Mechanical Testing of Orthopedic Suture Material Used for Extra-Articular Stabilization of Canine Cruciate Ligament-Deficient Stifles

Abstract

Objective

To determine (1) if braided, polyblend orthopedic suture materials are mechanically superior to monofilament nylon leader and (2) have mechanical properties similar to biomechanical properties of the canine cruciate ligament.

Sample Population

Different suture material types.

Methods

Mechanical testing was performed on 5 different orthopedic suture materials: 80# test Mason monofilament nylon leader (MNL), FiberTape (FT), FiberWire (FW), Xgen OrthoFiber (XOF), and LigaFiba (LF) using a servohydraulic materials-testing machine. Materials were loaded to failure while collecting data for tensile strength, load at 3 mm and 5 mm of elongation and stiffness. Cyclic elongation of each suture material was tested under physiologic loading between 70 and 150 N for 1000 cycles using 3 mm of elongation to describe excessive elongation. Load at 3 mm of elongation and performance during cyclic testing were compared to previously published physiologic loads in the dog stifle.

Results

Ultimate tensile strength was greatest with LF, followed by XOF that was stronger than FT and FW, and the weakest was MNL. LF was the stiffest of all tested materials at 3 mm of elongation. Cyclic elongation was greatest for the MNL elongating 3.75 mm after 1000 cycles. All polyblend braided materials continued to elongate throughout the 1000 cycles under physiologic loads.

Conclusions

Polyblend suture materials are stronger and elongate less than MNL in pure tension. The mechanical performance of all sutures tested is questionable when compared with the mechanical demands of the normal stifle in a mid-sized dog.

Cranial cruciate ligament (CCL) rupture, the most common orthopedic disease in dogs,1 is the leading cause of osteoarthritis (OA) in the canine stifle2-4 and has been reported to cost pet owners over 1 billion dollars annually.5 Whereas many surgical procedures have been described to stabilize the CCL deficient stifle none have proven to re-establish the biomechanics of the stifle,6-8 consistently stop the development or progression of OA9, 10 or routinely provide a superior outcome.11, 12 One result of this is that many surgeons perform extracapsular procedures that rely on the suture material to provisionally counteract cranial drawer, cranial tibial thrust, and internal rotation of the tibia.3, 4 Because most surgeons recognize that the suture materials used temporarily provide stabilization, investigations have continued to search for the ideal material.

Numerous extra-articular suture methods have been described including a lateral fabellotibial suture;13 lateral and medial fabellopatellar sutures;14 and more recently the “tight rope” procedure.15 Regardless of the exact procedure performed, the suture material must tolerate great mechanical demands to perform without excessive elongation. Some surgeons only consider these procedures useful for small dogs, whereas others perform these procedures in dogs of all body weights.2, 15, 16 Certainly as dog body weight increases, the mechanical demands on the suture material increases. Some extra-articular procedures focus on placement of the sutures in isometric attachment sites on the femur and tibia17 with the goals of increasing the range of motion of the stifle after surgery and increasing the life of the suture material. However, all reported techniques place the suture material in a mechanically compromised situation at the fixation sites whether fixation is secured by a knot, crimp clamp,18-20 or washer.15 According to a recent study, isometric attachment sites are unlikely to be achieved with extracapsular suture repair.21 In addition, suture materials are weaker, compared to their ultimate tensile strength, when they interfere with bone through a bone tunnel or metal through the eyelet of a suture anchor because of fraying.22 Many surgeons recommend early activity after extracapsular stabilization because postoperative rehabilitation improves outcome.23 The suture material will arguably face more cyclic loading if early patient activity is recommended.

An assortment of materials have been used for these stabilization procedures and many mechanical studies have been performed using a variety of mechanical scenarios. For example, when tested in pure tension, Lewis reported that monofilament nylon leader (MNL) line was stronger than monofilament polypropylene.24 A similar finding was reported when the same materials were tested in loop constructs.25 Wallace reported a 36 kg MNL line in an interlocking double loop with a single strand configuration was superior to all double loop configurations with double strands26 and stated that this was likely because clamps create a weakness in the material. However, crimp clamp systems appear to be advantageous, because clamped monofilament leader line has higher load to failure and less elongation when cycled and compared with the same material knotted.19 Finally, it has been reported that sterilization has limited effects on MNL line.25, 27

Large gauge braided, polyblend materials (e.g. braided ultrahigh-molecular weight polyethylene ± polyester) are recommended by some surgeons,15 for extracapsular suture procedures. A recent study compared loop fixation of polyblend material to MNL using different modes of fixation28 but did not examine physiologic cycling or elongation during cycling. Burgess concluded that the polyblend materials were stronger and stiffer than monofilament leader line. Many previous studies of suture material omitted cyclic fatigue,18, 21 truncate cyclic testing6, 12, 25, 26 or overlook clinical failure because of suture elongation.15, 20 Cook et al performed cyclic testing on 5 commercially available orthopedic suture materials concluding that FiberTape (FT) had significantly lower elongation than other materials tested; however, cyclic testing was limited to 100 cycles and excessive elongation of the materials (elongation during tensile testing) was not reported.15

Our objectives were to compare the mechanical properties (load to failure, load to excessive elongation, and cyclic elongation) of 5 commercially available orthopedic suture materials in pure tension. We hypothesized that braided polyblend materials would be stronger and stiffer compared with MNL. Further, we hypothesized that none of the materials tested would demonstrate mechanical properties sufficient to provide long-term stabilization of the stifle when compared to the previous reports of the mechanical demands in the canine stifle.

MATERIALS AND METHODS

Suture Materials

The materials tested were 36 kg (80 lb) test MNL line (Hard Type Nylon Leader Material, Mason Tackle Co, Otisville, MI); 2-mm braided polyblend tape suture material (FT; FiberTape® Arthrex Inc. Naples, FL); No.5 braided polyblend suture material (FW; FiberWire® Arthrex Inc. Naples, FL); No.5 polyethylene polyblend suture material (XOF; Xgen OrthoFiber Securos, Charlton, MA); and 227 kg (500 lb) test braided polyethylene (LF; LigaFiba Suture Material, Jorgensen Laboratories Inc, Loveland, CO). MNL was sterilized by 100% ethylene oxide sterilization for 30-minute exposure followed by 12-hour aeration at 37°C, all other materials were in sterile packaging when purchased.

Mechanical Testing

Five samples of each suture were tested for load to failure and cyclic elongation. Material testing was performed using a servohydraulic materials-testing machine (MTS 858 Mini Bionix II Testing System MTS Systems Corporation, Eden Prairie, MN). Material fixation and slippage was prevented by wrapping material over a 12.7-mm diameter steel rod and secured with a custom-made clamp (Fig 1) Gauge length was controlled for all samples by setting the rods at 100 mm using a digital caliper. The tails of each material were marked with black ink and tail measurements were made using a digital caliper. Material tail length was measured again after testing to ensure slippage did not occur. Data collection scopes for axial displacement and loads were zeroed before testing each sample. Care was taken to prevent creation of defects or twists in the suture material when positioning the material for mechanical testing.

Tensile Loading to Failure

To standardize testing, a custom program was developed to ramp up to a preload of 70 Newtons (N) over 10 seconds followed by a 6 seconds dwell before loading to failure. A preload of 70 N was used to assure all slack was taken out of the material before starting data collection. The preload of 70 N was selected because it is a rough estimate of the vertical ground reaction force of a rear leg of a 35 kg dog at a stance (35 kg × 20% × 9.8 m/s2). Samples were loaded at a constant distraction rate of 12 mm/s until failure (suture breakage). The 12 mm/s distraction rate was selected by using an estimated stance time of a dog at a trot (2.0 m/s) of 0.25 seconds. Excessive elongation was defined by suture elongation of 3 mm and 5 mm as many surgeons would consider these values to be an unacceptable amount of drawer after surgery. Although 3 mm and 5 mm of suture elongation does not necessarily equate to drawer, elongation > 3 mm is considered failure of arthroscopically repaired ligaments.22, 29 Only mid-body suture failure tests were accepted for data analysis (suture failure at least 2 cm from the point of suture fixation). Mode and location of failure was recorded. Ultimate tensile strength and total elongation was determined when the material failed with progressive loading. Stiffness (N/mm) was calculated by taking the linear slope from the load-deformation curve in the elastic phase to 3 mm of elongation of the 100-mm gauge length. Loads were collected and assessed at 3 mm and 5 mm of elongation of each material.

Cyclic Elongation Testing

For cyclic testing, 5 samples of each material underwent 1000 cycles at 0.5 Hz. Each sample underwent preloading by ramping up to 70 N over 10 seconds followed by a 6 seconds dwell before cycling between 70 N and 150 N. Similar to load to failure testing, distraction rate was set at 12 mm/s and controls for failure location and slippage remained the same. Elongation was assessed by determining the difference between initial axial displacement after the 1st cycle and final axial displacement after 1000 cycles.

For the purposes of comparing suture material performance to normal physiologic loading (instantaneous and cyclic), normal physiologic demands on the canine stifle were estimated using data from previous reports of the mechanical properties of the CCL and the biomechanics of canine gait for 30–60 kg dogs. To determine if the tensile strength of suture materials exceeded the tensile strength of the normal CCL,6, 8 the tensile strength of the intact CCL (1264–2449 N) were used. To determine if the tensile strength of suture materials exceeded normal physiologic loads in the dog, previous reports6, 8 that recognized physiologic loads as 10–25% of the CCLs ultimate tensile strength were used. In effect, the most conservative estimate of normal physiologic loads in the stifle used was: 1264 N×10% = 126 N and the more demanding estimate was: 2449 N × 25% = 612 N. To determine if the load tolerated by the suture material was “clinically relevant” elongation was defined at 3 mm. This paralleled previous reports for people and canine general ligament repair22, 25, 29-31 and is supported by evidence that the normal intact canine CCL has an elongation in the elastic phase of 0.70–1.8 mm.6, 32

Statistical Analysis

Groups were compared for statistical differences using pairwise nonparametric Wilcoxon tests when the preceding Kruskal–Wallis nonparametric ANOVA were statistically significant. Values were reported as the mean ± SD of the 5 samples tested. Significance was accepted if the P value was < .05. Levene's test was used to compare group's standard deviations.

RESULTS

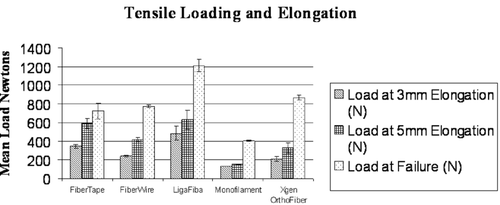

Ultimate tensile strength was greatest with LF (1210 N) followed by XOF (867 N; Table 1). FW (774 N) and FT (725 N) performed in a similar manner but were significantly weaker. MNL (403 N) was the weakest of the 5 suture materials. However, LF had over 29 mm of elongation at failure; this was significantly greater than that of all other polyblend sutures. Load at 3 mm of elongation, was greatest for LF (484 N; Fig 2). This was followed by FT (344 N), FW (238 N), XOF (210 N), and MNL (130 N). Loads for 5 mm of elongation were somewhat consistent to 3 mm of elongation. LF (630 N) and FT (590 N) had the greatest loads followed by FW (418 N) and XOF (329). Again, MNL (329 N) had the lowest loads at 5 mm of elongation. Stiffness at 3 mm of elongation for LF (161.4 N/mm) was significantly greater than that of all other suture materials. FT (114.7 N/mm), FW (79.5 N/mm), and XOF (69.8 N/mm) performed similarly and all had a stiffness significantly greater than MNL (43.3 N/mm; Table 2).

| Ultimate Tensile Strength (N) | Elongation at Failure (mm) | Load at 3-mm Elongation (N) | Load at 5-mm Elongation (N) | |

|---|---|---|---|---|

| FiberTape | 724.6c ± 84.9 | 6.2a ± 1.0 | 344.2b ± 17.5 | 590.4a ± 54.5 |

| FiberWire | 773.9c ± 11.0 | 8.7a ± 0.6 | 238.4c ± 11.9 | 417.5b ± 24.9 |

| LigaFiba | 1210.2a ± 65.6 | 29.3c ± 4.1 | 484.1a ± 75.4 | 629.7a ± 102.0 |

| Monofilament | 402.9d ± 5.2 | 36.3d ± 2.8 | 130.0d ± 2.6 | 156.1c ± 3.4 |

| Xgen OrthoFiber | 867.4b ± 25.4 | 13.5b ± 1.2 | 209.5c ± 27.2 | 329.3b ± 53.1 |

- Different letters within a column denote means are significantly different (P < .05).

| Stiffness at 3-mm Elongation (N/mm) | |

|---|---|

| FiberTape | 114.7b ± 5.8 |

| FiberWire | 79.5c ± 3.9 |

| LigaFiba | 161.4a ± 25.1 |

| Monofilament | 43.3d ± 0.9 |

| Xgen OrthoFiber | 69.8c ± 9.1 |

- Different letters within a column denote means are significantly different (P < .05).

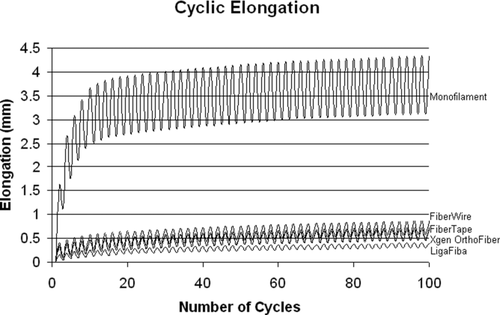

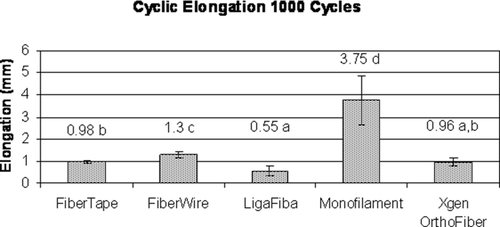

Cyclic loading between 70 N and 150 N caused elongation in all samples tested. No suture broke or slipped during cycling. The pattern of fatigue was similar for all sutures tested with the majority of elongation occurring early (Fig 3); however, no suture reached a level elongation plateau at 1000 cycles. In other words, our data suggest that all sutures would have continued to elongate beyond the 1000 cycles used in testing. Cyclic elongation was lowest and similar for LF (0.549 mm) and XOF (0.962 mm; Fig 4). FT (0.976) performed similar to XOF but its elongation was significantly greater than that of LF. These were followed by FW (1.32 mm) and MNL (3.75 mm). MNL was the only suture material to surpass the 3-mm threshold established for excessive elongation.

DISCUSSION

The mechanical properties of the ideal orthopedic suture material include high tensile strength without elongation, stiffness under cyclic fatigue, and good knot security without being bulky.33 As hypothesized, polyblend orthopedic materials performed significantly better than MNL in nearly every mechanical test. Comparison between the polyblend materials suggests that LF has the greatest tensile strength, stiffness at failure, and the highest loads at 3 mm and 5 mm of elongation. LF also had the greatest resistance to cyclic elongation.

The ideal orthopedic suture material should also have mechanical characteristics that tolerate the environment where it is expected to perform. To test this for CCL stabilization surgeries, and give the materials a reasonably fair chance to succeed, we suggest that the material should minimally tolerate 2 mechanical thresholds. First, the material should not have excessive elongation for an instantaneous load at the lowest estimated physiologic load (the physiologic loads were estimates for dogs between 30 and 60 kg) of the CCL (126 N). Whereas all of the materials exceeded this threshold, it is important to note that none exceeded the highest estimated minimum physiologic load (612 N) when using a single unknotted strand. It is also important to note that in vivo physiologic forces of the canine cruciate have not been defined. It is important to note that for this study we used 3 mm and 5 mm of elongation for a single strand of 100-mm suture material as previously described for arthroscopic knot failure.22 This equates to a 3–5% elongation that could be applied as the suture gauge length differs for lateral fabello-tibial, intracapsular repair and Tightrope suturing. In comparison to clinical applications, the data may support the use of 2 loops for lateral fabellotibial repairs and 4 stands for Tightrope suturing. Second, the material should not have excessive elongation during cyclic loading. We performed cyclic loading to equate to the ground reaction force of a 35 kg dog that cycled between standing (∼20% of body weight or 68.6 N) and walking (∼40% of body weight or 137.2 N). To simplify the cyclic loading protocol, materials were cycled between 70 N and 150 N. The cyclic testing was limited to 1000 cycles (approximately equates to a 40-minute walk) because the MNL had already achieved excessive elongation and the polyblend materials were hypothesized to be superior. Although we did not take the polyblend materials out to failure with the cyclic loading test, we were still able to identify significant differences between suture performances. Unfortunately, we cannot estimate when 3 mm of elongation would have occurred with these materials. With these considerations, we would suggest that the polyblend materials we tested appear to satisfy the minimum biomechanical loading demands of the normal canine stifle but do not perform in a manner that suggest they can tolerate the loads or number of cycles much greater than those minimum cutoffs without excessively elongation, especially in large dogs. These data may also suggest that surgeons should consider the short- and long-term biomechanical demands the dog may place on the suture before use; this may include considering patient body weight and postoperative activity.

The data we report must be compared to other reports with caution. We were not aware of any American Society for Testing and Materials (ASTM) standard for testing suture material at the time of the method development and data collection. Since that time an ASTM standard has been suggested for medical-grade ultra-high molecular weight polyethylene yarns (ASTM F2848). We understand that many studies look at loops of material. Although loops may be more relevant for some applications they tend to overshadow the fundamental material properties of the suture with knot security. We would suggest both are important. The rods we used in this study decreased the stress on the suture making it less likely to fail at the clamp suture interface and likely created uneven strain throughout the suture. For this reason, strain and stress were omitted from this study. The custom clamp apparatus we used was effective, but required continuous monitoring for material slippage and location of material failure. Further studies should consider using the new ASTM standards for suture testing to avoid these problems.

Orthopedic suture materials must be sterilizable (all high molecular weight polyblend materials were purchased in sterile packaging), resistant to infection34, 35 and cause minimal tissue reaction.36 We did not evaluate these characteristics.

Whereas we attempted to test the materials at clinically relevant loads and identify clinically relevant elongation other limitations should be considered when interpreting our data. First, we only tested the single strands of the material in pure tension with no loops or knots as typically used in a clinical situation. By testing a single strand excessive elongation of 3-mm or 5-mm translation of these in vitro findings to the clinical situation needs to be done with caution (as with all in vitro studies). Clinically, a 100-mm length suture that is looped may have less elongation because the functional length of the suture has been decreased. However, this may be offset by weaknesses created in the suture by kinks and knots. We elected to test in pure tension because it eliminated the bias introduced by knot tying, the materials are most likely evaluated in tension when one evaluates for a cranial drawer sign after suture placement, the sutures are likely strongest in tension22, 30 and it allowed for a comparison to the CCL that has also been tested in tension. Second, the physiologic loads about the stifle used to establish guidelines that suture materials should exceed were estimated from previous studies that used different mechanical testing methodologies and environments and should be extrapolated with caution. The purpose of reporting these estimates was not to provide a direct comparison, for example, suture material “X” has only 5% the ultimate tensile strength of the intact CCL but to provide some clinical perspective to the mechanical performance needed of the suture material used to counter normal stifle forces.

Polyblend orthopedic suture materials performed significantly better than the MNL tested. Whereas all polyblend sutures exceeded the lowest calculated minimum physiologic loads about the canine stifle, none performed in a manner that would suggest that they would tolerate mechanical loads that a medium-sized dog would likely generate during daily activity. We also found that whereas many sutures had reasonably high ultimate tensile strength, this might be after excessive elongation has occurred if a single strand of suture were used.