The urban mine of the Netherlands: The material basis for a circular economy

Editor Managing Review: Wei-Qiang Chen

Abstract

Resources are essential for humanity's well-being and development. At the same time, resources lay at the heart of many environmental problems. A sustainable resource use facilitates development but reduces environmental problems. This apparent contradiction can be solved by moving toward a circular economy: keeping resources, once extracted, in use for as long as possible. The services fulfilled by the in-use stocks of resources can thus be maintained or even increased, while the inflow of virgin materials into the stocks can be reduced. In this view, society's material basis shifts from geological mines to urban mines: materials locked in products and infrastructures presently used by societies. Although very important, the information on such urban mines is scarce. In this paper, we present the results of an inventory of the urban mine of the Netherlands. We assessed 86 categories of applications, both products and infrastructures, and 53 different materials. The Dutch urban mine adds up to 447 tonnes of materials per inhabitant, mostly construction materials. The inventory can be regarded as a pilot project. It indicates an approach for assessing the urban mine and how to standardize such an effort. It can also be seen as a first estimate of what we collectively have to work with to realize a circular economy. The overall conclusion is that the urban mine is of considerable size and could be a major source of materials but it will take a considerable time and some major changes in the organization to realize that.

1 INTRODUCTION

1.1 The resource challenge

Resource extraction is the root cause of many environmental problems. In the Global Resource Outlook, the UN-IRP concludes that resource extraction is now responsible for over 55% of greenhouse gas (GHG) emissions, 90% of land use, and 40% of particulate matter-related health impacts (United Nations Environment Programme 2024). It is also argued that for solving climate change, the major challenge of our times, a focus on resource extraction is as least as important as a change in energy technology (Bleischwitz et al., 2018; Pauliuk et al., 2021; United Nations Environment Programme 2024).

Reducing resource use in a situation of a growing world population and the need for development in many parts of the world is not an easy road to travel. This tension can be felt also in the UN Sustainable Development Goals (SDGs, https://sdgs.un.org/goals): While the environment-oriented SDGs call for reduced resource extraction, the development-related SDGs often require increased resource use.

Resource use cannot be treated as a problem similar to greenhouse gas emissions. For GHG emissions, the target is zero. For resource use, it can never be zero. Resource extraction causes certain problems, but on the other hand, resources fulfill essential functions for society. We need food, we need shelter, and we need transport and communication, and to provide these functions, we need resources. Resource use therefore is unavoidable, and reducing resource extraction must be done with care to avoid negative impacts on people and society as a whole.

1.2 Circular economy as a solution

One way out of this dilemma is to transform society from a linear economy into a circular economy. Instead of wasting resources by landfilling or incineration of discarded products and materials, the idea is to keep resources in use for as long as possible. The circular economy is a concept that is not yet very well defined (Kirchherr, Urbinati, et al., 2023; Kirchherr et al., 2017; Kirchherr, Yang, et al., 2023). Nevertheless, it is shaping into a research field of considerable size (Geissdoerfer et al., 2017; Kirchherr et al., 2023; Korhonen et al., 2018; Murray et al., 2017; Velenturf & Purnell, 2021; Zeng & Li, 2021). It is primarily linked to strategies using resources more efficiently, but also is branching out into business as a new business model (Henry et al., 2020; The Ellen MacArthur Foundation 2015; Tunn et al., 2019) linked to innovation (Esposito et al., 2018; Suchek et al., 2021), and into policy (Braun & Toth, 2021; Department for Environment, Food, & Rural Affairs U., Department of Agriculture, E., & R. A. N. I. 2020; European Commission 2020, Government of United Arab Emirates 2021; Ministry of Infrastructure and Water Management, Ministry of Economic Affairs and Climate Policy, Ministry of the Interior and Kingdom Relations, Ministry of Agriculture, N. and F. Q., & Ministry of Foreign Affairs 2023; Ministry of the Environment 2019, National Development & Reform Commission 2021).

It becomes increasingly clear that resource use is one of the main causes of the triple planetary crisis (Desing et al., 2020; Garcia-Saravia Ortiz-de-Montellano et al., 2023; Hellweg et al., 2023; United Nations Environment Programme 2024; Vann Yaroson et al., 2024; Xie et al., 2023; Yang et al., 2023), and therefore, a resource transition is needed in addition to an energy transition. Circular economy strategies are an essential part of such a transition (Garcia-Saravia Ortiz-de-Montellano et al., 2023; Geissdoerfer et al., 2017; Vann Yaroson et al., 2024).

While there is as yet no accepted definition of a circular economy, the ideas behind the concept are relatively clear. A circular economy aims at keeping resources in use as long as possible. This reduces waste generation but also has the potential to reduce resource extraction. By different strategies, such as lengthening the life span of applications, re-using discarded products or components, and recycling materials, it should be possible to retain the functionality of resources while seriously reducing the need for extraction of virgin resources. Frameworks of circularity strategies have been developed that are less or more comprehensive (De Pascale et al., 2021; Geissdoerfer et al., 2017; Moraga et al., 2019; Murray et al., 2017; Velenturf & Purnell, 2021)—these frameworks differ somewhat in scope or details, but they all aim at the same: reducing extractions, waste, and emissions by keeping resources in the use phase.

A circular economy thus relies on resources already extracted in the past and locked in structures, applications, and products that are presently in use: the in-use stocks in society. Industrial ecologists increasingly use the concept of the stocks–flows–service nexus (Haberl et al., 2021; Pauliuk et al., 2021; Tanikawa et al., 2021): The in-use stocks of products and structures (containing materials) provide services to society, such as shelter and mobility. The flows, the main focus of economic accounting, in this view only exist to maintain or grow the stocks at or to a desired level. This way of viewing society's metabolism offers new insights into the potential of a circular economy. It is not just about process efficiency and closing loops but about asset management: maintaining in-use stocks with far less input of new materials, thereby effectively decoupling economic development from resource extraction, and potentially reconciling the conflicting SDGs. These ideas are highly valuable and show a way forward, albeit at a very abstract level.

1.3 Prospecting the urban mine of the Netherlands

In this view, these in-use stocks can be regarded as a potential source of materials: the urban mine (Chen & Graedel, 2015; Hu et al., 2010; Krook et al., 2011; Rauch, 2009; Wittmer & Lichtensteiger, 2007; Zhao et al., 2024). In a circular economy, not the mines in the environment, but the urban mine is the material basis of our society (Aldebei & Dombi, 2021; Di Maria et al., 2013; Kakkos et al., 2020; Krook et al., 2020; Nakamura & Halada, 2015; Simoni et al., 2015; Wen et al., 2015). To actually make this work, many steps need to be taken, conceptually and in practice. It would mean a re-thinking of society's metabolism and therefore also of the way we do business. Urban mining is not a synonym for recycling, it goes much further. Not just waste management, but also use, production, and design needs to be different, and organizational changes must be made as well to enable a continued use of resources in society. The challenge is large, but if we just start one step at a time, we might get there in the end.

An obvious first step is an inventory: prospecting the urban mine. Our knowledge of geological resources is extensive and we have geological surveys keeping track, but comparatively little is known about the resources in our urban mine. While to some extent statistical offices have kept track of material flows as part of the system of national accounts (Delahaye et al., 2023), stocks have been ignored. This lack of information makes it very difficult to do any kind of planning. Several studies attempt to quantify in-use stocks for particular materials or specific applications in specific countries or areas, often in time series, using dynamic material flow analysis, (Chen & Graedel, 2015; Deetman et al., 2020; Elshkaki & Graedel, 2013; Elshkaki et al., 2004; Heeren & Hellweg, 2019; Hu et al., 2010; Kalt et al., 2021; Kleijn et al., 2000; Krausmann et al., 2020; Krook et al., 2011; Lifset et al., 2002; Rauch, 2009; van Oorschot et al., 2022; Wallsten et al., 2015; Wiedenhofer et al., 2015; Wittmer & Lichtensteiger, 2007) but at the moment these are still isolated academic efforts.

In this paper, we show the results of a research program of a number of years (Netherlands Environmental Assessment Agency 2021; Netherlands Environmental Assessment Agency 2023) conducted for the Dutch government to support their circular economy policy (Ministry of Infrastructure and Water Management, Ministry of Economic Affairs and Climate Policy, Ministry of the Interior and Kingdom Relations, Ministry of Agriculture, N. and F. Q., & Ministry of Foreign Affairs 2023): an inventory of the urban mine of the Netherlands. It is, unlike most of the previously cited examples, a bottom-up study, covering a great many individual applications and the resources locked in them. It is only a first step, but an essential and important one: it represents the information base of a circular economy. In view of the abovementioned lack of attention to stocks in policies and (therefore) statistics, this endeavor can also be regarded as a pilot study: Is it actually possible to find the necessary information to compile a comprehensive database of the Dutch urban mine? If successful, could the approach be used in other parts of the world as well?

The study has resulted in a number of reports and databases (in the Dutch language) (van Oorschot et al., 2020; van Oorschot et al., 2020; van Oorschot et al., 2023; Verhagen et al., 2022), and a number of MSc thesis reports (in English) (Pieters, 2021; Roelofs, 2020; van Beijnum, 2021; van der Bent, 2022; van der Zaag, 2020; Verschelling, 2020). Below, we elaborate on the methods and data we used. Then, we show some results and some first interpretations. The database itself can be found in Supporting Information S1. Finally, we comment on the possibilities for improvement and next steps to take and perhaps even more importantly on how these data can be used to set out a road toward a circular economy.

2 METHODS AND DATA

2.1 Demarcation

Geographical boundaries refer to the European part of The Netherlands, and the inventory is made for the year 2020 or as closely as we could get to that.

Our inventory focuses on in-use stocks of materials in nine sectors, here to be understood as nine major categories of applications. We did not include inherently linear applications of resources, such as food or packaging. While such linear applications could and should be part of a circular economy policy, we do not consider them to be part of the urban mine. We focus on applications with an average life span of longer than one year. Within that focus, we tried to be as comprehensive as possible. For materials, we distinguish six major categories. For our categories of applications, we try to stay as close as possible to categories used in national statistics. This enables us to use statistical data whenever possible, but it also allows for harmonization with other countries, if they would embark on a similar journey.

Within the nine sectors and six material categories, we distinguish many subcategories. These are specified in S1 of the Supplementary information.

3 METHOD

- Specify in-use stocks in terms of the applications as mentioned above. The unit may differ per application. For buildings, for example, we used m2 useful floor area. For infrastructural elements such as road, rail, or cables, we used length in km. For consumer products, we used pieces: the number of cars, computers, mobile phones, musical instruments, etc.

- Specify the material contents of the application per category, subcategory, and material, in terms of kilograms of specific materials per m2 useful floor area, per km pipeline, or per product. This information is also referred to as the material intensity. The added weight of specific materials per unit of application should add up to the total weight of the unit.

- Multiply units of applications with material content per unit of application to obtain kilograms of materials. This is done for total weight but also for individual materials. Thus, a long list emerges showing kilograms of materials per (sub)category of application at the most detailed level. This, essentially, is the database of the Dutch urban mine.

These numbers can be combined in different ways to allow for different interpretations.

4 DATA

Table 1, further down, shows the nine major categories of applications and six major categories of materials. In Supporting Information S1, this list is further detailed: Within each application category, we distinguish a list of products or product groups that varies from 7 (buildings) to 15 (consumer goods), to a total of 86 products. Within each category of materials, we distinguish individual materials, to a total of 53. This leads to a total of 4558 entries, although many of these are empty since not all materials occur in every product. The database, in the shape of a spreadsheet added to Supporting Information S4, shows all of these values with the data sources we used.

|

Categories of materials Categories of applications |

Construction minerals | Construction materials | Metals | Biobased materials | Other materials | Critical raw materials (CRM) | Total | % of total |

|---|---|---|---|---|---|---|---|---|

| Buildings | 4.93E+08 | 2.02E+09 | 1.03E+08 | 4.70E+07 | 4.26E+07 | 0.00E+00 | 2.71E+09 | 35% |

| Road, rail, and waterways infrastructure | 3.84E+09 | 1.11E+09 | 2.12E+07 | 6.42E+04 | 2.56E+05 | 0.00E+00 | 4.98E+09 | 64% |

| Energy system | 0.00E+00 | 6.21E+06 | 4.85E+06 | 1.56E+03 | 8.96E+05 | 1.61E+04 | 1.20E+07 | 0% |

| Drinking and sewage water infrastructure | 0.00E+00 | 2.36E+07 | 1.81E+06 | 0.00E+00 | 5.96E+06 | 0.00E+00 | 3.14E+07 | 0% |

| Vehicles | 0.00E+00 | 0.00E+00 | 3.21E+07 | 2.42E+06 | 1.26E+06 | 4.74E+03 | 3.58E+07 | 0% |

| Machinery | 0.00E+00 | 1.95E+06 | 7.26E+06 | 0.00E+00 | 1.13E+06 | 3.32E+02 | 1.03E+07 | 0% |

| Textiles | 0.00E+00 | 0.00E+00 | 3.23E+05 | 1.06E+06 | 3.17E+06 | 0.00E+00 | 4.55E+06 | 0% |

| Consumer electronics | 0.00E+00 | 0.00E+00 | 7.21E+05 | 0.00E+00 | 3.70E+05 | 3.42E+04 | 1.13E+06 | 0% |

| Other consumer goods | 0.00E+00 | 1.54E+05 | 3.43E+06 | 5.45E+06 | 5.19E+06 | 2.17E+04 | 1.42E+07 | 0% |

| Total | 4.34E+09 | 3.16E+09 | 1.75E+08 | 5.60E+07 | 6.08E+07 | 7.70E+04 | 7.79E+09 | 100% |

| % of total | 56% | 41% | 2% | 1% | 1% | 0% | 100% |

- Note: Section 1 of Supporting Information S1 contains the specification of the application categories and the products that belong to them, as well as the material categories and the materials that fall under them.

Following the method we used, two types of data are required: data on the applications and data on the material content of the applications.

For data on applications, the starting point always was the official statistical data of CBS, the Netherlands’ Central Bureau of Statistics. For example, the official registration of buildings in the BAG (Basisadministratie Adressen en Gebouwen, https://www.digitaleoverheid.nl/overzicht-van-alle-onderwerpen/stelsel-van-basisregistraties/10-basisregistraties/bag/) is very detailed and quite comprehensive and contains among others data on m2 useful floor area of different types of buildings. Also, in-use road vehicles are centrally registered, which allows specifying the in-use stock of vehicles in terms of numbers or, in other words, the vehicle fleet. For most other applications, stock data are lacking in the official statistics. The next step we took was contacting the managers of the stocks themselves. Especially for infrastructural stocks, this proved to be effective. We obtained data, often in great detail, directly from the electricity and gas grid managers, the water supply companies, the sewage grid managers, and the railway managers. For the stocks in road and waterway infrastructure, we relied on a parallel study done by EIB and Metabolic (Arnoldussen et al., 2022) for Rijkswaterstaat, the governmental body that is responsible for maintaining this infrastructure at the national level. Consumer products and industrial machinery data are available from CBS in terms of flows: annual purchases. For these applications, CBS made the conversion to in-use stocks based on estimated life spans, following the method developed in the ProSUM project for electronics (https://prosumproject.eu/) (Wagner et al., 2021).

While we were pleasantly surprised by the amount and quality of data on in-use stocks we could put together in terms of applications, data on the material content of applications proved to be much more difficult to collect. Product compositions are highly variable even within the subcategories we used, and systematic reporting of product compositions is not happening. For some categories of applications, a modest body of literature is developing. Examples are buildings and electronics, so far the primary applications of interest of circular economy initiatives, and the subject of a number of scientific publications (Aldebei & Dombi, 2021; Deetman et al., 2020; Deetman et al., 2018; Heeren & Fishman, 2019; Heeren & Hellweg, 2019; Hu et al., 2010; Huang et al., 2020; Kleemann et al., 2017; Marcellus-Zamora et al., 2016; Marinova et al., 2020; Miatto et al., 2019; Rose & Stegemann, 2019; Schiller et al., 2019; Stevels et al., 2013; Wagner et al., 2021; Yang et al., 2020). Buildings are by far the best-researched application. Initiatives are underway to provide material passports for new buildings, for example, through institutions like Madaster (https://madaster.com/). Madaster Netherlands has plans to expand its inventory also to older buildings and road infrastructure. For energy infrastructure, the grid managers (six in total, three large ones) provided the information. For the other applications, we started with a survey of projects that are dedicated to specifying material contents (see Section 3 of Supporting Information S1). For applications such as cars, we used life cycle inventory databases from the background reports of the Ecoinvent database (https://ecoinvent.org/) and did some extrapolations from there. Consumer products again were the most difficult category due to the enormous variability of that category in terms of products, and the even greater variability of material composition. Our data here are weak and can only serve as a first approximation.

The database that is the result of our investigations is provided in the description in Supporting Information S4, with references to the reports and databases we used (specified in Supporting Information S3 where a link is provided to all reports and data of the Dutch urban mine series of projects, including the MSc thesis reports of contributing students.

5 RESULTS

5.1 The database

The main result of the investigation is the database itself, which can be used for a variety of purposes, but it may also be interesting to have a closer look at the data. What does this inventory tell us of the urban mine of the Netherlands, in terms of size and composition? Being the first comprehensive effort of its kind, what meaning can be attached to the numbers?

5.1.1 Aggregate results

Table 1 shows the overall, aggregate results in metric tons of materials.

At the most aggregate level, there is just one number: the total weight of the urban mine of the Netherlands. How much of resources, in terms of kilograms, are locked in in-use stocks of applications? This number is, as can be seen from Table 1, 7.79 billion tons of materials, or roughly 450 tons of materials per inhabitant of the Netherlands.

What is the significance of that number? The number of studies investigating the urban mine is limited. We know of one study estimating in-use stocks at a world scale: the study by Kraussman and colleagues (2017). According to their estimation, the in-use stocks at the global level add up to approximately 100 ton/cap, and for industrialized countries, this is 320 ton/cap. Our inventory delivers numbers in the same order of magnitude, which is encouraging. Even so, the Dutch urban mine according to our estimate is large compared to the global average from Krausmann et al., which is to be expected. It is even larger compared to the industrialized countries’ average. It is difficult to assess the underlying reason for this difference, also because the approach in both studies is really different.

From Table 1, it is clear that construction minerals (mostly sand and gravel) and construction materials (mostly concrete) form the bulk in terms of materials, and that buildings and road, rail, and waterways are the sectors where most of the materials are stocked. These are also the applications with the longest life span, from decades to centuries.

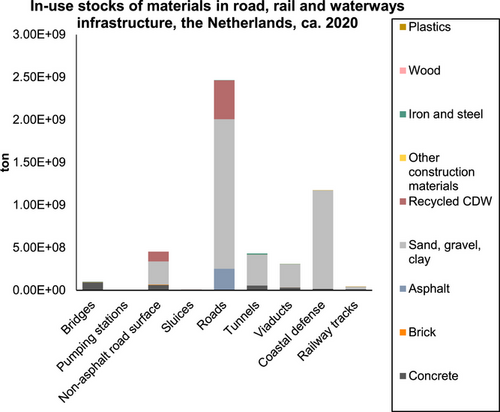

5.1.2 Road, rail, and waterways infrastructure

Construction minerals are found mainly in the largest stock, infrastructure. Figure 1 shows the distribution of the minerals over the different parts of the infrastructure system.

Most materials are present in roads; the second are coastal defense structures. This last number is probably going to increase in the coming years as the sea level rises. While sand is an abundant material, it is increasingly identified with supply problems and ecosystem damage and might become a “critical material” before long (Wang et al., 2024). This stock is also an interesting one from a management point of view: the infrastructure elements are in the hands of only a few actors, these actors are mostly linked to the government, and the resources mostly come from within the country. This makes it a promising case to experiment with the organization of the mining of this huge urban mine.

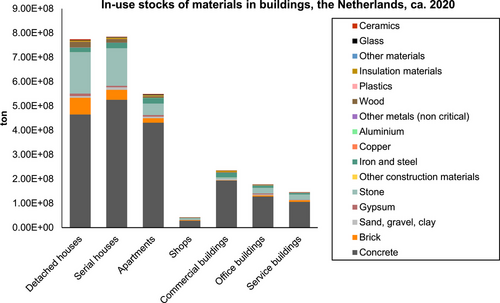

5.1.3 Buildings

The second largest stock is found in buildings. There is somewhat more variety in the composition of this stock. Not just minerals-based construction materials, but also metals and biobased materials are included here. Figure 2 shows this.

Stocks include residential buildings of three types, but also commercial and service buildings such as storehouses, schools, and hospitals. The composition of these buildings is not very different, although this overview does hide a lot of smaller variations. Concrete, brick, and stone dominate, but steel and wood are also visible at the top of the graphs (for steel and wood, buildings are actually the major application). This stock, like the infrastructure stock, is mostly sourced domestically as far as the construction minerals and derived construction materials are concerned. On the other hand, ownership is very different and includes millions of private residents as well as local governments and many smaller and larger businesses.

5.1.4 Vehicles

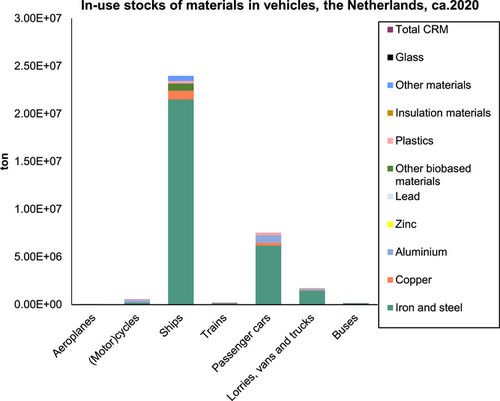

A third stock we would like to show is the stock of materials in vehicles (see Figure 3).

This stock is one order of magnitude smaller than buildings. The main material in this stock is steel. Vehicles contain the second largest stock of steel, after buildings. Contrary to our expectations, the largest steel stock is not found in passenger cars owned by Dutch inhabitants, but in ships sailing under the Dutch flag. When thinking about how to retrieve that steel after the useful life span of the vehicles, this is relevant information (Kong et al., 2022).

5.1.5 The electricity system

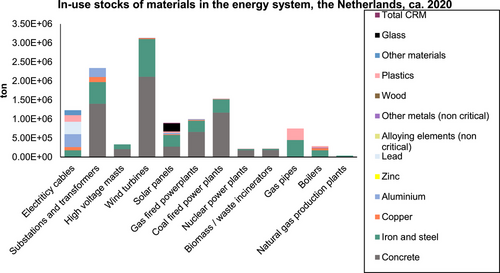

Finally, an interesting in-use stock is that of the electricity system. Figure 4 shows this.

This stock is subject to large changes. At the moment, the system is dominated by fossil fuel technologies: gas and coal-fired power plants for electricity, and natural gas for heating. Renewable technologies are rapidly increasing and taking over. Presently, their share in energy generation is still minor, but already the stocks are major as can be seen in Figure 4: The largest stock is to be found in wind turbines, consisting of concrete and steel but also some critical materials. The emerging renewable energy system is thus much more material intensive than the old fossil system, not just regarding critical raw materials but also in terms of “ordinary” materials such as concrete, steel, and copper. The present distribution system for electricity will have to increase its stock as well, as the heating system and the vehicle fleet transfer from fossil fuels to electricity. Old stocks of the fossil system, including the gas grid, will become obsolete and will become available for reuse or more likely for recycling. Studies show that obsolete materials from the old system may fulfill some of the demands of the new system (Le Boulzec et al., 2022; Liang et al., 2024).

5.1.6 Hibernating stocks

A stock of a special nature is the so-called hibernating stock. Hibernating stocks are no longer in use but also not yet discarded and handed over to some waste management facility. Examples are underground electricity cables, gas pipes, or sewage elements that are no longer functional but just left in the ground. Other examples are no longer-used electronic appliances or mobile phones that still remain in peoples’ homes. We have been able to quantify some parts of the Dutch hibernating stocks: underground pipes and cables, monopiles, sewage pipes, and abandoned railways. This totals over a million tons, three-quarters of which are construction materials and minerals, around 15% metals, mainly copper and aluminum, and 10% biobased materials, mainly wood. Such stocks can be seen as an ideal starting point for urban mining: Unlike the bulk of the urban mine, the hibernating stocks are no longer used and therefore immediately available. A handful of studies focus on such hibernating stocks and explore the feasibility of mining them (Daigo et al., 2015; Krook et al., 2011; Wallsten et al., 2015).

In Supporting Information S2, overviews of the other stocks can be found. These stocks are smaller but contain some valuable materials and, therefore, are still important as urban mines.

5.2 Interpretation of the data: Uncertainties and relevancy

The interpretation of these numbers is the next step. What do they mean, in terms of uncertainty and reliability? And what do they mean in terms of the magnitude of the urban mine and its potential to become a major source of materials?

5.2.1 Data uncertainties

-

The data on the applications themselves are generally reliable and well-registered. Especially, data on stocks of buildings, infrastructure of different types, and vehicles are trustworthy. For machinery, textiles, and consumer products, stock data are an estimate based on flow data and an assumed life span distribution. At the moment, it is the best we could do, but the uncertainties for these stocks are considerable.

-

The uncertainties in the material contents generally are much larger. With some exceptions, data on material contents for major applications such as buildings and infrastructure are taken from the scientific literature. At best, these data represent an average for the Netherlands, and sometimes not even that, but for Western Europe or even larger parts of the world. There is a large variability in material contents that is not well represented in our database.

-

Buildings and electronics are the best-researched application categories. Here, the different studies show some convergence regarding material contents. In addition, tracking the material composition of consumer electronics is supported by the waste legislation on electronics currently in place at the EU level: Countries are obliged to keep track of their waste electronics.

-

For some application categories, the sectors themselves could provide roughly reliable data on material composition, such as the road, rail, and waterway infrastructure, and the underground infrastructures of the energy and drinking/wastewater system. These infrastructure elements are relatively simple in their composition, so we feel comfortable using these data.

-

Vehicles, especially cars, have the advantage of being well-studied in general. However, their wide variety makes it necessary to make choices and provide averages. The rapid developments in hybrid and electric vehicles cause composition data to be outdated quite soon. For less well-researched vehicles such as ships and bicycles, we used LCI data and had to take quite some shortcuts. Still, as a first approach, it makes sense.

-

Composition data on other consumer goods, industrial machinery, and textiles are highly uncertain and often serve as guestimates. These are mostly based on LCI data that may not even be representative of the subcategory as a whole, and where there is actually a large variety in product composition.

-

Some material categories are better researched than others. For many applications, the major materials are well-reported, while the small-scale ones are neglected. The urban mine for individual small-scale materials in our study is therefore probably underestimated, or is hidden in categories such as “other metals,” “alloying elements,” or “CRM unspecified.” For others, especially electronics, energy technologies, and other technological products, the focus is often on the minor metals, especially on critical raw materials; therefore, the information is much better for these applications. In general, alloys are not well accounted for and the many, many types of steel or aluminum are all lumped together.

We have not attempted a quantification of these uncertainties.

5.2.2 Relevancy

There are not many inventories of the urban mine that we could use as a comparison. There are studies for individual materials, such as steel (Pauliuk et al., 2013; Song et al., 2020) or copper (Ciacci et al., 2017; Dong et al., 2020; Lifset et al., 2002) in different countries and even at the global level (Pauliuk et al., 2013), and there are sector studies related to buildings (Deetman et al., 2020; Guo et al., 2019; Haberl et al., 2024; Hu et al., 2010; Kleemann et al., 2017; Lotz et al., 2024; Marinova et al., 2020; Miatto et al., 2019; Schiller et al., 2019; Yang et al., 2020), infrastructure (Deetman et al., 2021; Kalt et al., 2021; Krausmann et al., 2020; van Engelenburg et al., 2024), or vehicles (Carmona et al., 2021; Gassner et al., 2020; Wiedenhofer et al., 2015). Stocks of electronics have been assessed, mostly at the EU level, including detailed information on their composition (Murthy & Ramakrishna, 2022; Wagner et al., 2021; Wagner et al., 2023; Xavier et al., 2021). These sectoral studies have been useful for our inventory, and we have used their data on material composition either directly, or to check our own data.

Regarding the potential to become a major source of materials in the future, the first step after quantification is to add an interpretation step: Now we have the numbers, but what is their meaning: is that a lot, or not so much? We did an attempt to answer this question for two metals, copper and cobalt, by comparing the “urban reserves” with the geological reserves.

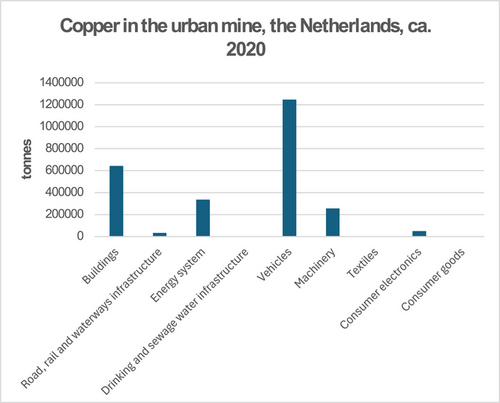

For copper, the total Dutch urban mine adds up to roughly 2.5 million tons. The distribution over the different stocks is shown in Figure 5.

Per Dutch inhabitant, this comes down to about 0.15 tons. Global copper reserves are estimated at 886 million tons in 2022. Per global inhabitant, this is 0.11 tons. At least in size, the Dutch urban mine appears to be significant. In practice, it is important to assess whether this copper is actually reusable or recyclable. If we take a look at the applications, we see that vehicles represent the largest stock. The copper in vehicles should not be too difficult to recycle, in view of the fact that the treatment of end-of-life vehicles is regulated quite strictly in the Netherlands. Also, copper in buildings and the energy system is probably well reusable or recyclable, as it is used mainly in pipes and wires with a very high copper concentration. For copper, at least, the urban mine appears to be promising as a significant source of materials.

For cobalt, our estimates are much more uncertain and probably incomplete or partly hidden in other categories of materials. Such as it is, our total comes down to 3000 tons, mostly in the energy system and electronic apparatus of different types. This is 0.17 kg/person. Geological reserves are estimated at 83 million tons in 2022 (excluding marine reserves), which translates into 10 kg/person at the global level. The urban mine for cobalt is therefore not significant. At least not yet: The build-up of this stock is now happening rapidly due to the electrification of the car fleet (Du et al., 2024).

6 DISCUSSION

6.1 What to do with these data?

6.1.1 Standardization and institutionalization

We have now produced an inventory of the Dutch urban mine at one point in time. This information is essential to support a circular economy policy. Therefore, it should be standardized and institutionalized by governmental organizations. Statistics Netherlands (CBS) would be a good place to host this and add a stock inventory to the flow inventories they are already producing (Delahaye et al., 2023) in the bi-annual MateriaalMonitor (https://www.cbs.nl/nl-nl/maatwerk/2023/04/materiaalmonitor-2014-2016-2018-en-2020). In that way, developments over time can be traced and evaluated and the planning for exploiting the urban mine can be based on facts. A feasibility study done by CBS to investigate the possibility of adding a stock dimension to the flows of the MateriaalMonitor has just been finalized, concluding in positive advice (https://www.cbs.nl/nl-nl/longread/aanvullende-statistische-diensten/2024/materiaalvoorradenmonitor).

Standardization refers to both the inventory of buildings, infrastructures, and products and the material contents of these items. The former, as mentioned before, is less problematic than the latter. For difficult categories such as consumer goods and electronics, we may have to rely on approximations also in the future. The approach outlined in the ProSUM project, calculating stocks from inflows and a life span, may be the starting point (Wagner et al., 2021). Dedicated consumer investigations such as those done by, for example, consumer organizations (https://www.consumentenbond.nl/test/woning-huishouden/levensduur-van-huishoudelijke-apparaten), and waste registrations obliged by the government such as, for example, e-waste registration (https://www.producenten-verantwoordelijkheid.nl/stichting-open/), could play a role here as well.

For the material contents, the present and announced policies of obliging producers to add a material passport to their products are promising. For buildings, these plans are already advanced, and organizations like Madaster play an important role as registration offices.

6.1.2 Recommendations for future research

This inventory has provided an overview of the Dutch urban mine in quite some detail. On the one hand, it is fairly comprehensive, and on the other hand, it is quite detailed. It can be used to support both overall and very detailed circular economy policy efforts.

As a first effort of its kind, there are many uncertainties in the data that could be improved, in the inventory of applications but especially in the material intensities of the applications. We trust that in coming years, these data will improve.

The inventory is a snapshot in time. We recommend repeating the exercise, and perhaps also doing some retrospective studies, to create a time series of the urban mine. This would offer many insights into how the urban mine develops.

In the end, it is not what is in the urban mine, but what can come out of it that is relevant. This database could be the starting point of scenario exercises to explore the future potential of the urban mine. We did two such exercises ourselves, regarding the electricity system and residential buildings (van Oorschot et al., 2022, van Oorschot et al., 2023). These studies provided some relevant insights into the dynamics of the urban mine. Other applications could have completely different dynamics, so forward-looking studies could be really relevant.

Finally, this inventory may be an inspiration for similar endeavors in other parts of the world. For the Netherlands, data availability is probably relatively good. Our estimates may serve as the first approaches for countries with a less detailed database.

6.2 Accessing the urban mine

6.2.1 Urban mines versus geological mines

People have been accessing geological mines for thousands of years. The procedures have been tested and refined to great lengths. Accessing the urban mine is in its earliest stages. Of course, recycling happens, and for some materials such as steel or copper, recycling is part of usual production methods. However, recycling is only one step in the sequence. Recycling is not pro-active but reactive: Whatever materials happen to enter the waste stage are considered for recycling. Urban mining, just like geological mining, starts way before the first kilogram of a material is produced. The sequence starts with exploration: finding locations with potential. The next step is prospecting: estimating whether establishing a mine at this location would have potential. If the answer is yes, a lengthy process follows where plans are made for exploitation, often involving new roads and facilities, and costs and benefits are estimated. When all signs are positive, the lengthy process of acquiring permits and workers can start. Usually, the period from exploration to exploitation is long, sometimes even decades.

Urban mining is presently in the stage of prospecting, and this study adds to that. Before anything else, we need to know whether the urban mine has potential. In all, we can now conclude that this is indeed the case. Planning is then the next step, and this differs from geological mining in a number of ways.

First and foremost, the material in the urban mine is presently used and cannot be accessed at will. Only when the products or structures enter the waste stage can they be considered for reuse or recycling. In the case of long-lived applications such as buildings, this can be decades or even centuries. Still, it is possible to make forecasts to estimate the future outflows from the in-use stock, and such forecasts in the case of urban mining belong to the prospecting stage. We have done such scenario assessments for a few of the stocks: buildings and the energy system, published in separate papers (van Oorschot et al., 2022; van Oorschot et al., 2023), based on dynamic material flow analysis. A crucial factor is the life span of the applications. For exploring the potential of the urban mine, life span estimates are therefore of vital importance, and like many other things related to the urban mine, information on life spans is scarce, especially for the diverse groups of consumer products (Erumban, 2008; Murakami et al., 2010; Oguchi et al., 2010; Vendrell-Herrero et al., 2022).

Second, the material composition and configuration of the “urban ore” can be quite different from that of the geological ore, making recycling a complicated process. Many articles and reports have been published on the need for a different design of products to better enable recycling (see, e.g., the proceedings of the PLATE conferences—https://researchrepository.ul.ie/). Product design-for-disassembly and design-for-simplicity can be mentioned (De Fazio et al., 2021; Formentini & Ramanujan, 2023). If products can be disassembled, they can be more effectively recycled, and if materials are designed to contain fewer additives, their second life is not limited to one very specialized application (Dumée, 2022; Nickless & Yakovleva, 2022).

Fortunately, the options to access the urban mine are not limited to recycling and the production of secondary materials, but various forms of reuse can also be practiced. This, too, is really different from geological mining. Reuse of a product is often a good possibility, as the flourishing online second-hand platforms illustrate. For cars, clothing, furniture, and other consumer goods, reuse of products is already practiced but could be optimized further. Another option is component reuse, for example, related to buildings and infrastructure. This type of reuse is rather new and needs new actors that can operate as brokers and/or could provide storage for the old stocks.

Product design is also very important for another option: prevention of waste, or in other words keeping products in the use phase by lengthening their life span. Many products are meant for a short lifespan. Design-for-robustness could prevent products from becoming waste very soon, and design-for-disassembly may facilitate repair. Both result in a longer life span.

6.2.2 Toward a circular economy

Ultimately, we have to deal with the fact that stocks in many places in the world still have to be built up. This is obviously the case for the renewable energy system but also for accommodating residential buildings and all kinds of infrastructure in parts of the world that presently have no access to a decent standard of living. After all, the SDGs are not just about climate and the environment but also about development and justice. This is important information for reaching circular economy targets. As dynamic MFA studies teach us, the outflow of waste products and materials from stocks in the building-up phase lags behind the inflow, the required materials for establishing the stock. The worst thing we can do is to conclude that circularity is not important because at present we cannot meet the demand with secondary products and materials only. Rather we have to realize that one day, these stocks will be saturated, and outflow will catch up with the inflow. Studies show that this may happen in the second half of this century (United Nations Environment Programme 2024; Wiedenhofer et al., 2021). If we want to be ready for that moment, we have to start getting our new systems in place now.

The task of transforming our society to a circular one is large, in a sense even larger than the energy transition. The energy transition is mainly a technical one, moving from fossil energy generation technologies to renewable ones. This already has many consequences—building up a new system, dealing with legacies of fossil production, changes in mining and trade, etc., but the basics of our society are unchanged. Transformation to a circular economy has consequences for all parts of our production system and also for consumers and waste managers. We now only see the first contours of such a society. In a sense, the long delays and slow responses of the production–consumption system may even help us—we have some time to get it right. If we start now!

ACKNOWLEDGMENTS

This series of projects were conducted for the Working programme on Monitoring and Steering the Circular Economy of PBL, the Dutch Environmental Assessment Agency. Besides the core team of investigators of the Institute of Environmental Sciences (CML) of Leiden University and the Central Bureau of Statistics, others have provided contributions, especially Merlijn Blok, Nico Schouten, and Pieter Witteveen of the Metabolic consultancy and students of the Leiden/Delft MSc industrial Ecology, Jochem van der Zaag, Bas Roelofs, Judith Verschelling, Lowik Pieters, Boris van Beijnum, and Emma van der Bent.

CONFLICT OF INTEREST STATEMENT

The authors declare no conflict of interest.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are openly available on the Urban Mine of the Netherlands project page of Leiden University at https://www.universiteitleiden.nl/en/research/research-projects/science/cml-urban-mine-of-the-netherlands