, Vinh Phuc province (Vietnam). The alginate/chitosan/polyphenol nanoparticles were prepared by ionic gelation method at different polyphenol content. The characteristics and morphology of these nanoparticles were investigated using infrared spectroscopy (IR), ultraviolet-visible spectroscopy (UV-Vis), and scanning electron microscopy (SEM). Release kinetic of polyphenols from the alginate/chitosan/polyphenol nanoparticles was conducted in simulated human body fluids. The release kinetics of polyphenols from the above nanoparticles were also evaluated and discussed. The experimental results showed that the release process of polyphenols from the nanoparticles was dependent on three factors: time, pH of solution, and amount of polyphenols.

1. Introduction

Polyphenols are family of naturally occurring compounds found in plants, with highly effective anti-inflammatory and antioxidation properties. It has been hypothesized that polyphenols are able to protect cellular constituents against deterioration. They share a common structural motif, which consists of a benzene ring with one or more hydroxyl substituents attached directly to the aromatic nucleus. Depending on the number and location of attached hydroxyl groups, physical, chemical properties and biological activities of polyphenols can be varied [1–3].

Camellia chrysantha, colloquially known as the golden flower tea, is a rare plant species found in Vietnam and China. It has many applications in biomedical field, with more than 400 valuable active ingredients, including polyphenol saponins, trace elements such as selenium (Se), germanium (Ge), kalium (K), zinc (Zn), molybdenum (Mo), vanadium (V), manganese (Mn), and vitamins B1, B2, and C. Additionally, golden flower tea also has the ability to prevent cardiovascular disease, hypertension, diabetes, and tumors [4]. Furthermore, polyphenols extracted from these species possess antibacterial and antioxidation characteristics that are attractive to research in the food and pharmaceutical fields.

Based on chemical component and polyphenol content of some species of the Camellia genus, Lixia et al. investigated the antioxidation activity of polyphenols from 6 different Camellia species (C. impressinervis, C. euphlebia, C. microcarpa, C. nitidissima, C. tunghinensis, and C. chrysantha) using 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging assay and confirmed their validity [5]. Lin et al. demonstrated that each variety of Camellia chrysantha had its own unique polyphenolic content, which corresponds to different ability to destroy breast cancer cells MDA-MB-231 [6]. Yokozawa et al. investigated the effects of polyphenols extracted from green tea on serum antioxidant activity and cholesterol levels in obese mice in comparison with probucol, a cholesterol-lowering antioxidant [7]. Specifically, the green tea polyphenols were able to inhibit the oxidation of low-density lipoproteins and increased serum antioxidation activity in mice to a level equal to that of probucol. Additionally, the tested polyphenols also exhibited the ability to increase the cholesterol high-density lipoprotein (HDL) content, which led to the improvement of arteriosclerosis depending on the administered dose, a characteristic not observed in probucol [8].

However, tea polyphenols are also susceptible to two major disadvantages, which are their sensitivity to light and temperature, and their weak biological interactions, caused by poor solubility in water. It is possible to solve these two problems by encapsulating polyphenols in nanoparticles prepared from natural polymers. Amongst a myriad of candidates, sodium alginate (AGN) and chitosan (CS) have the highest potential thanks to their great advantages. Chitosan is a highly bioactive natural polymer that is used commonly as a carrier for drugs with outstanding advantages such as nontoxic, highly biocompatible, hemostasis, and wound healing [9–11]. Alginate is also a rich marine biopolymer extracted from brown algae. Alginate is nontoxic, nonimmunogenic, and highly biodegradable. By using nanotechnology, nano-alginate has been used for the preparation of anti-inflammatory drugs, slow-release drugs to maintain long-term drug concentrations and avoid rapid increase or early rejection like infusion drugs, leading to the increase in the effectiveness of treatment [12]. Radoslava et al. synthesized an alginate/chitosan/polyphenol composite which had a significantly better diffusion coefficient than alginate/inulin composite [13]. Wang et al. studied the morphology, structure, and kinetics of polyphenol released from the alginate/chitosan/polyphenol [14]. Experimental results showed that in pH 7.4 solution, the polyphenol release process was better than that in pH 1.2 solution. This could be due to the electrostatic interaction between alginate and chitosan in the slightly alkaline environment (pH 7.4). After 6 hours of testing, the released polyphenol amount reached to 80-93%. The authors also suggested that some tea polyphenols can interact with either alginate or chitosan in solution of pH 7.4 [14]. Kopjar et al. proved that the total polyphenol content in yellow tea is higher than that in green tea and black tea. The antioxidation activity which was evaluated by DPPH and 2,2 ′azinobis-(3-ethylbenzthiazoline-6-sulphonic acid (ABTS) free radicals also showed that yellow tea extract has higher antioxidant activity than green tea and black tea extracts [15]. The preparation and characterization of alginate/chitosan nanoparticles loading golden flower tea polyphenol leaves harvested in Tam Dao, Vinh Phuc (Vietnam) have not been investigated before. Therefore, the purpose of this study is preparation of alginate/chitosan nanoparticles loading golden flower tea polyphenols extracted from Golden Flower Tea leaves collected at Tam Dao district, Vinh Phuc province (Vietnam). The characteristics, morphology, and polyphenol release process of alginate/chitosan/polyphenols nanoparticles will be evaluated and compared to those of polyphenols.

2. Experimental

2.1. Materials

Sodium alginate (AGN, white powder, viscosity of 300-500 mpa·s) and chitosan (CS, powder, deacetylation degree of 75–85%, molecular weight of 1.61 × 105 Da) were purchased from Sigma-Aldrich Co. (United States). Ethanol (99.7%) and acetic acid (99.5%) calcium chloride (CaCl2) (solid) were purchased from Xilong Scientific Co. (China). Sodium tripolyphosphate (STPP) (white granules, purity of 85%) was provided by Sigma-Aldrich Co. (United States).

2.2. Preparation of Polyphenol Extract Using Leaves of Golden Flower Tea

Leaves of golden flower tea were harvested in December 2019 at the Tam Dao district, Vinh Phuc province (Vietnam). The leaves were sun dried, crushed into fine powder, and marcerated in ethanol 96%, with sonication. The extract was then filtered, and ethanol was removed under reduced pressure using a rotary evaporator (Buchi R220) at 70°C. The condensed total extract was then fractionated with n-hexane 7 times to remove the impurities. The washed extract was then fractionated with ethyl acetate 7 times. Ethyl acetate fractions were then combined and condensed to obtain the polyphenol extract which was enriched up to 30.25 mg/kg (FIRI.M.277 testing method, TCVN 9745-1:2013 [16, 17]) (abbreviated as PP).

2.3. Preparation of Alginate/Chitosan/Polyphenol Nanoparticles

Alginate/chitosan/polyphenols (AGN/CS/PP) nanoparticles were prepared by ionic gelation method according to the following procedure: Firstly, 0.08 g of AGN was dissolved in 80 mL of distilled water. Then, 10 mL of CaCl2 and 20 mL of absolute ethanol containing polyphenol were dropped slowly to the AGN solution. The mixture was stirred continuously on a magnetic stirrer for 1 hour at room temperature with a speed of 400 rpm, followed by 3 times of 5 minutes ultrasonic stirring to form a homogenous solution (solution 1).

Next, 0.04 grams of chitosan was dissolved in 80 mL of 1% acetic acid solution. Then, 0.02 g of sodium tripolyphosphate (STPP) was added into the above solution. The mixture was stirred on a magnetic stirrer for 1 hour at room temperature with a speed of 400 rpm to form a homogenous solution (solution 2).

Finally, solution 2 was poured slowly into solution 1 to form the final mixture. This mixture was then continuously stirred on a magnetic stirrer for 2 hours at room temperature with a speed of 400 rpm and then cooled by ice for 2 hours. The stabilized and cooled solution was then centrifuged at a rate of 6000 rpm for 6 minutes. The supernatant was discarded, and the bottom sediment layer containing the nanoparticles was collected and freeze-dried on a FreeZone 2.5 device (Labconco, USA) to obtain the AGN/CS/PP nanoparticles.

The other nanoparticles were prepared using the same procedure as presented above, with the AGN/CS ratio was fixed at 8/4 and PP amount was varied 10, 20, 30, and 50% as compared to total weight of AGN and CS. The composition and abbreviation of AGN/CS/PP (ACP) nanoparticles were listed in Table 1.

| Weight of AG : CS : PP (g : g : g) | Ratio weight of AGN/CS/PP (%/%/%) | Abbreviation |

|---|---|---|

| 0.08 : 0.04 : 0.012 | 60.60/30.30/9.09 | ACP10 |

| 0.08 : 0.04 : 0.024 | 55.56/27.78/16.67 | ACP20 |

| 0.08 : 0.04 : 0.036 | 51.28/25.64/23.08 | ACP30 |

| 0.08 : 0.04 : 0.060 | 44.44/22.22/33.33 | ACP50 |

2.4. Characterization

2.4.1. Fourier Transform Infrared Spectroscopy (FTIR)

FTIR spectra of the ACP nanoparticles were recorded by using a Nicolet/Nexus 670 spectrometer (USA). These nanoparticles were pressed with KBr and taken IR spectra in the wavenumbers of 400 cm-1-4000 cm-1, with the resolution of 8 cm-1 and scans of 32 times.

2.4.2. Dynamic Light Scattering (DLS)

The size distribution of the ACP nanoparticles was determined on a Zetasizer Ver 620 (USA) with a range of particle size from 0.6 nm to 6 μm. The nanoparticles were dispersed in distilled water before recording size distribution diagrams.

2.4.3. Field Emission Scanning Electron Microscopy (FESEM)

The morphology of the ACP nanoparticles was taken by using the S-4800 FESEM (Hitachi, Japan) in nitrogen environment. The samples were coated with platinum to increase conducting.

2.4.4. Ultraviolet-Visible Spectroscopy (UV-Vis)

The data of standard curve and PP release content from the ACP nanoparticles were calculated basing on optical absorption recorded by UV-Vis spectrometer (Cintra 40, GBC, USA) in the wavelength range of 200 nm to 400 nm.

2.5. Polyphenol Release Study

2.5.1. Setting of Standard Curve of PP in Different pH Buffer Solutions (pH 2, pH 4.5, pH 6.8, and pH 7.4 Corresponding to Simulated Lower Stomach, Upper Stomach, Duodenum, and Intestinal Fluids, Respectively)

The standard curves of PP in different pH buffer solutions were built basing on dependence of PP concentration in solution (C) on optical absorption (A) by diluting method from a standard concentration solution. The regression coefficient and the errors of data were calculated by Student’s t test statistical analysis using Sigma Plot software 14.0.

2.5.2. Study on the In Vitro PP Release Content from AGN/CS/PP Nanoparticles in Different pH Buffer Solutions

t: time for releasing drug

Mt/M∞: the amount of drug releasing in the solution

k5: constant characterizing the drug-polymer complex

n: diffusion constant characterizing the drug releasing mechanism

Wt: the amount of drug releasing at time t

W0: the amount of drug releasing at the beginning

k1, k2, k3, k4: the constants of reaction rate

C: the drug concentration at time t

C0: the drug concentration in at the beginning.

3. Results and Discussion

3.1. IR Spectra of the AGN/CS/PP Nanoparticles

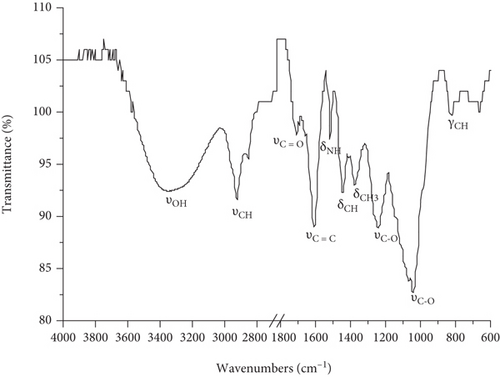

The IR spectrum of polyphenols is shown in Figure 1. The stretching vibrations of –OH, C-H, and C-O groups in polyphenols were assigned at wavenumbers of 3347 cm–1, 2924 cm–1 and 1241, 1041 cm–1, respectively. The bending vibrations of –OH and C-H groups were found at 1609 cm–1 and 1444, 1377 cm–1, respectively. The vibrations of C=C bonds can be overlapped by bending vibrations of –OH. Moreover, the peak having weak intensity at 1709 cm-1 was attributed for the vibration of C=O groups in PP [22, 23]. The peak at 1515 cm-1 can be assigned for vibration of N-H groups of substance residues in PP extract.

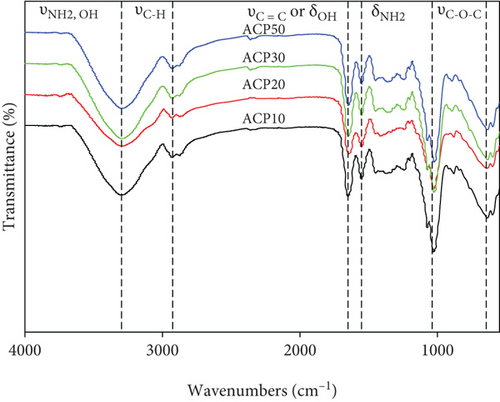

As observed in Figure 2, the vibrations of –OH, C-H, and C-O in polyphenols also appeared. In addition, the new peak at about 1554 cm-1 which was characterized for the bending vibration of N-H group in chitosan was attributed to the presence of chitosan in the nanoparticles. In general, the main functional groups in AGN are OH, C=O, and C-O and that in CS are OH, C-O, and NH while that in PP are OH, C-O, C=C, and C=O. These similar functional groups in the nanoparticles were assigned at the same region but they can be resonance to each other. Therefore, the intensity of these vibrations in the FTIR spectra of the nanoparticles is higher than that of CS or AGN or PP.

From the data of the position of some main vibrations in the IR spectra of the ACP nanoparticles in Table 2, it can be seen a slightly shift for the vibrations of the ACP nanoparticles as compared to those of the PP. This indicated that AGN, CS, and PP can interact with each other through their hydroxyl, carbonyl, and amine groups [24]. When the polyphenol content in the nanoparticles was increased, the position of characteristic vibrations for main functional groups in the nanoparticles was similar.

| Sample | Wavenumber (cm–1) | ||||

|---|---|---|---|---|---|

| Vibration | PP | ACP10 | ACP20 | ACP30 | ACP50 |

|

|

3438 | 3295 | 3293 | 3288 | 3209 |

| νCH | 2978 | 2929 | 2931 | 2927 | 2928 |

| νC=C or δOH | 1637 | 1651 | 1648 | 1649 | 1649 |

|

|

— | 1554 | 1554 | 1553 | 1554 |

| δCH | 1390 | 1455 | 1416 | 1416 | 1453, 1362 |

| νC−O−C |

|

|

|

|

|

3.2. Morphology of the AGN/CS/PP Nanoparticles

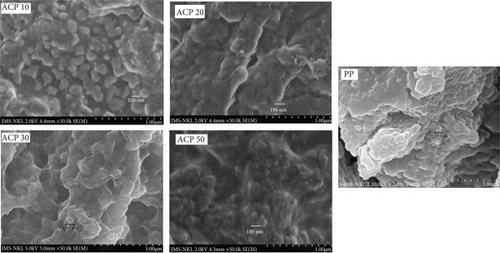

The FE-SEM images of polyphenols and the ACP nanoparticles containing different PP content are performed in Figure 3. The ACP nanoparticles have size in the range from 100 nm to 400 nm; however, they were agglomerated together to clumps leading to the difficulty in observing the shape of nanoparticles. This agglomeration can cause the interaction between polyphenols and polymer matrix [25]. Among investigated samples, the ACP10 nanoparticles were separated well, and their shape is nearly spherical. The morphology of the ACP nanoparticles in this study defers significantly with that of the tea polyphenol-loaded alginate-chitosan microspheres as reported by Wang et al. [14, 24, 26]. The tea polyphenol-loaded alginate-chitosan microspheres have a uniform porous structure with ridges. This is explained by the difference in the preparation method of the nanoparticles as well as the source of polymers and polyphenols used. The particle size of the ACP nanoparticles is one of the important parameters related to their biocompatibility and bioactivity. Besides, it also exhibits the bonding and interaction between drug and carrier in the nanoparticles [25, 27–29]. Al-Musawi et al. showed that the drug release and targeted processes to treat cancer diseases are greatly influenced by the size of the drug-carrying nanoparticles. The small size of the nanoparticles can help the drug release process to become more convenient and easier control [25]. As compared to other report, Stoica et al. confirmed that the particle size of alginate/chitosan containing natural polyphenols can be affected by the ratio of alginate/chitosan and solution pH [28].

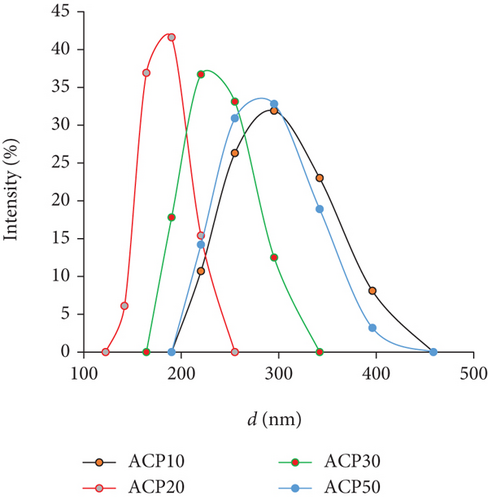

3.3. Particle Size Distribution of the AGN/CS/PP Nanoparticles

The size distribution diagrams and average particle size of the ACP nanoparticles dispersed in distilled water are indicated in Figure 4 and Table 3. The nanoparticles displayed a uniform size in the range of 141.8–396.1 nm. The peak of size distribution of ACP10, ACP20, ACP30, and ACP50 were 295.6 nm, 182.3 nm, 235.8 nm, and 284.3 nm, respectively. However, the average particle size of these samples was larger than their peak size showing that these samples were distributed in polydisperse in distilled water. Moreover, the polydispersity index (PDI) < 0.4 shows that the ACP samples have a moderate polydisperse. The average particle size and PDI of the ACP samples were similar as varying the PP contents. This suggests that the dispersibility of the ACP samples containing different PP contents in distilled water is similar. The particle size and distribution shown in Figure 4 and Table 3 are inconsistent with the SEM images in Figure 3 because for SEM analysis, the samples were in powder, while for the DLS analysis, the samples were dispersed in distilled water.

| Sample | Particle size range (nm) | Peak (nm) | Average particle size (nm) | PDI |

|---|---|---|---|---|

| ACP10 | 190.1-458.7 | 295.6 ± 24.26 | 364.2 | 0.363 |

| ACP20 | 122.4-255.0 | 182.3 ± 10.82 | 329.9 | 0.362 |

| ACP30 | 164.2-342.0 | 235.8 ± 16.00 | 358.5 | 0.363 |

| ACP50 | 190.1-458.7 | 284.3 ± 21.91 | 303.9 | 0.329 |

3.4. Study on Polyphenols Release from the AGN/CS/PP Nanoparticles

3.4.1. Calibration Equation of Polyphenols

To determine the concentration of PP released from the ACP nanoparticles, the calibration equation of PP was set-up in pH 2, pH 4.5, pH 6.8, and pH 7.4 solutions. The calibration equation and linear coefficient of regression (R2) values of polyphenol in different pH solutions are presented in Table 4. These equations all have R2 values higher than 0.99, which implied that the regression equations are suitable for evaluating the concentration of released PP in the solutions.

| Solution | λmax | Calibration equation | R2 |

|---|---|---|---|

| pH = 2 | 222 | y = 5823.3x + 0.0606 | 0.9991 |

| pH = 4.5 | 233 | y = 7640.5x + 0.0451 | 0.9991 |

| pH = 6.8 | 225 | y = 9542.5x + 0.0299 | 0.9979 |

| pH = 7.4 | 226 | y = 13716x + 0.048 | 0.9990 |

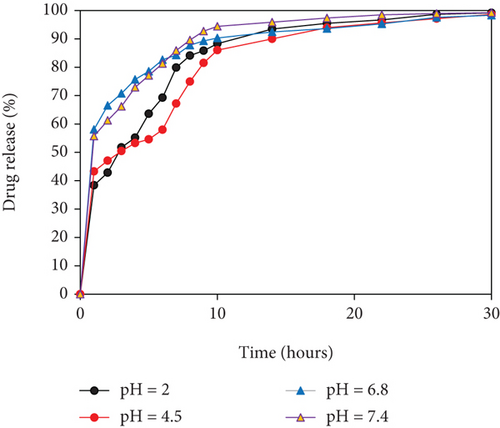

3.4.2. Effect of Time and Solution pH on the PP Release from the AGN/CS/PP Nanoparticles

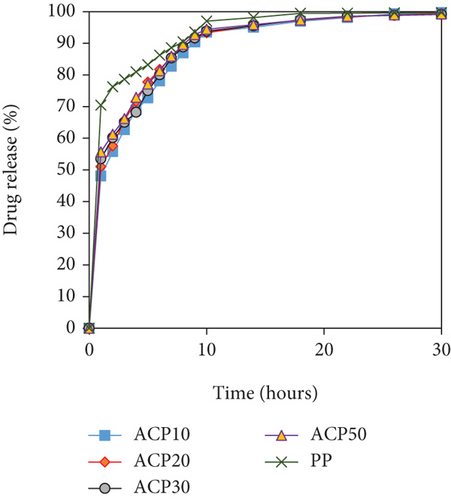

As viewing in Figure 5, it can be seen that the PP release content was increased proportionally with the testing time. The PP release from the nanoparticles was followed to two stages: fast and continuous release stage for first 10 hours of tesing and controlled and stable release stage for following hours. The fast release of PP from the nanoparticles for first 10 hours of testing were occurred due to the immediate release of PP on the surface of the nanoparticles and partly PP inside the nanoparticles through the swelling of polymer matrix and the diffusion of PP placed inside the nanoparticles through polymer matrix into the solution. This stage was mainly with over 90% of PP content released from the nanoparticles. Then, the release process became to be controlled due to the diffusion of remaining part of PP placed inside the nanoparticles into the solution. As increasing the testing time, the PP content release from the nanoparticles was increased. This indicated that the testing time has an effect on the PP release from the nanoparticles.

As also seen in Figure 5, the pH of solution has also an effect on the release of PP from the nanoparticles. For examples, to the ACP50 sample, more than 55% of PP content was released in first 1 hour in pH 7.4 solution, while it took up to 4 hours to release nearly 55% of the PP in pH 2 and pH 4.5 solutions. In the first 10 hours of testing, the PP content released from the nanoparticles was relatively uniform and reached over 90% for all samples in all tested pH solutions. For the next 20 hours of testing, the release process became controlled, slowed down, and reached approximately 100%. The release of PP from the nanoparticles in the different pH solutions was in the order pH 6.8 ≈ pH 7.4 > pH 4.5 ≈ pH 2. These results are almost similar to the release of some drugs from the chitosan systems [30–32]. In the acidic environment, the protonization of amine groups in chitosan can limit the diffusion of PP into the solution; therefore, the PP content released from the nanoparticles in the acidic environment is lower than that in the neutral environment.

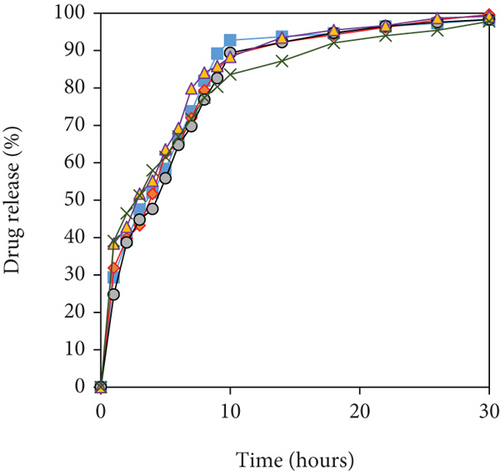

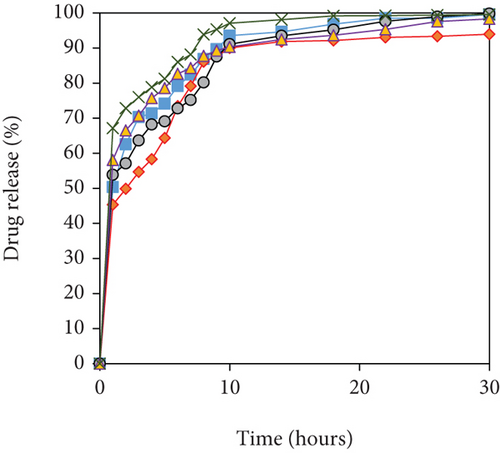

3.4.3. Effect of Initial Polyphenol Content on PP Release from the AGN/CS/PP Nanoparticles

The influence of initial PP content on the PP release from the ACP nanoparticles was also evaluated. As shown in Figure 6, the PP release content from the nanoparticles is lower than that from free PP at the same investigated condition. This is due to the PP release from free PP is not affected by interactions between PP and polymers [33–35]. In the fast stage, the nanoparticles containing a lower PP content exhibited a slower release rate because of the difference in particle size of the nanoparticles [33]. From the obtained results, the ACP10 and ACP20 samples are suitable for the requirements of long-acting drug delivery because these nanoparticles could remain in the stomach for 1 to 3 hours before they are transported to the small and large intestine. Therefore, the ACP nanoparticles are potential candidates for further studies and applications on drug formulation [34].

3.4.4. Kinetics of PP Release from the AGN/CS/PP Nanoparticles

Kinetic equations including zero-order kinetic (ZO), first-order kinetic (FO), Higuchi model (HG), Hixson-Crowell model (HCW), and Korsmeyer-Peppas (KMP) models have been used to investigate the mechanism of PP released from the ACP nanoparticles in the solutions of pH 2, 4.5, 6.8, and 7.4. The R-square (R2), p value, and loss functions including sum of squared error (SSE) and mean squared error (MSE) were applied to determine the most suitable kinetic model which can represent the PP release mechanism from free PP and the ACP nanoparticles.

The parameters of the kinetic models reflecting the PP release from free PP and the nanoparticles in the fast release stage were displayed in Table 5. The p values < 0.05 show that there is a statistically significant difference between groups. In all tested pH solutions, the R2 of kinetic models reflecting the PP release process from free PP was lower than that from the nanoparticles. From the R2 values, it was inferred that PP release from the free PP and the nanoparticles in different pH solutions was followed different kinetic models with high coefficient of regression. The R2 of the kinetic models is similar; therefore, combined with SSE and MSE, it can be suggested that the Hixson-Crowell model was the most suitable for PP release process from the nanoparticles. The PP release mechanism was complex and combined by different processes including to swelling, dissolution, diffusion, and protonation. However, the PP released from the nanoparticles by dissolution process with the changes in surface area and diameter of the particles was mainly.

| Sample | Zero order kinetic | First order kinetic | Higuchi model | Hixson - Crowell model | Korsmeyer-Peppas model | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | SSE | MSE | p | R2 | SSE | MSE | p | R2 | SSE | MSE | p | R2 | SSE | MSE | p | R2 | SSE | MSE | p | n | |

| pH 2 | |||||||||||||||||||||

| PP | 0.988 | 607.305 | 67.478 | <0.001 | 0.980 | 0.165 | 2.10-3 | <0.001 | 0.986 | 4.518 | 0.502 | <0.001 | 0.994 | 8.10-4 | 9.10-5 | <0.001 | 0.980 | 0.017 | 2.10-3 | <0.001 | 0.014 |

| PP10 | 0.996 | 4133.539 | 459.282 | <0.001 | 0.960 | 0.238 | 0.026 | <0.001 | 0.982 | 4.518 | 0.502 | <0.001 | 0.978 | 2.10-3 | 3.10-4 | <0.001 | 0.996 | 0.309 | 0.034 | <0.001 | 0.061 |

| PP20 | 0.992 | 3508.085 | 389.787 | <0.001 | 0.963 | 0.205 | 0.023 | <0.001 | 0.980 | 4.518 | 0.502 | <0.001 | 0.976 | 3.10-3 | 3.10-4 | <0.001 | 0.963 | 0.205 | 0.023 | <0.001 | 0.049 |

| PP30 | 0.990 | 3873.501 | 430.389 | <0.001 | 0.930 | 0.267 | 0.030 | <0.001 | 0.984 | 4.518 | 0.502 | <0.001 | 0.959 | 4.10-3 | 5.10-4 | <0.001 | 0.930 | 0.267 | 0.030 | <0.001 | 0.055 |

| PP50 | 0.978 | 3047.075 | 338.564 | <0.001 | 0.958 | 0.152 | 0.017 | <0.001 | 0.975 | 4.518 | 0.502 | <0.001 | 0.967 | 4.10-3 | 4.10-4 | <0.001 | 0.958 | 0.152 | 0.017 | <0.001 | 0.042 |

| pH 4.5 | |||||||||||||||||||||

| PP | 0.988 | 923.835 | 102.648 | <0.001 | 0.981 | 0.026 | 3.10-3 | <0.001 | 0.983 | 4.518 | 0.502 | <0.001 | 0.984 | 1.10-3 | 1.10-4 | <0.001 | 0.981 | 0.026 | 0.003 | <0.001 | 0.018 |

| PP10 | 0.994 | 2884.072 | 320.352 | <0.001 | 0.976 | 0.135 | 0.015 | <0.001 | 0.977 | 4.518 | 0.502 | <0.001 | 0.986 | 1.10-3 | 1.10-4 | <0.001 | 0.981 | 0.194 | 0.022 | <0.001 | 0.048 |

| PP20 | 0.977 | 3000.095 | 333.334 | <0.001 | 0.993 | 0.168 | 0.019 | <0.001 | 0.923 | 4.518 | 0.502 | <0.001 | 0.991 | 2.10-3 | 2.10-4 | <0.001 | 0.995 | 0.227 | 0.025 | <0.001 | 0.052 |

| PP30 | 0.994 | 3696.342 | 410.705 | <0.001 | 0.970 | 0.213 | 0.024 | <0.001 | 0.977 | 4.518 | 0.502 | <0.001 | 0.982 | 3.10-3 | 4.10-4 | <0.001 | 0.975 | 0.280 | 0.031 | <0.001 | 0.058 |

| PP50 | 0.951 | 2005.854 | 222.873 | <0.001 | 0.976 | 0.091 | 0.011 | <0.001 | 0.883 | 4.518 | 0.502 | <0.001 | 0.969 | 2.10-3 | 3.10-4 | <0.001 | 0.990 | 0.144 | 0.016 | <0.001 | 0.042 |

| pH 6.8 | |||||||||||||||||||||

| PP | 0.969 | 1256.285 | 139.587 | <0.001 | 0.940 | 0.047 | 0.005 | <0.001 | 0.995 | 4.518 | 0.502 | <0.001 | 0.951 | 2.10-3 | 2.10-4 | <0.001 | 0.940 | 0.047 | 0.005 | <0.001 | 0.023 |

| PP10 | 0.951 | 1558.834 | 173.204 | <0.001 | 0.903 | 0.059 | 0.007 | <0.001 | 0.981 | 4.518 | 0.502 | <0.001 | 0.921 | 6.10-4 | 7.10-5 | <0.001 | 0.942 | 0.106 | 0.012 | <0.001 | 0.035 |

| PP20 | 0.983 | 2470.368 | 274.485 | <0.001 | 0.977 | 0.106 | 0.012 | <0.001 | 0.963 | 4.518 | 0.502 | <0.001 | 0.980 | 2.10-3 | 2.10-4 | <0.001 | 0.985 | 0.160 | 0.018 | <0.001 | 0.044 |

| PP30 | 0.981 | 1330.367 | 147.819 | <0.001 | 0.980 | 0.050 | 0.006 | <0.001 | 0.955 | 4.518 | 0.502 | <0.001 | 0.982 | 1.10-3 | 1.10-4 | <0.001 | 0.989 | 0.093 | 0.010 | <0.001 | 0.033 |

| PP50 | 0.946 | 1022.319 | 113.591 | <0.001 | 0.914 | 0.035 | 0.004 | <0.001 | 0.991 | 4.518 | 0.502 | <0.001 | 0.926 | 1.10-4 | 1.10-4 | <0.001 | 0.914 | 0.035 | 0.004 | <0.001 | 0.020 |

| pH 7.4 | |||||||||||||||||||||

| PP | 0.991 | 2032.912 | 225.879 | <0.001 | 0.963 | 0.108 | 0.012 | <0.001 | 0.993 | 4.518 | 0.502 | <0.001 | 0.975 | 5.10-3 | 6.10-4 | <0.001 | 0.963 | 0.108 | 0.012 | <0.001 | 0.035 |

| PP10 | 0.983 | 2068.180 | 229.798 | <0.001 | 0.951 | 0.081 | 0.009 | <0.001 | 0.999 | 4.518 | 0.502 | <0.001 | 0.963 | 9.10-4 | 1.10-4 | <0.001 | 0.966 | 0.134 | 0.015 | <0.001 | 0.040 |

| PP20 | 0.959 | 1920.721 | 213.413 | <0.001 | 0.924 | 0.072 | 0.008 | <0.001 | 0.993 | 4.518 | 0.502 | <0.001 | 0.937 | 1.10-3 | 1.10-4 | <0.001 | 0.953 | 0.123 | 0.014 | <0.001 | 0.038 |

| PP30 | 0.986 | 1770.371 | 196.708 | <0.001 | 0.968 | 0.063 | 0.007 | <0.001 | 0.989 | 4.518 | 0.502 | <0.001 | 0.975 | 1.10-3 | 2.10-4 | <0.001 | 0.979 | 0.111 | 0.012 | <0.001 | 0.036 |

| PP50 | 0.984 | 1636.824 | 181.896 | <0.001 | 0.963 | 0.056 | 0.006 | <0.001 | 0.995 | 4.518 | 0.502 | <0.001 | 0.971 | 1.10-3 | 2.10-4 | <0.001 | 0.977 | 0.103 | 0.011 | <0.001 | 0.034 |

Similarly, the kinetics of PP controlled release process from free PP and the nanoparticles in the second stage (after 10 hours) were evaluated. The parameters of the kinetic equations reflecting the slow release stage of PP from free PP and the nanoparticles at different pH solutions are presented in Table 6. From R2, SSE, and MSE values, it can be seen that the release process of PP from the nanoparticles in the second stage was complied with the Korsmeyer-Peppas model. For two stages, the diffusion constant (n) values <0.5 showing that the release of PP followed Fick’s first law of diffusion [13, 36].

| Sample | Zero-order kinetic | First-order kinetic | Higuchi model | Hixson-Crowell model | Korsmeyer-Peppas model | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | SSE | MSE | p | R2 | SSE | MSE | p | R2 | SSE | MSE | p | R2 | SSE | MSE | p | R2 | SSE | MSE | p | n | |

| pH 2 | |||||||||||||||||||||

| PP | 0.630 | 1.734 | 0.434 | 0.109 | 0.629 | 3.10-4 | 8.10-6 | 0.109 | 0.676 | 1.897 | 0.470 | 0.088 | 0.615 | 2.10-6 | 5.10-7 | 0.109 | 0.629 | 3.10-5 | 8.10-6 | 0.109 | 0.001 |

| PP10 | 0.983 | 14.124 | 3.531 | <0.001 | 0.982 | 3.10-4 | 7.10-5 | 0.001 | 0.986 | 1.879 | 0.470 | <0.001 | 0.982 | 4.10-6 | 1.10-6 | 0.001 | 0.998 | 2.10-3 | 5.10-4 | <0.001 | 0.004 |

| PP20 | 0.997 | 35.463 | 8.866 | <0.001 | 0.996 | 7.10-4 | 2.10-4 | <0.001 | 0.999 | 1.879 | 0.470 | <0.001 | 0.997 | 2.10-5 | 4.10-6 | <0.001 | 0.996 | 7.10-4 | 2.10-4 | <0.001 | 0.002 |

| PP30 | 0.944 | 23.809 | 5.952 | 0.006 | 0.940 | 5.10-4 | 1.10-4 | 0.006 | 0.967 | 1.879 | 0.470 | 0.003 | 0.942 | 1.10-5 | 4.10-6 | 0.006 | 0.940 | 4.10-4 | 1.10-4 | <0.001 | 0.002 |

| PP50 | 0.972 | 21.856 | 5.464 | 0.002 | 0.971 | 4.10-4 | 1.10-4 | 0.002 | 0.983 | 1.879 | 0.470 | <0.001 | 0.971 | 1.10-5 | 4.10-6 | 0.002 | 0.971 | 4.10-4 | 1.10-4 | 0.002 | 0.002 |

| pH 4.5 | |||||||||||||||||||||

| PP | 0.744 | 1.340 | 0.335 | 0.060 | 0.742 | 3.10-5 | 6.10-6 | 0.060 | 0.784 | 1.879 | 0.470 | 0.046 | 0.743 | 2.10-6 | 4.10-7 | 0.060 | 0.742 | 3.10-5 | 6.10-6 | 0.060 | 0.001 |

| PP10 | 0.994 | 25.378 | 6.344 | <0.001 | 0.994 | 5.10-4 | 1.10-4 | <0.001 | 0.995 | 1.879 | 0.470 | <0.001 | 0.994 | 7.10-6 | 2.10-6 | <0.001 | 0.999 | 3.10-3 | 6.10-4 | <0.001 | 0.004 |

| PP20 | 0.875 | 47.403 | 11.851 | 0.019 | 0.869 | 1.10-4 | 2.10-4 | 0.021 | 0.910 | 1.879 | 0.470 | 0.012 | 0.871 | 2.10-5 | 5.10-6 | 0.021 | 0.971 | 4.10-3 | 8.10-4 | 0.002 | 0.005 |

| PP30 | 0.993 | 11.343 | 2.836 | <0.001 | 0.993 | 2.10-4 | 6.10-5 | <0.001 | 0.991 | 1.879 | 0.470 | <0.001 | 0.993 | 6.10-6 | 2.10-6 | <0.001 | 0.999 | 2.10-3 | 5.10-4 | <0.001 | 0.004 |

| PP50 | 0.946 | 44.543 | 11.136 | 0.005 | 0.939 | 9.10-4 | 2.10-4 | 0.006 | 0.966 | 1.879 | 0.470 | 0.003 | 0.942 | 3.10-5 | 8.10-6 | 0.006 | 0.986 | 3.10-3 | 8.10-4 | <0.001 | 0.005 |

| pH 6.8 | |||||||||||||||||||||

| PP | 0.971 | 24.392 | 6.098 | 0.002 | 0.969 | 5.10-4 | 1.10-4 | 0.002 | 0.985 | 1.879 | 0.470 | <0.001 | 0.970 | 3.10-5 | 7.10-6 | 0.002 | 0.969 | 5.10-4 | 1.10-4 | 0.002 | 0.002 |

| PP10 | 0.949 | 14.032 | 3.508 | 0.005 | 0.947 | 3.10-4 | 7.10-5 | 0.005 | 0.970 | 1.879 | 0.470 | 0.002 | 0.948 | 4.10-6 | 9.10-7 | 0.005 | 0.994 | 2.10-3 | 5.10-4 | <0.001 | 0.004 |

| PP20 | 0.931 | 9.182 | 2.296 | 0.008 | 0.928 | 2.10-4 | 5.10-5 | 0.008 | 0.956 | 1.879 | 0.470 | 0.004 | 0.929 | 4.10-6 | 9.10-7 | 0.008 | 0.994 | 2.10-3 | 4.10-4 | <0.001 | 0.003 |

| PP30 | 0.853 | 8.749 | 2.187 | 0.025 | 0.850 | 2.10-4 | 4.10-5 | 0.026 | 0.890 | 1.879 | 0.470 | 0.016 | 0.851 | 5.10-6 | 1.10-6 | 0.026 | 0.989 | 2.10-3 | 4.10-4 | <0.001 | 0.004 |

| PP50 | 0.910 | 7.549 | 1.887 | 0.012 | 0.908 | 2.10-4 | 4.10-5 | 0.012 | 0.939 | 1.879 | 0.470 | 0.007 | 0.908 | 5.10-6 | 1.10-6 | 0.012 | 0.993 | 2.10-3 | 4.10-4 | <0.001 | 0.004 |

| pH 7.4 | |||||||||||||||||||||

| PP | 0.942 | 63.907 | 15.977 | 0.006 | 0.934 | 1.10-3 | 3.10-4 | 0.007 | 0.961 | 1.879 | 0.470 | 0.003 | 0.937 | 9.10-5 | 2.10-5 | 0.007 | 0.934 | 1.10-3 | 3.10-4 | 0.007 | 0.003 |

| PP10 | 0.896 | 15.046 | 3.762 | 0.015 | 0.893 | 3.10-4 | 8.10-5 | 0.015 | 0.923 | 1.879 | 0.470 | 0.009 | 0.894 | 4.10-6 | 1.10-6 | 0.015 | 0.988 | 2.10-3 | 5.10-4 | <0.001 | 0.040 |

| PP20 | 0.976 | 3.028 | 0.757 | 0.002 | 0.976 | 6.10-5 | 2.10-5 | 0.002 | 0.972 | 1.879 | 0.470 | 0.002 | 0.976 | 1.10-6 | 4.10-7 | 0.002 | 0.999 | 1.10-3 | 4.10-4 | <0.001 | 0.038 |

| PP30 | 0.972 | 27.474 | 6.868 | 0.002 | 0.970 | 6.10-4 | 2.10-4 | 0.002 | 0.984 | 1.879 | 0.470 | <0.001 | 0.970 | 1.10-5 | 3.10-6 | 0.002 | 0.995 | 3.10-3 | 6.10-4 | <0.001 | 0.036 |

| PP50 | 0.981 | 25.055 | 6.264 | 0.001 | 0.982 | 6.10-4 | 1.10-4 | 0.001 | 0.979 | 1.879 | 0.470 | 0.001 | 0.982 | 2.10-5 | 4.10-6 | 0.001 | 0.982 | 5.10-4 | 1.10-4 | 0.001 | 0.034 |

4. Conclusion

In this study, the polyphenols were extracted from the leaves of golden flower tea (Camellia chrysantha) collected in Tam Dao district, Vinh Phuc province (Vietnam). The extract was enriched and had a total polyphenol content of 30.25 mg/kg. This extract was used as a drug model for alginate/chitosan system. The alginate/chitosan/polyphenols (AGN/CS/PP) nanoparticles were prepared by ionic gelation method with different content of PP. The nanoparticles were agglomerated with the basic size of 100-400 nm. As increasing the PP content, the nanoparticles tend to agglomerate together. There are physical interactions (hydrogen bonding and dipole-dipole interaction) between PP and the polymers. PP release process from free PP and the nanoparticles in different pH solutions occurred in two stages. Initially, the fast release process occurred during the first 10 hours of testing, followed by the controlled release process in the next 20 hours. Some factors such as pH of solution, testing time, and initial polyphenol content significantly affected to the PP release process from free PP and the nanoparticles into solutions. The fast release process of PP followed the Hixson-Crowell model while the controlled release process complied with the Korsmeyer-Peppas model.

Conflicts of Interest

There are no conflicts to declare.

Acknowledgments

This research is funded by Vietnam Academy of Science and Technology under grant number DLTE00.04/20-21, period of 2020–2021.

Open Research

Data Availability

The data used to support the findings of this study are included within the article.