Process Parameter Identification in Thin Film Flows Driven by a Stretching Surface

Abstract

The flow of a thin liquid film over a heated stretching surface is considered in this study. Due to a potential nonuniform temperature distribution on the stretching sheet, a temperature gradient occurs in the fluid which produces surface tension gradient at the free surface of the thin film. As a result, the free surface deforms and these deformations are advected by the flow in the stretching direction. This work focuses on the inverse problem of reconstructing the sheet temperature distribution and the sheet stretch rate from observed free surface variations. This work builds on the analysis of Santra and Dandapat (2009) who, based on the long-wave expansion of the Navier-Stokes equations, formulate a partial differential equation which describes the evolution of the thickness of a film over a nonisothermal stretched surface. In this work, we show that after algebraic manipulation of a discrete form of the governing equations, it is possible to reconstruct either the unknown temperature field on the sheet and hence the resulting heat transfer or the stretching rate of the underlying surface. We illustrate the proposed methodology and test its applicability on a range of test problems.

1. Introduction

The analysis of thin film flow and heat transfer over a stretching surface has been a subject of fundamental importance as it is relevant to several industrial applications such as metal and polymer extrusion, continuous casting, drawing of plastic sheets, or cable coatings to name a few. This industrial context has drawn fluid dynamists and applied mathematicians alike to study this problem from a more canonical angle. The first important contribution to the understanding of this problem is the work of Wang [1] who formulated a mathematical model and developed a solution strategy based on the homotopy analysis method (HAM). The problem has been revisited several times since this seminal work with the inclusion of additional physics or more complex rheology. Andersson et al., for example, extended Wang’s contribution by analyzing the associated heat transfer problem [2, 3], while Noor and Hashim built on the work of Dandapat et al. [4, 5] to consider the thermocapillary and magnetic field effects [6] and Aziz and Hashim that of viscous dissipation [7]. Khan et al. focused on the effect of the temperature-dependency on the viscosity and thermal conductivity on the flow in the film [8] and Andersson et al. extended the standard formulation to power-law fluids [9]. A common feature of the literature cited above is that it is implicitly assumed that the film thickness is uniform in the domain, a required assumption to enable the similarity transformation which reduces the set of partial differential equations to a more tractable one of ordinary differential equations.

Recognizing the restrictions of the plane interface assumption, Dandapat and co-workers were the first to extend the formulation to account for local deformation of the free surface in [10, 11]. The authors exploit the slenderness of the flow domain to derive a long-wave approximation of the Navier-Stokes equations and solve the resulting governing equation using the matched asymptotic method. Lately, this work was extended to include the heat transfer problem [12]. In this work, the nonuniform temperature distribution at the stretching sheet induces an inhomogeneous temperature field in the film. Consequently, a surface temperature gradient develops at the film free surface. As a result of the surface tension gradients, the film thickness varies along the flow and these deformations are advected in the stretching direction.

This work focuses on the flow of a thin liquid film over a heated stretching surface. The aforementioned literature provides solid modeling foundations upon which one can build to indirectly infer process parameters difficult to measure in practice. More specifically, since the developed models correlate the film thickness to the sheet stretch rate and/or temperature through a set of differential equations, it is only natural to wonder whether the knowledge of the film thickness variation allows the reconstruction of either the sheet temperature or the sheet stretch rate. It is precisely this problem which this paper tackles. The motivation for this work is to demonstrate theoretically that it is possible to infer either the stretching rate or the surface temperature from the knowledge of the free surface evolution. This could have interesting practical outcome such as indirectly inferring the heat transfer involved in the process. The solution strategy to solve this inverse problem is inspired from the recent work of Sellier and Panda [13–15], which proposed a strategy to reconstruct an unknown field from free surface data in thin film flows. The general idea is to algebraically manipulate the field equation in order to obtain an explicit differential equation governing the inverse problem. This solution can then be solved using standard numerical techniques. This concept is applied for the first time here to a transient problem. The simplicity of the proposed approach contrasts with the traditional way of dealing with such inverse problems which rely on pde-constrained optimization framework, [16].

The following section briefly describes the mathematical model and numerical solution procedure used to compute the free surface evolution. This section is followed by the development of the inverse problem solution methodology. Some examples illustrating the success of the proposed approach are presented in the penultimate section and finally concluding remarks are drawn in the final section.

2. Description of the Direct Problem

2.1. Mathematical Model

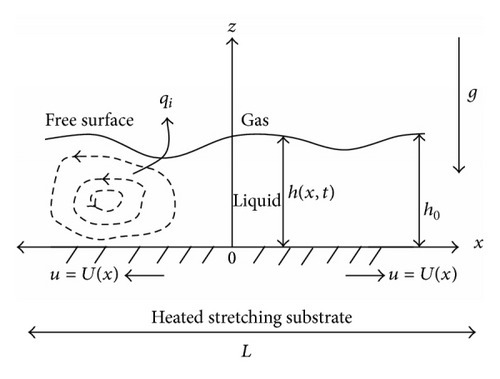

We consider here an unsteady liquid film which lies over a horizontal plane heated elastic sheet as shown in Figure 1. Because surface tension tends to be a monotonically decreasing function of temperature, temperature gradients at the stretching sheet surface induce surface tension variations at the free surface. As regions of high surface tension tend to “pull” on regions of lower surface tension, convective flow cells develop which deform the free surface. This deformation is advected by the flow in the stretching direction. The question this work addresses is how the temperature field at the sheet surface and the stretching velocity can be reconstructed from a known deformation of the free surface.

This study is based on the model developed by Santra and Dandapat [12] using the long wave theory. This model is briefly described here for completeness. The elastic sheet lies at z = 0 and the liquid gas interface lies at z = h(x, t), where the x-axis is directed along the stretching sheet and the z-axis is normal to the sheet in the outward direction toward the fluid. Gravity acts along negative z-direction. Further, the surface at z = 0 starts stretching from rest and within a very short time attains the stretching velocity u = U(x). The elastic surface is heated with its temperature Θ a function of x alone and the ambient gas phase is at constant temperature Ta.

- (i)

the Froude number that expresses the ratio of inertia to body forces;

- (ii)

the Prandtl number Pr = ρcpν/k that represents the ratio of momentum to thermal diffusivity;

- (iii)

the Marangoni number that characterizes the relation between the temperature dependent surface tension and viscous forces;

- (iv)

the Biot number Bi = αh0/k that compares the relative magnitudes of resistances to internal conduction and surface convection;

- (v)

the dimensionless number S = ϵ2σah0/ρν2 is known as surface tension parameter and ϵ = h0/L is the aspect ratio.

At the origin, we apply the symmetry conditions hx = 0 and hxxx = 0 and at the other end of the domain; we assume that the same sheet temperature profiles and the sheet stretching rate continues beyond the computed domain. We also assume that the gradient of the free surface extends out of the computational domain. These boundary conditions are consistent with those mentioned in [12].

2.2. Numerical Solution Procedure

There are many different numerical methods that have been presented in the past for this kind of analysis [12, 17] and in this paper, we mostly follow the finite volume technique described in Sellier and Panda [14] on a uniform grid system with implicit flux discretization.

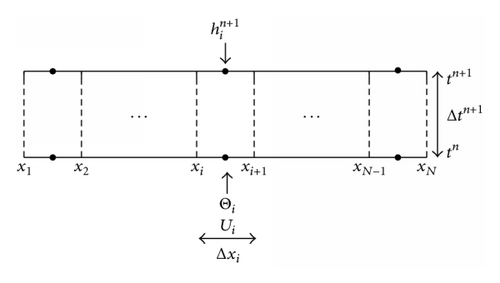

We discretize our flow domain into the uniform grid and the flow variable h, the steady stretching velocity U, and sheet temperature Θ are located at the cell centers as shown in Figure 2. Let N spatial grid points x1 < x2 < ⋯<xN be equally distributed over the domain [0, L] with spatial increment Δxi = xi+1 − xi = L/(N − 1), i = 1,2, …, N − 1. The numerical solution is sought at the discrete time levels tn, n = 0,1, 2, … with time step Δtn+1 = (tn+1 − tn).

Equation (6) describes an implicit time discretization scheme. Since the governing equation is nonlinear, a system of nonlinear algebraic equations needs to be solved at each time step. We use fsolve in MATLAB for this purpose. A good initial starting guess is required to solve the nonlinear equations. A reasonable initial guess for the free surface is chosen to be unity throughout the discrete domain at the first time step. The solution from the previous time step can be used otherwise. Convergence is usually achieved in less than 10 iterations and the convergence criterion is that the norm of the residuals should be less than 10−7.

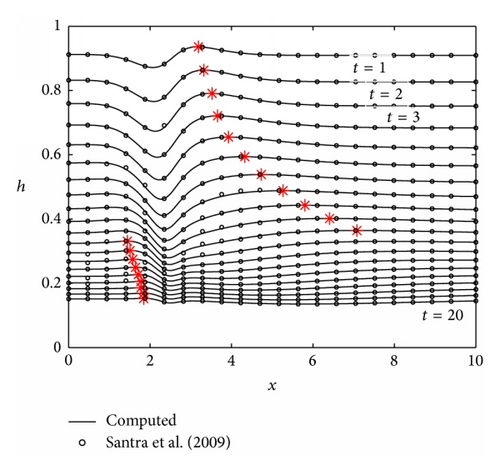

Figure 3(b) illustrates the evolution of free surface at different times. The observed results replicate well those obtained by Santra and Dandapat in [12], and thereby validating the formulation and implementation of the proposed numerical scheme. It is clear from Figure 3(b) that thermocapillary deforms the free surface during the early stages and this deformation is advected downstream by the stretching sheet. To clearly see the motion of the free surface disturbance, the local maximum on each curve is identified with star.

3. The Inverse Problem

The evolution of the free surface provides valuable information on the flow process parameters. Such information can be used to infer unknown conditions otherwise difficult to measure. In the following, we will consider two inverse problems which can be solved using the same conceptual idea.

3.1. Temperature Reconstruction from Two Free Surface Snapshots and Prescribed Stretching Velocity

- (i)

hn+1, hn, and U are known and Θ is sought;

- (ii)

hn+1, hn, and Θ are known and U is sought;

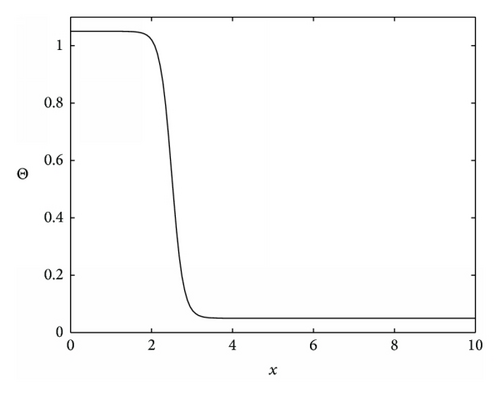

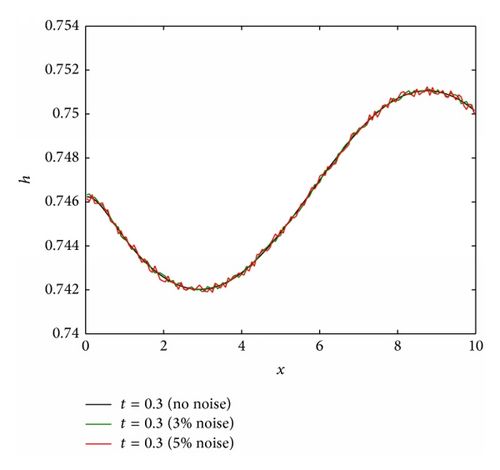

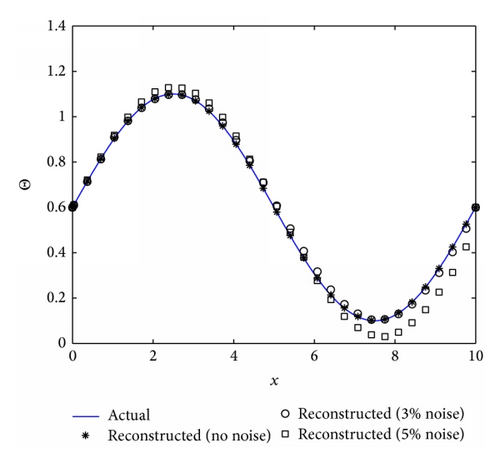

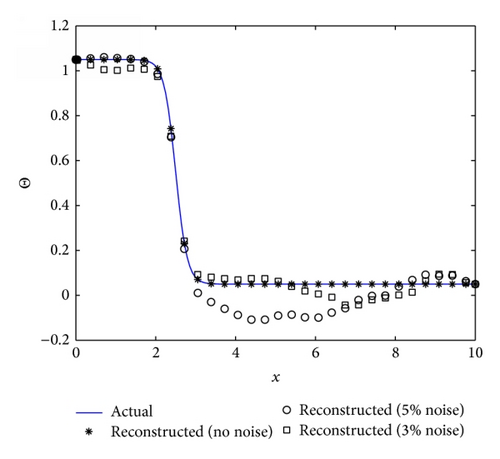

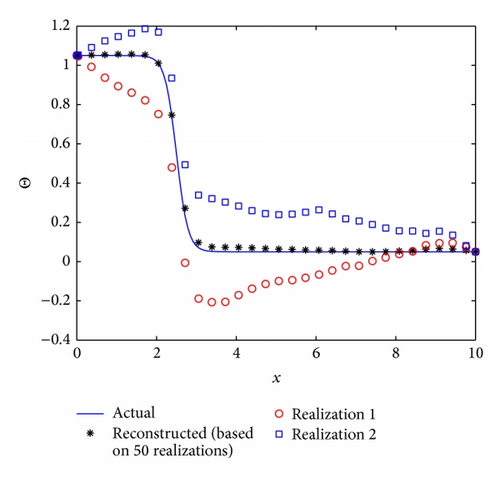

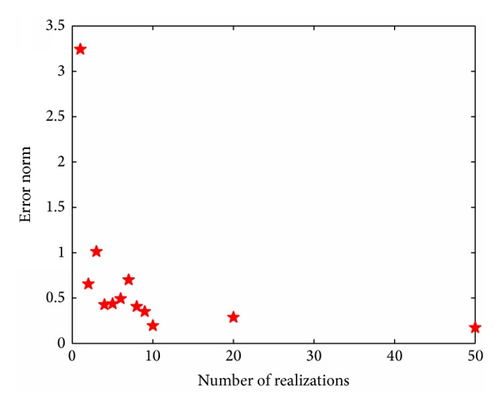

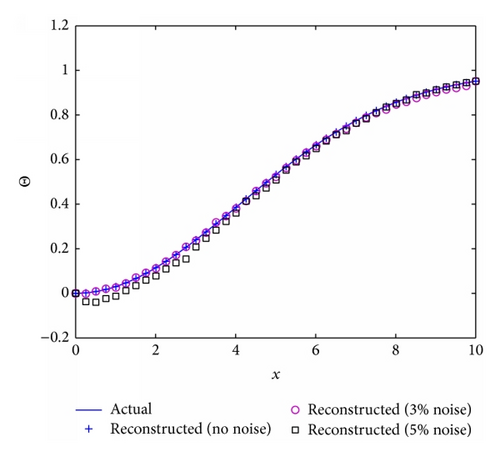

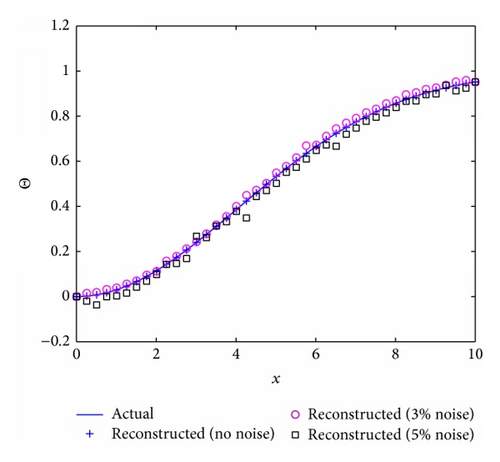

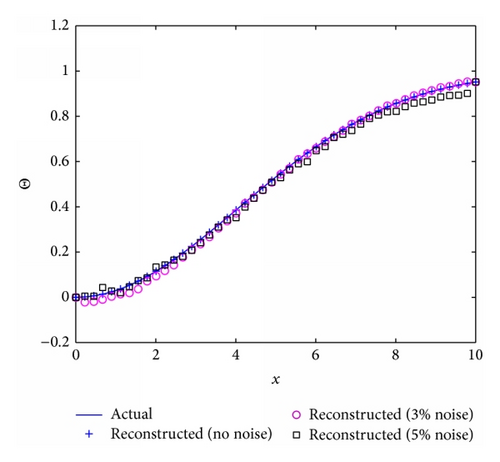

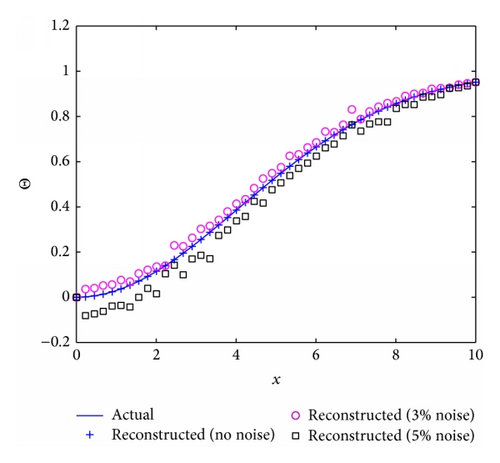

In the inevitable presence of noise in an experimental system, the natural procedure is to run several realizations of the same experiment and average the output data. This is precisely what we proceeded to do in order to check whether, as the number of realization increases, the agreement between the reconstructed and actual temperature profile improves, as one would expect. Results are reported in Figure 7 for the 5% noise case for which the agreement between the actual and reconstructed temperature profiles was the poorest. In effect, we ran numerous reconstruction with 5% noise added to the film thickness and averaged the reconstructed temperature profiles. Figure 7(a) shows two realizations of the reconstructed temperature profiles (Realizations 1 and 2) which are rather poor. However, averaging the reconstructed temperature profile over 50 realizations yields a very good agreement with the actual distribution, as anticipated. Figure 7(b) shows the norm of the difference between the actual and reconstructed temperature profiles. It is clear from this graph that the norm decreases very rapidly for the first few realizations with very marginal reduction of this norm between 10 to 50 realizations. This indicates that, in practice, few realizations of the experiment would be necessary in order to obtain a reliable reconstruction of the temperature distribution.

To explore the effects of the Prandtl number (Pr), the Biot number (Bi), and the surface tension parameter (S) on the reconstruction algorithm the algorithm was run for four different scenarios where Fr = 1, M = 4, and ϵ = 0.05 are fixed and the Biot number, Prandtl number and surface tension parameter vary, that is, Bi ∈ {0.1,1, 2}, Pr ∈ {1,5}, and S ∈ {1,2}. A nonlinear parabolic (concave) profile is considered for the stretching velocity that is, U = 0.6(0.1x + 0.005x2) for all four cases. Considering Figures 8(b), 9(b), and 10(b), it can be seen that the reconstruction algorithm recovers the temperature profile extremely well without noise even if the imposed stretching velocity is nonlinear. For 2% and 5% added noise, the quality of the reconstruction is still reasonable. The corresponding free surface profiles can be seen in Figures 8(a), 9(a), and 10(a). Slightly larger discrepancies can be observed when the surface tension parameter is increased from S = 1 to S = 2, see Figure 11(b).

3.2. Stretching Velocity Reconstruction from Two Free Surface Snapshots and Prescribed Temperature Distribution

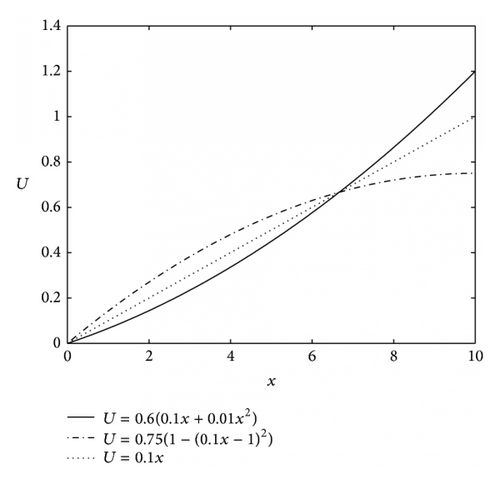

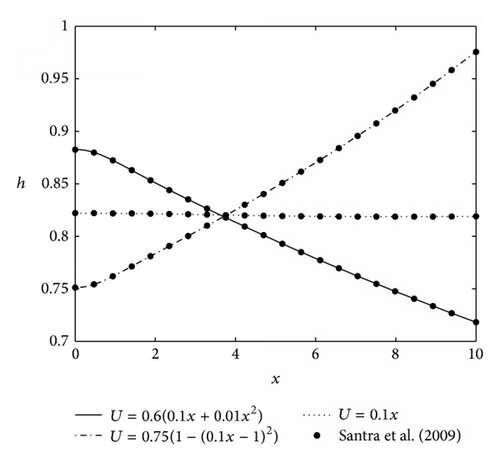

It is clear from the work of [10–12] that the stretching velocity plays an important role in the evolution of the thin film height. In addition to the Marangoni effect, the type of stretching applied at the bottom sheet mainly influences the film profile. In the following analysis, we discuss how to reconstruct the stretching velocity from given free surface data and temperature distribution at the surface. For this purpose, we first solve the forward problem for the film thickness profile up to a particular time for a given temperature distribution and stretching sheet velocity. To reconstruct the stretching velocity profile, we consider the same governing equations: (3) in continuous form and (6) in discretized form. In order to solve the nonlinear algebraic equation (6) for the stretching velocity U from the known two successive free surface profiles and the temperature function Θ, we first prescribe the stretching sheet velocity at the boundary points and then solve the equation using MATLAB fsolve routine. It is observed that for any nonzero constant initial guess, the MATLAB solver converges within less than 10 iterations.

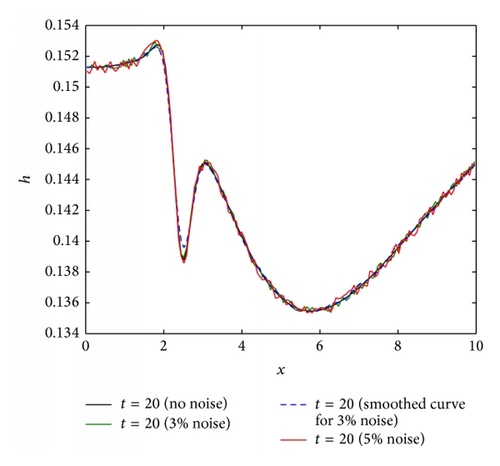

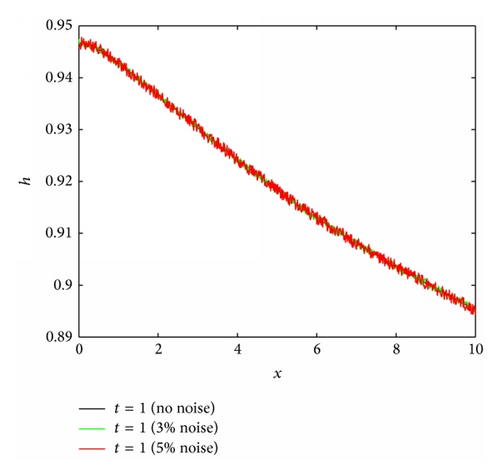

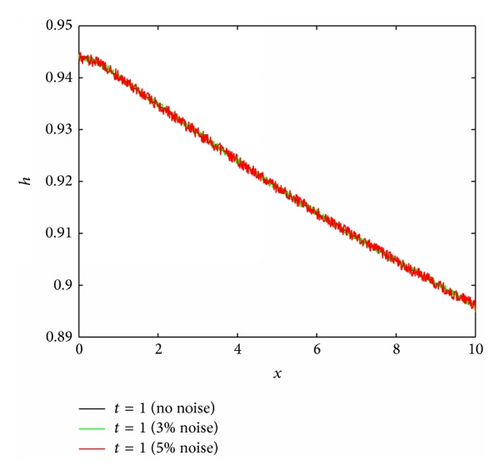

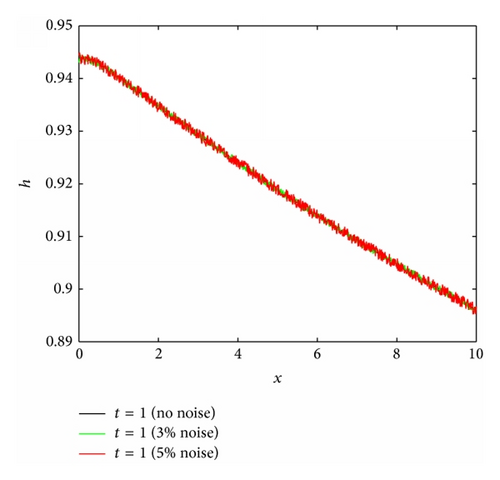

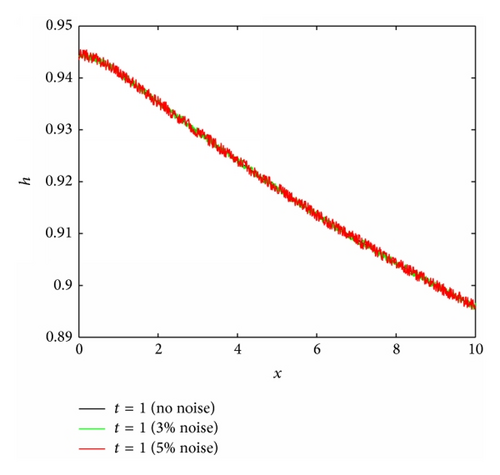

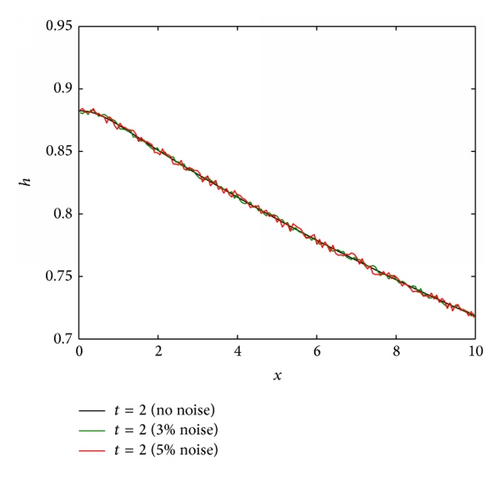

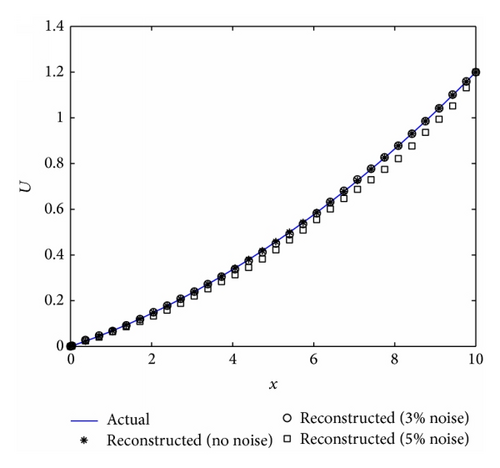

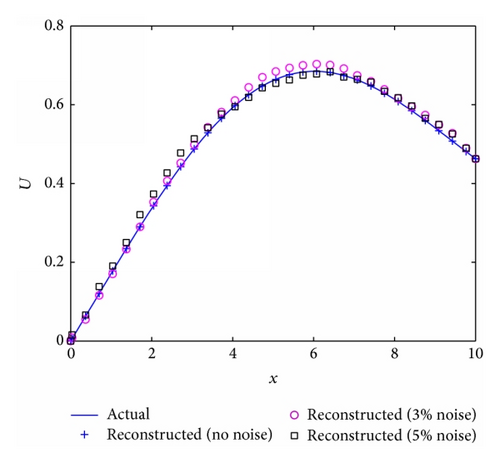

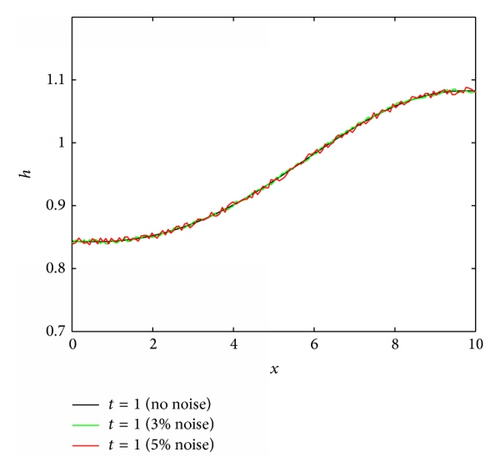

For the first case, the film thickness is obtained up to a particular time of t = 2 for the stretching velocity U(x) = 0.6(0.1x + 0.01x2), and temperature profile is given by (12). The other flow parameters used in the simulation are reported in the figure caption. The transient solution is obtained by solving (6), for 150 grid points and time steps of 0.1. The film thickness at t = 2 is shown in Figure 12(a) without noise and with 3% and 5% noise. Figure 12(b) shows the reconstructed and actual stretching velocity profiles. In the absence of noise, the perfect agreement between the two profiles confirms that the reconstruction algorithm is able to recover the stretching velocity equally well as it could recover the substrate temperature profile. The addition of up to 5% noise still lead to a reasonable reconstruction.

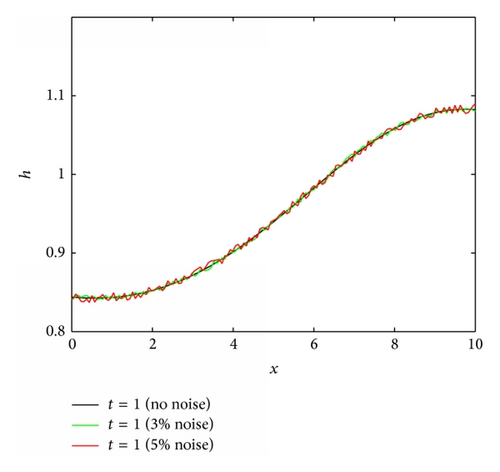

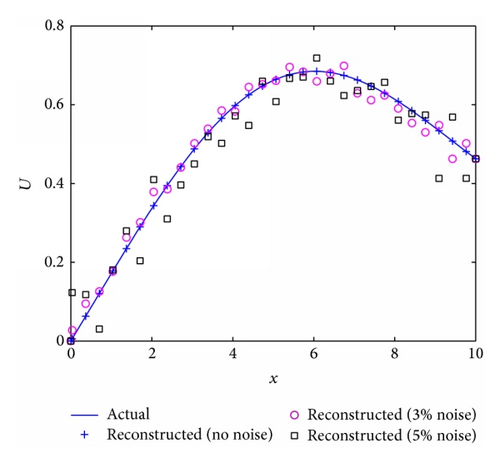

For the second case, the film thickness is obtained up to a particular time of t = 1 for the nonmonotonic stretching velocity and temperature profile . The other flow parameters used in the simulation are reported in the figure caption. The simulation results for reconstructed surface velocity without surface tension (S = 0) and with surface tension (S = 0.1) are given in Figures 13(b) and 14(b), respectively. In the absence of surface tension the reconstruction algorithm is able to recover the stretching velocity profile. It can be seen that with the inclusion of surface tension the algorithm perfectly reconstruct the sheet velocity in the absence of noise (Figure 14(b)). With the addition of noise the reconstructed results differ mildly from the actual one.

4. Concluding Remarks

A solution strategy is presented in this work to reconstruct the surface temperature profile or the surface stretching rate from the knowledge of the thickness at a given time and its rate of change. The main idea is simply based on a rearrangement of the equations derived by Santra and Dandapat in [12] for nonisothermal thin liquid films on stretching surfaces. This rearrangement of the governing equations leads to an explicit partial differential equation which governs the inverse problem. This allows to solve the inverse problem in “one shot” which is a considerable advantage compared to the traditional way of approaching such inverse problems based on pde-constrained optimization theory. We have demonstrated that the algorithm is quite robust in the sense that noise in the input data is not too amplified provided the input data is smoothed using a cubic spline. Whilst the focus of this paper is on the presentation of the conceptual idea, future work will assess the feasibility and practicality of the suggested approach using true experimental data.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.