Designing a Diversified Indian Mustard Production System for Energy-Carbon-Cum-Heat Use Efficiency and Sowing Dates Assessment

Funding: This work was supported by RUDN University Strategic Academic Leadership Program, the Science and Engineering Research Board (EEQ/2021/000053), and the Institute of Agricultural Sciences.

Sunil Kumar, Ram Swaroop and Sandeep Kumar are equally contributed to this work.

ABSTRACT

The rice (Oryza sativa L.)–wheat (Triticum aestivum L.) cropping system faces major challenges such as stagnant yields, high input and energy demands, and increasing soil and air pollution. Indian mustard (Brassica juncea L.) is a promising crop for diversification within rice-based ecosystems. The objective of this study was to evaluate the effects of different sowing dates and nutrient sources on energy budgeting in diversified Indian mustard and to assess the impact of these nutrient sources on heat-cum-carbon efficiency. The experiment was conducted using a split-plot design (SPD) with three sowing dates—November 17, November 27, and December 07—in the main plots, and eight nutrient sources in the subplots, where the recommended dose of fertilizer was 100 N:50 P2O5:50 K2O:40 S kg ha−1. The results, based on pooled data, indicated that among the sowing dates, November 17 recorded the highest values for several key metrics. These include energy use efficiency (EUE: 3.46, 5.12, and 12.16), energy production (EP: 0.152, 0.41, and 0.56 kg MJ−1), net energy (NE: 29,712, 50,483, and 92,558 MJ ha−1), energy profitability (EPr: 2.46, 2.88, and 6.34), human energy profitability (HEP: 364.82, 412.60, and 777.42), energy output efficiency (EOE: 364.69, 412.49, and 777.18 MJ d−1), carbon output (CO: 815, 2215, and 3030 kg CE ha−1), carbon efficiency (CE: 2.07, 5.59, and 7.66), and carbon sustainability index (CSI: 1.07, 4.59, and 6.66) for seed, stover, and biological yield, respectively, compared to the crops sown on November 27 and December 07. The study also revealed significant increases in heat use efficiency (HUE) on dry matter at 45 and 90 days after sowing (DAS) and on seed, stover, and biological yield (13.3, 8.46, 1.52, 4.16, and 5.69 kg ha−1°C days, respectively). In the subplots, the highest EUE (3.92, 5.10, and 12.1), EP (0.172, 0.408, and 0.58 kg ha−1), and EPr (2.92, 2.86, and 6.78) for seed, stover, and biological yield were observed in the control treatment, outperforming the other nutrient sources on a pooled basis. The highest SE production (8.59, 3.48, and 2.47 MJ kg−1) for seed, stover, and biological yield was recorded with the application of 100% of the recommended dose of fertilizer (RDF) combined with Azotobacter and phosphorus-solubilizing bacteria (PSB). Furthermore, the highest NE (35,427, 52,203, and 102,370 MJ ha−1), HEP (434.02, 438.67, and 872.68), EOE (448.37, 452.68, and 901.04 MJ d−1), CO (972, 2359, and 3331 kg CE ha−1), CE (2.48, 6.01, and 8.48), CSI (1.48, 5.01, and 7.48), and HUE (1.67, 4.12, and 5.81 kg ha−1°C days) for seed, stover, and biological yield were observed with the application of 75% RDF + 25% nitrogen from pressmud, combined with Azotobacter and PSB. This study provides a novel framework for optimizing sowing dates and nutrient sources that can lead to the development of an energy-efficient, heat-cum-carbon-efficient, and eco-friendly production system. Its findings offer scalable solutions for enhancing sustainability and reducing environmental footprints in rice-based cropping systems.

Abbreviations

-

- BNFB

-

- Biological nitrogen fixation

-

- CE

-

- Carbon equivalent

-

- CE

-

- Carbon efficiency

-

- CF

-

- Carbon footprint

-

- CO

-

- Carbon mono-oxide

-

- CO

-

- Carbon output

-

- CO2

-

- Carbon dioxide

-

- COP

-

- Conference of Parties

-

- CSI

-

- Carbon sustainability index

-

- DAP

-

- Diammonium phosphate

-

- DAS

-

- Days after sowing

-

- EE

-

- Energy equivalent

-

- EJ

-

- Exajoules

-

- EOE

-

- Energy output efficiency

-

- EPr

-

- Energy profitability

-

- EP

-

- Energy production

-

- EUE

-

- Energy use efficiency

-

- GDD

-

- Growing degree days

-

- GHG

-

- Greenhouse gas

-

- GJ

-

- Gigajoules

-

- HEP

-

- Human energy profitability

-

- HUE

-

- Heat use efficiency

-

- IGP

-

- Indo-Gangetic plains

-

- IPCC

-

- Intergovernmental Panel on Climate Change

-

- K

-

- Potash

-

- MOP

-

- Muriate of potash

-

- MT

-

- Million ton

-

- N

-

- Nitrogen

-

- N2O

-

- Nitrous oxide

-

- NE

-

- Net energy

-

- NO2

-

- Nitrogen dioxide

-

- NUE

-

- Nutrient use efficiency

-

- OC

-

- Organic carbon

-

- P

-

- Phosphorus

-

- PET

-

- Potential evapotranspiration

-

- PSB

-

- Phosphorus-solubilizing bacteria

-

- PTI

-

- Photothermal index

-

- RDF

-

- Recommended dose of fertilizer

-

- RWCS

-

- Rice–wheat cropping system

-

- S

-

- Sulfur

-

- SDGs

-

- Sustainable Development Goals

-

- SE

-

- Specific energy

-

- SOC

-

- Soil organic carbon

-

- SOM

-

- Soil organic matter

-

- SPD

-

- Split-plot design

1 Introduction

The fertile Indo-Gangetic Plains (IGPs) in South Asia span across Nepal, Bangladesh, Pakistan, and India, covering approximately 62 million hectares (M ha) under the rice (Oryza sativa L.)–wheat (Triticum aestivum L.) cropping system (RWCS) (Bhuvaneshwari et al. 2009). However, this cropping system faces significant challenges, including yield stagnation, declining groundwater levels, and soil and atmospheric pollution (Kumar et al. 2021; Meena et al. 2017). Rice-based ecosystems, in particular, are characterized by high input and energy demands, which contribute to elevated carbon dioxide (CO2) emissions (Joshi et al. 2007). Additionally, the soil organic carbon (SOC) stocks in these regions have reached critically low levels, leading to macro- and micronutrient deficiencies and reduced microbial activity, as observed by several researchers (Choudhary et al. 2017; Kumar et al. 2018; Singh et al. 2014). Moreover, chemical fertilizers represent the most energy-intensive and costly agricultural input after tillage in rice-based ecosystems (Yadav et al. 2017). The heavy reliance on these inputs not only demands substantial energy but also results in a significant carbon footprint (CF), undermining efforts to achieve a sustainable food system (Chaudhary et al. 2009). The manufacturing of synthetic fertilizers is highly energy-intensive, generating significant greenhouse gas (GHG) emissions that play a major role in driving global climate change. Globally, the agriculture industry consumes approximately 670 Exajoules (EJ) of energy annually (1 EJ = 1018 J) (Raihan 2023), with fertilizer production alone accounting for about 3.7 EJ (Ramírez and Worrell 2006). The global agricultural sector emits roughly 5.2 gigatons (Gt) of CO2 equivalent per year, which represents 12.6% of total CO2 emissions (Chojnacka et al. 2019). In India, the production of 1000 kg of urea needs 38 gigajoules (GJ) energy (Gielen and Taylor 2009).

Consequently, crop diversification with Indian mustard (Brassica juncea L.) offers a promising solution to the challenges faced by rice-based ecosystems, including the reduction of GHG emissions (Newport et al. 2020). Indian mustard is a crucial crop for diversification, as it can enhance soil fertility and boost productivity while requiring lower input levels. By reducing the reliance on energy-intensive chemical fertilizers and other inputs, Indian mustard helps lower production costs and increase the overall productivity of the system (Panesar and Bhatnagar 1994). Moreover, Indian mustard plays a vital role in meeting essential needs for edible oil, stabilizing prices, ensuring a balanced food supply, and withstanding weather anomalies. It also promotes the conservation of natural resources, the efficient, sustainable use of land and water, and the reduction of chemical energy use, leading to lower carbon emissions. Thus, integrating Indian mustard into crop diversification strategies is crucial for achieving long-term sustainability in rice-based ecosystems (Yadav et al. 2017). In addition, replacing wheat with Indian mustard in crop diversification has demonstrated significant benefits, such as minimizing tillage operations, reducing the system's water requirements, and increasing water productivity. It also improves soil health by restoring SOC and enhancing the soil's physicochemical and biological properties (Hernanz et al. 1995). Furthermore, Indian mustard helps control mimicry weeds like Phalaris minor, enhancing the productivity and profitability of rice-dominated agricultural systems (Kumar et al. 2017). The sowing date is also crucial for the optimal growth and yield of mustard. Timely sowing allows the crop to meet its optimum climatic requirements, resulting in better yields than early or late sowing. However, in some cases, the sowing time depends on the duration of the previous crop.

In addition, the use of organic manures can help balance system production, reduce reliance on chemical fertilizers, and sustainably maintain soil fertility. Incorporating biofertilizers into agricultural practices serves as a cost- and energy-efficient input while providing indirect nutrients (Garg et al. 2004). Biofertilizers not only supply essential nutrients to plants but also enhance the nutrient connection within the soil–plant system (Majumdar et al. 2000). Moreover, managing sowing dates can minimize energy consumption and CFs while improving the efficient use of solar radiation in rice-dominated ecosystems (Jatav et al. 2017). The aim of the current experiment was to determine the effect of Indian mustard sowing dates and nutrient sources on heat-cum-carbon efficiency and energy budgeting in a diversified rice-based ecosystem.

2 Materials and Methods

2.1 Experimental Site and Soil

The study was carried out over two consecutive Rabi seasons (2017–2018) at the Agricultural Farm of the Institute of Agricultural Sciences, B.H.U., Varanasi, India, located between 25°18′56 “N and 83°59′30” E at an elevation of 76.2 m above mean sea level (Kumar et al. 2018). The experimental soil was a deep, flat, well-drained sandy clay loam with a SOC of 0.42% (Jackson 1973), 210.4 kg ha−1 of available N (Subbiah and Asija 1956), 21.2 kg ha−1 of available P (Olsen 1954), 219.8 kg ha−1 of available K (Jackson 1973), 2.5 mg kg−1 of available sulfur (Williams and Steinbergs 1959), and pH 7.83 (Jackson 1973) in-furrow depth of the experimental site.

2.2 Climatic Conditions of the Experimental Site

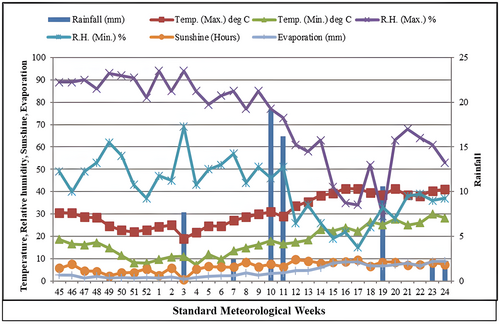

From 1941 to 2022, average weather data recorded annual rainfall of 1081.5 mm, of which 944.5 mm (87.30%) was obtained during the monsoon season and 138.0 mm (13.70%) in the postrainy season. Potential evapotranspiration (PET) has a mean yearly value of 1525 mm (Figure 1).

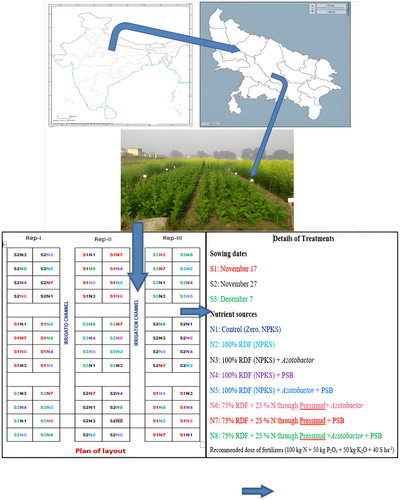

2.3 Experimental Details

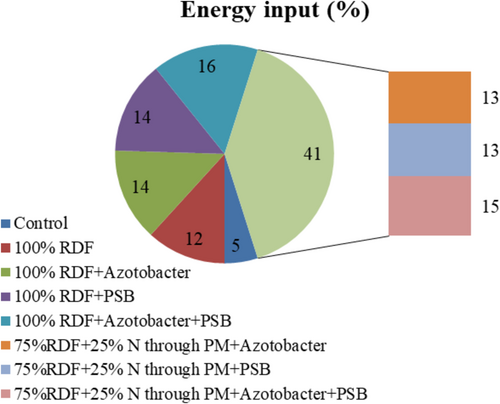

The experiment was carried out using a split-plot design (SPD) with three replications (Figure 2). Sowing dates and nutrient supplies were provided for the main plots and subplots, respectively. Three sowing dates (November 17 and 27, and December 07) and eight nutrient source combinations (i.e., N1 = control (zero, NPKS), N2 = recommended dose of fertilizer (RDF) 100% (NPKS), N3 = RDF 100% (NPKS) + Azotobacter, N4 = RDF 100% (NPKS) + phosphorus solubilizing bacteria (PSB), N5 = 100% RDF (NPKS) + Azotobacter + PSB, N6 = 75% RDF + 25% N through Pressmud + Azotobacter, N7 = 75% RDF + 25% N through Pressmud + PSB, and N8 = 75% RDF + 25% N through Pressmud + PSB + Azotobacter) were used as treatments. The RDF (100 N:50 P2O5:50 K2O:40 S kg ha−1) was employed as a suggestion for the area. All the nutrient sources were applied before planking. The trial field was prepared using a cultivator and rotavator.

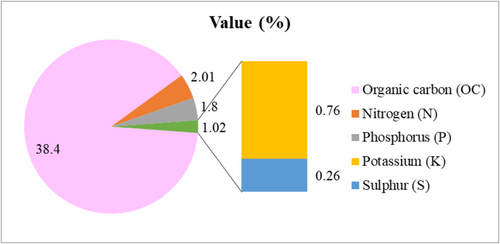

2.4 Treatment Management Details

Pressmud compost was collected from KM Sugar Mills, Moti Nagar, Faizabad, Uttar Pradesh. After drying, it was sieved using a 2.0 mm mesh and analyzed for nutrient content (Figure 3) before application in the field.

The RDF was applied using diammonium phosphate (DAP; 18%–46% NP), urea (46% N), muriate of potash (MOP; 60% K), and elemental sulfur (90% S). One week before planting, pressmud compost was well mixed into the soil and used in pressmud compost treatments. The remaining 75% RDF was applied as previously mentioned. Azotobacter and PSB, two biofertilizers, were applied to the seed at the rate of 200 g of each (Azotobacter/PSB) per 10 kg of seed. Ashirwad (RK-01-03) variety was selected for the experiment by using the seed rate of 5.0 kg ha−1. Its yield potential is 1450–2358 kg ha−1 with an oil content of 31%–41% in late sown conditions. The seeds of mustard were sown at 45 × 15 cm (row–row × plant–plant) during both years, and the depth of sowing was 3–4 cm. The crop was harvested at physiological maturity as 80% of siliqua turned yellowish brown. Each net plot area was harvested, and each plot's crop was packed and weighed after sun drying. Each plot was independently threshed by hammering (beating the plant material with sticks) the stover on a concrete threshing floor.

2.5 Energy Budgeting

2.6 Carbon Budgeting

By multiplying the inputs (chemical fertilizer, diesel, pesticides, etc.) with the associated emission coefficient (emission coefficients for diesel, N, P2O5, K2O, herbicide, insecticide, and fungicide are 0.074, 1.3, 0.2, 0.15, 3.9, 5.1, and 6.3 kg CO2 eq. per unit, respectively), carbon equivalent (CE) was calculated (Lal 2004; West and Marland 2002; Gan et al. 2009). The sum of the inputs/outputs of the crop was used to compute the total input and output of C. The CF of the crop was considered as per the practice by Ma et al. (2012):

(*Biomass of crop ~44% carbon).

2.7 Heat Use Parameters

where Tb = base temperature.

2.8 Statistical Analysis

The data were statistically analyzed using the analysis of variance (ANOVA) method appropriate for a split-plot design, as described by Gomez and Gomez (1976). The significance of various sources of variation was evaluated using Fisher and Snedecor's F-test at the relevant degrees of freedom. Fisher and Yates' table was referred to for interpreting the F-statistics and calculating the least significant difference (LSD) at the 5% significance level (p ≤ 0.05).

3 Results

3.1 Effect of Sowing Dates

3.1.1 Effect of Sowing Dates on Energy Parameters

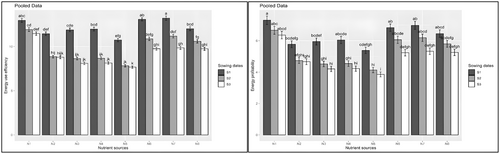

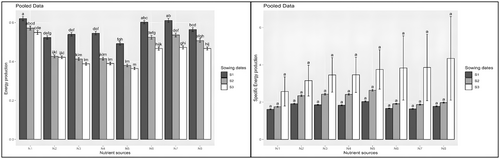

The data reveal that the maximum EUE (3.46, 5.12, and 12.16), EP (0.152, 0.410, and 0.562), NE (29,712, 50,483, and 92,558), EPr (2.46, 2.88, and 6.34), HEP (364.82, 412.60, and 777.42) and EOE (364.69, 412.49, and 777.18) of seed, stover, and biological yield (Tables 1, 2 and Figures 4-6) was for the November 17 sown crop, followed by the November 27 sown crop, respectively. Likewise, the lowest EUE, EP, NE, energy profitability, HEP, and EOE of seed, stover, and biological yield were noted for the December 07 sowing. However, the reverse trend has been observed for SE.

| Treatment | EUE (seed yield) | EUE (stover yield) | EP (seed yield) | EP (stover yield) | SE (seed yield) | SE (stover yield) | NE (seed yield) | NE (stover yield) | NE (biological yield) |

|---|---|---|---|---|---|---|---|---|---|

| Sowing dates | |||||||||

| Sowing I (November 17) | 3.46a | 5.12a | 0.152a | 0.410a | 6.66c | 2.45c | 29712a | 50483a | 92558a |

| Sowing II (November 27) | 3.20b | 4.13b | 0.141b | 0.331b | 7.26b | 3.09b | 26483b | 37724b | 76570b |

| Sowing III (December 07) | 2.96c | 3.87c | 0.130c | 0.310c | 7.83a | 3.29a | 23438c | 34380c | 70182c |

| SEM ± | 0.04 | 0.05 | 0.002 | 0.004 | 0.08 | 0.03 | 535 | 579 | 1077 |

| CD (p = 0.05) | 0.12 | 0.17 | 0.005 | 0.014 | 0.27 | 0.10 | 1745 | 1887 | 3511 |

| Nutrients sources | |||||||||

| Control (zero, NPKS) | 3.92a | 5.10a | 0.172a | 0.408a | 5.87e | 2.46f | 15041e | 21124f | 41313g |

| 100% RDF (NPKS) | 2.97d | 4.08d | 0.131c | 0.327d | 7.69c | 3.11c | 22446d | 35108e | 68943f |

| 100% RDF (NPKS) + Azotobacter | 2.85d | 4.01d | 0.125c | 0.321d | 8.04b | 3.20b | 24784c | 40388c | 78552e |

| 100% RDF (NPKS) + PSB | 2.88d | 4.04d | 0.127c | 0.323d | 7.96b | 3.19b | 25196c | 40695c | 79270e |

| 100% RDF (NPKS) + Azotobacter + PSB | 2.67e | 3.68e | 0.118d | 0.295e | 8.59a | 3.48a | 25722c | 41229c | 82323d |

| 75% RDF + 25% N through PM + Azotobacter | 3.46c | 4.73b | 0.152b | 0.378b | 6.61d | 2.69e | 31453b | 47589b | 91791c |

| 75% RDF + 25% N through PM + PSB | 3.53b | 4.80b | 0.155b | 0.385b | 6.49d | 2.64e | 32287b | 48562b | 93597b |

| 75% RDF + 25% N through PM + Azotobacter + PSB | 3.40bc | 4.54c | 0.150b | 0.363c | 6.73d | 2.78d | 35427a | 52203a | 102370a |

| SEM ± | 0.05 | 0.04 | 0.002 | 0.003 | 0.09 | 0.03 | 417 | 425 | 529 |

| CD (p = 0.05) | 0.13 | 0.11 | 0.006 | 0.009 | 0.25 | 0.07 | 1173 | 1195 | 1487 |

- Note: a–gDifferent letters in the same column indicate a significant difference at the 0.05 probability level. Abbreviations: NPKS = nitrogen, phosphorus, potassium, and sulfur; PM = pressmud; PSB = phosphorus-solubilizing bacteria; RDF = recommended dose of fertilizers.

| Treatment | EPr (seed yield) | EPr (stover yield) | HEP (seed yield) | HEP (stover yield) | EOE (seed yield) | EOE (stover yield) |

|---|---|---|---|---|---|---|

| Sowing dates | ||||||

| Sowing I (November 17) | 2.46a | 2.88a | 364.82a | 412.60a | 364.69a | 412.49a |

| Sowing II (November 27) | 2.20b | 2.13b | 336.83b | 328.97b | 347.35b | 339.14b |

| Sowing III (December 07) | 1.96c | 1.93c | 310.47c | 307.02c | 330.90c | 327.07b |

| SEM ± | 0.04 | 0.04 | 4.62 | 3.81 | 4.710 | 3.87 |

| CD (p = 0.05) | 0.12 | 0.13 | 15.06 | 12.44 | 15.36 | 12.61 |

| Nutrients sources | ||||||

| Control (zero, NPKS) | 2.92a | 2.86a | 180.80f | 178.20f | 180.48f | 177.82f |

| 100% RDF (NPKS) | 1.97d | 2.09d | 292.71e | 304.68e | 302.56e | 314.21e |

| 100% RDF (NPKS) + Azotobacter | 1.85d | 2.04d | 330.16d | 352.32d | 340.90d | 362.87d |

| 100% RDF (NPKS) + PSB | 1.88d | 2.06d | 333.73d | 354.33d | 344.52d | 364.92d |

| 100% RDF (NPKS) + Azotobacter + PSB | 1.67e | 1.79e | 355.52c | 370.89c | 367.01c | 382.19c |

| 75% RDF + 25% N through PM + Azotobacter | 2.46b | 2.58b | 382.41b | 395.37b | 394.98b | 407.62b |

| 75% RDF + 25% N through PM + PSB | 2.53b | 2.64b | 389.62b | 401.76b | 402.38b | 414.22b |

| 75% RDF + 25% N through PM + Azotobacter + PSB | 2.40c | 2.44c | 434.02a | 438.67a | 448.37a | 452.68a |

| SEM ± | 0.05 | 0.03 | 3.64 | 2.79 | 3.75 | 2.88 |

| CD (p = 0.05) | 0.13 | 0.08 | 10.23 | 7.84 | 10.56 | 8.10 |

- Note: a–fDifferent letters in the same column indicate significant differences at the 0.05 probability level.

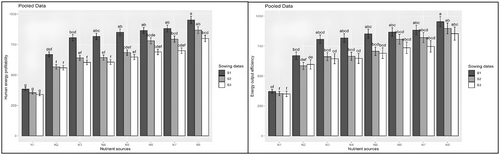

3.1.2 Effect of Sowing Dates on Carbon Parameters

According to an analysis of the data (Table 3), the sowing dates with the highest CO on seed (815 kg CE ha−1), stover (2215.0 kg CE ha−1), and biological yield (3030.0 kg CE ha−1) were November 17, followed by November 27. In the study, the sowing on December 07 had the lowest CO. The results (Figure 7) also showed that the crop seeded on November 17 had the highest CE on biological yield (7.66), followed by the crop sowed on November 27. In the experimental results, the sowing on December 07 had the lowest CE. Also, Table 3 shows that the crop seeded on December 07 had the highest CF (0.26 kg CE kg−1 seed; 0.11 kg CE kg−1 stover; and 0.08 kg CE kg−1 biological yield) followed by the crop sown on November 27, while the crop sown on November 17 had the lowest CF in the study. In the pooled study, the crop seeded on December 07 had the lowest CSI, whereas the crop sown on November 17 had the highest (Table 3 and Figure 7). The highest CSI was seen for seed (1.07 MJ d−1), stover (4.59 MJ d−1), and biological yield (6.66 MJ d−1).

| Treatment | CO (seed yield) | CO (stover yield) | CO (biological yield) | CE (seed yield) | CE (stover yield) | CF (seed yield) | CF (stover yield) | CF (biological yield) | CSI (seed yield) | CSI (stover yield) |

|---|---|---|---|---|---|---|---|---|---|---|

| Sowing dates | ||||||||||

| Sowing I (November 17) | 815a | 2215a | 3030a | 2.07a | 5.59a | 0.22c | 0.08c | 0.06c | 1.07a | 4.59a |

| Sowing II (November 27) | 752b | 1765b | 2518b | 1.91b | 4.48b | 0.24b | 0.10b | 0.07b | 0.91b | 3.48b |

| Sowing III (December 07) | 693c | 1647c | 2341c | 1.76c | 4.18c | 0.26a | 0.11a | 0.08a | 0.76c | 3.18c |

| SEM ± | 10 | 20 | 30 | 0.02 | 0.05 | 0.00 | 0.0005 | 0.0005 | 0.03 | 0.05 |

| CD (p = 0.05) | 34 | 66 | 97 | 0.08 | 0.17 | 0.01 | 0.001 | 0.001 | 0.08 | 0.17 |

| Nutrients sources | ||||||||||

| Control (zero, NPKS) | 391f | 926f | 1317g | 1.39f | 3.30f | 0.32a | 0.13a | 0.09a | 0.39f | 2.30f |

| 100% RDF (NPKS) | 656e | 1639e | 2294f | 1.57e | 3.92e | 0.28b | 0.11b | 0.08b | 0.57e | 2.93e |

| 100% RDF (NPKS) + Azotobacter | 739d | 1895d | 2634e | 1.77d | 4.54d | 0.25c | 0.10c | 0.07c | 0.77d | 3.54d |

| 100% RDF (NPKS) + PSB | 747d | 1906d | 2653e | 1.79d | 4.56d | 0.25c | 0.10c | 0.07c | 0.79d | 3.56d |

| 100% RDF (NPKS) + Azotobacter + PSB | 796c | 1995c | 2791d | 1.91c | 4.78c | 0.23d | 0.09d | 0.07c | 0.91c | 3.78c |

| 75% RDF + 25% N through PM + Azotobacter | 856b | 2126b | 2983c | 2.18b | 5.42b | 0.20e | 0.08e | 0.06d | 1.18b | 4.42b |

| 75% RDF + 25% N through PM + PSB | 873b | 2161b | 3033b | 2.22b | 5.50b | 0.20e | 0.08e | 0.06d | 1.22b | 4.50b |

| 75% RDF + 25% N through PM + Azotobacter + PSB | 972a | 2359a | 3331a | 2.48a | 6.01a | 0.18f | 0.07f | 0.05e | 1.48a | 5.01a |

| SEM ± | 8 | 15 | 15 | 0.02 | 0.04 | 0.004 | 0.001 | 0.00 | 0.02 | 0.04 |

| CD (p = 0.05) | 23 | 42 | 43 | 0.06 | 0.11 | 0.010 | 0.003 | 0.06 | 0.06 | 0.11 |

- Note: a–gDifferent letters in the same column indicate a significant difference at the 0.05 probability level.

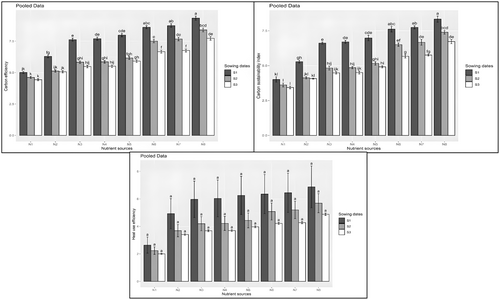

3.1.3 Effect of Sowing Dates on the Thermal Requirement

The data (Table 4 and Figure 7) show that the November 17 sown crops had the highest HUE on seed (1.52 kg ha−1°C days), stover (4.16 kg ha−1°C days), and biological yield (5.69 kg ha−1°C days), and 13.30 kg ha−1°C days for dry matter at 45 DAS, and 8.46 kg ha−1°C days for dry matter at 90 DAS. In the results, the sowing on December 07 had the lowest HUE.

| Treatment | HUE (dry matter at 45 DAS) | HUE (dry matter at 90 DAS) | HUE (seed yield) | HUE (stover yield) |

|---|---|---|---|---|

| Sowing dates | ||||

| Sowing I (November 17) | 13.30a | 8.46a | 1.52a | 4.16a |

| Sowing II (November 27) | 5.79b | 6.33b | 1.29b | 3.05b |

| Sowing III (December 07) | 4.09c | 5.25c | 1.08c | 2.65c |

| SEM ± | 0.18 | 0.09 | 0.02 | 0.04 |

| CD (p = 0.05) | 0.59 | 0.29 | 0.06 | 0.12 |

| Nutrients sources | ||||

| Control (zero, NPKS) | 3.93f | 3.32f | 0.67f | 1.62f |

| 100% RDF (NPKS) | 6.58e | 5.72e | 1.13e | 2.87e |

| 100% RDF (NPKS) + Azotobacter | 7.57d | 6.69d | 1.27d | 3.33d |

| 100% RDF (NPKS) + PSB | 7.68d | 6.74d | 1.29d | 3.35d |

| 100% RDF (NPKS) + Azotobacter + PSB | 8.18c | 7.11c | 1.37c | 3.50c |

| 75% RDF + 25% N through PM + Azotobacter | 8.68b | 7.59b | 1.47b | 3.73b |

| 75% RDF + 25% N through PM + PSB | 8.87b | 7.73b | 1.50b | 3.79b |

| 75% RDF + 25% N through PM + Azotobacter + PSB | 10.31a | 8.55a | 1.67a | 4.12a |

| SEM ± | 0.11 | 0.06 | 0.01 | 0.03 |

| CD (p = 0.05) | 0.31 | 0.18 | 0.04 | 0.07 |

- Note: a–gDifferent letters in the same column indicate a significant difference at the 0.05 probability level.

3.2 Effect of Nutrient Sources

3.2.1 Effect of Nutrient Sources on Energy Parameters

In the study, the control group had higher EUEs for seed (3.92), stover (5.10), and biological yield (12.11) than the other nutrient sources (Table 1 and Figure 4). Results also showed that the applications of 75% RDF + 25% N through pressmud + PSB, 75% RDF + 25% N through pressmud + Azotobacter, and 75% RDF + 25% N through pressmud + Azotobacter + PSB were all determined to be equivalent. Furthermore, the analysis observed minimum EUE in 100% RDF + Azotobacter + PSB. Results also showed (Table 1 and Figure 5) that in the study, the control had the greatest EP on seed (0.172 kg ha−1), stover (0.408 kg ha−1), and biological yield (0.58 kg ha−1). The second-best treatment for EP was 75% RDF + 25% N through pressmud + PSB. However, 75% RDF + 25% N through pressmud + Azotobacter and 75% RDF + 25% N through pressmud + Azotobacter + PSB responses were also demonstrated to be superior. Furthermore, it was established that the effects of 100% RDF, 100% RDF + PSB, and 100% RDF + Azotobacter on EP were equivalent. In the trial results, the minimum EP was seen in 100% RDF + Azotobacter + PSB. Further critical examination of data (Table 1 and Figure 5) significantly recorded the highest SE production on seed (8.59 MJ kg−1), stover (3.48 MJ kg−1), and biological yield (2.47 MJ kg−1) in 100% RDF + Azotobacter + PSB. Moreover, the minimal values of SE production in the study were 75% RDF + 25% N through pressmud + Azotobacter + PSB, 75% RDF + 25% N through pressmud + Azotobacter, 75% RDF + 25% N through pressmud + PSB, and control. In the study, the results on NE production (Table 1) showed that the maximum NE of seed (35,427 MJ ha−1), stover (52,203 MJ ha−1), and biological yield (102,370 MJ ha−1) in 75% RDF + 25% N via pressmud + Azotobacter + PSB. Although applying 75% RDF + 25% N through pressmud + PSB and 75% RDF + 25% N through a pressmud + Azotobacter response were determined to be equivalent. In the study, the minimum NE was noted in control. In the experiment results study, the control had the greatest EPr for seed (2.92), stover (2.86), and biological yield (6.34) among the sources (Table 2 and Figure 4). Also, the combined research found that 100% RDF + Azotobacter + PSB from applied nutrition sources had minimal energy profitability. According to HEP data (Table 2 and Figure 6), applying 75% RDF + 25% N through pressmud + Azotobacter + PSB resulted in considerably higher values (seed 434.02, stover 438.67, and biological yield 872.68) than other sources. In the pooled study, the control also reported the lowest HEP levels.

The results on EOE (Table 2 and Figure 6) indicated the highest values for seed (448.37 MJ d−1), stover (452.68 MJ d−1), and biological yield (901.04 MJ d−1) with the treatment of 75% RDF + 25% N using pressmud + Azotobacter + PSB, compared to other nutrient sources. Additionally, the applications of 75% RDF + 25% N with pressmud + PSB and 75% RDF + 25% N with pressmud + Azotobacter showed equivalent responses. The control treatment exhibited the lowest EOE in the analysis.

3.2.2 Effect of Nutrient Sources on Carbon Parameters

Data from the analysis show that 75% RDF + 25% N through pressmud + Azotobacter + PSB had greater CO on seed (972 kg CE ha−1), stover (2359 kg CE ha−1), and biological yield (3331 kg CE ha−1) than other nutrient sources (Table 3). On a pooled basis, the highest CE on seed (2.48), stover (6.01), and biological yield (8.48) was recorded with 75% RDF + 25% N via pressmud + Azotobacter + PSB as compared to other treatments (Table 3 and Figure 7). On the other hand, applications of 75% RDF + 25% N via pressmud + PSB and 75% RDF + 25% N via pressmud + Azotobacter reaction on CE were found to be equivalent. Nevertheless, it was shown that using 100% RDF + Azotobacter + PSB, CE was superior to the remaining treatments. During the analysis, the control showed the lowest CE. Also, according to the findings in Table 3, the control had the greatest CF (0.32 kg CE kg−1 seed), (0.13 kg CE kg−1 stover), and (0.09 kg CE kg−1 biological yield). Even though 100% RDF caused considerably more CF than other treatments, it was nevertheless used. Also, it was shown that the CF impacts of 100% RDF + Azotobacter and 100% RDF + PSB were equivalent. Moreover, a minimum CF of 75% RDF + 25% N through pressmud + Azotobacter + PSB was reported in the trial result (seed 0.18, stover 0.07, and biological yield 0.05 kg CE kg−1). In addition, compared to other nutrient sources, the combination of 75% RDF + 25% N through pressmud + Azotobacter + PSB had the highest CSI (1.48 seed, 5.01 stover, and 7.48 biological yield) in the trial outcomes (Table 3 and Figure 7). Applications of 75% RDF + 25% N through pressmud + PSB and 75% RDF + 25% N through pressmud + Azotobacter were useful on CSI noted equivalent in the study.

3.2.3 Effect of Nutrient Sources on Thermal Requirement

The HUE on seed (1.67 kg ha−1°C days), stover (4.12 kg ha−1°C days), biological yield (5.81 kg ha−1°C days), dry matter at 45 DAS (10.31 kg ha−1°C days), and dry matter at 90 DAS (8.55 kg ha−1°C days) was highest when 75% RDF + 25% N through pressmud + Azotobacter + PSB were used in comparison to other nutrient sources (Table 4 and Figure 7). It was established that 75% RDF + 25% N applied through a pressmud + Azotobacter and 75% RDF + 25% N applied through a pressmud + PSB were similar. The lowest HUE was seen in the control in the study.

4 Discussion

4.1 Effect of Sowing Dates

According to the energy parameter data (Tables 1, 2), the crop seeded on November 17 in the study had the highest EUE, EP, and NE values. Depending on the agroclimatic circumstances, meteorological factors (Figure 1 and Table 5), crop development patterns, days to maturity, cultural practices, and crop production technologies, this can result from EUE. Thus, the Indian mustard's suitability to replace the wheat crop under a rice-dominated ecosystem seems to be a more efficient crop with first sowing. The first sowing crop produces maximum yields through more utilization of resources. The crop sown on November 17 to attain maturity took more days (114 days) during both years (Table 5), respectively. However, the first sown crop utilized the applied inputs more efficiently to produce higher energy output. Meanwhile, the crop sown on the next dates (November 27 and December 07) took fewer days: 110, 114, and 105, 112, respectively (Table 5), and utilized less energy input during both years to attain maturity. Thereby, the growth period of these two sown crops was shortened, reducing the growth parameters and efficiency of input utilization up to the optimum level (Figure 8). Furthermore, yield contributing characters were also decreased as compared to the first sown crop and ultimately decreased EP, NE, EUE, energy profitability, HEP, and EOE (Tables 1, 2 and Figures 4-6). While maximum SE production (7.83 MJ kg−1) was recorded on the December 07 sown crop followed by November 27, the minimum SE production was observed on the November 17 sown crop (Table 1). This may be because low yield was obtained in the last sowing and energy input was constant for all three sowing dates. Thus, the SE was maximum in the last sowing (Choudhary et al. 2017; Firrisa et al. 2014).

| Sowing | Days to maturity | Photothermal index (degree days day−1) | Growing degree days (degree days day−1) |

|---|---|---|---|

| Sowing I (November 17) | 114 | 13.87 | 1582 |

| Sowing II (November 27) | 110 | 13.88 | 1527 |

| Sowing III (December 07) | 105 | 13.94 | 1463 |

Among sowing dates, highest CO and CE were found highest in the first sowing (Table 3 and Figure 7) which may be due to the favorable growing environment in terms of suitable temperature (Figure 1) and nutrient mineralization for the crop, resulting in increased growth parameters and yields of Indian mustard (Kumar and Meena 2020), and ultimately increased biomass CO (Table 3) in the crop. The lower C input and greater CO in the first seeded crop can be used to explain the increased CE (Table 3 and Figure 6). Moreover, the crop seeded on December 07 had the highest CF (Table 3), followed by the crop sown on November 27. This analysis recorded the lowest CF on November 17 sowing. This is because of maximum C utilization and storage in biomass from the first sowing and higher CO (Table 3). Maintaining soil fertility and productivity on a long-term basis under the intensive cropping system of India, C sustainability is essential in the rice-dominated ecosystem. The crop growing period mainly decides the amount of C stored in the dry matter of crop residue. Therefore, in the experiment, the crop sown on November 17 exhibited the highest values of CSI (Table 3 and Figure 7). These results are supported by the findings of (Yadav et al. 2017; Yadav et al. 2017; Singh et al. 2014).

The results for the HUE parameters are shown in Table 4, and Figure 7 shows that the planting dates strongly impacted the HUE of the Indian mustard. The November 17 sown crop in the study indicated the highest HUE at 45 and 90 DAS, with seed, stover, and biological yield among all sowing dates. The HUE discovered that all three sowings were nonsignificant in the first year. This can occur as a result of the right weather (Figure 1). Due to increased GDD at initial sowing, the optimal values of the HUE (Table 4 and Figure 8) indices were needed for early-planted crops to reach maturity and provide higher yields (Table 5). First sowing had better efficiency than late sowing; this could be because the crop experienced less-than-ideal temperature conditions when the seeding was postponed, which led to reduced HUE (Kumar et al. 2021; Singh et al. 2014).

4.2 Effect of Nutrient Sources

The highest EUE, EP, and EPr were observed in control (Tables 1, 2) than in nutrient sources. In control, the lowest energy input (Figure 8) was used. Therefore, the highest EUE, EP, and EPr were observed. The NE production (Table 1) was highest with 75% RDF + 25% N through pressmud + Azotobacter + PSB because of the maximum yields with this treatment, which produced the higher energy output in this treatment. At the same time, the highest values of NE, HEF, and EOE (Tables 1, 2, and Figure 6) were calculated with the application of 75% RDF + 25% N through pressmud + Azotobacter + PSB. It may be because higher yields from this treatment show higher NE, HEF, and EOE. The field trials were conducted in fully irrigated Eastern-Gangetic plains to diversify the intensive rice-dominated agroecosystem. Among the nutrient sources, 25% N was applied through pressmud compost, which is organic manure and utilized less amount of energy (0.30 MJ) as compared to fertilizer nitrogen (60.60 MJ) (Choudhary et al. 2017; Firrisa et al. 2014). With pressmud compost, treatments also included biofertilizers (Azotobacter and PSB) which also utilized lower energy and enhanced the nutrient availability to the crop and helped in balanced nutrition to the growing crop which helps in higher energy output and reducing the chemical fertilizer demand or energy input. Among the nutrient sources, the highest SE production (Table 1 and Figure 6) was observed in 100% RDF + Azotobacter + PSB than other nutrient sources. This may be because of this treatment's highest energy input (Figure 8), related to the highest SE (Choudhary et al. 2017; Firrisa et al. 2014).

Among all the treatments, the highest CO and CE were recorded in 75% RDF + 25% N through pressmud + Azotobacter + PSB compared to other treatments. On average, the plant contains 44% C of its biomass (Erdal et al. 2007; Lal 2004). The highest CO (Table 3) in the given treatment may be due to the high biomass yield obtained with this treatment, and the highest CE (Table 3 and Figure 7) in treatment could be attributed to lower C input and high CO-increased CE. The highest CF (0.307, 0.333, and 0.320 kg CE kg−1 seed) was found in control than other treatments (Table 3). Among the applied nutrient sources, the application of 100% RDF response on CF was significantly higher than other treatments. This may be attributed to higher C input and lower yields, resulting in low C accumulation in plant parts as biomass production (Pimentel 2009). C sustainability can be achieved with an excellent source of organic manure and a combination with an optimum dose of fertilizers and best soil management practices (Srinivasarao et al. 2012). It is very difficult to increase organic matter in the soil, mainly in tropical and subtropical conditions of India. Including legumes or adding well-composted organic manure in the soil is essential. The experiment achieves it by adding a combination of pressmud compost and recommended fertilizer dose to maintain or increase carbon content in soil and crop productivity. Therefore, the CSI is found to be maximum with 75% RDF + 25% N through pressmud + Azotobacter + PSB treatment. Similar results were found by Yadav et al. (2017)); Kumar et al. (2021)).

Nutrient sources significantly changed the information on thermal requirements. Careful analysis of the data revealed that the study's maximum HUE was represented by 75% RDF + 25% N through pressmud + Azotobacter + PSB (Table 4 and Figure 7). The length of a particular development stage is directly influenced by temperature. For a particular crop, its length may be predicted using the mean total of daily air temperatures (Figure 1). Effects of temperature on the phenology and production of Indian mustard in field circumstances, as measured by the growing degree days and the accumulated heat unit system (Table 5). The greatest HUE values were also attributable to generating substantially more seeds. This might be a result of the favorable weather that is now present, which favors the ideal temperature and high mineralization of nutrients in the soil. Applying high heat as input for photosynthesis may boost crops' balanced nutrient availability for robust development. Consequently, in this treatment, the heat used to create one biomass unit is more important (Kumar et al. 2021).

5 Conclusions

Based on the conclusions drawn from the experiment, the highest energy parameters—including energy use efficiency (EUE), energy production (EP), net energy (NE), energy profitability (EPr), human energy profitability (HEP), and energy output efficiency (EOE)—as well as carbon output (CO, kg CE ha−1), carbon efficiency (CE), carbon sustainability index (CSI, MJ d−1), and heat use efficiency (HUE, kg ha−1°Cdays) were recorded for the crop sown on November 17 in the pooled analysis. Additionally, this sowing date was associated with the lowest specific energy (SE) and carbon footprint (CF, kg CE kg−1). The control treatment exhibited higher EUE, EP (kg ha−1), and EPr values compared to the nutrient sources. However, the pooled analysis revealed that the treatment with 75% of the recommended dose of fertilizer (RDF) + 25% nitrogen via pressmud, combined with Azotobacter and phosphorus-solubilizing bacteria (PSB), achieved the highest NE (MJ ha−1), HEP, and EOE (MJ d−1). Additionally, the application of 100% RDF + Azotobacter + PSB resulted in the highest SE (MJ kg−1). Therefore, diversifying with Indian mustard significantly reduces the carbon footprint by decreasing carbon emissions and enhancing CO2 sequestration, contributing to climate change mitigation. This approach also lowers energy demand, improves EUE, enhances crop yield, and promotes environmental sustainability, ultimately ensuring food and nutritional security in rice-based cropping systems.

Author Contributions

Sunil Kumar: conceptualization, data curation, formal analysis, methodology, resources. Ram Swaroop Meena: conceptualization, data curation, formal analysis, funding acquisition, investigation, methodology, project administration, resources, software, supervision, validation, visualization, writing – original draft, writing – review and editing. Sandeep Kumar: software, validation, visualization, writing – original draft, writing – review and editing. Gourisankar Pradhan: data curation, formal analysis, methodology, resources, supervision. Chetan Kumar Jangir: software, validation, visualization. Shambhunath Ghosh: writing – review and editing. Himani Punia: writing – review and editing. Parvender Sheoran: supervision, writing – review and editing. Ramawatar Meena: writing – review and editing. Md. Afjal Ahmad: writing – review and editing. Suneel Kumar Goyal: writing – review and editing. Nazih Y. Rebouh: writing – review and editing.

Acknowledgments

The leading authors are thankful to the SERB (DST, Govt. of India), New Delhi (Letter No. EEQ/2021/000053), and the Institute of Agricultural Sciences, B.H.U., Varanasi, for providing the necessary facilities to experiment. This paper has been supported by the RUDN University Strategic Academic Leadership Program.

Ethics Statement

The authors have nothing to report.

Consent

The authors have nothing to report.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data will be provided on request.