Solution of Turbine Blade Cascade Flow Using an Improved Panel Method

Abstract

An improved panel method has been developed to calculate compressible inviscid flow through a turbine blade row. The method is a combination of the panel method for infinite cascade, a deviation angle model, and a compressibility correction. The resulting solution provides a fast flexible mesh-free calculation for cascade flow. A VKI turbine blade cascade is used to evaluate the method, and the comparison with experiment data is presented.

1. Introduction

The design of modern aeroengine gas turbine adopts various numerical methods to increase design efficiency. At the preliminary design stage, the major work for numerical method is repetitive calculations of flow fields over a wide range of blade geometries. This task has been dominated by field methods such as finite differential methods and finite element methods with the advent of computers. However, the use of these field methods requires an experienced user to generate a body-fitted mesh, which is labor intensive. On the other hand, panel method only requires boundary meshes that are one dimension lower than the flow field, reducing the work and difficulty for mesh generation enormously. This method is based on boundary integral equation: it formulated the flow about arbitrary configurations as integration of analytic solutions of singularity distribution over boundary surface [1]. It was initially developed for incompressible potential flow [2]. Soon, the implement of linearised potential equation endowed the method with the capability of solving subsonic and supersonic external flow [3]. Various panel methods were developed using different kind of singularities and higher order panel elements since then eventually evolved into series of computer codes commonly in industrial use [4–7].

The main drawback of the panel method is the limitation of its application to linear potential flow. To be specific, the flow should either be incompressible or possess a sole free stream as linearization reference. But modern aeroengine gas turbines generally work at high subsonic/transonic condition and adopt blades with large deflection, implying that (1) the incompressible assumption is not applicable and (2) the free streams upstream and downstream of the blades are quite different. There are two schemes to overcome this restriction: the field panel method that uses a field mesh to account for nonlinear effects [8] or the correction correlations that transform the incompressible solution to compressible solution. Since the aim of this paper is to develop a mesh-free method, the correction correlations are chosen as the scheme to be used.

There are several forms of corrections based on free stream Mach number [2]. Their combination with the panel method is straightforward and reliable [9]. But as mentioned before, the free stream Mach numbers upstream and downstream of aeroengine gas turbine blades are not the same. Lieblein and Stockman developed a correction for this circumstance [10], which is deduced from empirical observation on the compressible flow in a turbine nozzle passage. However, the error of this method is very large at high subsonic Mach number when compared with experiment data.

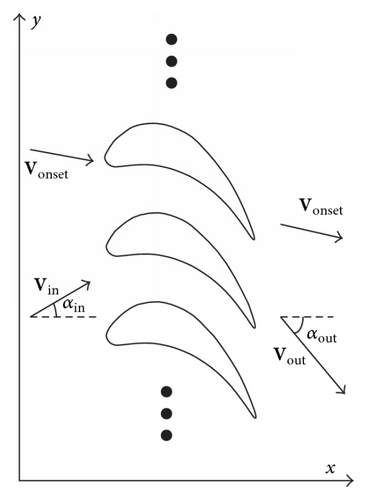

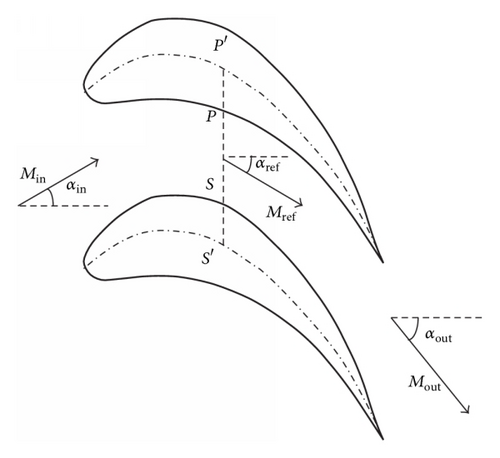

A method to rapidly calculate turbine blade cascade flow is presented in this paper. The flow field is solved with the panel method at first to obtain an incompressible solution. Then, the free stream velocities upstream and downstream are modified with a deviation angle model. The compressible solution is obtained by applying compressibility corrections at each cross section with local average Mach number on the cross section as a reference value. Examples are given to demonstrate the capabilities of the method.

2. Modeling Method

2.1. Panel Method

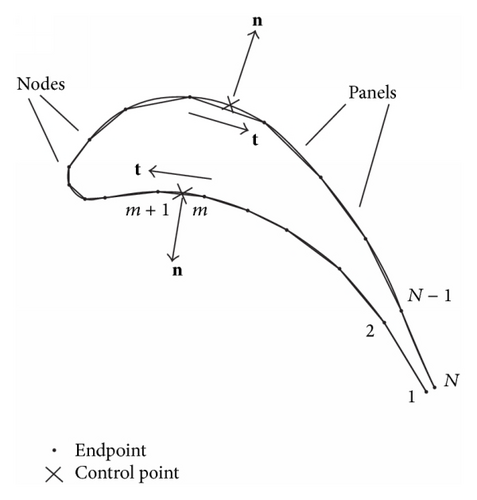

Laplace’s equation governs the disturbance potential (7). Since it is a linear equation, simpler solutions of Laplace’s equation may be added together to develop solutions with higher complexity. A general solution to flow over a body or cascade of bodies may be developed by using basic incompressible potential flow solutions for source and vortex flows distributed along the body surfaces and varying the strength of the source and vortex singularities so that the problem’s boundary conditions are satisfied.

In this paper, the surface of the body is represented by inscribing a polygon as shown in Figure 2. Flat panel elements with constant source and vortex singularity strengths are used for simplicity. The source strength varies for each element, while the vortex strength is identical over the whole blade surface. A control point is selected on each element centroid where the normal velocity boundary condition is to be applied. There will be N element endpoints and N − 1 control points. All the endpoints are arranged clockwise. The trailing edge is left open to avoid a velocity peak in the inviscid calculation.

2.2. Compressibility Correction

2.3. Deviation Angle Model

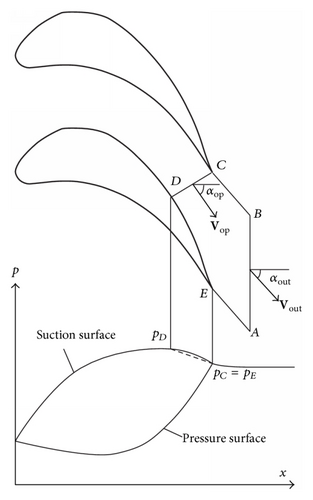

Equation (17) indicates that the exit flow angle αout must be obtained in advance to calculate Mref. However, in practice, the downstream boundary condition is usually back pressure pout or exit Mach number Mout rather than αout. The panel method mentioned above is only able to provide the incompressible exit flow angle, the value of which is obviously different from compressible flow. Under this circumstance, a deviation angle model based on momentum balance is introduced to calculate αout.

3. Comparison of Results

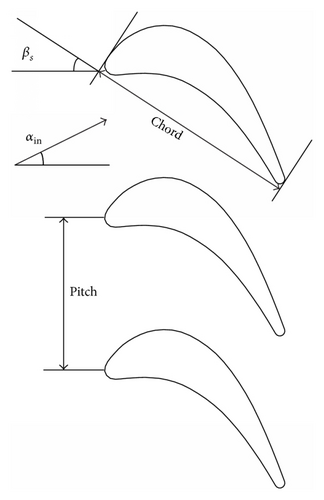

VKI LS 59 turbine cascade data [12] is used to evaluate the modeling method for that its geometry and working condition are similar to those of the aeroengine turbine blades. Lieblein’s method is also used for reference. The blade geometry and general parameters are shown in Figure 5 and Table 1. A FORTRAN computer code of the new method was developed for the calculation. The blade was approximated with 50 elements and the solution required less than 1 second of computer time using a 2.6 GHz Pentium CPU core.

| Parameter | Value |

|---|---|

| Pitch/chord | 0.71 |

| Install angle βs | 33° |

| Inlet flow angle αin | 30° |

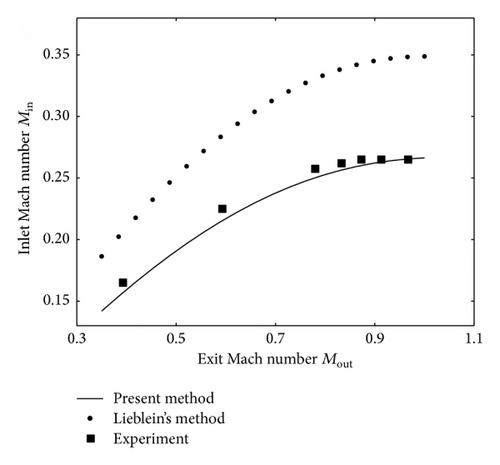

3.1. Inlet Mach Number

In Figure 6, the prediction of the inlet Mach number is compared between the new method, Lieblein’s method, and experimental data. As the experiment data shows, the mass flow will not increase with the exit Mach number as the latter approaches unity. The new method shows better consistency with experimental results.

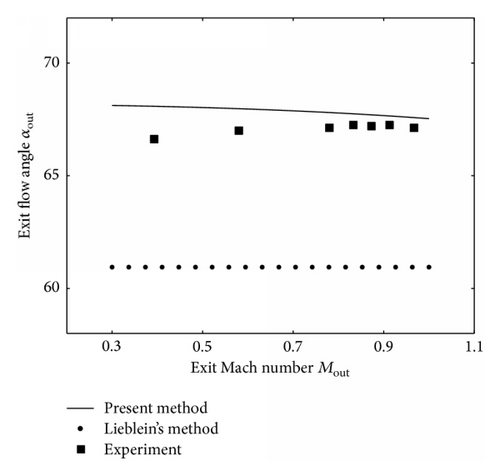

3.2. Exit Flow Angle

The comparison of the exit flow angle is shown in Figure 7. The exit angle of Lieblein’s method does not vary with exit Mach number, since it conserves the mass flow rate of the incompressible solution, which is fixed for a given inlet flow angle, but disagrees with the true value when compressibility effect is strong. In this case, the new method also provides better agreement.

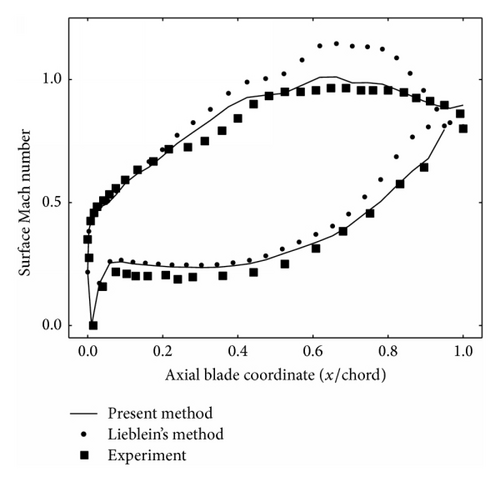

3.3. Surface Mach Number

Figure 8 shows the comparison of the blade surface Mach number distribution. The Mach number given by Lieblein’s method overpredicts the data over the entire blade surface. On the other hand, the new method compares well with the experimental data for the majority of the blade surface.

4. Summary

The panel method has been adopted to calculate the flow through turbine blades. The inherent computational speed and flexibility of the integral equation solution can make this method useful for design calculations. The method presented combines a panel method, a deviation angle model, and a compressibility correction to yield a compressible solution. Comparison with experiment shows that this method is sufficiently accurate to provide a means of selecting aeroengine turbine blade designs for further analysis.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.