Analysis of the Elastic Large Deflection Behavior for Metal Plates under Nonuniformly Distributed Lateral Pressure with In-Plane Loads

Abstract

The Galerkin method is applied to analyze the elastic large deflection behavior of metal plates subject to a combination of in-plane loads such as biaxial loads, edge shear and biaxial inplane bending moments, and uniformly or nonuniformly distributed lateral pressure loads. The motive of the present study was initiated by the fact that metal plates of ships and ship-shaped offshore structures at sea are often subjected to non-uniformly distributed lateral pressure loads arising from cargo or water pressure, together with inplane axial loads or inplane bending moments, but the current practice of the maritime industry usually applies some simplified design methods assuming that the non-uniform pressure distribution in the plates can be replaced by an equivalence of uniform pressure distribution. Applied examples are presented, demonstrating that the current plate design methods of the maritime industry may be inappropriate when the non-uniformity of lateral pressure loads becomes more significant.

1. Introduction

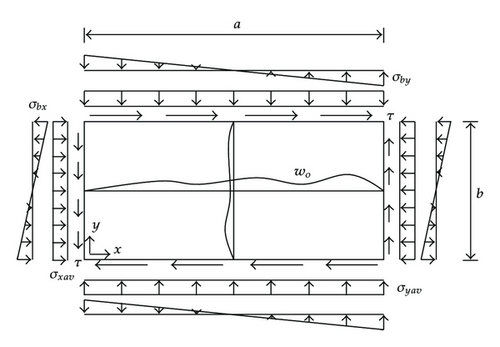

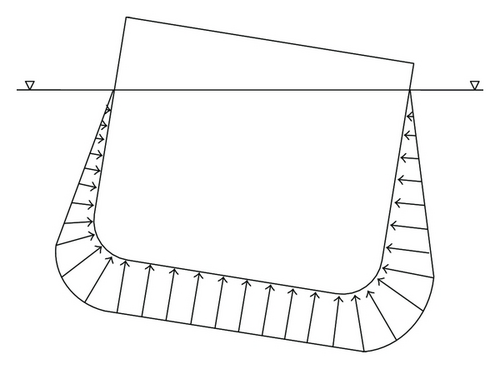

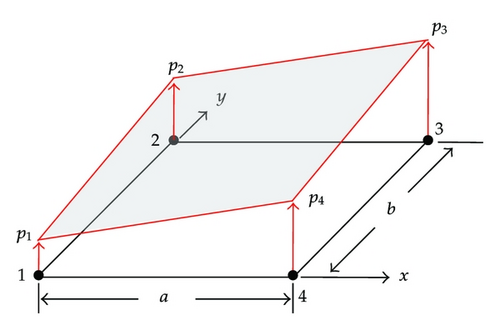

Ships and ship-shaped offshore structures are composed of metal plate elements, and the accurate computation of nonlinear behavior of the plate elements in deck, bottom and side shells up to the ultimate limit state is a basic requirement for the structural safety assessment. The plate elements in ships and ship-shaped offshore structures are generally subjected to combined inplane and lateral pressure loads. Inplane loads include biaxial compression/tension, biaxial inplane bending and edge shear, as shown in Figure 1, which are mainly induced by overall hull girder bending and/or torsion of the vessel. Lateral pressure loads are due to water pressure and/or cargo. In rough weather, roll and/or pitch motions of vessels are typical as shown in Figure 2, and, subsequently, the distribution of lateral pressure loads often becomes non-uniform as shown in Figure 3. For simplicity, however, the maritime industry usually applies a simplified design method in which the non-uniform distribution of lateral pressure loads is replaced by an equivalence of uniformly distributed lateral pressure loads with an average magnitude of applied pressure loads.

A large number of studies have been available in the literature, for example [1–6]. In the present paper, a mathematical algorithm is derived to analyze the elastic large deflection behavior, including buckling and postbuckling response, of plate elements under combined inplane and lateral pressure loads noted previously, with the emphasis on the non-uniformly distributed lateral pressure loads. The Galerkin method is applied to solve the nonlinear governing differential equations of elastic large deflection plate theory for plate elements. In the literature, the studies of metal plate buckling are also available, for example [7–13].

2. Elastic Large Deflection Analysis

3. Application to the Elastic Large Deflection Analysis of Simply Supported Plates

4. Applied Examples and Discussion

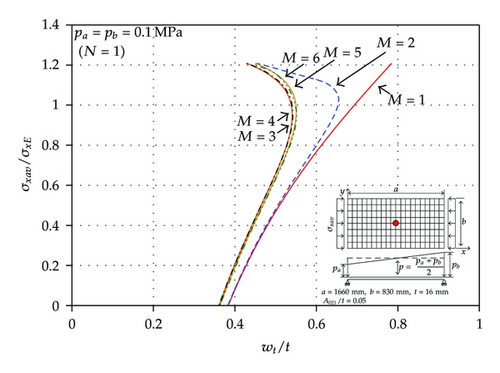

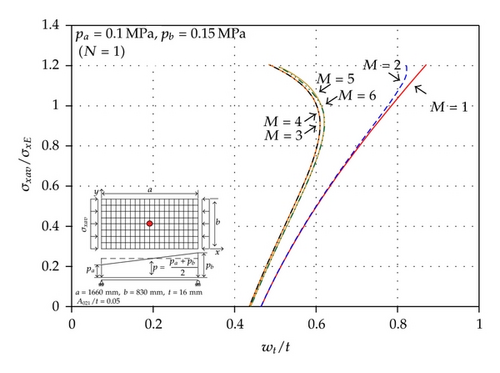

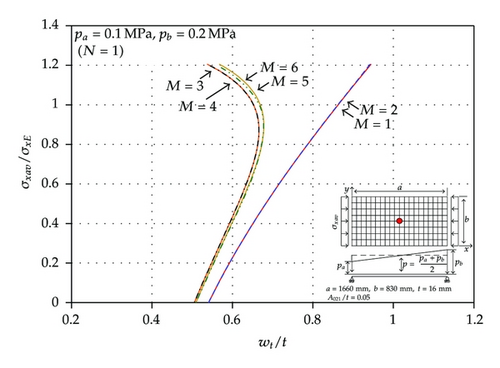

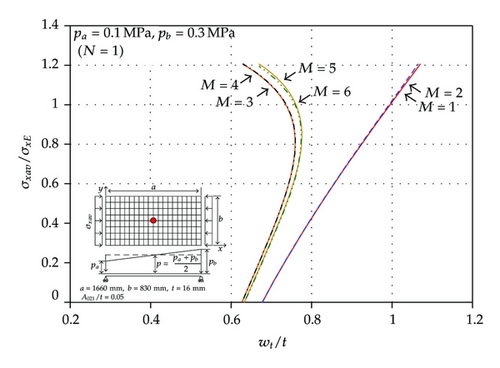

Figures 5(a) to 5(d) present the relation between the axial compressive loads versus total deflection at the center of the plate, that is, at x = a/2 and y = b/2, where the magnitude of lateral pressure loads and the maximum number of deflection amplitudes are varied. It is found that M = 5 may be sufficient enough in terms of accuracy and efficiency of the resulting computations. Table 1 represents the deformed shapes of the plate with different magnitudes or shapes of lateral pressure loads when σxav/σxE = 0 or 1.2 where M = 5 is taken. It is observed that the deflection modes of the plate are changed due to the application of axial compressive loads. This is because the plate tends to deflect as per the original buckling pattern associated with axial compressive loads.

pa (MPa) |

pb (MPa) |

σxav/σxE = 0.0 | σxav/σxE = 1.2 |

|---|---|---|---|

| 0.1 | 0.1 |  |

|

| 0.1 | 0.15 |  |

|

| 0.1 | 0.2 |  |

|

| 0.1 | 0.3 |  |

|

| 0.1 | 0.4 |  |

|

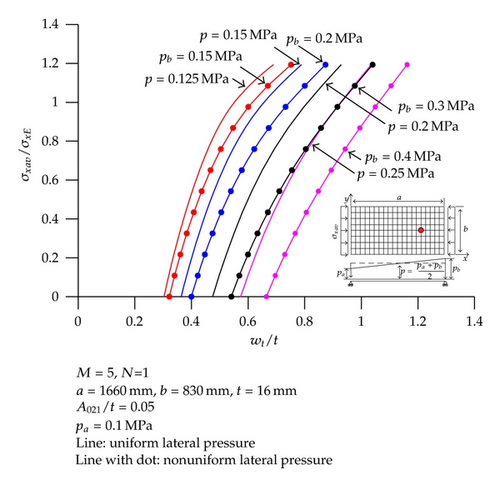

Figure 6 presents a comparison of the elastic large deflection responses of the plate between non-uniform and uniform pressure loads, the latter being taken as the average value of the pressure loads as per the current practice of the maritime industry.

It is found that the current practice of the maritime industry with an average magnitude of applied pressure loads underestimates the lateral deflection of the plate compared to the real condition of the pressure load application, that is, with a non-uniform distribution. The difference between the two cases becomes larger and larger as the non-uniformity of lateral pressure loads becomes more significant.

The underestimation of the plate deflection due to external pressure loads gives rise to the overestimation of plate strength performance which may lead to unsafe design at optimistic side.

5. Concluding Remarks

The aim of the present paper has been to analyze the elastic large deflection behavior of metal plates subject to combined inplane and lateral pressure loads. When lateral pressure loads applied in plate elements are non-uniform, the current practice of the maritime industry applies some simplified design methods in which the non-uniform pressure distribution in the plates is replaced by an equivalence of uniform pressure distribution.

In the present paper, the Galerkin method was used to solve the nonlinear governing differential equations of plate elements under non-uniformly distributed lateral pressure loads in addition to inplane loads. Some applied examples are presented, demonstrating that the current practice of the maritime industry, that is, with an average magnitude of applied pressure loads as an equivalence, results in a great underestimation of lateral deflection calculations when the non-uniformity of lateral pressure loads becomes more significant. The underestimation of the plate deflection may lead to unsafe design of plates at optimistic side.

Thin plates buckle in elastic regime, while stocky plates may buckle in elastic-plastic or plastic regime. The present paper deals with elastic behavior only, and further studies are then recommended to take into account the effect of plasticity which is dominant in thick plates. Also, it is highly desirable for practical design purpose to develop a simpler method or design formulation.

Nomenclature

-

- a:

-

- Length of the plate

-

- b:

-

- Breadth of the plate

-

- D:

-

- Plate bending rigidity ( = Et3/12(1 − ν2))

-

- E:

-

- Young’s modulus

-

- F:

-

- Airy’s stress function

-

- M, N:

-

- Maximum half-wave number of the assumed added deflection function in the x and y directions

-

- Mx:

-

- In-plane bending moment in the x direction ( = σbxt)

-

- My:

-

- In-plane bending moment in the y direction ( = σbyt)

-

- p:

-

- Lateral (out-of-plane) pressure load on the surface area

-

- Px:

-

- Axial force in the x direction ( = σxavbt)

-

- Py:

-

- Axial force in the y direction ( = σyavat)

-

- t:

-

- Thickness of the plate

-

- w:

-

- (Added) deflection of the plate due to the action of external loads

-

- wo:

-

- Initial deflection of the plate

-

- wt:

-

- Total deflection of the plate

-

- z:

-

- Axis direction normal to the xy plane

-

- α:

-

- Aspect ratio of the plate ( = a/b)

-

- ν:

-

- Poisson’s ratio

-

- σbx, σby:

-

- Bending stresses in the x and y directions

-

- σx, σy:

-

- Normal stresses in the x and y directions

-

- σxav, σyav:

-

- Mean stresses in the x and y directions

-

- τ = τxy:

-

- Shear stress.

Acknowledgments

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (Grant no. K20903002030-11E0100-04610).