Present status and future directions: Canal shaping

Funding information

Open access publishing facilitated by The University of Queensland, as part of the Wiley - The University of Queensland agreement via the Council of Australian University Librarians. WOA Institution: The University of Queensland Blended DEAL: CAUL 2022

Abstract

This narrative review will focus on the evolution, present and future of engine-driven root canal preparation. Root canal preparation changed drastically when Walia in 1988 introduced the use of nickel-titanium (NiTi) alloys in Endodontics. In 2013, five generations of NiTi endodontic instruments had been established based on their metallurgical, mechanical properties and design features. Since then, manufacturers have been introducing further major changes in instrument design and characteristics that have not been translated in new recognized generations of instruments. In general, those changes have demonstrated enhanced instrument properties, but it is not clear yet if all those improvements are directly translated to an improvement in clinical success. This narrative review attempts to address the present status of engine-driven instruments in terms of both evidence from laboratory-based studies and clinical data, to identify potential further generations of instruments, and last to anticipate future directions for research and development.

INTRODUCTION

Clinicians agree that a major biologic aim of root canal treatment is to address apical periodontitis by disinfection and subsequent sealing of root canal systems. However, while there seems to be a principal consensus what the radiographic appearance of a well-shaped root canal system should look like (Figure 1), there are many possible variations of shaping outcomes as evident in radiographic appearance. Moreover, considerable disagreement exists over how root canal shaping should be performed in clinical practice.

A well-established mechanical objective of root canal instrumentation is complete and centred incorporation of the original canals into the prepared shape, which in turn means that all root canal surfaces are mechanically prepared. It is now clear that this goal is unlikely to be met with any mechanical shaping techniques (Paqué et al., 2009; Peters et al., 2001). Moreover, preparation errors such as ledge and block formation, apical zipping and perforations should be absent. Although these untoward sequelae of canal shaping and other procedural mishaps may not directly affect the probability of a favourable outcome (Lin et al., 2005), they leave parts of the root canal system inaccessible for disinfection and are undesirable for that reason alone.

Another important mechanical objective is to retain as much cervical and radicular dentine as possible so as not to weaken the root structure, thereby preventing root fractures. Before root canal shaping, dentine wall thickness dimensions of 1 mm and below have been demonstrated in anatomical studies (Degerness & Bowles, 2010; Garala et al., 2003). The straightening of canal paths can lead to precarious thinning of curved root walls. Although no definitive minimal radicular wall thickness has been established scientifically, a dentine thickness of 0.3 mm is considered critical (Lim & Stock, 1987).

For the overall shape, it has been suggested that canals should be prepared to a uniform and continuous taper (Schilder, 1974); however, that principle was aimed at facilitating a specific root filling technique rather than at antimicrobial efficacy. For optimal disinfection, preparation shape and antimicrobial efficacy are intimately related through efficient removal of infected pulp and dentine and creation of space for delivery of irrigants.

Traditionally, irrigation solutions have been dispensed passively into root canals with syringe and needle. In that system, irrigants have been shown to progress only about 1 mm farther than the tip of the needle (Ram, 1977; Salzgeber & Brilliant, 1977). Enlarged apical canals and finer more flexible needles allow increasingly deeper needle placement and this improves root canal disinfection (Albrecht et al., 2004; Usman et al., 2004).

While a continuous taper that encompasses the original shape and curvature of a given root canal is an accepted goal, final apical preparation size remains a much-disputed entity in root canal treatment, as does final taper of the preparation (Baugh & Wallace, 2005). Arguments have been made for better disinfection with larger sizes, i.e., size 50 or greater (Card et al., 2002; Rollison et al., 2002) in combination with smaller tapers of 0.02 to 0.05. Others reported no difference whether the selected final size was small or large (Coldero et al., 2002; Yared & Dagher, 1994).

The combined clinical goals of a sufficiently sized shape, while minimizing the frequency of preparation errors, may be achieved with diligent clinical techniques and with contemporary canal preparation instruments. Consequently, this review aims to describe the current state of the art in root canal shaping technology, specifically in relation to nickel-titanium rotary instruments.

REVIEW

Generations of nickel-titanium instruments for canal preparation

There are currently more than 200 brands of instrument systems marketed for root canal preparation. Therefore, rather than describing all available engine-driven systems, this review intends to systematically categorize instruments, based on purported or demonstrated characteristics and manufacturing processes. To this end, this review will try to summarize the properties that they share and suggest new generations from those advancements that induced a true improvement for root canal preparation. Of note, some manufacturers recently developed instruments without an obvious intent to improve functionality, but merely to create low-cost instruments.

One way to classify powered, rotary, or reciprocating, nickel-titanium instruments is to name them in generations. It is reasonable to expect for a new generation to be considered significantly different from the previous ones that the development translates to a continuous and effective improvement over the previous generations. Haapasalo and Shen (2013) codified the notion of, at that time, five different generations of instruments in 2013 (Table 1). These generations can be described as follows.

| Generation | Cross-section | Alloya | Descriptors | Examples of commercialised instruments |

|---|---|---|---|---|

| 1 | u-shape | SE | “passive cutting”, “radial lands”, “fixed tapers”, “neutral/negative rake angles”, “instrument breakage” | ProFile, Tulsa Dental, Tulsa, OK, USA |

| 2 | Triangular, convex | SE | “active cutting”, “radial lands”, “multiple tapers”, “positive rake angles”, “surface treatment” | Flexmaster, VDW, Munich, Germany |

| 3 | Triangular, convex or quadrilinear | Heat-treated | “heat treatment”, “metallurgy”, “M-wire”, “R-phase”, “CM-wire”, “Blue-wire”, “Gold-wire”, | Hyflex CM, Coltene, Altstätten, Switzerland |

| 4 | Triangular, convex or quadrilinear | Heat-treated | “kinematics”, “reciprocating motion”, “reciprocation”, “single-file”, “single- use”, “reverse helix” | WaveOne, Dentsply Maillefer, Ballaigues, Switzerland |

| 5 | quadrilinear | Heat- treated | “off-centred cross-section”, “swaggering effect” | ProTaper Next, Dentsply Maillefer |

| 6 | Variable | SE or Heat-treated | “glide path”, “retreatment”, “orifice modification” | ProGlider, Dentsply Maillefer |

| 7 | Variable | Heat-treated | “manufacturing methods”, “twisting”, “shape-setting” “electric discharge machining” | TRUShape, Dentsply Tulsa Dental, Tulsa OK, USA |

- a All instruments are manufactured from nickel-titanium alloy, which is either standard stock (SE) or subjected to various types of heat treatment (see text for more details).

First generation

The first NiTi rotary instruments appeared in the market by the 1990s. One of the major advancements in this generation was the paradigm change related to instrument taper, compared with typically ISO-normed hand files with 0.02 taper. The flexibility of NiTi alloy compared with stainless steel made it possible to increase the taper of the instrument and still mechanically prepare curved root canals safely. This rendered ISO 0.02 tapered instruments not to be the only option to prepare root canals, despite the ISO norm 3610-1 for stainless steel hand files remained, up to the present, as the descriptive and testing standard for all types of canal shaping instruments.

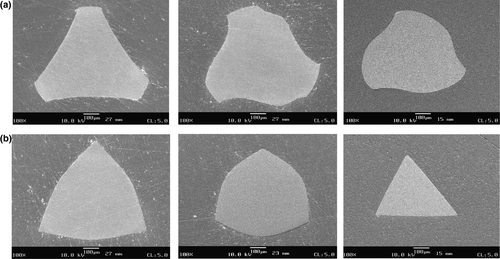

In the early stages of the NiTi era, rotary instruments in the first generation were characterized by their rounded non-cutting tips that served as a guide in the root canal. The classical cross-sectional design had radial lands next to the grooves to allow the expulsion of dentine after the instrument passive cutting action; this is the typical U-shape cross section with radial lands shown in Figure 2a. This cross section was the result of the machining of three equally spaced U-shaped grooves around the shaft of a tapered NiTi wire.

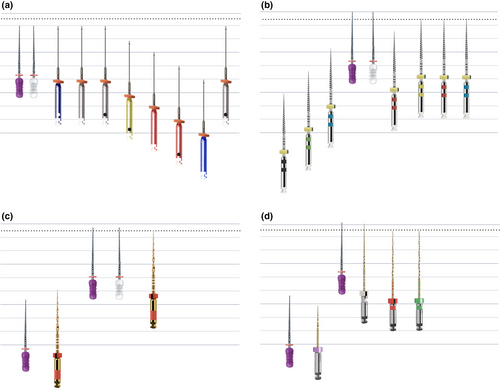

Likewise, at that time, the recommended rotational speed was low, varying between 250 and 300 rpm. Cyclic fatigue (CF) resistance of instruments was considered problematic; rotary instruments were expected to last a certain number of cycles and a low rotational speed would increase the time for breakage by decreasing the number of rotations per minute (Pruett et al., 1997). Those authors also specified that the parameters of angle of curvature and radius of curvature, as well as the instrument cross-sectional core diameter should be considered to retrieve accurate information for the safe use of NiTi engine-driven rotary instruments (Pruett et al., 1997). Moreover, light apical pressure and the restricted use of each instrument for only a few seconds were recommended for a safe use (Yared & Dagher, 1999); therefore, a rather large number of instruments made up a set of these first generation NiTi rotary systems (Figure 3a,b).

The recommended technique for the NiTi instruments in this generation was either a step-back or alternatively a crown-down approach with the apical advancements of smaller instruments either in terms of taper or apical diameter (Figure 3b). Some clinicians preferred the use of a crown down sequence based on instruments with a constant taper and variable ISO tip sizes (example: a size 0.06/45 file is used until resistance, followed by the 0.06/40, 0.06/35, 0.06/30, 0.06/25, and 0.06/20). Others prescribed the use of nickel-titanium instruments with constant tip diameters, but different tapers also used in a crown down sequence (a size 0.10/20 instrument would shape the coronal portion of the root canal, and then progressively advanced to working length by decreasing the taper of the instrument 0.08/20, 0.06/20, 0.04/20).

Examples of instruments from this generation are the widely used ProFile (Dentsply Maillefer, Ballaigues, Switzerland) developed by McSpadden and Johnson and others that appeared later such as LightSpeed developed by Senia and Wildey (now marketed by Kerr, Brea, CA, USA), Quantec developed by McSpadden (Kerr, Brea, CA, USA) and the Greater Taper (Dentsply Maillefer) files developed by Buchanan. Particularly in the case of Lightspeed the instrument was quite different to all the others from this first and subsequent generations (see Figure 3a). The active part is short, less than 2 mm compared with the 166 mm for most other instruments, and is designed to only prepare the apical portion of the root canal. The long and thin shaft is not cutting and flexible, while allowing the active part to reach the apical millimetres of the root canal.

Second generation

Differences between this second generation and the first one is primarily related to the design of the instruments (Figure 2b). Cross-section of instruments drastically changed and radial lands disappeared. Overall design, as well as the positive rake angles that some instruments from this second generation included, allowed active cutting and hence, fewer instruments were needed to accomplish the goals of root canal preparation.

If a changing paradigm related to taper occurred in the first generation of instruments, an important evolution in this second generation was also related to the taper along the cutting blades. Multiple tapers inside a single instrument along their cutting portions could provide asymmetrical cutting in different portions of the root canal. A clear example to describe this generation and this mechanism of action is the widely used ProTaper rotary system (Dentsply Maillefer). The system includes six main instruments of two different types, the so-called “shapers” and “finishers”. Among others, the main difference between shapers and finishers is the increasing or decreasing evolution of tapers along the cutting blades. While the shapers have increased tapers in their coronal portions, the finishers decreased the taper coronally. This geometry allows the instrument to prepare the coronal and middle thirds (shapers) or the apical third (finishers) of the root canal, while all the instruments (except the SX) are taken to working length. One may think that the instrument might be subjected to higher chances of breakage for the full contact of the instrument with the root canal walls, but only the areas of the instrument with greater tapers work in the root canal walls. At the same time, the different increasing or decreasing tapers and hence, different diameters, provided more flexibility to those instruments with smaller apical portions and much more rigidity to those with larger apical diameters. In fact, literature described how root canals shaped with rotary ProTaper were progressively straightened after the use of F1 producing transportation, despite the different cross-section design for large finisher instruments (Zhang et al., 2008).

Other instruments that belong to this second generation are: the K3 system (Kerr) the only one that maintained some sort of radial lands (Figure 2a), EndoSequence (Brasseler USA) and RaCe (FKG Dentaire) with triangular cross-sections.

Interestingly, varying techniques were incorporated in several instruments at the time to address clinical problems such as the so-called threading-in effect. For example, manufacturers included alternating cutting edges (RaCe, FKG Dentaire) or varying pitch (MTwo, VDW). Another innovation was the use of electro-chemical polishing after the grinding process to reduce surface defects, for example, in RaCe and EndoSequence instruments.

Third generation

After two generations based on modifications in the design of the instruments, this third generation represented a paradigm shift because of the advances in the alloy itself. A series of thermo-mechanical treatments applied to NiTi wire blanks have demonstrated an enhancement of the microstructure of NiTi and better instrument properties, both in terms of flexibility and durability (Arias et al., 2014; Johnson et al., 2008; Larsen et al., 2009; Ye & Gao, 2012). This development is based on the ability of NiTi alloy to acquire different crystal configurations depending on temperature and applied strain: martensitic and austenitic crystal lattices (Pereira et al., 2015). Previous generations of instruments were in the austenitic conformation both at room and body temperature. Heat treatments modify the specific temperatures that describe the conformational changes. Martensite exists at comparatively low temperature and is inherently more flexible compared with austenite. Therefore, heat treated instruments benefit from a higher martensitic component (De-Deus et al., 2017a; Shen et al., 2013).

Many manufacturers have developed their own thermo-mechanical process and as a result several new alloys have been developed with different phase transformation temperatures and behaviours. The earlier introduction of M-wire (Sportswire LLC) and R-phase processes (SybronEndo) had already suggested that heating/annealing of NiTi wires was associated with better mechanical properties. Later instruments manufactured with CM-Wire (Typhoon, DS Dental) appeared in the market, followed by the introduction of so-called “Blue” and “Gold” alloys (Dentsply Sirona); these were named after the blue/gold coloured surface layer that results from the oxidation that the proprietary heating and cooling processes induced on the surface of the instruments (De-Deus et al., 2017a; Nguyen et al., 2014; Plotino et al., 2014).

Many different thermically treated alloys have been incorporated to the market and still are these days. This has created a vast range of instruments of different colours constituting the root canal shaping panorama these days. In fact, the beginning of the third generation is dated in 2007, but it lasts until today since manufacturers keep developing proprietary thermomechanical process to enhance the structure and properties of NiTi alloys. To be realistic, all engine-driven systems for root canal preparation based on thermomechanical treatments to NiTi alloys could be included in this generation of instruments. If raw superelastic (SE) NiTi alloy has been subjected to a thermomechanical process to optimize the microstructure of NiTi, no matter if all instruments in the system are manufactured with a single processing or if multiple thermomechanical processing has been used for the variety of instruments, the system belongs to this generation of instruments. This generation of instruments exhibits drastically enhanced CF resistance; this is the main reason for new instruments released to the market manufactured with proprietary thermomechanical processes, but with the same shaping concept.

There are so many NiTi rotary systems that belong to this third generation that this narrative review does not aim to cite all available systems in the market. Basically, from the first M-Wire and R-phase instruments that maintained the original colour of SE NiTi, all instruments with different colour layers produced by the oxidation that the thermal process induces belong here.

Fourth generation

The main difference between this fourth generation and previous ones is the suggestion of different kinematics or motions instead of the clockwise continuous rotation of former instruments (Figure 3c). A repetitive back-and-forth motion, the so-called balanced force technique, had been used for root canal preparation with stainless steel hand files (Roane et al., 1985). Meanwhile, until this fourth generation appeared, NiTi instruments were normally used in a clockwise continuous rotation motion (360°). Then, Yared (2008) demonstrated, through a case series, that shaping with a ProTaper F2 instrument (Dentsply Sirona, Ballaigues, Switzerland) and a reciprocating motion instead of the classic continuous rotation could have some advantages such as reducing working time, cost, instrument fracture, and cross contamination. Although, this instrument had not been designed for this specific motion, the idea inspired manufacturers who rapidly developed two specific instruments to shape root canals using this concept: Reciproc (VDW) and WaveOne (Dentsply Sirona). Both instruments were manufactured with M-Wire and hence, already benefited from the advantages of the third generation of instruments.

The concept was further developed by establishing the appropriate angles for both the clockwise (CW) and counterclockwise (CCW) directions needed for efficient cutting. In earlier work, the angles for CW and the CCW rotations had been set at four-tenth and two-tenth of a circle (Yared, 2008).

The first motors that permitted the use of an instrument in reciprocation allowed equal CW and CCW degrees of rotation. However, directions for use for new developed reciprocating systems suggested to start in a CCW direction and advanced with unequal bidirectional angles. To be able to cut in a CCW direction, the instruments had left-leaning flutes. The initial stroke in the root canal in the cutting direction would allow to engage dentine while advancing in the root canal and with an opposite (and smaller) rotation the instrument immediately disengaged dentine avoiding the screwing effect. After a series of CCW and CW movements with graded angles of rotation, the file would have completed a full 360° rotation. This was the so-called reciprocating motion as we understand it today for root canal shaping. Therefore, opposite to the balanced force technique, the initial dentine engagement is performed with a large CCW angle of rotation, and angles of rotation were determined based on stress-strain curves for safe torque levels and ranged 150° to 170°in the direction of the flutes and 30° to 50°in reverse rotation (Kim et al., 2012).

The different motion was not the only change that appeared with these two new developed shaping systems. A different concept of use was suggested with the motto “single-use, single-file system to shape the root canal completely from start to finish” (Webber et al., 2011). These systems tried to limit the number of instruments needed to shape the root canal. In fact, a single instrument is used to fully shape any given canal, although the systems included two more instruments for small and large root canals. Still, it felt strange that root canals with different sizes and configurations would end with the exact same shape and enlargement in the three thirds. The single use of the instrument per patient was guaranteed by the plastic colour-coding in the handle that deformed when the instrument was sterilized, preventing the file from being placed back into the handpiece (Webber et al., 2011).

Both, WaveOne and Reciproc had their successors in WaveOne Gold (Dentsply Sirona) and Reciproc Blue (VDW), manufactured respectively with “Gold” and “Blue” alloys.

Further evolution of motions was accomplished with the so-called Adaptive motion, a patented feedback algorithm to change the motion of the file based on the applied load. When the instrument encounters an impediment, the stress makes the motor to adapt and modify the kinematics from continuous rotation to reciprocation (Duarte et al., 2018).

Another instrument with an oscillation (transaxial in-and-out) is the self-adjusting file (SAF) (ReDent-Nova), a hollow, compressible NiTi file with no central metal core, through which a continuous flow of irrigant is provided while the root canal is prepared (Metzger, 2014).

Fifth generation

In variance from the third and fourth generations that did not focus on the design of the instruments but in different concepts such as alloys and motions, this fifth generation responds again to changes in instrument design. The main difference with previous generations is the incorporation of off-centred cross-sections. An offset mass of rotation allows the instrument the asymmetrical advance of the instrument inside the root canal, producing a mechanical wave of motion when in rotation. This offset design reduces the contact or cutting points of the instrument along the canal walls, allowing some edges not to touch the canals reducing the engagement of the instrument with dentine, the risk of taper lock and increasing the non-contact space for a better removal of debris. The resulting envelope of motion has also been described as “swaggering effect”.

Examples of instruments in this generation are Revo-S, One Shape® (Micro-Mega®) and ProTaper Next (PTN; Dentsply Tulsa Dental Specialties/Dentsply Maillefer; Haapasalo & Shen, 2013).

Those five generations present over more than 20 years of NiTi root canal preparation allowed major improvements for the safe use of NiTi instruments inside narrow and curved root canals. Since that fifth generation, no further generations of instruments have been scientifically determined or in other ways codified. One of the goals of this narrative review was to identify further generations of instruments not yet acknowledged, which have contributed to the continual improvement of the physical or handling properties of NiTi instruments and the safe and reliable preparation of root canals, based on scientific parameters and game-changing properties. The definition of new generations will also help to anticipate future directions.

- the availability of engine-driven NiTi instruments for glide path preparation or other special purposes such as irrigation enhancement or retreatment.

- the development of different manufacturing methods to the traditional grinding method (twisting, shape-setting, and electric discharge machining are some examples).

Those major improvements could lead to two further generations: sixth and seventh.

Sixth generation

Different from the classic five generations, this sixth generation initially focused on a completely new concept, the incorporation of engine-driven instruments for glide path preparation prior to root canal shaping (Figure 4) or other purposes rather than the conventional root canal preparation only purpose of engine-driven instruments from prior generations.

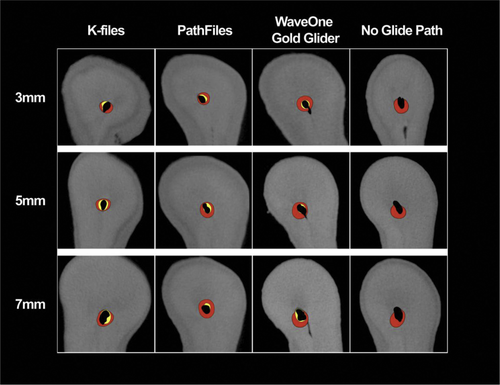

The creation of a glide path to working length is an essential step to reduce the risk of torsional failure (Ha & Park, 2012) by minimizing the so-called threading-in effect and avoiding the taper lock that may occur when the canal cross section is smaller than the tip of the instrument (Peters et al., 2003a). Glide path preparation was originally performed with manual files, but NiTi rotary instruments were then created specifically to simplify the process. In fact, better preservation of the root canal original morphology was reported when the glide path was mechanically prepared instead of with hand files (Berutti et al., 2009; Pasqualini et al., 2012).

The first rotary instruments for glide path preparation were marketed in 2009; these first instruments were designed with small tapers and diameters to avoid the contact of the instrument and the root canal walls in the middle or coronal thirds. The initial purpose of engine-driven rotary NiTi instruments for glide path preparation was only to prepare enough space in the apical millimetres for the safe advancement of consequent shaping instruments. This initial concept later evolved to larger taper instruments with larger diameters that would also contribute to the root canal final preparation. Moreover, the instruments for glide path also followed the pattern of the different generations previously described for shaping instruments. Thermally treated alloys were soon incorporated to glide path instrument, as well as the concept of single-file different from the first multiple-instrument systems. Later, reciprocating instruments were also designed for the purpose.

Following the development of glide path files, other instruments were created not to shape the root canal but with another specific purpose in mind. For example, the ProTaper Retreatment kit (Dentsply Maillefer) has tip designs and overall dimensions that are dedicated to expediting gutta-percha removal. Other instruments were also later designed for the same purpose. Last, instruments developed for irrigation enhancement could also be grouped in the sixth generation. Among them are the already mentioned self-adjusting file (SAF) or the XP Finisher (FKG Dentaire), both of which require special manufacturing and will be discussed below.

Seventh generation

After instruments for root canal shaping changed greatly after five generations by enhanced design characteristics, optimization of the microstructure of NiTi alloy with different series of heating and cooling treatments and new suggested motions, the seventh generation would focus on the incorporation of new manufacturing processes. Manufacturers have developed different production methods to the traditional grinding method such as twisting, shape-setting, and electric discharge machining. The first instrument not manufactured by grinding was the so-called Twisted File (Kerr) launched in 2008. It was manufactured by twisting the wire to avoid the grinding marks that micro-grinding produces that might lead to micro-fractures in the NiTi wire (Gambarini et al., 2012).

More recently, several production processes have been developed that were not used to manufacture endodontic instruments before, enabling radically different designs to materialise. For example, the SAF, as a hollow tube with thin NiTi connections also required a novel manufacturing process; in this case, laser cutting that can remove metal in a precise manner.

Another process is shape setting, which allows a three-dimensional shape to be created from a wire blank. The goal of the non-round shape that this production method provides to the instrument is to enhance the three-dimensional final geometry of oval root canals (Arias et al., 2018a). Shape setting of NiTi alloy requires the application of controlled pressure and temperatures to create shapes that cannot be manufactured my micromilling. The result could be an instrument that is stable across clinically relevant temperature ranges, for example, TRUShape (Dentsply Tulsa) and XPShaper (FKG Dentaire). It is also possible, with appropriate conditions, to create instruments that change their shape on temperature change, such as the already mentioned XP Finisher.

Electric discharge machining (EDM) is yet another different manufacturing method. Through the process of EDM, instruments are manufactured by a non-contact thermal erosion through controlled sparks that occur between an electrode and a workpiece in the presence of a dielectric fluid. Each spark removes material from both the electrode and workpiece by being heated until material vaporizes. For the first time, a manufacturing process does not use physical contact for material removal, but the local vaporization of the metal and the properties of the instruments are enhanced as a result (Jameson, 2001).

Evidence based on laboratory data

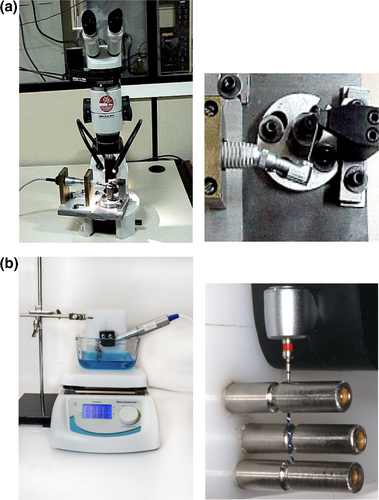

This section will try to provide evidence about the contributions that each generation was responsible for the advancement of the physical properties and performance of NiTi instruments. Many of these parameters and characteristics have been traditionally tested in laboratory studies (Figure 5).

Physical properties

The reasons why NiTi instruments were incorporated to the endodontic armamentarium and have become the widely used method for root canal preparation (Logsdon et al., 2020) were the improved physical properties of the alloy when compared with stainless-steel (Walia et al., 1988) in terms of flexibility (Pereira et al., 2015), efficiency, and cutting ability (Peters et al., 2014). Moreover, the superior properties allow NiTi files to be used both manually or engine-driven and endodontic literature confirmed the better root canal shape that NiTi instruments provides in comparison to stainless steel instruments (Peters et al., 2001, 2010; Pettiette et al., 2001).

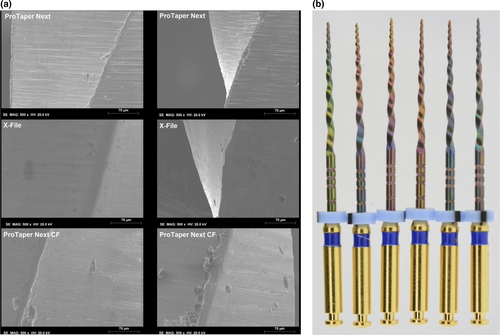

The new designs, heat treatments of SE-NiTi alloy, motions and manufacturing techniques implemented in the different generations of instruments described earlier have significantly affected the cutting efficiency, cyclic fatigue (CF) resistance, and torsional performance of endodontic instruments.

First, a desirable property of NiTi instruments is the ability to cut dentine from the orifice to the apical terminus of the root canal. The main difference from the first and second generation is associated with the ability to cut dentine. Instruments in the first generation had radial lands and hence, neutral cutting angles. The second generation incorporated active cutting blades with positive cutting angles. Changes in the cross-sectional design seemed to be a decisive parameter concerning cutting efficiency. A triple-U cross-sectional designs demonstrated significantly lower penetration depths when compared with convex triangular, S-shaped and triangular cross-sections (Schäfer & Oitzinger, 2008). Radial lands produced more friction with the root canal walls whereas active cutting edges were more effective when cutting dentine. When ProFile and ProTaper instruments were compared, ProFile was more elastic but accumulated dangerous stress levels more rapidly (Berutti et al., 2003); conversely, ProTaper had greater torsional strength, was less flexible, and less resistant to bending forces (Berutti et al., 2014). In fact, stiffness and flexibility are related to the geometric design of the instrument such as taper, helix angle, and cross-sectional design. The stiffness of instruments with greater tapers and certain cross-sections led to canal transportation. For example, it was suggested that ProTaper Finisher instruments progressively straightened the root canal and produced transportation (Zhang et al., 2008).

The incorporation of the second generation also led to a different preparation concept, the hybrid techniques. The preparation of different portions of the root canal with a combination of instruments from both generations would benefit from the advantages and avoid the shortcomings of each generation. After the detailed knowledge of the benefits and limitations of each system, a combined sequence gained in efficacy while allowing conservative preparations in root canals presenting apical anatomical challenges. At the time, convex triangular design demonstrated to be appropriate for the initial canal shaping phase (coronal and middle third), whereas the U-shape cross-section seemed more suitable for the preparation of the apical third (Berutti et al., 2014).

The better properties of instruments in subsequent generations changed the conformation panorama with instruments that were efficient and conservative.

The introduction of more flexible alloys in the third generation allowed the use of efficient cross-sections able to better maintain the original anatomy of the root canal (Pereira et al., 2015). However, some concerns arouse in terms of the cutting capacity for those alloys that transform into a martensite phase close to body temperature and hence would be working in that state inside the root canal in clinical settings. The literature demonstrated not only their great flexibility but also an acceptable cutting efficiency for martensitic alloys (Morgental et al., 2013; Vasconcelos et al., 2018). Also, instruments actioned with different motions as suggested in the fourth generation, demonstrated similar cutting efficiency after prolonged use (Gambarini et al., 2016). Cutting ability might also be important for instruments designed for glide path preparation. Those used in reciprocation were more cutting efficient than instruments used in continuous rotation (Pedullà et al., 2020).

Second, a relevant limitation of engine driven NiTi instruments was the occurrence of fracture inside a root canal while shaping. The first generation of instruments, with triple-U cross-sections and manufactured from stock (non-heat treated) NiTi alloys, were associated with risk of instrument breakage, because of torsional failure or CF in curved root canals (Sattapan et al., 2000). In fact, fracture risk might be the major reason responsible for the investment of manufacturers in the enhancement of NiTi instruments. However, the evolution of instruments through the different generations can truly be appreciated in the great enhancement of this physical property. On the one hand, the accumulated years of experience using NiTi instruments have helped clinicians to identify the challenging situations in which a specific instrument might fracture. Moreover, the third, fourth, and the latest generation of instrument development have created substantial benefits in terms of CF resistance. Heat-treated alloys, reciprocating motions and some new manufacturing methods have helped to minimize fear of clinicians to instrument fracture.

First, heat treated alloys that transform the crystallographic phase of the instruments and make them work in a more martensitic state have increased fatigue resistance considerably. Additionally, this technological advancement did not only help to increase the CF resistance of instruments but also led to rethink the laboratory methods classically used to test CF resistance. In the absence of standardized specifications to test CF resistance of engine-driven NiTi instruments, most studies had been traditionally performed at room temperature, until a clinical study demonstrated that when sodium hypochlorite was delivered at room temperature inside the root canal it rapidly approached body temperature (de Hemptinne et al., 2015).

For this reason, studies on CF resistance performed at body temperature were appropriate when alloys of instruments were mainly austenitic and maintained the same crystallographic phase at room temperature or when inserted in the root canal at a given clinical situation. However, modern alloys have higher transformation temperatures (Miyai et al., 2006) and some undergo a crystallographic transformation close to body temperature (Shen et al., 2013) and hence if tested at room temperature might show optimistic results. There has been an important evolution of the scientific methods to test CF resistance and new methodological approaches include the control of temperature after several studies confirmed different fatigue behaviour of instruments when tested at room versus body/intracanal temperatures (Dosanjh et al., 2017; Plotino et al., 2017; de Vasconcelos et al., 2016).

Irrespective of the testing conditions, it has been demonstrated that the lifespan of instruments with heat-treated alloys is considerably longer than those of conventional NiTi (Arias et al., 2014; De-Deus et al., 2017a; Gao et al., 2012), as well as reciprocating motions increase the mean life of instruments when compared to continuous rotation (Castelló-Escrivá et al., 2012; De-Deus et al., 2010; Pérez-Higueras et al., 2013; Pirani et al., 2014; You et al., 2010). In fact, it has also been suggested that reciprocating motion might be the main factor to increase CF resistance of instruments over other variables considered decisive related to root canal anatomy (angle or radius of curvature) or instrument design (geometry, taper and surface characteristics of NiTi instruments; Ferreira et al., 2017). Moreover, the incorporation of post-manufacture heat-treated alloys has further increased the comparatively high CF resistance of reciprocating instruments (Iacono et al., 2019; Scott et al., 2019).

The literature has never shown such resistant instruments as those included in the new proposed seventh generation of instruments manufactured with EDM technology. This non-contact thermal erosion process based on electrical discharges able to avoid any tool contact, contrary to conventional abrasive grinding processes, are apparently associated with a very considerable increase in the fatigue life of rotary instruments (Arias et al., 2018b, 2020; Iacono et al., 2017; Jameson, 2001; Pirani et al., 2015).

Last, engine-driven shaping instruments may also fracture because the torsional load suffered when the tip of a specific instrument binds in a narrowness of a root canal that does not allow the instrument to operate freely (Sattapan et al., 2000); hence, torsional performance is the third important physical property that has also evolved along the different generation of instruments. Some specific advancements incorporated to NiTi instruments over time enhanced the chances of the typical torsional fracture in apical 3 to 5 mm of the instrument. Following the ISO standard 3630-1 or ADA No. 28 for hand instruments, studies simulate torsional failure of rotary instruments in vitro by clamping the apical 3 mm and loading the instrument until fracture occur or via numerical simulation with Finite Element Analysis (FEA). The torque induced by a rotary instrument during root canal preparation mostly depends on the amount of contact instrument/root canal walls (influenced by the diameter of the instrument and volume of the root canal) and the apical force applied to the instrument (Bahia et al., 2006; Peters et al., 2003b; Schrader & Peters, 2005). Therefore, logical strategies to enhance the torsional performance of instruments include reducing the contact surface between shaping instruments and canal walls, as well as the force that is needed to apply to the instruments during the insertion in the root canal. A very important evolution in the concept occurred with the introduction of the new proposed sixth generation of instruments, those specifically manufactured to achieve glide path mechanically. In fact, the first instruments developed for glide path preparation were not designed to contact the root canal walls in the middle or coronal thirds but only to prepare enough space in the apical millimetres for the safe advancement of consequent shaping instruments while applying very low peak torque and force in the root canal walls (Arias et al., 2016; Berutti et al., 2009; Pasqualini et al., 2012).

Numerical simulation has demonstrated how further generations of instruments have also contributed to a better torsional performance, through different cross-sections, helix angles, or flute lengths (Arbab-Chirani et al., 2011; He & Ni, 2010; Santos et al., 2013; Zhang et al., 2010a), as well as through the understanding of how stress distributes from the periphery to the centre in different cross-sections of NiTi rotary files (Berutti et al., 2003; Kim et al., 2009; Zhang et al., 2010b). At the same time, thermal-treated alloys from the third generation has also been associated with better torsional behaviour because of the increase in flexibility at small deflections (Bonessio et al., 2015). At the same time, the different kinematics suggested in the fourth generation by periodically reversing the rotation direction of the instrument releases the torsional stress in the noncutting direction (Kim et al., 2014). In fact, the Adaptive motion described above makes an instrument functioning in continuous rotation to modify to reciprocation when the torque increases. This torque-sensitive motions generated significantly lower maximum torque and may have advantages in reducing stress generation caused by screw-in forces when compared with continuous rotation (Tokita et al., 2017).

For a thorough critical analysis of research methods and experimental models to study the physical properties of NiTi instruments and their fracture characteristics, please see Schäfer et al. (2021).

Root canal shaping performance

As stated before, the goal of the present review is to provide evidence about the contributions that each generation was responsible for in the topics addressed. For a thorough critical appraisal of research methods and experimental models for studies on root canal preparation, please see Hülsmann (2021).

There is agreement among most clinicians that mechanical shaping with NiTi instruments (see Figure 1) creates better canal shapes overall than manual shaping; however, not all generations of engine-driven shaping instruments might have contributed to a better root canal preparation performance. For example, the simplification that the “single-file” concept implied at a given time might not be convenient for the final anatomy of all root canals. A fixed preparation with the geometry of the reciprocating instruments of the time could produce an over-enlargement for narrow root canals with complex anatomies. Since the initial morphology of root canals vary, a standardized final root canal morphology and apical canal size might not be a reliable solution, rather each independent canal with different preoperative dimensions along the root canal would require a different final shape and apical preparation. In fact, a literature review observed a trend for decentralization and transport of the root canals in the apical third of root canals with moderate curvatures with the use of “single-file” reciprocating concepts (Sousa-Neto et al., 2018). A greater accumulation of debris has also been associated with single-file reciprocating versus multifile rotary techniques (Robinson et al., 2013). Similarly, root canal preparation using a multifile system promoted significantly greater bacterial elimination than a single-file system (Gazzaneo et al., 2019). Irrigation plays an even more important role than usual with “single-file” reciprocating techniques. For a thorough critical analysis of research methods and experimental models to study the root canal microbiome, please see Siqueira and Rôças (2021). On the other hand, the concept of single reciprocating instruments shortens the learning curve for novice operators (Hamid et al., 2018). Two challenging types of root canals have required major attention in the endodontic literature. On the one hand, studies have focused on changes in the geometry of curved root canals after preparation, because of the greater chances of preparation errors and canal straightening and transportation. On the other hand, the special shape of oval root canals with concavities and convexities at different levels of the entire root canal length is a major challenge considering that instruments tend to remain centred in the canal axis of the root canal creating round preparations and leaving un-instrumented recesses in both buccal and lingual extensions (Metzger et al., 2010; Paqué & Peters, 2011; Wu & Wesselink, 2001).

In general, there are few major procedural errors in published studies with different rotary NiTi systems when assessed with microcomputed tomography (micro-CT; Peters et al., 2003a). Using micro-CT with adequate resolution should be regarded as the gold-standard in research on root canal preparation (Hülsmann, 2021).

There is no consensus or clinical evidence on which technique or instrument design is clinically superior, but there is a consensus in the fact that no instrument can prepare the entire walls of the root canal systems. All instrumentation techniques leave untouched surface along the root canal walls (Peters, 2004; Peters et al., 2010). From the first generation of instruments, the super-elasticity of NiTi alloy enabled the manufacturing of more tapered instruments still flexible enough to properly shape canals with different angles and radius of curvature. The increase in the taper provides better and more continuous shapes with the use of fewer instruments and in a shorter time. Martensitic instruments should be preferred in cases of severely curved root canals or those with a double curvature (Zupanc et al., 2018). In fact, the greater flexibility of martensitic instruments combined with shape-setting manufacturing methods makes it possible to avoid apical transportation while limiting the removal of dentine in the coronal third of the root canal (Peters et al., 2015). Indeed, greater preservation of dentine in the coronal third of root canal may contribute to a better distribution of functional stresses and the maintenance of the strength of the tooth by the preservation of the pericervical dentine above and below the crestal bone (Clark & Khademi, 2010). Even masticatory stress seemed to be reduced with small changes in the amount of pericervical dentine preserved (Bonessio et al., 2017). The advancement of manufacturing methods has also allowed the development of instruments with specific shapes to better address the geometry of oval root canals and create ribbon-shaped preparations compared with the round preparations produced with previous generations of engine-driven NiTi instruments (Arias et al., 2018a).

A major concern in the previous decade was the identification of different preparation techniques and instruments designs as responsible for different degrees of dentinal damage and induction of microcracks in the root canals when using research methodologies based in extracted teeth (Adorno et al., 2009, 2011; Bier et al., 2009; Hin et al., 2013; Yoldas et al., 2012). Specifically, reciprocating instruments operating under the “single-file” concept were supposed to increase the mechanical stress in the root canal leading to significant development of dentinal cracks than full-sequence rotary systems (Bürklein et al., 2013). However, studies that have used cadavers have demonstrated the lack of relationship between the induction of microcracks and shaping (Arias et al., 2014; Bahrami et al., 2017) and completely discarded the presence of postoperative microcracks that were not in the tooth before treatment (De-Deus et al., 2014, 2017b). Sound research methodologies have ended the controversy demonstrating that the occurrence of microcracks is a laboratory phenomenon and hence should be referred to as experimental dentinal microcracks (De-Deus et al., 2019). For a thorough critical analysis of research methods and experimental models to study dentinal microcracks, please see Versiani et al. (2021).

Evidence based on clinical data

From the evidence provided above, a better clinical outcome may be anticipated if the root canal treatment was performed with instruments from later generations compared with former ones; however, despite the great number of laboratory studies suggesting the translation to an improvement in clinical performance, clinical evidence from well-designed clinical studies is scarce. In fact, the extent to which the improvement of instruments is related to clinical outcomes has been forecast in terms of surrogate parameters related to current generations of instruments. The link from root canal preparation with different instruments to clinical success still needs to be investigated through well-planned clinical studies, and this is not an easy task to achieve.

Retrospectively, manual root canal preparation with stainless steel resulted in greater incidence of procedural errors and was associated with a lower healing rate [Odds Ratio (OR) = 0.255, 95% CI 0.108–0.600] than NiTi rotary shaping in primary root canal treatments performed in a dental teaching setting (Cheung & Liu, 2009). On the other hand, a randomized clinical trial reported similar 12-month success rates after root canal treatment with a reciprocating single-file instrumentation and matching single-cone root filling or hand-file instrumentation and lateral compaction (de-Figueiredo et al., 2020).

However, there is a lack of studies on long-term clinical outcomes comparing different engine-driven preparation techniques in terms of tooth survival, periapical healing, or the binomial success/failure in general.

A lower incidence of postoperative pain has also been reported when using rotary than manual shaping (Arias et al., 2015), and a poorer oral health–related quality of life 6 months after the manual shaping of anterior teeth compared with a reciprocating preparation, although with no differences after 12 months (Diniz-de-Figueiredo et al., 2020). Root canal preparation time was also lower for rotary shaping when compared with manual preparation in a clinical study that also demonstrated a comparable flare-up incidence with both (Makanjuola et al., 2018). Less pain was also reported with a modified manual step-back technique compared with rotational or reciprocal shaping techniques (Çiçek et al., 2017).

The most studied clinical outcome in the endodontic literature has been immediate postoperative pain. There has been little comparison regarding postoperative pain associated with different rotary systems, but what to expect with the different kinematics of engine-driven instruments has attracted more attention. On the one hand, there is no consensus in the literature in the incidence and severity of postoperative pain and the need for analgesic intake after a rotary or reciprocating instrumentation technique. Some observed similar rates of pain (Relvas et al., 2016) and analgesic consumption (Kherlakian et al., 2016), others reported lower incidence when root canal shaping was performed with a multi-file rotary system rather than a single-reciprocating instrument (Hou et al., 2017; Nekoofar et al., 2015), and others lower pain after reciprocating motions (Shokraneh et al., 2017). If a single file was used with both motions, the reciprocating instruments seemed to induce less intensity (Arslan et al., 2016) and duration of postoperative pain (Neelakantan & Sharma, 2015). On the other hand, when the impact of rotary and reciprocating instrumentation was compared in terms of postoperative quality of life, similar impacts were reported 24 h after rotary or reciprocating shaping (Oliveira et al., 2019); however, reciprocating motion negatively influenced the quality of life of patients when tested 7 days after treatment in terms of eating, performing daily activities, sleeping and social relations compared with rotary shaping, although there was no difference in speaking (Pasqualini et al., 2015).

At the same time, the sixth generation of instruments proposed seems to have contributed to a better immediate postoperative outcome. No difference in the incidence and level of discomfort was reported after glide path preparation with rotating or reciprocating NiTi instruments, but both resulted in lower incidence and level of discomfort compared with manual glide path preparation (Keskin et al., 2019).

Future directions

In addition to continuous incremental innovations, future development of instruments may involve different approaches. One direction, potentially concerning, is the development of low-cost instruments in recent years (Figure 6). Manufacturers that were not engaged in the field of endodontics before have now started manufacturing rotary instruments with sometimes variable quality; this has gone as far as directly copying designs developed by competing companies. Not only is the public not benefitting from the best quality anymore, but also for the first time, efforts are not being focused on enhancing the specialty and the outcome of patients, but merely on a “false” economic benefit for practitioners. The authors consider this “false”, since inferior properties of low-cost instruments will render some time instruments to deform even in a single root canal treatment; therefore, more instruments are needed at the end. This, and other non-conforming properties may very well in the end be detrimental to patient treatment.

Another approach is continued product development, with possibly inclusion of further innovations in terms of motors and the actual instrument itself. Irrespective, it is anticipated that the future will bring a need for regulation in the manufacturing of instruments. No standard has been established yet to guarantee a minimum quality before being marketed. It seems reasonable that manufacturers demonstrate the quality of new instruments before marketing them following some sort of standardization. A proposal for a minimum quality criterion in terms of cyclic fatigue has been published recently (Peters et al., 2021). Minimum quality criteria that all tested samples should pass individually for the product to comply seems desirable. Some samples of low-cost instruments may successfully pass the tests, but scientific literature have reported the lower reliability of low-cost instruments (Arias et al., 2019; Scott et al., 2019). In fact, Hülsmann suggested (Hülsmann, 2013, 2019) that the responsibility to demonstrate the reliable use of new instruments in clinical settings before marketing a new product should lie in manufacturers. That said, from the authors’ perspective, the efforts of researchers and experts on the field should focus on the development of standards that address minimal acceptable requirements. These standards should also evolve continuously at the same pace as industry launches new developments. As an example, the proposal described before (Peters et al., 2021) suggested a correction factor based on the austenite finish temperature of the alloy of the tested instrument, determined with differential scanning calorimetry and the testing temperature. This stipulation was not included in any standard before, but the literature has thoroughly demonstrated how CF resistance of martensitic alloys is considerably affected by temperature (Jamleh et al., 2016; Plotino et al., 2017; de Vasconcelos et al., 2016). Each further development would probably require a review of pre-existing proposals and standards and new implementations or proposals with factor corrections.

Last, enhancement in instruments and devices would be probably accompanying the goal of preservation of natural tissue for a minimally invasive endodontics and hence for a long-lasting preservation of natural dentition.

FINAL REMARKS

This narrative review aimed to guide potential readers through the evolution of NiTi instruments and to highlight effective contributions for the advancement of root canal preparation. It was never intended and indeed impractical to include all publications on the topic. In fact, a recent bibliometric analysis of research published in the International Endodontic Journal and the Journal of Endodontics revealed that from 2010 to 2019, the most used terms were “review” and “instrument”, being nickel-titanium instruments one of the more frequents research themes during this period (Ordinola-Zapata et al., 2020). Therefore, the reader is advised to keep informed about current and future developments in this rapidly moving field.

CONFLICT OF INTEREST

Dr. Peters has served as a consultant for Dentsply Sirona, Dr Arias denies any conflict of interest.

AUTHOR CONTRIBUTIONS

Both authors contributed equally to concept and writing of the text.