Silver-Nanoparticle-Based Screen-Printing and Film Characterization of a Disposable, Dual-Band, Bandstop Filter on a Flexible Polyethylene Terephthalate Substrate

Abstract

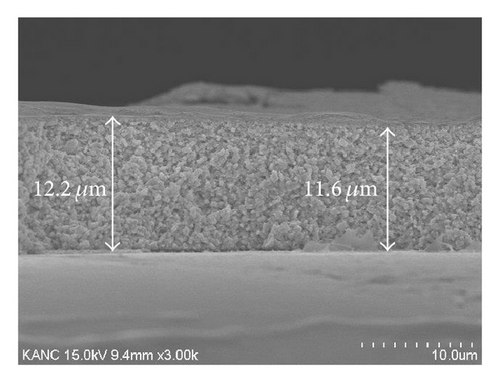

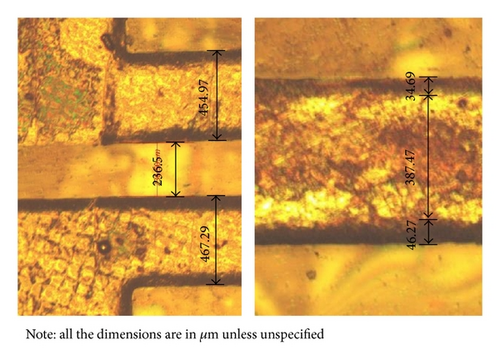

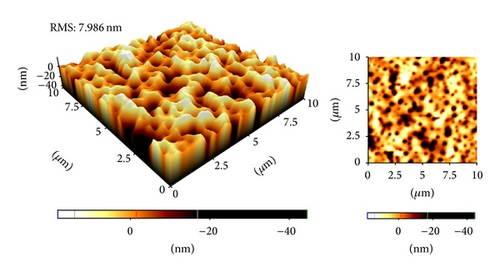

This paper presents a silver-nanoparticle-based, screen-printed, high-performance, dual-band, bandstop filter (DBBSF) on a flexible polyethylene terephthalate (PET) substrate. Using screen-printing techniques to process a highly viscous silver printing ink, high-conductivity printed lines were implemented at a web transfer speed of 5 m/min. Characterized by X-ray diffraction (XRD), optical microscopy, atomic force microscopy (AFM), and scanning electron microscopy (SEM), the printed lines were shown to be characterized by smooth surfaces with a root mean square roughness of 7.986 nm; a significantly higher thickness (12.2 μm) than the skin depth; and a high conductivity of 2 × 107 S/m. These excellent printed line characteristics enabled the implementation of a high-selectivity DBBSF using shunt-connected uniform impedance resonators (UIRs). Additionally, the inductive loading effect of T-shaped stubs on the UIRs, which were analyzed using S-parameters based on lumped parameter calculations, was used to improve the return losses of the geometrically optimized DBBSF. The measured minimum return loss and maximum insertion loss of 28.26 and 1.58 dB, respectively, at the central frequencies of 2.56 and 5.29 GHz of a protocol screen-printed DBBSF demonstrated the excellent performance of the material and its significant potential for use in future cost-effective, flexible WiMax and WLAN applications.

1. Introduction

Screen-printing, which is also widely known as thick-film printing, is a promising candidate for creating high demand, environmentally friendly, light-weight, and cost-effective electronic products at low cost, high throughput, and high reproducibility [1–3]. Due to its numerous advantages, such as its high processing speed, high throughput, and high reproducibility, as well as its capacity to process highly viscous printing ink, this technique has been used in a diverse range of applications, including printed energy sources, diodes, resistors, sensors, microwave antennas, and filters [4, 5]. Its capacity to work with several cheap substrates, such as paper, plastics, and glass, makes it suitable for creating light-weight, flexible, transparent, and disposable products [6, 7]. However, using these substrates dictates low working temperatures; to meet this requirement, conductive inks with metal micro-/nanoparticles have been widely researched and have been shown to be promising, because the increase in the ratio of surface area to volume with the reduction of the particles in volume significantly lowers the melting point of the particles compared with that of bulk materials [8]. As a consequence, several nanoparticles of noble metals, such as gold (Au), silver (Ag), platinum (Pt), palladium (Pd), or combinations of these metals, have been extensively investigated for the preparation of conductive pastes. However, Ag-particles-based ink is most widely used to manufacture conductive patterns in electronic devices due to its high stability in air and its high-conductivity [8, 9].

Currently, screen-printing-based implementations of radio-frequency, printed antennas and filters that are compact and highly selective are being investigated in many studies [10]. Various aspects such as the viscosity and surface tension of printing ink and the selection of an appropriate substrate and optimization of printing and sintering processes must be considered to successfully create a high-performance radio-frequency component. Kao et al. presented a silver-nanoparticle-colloidal-solution-based, inkjet-printed, radio-frequency bandpass filter on a liquid crystal polymer (LCP) substrate. Increasing the printed line conductivity and optimization of the line thickness with a uniform width were primarily considered to improve the performance of the filters. A hairpin bandpass filter [11], an interdigital coupled-line-based bandpass filter [12], and a third-order, dual-behavior resonator (DBR) bandpass filter [13] were inkjet-printed onto an LCP substrate. However, the large insertion losses indicated by the measurement results, which degraded the selective performance of the filters, were most likely caused by an insufficient conductivity of the printed lines. Therefore, increasing the conductivity of the printed lines to create a high-performance microwave filter is still an ongoing challenge.

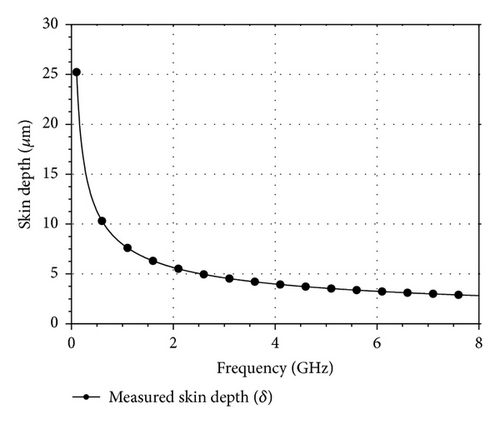

In this study, we propose using Ag-nanoparticle-based screen-printing technique to create a high-performance, dual-band bandstop filter (DBBSF) on a flexible PET substrate. High-conductivity printed lines to obtain high return and low insertion losses that are indicative of excellent in-band and out-of-band selectivity were the primary objectives of this study. The Ag-nanoparticle-based ink used in this study was formulated to have a high viscosity that was suitable for screen-printing of high-conductivity, uniform filter lines with smooth surfaces. Screen-printed Ag line characterization, which was performed by optical microscopy, scanning electron microscopy (SEM), and atomic force microscopy (AFM), indicated that the printed lines exhibited uniform widths with a thickness (e.g., 12.2 μm) significantly larger than the skin depth (δ) over nearly the entire operating frequency band; these analyses also showed that the lines had smooth surfaces with root mean square (RMS) value of roughness equal to 7.986 nm and a high-conductivity of 2 × 107 S/m. All of these excellent line characteristics allowed the creation of high-performance DBBSF with excellent selectivity and design flexibility based on stub-loaded, shunt-connected, uniform-impedance resonators (UIRs). A measured minimum return loss of 28.26 dB and a maximum insertion loss of 1.58 dB in the stop bands demonstrated the excellent selectivity of a protocol DBBSF operating at central frequencies of 2.56 and 5.29 GHz; and, therefore, the proposed process is a suitable candidate for use in low-cost WiMax and WLAN applications.

2. Methods and Materials

2.1. Layout Design, Simulation, and Screen-Printing

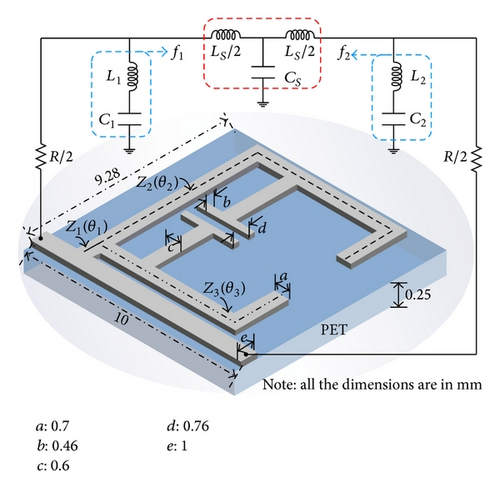

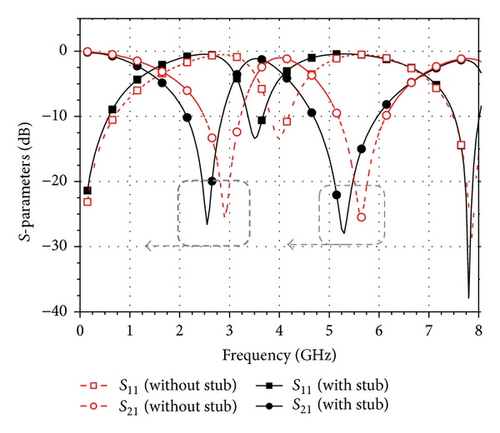

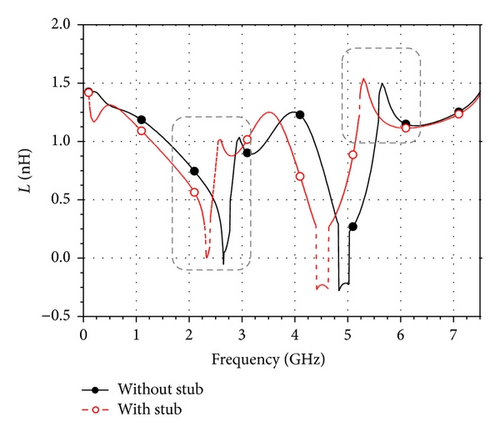

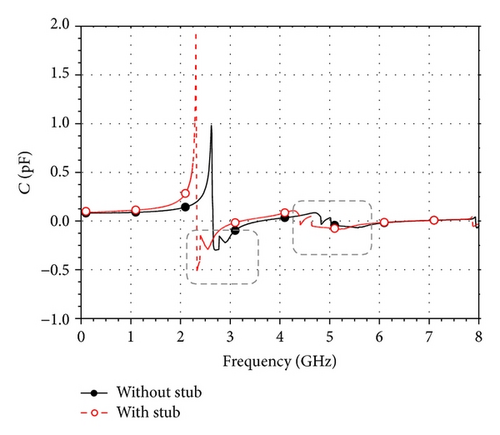

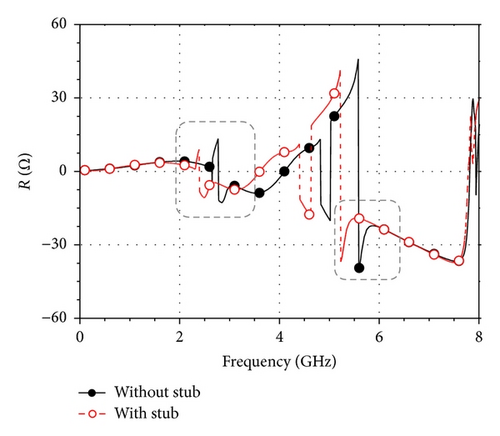

The use of stub-loads resulted in DBBSF with central frequencies of 2.55 and 5.3 GHz, each of which was shifted downward by 0.35 GHz with respect to the resonant frequencies of the UIRs. To evaluate the effect of the T-shaped stub-load on the central frequencies and return loss, the net lumped element parameters for a propagation distance of 10 mm were calculated from the simulated S-parameters for UIRs and DBBSF [17]. The calculated net lumped parameters, which are displayed in Figure 2, indicated that the use of stub-loads resulted in a significant increase in the net lumped inductance from 0.896 to 0.995 nH and 1.183 to 1.501 nH at the central frequencies of 2.9 and 5.65 GHz, respectively, as shown in Figure 2(b). Similarly, the net lumped capacitance increased from 0.055 to 0.224 pF and 0.034 to 0.061 pF at 2.9 and 5.65 GHz, respectively, as shown in Figure 2(c). Therefore, the increase in net lumped inductance and capacitance shifted the central frequencies (f = 1/2π(LC)1/2) downward and noticeably increased the return losses. Additionally, Figure 2(d) shows that the net lumped resistance exhibited peak values, whose magnitude and frequency decreased and shifted downward, respectively, due to use of the stub-loads.

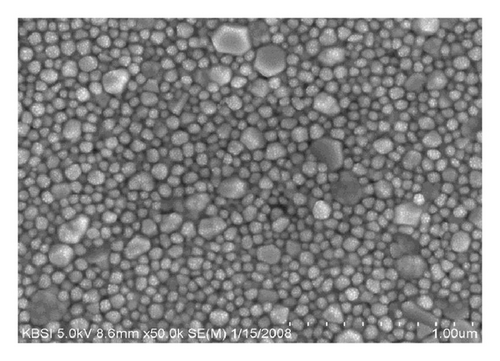

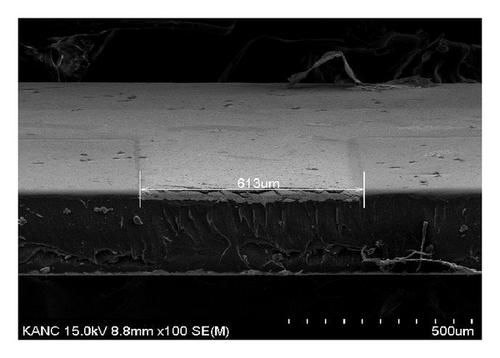

SM-S320 model Sun Mechanix screen printer system, as shown in Figure 3(a), with 250-mesh screen was used to print the Ag conductive lines onto a roll of polyethylene terephthalate (PET) film, which has a width of 200 mm and a thickness of 250 μm and was purchased from SKC Korea. The PET substrate is suitable for screen-printing due to its excellent flexibility and durability. Ag-nanoparticle-based conducting ink (PG-007 BB type, Paru Co., Korea) was used during printing. Because this ink contained 62 wt% of silver nanoparticles that were 20 to 200 nm in diameter, as shown in the SEM image displayed in Figure 2(b), the viscosity and surface tension of the silver inks required tuning through a simple ink formulation process. We first formulated the conductive inks to meet the wetting requirements on the PET substrate; then, we adjusted the viscosities by raising the silver-nanoparticle content to 75 wt%. The viscosity of the formulated ink was evaluated using a viscometer (SV-10 Vibro Viscometer, A&D Co., Japan). Additionally, the surface tension was measured using DCAT 21 (Dataphysics Co., Germany). Ethylene glycol (Aldrich) was used to formulate the Ag ink to achieve a viscosity of 15,000 cp and a surface tension of 47 mN/m. The ethylene glycol stabilized the metal nanoparticles using its ether group, which contains unshared electron pair, to allow the stable use of high concentrations of metal nanoparticles and to increase the viscosity of the solution. A higher viscosity in the printing ink is preferred to obtain a lower resistivity in the printed conductive films with optimized widths. The web transfer speed was set to 5 m/min under a roll pressure of 2.5 MPa. The printed silver layer was cured for 10 min by passing through an oven of 150°C without additional treatments. To make the back coating a ground conductive layer, we used same ink.

3. Results and Discussions

3.1. Characterization of the Printed Ag Lines

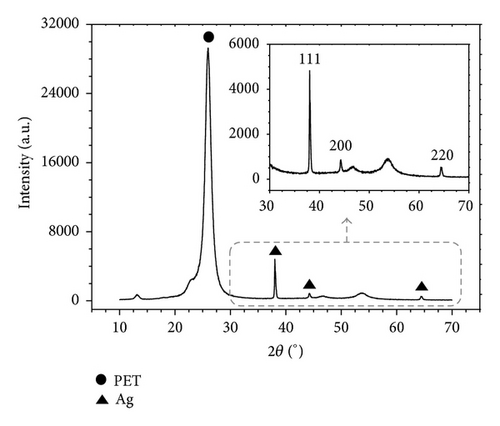

Ag-nanoparticle-based, screen-printed conductive films on PET substrates were characterized by XRD to study their crystallinity and structural characteristics. The XRD pattern, which is shown in Figure 4(a), shows a high intensity peak corresponding to the PET substrate at 2θ angle of 38.1°; this agrees with that reported in the literature [18, 19]. The presence of peaks at the 2θ values of 38.4°, 44.09°, and 64.36° corresponds to the (111), (200), and (220) planes of silver, respectively. Thus, the XRD spectrum confirmed the crystalline structure of the silver nanoparticles. No peaks of other impurity crystalline phases were detected, and all peaks in the XRD pattern can be readily indexed to the face-centered cubic structure of silver as per available literature (JCPDS, file number 4-0783).

3.2. Measurement Results of the Printed DBBSF

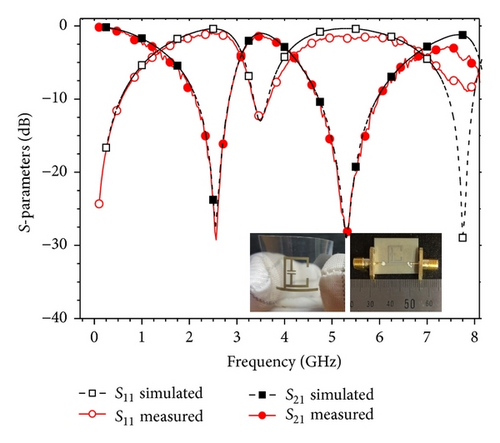

The screen-printed DBBSF, whose photographs in both normal and bent position are shown in Figure 6, was connected with port connectors using Ag paste to perform electrical measurements. The central frequencies of the fabricated DBBSF that were tested and characterized using Agilent 8510C vector network analyzer (VNA) were 2.55 and 5.3 GHz, each of which was shifted upward by 10 MHz with respect to the simulation results. This shift in frequency may be attributed to the slight difference between fabricated conductive line dimensions compared with the theoretical dimensions; the dielectric loss of the PET substrate; and the dispersion loss at the bends of the UIRs. The return and insertion losses of the first and second stop band were measured to be 27.4 and 28.9 dB and 1.17 and 1.58 dB, respectively. The measured maximum insertion loss and minimum return loss of 0.68 and 14.5 dB, respectively, for all of the pass bands between the stop bands indicated the excellent out-of-band selectivity of the fabricated DBBSF. The 3-dB fractional bandwidths of the first and second stop bands were measured to be 1.8 and 3.09 GHz, respectively.

Table 1, which displays the comparison of the performance of the proposed Ag-nanoparticle-based screen-printed bandstop filter with recently reported several inkjet-printed bandpass filters, indicates that our printed filter exhibits significantly lower insertion losses because of its geometrical structure and relatively higher conductivity printed Ag lines. Additionally, the present DBBSF exhibits higher number of operation bands with large return losses. Moreover, the proposed DBBSF has a compact size of 92.8 mm2.

| S. number | State-of-the-art in printed microwave filters | fc (GHz) [IL (dB)/RL (dB)] |

Film conductivity (σ) (Siemens/m) |

|---|---|---|---|

| This work | T-shaped stub-loaded UIRs based DBBSF using Ag-nanoparticle-based screen-printing on PET substrate |

|

2 × 107 |

| Reference [11] | Hairpin bandpass filter using Ag-nanoparticle-based inkjet-printing on liquid crystal polymer (LCP) substrate | 30 [2.41/18.9] | 2 × 107 |

| Reference [12] | Interdigital coupled line based bandpass filter using Ag-nanoparticle-based inkjet-printing LCP substrate | 25.7 [3.7/24] | 1 × 107 |

| Reference [13] | DBR bandpass filter using Ag-nanoparticle-based inkjet-printing on LCP substrate | 5.4 [2.18/27.8] | 4 × 106 |

| Reference [25] | Suspended microstrip lines based bandpass filter using Ag-nanoparticle-based inkjet-printing on dupont kapton HN polyimide substrate | 17 [3.6/40] | 1.5 × 107 |

- S. number = serial number; fc = central frequency; IL = insertion loss; RL = return loss.

4. Conclusion

In this study, we created an environmentally friendly, high-performance DBBSF based on shunt-connected, T-shaped stub-loaded UIRs. The proposed DBBSF was screen-printed on a low weight, cost-effective PET substrate via screen-printing. Highly conductive (σ = 2 × 107 S/m) lines with favorable characteristics such as uniformity and smooth surfaces were successfully printed using highly viscous Ag conductive paste. The agreement of the simulated and measured results of DBBSF with a compact size of 10 × 9.28 mm2, measured central frequencies of 2.56 and 5.29 GHz, and excellent in-band and out-of-band selectivity indicated that silver-nanoparticle-based screen-printing can be used to successfully fabricate high-performance microwave filters.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Acknowledgments

This research was supported by the Basic Science Research Program through the National Research Foundation (NRF) of Korea funded by the Ministry of Science, ICT and Future Planning (no. 2011-0030079) and a grant support from the Korean government (MEST) no. 2012R1A1A2004366. This work was also supported by a Research Grant of Kwangwoon University in 2015. The authors also appreciate the financial support provided by the Ministry of Education of Korea through the Basic Science Research Program at Sunchon National University and by the Global Leading Technology Program of the Office of Strategic R&D Planning (OSP) through the Ministry of Commerce, Industry and Energy, Republic of Korea (10042537, Printed Electronics Total Solution Development).