Scalar Method of Fault Diagnosis of Inertial Measurement Unit

Abstract

The scalar method of fault diagnosis systems of the inertial measurement unit (IMU) is described. All inertial navigation systems consist of such IMU. The scalar calibration method is a base of the scalar method for quality monitoring and diagnostics. In accordance with scalar calibration method algorithms of fault diagnosis systems are developed. As a result of quality monitoring algorithm verification is implemented in the working capacity monitoring of IMU. A failure element determination is based on diagnostics algorithm verification and after that the reason for such failure is cleared. The process of verifications consists of comparison of the calculated estimations of biases, scale factor errors, and misalignments angles of sensors to their data sheet certificate, kept in internal memory of computer. As a result of such comparison the conclusion for working capacity of each IMU sensor can be made and also the failure sensor can be determined.

1. Introduction

In recent years, the strong requirements for safety of autonomous vehicles caused new demands for reliability of the Inertial Navigation Systems and inertial measurement units as their component parts. It is a reason for increasing and expanding their testing program and using fault diagnosis systems, which includes the capacity of detecting, isolating, and identifying faults.

There are different methods of fault diagnosis systems of Inertial Navigation Systems (INS). More simple and wide application is monitoring of output level of signals of INS components parts made by technology of Built-In Test Equipment (BITE) [1]. Besides, diagnostics could be made by multiple-choice alternative methods of optimal filtration [2–4] and functional diagnostic model methods [5]. If the last mentioned methods are used for IMU and based on application of redundant or extra number of sensors, optimal filtration methods are using whole INS and required other information of instruments, working on diverse form inertial technology principles (e.g., information from satellite navigation receiver or Doppler radar).

The above-mentioned approaches are based on quantitative or numerical models, when using or generating signals that reflect inconsistencies between nominal and faulty system operation.

During the last time many investigations have been made using qualitative or analytical models, using neural networks [6–9] and fuzzy logic techniques [10, 11].

This paper has suggested to use scalar calibration method of gyroscopes and accelerometers [12] for fault diagnosis systems of IMU of Inertial Navigation Systems and also functional diagnostics model methods together, but doing without extra number of sensors—with three gyros and three accelerometers only.

2. Description of the Method

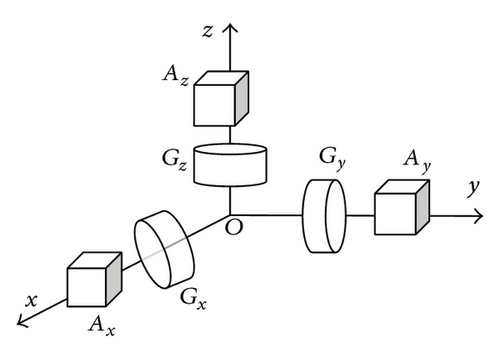

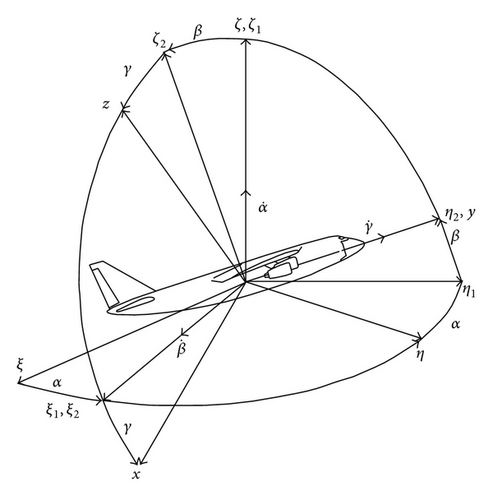

Let IMU of Strapdown INS consist of a triad of single degree-of-freedom gyroscopes Gx, Gy, Gz and a triad of accelerometers Ax, Ay, Az that are mounted to a vehicle with body frame Oxyz with orthogonal sensitivity axes, as shown on Figure 1.

Here, in notification of Δxz angle, the first index has shown that the unit is mounted on ox axes and has been rotated about oz axes on Δxz angle.

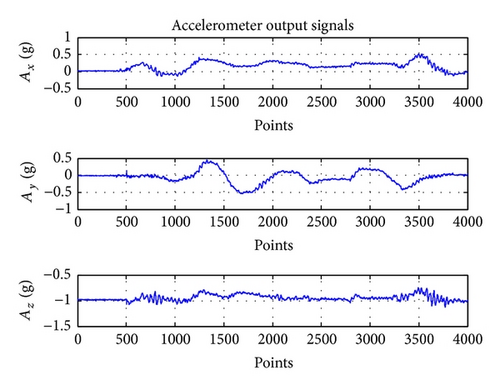

Figure 2 shows examples of real output signals of accelerometers of IMU with USB-port [13] on the moving base.

Let us assume that calibration of IMU has been done before and all the above-mentioned parameters as fixed biases, scale factor errors, and mounting misalignments angles of gyroscopes and accelerometers are measured and reserved in internal INS computer’s memory.

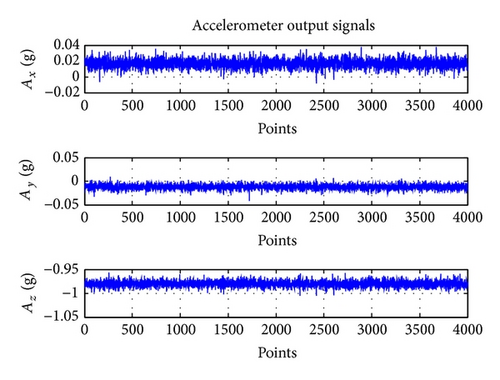

Figure 3 shows examples of real output signals of accelerometers on the fixed base.

It is noted that listed above model (4) is present for conventional gyroscopes and dynamical tuned gyro.

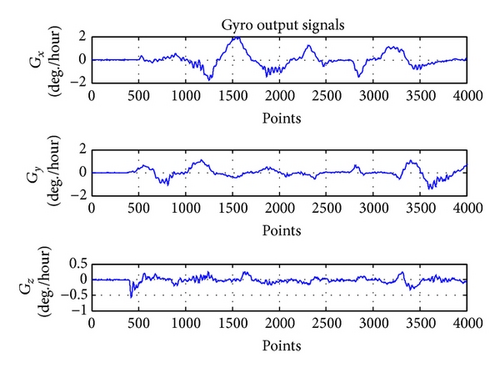

Figure 4 shows examples of output signals of gyroscopes of IMU with USB-port [13] on the moving base.

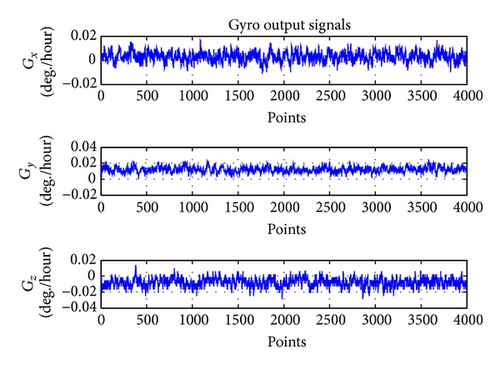

Figure 5 shows examples of output signals of gyroscopes of IMU with USB-port [13] on fixed base.

Hence, the difference between the scalar value of the normalized measurable vector and its actual value is equal to one, proportional to the errors of the inertial instrument cluster. Coefficients in this dependence are the normalized values of measurable acceleration for accelerometers and angular rate for gyros, their exponential orders, and compositions.

Here in right part a value “1” means an operable state of a triad of accelerometers or gyroscopes, a value “0” its failure, and λ0g a border value of function (1/2)(ugx2 + ugy2 + ugz2 − 1). If the value of function (ugx2 + ugy2 + ugz2 − 1) will not be more than a value 2λ0g, a triad of accelerometers has been in operable state. If not, therefore there is a failure. The same rule is valid for quality monitoring of gyros.

When the task of the quality monitoring is solved it is necessary to find a place and clear the reason for failure.

3. The Scalar Method of Fault Diagnosis

When the task of the quality monitoring is solved it is necessary to find a place and clear the reason for failure.

To scalar-calibrate the inertial measurement unit we should in the gravity field turn around the certain direction at fixed angles and in every position get the normalized output signals. To solve (12) and (14) it requires at least nine of the inertial measurement unit positions, so number of tests should be more than or equal to nine. The fact is that in each position of the inertial measurement unit its output signals simultaneously have been measuring either gyroscopes or accelerometers, so the minimum number of positions in the two times is less than the total number of required parameters.

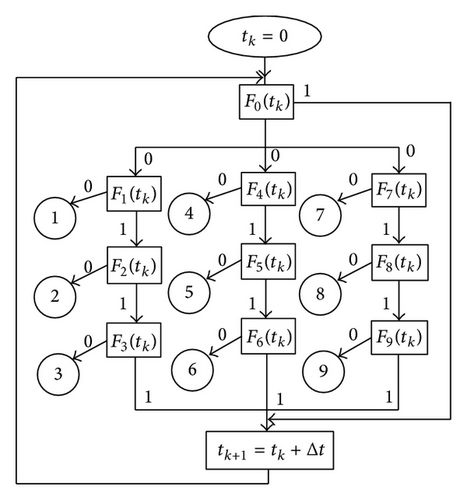

The scheme of scalar method of fault diagnosis systems of IMU is depicted in the Figure 6. Here numbers 1,2, 3 are shown in the gyro’s failures via biases discrepancy, numbers 4,5, 6 in gyro’s failures via scale factor errors discrepancy, and numbers 7,8, 9 in gyro’s failures via mounting misalignments discrepancy.

4. Simulations

Output signals of IMU’s gyros were used for calculation of estimated values of (23).

| Position number | Alpha (deg.) | Beta (deg.) | Gamma (deg.) |

|---|---|---|---|

| 1 | 0 | 0 | −90 |

| 2 | 0 | 0 | 90 |

| 3 | 0 | 90 | 0 |

| 4 | 0 | −90 | 0 |

| 5 | 0 | 0 | 0 |

| 6 | 0 | 0 | 180 |

| 7 | 0 | −90 | −45 |

| 8 | 0 | 90 | 45 |

| 9 | 0 | 180 | −45 |

| 10 | 0 | 0 | 45 |

| 11 | 0 | 135 | 0 |

| 12 | 0 | −45 | 0 |

| 13 | 0 | 90 | −45 |

| 14 | 0 | 90 | 135 |

| 15 | 0 | 0 | −45 |

| 16 | 0 | 0 | 135 |

| 17 | 0 | 45 | 0 |

| 18 | 0 | −135 | 0 |

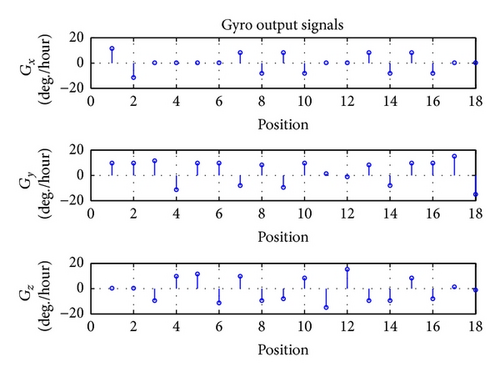

Figure 8 shows output signals of gyroscopes, which were calculated by (5) for IMU positions of Table 1.

Good results were received (error between nominal value and estimated value on static base not more than 5%) and it was shown [12] that absolute value of relative error of the biases depends on the number of digits after the decimal point in the output signals of gyro and accelerometers. In other words it requires sufficiently high accuracy of measurement of the output signals of sensors.

5. Conclusions

In this paper we have proposed a new method of fault diagnosis systems IMU of Strapdown Inertial Navigation Systems. The scalar calibration method is a base of the scalar method of quality monitoring and diagnostics. In accordance with scalar calibration method algorithms of fault diagnosis systems are developed. As a result of quality monitoring algorithm verification is implemented in the working capacity monitoring of IMU. A failure element determination is based on diagnostics algorithm verification and after that the reason for such failure is cleared.

The process of verifications consists of comparison of the calculated estimations of biases, scale factor errors, and misalignments angles of sensors to their data sheet certificate, kept in internal memory of computer. As a result of such comparison the conclusion for working capacity of each IMU sensor can be made and also the failure sensor can be determined.

Conflict of Interests

The author declares that there is no conflict of interests regarding the publication of this paper.