In vitro rumen fermentation characteristics of bakery by-products containing high starch and sugar

Abstract

The objectives of this study were to evaluate the nutritional characteristics of bakery by-products (castella, pancake, baumkuchen) and their effect on rumen fermentation in vitro as compared with steam-flaked corn and barley as human-edible grains. The fermentation pattern of sugar and starch as pure components was also investigated. Additionally, rumen pH was evaluated using a low-capacity buffer. Bakery by-products contained high sugar (212–590 g/kg DM) and starch (262–545 g/kg DM). Castella exhibited the highest sugar content, whereas pancake and baumkuchen were rich in starch and ether extract within bakery by-products, respectively. The gas production rate at the early phase of incubation was higher in bakery by-products than in grains, and the highest in castella among all feeds. Bakery by-products produced higher total organic acids and propionate than grains. Bakery by-products also exhibited a lower rumen pH than grains during twenty-four hours of incubation with a low-capacity buffer. As pure components, sucrose showed a higher gas production rate and lower pH than starch. Overall, compared with grains, bakery by-products have the potential not only to supply more energy to ruminants but also decrease rumen pH because sugar and starch in bakery by-products ferment rapidly and produce higher organic acids in the rumen.

1 INTRODUCTION

Cereal grains, such as corn and barley, are essential feed resources in the diet of high-producing dairy cows and fattening cattle. These grains are widely used because they are rich in energy and their nutritional value can be improved by processing (Humer & Zebeli, 2017; Nikkhah, 2015; Qiao et al., 2015). However, the global demand for cereal grains is predicted to increase because of the continuous growth of the human population. Therefore, future food security concerns are rising (Godfray et al., 2010) leading to pressure on livestock systems (Bradford, 1999). However, the high performance of recent livestock systems requires massive amounts of grains (Knaus, 2009), thus causing increased feed versus food competition. One approach to reducing grain competition is introducing food by-products as non-edible feed sources to animal diets. The utilization of food by-products has been widely investigated in ruminant feeds, including brewers grains (Hatungimana et al., 2020; Homm et al., 2008), soybean curd (Yang et al., 2010), and dried distillers grains with solubles (DDGS) (Abdelqader et al., 2009; Abdelqader & Oba, 2012). Most of these are rich in crude protein. In contrast, few reports have evaluated sugar- or starch-rich by-products for ruminants.

Based on economic value and availability, bakery by-products have the potential to be used as substitutes for concentrate sources because they contain total digestible nutrients in similar quantities found in grains (França et al., 2012). Nutritionally, bakery by-products contain high sugar and/or starch as non-fibrous carbohydrate (NFC) and fat (Arosemena et al., 1995). Research by Stein et al. (2023) utilizing 11 kinds of bakery meals showed that the average starch content of by-products is 379.5 g/kg dry matter (DM), whereas the average sugar content is 125.8 g/kg DM. Kaltenegger et al. (2020) showed that bakery by-products contain starch and sugar at 504 g/kg DM and 106 g/kg DM, respectively. Bakery products are made from various ingredients (Arosemena et al., 1995; Waldroup et al., 1982). The nutritional characteristics of their by-products may vary. Castella, pancake, and baumkuchen, which are mainly made of sugar and wheat flour, are popular bakery products in Japan. Owing to the current business policies and consumer preference for fresh food (MAFF, 2017), the food factories possess tons of waste of these bakery products, which may be used as animal feed.

Feeding high amounts of sugar and starch contained in bakery by-products has the potential to decrease ruminal pH and increase the risk of ruminal acidosis (Krause & Oetzel, 2006). In the case of corn, the starch fermentability in the rumen was improved due to gelatinization by steam-flaking process (Han et al., 2022). Starch gelatinization indicates the alteration of the hierarchical structure of starch due to high pressure and temperature (Ding et al., 2007; Han et al., 2022; Wang et al., 2016). However, few studies have investigated the effects of bakery by-products on rumen fermentation (Humer et al., 2018; Liu et al., 2018). Therefore, this study aimed to reveal how the sugar and/or starch content in bakery by-products affects the ruminal fermentation pattern and the by-products that are more prone to induce rumen acidosis. This study was conducted (1) to evaluate the nutritional composition and gelatinization rates of castella, pancake, and baumkuchen and their effects on rumen fermentation characteristics as compared with grain feeds; (2) to evaluate the fermentation pattern of sugar and starch as pure components that are rich in bakery by-products; (3) to investigate the changes of rumen pH by sugar- and/or starch-rich feeds with in vitro batch culture using a low-capacity buffer. Understanding the detailed characteristics of each individual bakery by-product is necessary to utilize it as ruminant feedstuff.

2 MATERIALS AND METHODS

2.1 Preparation of feedstuff

Steam-flaked corn and steam-flaked barley were obtained from a local feed company. The by-products of castella, pancake, and baumkuchen were provided by local food companies. The by-product of castella was mainly produced by cutting the edge of castella after the baking process. The by-products of pancake and baumkuchen came from shapeless products and leftovers. Approximately 10 kg of each by-product were collected randomly at the companies. These by-products were freeze-dried and ground using a 1-mm sieve for further nutrient analysis and in vitro incubation. Corn starch, wheat starch, and sucrose were purchased from FUJIFILM Wako Pure Chemical Corporation (Osaka, Japan).

2.2 In vitro rumen fermentation

All animal experimental procedures in this study were conducted in accordance with the guidelines for animal experiments at Mie University. Two sets of in vitro experiments, including (1) bakery by-products and grain feeds and (2) pure components, were performed using the modification of the method presented by Kondo et al. (2016). The first experiment was conducted using single substrates of steam-flaked corn, steam-flaked barley, castella, pancake, and baumkuchen (n = 3). The second experiment used corn starch, wheat starch, and sucrose (n = 4) as pure components. The feed weight was measured as 0.5 g in a 100 ml glass vial. Rumen fluid collected using stomach tubes from three sheep before morning feeding was pooled. The ratio of forage and concentrate in a diet for sheep was 3:1. The diet consisted of oat hay as the forage source and soybean meal, wheat bran, steam-flaked corn, and alfalfa pellet as the concentrate sources. Four layers of cheesecloth were used to filter the rumen fluid. Fifty milliliters of a medium, with a ratio of 1:3 rumen fluid and buffer solution, respectively, was placed into a glass vial and flushed with CO2, and shaken manually in an incubator set at 39°C. Furthermore, substrates were incubated for 24 h. In the present study, two types of buffer solutions were applied in each batch: normal buffer and buffer with low buffering capacity, according to Orton et al. (2020) to create ruminal acidosis conditions in the in vitro model. The gas production was recorded at 2, 4, 6, 8, 12, 16, and 24 h using a calibrated glass syringe. Gas production rates from 0–4 h, 4–12 h, and 12–24 h as early, middle, and late phase, respectively, were calculated as the amounts of gas produced in each period divided by the number of hours. At 4, 8, and 24 h of incubation, 0.5 ml of the medium was withdrawn from each vial using a sterile syringe to measure pH and organic acids. The in vitro ruminal studies were repeated twice for bakery by-products and grain feeds and once for pure components.

2.3 Chemical analysis

DM content of each feed was measured using freeze drying. Organic matter (OM), crude protein (CP, total nitrogen × 6.25), and ether extract (EE) contents were measured according to the official methods of the Association of Official Analytical Chemists International (AOAC International, 2000). OM was determined by subtracting the ash content (method no. 942.05). CP and EE were calculated using the Kjeldahl method (method no. 984.13) and soxhlet extraction (method no. 920.39), respectively. Neutral detergent fiber content was determined with a heat-stable α-amylase and in an ash-free (aNDFom) form using the method by Van Soest et al. (1991). NFC content was calculated using the following equation: NFC = OM − CP − aNDFom – EE. Starch content was measured according to the method by McCleary et al. (2019). Sugars were extracted with pure water and sugar content was determined using high-performance liquid chromatography (HPLC) (Kondo et al., 2021). The degree of gelatinization of starch was measured using the colorimetric method described by Yagi et al. (2007). The pH in the in vitro rumen was measured using a pH meter (9618S-10D; HORIBA, Japan). Concentrations of lactic acid and short-chain fatty acids (SCFA), including acetic acid, propionic acid, and butyric acid, were determined using HPLC through an ion-exclusion column method with a post-column pH-buffered electron conductivity detection (Kondo et al., 2016).

2.4 Statistical analysis

Statistical analysis was carried out using linear mixed-effects models (PROC MIXED procedure in SAS 9.4; SAS Institute Inc.). Feed was categorized as a fixed effect and replicates (vial and run) as random effects. For rumen pH, feed, buffer (normal or low), and their interactions were categorized as fixed effects. Further analysis was conducted using the post hoc Tukey–Kramer test to compare the means if a significant difference (p < 0.05) was identified. In addition, to compare the effects of by-products (castella, pancake, and baumkuchen) and grain (corn and barley) groups on ruminal fermentation characteristics, an orthogonal contrast was tested. Significance was inferred at p < 0.05 and tendencies at 0.05 ≤ p < 0.1 for all statistical tests.

3 RESULTS

The nutrient composition of bakery by-products and grain feeds are presented in Table 1. The main difference between grain feeds and bakery by-products was higher sugar and lower aNDFom content in the bakery by-products. Among the by-products, castella exhibited the highest sugar content, whereas pancake was rich in starch and CP. Baumkuchen had equal starch and sugar contents and also higher EE content than the other bakery by-products. Bakery by-products also revealed a higher percentage of starch gelatinization compared with steam-flaked corn and barley.

| Item | Feed | ||||

|---|---|---|---|---|---|

| Corn | Barley | Castella | Pancake | Baumkuchen | |

| Chemical composition | |||||

| DM (g/kg) | 887 | 894 | 775 | 543 | 816 |

| OM (g/kg DM) | 986 | 981 | 994 | 973 | 990 |

| CP (g/kg DM) | 83 | 96 | 85 | 124 | 76 |

| aNDFom (g/kg DM) | 123 | 203 | 15 | 43 | 27 |

| EE (g/kg DM) | 35 | 21 | 29 | 39 | 199 |

| NFC (g/kg DM) | 745 | 662 | 866 | 766 | 688 |

| Sugar (g/kg DM) | 23 | 26 | 590 | 212 | 340 |

| Starch (g/kg DM) | 747 | 616 | 262 | 545 | 320 |

| Degree of starch gelatinization (%) | 51.4 | 30.5 | 100 | 92.4 | 87.8 |

- Note: DM, dry matter. OM, organic matter. CP, crude protein. aNDFom, neutral detergent fiber. EE, ether extract. NFC, non-fibrous carbohydrate.

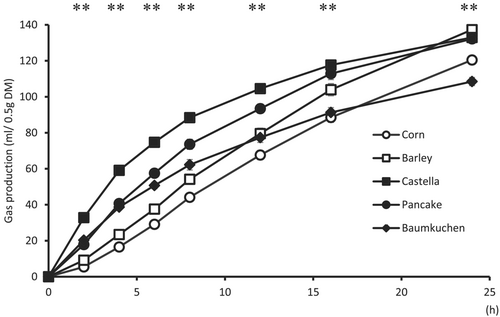

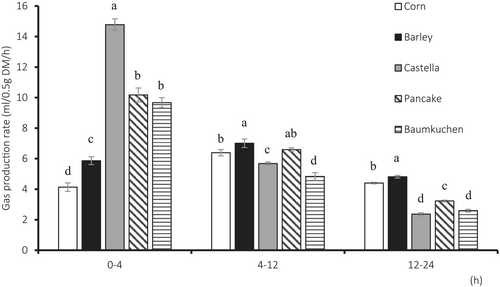

In vitro gas production and rates of gas production are presented in Figures 1 and 2, respectively. Gas production was higher in bakery by-products than in grains for 8-h incubation (p < 0.01). Among all feed treatments, the cumulative gas production for 24-h incubation was the highest in castella, pancake, and barley and lowest in baumkuchen (p < 0.01). Bakery by-products demonstrated a faster gas production rate from 0 to 4 h incubation than grains (p < 0.01). During 0–4 h, castella had the highest rate of gas production than other bakery by-products (p < 0.01). Starting at 4 h, bakery by-products showed a decline in gas production rate.

In vitro, ruminal SCFA and lactate were measured during 24-h incubation (Table 2). Bakery by-products showed higher total organic acid, acetate, and propionate concentrations than grains at 4-h, 8-h, and 24-h incubation periods (p < 0.05), but not butyric acid (p > 0.05). Among the bakery by-products, castella produced the highest propionate (p < 0.01), whereas pancake had the highest acetate after 24-h incubation (p < 0.01). Lactate was higher in bakery by-products than in grains at 4-h incubation (p < 0.01). Castella showed the highest lactate at 4 h and 8 h (p < 0.01) among all feeds.

| Item | Feed | SEM | p value | |||||

|---|---|---|---|---|---|---|---|---|

| Corn | Barley | Castella | Pancake | Baumkuchen | Feed | Grain vs by-product | ||

| 4 h | ||||||||

| Total organic acid (mmol/L) | 22.5d | 26.1c | 51.8a | 40.4b | 41.5b | 0.83 | <0.01 | <0.01 |

| Lactate (mmol/L) | 0.05d | 0.11d | 14.4a | 2.35c | 5.03b | 0.20 | <0.01 | <0.01 |

| Acetate (mmol/L) | 13.6d | 15.4c | 19.3a | 19.2a | 17.7b | 0.44 | <0.01 | <0.01 |

| Propionate (mmol/L) | 5.86d | 7.20c | 13.72b | 14.9a | 14.7a | 0.32 | <0.01 | 0.01 |

| Butyrate (mmol/L) | 2.94d | 3.42c | 4.40a | 3.83b | 4.02b | 0.25 | <0.01 | 0.97 |

| 8 h | ||||||||

| Total organic acid (mmol/L) | 32.5e | 36.7d | 62.2a | 52.2b | 49.4c | 0.59 | <0.01 | <0.01 |

| Lactate (mmol/L) | 0.00c | 0.00c | 7.63a | 0.00c | 0.52b | 0.13 | <0.01 | <0.01 |

| Acetate (mmol/L) | 19.1d | 21.4c | 25.2a | 25.8a | 23.2b | 0.27 | <0.01 | <0.01 |

| Propionate (mmol/L) | 8.74d | 10.1c | 23.0a | 20.8b | 19.9b | 0.35 | <0.01 | <0.01 |

| Butyrate (mmol/L) | 4.67c | 5.18bc | 6.33a | 5.61b | 5.69b | 0.26 | <0.01 | 0.37 |

| 24 h | ||||||||

| Total organic acid (mmol/L) | 63.1e | 66.6d | 81.2a | 78.4b | 71.5c | 0.76 | <0.01 | <0.01 |

| Lactate (mmol/L) | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | - | - | - |

| Acetate (mmol/L) | 34.7d | 38.4b | 37.3c | 39.7a | 34.7d | 0.33 | <0.01 | <0.01 |

| Propionate (mmol/L) | 16.1d | 15.5d | 33.2a | 28.5b | 26.4c | 0.50 | <0.01 | <0.01 |

| Butyrate (mmol/L) | 12.2a | 12.7a | 10.6b | 10.2b | 10.3b | 0.53 | <0.01 | 0.20 |

- Note: a,b,c,d,eDifferent letters in a row indicate differences at p < 0.05.

- SEM, standard error of the mean.

The results of ruminal pH are shown in Table 3. Feed, buffer solution, and their interaction were significant at 4 h, 8 h, and 24 h (p < 0.01). Rumen pH was different between grains and by-product groups at 8-h and 24-h incubations in normal buffer (p < 0.01) and differed at 4 h, 8 h, and 24 h in low buffer (p < 0.05). The decreasing pH of the low buffer was more profound than that of the normal buffer (p < 0.01). In normal buffer conditions, ruminal pH was lower in bakery by-products than in grains at 8 h (p < 0.01). Except for baumkuchen, all bakery by-products also demonstrated lower pH at 24 h than corn and barley (p < 0.01). In addition, at 4 h and 8 h, castella produced a decrease in pH than other feed treatments (p < 0.05). In low buffer conditions, bakery by-products revealed lower pH than grains at 4 h, 8 h, and 24 h (p < 0.01). Castella exhibited the lowest pH among all feeds during 24-h incubation period (p < 0.01).

| Buffer type | Feed | 4 h | 8 h | 24 h |

|---|---|---|---|---|

| Normal buffer | Corn | 6.74a | 6.58a | 6.36a |

| Barley | 6.64ab | 6.55a | 6.33a | |

| Castella | 6.36c | 6.31c | 6.14b | |

| Pancake | 6.50bc | 6.43b | 6.19b | |

| Baumkuchen | 6.56ab | 6.42b | 6.30a | |

| Low buffer | Corn | 6.07° | 5.70° | 4.86° |

| Barley | 5.93p | 5.47p | 4.88° | |

| Castella | 5.04s | 4.46r | 4.29r | |

| Pancake | 5.50q | 4.87q | 4.53q | |

| Baumkuchen | 5.25r | 4.94q | 4.64p | |

| SEM | 0.04 | 0.02 | 0.02 | |

| p values | ||||

| Feed | <0.01 | <0.01 | <0.01 | |

| Buffer | <0.01 | <0.01 | <0.01 | |

| Feed × buffer | <0.01 | <0.01 | <0.01 | |

| Grain vs by-product | ||||

| Normal buffer | 0.08 | <0.01 | <0.01 | |

| Low buffer | 0.01 | <0.01 | <0.01 | |

- Note: a,b,c,d,eDifferent letters in a column of normal buffer indicate differences at p < 0.05.

- o,p,q,r,s Different letters in a column of low buffer indicate differences at p < 0.05.

- SEM, standard error of the mean.

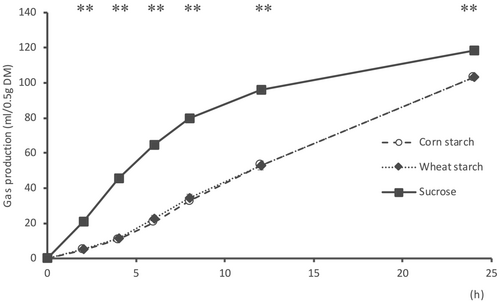

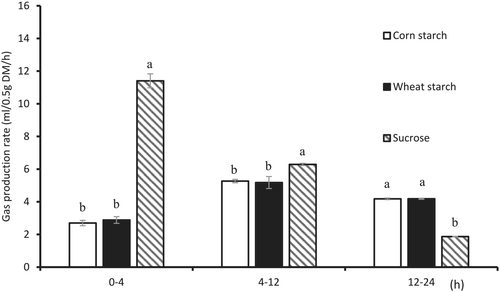

In vitro gas production and gas production rate for pure components (Figures 3 and 4) also revealed that sucrose had a higher gas production rate than both types of corn and wheat starches from 0 to 4 h of incubation (p < 0.01). Of the pure components, sucrose produced the most gas throughout 24-h incubation period (p < 0.01).

SCFA and lactate for pure components were presented in Table 4. The in vitro experiment for pure components revealed that sucrose produced a higher total organic acid, propionate, and lactate than corn and wheat starches at 4 h, 8 h, and 24 h (p < 0.01). In addition, at 4 h and 8 h, more acetate was produced by sucrose than corn and wheat starches (p < 0.01). Conversely, at 24 h, acetate and butyrate were higher in corn and wheat starches than sucrose (p < 0.05).

| Item | Feed | SEM | p value | ||

|---|---|---|---|---|---|

| Corn starch | Wheat starch | Sucrose | |||

| 4 h | |||||

| Total organic acid (mmol/L) | 17.9b | 18.8b | 43.8a | 0.38 | <0.01 |

| Lactate (mmol/L) | 0.00b | 0.00b | 15.1a | 0.21 | <0.01 |

| Acetate (mmol/L) | 11.8c | 12.2b | 17.9a | 0.13 | <0.01 |

| Propionate (mmol/L) | 3.59c | 3.88b | 7.45a | 0.06 | <0.01 |

| Butyrate (mmol/L) | 2.59b | 2.73b | 3.31a | 0.06 | <0.01 |

| 8 h | |||||

| Total organic acid (mmol/L) | 27.2b | 27.5b | 61.9a | 0.67 | <0.01 |

| Lactate (mmol/L) | 0.00b | 0.00b | 20.6a | 0.17 | <0.01 |

| Acetate (mmol/L) | 17.4b | 17.3b | 23.9a | 0.33 | <0.01 |

| Propionate (mmol/L) | 5.84b | 6.08b | 12.6a | 0.28 | <0.01 |

| Butyrate (mmol/L) | 3.93c | 4.14b | 4.70a | 0.05 | <0.01 |

| 24 h | |||||

| Total organic acid (mmol/L) | 58.8b | 58.1b | 91.6a | 0.72 | <0.01 |

| Lactate (mmol/L) | 0.00b | 0.00b | 17.8a | 0.56 | <0.01 |

| Acetate (mmol/L) | 35.7a | 34.6a | 33.3b | 0.46 | <0.01 |

| Propionate (mmol/L) | 10.9b | 11.3b | 31.6a | 0.27 | <0.01 |

| Butyrate (mmol/L) | 12.2a | 12.2a | 8.90b | 0.27 | <0.01 |

- Note: a,b,cDifferent letters in a row indicate differences at p < 0.05.

- SEM, standard error of the mean.

The ruminal pH for pure components is shown in Table 5. Feed, buffer solution, and their interaction were significant at 4 h, 8 h, and 24 h (p < 0.01). Normal buffer showed higher pH values than low buffer (p < 0.01). Throughout the incubation, sucrose had the most significant pH reduction as compared with corn and wheat starches in normal and low buffer conditions (p < 0.01).

| Buffer type | Feed | 4 h | 8 h | 24 h |

|---|---|---|---|---|

| Normal buffer | Corn starch | 6.81a | 6.71a | 6.49a |

| Wheat starch | 6.78a | 6.72a | 6.51a | |

| Sucrose | 6.36b | 6.02b | 5.83b | |

| Low buffer | Corn starch | 6.16° | 5.77° | 4.85° |

| Wheat starch | 6.10° | 5.76° | 4.83° | |

| Sucrose | 5.18p | 4.56p | 3.84p | |

| SEM | 0.04 | 0.02 | 0.02 | |

| p values | ||||

| Feed | <0.01 | <0.01 | <0.01 | |

| Buffer | <0.01 | <0.01 | <0.01 | |

| Feed ×buffer | <0.01 | <0.01 | <0.01 | |

- Note: a,bDifferent letters in a column of normal buffer indicate differences at p < 0.05.

- o,p Different letters in a column of low buffer indicate differences at p < 0.05.

- SEM, standard error of the mean.

4 DISCUSSION

4.1 Chemical composition

As feedstuffs, specific points of chemical composition in bakery by-products are carbohydrates. NFC content was comparable between grain feeds and bakery by-products, but the composition was clearly different. NFC in grain feeds is mainly composed of starch, but that in bakery by-products comes from relatively higher sugar and lower starch. Castella, pancake, baumkuchen are made of sugar and wheat flour as ingredients. These ingredients could reflect higher sugar contents in these by-products than in grain feeds. In addition to wheat flour as the main ingredient in the bakery materials, the gelatinization process that occurs during baking provides a high fermentability of starch. Pancake and baumkuchen mainly contain starch. Compared with bakery by-products utilized by Kaltenegger et al. (2020) and Humer et al. (2018), starch content in pancake has comparable findings. Pancake contains higher starch than that reported by Stein et al. (2023). Although castella has a lower starch than other bakery by-products, the sugar was higher. The high sugar content of castella exceeds the research findings of bakery by-products by Stein et al. (2023), Kaltenegger et al. (2020), and Humer et al. (2018). Baumkuchen contains high EE owing to butter and vegetable oil as its ingredients. EE can provide energy, although EE levels beyond 60–70 g/kg DM reduce nutrient digestibility and suppress rumen fermentation (NRC, 2001). Other studies also show that bakery by-products have varying EE content of less than 35 g/kg DM (França et al., 2012) and more than 80 g/kg DM (Champe & Church, 1980). The lack of consistency in nutritional value is the shortcoming of bakery by-products. Some factors would affect the nutritional content of a bakery, namely the ingredient compositions and the proportion of ingredients.

4.2 Kinetics of gas production

The higher gas production rate of bakery by-products as compared to that of grain feeds at an early phase of incubation could be caused by sugar content and the gelatinization of starch. Corn and barley utilized in this study were processed via steam-flaking at a feed company. Based on our findings, the steam-flaking process for grain feed does not completely gelatinize the starch. Compared to these grains, most starch in the bakery by-products was gelatinized. Other studies indicate that increased gas production is promoted by starch gelatinization after 24 hours of incubation in corn (Han et al., 2022), wheat, and rice (Qiao et al., 2015). A previous in vitro study by Humer et al. (2018) reported that the gradual replacement of cereal grains by bakery by-products linearly improved the ruminal degradation of starch, which could be related to starch gelatinization. High pressure and temperature during gelatinization disintegrate starch granule structure (Han et al., 2022), which may contribute to improved starch fermentability in rumen.

Castella and pancake produced the highest gas, followed baumkuchen. Starch in castella was fully gelatinized. In addition to starch gelatinization, castella contained high sugar. After 4 h of incubation, castella showed the highest gas production rate (Figure 2), indicating that castella was rapidly fermentable. Rapid sugar fermentation in the rumen influences fermentation and microbial activity (Weisbjerg et al., 1998) and leads to a spike in gas production early in the incubation period. The pure component experiment showed supportive evidence. Sucrose was rapidly fermentable (Figure 4) and hence produced the highest gas (Figure 3). The former research also showed rapid fermentation rates of sugar at 300%/h in the rumen, whereas the rate of starch fermentation ranges from 5% to 50%/h (O'Connor et al., 1993). Previous in vitro research by Dong et al. (2021) showed that increasing sugar levels in the diets substantially improved gas production. The combined effect of sugar content and starch gelatinization generates more gas. Pancake that contains high starch showed lower gas production than castella, especially during early incubation (Figure 1). Pancake produced a high amount of gas after 24 h. It might be because of the high starch gelatinization with a high starch concentration. Compared to castella and pancake, baumkuchen produced lower gas, which could be a result of the high-fat content in baumkuchen. Lipids can form amylose-lipid complexes, which may decrease enzyme accessibility and consequently reduce starch digestibility (Wang et al., 2014).

4.3 Organic acids

The higher propionate production of bakery by-products as compared to that of grain feeds may be attributed to lactate utilization. In feeds containing rapidly fermentable carbohydrates, rumen bacteria produce ethanol or lactate (Moss et al., 2000). Lactate can be utilized as a secondary compound by lactate-fermenting bacteria (e.g., Veillonella alcalescens, Megasphaera elsdenii, and Selenomonas ruminantium) to produce propionate (Russell & Wallace, 1997). In addition, propionate production is also augmented by starch gelatinization because gelatinization promotes the accessibility of degrading enzymes to starch granules (Han et al., 2022). This concurs with previous research by Humer et al. (2018) who reported that the inclusion of bakery by-products as a substitute for corn grain in total mixed ration (TMR) increased propionate.

Previous research suggests that the feeding of sugar sources partly replaced by starch decreased propionate (DeFrain et al., 2004; Schingoethe et al., 1980), or was not affected (Vallimont et al., 2004). This is in contrast with castella, which produces the highest propionate, although the starch content is lower than in other bakery by-products and grain feeds. The effect of sugar on rumen fermentation gives inconsistent results (Oba, 2011). It can be influenced by the type of sugar (Sutton, 1968) and feedstuffs replaced by sugar (Oba, 2011). Several studies revealed that substituting starch with lactose leads to a decrease in propionate concentration in the rumen (DeFrain et al., 2004; Schingoethe et al., 1980). In contrast, the inclusion of fructose (Chamberlain et al., 1993) and glucose (Piwonka & Firkins, 1996; Sutton, 1968) as a component of sucrose increased the production of propionate. In the present study, the fermentation of the pure components indicated that sucrose produced a higher propionate concentration than corn and wheat starch (Table 4). Based on the ingredient information of castella, sugar in castella consists mainly of sucrose, which would lead to propionate synthesis in the rumen. Further research is needed to evaluate fermentation products in the rumen underfeeding of sugar-rich bakery by-products in in vivo trials.

Humer et al. (2018) showed that the feeding of bakery by-products had no marked effect on butyrate production. Some studies indicate that the feeding of starch and sugar sources to dairy cows does not affect butyrate production (Broderick et al., 2008; Penner et al., 2009). Other studies by Gao and Oba (2016) and in vitro experiments by Vallimont et al. (2004) showed different results, which suggested that sugar produces higher butyrate than starch sources. The provision of sugar-replaced starch does not produce consistent results in terms of butyrate production. Humer et al. (2018) reported that the inclusion of bakery by-products decreased 28% of the abundance of Butyrivibrio bacteria, known as fibrolytic rumen microorganisms (Derakhshani et al., 2017), due to the lower availability of fiber and high EE. Based on this, the lower butyrate in bakery by-products might be due to lower fiber content.

4.4 Rumen pH

In the present study, two different buffers were used. Compared to normal buffers that are designed to maintain rumen pH, the low buffer was developed by decreasing the concentration of bicarbonate (20 mmol/l and 25 mmol/l) and phosphate (10 mmol/l), compared to a modified McDougall buffer (bicarbonate 97.9 mmol/l, phosphate 20 mmol/l) (Orton et al., 2020). Hence, a normal buffer is suitable to maintain the activity of rumen microbes and to evaluate the fermentability of nutrients in the feedstuffs, whereas a low buffer would be suitable to evaluate the potential to lower rumen pH. The results of the present research revealed that in vitro rumen pH with low buffers clearly changed due to a lack of buffering capacity (Orton et al., 2020).

Bakery by-products produced a lower rumen pH than did grain feeds. This corresponded to higher sugar content in the bakery by-products. Castella produced a lower pH than pancake and baumkuchen because castella contain high sugar. Sucrose itself produced a lower rumen pH than starch sources (corn and wheat starch). Sugar ferments faster than starch (Oba, 2011), and the rumen pH decreases because the sugar ferments rapidly to produce acids (Evans & Messerschmidt, 2017). Corn and barley had a higher starch content than that of pancake; however, pancake had a lower pH because the starch gelatinization of pancake was greater than that of corn and barley (Table 1). Moreover, corn and barley contain lower sugar than pancake. This is supported by the lactate production in the present study. Under conditions of high NFC, Streptococcus bovis could shift the fermentation pattern to produce lactate, which decreases rumen pH. Previous in vitro research by Humer et al. (2018) reported that replacing grains with bakery by-products increased the content of starch and sugar in the diets and decreased rumen pH compared to the control diets. Conversely, several studies have reported that feeding sugar does not markedly affect the decrease in rumen pH, in vitro and in vivo (Broderick et al., 2008; Vallimont et al., 2004). In the present study, bakery by-products and grain feeds were used as a single feed in the in vitro rumen to evaluate the rumen fermentability. The proportions of sugar- and starch-rich feeds in diets and/or other factors (i.e. forage: concentrate ratio) could influence rumen pH. These points should be revealed in future studies of bakery by-products.

In summary, bakery by-products have the potential to supply more energy to ruminants compared with grain feeds owing to a high sugar and/or starch content and fully gelatinized starch. Among the by-products, castella contained the highest sugar content, whereas pancake was rich in starch, and among the feeds used in this study, baumkuchen contained the highest ether extract. These bakery by-products were fermented in the in vitro rumen more rapidly and caused lower ruminal pH than grain feeds. Castella showed the highest rumen fermentability followed by pancake and baumukuchen. Nutrient characteristics and rumen fermentability were varied in bakery by-products. According to our results, understanding the detailed characteristics of each individual bakery by-product is necessary to utilize it as ruminant feedstuff.

ACKNOWLEDGMENTS

This work was supported by the Mayekawa Houonkai Foundation (Tokyo, Japan).

CONFLICT OF INTEREST STATEMENT

All authors declare that there is no conflict of interest for this article.