Product–Service Systems Applied to Reusable Packaging Systems: A Strategic Design Tool

Abstract

Environmental sustainability is under the threat of excessive single-use plastic packaging waste, which current waste management fails to address. Therefore, the issue has led to an identification of the solution that can curb packaging waste without sacrificing social needs.

Reusable packaging systems (RPSs) represent a circular approach to close the loop of consumption in which packaging can stay longer in the system to satisfy social needs. However, the implementation of reusable packaging is limited. Product–service systems (PSSs) are widely regarded as a sustainable business model innovation for embracing circular consumption. As a result, applying PSSs to RPSs should be promising in addressing the packaging waste issue. Even so, there is limited knowledge regarding adopting this approach to address the packaging crisis. This paper explores how to apply PSSs to RPSs to support professionals in addressing the packaging crisis in the food and household products industry.

The methodology of this paper is a combination of case studies and expert interviews. Fifty-seven case studies are collected, analyzed, and formulated into 15 archetypal models that represent all types of RPSs in the current market. In parallel, a classification is developed to embrace those 15 archetypal models, and a total of 24 experts—packaging consultants, NGO professionals who address plastic waste, and reusable packaging entrepreneurs—were invited for the evaluation of the design tool.

This research provides a strategic design tool to support packaging professionals to design RPSs. The application of the tool is to support understanding RPSs, analyzing the markets, and identifying new opportunities, and to generate RPSs. The implication of this research is to provide insights for academics and businesses in terms of tackling single-use packaging waste and to build a foundation to further develop the design tool for generating RPSs.

1 Introduction

1.1 Plastic problem

There is no doubt that plastic plays a critical role in our era (Thompson et al., 2009). Plastic is low-cost, durable, long-lasting, and flexible, which makes plastic an indispensable element in daily life (Heidbreder, Bablok, Drews, and Menzel, 2019). However, clear evidence indicates that our world is under the threat of plastic waste that the current waste management approach cannot properly address. For instance, there is an estimated 250,000 tons of plastic in the ocean, thus affecting the marine ecosystem (Eriksen et al., 2014); the beaches are littered with an estimated 37 million pieces and 18 tons of plastic debris (Cookson, 2018). Without proper strategies to curb the issue, the total quantity of plastic leakages in the ocean will be more than the total quantity of fish (by weight) in 2050 (Ellen MacArthur Foundation, 2017). The plastic waste will not only damage the diversity of species in the ocean but also negatively affect animal health individually. Cookson (2018) reports an example of 225 pieces of plastic in the stomach of one three-month-old chick, weighing 10% of its body mass. That would be equivalent to an average human carrying about 6–10 kg of plastics. Furthermore, Royer, Ferron, Wilson, and Karl (2018) argue that plastic could be a contributor to climate change because it may generate greenhouse gases if it is exposed to sunlight. Under those circumstances, it is time to explore the alternative to address the plastic issues.

1.2 Reusable packaging systems

1.2.1 What are they?

According to Palsson (2018), the types of packaging are classified as primary packaging (i.e., packaging in direct contact with commodities), secondary packaging (i.e., packaging that wraps primary packaging), and tertiary packaging (i.e., packaging that facilitates the protecting, handling, and transporting of secondary packaging). Inside plastic waste, most of it is primary packaging waste. Hence, addressing primary packaging waste is critical (Geyer, Jambeck, and Law, 2017). Many scholars endorse reusable packaging systems (RPSs) as a promising approach to address packaging waste (Ellen MacArthur Foundation, 2017; Gregoire and Chauvelot, 2019; Kunamaneni, Jassi, and Hoang, 2019; Lofthouse and Bhamra, 2006; Monkhouse, Bowyer, and Farmer, 2004; Wood and Sturges, 2010). Generically, RPSs are to enable packaging to be used multiple times in an attempt to maximize its value within the lifespan (Ellen MacArthur Foundation, 2019). Understanding primary RPSs is a novelty research pathway, and most relevant knowledge is based on the studies of reusable packaging from the supply chain (Mahmoudi and Parviziomran, 2020; McKerrow, 1996; Monkhouse et al., 2004). This knowledge can provide insights to explore primary RPSs. For instance, Loop is a circular online shopping platform in which consumers can order their food and household products in durable reusable packaging. Loop follows the operation of reverse logistics. Consumers will need to pay a deposit for renting the packaging. The deposit will be refunded when consumers stop using the service, and the empty packaging will be collected and put back into the phase of use by Loop.

1.2.2 RPSs’ role in tackling the plastic problem

The current consumption model is a linear process in which single-use packaging products can temporarily satisfy social needs but are being thrown away when they become empty (Ellen MacArthur Foundation, 2017; Gullstrand Edbring, Lehner, and Mont, 2016; Wastling, Charnley, and Moreno, 2018). Waste generation is inevitable: The amount of waste is correlated with the amount of production, and satisfying increasing demand will have to increase production. Considering that the current waste management approaches fail to address the environmental impact of plastic waste (e.g., landfills cause water contamination, incineration causes air pollution, and recycling consumes energy), it reveals how the current plastic crisis has developed (Ellen MacArthur Foundation,2017). To minimize waste, transitioning toward the circular consumption model is the main trend (Ellen MacArthur Foundation, 2017). Essentially, RPSs’ role in tackling the plastic problem is to close the loop of consumption so that the amount of packaging is always satisfactory in the system. As a result, it reduces the need to produce new packaging, maximizes the value of each packaging type in the system, and pushes down the overall quantity of plastic waste.

1.3 Research questions

This research aims to explore how to tackle plastic waste by supporting professionals to design primary RPSs. The scope of this research is within the food and household products industry. Two research questions are defined: how to develop a design tool to classify current RPSs and how the design tool can support professionals in addressing the plastic problem. This paper is structured into five sections. The introduction provides background regarding the plastic problem and RPSs. The literature review provides information relating to PSSs and RPSs. The methodology section explains how the design tool is developed and evaluated. The results and discussion section presents and examines the results. Finally, a conclusion provides a summary of this research, limitations, and implications for the future study path.

2 Literature review

2.1 Definition of RPSs

Generically, the roles of packaging are to facilitate carrying, protecting, and containing a subject (Hansch and Kinkel, 1995). The definition of packaging has been given by Hansch and Kinkel (1995, p. 327):

‘Packaging’ shall mean all products made of any materials of any nature to be used for the containment, protection, handling, delivery, and presentation of goods, from raw materials to processed goods, from the producer to the user or the consumer. ‘Non-returnable’ items used for the same purposes shall also be considered to constitute packaging.

The definition of primary RPSs is limited in the literature, and most definitions are related to secondary and tertiary packaging. Nevertheless, the definition of RPSs has been underlined by Hansch and Kinkel (1995, p. 328):

‘Reuse’ shall mean any operation by which packaging, which has been conceived and designed to accomplish within its life cycle a minimum number of trips or rotations, is refilled or used for the same purpose for which it was conceived, with or without the support of auxiliary products present on the market enabling the packaging to be refilled.

Besides, according to European Standard BS EN 13429:2004, the definition of RPSs is “packaging component which has been conceived and designed to accomplish within its life cycle a minimum number of trips or rotations in a system for reuse"” (British Standards Institution, 2004, p. 34).

Implementing RPSs can bring many benefits to companies (e.g., cutting costs, improving user experience, and optimizing operations; Ellen MacArthur Foundation, 2019). Hence, properly identifying a business model that can be applied for RPSs is critical for implementation (Lewandowski, 2016; Lofthouse and Prendeville, 2018).

2.2 Product–Service Systems (PSSs) and RPSs

Several authors argue that applying PSSs is a promising approach to close the loop of consumption (Baines et al., 2007; Mont, 2004; Tukker and Tischner, 2006; Ceschin and Gaziulusoy, 2016). The concept of PSSs is to decouple value from material by offering consumers satisfaction rather than sell goods to meet demand (Tukker, 2004). One definition is “a mix of tangible products and intangible services designed and combined so that they are jointly capable of fulfilling final customer needs” (Tukker andTischner, 2006, p. 1552). PSSs are not novelty concepts that have been implemented by various companies (Goedkoop, Van Halen, Te Riele, and Rommens, 1999; Mont, 2004; Vezzoli, 2010). All of the implemented PSSs highlight that a properly designed PSS solution can dematerialize consumption, intensify resource use, and maximize resource efficiency (Ceschin, 2010; Manzini and Vezzoli, 2003; Mont, 2004; Tukker and Tischner, 2006).

Applying PSSs to RPSs is suitable. For instance, Kuzmina, Prendeville, Walker, and Charnley (2019) argue that PSSs are particularly relevant to fast-moving consumable goods (FMCG) sectors in terms of reducing the amount of packaging waste. Kunamaneni, Jassi, and Hoang (2019) believe that offering PSSs can intensify the use of the same packaging, which reduces the social demand for packaging usage. Lofthouse and Bhamra (2006) affirm that it is feasible to apply PSSs to the personal care industry regarding achieving environmental and financial sustainability.

Understanding what role PSSs play in RPSs is important. According to Zeeuw van der Laan and Aurisicchio (2019), the role that PSSs play in RPSs is to offer revalorization services to close the loop of consumption. The definition of revalorization services is “offers that aim at closing the product material cycle by taking products back, reusing usable parts in new products and recycling materials if reuse is not feasible” (Mont, 2002, p. 241). Applying this concept to RPSs, two types of revalorization services can be designed: The first one provides additional services to enable consumers to reuse the packaging. In the second one, companies collect empty packaging from consumers with the aim of putting it back into the phase of use. Based on the literature review and case collection (Ellen MacArthur Foundation, 2019; Lofthouse and Bhamra, 2006), additional services have two subcategories, which are to offer refill pods service and refill station service. Refill pods service means consumers can acquire refill pods and self-refill their packaging. Refill station service means that consumers bring their packaging to a refill station. Companies’ take-back services have two subcategories, which are to offer collection service and drop-off locations. Collection service means that companies will reach consumers for the collection of empty used packaging. Offering drop-off locations means that consumers will return the empty used packaging to a location where companies will come to collect it. Accordingly, those four revalorization services are designed to close the consumption loop.

2.3 Environmental benefits and limitations

One of the explicit environmental benefits of implementing RPSs is reducing the overall amount of packaging waste that goes to waste schemes and recycling processes (Karst, 2013). Not only does it reduce the overall packaging waste, but it also reduces the workload on waste management and energy consumption of recycling processes. Implementing RPSs can reduce product waste as well. According to Karst (2013), when the Foundation for Reusable System compared the product damage rate between RPSs and single-use packaging systems based on lifecycle span, the results showed that products in RPSs will suffer a lower damage rate because of the packaging’s strength, consistent size, and compatibility. In parallel, from the consumers’ perspective, some RPSs require customers to finish their products before refilling, so it also leads to less product waste (Lofthouse and Bhamra, 2006). Furthermore, customers can customize the quantities of products as much as they need. Consequently, products can be consumed properly and less product waste will be generated (Beitzen-Heineke, Balta-Ozkan, and Reefke, 2017).

However, the environmental limitations of implementing RPSs are also identified. First, all of the environmental benefits of RPSs are built on the hypothesis that RPSs can work perfectly well in the ideal situation (Lofthouse and Bhamra, 2006). However, implementing successful RPSs will depend on consumers’ participation (Steenis, van der Lans, van Herpen, and van Trijp, 2018; Wastling, Charnley, and Moreno, 2018; Zeeuw van der Laan and Aurisicchio, 2019). If consumers still treat reusable packaging as single-use packaging, those environmental benefits will not be achieved (Lofthouse and Bhamra, 2006). Second, limitations can be perceived from the refill process, which may involve intensified transporting activities (e.g., delivering refill pods to consumers for self-refill, companies collecting empty packaging from consumers to refill). Therefore, it could generate more gas emissions and consume more fuel than operating single-use packaging products (Gardas, Raut, and Narkhede 2019; Boehm and Thomas, 2013). The gas emissions and fuel consumption are both negative to the environment. Third, Garrido and Del Castillo (2007); Ferrara and Plourde (2003) also pinpoint the significance of washing operations. They argue that mass washing is correlated with electricity and water consumption, which means that more washing operations will result in more electricity and water consumption. Consequently, although RPSs push down the amount of packaging and product waste, the issues of resource consumption and gas emissions will emerge.

2.4 Existing dimensions for classifying PSSs and RPSs

There are several dimensions to classify PSSs and RPSs. Most PSS dimensions are identified from the literature, but RPS dimensions are dependent on the literature and case collection. Those dimensions are explained below.

2.4.1 PSS dimensions

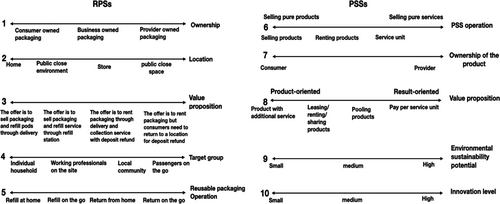

Most PSS dimensions can be defined from the literature. For instance, Gaiardelli, Resta, Martinez, Pinto, and Albores (2014) concluded that value proposition is a significant dimension for characterizing PSS offerings in B2C and B2B contexts (B2C refers to a sales model which directly targets at individual consumers; B2B refers to a transaction betwen one business and another such as retailer and wholesaler), and it can strictly influence other dimensions. PSS dimensions are shown below.

Product ownership is identifying who owns the product in the PSS offering. The product’s ownership is important because it determines whose responsibility it is to maintain the function of products (Aurich and Fuchs, 2004; Manzini and Vezzoli, 2003; Tukker, 2004).

The PSS operation can be understood as how the product is operated by stakeholders, such as consumers or PSS providers, and this is associated with product ownership. PSS providers can sell products, rent products, or offer pure services to consumers (Ceschin, 2014; Mont, 2004; Tukker, 2004; Vezzoli and Ceschin, 2015).

Environmental sustainability and innovation level are closely connected. Environmental sustainability can measure the degree of environmental impacts, and innovation level can measure the level of the novelty of the business models. Several scholars point out that result-oriented PSS offers have the highest environmental sustainability and innovation level, followed by user-oriented PSS offers and product-oriented PSS offers (Mont, 2004; Reim, Parida, and Ortqvist, 2015; Tukker, 2004; Vezzoli and Manzini, 2008).

2.4.2 RPS dimensions

The literature and analysis of collected cases offer insights to define the RPS dimensions, which are shown below.

The ownership of packaging is important in classifying RPSs. According to McKerrow (1996) and Dubiel (1996), if the collection mechanism is properly designed, the ownership of packaging determines whose responsibility it is to put the empty packaging back into the phase of use. The collected cases suggest that PSS providers, businesses, and consumers can claim ownership of packaging.

The value proposition dimension is implicated by the Ellen MacArthur Foundation (2019), and it defines how the RPS offers will be delivered to consumers. According to Tukker (2015), the value proposition is a mixture of products and services. RPS offers include packaging with different ownership and different revalorization services.

According to Zeeuw van der Laan and Aurishchio (2019), the location of RPSs refers to where the revalorization services take place. (e.g., companies collect the packaging from consumers’ homes or consumers will need to go to a place for a refill). Based on the case studies collection and Ellen MacArthur Foundation (2019), the location can be defined as the home, a public close environment (i.e., a place where certain people can enter, such as an office), the store, and a public open environment (i.e., a place where everyone can go).

The target group can be found heavily associated with the location and identified as another dimension. For instance, if the location is the home, then the target group should be the household; if the location is the public close environment, then the target group should be on-site working professionals (e.g., in an office); if the location is the store, then the target group should be the local community; if the location is a public open environment, then the target group should be passengers on the go.

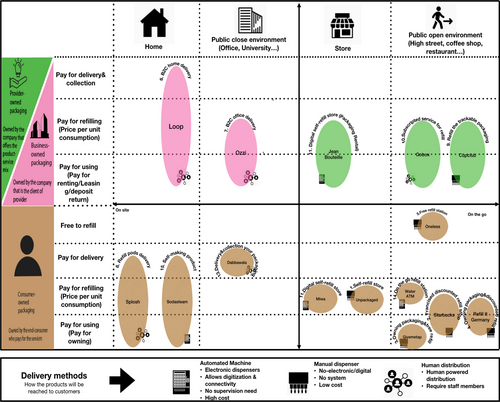

The reusable packaging operation is used to classify how stakeholders work together to deliver the solutions, and it is associated with the value proposition. Based on Ellen MacArthur Foundation (2019), the operation can be “refill at home,” “refill on the go,” “return from home,” and “return on the go.” In conclusion, Figure 1 will show the existing dimensions for RPSs and PSSs.

3 Methodology

Here, we explain the two phases that illustrate how the design tool was developed by the researchers and evaluated by participants.

3.1 Developing the design tool

First, dimensions offer an insight to characterize PSSs and RPSs. A case collection that aimed to collect all types of PSSs applied to RPSs was conducted to understand the widest range of the characteristics. Hence, the maximum variation strategy was adopted to ensure the heterogeneity of the case collection (Miles and Huberman, 1994). To determine the number of case collections, the principle of theoretical saturation was adopted. The principle of theoretical saturation is to continually collect data until no new information can be generated (Strauss and Corbin, 1990). Triangulation was adopted to achieve the credibility and reliability of the cases (Yin, 1994). Triangulation refers to using multiple methods to collect data to ensure all sources converged on facts of a single case. Within this research, the data of each case include academic papers, the company’s reports, websites, and newspapers. Fifty-three cases were collected during this phase.

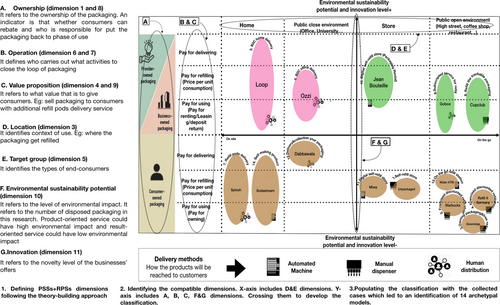

Second, based on the previous outcomes, the dimensions were used to develop the classification. First, a theory-building approach was adopted to identify PSS and RPS dimensions. The procedure of the theory-building approach is defining variables, specifying the domain, developing the internal relationship, and making the specific predictions (Wacker, 1998). After PSS and RPS dimensions were identified, they were used to develop the classification. Dimensions can be defined as x-axis and y-axis. Crossing the x-axis and y-axis was the principle used to create the classification. Subsequently, the classification was populated with all cases, which led to the identification of 14 archetypal models. The archetypal model refers to certain types of business models that share similar characteristics, and each of the archetypal models is named based on their characteristics. Figure 2 explains the process of developing the classification and identification of the archetypal models.

3.2 Evaluating the design tool

This phase tested the design tool’s usefulness. The activity involved a pilot study with four design doctoral researchers and evaluation with 24 experts. The relevant experts were reusable packaging consultants, reusable packaging entrepreneurs, and NGO professionals for reducing single-use packaging waste. Regarding the sampling strategies, the purposive sampling strategy was adopted to find those experts (Glaser, 1978). During this phase as well, the principle of theoretical saturation was adopted to determine the sample size. Consequently, 15 and nine experts were recruited during the first evaluation and second evaluation, respectively. The process of testing the design tool is explained below.

The pilot study initially tested the clarity and feasibility of the design tool. Since four doctoral researchers may not have the relevant background, the activities started with introducing the project, along with the concepts of PSSs and RPSs. Subsequently, the elements of the design tool and how the design tool works were explained to them. Finally, they were asked to reflect on this activity and data were recorded.

The feedback of the pilot study was implemented to improve the design tool. Next, the experts’ evaluations were to include testing the completeness, clarity, and applications of the design tool.

The activities testing the completeness and clarity of the design tool were to show experts the design tool and allow them to consider whether there were any other types of business models that archetypal models cannot embrace or other dimensions that could be added to the classification. After that, the research activity was to explain the elements in the design tool, and respondents were asked to rate its clarity.

As for testing the applications of the design tool, the evaluation consisted of showing the applications of the design tool and asking experts to rate them. First, the evaluation involved showing three cases in the classification and explaining how the classification could characterize the different RPSs. Afterward, the research activity was to give a populated classification that implicated a market analysis scenario and then explain how this application could support analyzing the market and identifying new opportunities (e.g., what other competitors are doing, which delivery method is most effective in the market, which service is most prevalent in the market). Finally, the research activity was to show the classification with market opportunities and ask respondents to generate business ideas by using archetypal models. A questionnaire was used to collect all the data.

4 Results and discussion

One result of this research was to have the classification and archetypal models. This section will explain the elements of the classification, an example of the archetypal models, and the applications of the design tool.

4.1 Classification

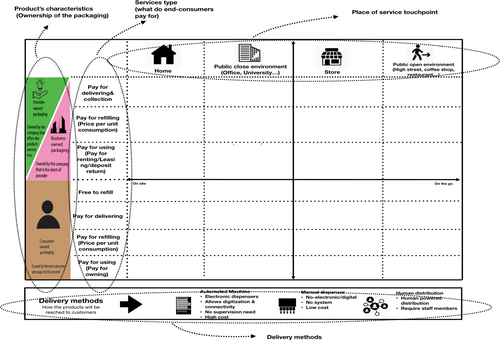

The classification is a polarity diagram in which the elements are the product’s characteristics, service types, place of service touchpoint, and delivery methods. The elements of the classification are shown in Figure 3.

4.1.1 Product’s characteristics (ownership of the packaging)

Ownership can differentiate PSS types. However, consumers always pay for the ownership of the packaging and the content in the food and household products industry. Therefore, the justification of the packaging’s ownership will be different compared to other products (e.g., cars). Two key indicators can determine the ownership of the packaging: whether the empty packaging can be returned somewhere for a deposit refund and who is responsible for putting the packaging back into the phase of use. According to this point, the ownership of the packaging can be classified as consumer’s owned packaging (i.e., the packaging cannot be returned for a deposit refund, and consumers are responsible for putting the empty packaging back into the phase of use), business’s owned packaging (i.e., consumer can return the packaging for a deposit refund, and businesses will put the packaging back into the phase of use), and provider’s owned packaging (i.e., consumer can return the packaging for a deposit refund, and providers are responsible for putting the packaging back into the phase of use). Graphically, colors were used to indicate the types of ownership.

4.1.2 Service type (what do end consumers pay for?)

This explains what services will be provided to consumers. Within consumer-owned packaging, there are four services: “pay for using (pay for owning),” “pay for refilling (price per unit consumption),” “pay for delivering,” and “free to refill.” Regarding provider-owned packaging and business-owned packaging, the services are “pay for delivery and collection,” “pay for refilling (price per unit consumption),” and “pay for using (pay for renting/subscription/deposit return). The combination of ownership of the packaging and service types represents how the RPSs will be delivered to consumers.

4.1.3 Place of service touchpoint (location)

This explains the location where the consumers receive the services. The locations are the home (on the site), public close environment (i.e., the place that certain people can enter), the store, and public open environment (on the go; i.e., the place that all people can enter). Moreover, within provider-owned packaging and business-owned packaging, the location is also associated with the return rate. Empty packaging will be more likely to be returned to service providers than those in the public open environment. If the location is home, consumers will not need to spend much effort in moving the empty packaging but leave the packaging at their homes. Accordingly, the return rate of the packaging could be higher. If the location is a public open environment, consumers will need to spend their time and efforts to return the packaging. Therefore, the return rate could be lower.

4.1.4 Delivery methods

This refers to the ways in which the content will be delivered to consumers. The way to deliver can be through automated machine, manual dispenser, and human distribution. Their characteristics can be seen from the classification.

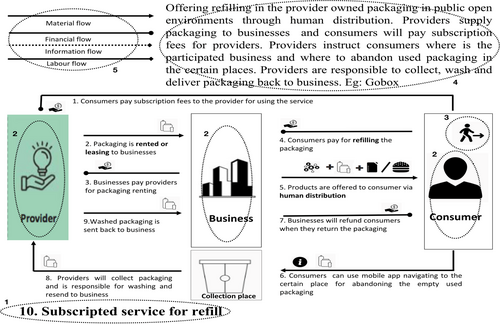

4.2 Archetypal models

The archetypal models in this research are used to describe a group of cases that share similar key characteristics. A stakeholder system map is adopted to visualize the interaction among key stakeholders. The elements of the example of an archetypal model can be found in Figure 4.

This example explains each element in the archetypal model: (1) It refers to the name of the archetypal model, which summarizes some key characteristics. (2) It indicates the key stakeholders operating in the business. Moreover, the color refers to the ownership of the packaging, which will be circulated among those three stakeholders. (3) It refers to where consumers receive the service; the icon corresponds to the classification. In this case, the location is a public open environment. (4) It explains how each archetypal model works. (5) It refers to different flows in the archetypal model. In this model, it has four flows: material flow, financial flow, information flow, and labor flow. Fifteen identified archetypal models can be found in the appendix.

4.3 Potential applications of the design tool

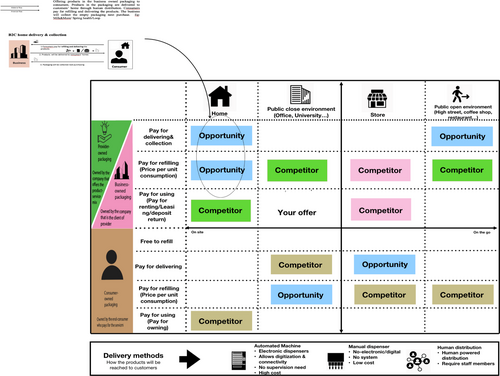

Three applications are defined and shown in Figure 5 and Figure 6.

- Supporting the understanding of RPSs

First, using the populated classification can lead to a systematic understanding of different RPSs (see Figure 5). In this research, all cases were collected and formulated into archetypal models that represent all types of RPSs. The classification can embrace all of them. As a consequence, it can support professionals to systematically understand different RPSs.

- Supporting identifying the market opportunities

The design tool can be used to acquire an overview of the market by positioning competitors’ offers in the classification that can lead to strategic analysis and identify market opportunities in the selected location. Figure 6 shows that if a company can position its offer and competitors’ offers in the classification, it can give an overview of the market, which supports the company in knowing what other competitors are doing as well as identify market opportunities.

- Supporting idea generation

After market opportunities are identified, the design tool can support idea generation by using the archetypal models to inspire new business ideas. Figure 6 can also show that when opportunities are identified, professionals can look at the archetypal models and select a suitable one to fill the market gaps.

4.4 Validation with experts

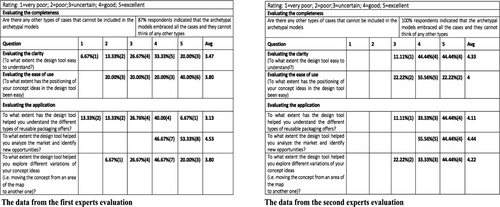

The validation of the design tool included two phases. During the first phase, 15 experts were involved. The data of the first and the second phases of the evaluation can be found in Figure 7.

4.4.1 The first phase of the evaluation

First, Expert 7 and Expert 8, who were environmental NGO professionals, introduced three NGO cases that could not be embraced by the archetypal models. The cases were to offer free refills for consumers who bring their own packaging. Accordingly, the improvements were to add “free refill” to the dimension of consumer-owned packaging in the classification and also to formulate the corresponding archetypal model. The total number of collected cases reached 57.

Regarding clarity, the average point was 3.47, which suggested that it was below a satisfactory level. The clarity of the design tool was significantly important, as all other applications were built upon it. The most mentioned issue was that the design tool should be self-explanatory with a description of its use (7/15); how to address this issue is the priority. For instance, Expert 4 confessed, “I need to figure out what did each ‘box’ mean and it was nothing there.” Expert 2, Expert 6, Expert 7, and Expert 8 similarly argued that the classification needs descriptive texts to tell users how to use it. Expert 15 explained, “I am not confident in understanding everything if I am not verbally explained.”

The average point of ease of use was 3.8, which was close to satisfaction. Two specific comments were raised in concern. First, a better explanation of the business’s own packaging and provider’s own packaging was needed. For instance, Expert 8 said, “What is the difference between provider’s own and business’s own? Cause it might confuse people”; Expert 11 asked, “Are provider and business same thing as they are together?” Second, improving the graphic aspects of the design tool was advised. For instance, Expert 4 said, “Making the classification graphical will be better for positioning the offers because I will not need to read many words.” Expert 3 suggested, “Location could be replaced by some graphic icons which can be integrated into archetypal models as well.”

Regarding the first application of the design tool, the average point was 3.13. Experts argued that more characteristics matter in a real business context and more elements could be added to the design tool. For instance, cost-related elements were frequently mentioned (8/15). Expert 5 rated 1 for this application because he said that “cost was the foundation to evaluate a business model and it was uncertain to know the feasibility to run the business without knowing the cost.” Another comment was associated with practicality. Expert 1 said that “the shape of the packaging should be corresponding to certain contexts. Some packaging shape may fit on the go contexts while some packaging shape may fit home contexts.” (Expert 5 and Expert 11 similarly agreed). Expert 6 believed that “material should also be considered because public open scenario needs light material for carrying away and public close context can have a glass or metal material to ensure the durability.”

The rating for the second application was 4.53, which indicated that most experts were satisfied with this application. The overall feedback was to endorse this application especially for identifying new opportunities. For instance, Expert 5 confirmed that “it is a very straightforward SWOT analysis for the marketplace for analyzing the market and seeing opportunities.” Expert 8 said, “I can see opportunities clearly when the classification is populated with competitors.” Expert 12 said that “it looks like a tool which is done by a marketing team and strong marketing purpose.” Expert 13 said that “the design tool will be so helpful when my company wants to enter a new marketplace.” Expert 15 said that “the way to overview the market is quite special and supportive, I can know what others are doing.” In conclusion, based on the satisfaction of this application, we can imply that this application is validated.

The average point for the last application was 3.8. Most respondents acknowledge this application. However, a few comments were raised in concern. Expert 1 argued that “there is nothing wrong with the design tool, it is just because I knew all those models so that I didn’t feel that it can support the idea generation for me.” Expert 5 argued, “How can this classification tell whether there is an opportunity or something that could never be implemented?” Furthermore, Expert 13 indicated, “If there are multiple options of archetypal models that could fit in the identified market gap, the design tool couldn’t optimise the choice.”

Accordingly, the feedback and data from the first expert’s evaluation were summarized: (1) adding more descriptive texts of each element to the classification; (2) providing graphic icons representing location in the classification and archetypal models; (3) adding real business names to archetypal models; (4) including clear and concise justification of “provider-owned” and “business-owned” to the classification; (5) adding an axis of return rate to the classification; and (6) adding “free to refill” to the classification and formulating the corresponding archetypal model. All of this feedback was used to refine the design tool after the first round of evaluation. Subsequently, the second phase of evaluation was conducted.

4.4.2 The second phase of the evaluation

During the second phase of evaluation, the improvements were endorsed by the experts. Because the average points of each question reached above 4, it confirmed that the improvements of the design tool were validated. The endorsements came from all aspects of the design tool. For instance, all respondents indicated that this tool embraced all types of reusable packaging offers, and they could not think any of other types. Clarity and ease of use were also endorsed by different experts. For instance, Expert 16 said that “the classification is very clear and archetypal models are even clearer, I would like to give 6 points for it.” Expert 20 said that “certainly the design tool is very clear and self-explanatory.” Regarding ease of use, Expert 16 affirmed that “positioning my products in the classification is not a problem for me at all.” Expert 18 confirmed that “since all characteristics of packaging can be reflected in the design tool, positioning products should be easy for any packaging professional.”

The applications also received high endorsements. For instance, Expert 22 supported this application by saying, “this tool captures important characteristics of reusable packaging offers and now I am more confident in explaining reusable packaging offers to others.” Expert 16 endorsed the second application by saying, “apparently when I positioned competitors’ offers in the classification, I will know what they are doing. Besides, opportunities are so clear.” For the third application, Expert 17 said that “the archetypal models explain everything, and it is so inspiring for coming up with new ideas.” Expert 20 said that “archetypal models self-explain everything and I have more ideas in my database.” Expert 23 said that “it is a great starting point for idea generation.”

5 Conclusions

The research questions were how to develop a design tool to classify current RPSs and how the design tool can support professionals in addressing the plastic problem. They were answered by developing a classification and 15 archetypal models, and also by conducting experts’ evaluations to reveal how the design tool can provide support. The development process included a literature review, a collection of 57 case studies, and an evaluation with 24 experts. The evaluation tested three applications, which were to support the understanding of RPSs, identifying the market opportunities, and generating business ideas. Positioning different RPSs in the classification led to a characterization of each case that supports the understanding of the RPSs. In the selected geographic location, positioning the company’s RPS and competitors’ RPSs can identify market opportunities. After identification of the market opportunities, using the archetypal models can provide insights to generate new business ideas.

Some limitations are also highlighted. First, 24 experts could be a small sample size that may yield limited knowledge. Even though respondents are relevant stakeholders, involving more respondents with a broader background could provide a more concrete evaluation, which leads to better improvements. Moreover, due to the limited condition, the testing process was unable to allow participants to use the tool in the practice. Accordingly, evaluating the design tool in the practice could produce richer data to improve the design tool.

Second, some key factors, such as market regulation and cost elements, were excluded when formulating the archetypal models. Due to the time constraint of this research, the archetypal models can only include some key factors to support professionals. Therefore, identifying other key factors can be the focus of future research.

Third, the design tool may only offer limited support for highly experienced professionals regarding idea generation, and this limitation was identified by some experts. In principle, 15 archetypal models embrace all types of RPSs in reality, and they can provide insights for professionals who are not familiar with those cases. However, if a professional is highly experienced and knows all those types of RPSs, the design tool can only provide limited support. For instance, Expert 19 said that “I know all those dry and liquid food business cases; therefore your tool cannot support me for idea generation.” Expert 21 said, “Your archetypal models cannot tell me something new.” Accordingly, the next focus could be how to support highly experienced professionals to stimulate new business models.

The future research path should focus on including more key factors in the design tool that can support different stakeholders better. For instance, the current classification can only characterize the ownership of the packaging. Comments from experts’ evaluation indicated that more characteristics, such as the material and shape of the packaging, should be included. Accordingly, the design tool can support the understanding of RPSs better. In parallel, adding more factors to archetypal models will not only elaborate on each archetypal model but also be able to support highly experienced professionals. Finally, the evaluation of the design tool can involve more experts with different backgrounds. For instance, the participants could be experts from reverse logistics or environmental policy makers. Consequently, there will be more concrete knowledge added to the design tool, which will benefit more stakeholders.

Appendix: The archetypal models:

| No. | Archetypal models | Value proposition |

|---|---|---|

| 1 | Self-refill store | Offering products through manual dispensers to consumer-owned packaging (e.g., Unpackaged). |

| 2 | Franchised discounted refill shop | Offering products in the packaging through manual dispensers (e.g., Starbucks). |

| 3 | Owning packaging and free refilling | Offering branded packaging to consumers who can have free products in the participating organizations (restaurants, coffee shops, and so forth) (e.g., Givemetap). |

| 4 | Owning packaging and discounted refill | Offering branded packaging to consumers who can have discounted products in the participating organizations (restaurants, coffee shops and so forth) (e.g., Refill it Germany). |

| 5 | Free refill station | Consumers can have free water in the participating organizations. Location is the public open space (e.g., Oneless). |

| 6 | B2C home delivery and collection | Offering products in the business-owned packaging to consumers. Products in the packaging are delivered to customers’ homes through human distribution (e.g., Milk&More/Spring health/Loop). |

| 7 | Canteen returnable packaging | Offering products in the business-owned packaging in the public close environment through human distribution. Businesses will refund the deposit to consumers once the packaging is returned (e.g., Ozzi). |

| 8 | Concentrated refill pods delivery | Offering products in the packaging through human distribution to consumers’ homes. Consumers pay for owning, refilling, and delivering the product. Consumers are able to only pay for refilling and delivering the packaging after consumers finish the previous packaging (e.g., Splosh). |

| 9 | Refill the trackable packaging | Offering products in the provider-owned packaging in public open environment through the manual dispenser. Businesses instruct consumers to put empty packaging in the certain places where providers will collect them (e.g., Cupclub). |

| 10 | Subscripted service for refill | Offering products in the provider-owned packaging in public open environment through human distribution. Consumers will pay subscription fees for providers (e.g., Gobox). |

| 11 | Digital self-refill store | Offering products to refill consumer-owned packaging at the store via automated machine (e.g., Miwa). |

| 12 | Digital self-refill store (packaging rental) | Offering products to refill provider-owned packaging at the store via automated machine (e.g., Algramo/Jean bouteille/Miwa). |

| 13 | Delivery and collection of your packaging | Offering delivery and collection service of consumer-owned packaging from their homes to public close space. Consumers pay for delivery service only, and content of the packaging will be delivered through human distribution (e.g., Dabbawala). |

| 14 | On-the-go refill station | Offering products to refill consumers’ owned packaging at public open space through the automated machine (e.g., Water ATM). |

| 15 | Self-making product | Offering the packaging and automated machine for consumers to self-make the products. The packaging and automated machine will be delivered to the homes of consumers (e.g., Sodastream). |

Biographies

Yuan Long is a doctoral researcher at Brunel University London. He carries out research in the areas such as product-service system, environmental sustainability, design for behaviour change and co-design.

Fabrizio Ceschin is a Senior Lecturer in Design for Sustainability, coordinator of the Design for Sustainability research group and member of the Design for Sustainable Manufacturing research theme and the Human Centred Design research at Brunel University London.

Noha Mansour was a master student majoring in integrated product design at Brunel University London. She finished the master degree in 2018.

David Harrison is a Professor of Design Research and lectures in Sustainable Design and Environmentally Sensitive Design at Brunel University London. His areas include exploring technological solutions to environmental problems.