An Approach for Simple Linear Profile Gauge R&R Studies

Abstract

Gauge repeatability and reproducibility studies are significant to quality improvement and quality control. The approaches are always applied to determine the capability of the measurement system. Much of the literature in this field mainly focuses on univariate and multivariate measurement systems. However, the state-of-the-art methods are not appropriate when the quality of a product is characterized by a profile. Therefore, this paper proposes a method for the measured values which can be characterized by a simple linear profile. In addition, the slopes and intercepts of these profiles often vary due to measurement error. Thus, the simple linear profile gauge studies can be considered as a two-response (slope and intercept) problem. X-values transformation is used to make the slope and intercept of each profile independent. ANOVA is utilized to estimate the variance component of measurement error and other sources of variation. Then, the criteria precision to tolerance ratio and percent R&R are introduced to assess the simple linear profile measurement system capability. Finally, the proposed approach is applied to the spring length and elasticity measurement which demonstrates how to implement the method.

1. Introduction

Gauge repeatability and reproducibility (GR&R) studies are usually adopted for determining the capability of the measurement systems. Burdick et al. [1] and Montgomery [2] proposed that one of the objectives of measurement systems capability analysis (MSCA) is to determine whether the gauge is capable. Evaluating the capability of measurement system is necessary for other researches, such as process capability analysis, control charts, and design of experiment. In practice, a reliable measurement system is significant to quality improvement and quality control.

Burdick et al. [1] reviewed the measurement system capability analysis. In their paper, the criteria, typical model, and GR&R experiment were all introduced. Attribute data are widely applied in industry; Lyu and Chen [3] evaluated the R&R of a measurement system for attribute data based on the generalized linear models (GLMs). Some papers considered confidence intervals for gauge capability studies. Borror et al. [4] presented two methods to construct confidence intervals for variance components: one is the restricted maximum likelihood (REML) method and the other is the modified large sample (MLS) method. Gong et al. [5] proposed an approach by applying unweighted sums of squares method when confidence intervals for unbalanced two-factor gauge study were considered.

In practice, many products need several critical characteristics to describe their quality. For these cases, the univariate MSCA method may not be appropriate especially when the measured characteristics have some correlations. Thus, numerous studies in this field considered multivariate MSCA. An approach to analyze the two-dimensional GR&R of imbalance measurement was introduced by Sweeney [6]. He concluded that the variation can be underestimated via treating such data as one-response. Majeske [7] proposed the method and the criteria for multivariate MSCA by regarding the measured values as a vector and assuming that the measured values follow a multivariate normal distribution. MANOA is applied to estimate the variance-component matrices.

Gauge repeatability and reproducibility studies are widely used in practice. Li and Al-Refaie [8] utilized the define-measure-analyze-improve-control (DMAIC) procedure to improve the quality system involving measurements. Erdmann et al. [9] gave an example of GR&R in a hospital, and the experiment is about an ear thermometer for temperature measurements.

The existing research proposed many methods for univariate and multivariate MSCA. However, the measured values in some situations can be characterized by profiles. The measurement for the elasticity and length of springs is a good example. In this case, the elasticity of spring is a simple linear profile of an independent variable: the length of spring. In this paper, an approach for the situation where the measured values can be expressed as a simple linear profile is proposed.

The remainder of this paper is organized as follows. A brief review of gauge R&R is presented in Section 2. Section 3 proposes the approach and criteria for simple linear profile gauge R&R. A case study is introduced in Section 4. The last section contains our concluding remarks.

2. The Model and Criteria for GR&R

3. The GR&R Method for Simple Linear Profile

3.1. The Transforming Model

3.2. The Model for Variance Analysis

A two-factor ANOVA with an interaction term is applied to estimate these variance components.

3.3. The Assessment Criteria

According to AIAG [10], the measurement system is unacceptable if one of the above assessed values exceeds 30%. It is acceptable if the values are all lower than 10%. If the values are all between 10% and 30%, the measurement system needs to be improved.

4. The Introductory Case

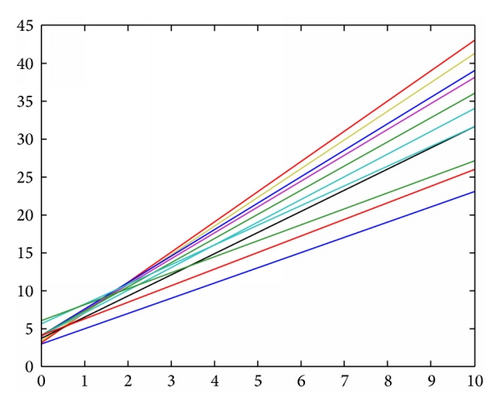

An example of gauge study about spring measurement is introduced in this section. In the quality improvement, it is necessary to measure the elasticity and the length of spring. According to Hooke’s law, when the spring has reached a state of equilibrium, its elasticity is a simple linear profile of the amount by which the free end of the spring is displaced from its relaxed position (when it is not stretched). In this case, three operators made three measurements on each of ten springs, Xijk is the length of spring after compression or elongation, and Yijk is the different elasticity when the spring is of different length.

The least-square method is used to fit profile and estimate the parameters and after the measurement. Then, and in (7) can be obtained via transforming X-values. A two-factor ANOVA with an interaction term is utilized to estimate the variance components of and , respectively. The variance components of are shown in Table 1. The variance components of are shown in Table 2.

| 0.007894 | |

| 0.000009 | |

| 0 | |

| 0.000149 |

| 0.000554 | |

| 0.000001 | |

| 0.000002 | |

| 0.000010 |

In this case, all of the criteria are between 10% and 30%. According to AIAG [10], the measurement system needs to be improved. The improvement will be made based on the gauge R&R experiment. In this case, the approach used to improve the capability of measurement system provides a clearer instruction. The instruction includes the precise location where the spring should be placed and the measurement operations that should be conducted. This improvement can decrease the differences among the operators.

5. Conclusion

Gauge repeatability and reproducibility studies are important to guarantee the validity of data, which is essential to other researches. Numerous existing studies in this area are about univariate and multivariate measurement systems, but these methods may not be suitable when the quality of a product should be characterized by a profile. This paper proposes an approach to assess the gauge capability when a simple linear profile is used to reflect product quality. Our proposed method can simplify the measurement problems effectively, especially for those with the multi-dimensional measured values. The example of spring measurement is presented in this paper which shows how to implement the proposed method. Further, more and more methods and criteria should be proposed to assess the capability of the measurement system.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Acknowledgments

The authors wish to thank Dr. Jinyu Yang for introducing the elementary idea of the paper. This research is supported by the National Natural Science Foundation of China (71102140) and the National Research Foundation for the Doctoral Program of Higher Education of China (20100032120030).

Appendix

In this appendix, the original measured values of the introductory case are provided as Table 3.

| Part | Operator | Xijk | |||||

|---|---|---|---|---|---|---|---|

| 17 | 16 | 15 | 13.5 | 12.5 | 11 | ||

| Yijk | |||||||

| 1 | 1 | 0.26 | 0.59 | 0.86 | 1.37 | 1.68 | 2.19 |

| 1 | 1 | 0.24 | 0.57 | 0.86 | 1.37 | 1.66 | 2.17 |

| 1 | 1 | 0.24 | 0.55 | 0.86 | 1.35 | 1.66 | 2.17 |

| 1 | 2 | 0.26 | 0.57 | 0.86 | 1.35 | 1.66 | 2.17 |

| 1 | 2 | 0.24 | 0.55 | 0.86 | 1.37 | 1.66 | 2.17 |

| 1 | 2 | 0.26 | 0.57 | 0.86 | 1.37 | 1.66 | 2.17 |

| 1 | 3 | 0.26 | 0.59 | 0.86 | 1.35 | 1.66 | 2.17 |

| 1 | 3 | 0.24 | 0.55 | 0.86 | 1.37 | 1.68 | 2.17 |

| 1 | 3 | 0.24 | 0.57 | 0.86 | 1.35 | 1.66 | 2.17 |

| 2 | 1 | 0.46 | 0.75 | 1.06 | 1.53 | 1.84 | 2.33 |

| 2 | 1 | 0.39 | 0.73 | 0.99 | 1.48 | 1.77 | 2.26 |

| 2 | 1 | 0.39 | 0.73 | 0.99 | 1.48 | 1.79 | 2.24 |

| 2 | 2 | 0.44 | 0.73 | 0.99 | 1.48 | 1.79 | 2.24 |

| 2 | 2 | 0.44 | 0.75 | 0.99 | 1.46 | 1.79 | 2.26 |

| 2 | 2 | 0.39 | 0.75 | 1.04 | 1.51 | 1.79 | 2.26 |

| 2 | 3 | 0.46 | 0.75 | 1.06 | 1.48 | 1.79 | 2.26 |

| 2 | 3 | 0.44 | 0.73 | 1.04 | 1.48 | 1.79 | 2.26 |

| 2 | 3 | 0.39 | 0.75 | 1.02 | 1.48 | 1.79 | 2.24 |

| 3 | 1 | 0.22 | 0.51 | 0.79 | 1.26 | 1.59 | 2.06 |

| 3 | 1 | 0.22 | 0.48 | 0.77 | 1.24 | 1.57 | 2.04 |

| 3 | 1 | 0.19 | 0.48 | 0.77 | 1.24 | 1.57 | 2.06 |

| 3 | 2 | 0.22 | 0.46 | 0.75 | 1.24 | 1.55 | 2.04 |

| 3 | 2 | 0.22 | 0.46 | 0.75 | 1.24 | 1.55 | 2.04 |

| 3 | 2 | 0.22 | 0.46 | 0.77 | 1.24 | 1.55 | 2.06 |

| 3 | 3 | 0.22 | 0.48 | 0.79 | 1.26 | 1.59 | 2.06 |

| 3 | 3 | 0.22 | 0.48 | 0.77 | 1.22 | 1.55 | 2.04 |

| 3 | 3 | 0.19 | 0.46 | 0.77 | 1.26 | 1.57 | 2.06 |

| 4 | 1 | 0.26 | 0.55 | 0.82 | 1.24 | 1.53 | 1.97 |

| 4 | 1 | 0.26 | 0.53 | 0.82 | 1.24 | 1.53 | 1.95 |

| 4 | 1 | 0.26 | 0.53 | 0.79 | 1.22 | 1.53 | 1.95 |

| 4 | 2 | 0.26 | 0.53 | 0.79 | 1.22 | 1.51 | 1.93 |

| 4 | 2 | 0.26 | 0.53 | 0.79 | 1.22 | 1.48 | 1.88 |

| 4 | 2 | 0.26 | 0.53 | 0.79 | 1.22 | 1.51 | 1.93 |

| 4 | 3 | 0.26 | 0.55 | 0.82 | 1.22 | 1.48 | 1.93 |

| 4 | 3 | 0.26 | 0.53 | 0.79 | 1.22 | 1.53 | 1.95 |

| 4 | 3 | 0.26 | 0.53 | 0.79 | 1.22 | 1.48 | 1.93 |

| 5 | 1 | 0.19 | 0.48 | 0.79 | 1.26 | 1.59 | 2.06 |

| 5 | 1 | 0.19 | 0.48 | 0.79 | 1.26 | 1.55 | 2.04 |

| 5 | 1 | 0.19 | 0.48 | 0.79 | 1.26 | 1.55 | 2.02 |

| 5 | 2 | 0.19 | 0.51 | 0.77 | 1.24 | 1.55 | 2.04 |

| 5 | 2 | 0.19 | 0.48 | 0.79 | 1.24 | 1.55 | 2.02 |

| 5 | 2 | 0.19 | 0.42 | 0.73 | 1.19 | 1.48 | 2.04 |

| 5 | 3 | 0.19 | 0.48 | 0.79 | 1.26 | 1.57 | 2.06 |

| 5 | 3 | 0.19 | 0.46 | 0.79 | 1.24 | 1.55 | 2.02 |

| 5 | 3 | 0.19 | 0.46 | 0.77 | 1.24 | 1.55 | 2.02 |

| 6 | 1 | 0.28 | 0.57 | 0.82 | 1.22 | 1.46 | 1.86 |

| 6 | 1 | 0.28 | 0.55 | 0.79 | 1.19 | 1.42 | 1.79 |

| 6 | 1 | 0.28 | 0.55 | 0.79 | 1.19 | 1.46 | 1.84 |

| 6 | 2 | 0.28 | 0.55 | 0.82 | 1.22 | 1.46 | 1.84 |

| 6 | 2 | 0.28 | 0.55 | 0.79 | 1.22 | 1.46 | 1.84 |

| 6 | 2 | 0.28 | 0.57 | 0.82 | 1.22 | 1.46 | 1.84 |

| 6 | 3 | 0.28 | 0.55 | 0.79 | 1.22 | 1.46 | 1.84 |

| 6 | 3 | 0.28 | 0.55 | 0.79 | 1.19 | 1.44 | 1.82 |

| 6 | 3 | 0.26 | 0.53 | 0.79 | 1.19 | 1.42 | 1.79 |

| 7 | 1 | 0.19 | 0.48 | 0.77 | 1.24 | 1.53 | 1.99 |

| 7 | 1 | 0.19 | 0.46 | 0.77 | 1.22 | 1.53 | 1.97 |

| 7 | 1 | 0.17 | 0.46 | 0.75 | 1.22 | 1.53 | 1.97 |

| 7 | 2 | 0.19 | 0.46 | 0.77 | 1.22 | 1.53 | 1.97 |

| 7 | 2 | 0.17 | 0.46 | 0.77 | 1.22 | 1.53 | 1.95 |

| 7 | 2 | 0.19 | 0.46 | 0.77 | 1.22 | 1.53 | 1.99 |

| 7 | 3 | 0.19 | 0.46 | 0.75 | 1.22 | 1.53 | 1.97 |

| 7 | 3 | 0.19 | 0.46 | 0.77 | 1.22 | 1.55 | 1.97 |

| 7 | 3 | 0.17 | 0.46 | 0.75 | 1.22 | 1.51 | 1.97 |

| 8 | 1 | 0.26 | 0.55 | 0.84 | 1.33 | 1.64 | 2.13 |

| 8 | 1 | 0.24 | 0.53 | 0.82 | 1.31 | 1.62 | 2.08 |

| 8 | 1 | 0.24 | 0.53 | 0.82 | 1.33 | 1.64 | 2.08 |

| 8 | 2 | 0.26 | 0.55 | 0.82 | 1.28 | 1.62 | 2.08 |

| 8 | 2 | 0.24 | 0.53 | 0.82 | 1.28 | 1.59 | 2.06 |

| 8 | 2 | 0.26 | 0.57 | 0.82 | 1.33 | 1.62 | 2.08 |

| 8 | 3 | 0.26 | 0.53 | 0.82 | 1.33 | 1.62 | 2.08 |

| 8 | 3 | 0.26 | 0.53 | 0.82 | 1.33 | 1.64 | 2.08 |

| 8 | 3 | 0.24 | 0.53 | 0.82 | 1.28 | 1.62 | 2.06 |

| 9 | 1 | 0.15 | 0.44 | 0.75 | 1.22 | 1.53 | 1.99 |

| 9 | 1 | 0.15 | 0.39 | 0.75 | 1.22 | 1.53 | 1.99 |

| 9 | 1 | 0.13 | 0.39 | 0.73 | 1.22 | 1.53 | 1.99 |

| 9 | 2 | 0.15 | 0.39 | 0.73 | 1.22 | 1.53 | 2.02 |

| 9 | 2 | 0.17 | 0.42 | 0.73 | 1.22 | 1.53 | 2.02 |

| 9 | 2 | 0.15 | 0.42 | 0.75 | 1.22 | 1.53 | 1.99 |

| 9 | 3 | 0.15 | 0.39 | 0.73 | 1.22 | 1.53 | 2.02 |

| 9 | 3 | 0.15 | 0.39 | 0.75 | 1.22 | 1.53 | 1.99 |

| 9 | 3 | 0.15 | 0.39 | 0.73 | 1.19 | 1.51 | 1.97 |

| 10 | 1 | 0.26 | 0.55 | 0.79 | 1.19 | 1.42 | 1.82 |

| 10 | 1 | 0.26 | 0.53 | 0.79 | 1.19 | 1.42 | 1.82 |

| 10 | 1 | 0.26 | 0.53 | 0.77 | 1.17 | 1.39 | 1.75 |

| 10 | 2 | 0.28 | 0.55 | 0.79 | 1.19 | 1.42 | 1.82 |

| 10 | 2 | 0.26 | 0.53 | 0.77 | 1.15 | 1.37 | 1.75 |

| 10 | 2 | 0.28 | 0.57 | 0.79 | 1.19 | 1.44 | 1.82 |

| 10 | 3 | 0.26 | 0.53 | 0.79 | 1.15 | 1.39 | 1.77 |

| 10 | 3 | 0.26 | 0.53 | 0.79 | 1.15 | 1.39 | 1.75 |

| 10 | 3 | 0.26 | 0.53 | 0.77 | 1.13 | 1.37 | 1.77 |