Impact Absorption Power of Polyolefin Fused Filament Fabrication 3D-Printed Sports Mouthguards: In Vitro Study

Funding: This work was supported by the Academy for Sports Dentistry.

ABSTRACT

Background/Aim

This study aims to evaluate and compare the impact absorption capacities of thermoformed ethylene vinyl acetate (EVA) mouthguards and 3D-printed polyolefin mouthguards used in sports dentistry applications. The objective is to determine whether 3D-printed polyolefin mouthguards offer superior impact toughness compared to traditional EVA mouthguards commonly used in sports settings.

Materials and Methods

Six material samples were assessed: five pressure-formed EVA mouthguards (PolyShok, Buffalo Dental, Erkoflex, Proform, and Drufosoft) and one 3D-printed synthetic polymer (polyolefin). The materials were evaluated using a modified American Society for Testing and Materials (ASTM) D256 Test Method A for Izod pendulum impact resistance of plastics. Polyolefin samples were 3D-printed using fused filament fabrication (FFF) technology. Notably, the FFF process included samples printed with notches placed either parallel or perpendicular to the build direction. This orientation served as a study factor, allowing for comparison of material behavior under different printing conditions. Impact testing was conducted using an Izod impact tester to assess the materials' performance under controlled impact conditions.

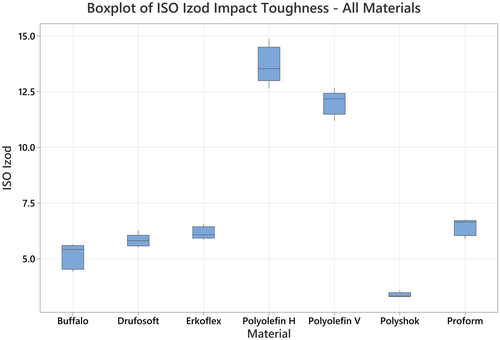

Results

The study achieved a high power (1.0) in power analysis, indicating strong sensitivity to detect significant differences. Among molded materials, PolyShok showed significantly lower impact toughness compared to others (p = 0.06). The mean impact absorption of EVA materials was 5.4 ± 0.3 kJ/m2, significantly lower than polyolefin materials, which demonstrated 12.9 ± 0.7 kJ/m2 and superior performance (p = 0.0). Horizontal-notched polyolefin samples exhibited higher impact strength compared to vertical-notched samples (p = 0.009).

Conclusions

3D-printed polyolefin mouthguards exhibited significantly higher impact toughness than thermoformed EVA mouthguards. While EVA materials demonstrated structural robustness, their lower impact resistance and observed tearing in other test specimens suggest the need for alternative testing standards to better reflect real-world conditions. 3D-printed mouthguards fabricated with build orientations perpendicular to the direction of impact demonstrate significantly enhanced impact absorption. Further research into manufacturing methods and testing protocols is recommended to optimize mouthguard performance under impact scenarios.

1 Introduction

The evolution of sports mouthguards from rudimentary constructs in the 1800s to sophisticated, custom-engineered devices today underscores the enduring commitment to innovation and safety in sports [1, 2]. Thomas Carlos's contributions in the 1930s marked a pivotal moment, laying the groundwork for modern mouthguard technology, which now serves as a staple protective measure for athletes across diverse sporting disciplines [3]. Amid this evolution, material advancements have played a pivotal role, particularly in enhancing impact absorption and force dispersion, vital for safeguarding both soft and hard tissues within the oral cavity [4].

Ethylene vinyl acetate (EVA) stands out as a predominant material in contemporary sports mouthguard production due to its demonstrated efficacy [1]. However, the pursuit of further advancements prompts exploration into alternative materials, with polyolefin (PO) fused filament fabrication (FFF) emerging as a notable contender in recent material science developments [5].

The FFF process entails loading PO filament into a 3D printer, where it is conveyed through a heated extruder, transforming into a semi-liquid state [6]. Layer by layer, according to specifications delineated in a computer-aided design (CAD) file, the molten PO is extruded onto a build platform. Each layer rapidly cools and solidifies upon deposition, forming a cohesive structure. POs are prized for their flexibility, chemical resistance, and cost-effectiveness, yet printing with these materials presents unique challenges. Their elevated melting point relative to common FFF materials like PLA or ABS complicates the printing process while achieving robust interlayer adhesion is hindered by the low surface energy of POs [7]. Consequently, meticulous calibration of printer parameters and meticulous surface preparation are essential for successful PO FFF printing.

To ascertain optimal protection for athletes through sports mouthguards, a comprehensive examination of both conventional and innovative materials is imperative. By scrutinizing established options like EVA alongside novel choices like PO FFF, researchers and dental professionals can acquire a nuanced comprehension of each material's attributes and limitations [8, 9]. This multifaceted research equips stakeholders with the requisite knowledge to effectively mitigate the incidence of oro-facial injuries among athletes, thereby fostering safer sporting environments for all involved parties.

The purpose of this study is to assess the energy absorption capabilities of both molded and 3D-printed materials, specifically focusing on their impact absorption reliability in the context of mouthguard fabrication. This research investigates whether additive manufacturing technology, using 3D-printed PO-based materials, can achieve impact energy absorption properties comparable to or better than traditional molded EVA materials commonly used in mouthguards. The study hypothesizes that 3D-printed PO mouthguards will demonstrate superior impact energy absorption, as evaluated by the Izod impact test, compared to EVA mouthguards. Conversely, the null hypothesis posits no significant difference in impact energy absorption between 3D-printed PO-based mouthguards and traditional molded EVA materials under Izod impact testing conditions.

2 Materials and Methods

Six material samples were prepared to quantify impact energy absorption following a modification of Test Method A of the American Society for Testing and Materials (ASTM) D256, “Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics,” as a reference test standard. This testing was conducted at the Ohio State University's Center for Design and Manufacturing Excellence (CDME) in collaboration with The Ohio State University College of Dentistry.

The materials evaluated in this in vitro study consisted of five commercially available examples of EVA, EVA hybrid, and PO 3D-printed polymer. The actual EVA and PO content of commercially available products is proprietary. EVA hybrid is the combination of EVA with polyurethane, the combination of the materials makes this a hybrid [9, 10]. The 3D-printed material is fabricated using the FFF technique with the Prusa Research Original i3 MK3S (Prusa Research, Prague, Czech Republic) printer.

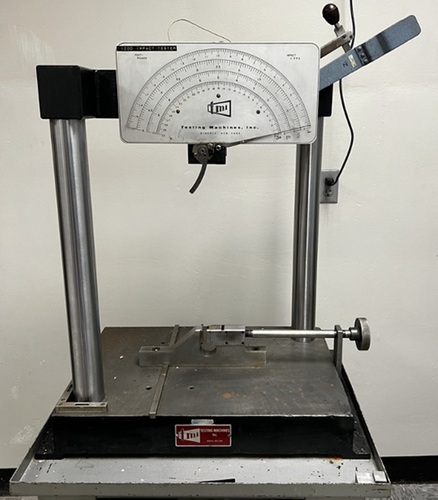

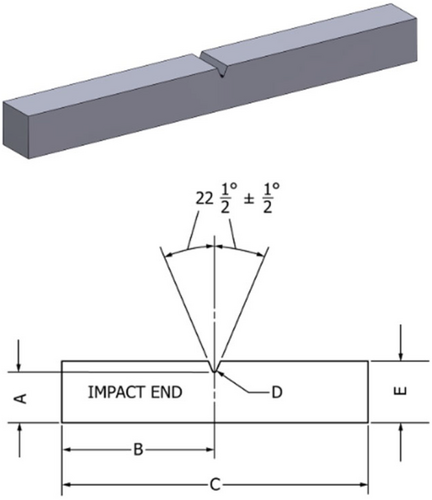

Modifying the testing protocol was necessary due to sample size constraints, resulting in the reporting of comparative impact strength values. The outer dimensions of specimens to ASTM D256 are specified to a length of 2.5 in (63.5 mm) and a height of 0.5 in (12.5 mm). The width of specimens may be between 0.118 in (3.0 mm) and 0.5 in (12.5 mm). The samples in this experiment are scaled to 50% of the standard height, using a quarter inch (6.4 mm) with no changes in other directions. The chosen 6.4 mm thickness for ASTM testing deviates from the recommended 4 mm thickness for mouthguards due to the fact that further reduction to 4 mm risks compromising the reliability of calculations and tests. This adjustment was necessary to balance practical feasibility with scientific rigor in our experimental approach. Testing was carried out using a benchtop Izod Impact Tester (Testing Machines Inc. New Castle, DE, USA), depicted in Figure 1. Five test samples were fabricated for each material under review (Table 1) using the described scaled geometry.

| Product | Source | Material type | Method of mouthguard fabrication | Sample size (n) |

|---|---|---|---|---|

| PS | Sportsguard, Kent, OH, USA | EVA hybrid | Pressure forming | Five |

| BD | Buffalo Dental Manufacturing Inc. Syosset, NY, USA | EVA | Pressure forming | Five |

| EF | Glidewell, Newport Beach, CA, USA | EVA | Pressure forming | Five |

| PR | Keystone Dental Group, Burlington, MA, USA | EVA | Pressure forming | Five |

| DF | Dreve America Corp, Eden Prairie, MN, USA | EVA | Pressure forming | Five |

| PO | Impact Gumshields, Blackrock, Dublin, Ireland | PO hybrid polymer | FFF 3D printing | 10 (five horizontal and five vertical) |

- Abbreviations: BD, Buffalo Dental; DF, Drufosoft; EF, Erkoflex; PO, Polyolefin; PR, Proform; PS, PolyShok.

For sample fabrication, raw materials were prepared by pressure molding or 3D printing to create a flat sheet at the desired thickness. Pressure-formed samples were molded using the Drufomat Scan (Dreve America Corp, Eden Prairie, MN, USA) into flat panels approximately 6.4 mm thick and sliced into samples approximately 8 mm wide and 62.5 mm in length (Figure 2, Table 2).

| ASTM D256 standard | This testing | |

|---|---|---|

| A | 10.2 mm | 5.1 mm |

| B | 31.8 mm | 31.8 mm |

| C | 63.5 mm | 63.5 mm |

| D | 0.3 mm | 0.3 mm |

| E | 12.7 mm | 6.4 mm |

The PO material samples were designed using CAD software Rhino 7 (Rhinoceros 3D; TLM Inc. dba Robert McNeel & Associates, Seattle, WA, USA) with the dimensions of 6.4 mm square bars, 125 mm in length. The PO samples are composed of proprietary base polymers compounded in pellet form. The material is then extruded and cooled into filament form. The samples for this study were manufactured by loading the filament on a Prusa i3 MK3S (Prusa Research, Prague, Czech Republic) printer. In the FFF process, the PO polymer filament melts and is extruded layer by layer to build the sample shape according to the design instructions. As it cools, it polymerizes, forming a solid, rigid structure. Once polymerized, the PO has a Shore A hardness of 90–95A at 37°C (98.6°F), or at body temperature. For reference, EVA has a Shore A hardness of approximately 80A [11]. In fact, PO hardness is comparable to thermoplastic elastomers (TPE), which are known for their adaptability and comfort. This demonstrates that PO can indeed be flexible enough to adapt to the teeth and support tissues, making it a suitable candidate for applications requiring both rigidity and adaptability, such as mouthguards.

For this testing, samples were notched to a thickness of approximately 80% of the original, or 5.1 mm, using the Instron W-3551 V-Notch Milling Cutter (Instron; Norwood, MA, USA) (Figure 3). Some variation in the machining of flexible materials was observed. The pressure-molded samples were not of consistent thickness, unlike the 3D-printed samples, so the notch depth varies from sample to sample. However, the remaining thickness is the critical value as it is responsible for the impact absorption. Effort was made to maintain sample consistency for the remaining thickness measurements. Actual dimensions for width and thickness are provided in Tables S1–S3 and S2. These dimensions are taken into account in the equation for impact absorption calculation. Notch depth and sample widths were measured with Mitutoyo 500-195-30 (Mitutoyo; Kawasaki, Kanagawa, Japan), an electronic caliper with a 0.01 mm resolution.

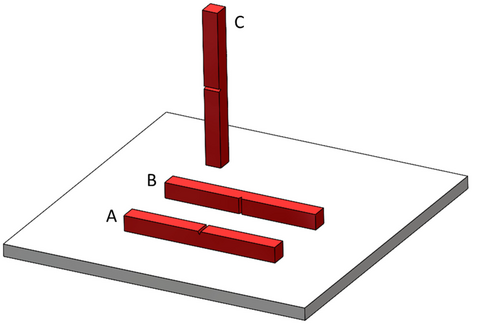

Considering PO samples were 3D printed using the FFF process, the notches could be placed parallel or perpendicular to the build direction. Notches in one set of five samples were cut vertically, parallel to the build direction (Figure 4A). The second set of five samples was notched horizontally, perpendicular to the build direction (Figure 4B). This provided two groups to the PO, one assessing the impact parallel to the build direction [group named PO vertical (POV)] and one assessing the impact perpendicular to the build direction [group named PO horizontal (POH)]. A third option would be possible if samples were printed vertically, the notch could be made in plane, or planar, of build direction (Figure 4C). However, samples in the current study were printed horizontally, so only notches vertical or horizontal to build direction were assessed.

For testing procedure, the samples were loaded into the jaws of the Izod Impact Tester (Testing Machines Inc. New Castle, DE, USA) so that the notch was aligned with the clamping surface and arranged facing the hammer (Figure 5). Utilizing W-3587-D Izod Tongs (Instron; Norwood, MA, USA) ensures consistent alignment of the notch and perpendicularity of the sample. A 2.0 lb. (8.9 N) hammer installed in the tester impacts the sample at approximately 3.4 m/s. The maximum energy available in this test is 2.0 ft lb. (2.7 J), and the measurement increment is 0.01 ft lb. (0.01 J). The hammer is released from its latch position and strikes the sample; the dial on the machine indicates the energy absorbed.

Data acquisition is via the analog dial affixed to the machine (Figure 6). The increment for a 2.0 lb. (8.9 N) hammer is 0.01 ft lb. precision. Values were recorded and converted to Joules at 1.4 J per 1 ft lb. The data are expressed in thousandths of a kilojoule per square meter; the unit used for ISO Izod impact toughness. The conversion between units does not diminish or improve the clarity of the analog dial readings and does not affect the precision level for scientific reporting. Recorded measurements ranged from 0.1 to 0.40 ft lb., corresponding to 0.1–0.5 J.

3 Results

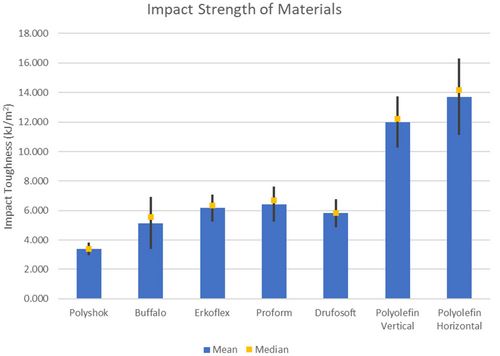

The mean and standard deviation of impact toughness were calculated for each material. For EVA, the mean was 5.4 ± 0.3 kJ/m2, and for 3D-printed materials, the mean was 12.9 ± 0.7 kJ/m2. These values were averaged from specific materials (POV and POH for PO) and are summarized in Table S3. A post hoc power analysis using G*Power software (Universitat Dusseldorf, Dusseldorf, Germany) version 3.1.9.4 indicated a high statistical power of 1.000 (100%), confirming the study's robustness in detecting significant differences between groups. The power for sample sizes 3 and 4 ranged from approximately 0.65 to nearly 0.97, reaching a maximum of 1.0 with a sample size of 5, consistent with a recent study [8]. A bar diagram was created to enable an unbiased examination of the impact absorption capabilities of the different materials (Figure 7).

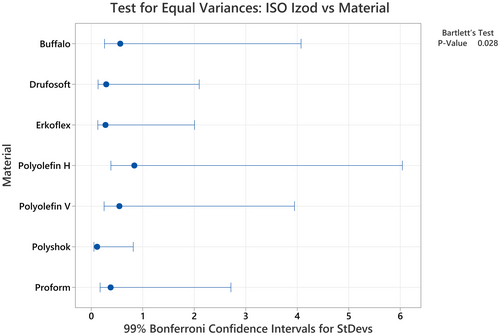

A preliminary normality test was performed using Minitab version 21.4.1 (Minitab LLC, State College, PA, USA). The Anderson–Darling test and probability plots yielded p-values, as shown in Table S3. p-values greater than 0.20 suggest that the data follow a normal distribution, while values between 0.05 and 0.20 indicate potential deviations. In this study, PS tests had the lowest p-value of 0.118, and BD and PR materials had p-values of 0.127 and 0.144, respectively. These results suggest that the data generally adhere to a normal distribution, although further data collection could enhance the normality for more robust analyses. Although the data are approximately normally distributed, verifying the data's variance is crucial for selecting appropriate statistical methods. Bartlett's test for equal variance, as depicted in Figure 8, indicated that the impact toughness of the materials did not have equal variance across samples. Consequently, a two-sample t-test was employed for comparisons, accounting for unequal variance among the data sets.

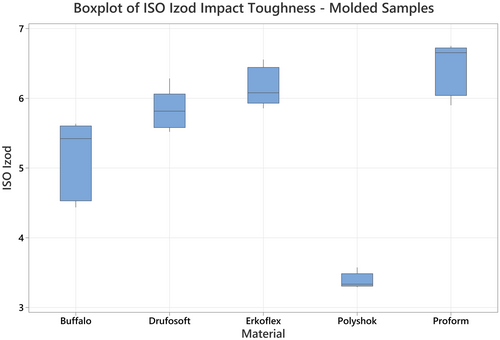

A comparative analysis of five molded materials was conducted. Table 3 and Figure 9 present the results. BD (5.1 ± 0.6 kJ/m2) and DF (5.8 ± 0.3 kJ/m2) did not show significant differences (p = 0.061), nor did EF (6.2 ± 0.3 kJ/m2) and DF (p = 0.096). EF and PR (6.4 ± 0.4 kJ/m2) were the most similar (p = 0.235). PS Izod impact test result was documented at 3.4 ± 0.1 kJ/m2. The lack of full rupture or tearing in the molded materials suggests that the impact toughness might be underestimated, as energy absorption could be impacted by incomplete failure or testing conditions [9].

| Material A | Mean | Material B | Mean | Difference | p |

|---|---|---|---|---|---|

| PS | 3.4 | BD | 5.1 | 1.8 | 0.002 |

| EF | 6.2 | 2.8 | 0.000 | ||

| PR | 6.4 | 3.1 | 0.000 | ||

| DF | 5.8 | 2.4 | 0.000 | ||

| BD | 5.1 | PS | 3.4 | 1.8 | 0.002 |

| EF | 6.2 | 1.0 | 0.015 | ||

| PR | 6.4 | 1.3 | 0.005 | ||

| DF | 5.8 | 0.7 | 0.061 | ||

| EF | 6.2 | PS | 3.4 | 2.8 | 0.000 |

| BD | 5.1 | 1.0 | 0.015 | ||

| PR | 6.4 | 0.3 | 0.235 | ||

| DF | 5.8 | 0.4 | 0.096 | ||

| PR | 6.4 | PS | 3.4 | 3.1 | 0.000 |

| BD | 5.1 | 1.3 | 0.005 | ||

| EF | 6.2 | 0.3 | 0.235 | ||

| DF | 5.8 | 0.6 | 0.023 | ||

| DF | 6.4 | PS | 3.4 | 3.1 | 0.000 |

| BD | 5.1 | 1.3 | 0.061 | ||

| EF | 6.2 | 0.3 | 0.096 | ||

| PR | 6.4 | 0.0 | 0.023 |

- Abbreviations: BD, Buffalo Dental; DF, Drufosoft; EF, Erkoflex; PR, Proform; PS PolyShok.

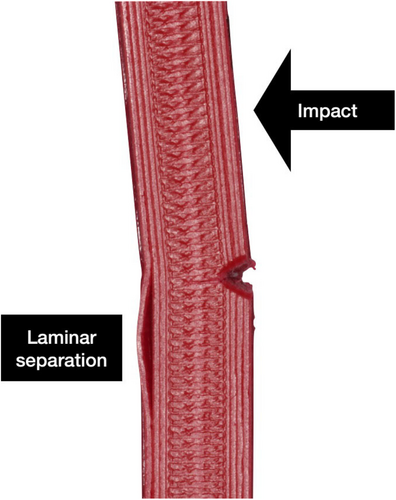

An unequal variance, two-sample t-test compared 3D-printed PO with various molded materials (BD, DF, EF, PR, and PS). Results indicated that PO had significantly higher Izod impact strength compared to all molded materials (p = 0.0 at 95% confidence), as summarized in Table 4 and Figure 10. PO samples demonstrated superior impact toughness, with abnormal failure modes such as tearing and laminar separation observed (Figure 11). No such failure modes were detected in molded materials. The impact absorption property of PO is consistent with previous research [11].

| Material A | Mean | Material B | Mean | Difference | p |

|---|---|---|---|---|---|

| POV | 12.0 | PS | 3.4 | 8.6 | 0.000 |

| BD | 5.1 | 6.9 | 0.000 | ||

| EF | 6.2 | 5.8 | 0.000 | ||

| PR | 6.4 | 5.6 | 0.000 | ||

| DF | 5.8 | 6.2 | 0.000 | ||

| POH | 13.7 | PS | 3.4 | 10.3 | 0.000 |

| BD | 5.1 | 8.6 | 0.000 | ||

| EF | 6.12 | 7.5 | 0.000 | ||

| PR | 6.4 | 7.3 | 0.000 | ||

| DF | 5.8 | 7.9 | 0.000 |

- Abbreviations: BD, Buffalo Dental; DF, Drufosoft; EF, Erkoflex; POH, Polyolefin H; POV, Polyolefin V; PR, Proform; PS, PolyShok.

A comparison of PO specimens notched vertically (parallel to the build direction) and horizontally (perpendicular to the build direction) revealed a significant difference in impact toughness. The mean toughness differed by 1.7 kJ/m2, or over 10%, with a 95% confidence interval of 0.6–2.8 kJ/m2. The T-test, conducted using Minitab v21.4.1 software, confirmed this significant difference (p = 0.009, Figure 10). The results indicate that horizontal samples exhibited significantly higher impact toughness compared to vertical samples, highlighting the impact of build direction on ISO Izod impact absorption.

4 Discussion

Custom mouthguards are essential for protecting the stomatognathic system from impact forces while ensuring proper retention and comfort for the wearer [5, 12, 13]. Polymeric materials, particularly EVA, are widely used in mouthguard fabrication due to their favorable mechanical and biological properties [14, 15-17]. However, alternative materials like polyvinyl chloride, latex rubber, acrylic resin, and polyurethane have also been utilized [2, 18, 19]. With the advent of additive manufacturing and CAD/computer-aided manufacturing (CAD/CAM) dentistry, there has been a growing interest in exploring new materials and fabrication methods to enhance the performance of mouthguards [20, 21].

This study specifically investigated the application of FFF 3D printing in producing PO sports mouthguards, employing the ASTM D256 testing methodology to compare their impact resistance with that of traditional molded materials. The results revealed that PO FFF-printed mouthguards exhibited significantly higher Izod impact strength values than their counterparts molded from BD, DF, EF, PR, and PS. These findings align with prior research demonstrating the superior resilience of multimaterial 3D-printed samples and enhanced energy dissipation in 3D-printed materials compared to EVA [20-23].

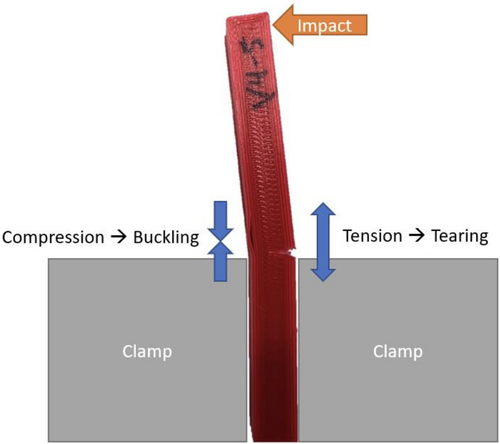

A critical observation from this study was the occurrence of tearing or laminar separation within the layers of 3D-printed samples during impact testing, as shown in Figure 12. This raises important questions about the structural integrity of 3D-printed mouthguards under impact conditions. In FFF 3D printing, the strength of the object relies on the bonding between layers, which is achieved through thermal bonding—where extruded semi-molten material fuses with the layer below—and mechanical interlocking, where the extruded material slightly deforms the underlying surface. However, the bonding interface can be a weak point when subjected to disruptive forces, potentially leading to issues such as laminar separation. During ASTM D256 testing, the hammer's impact induces bending, generating tension at the notch—the thinnest part of the sample—which can lead to tearing or cracking. Conversely, compression on the opposite side of the sample may cause buckling, resulting in laminar separation in the final layer. This deformation highlights the high-impact absorption capabilities of 3D-printed materials, which can lead to distortion not typically observed in traditional materials. This finding underscores the need to balance impact strength with structural integrity in the design and fabrication of 3D-printed mouthguards.

Compression-molded composite materials did not exhibit cracking or tearing, indicating a potential advantage in structural robustness due to their manufacturing process. However, this must be weighed against the significantly higher impact resistance demonstrated by 3D-printed mouthguards. The trade-off between maintaining structural integrity and optimizing impact resistance is a critical consideration in selecting materials for mouthguards, particularly as the performance under real-world conditions is a primary concern. Figure 7 illustrates the substantial variance in impact absorption between 3D-printed and molded materials, highlighting consistent patterns in the data that reinforce the statistical findings. Notably, the study found a significant difference in impact strength between vertically notched (aligned parallel to the build direction) and horizontally notched (perpendicular to the build direction) 3D-printed PO specimens. This directional sensitivity, with a variance exceeding 10% and a statistically significant p-value of 0.009, suggests that the manufacturing orientation plays a crucial role in the material's response to impact forces. This finding holds important implications for the design and manufacturing of 3D-printed mouthguards, underscoring the need to meticulously control build orientation during fabrication. Mouthguards produced with perpendicular build orientations exhibit improved impact absorption, highlighting orientation as a critical factor in optimizing performance. In contrast, this issue does not apply to compression-molded materials, which do not involve bonded layers and are therefore not susceptible to laminar separation.

The study also highlighted limitations in the ASTM D256 test for evaluating the impact resistance of mouthguard materials. The occurrence of laminar separation in 3D-printed samples suggests that this test may not fully replicate the real-world conditions experienced by mouthguards during sports activities. The explicit values reported for Izod impact toughness may not entirely reflect the materials' performance, as the samples did not fully separate during testing. Additionally, when the sample flexes during testing, friction between the hammer and the sample can lead to overreporting of the absorbed energy. This raises questions about the suitability of the test method for evaluating these materials, as the specimen shape used in the test might not align well with the properties of soft mouthguard materials. For instance, conducting impact tests at low temperatures, as commonly done in other industries, could enhance fracture mechanics and reliability, although the relevance to dental mouthguards remains uncertain. Alternatively, exploring the tear strength of mouthguard materials using ASTM D624, Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers, could offer a more accurate assessment. This method, which involves specialized molds or cutting dies to form specimen geometry, may provide a better understanding of the materials' tear resistance under conditions more representative of their use in sports.

Another important consideration is the potential for 3D printing to revolutionize mouthguard manufacturing by enabling the production of a single protective splint that can be printed and duplicated while maintaining consistent dimensions [1]. Given that intraoral appliances, including mouthguards, are generally recommended for frequent replacement due to hygiene concerns [24-26], the ability to easily reproduce identical mouthguards offers significant practical advantages. Furthermore, research has highlighted the ongoing need to establish effective cleaning standards for thermoplastic appliances, and 3D printing could facilitate a more hygienic and cost-effective production process [27].

While FFF 3D printers are affordable and widely available, investigating alternative 3D printing technologies that can produce more homogeneous components could present intriguing possibilities. Stereolithography (SLA), for example, which uses light to cure a liquid resin, is already employed for 3D printing occlusal splints and nightguards [28-32]. SLA's capability to produce high-resolution objects with intricate shapes and undercuts makes it particularly suitable for dental applications, including mouthguards. Further research into impact absorption and the development of novel materials using such advanced techniques could lead to significant improvements in mouthguard performance.

Despite the valuable insights provided, this study has several limitations. It focused solely on impact absorption properties using the Izod impact test, neglecting other important factors such as durability, comfort, and testing environment. The limited sample size and range of materials tested may restrict the generalizability of the findings to other mouthguard types and manufacturing techniques. Additionally, the study's in vitro design does not account for real-world conditions or dynamic sporting environments, potentially affecting material performance differently. Although ASTM D256 is a standard impact resistance test, its relevance for mouthguard materials may be limited, as shown by laminar separation in 3D-printed samples. Lastly, the study did not evaluate the long-term performance or clinical outcomes of the mouthguards, which are essential for understanding their effectiveness in preventing orofacial injuries. Overall, these limitations should be considered when interpreting and applying the study's results.

The study's results indicate that 3D-printed PO mouthguards demonstrate significantly higher impact toughness compared to their molded counterparts, such as BD, DF, EF, PR, and PS, leading to the rejection of the null hypothesis. However, the observed laminar separation during impact testing suggests a potential trade-off in structural integrity that must be carefully managed. While traditional molded materials offer advantages in robustness, the superior impact resistance of 3D-printed mouthguards highlights their potential for enhanced protection. Nevertheless, the findings also underscore the need for further research to refine testing methods and evaluate the long-term performance and clinical outcomes of these materials under real-world conditions.

5 Conclusion

This study demonstrates that 3D-printed PO-based mouthguards significantly outperform traditional molded EVA materials in impact energy absorption. These findings highlight the advantages of FFF in improving sports mouthguard protection. 3D-printed mouthguards fabricated with build orientations perpendicular to the direction of impact demonstrate significantly enhanced impact absorption. Future research should focus on refining material formulations, optimizing manufacturing processes, and exploring alternative testing methods to better replicate real-world impact scenarios for enhanced athlete safety and performance.

Author Contributions

Leonardo Mohamad Nassani: conceptualisation and study design, data analysis and interpretation, revision of the manuscript, approval of the manuscript. Samuel Storts: protocol elaboration, data collection and interpretation. Irina Novopoltseva: protocol revision, critical revision of the manuscript, approval of the manuscript. Lauren Ann Place: manuscript drafting, data collection. Matthew Fogarty: literature review, data collection. Pete Schupska: data collection and analysis, statistical interpretation, manuscript drafting. All the authors made substantial contributions to the manuscript.

Acknowledgments

The authors extend their gratitude to the Academy for Sports Dentistry for supporting this research through the Academy for Sports Dentistry Research Program and acknowledge the support of Sportsguard Laboratories Inc. and Impact Gumshields for manufacturing samples. The viewpoints and research findings presented in this report represent the perspectives of the authors and may not necessarily align with the policies or stance of The Academy of Sports Dentistry. Acknowledgment to Dr. Robert Seghi, Dr. Steve Mills and Dr. Howard W. Roberts for advising, Francine Bujnak for recommendation, Muhammad Marwan, Kanza Javed and Aklilu Abrham Roba for the logistic support.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.