Effect of defatted Lagenaria siceraria (Molina) Standley seed flour as a fat replacer on physicochemical, technological, and sensory properties of beef patty

Abstract

Defatted Lagenaria siceraria seed flour (DLSSF) was obtained from defatted seed cake, dried, and ground through a sieve of 500 μm and characterized. A 2 × 4 factorial design (two flour hydration rates and four fat substitution rates) was used to produce a low-fat beef patty by replacing fat with DLSSF. Beef kidney fat was used to formulate the control sample. Chemical, physical, technological, sensory, and nutritional characteristics of low-fat beef patties manufactured were evaluated. DLSSF contains mainly protein. As fat replacers, DLSSF induces a significant increase in the pH of the raw and cooked patty, the moisture and protein contents, the cooking yield, the cohesion, chewiness, springiness, and lightness of the cooked beef patty with fat substitution rate. There is a decrease in fat content, total calories, water retention capacity, hardness, and redness of the cooked patty with a fat substitution rate. From the sensory analysis, the substitution of fat improves the acceptability of samples. Based on the overall parameters analyzed, DLSSF containing 60% water can be used to produce low-fat beef patty by replacing fat at 100%. From these results, hydrated DLSSF could be an effective method to solve the problems of noncommunicable diseases related to animal fat consumption.

1 INTRODUCTION

In many developing countries, the convenience foods such as beef patty is increasing now and becoming part of the daily diet of many populations. Like many meat products, the patty is an important source of valuable nutrients as vitamins and essential minerals with a high degree of bioavailability. However, the patty is considered a high-fat food, as in conventional patty, animal fat is an essential ingredient representing up to 50% of the overall composition (Feiner, 2006), with an average of 36% fat in processed meat products (Naga & Prabhakar, 2011). Animal fat is rich in saturated fatty acids (SFA) (beef, 55%–60%; pork 42%–44%) (Feiner, 2006) and cholesterol with a negative effect on human health. The importance of SFA and cholesterol in the development of cardiovascular diseases, obesity, and some cancers (prostate, colon, and breast) are well documented (Lin et al., 2004). Due to relationship between the consumption of some meat products and certain diseases, the meat industry has been negatively affected by adverse publicity (Rehab et al., 2011). From a nutritional point of view, it is important to reduce this high level of dietary lipids, and health organizations all over the world have promoted lower intake of total dietary fat and cholesterol. For instance, dietary guidelines recommend limiting total and saturated fat intakes to <30% and <10% of total calories intake, respectively, and the American Heart Association (AHA) recommends that those with elevated LDL cholesterol levels or cardiovascular diseases restrict saturated fats to <7% of calories (Ognean et al., 2006). Replacing or reducing animal fat in meat products to appropriate limits could create a better image for the industry (Sanaa, 2015). Consumers' demand for decreasing fat led to the development of healthier low-fat food products (Rashidi et al., 2015) using many fat substitutes, which also contribute to lowering the caloric value of food. These fat substitutes are categorized as leaner meats (fat-reduced meat), animal and plant protein-based, carbohydrate, and synthetic compounds (polydextrose, olestra) (Cengiz & Gokoglu, 2007). As fat is a key determinant for various physicochemical and sensory characteristics of foods (flavor, mouthfeel, juiciness, texture, bite, heat transfer, etc.) (Rehab et al., 2011), its excessive reduction with improper substances may lead to bland, dry, hard, rubbery, or mealy products (Keeton, 1994). Different strategies have been used to minimize the problems related to fat reduction, mainly the use of hydrated functional additives such as carbohydrates (Sanaa, 2015) and protein-rich ingredients. Soy proteins that improve water and fat binding ability, enhance emulsion stability, improve nutritional content, and increase cooking yields (Fathy et al., 2010) have been widely used. However, the use of soy protein is limited due to its negative effect on the sensory properties of soy-added meat products (Arun et al., 2008; Wangang et al., 2010). Therefore, it is important to find other rich protein fat replacers that can maintain or improve the nutritive and sensory properties of the final product like some Cucurbitaceae seeds (Noumo et al., 2016).

Lagenaria siceraria is a climber or trailer plant belonging to the Cucurbitaceae family, mainly cultivated in the warm humid climate of African and Asian countries. It is a popular vegetable, grown almost all around the year (Kumar et al., 2015). L. siceraria is commonly known as bottle gourd (Antia et al., 2015), and it is an important vegetable with high genetic diversity for fruit shape and other fruit characteristics, resulting in a variety of uses including medicinal uses in different parts of the world (Antia et al., 2015; Parle & Kaur, 2011). L. siceraria is well documented as a food source, and both its fruits and aerial parts are used as a vegetable. In some African countries like Nigeria and Cameroon, the seeds are used to make some traditional meals (Djiogue et al., 2016) or as thickeners in some local soups. Some studies on the chemical composition of the seeds and the seed oil characteristics have shown to be highly nutritive. They contain high lipid levels (48.5%–53.69%) with around 80% of unsaturated fatty acids, of which 70% are polyunsaturated fatty acids (Fokou et al., 2009) and are also rich in proteins (around 34% and 69%, respectively, for whole seed and defatted seed cake) (Achu et al., 2005). Moreover, the study on the functional properties of defatted seed flour of L. siceraria revealed that it forms a heat-stable gel and emulsions (Noumo et al., 2017). However, despite its high nutritional and technological potential mainly for application as a fat replacer in meat products, defatted L. siceraria seed flour (DLSSF) remains under-valorized industrially. The current investigation was performed to evaluate the effects of adding various levels of hydrated DLSSF as fat a replacer on physicochemical, technological, and physical properties as well as sensory attributes of beef patties.

2 MATERIAL AND METHODS

2.1 Raw material

Decorticated L. siceraria seeds were collected at Garoua town (9°18′05″ N, 13°23′51″ E; North Region, Cameroon). They were transported in polyethylene bags to the laboratory where the defatted seed flour was produced using the protocol described by Noumo et al. (2017). Thigh muscle, liver, and kidney fat from beef Bororo breed cattle were purchased from Ngaoundere (7°19′39″ N, 13°35′04″ E; Adamawa Region, Cameroon) slaughterhouse for the formulations of samples used for sensory analysis and from Mysore (Kankrej cow breed) (12°18′13″ N, 76°38′46″ E; Karnataka, India) beef market for the remaining part of the study. The cows were raised on pasture and slaughtered following halal conditions. The required quantity for each part was purchased within 2–3 h of slaughter, packed in low-density polyethylene bags, and brought to the laboratory within 20 min in the icebox containing ice to maintain low temperature (about 4°C).

2.2 Chemical analysis of DLSSF

2.3 Production of beef patty

The muscle was trimmed of connective tissues and cut in bits of around 5 cm, mixed with 0.06% sodium nitrate at 20 g/kg, and kept at 4°C for 96 h for maturation. The cured and matured lean meat obtained was chopped using a vertical cutter (Robot Coupe R10 series 5, France) at 3000 rpm for 60 s, then the liver representing each 1/3 of the lean was added in the cutter, and the mixture was ground to obtain a homogeneous paste (1,500 rpm for 90 s) with temperature below 10°C. Kidney fat trimmed of connective tissues was chopped separately at 3000 rpm until obtaining a fine paste and was melted by heating at 80°C for 30 min in the oven (Heraeus RT 360; Hanau, Germany). Before the formulation, the fat content of the lean meat and beef kidney fat portions was determined. The lean beef (3% fat), kidney fat (91% fat), and L. siceraria pastes with 60% and 72% of moisture content obtained from DLSSF hydrated for 30 min using tap water and mixed at 1500 rpm for 2 min using a paddle mixer (Hobart A200; Arlington, USA) were used to formulate the beef patties. A control was formulated to contain 20% of kidney fat. For the test samples, the DLSSF pastes were used to replace fat at 0%, 25%, 50%, 75%, and 100%, respectively. Thereafter, ground liver and lean meat, spices, fat, and/or DLSSF paste were mixed for 3 min to obtain a homogeneous paste. The resulting batters were introduced into stainless aluminum molds (20 cm × 11.5 cm × 6 cm) and cooked in an electric oven (Heraeus RT 360; Hanau, Germany) at 120°C for 30 min and then at 90°C until a core temperature of 72°C, cooled at ambient temperature (25 ± 2°C), and stored at 4 ± 1°C (Noumo et al., 2016). The samples were packaged in metallized polyester pouches (oxygen transmission rate: 20 ml/m2/24 h at 27°C; water vapor transmission rate: 1.2 g/m2/24 h at 27°C, 65% RH) under aseptic conditions.

The different samples were coded as P0 for the control with animal fat, P25:60 for the sample with fat replaced at 25% using the DLSSF paste containing 60% of water; P50:60 for the sample with fat replaced at 50% using the DLSSF paste containing 60% of water, P75:60 for the sample with fat replaced at 75% using the DLSSF paste containing 60% of water, P100:60 for the sample with fat replaced at 100% using the DLSSF paste containing 60% of water, P25:72 for the sample with fat replaced at 25% using the DLSSF paste containing 72% of water, P50:72 for the sample with fat replaced at 50% using the DLSSF paste containing 72% of water, P75:72 for the sample with fat replaced at 75% using the DLSSF paste containing 72% of water, and P100:72 for the sample with fat replaced at 100% using the DLSSF paste containing 72% of water respectively. A total of nine samples were produced, including one control and eight test samples in two lots, one lot for sensory analysis and the second for the remaining analysis.

2.4 Determination of pH, proximate composition, cooking yield, and caloric value of beef patty

Ten grams of patty (raw and cooked) was ground in laboratory mortar mixed with 90 ml of double-distilled water. The pH of the suspension was measured using a pH meter (EUTECH Instruments pH Tutor, Vernon Hills, USA). Moisture and total lipid contents of raw and cooked patty were determined according to the AOAC (2005) methods. Before the determination of lipid content, the samples were dried for 24 h at 45 ± 1°C. The proximate composition of the cooked samples was completed by the determination of ash, protein, and total sugars using the AOAC (2005) and AACC (1999) methods.

The effect of fat substitution on the total calorie (kcal) of 100 g of cooked patties was evaluated using the Atwater values for fat (9.0 kcal/g), protein (4.02 kcal/g), and carbohydrates (4.0 kcal/g) as described by Kumar and Sharma (2004).

2.5 Color, texture, and water activity evaluation

The color parameters of cooked patties were measured using a colorimeter (Konica Minolta Optics, Inc., Japan). The samples were sliced through the center, parallel to the surface (about 5 mm of thickness), filled in the transparent Petri dish of 30 mm in diameter, and the CIE LAB color coordinate system L*, a*, and b* (L* = lightness, a* = redness, b* = yellowness) values were recorded. The L*, a*, and b* values of the standard white calibration plate were, respectively, 97.19, −0.21, and −0.13.

Texture parameters were measured using Lloyd Universal Tensile Testing Machine (LR-5K, Hampshire, England) fitted with a 0–1000 N load cell. The cooked patty samples were tempered to 25 ± 2°C and cut into squares of 30 mm with a thickness of 10 mm. The samples were compressed (60% of their height) at a crossed speed of 50 mm/min with a trigger of 0.01 N. Texture attributes (hardness, cohesiveness, springiness, and chewiness) were calculated from force–time deformation curves (Bourne, 1978).

The water activity of the patty tempered at 25°C was measured using a water activity meter (AquaLab Series 3, Washington, USA). The patty was sliced into samples of approximately 2 mm of thickness and 30 mm of diameter filled in a sample cup. The cup with the sample was kept in the airtight chamber of the equipment for about 5 min. The values of the water activity of the sample were noted from the display panel at equilibrium where a constant value is observed.

2.6 Sensory analysis

A sensory panel of 35 panelists of 21 and 28 years old, with 53.33% of males and 47.67% of females, willing to participate in the test was used to evaluate the effect of reducing fat levels on the sensory properties of the beef patty. Before the test, panelists recruited among the students of the University of Ngaoundere were trained on the product characteristics and terminology for 2 days with two sessions of 3 h per day. Codified samples (about 50 g each) were presented at room temperature (20 ± 2°C) to panelists in random order. Mineral water was provided to rinse the mouth between the samples. The sensory attributes evaluated were color, flavor, texture, juiciness, saltiness, and overall acceptability of samples. Panelists were instructed to evaluate on a 9-point scale ranging from extremely dislike to like extremely (flavor, overall acceptability); extremely tender to extremely hard (texture); extremely dry to extremely juicy (juiciness); pink to red (color); and slightly salty to extremely salty (saltiness). The images of the different samples were also taken to evaluate the fat distribution, thus the color homogeneity of the different samples.

2.7 Statistical analysis

For this study, a completely randomized factorial design 2 (water content of flour paste) × 4 (substitution rate) was used to assess the effect of fat substitution on beef patty properties. The experiment was carried out in triplicate, and the results were expressed as means ± SD. Data obtained were analyzed using Statgraphics® Centurion XVI software for analysis of variance. When main effects or interactions were significant, the Duncan multiple range was used to analyze significant differences between means. Correlations between variables were tested using the correlation table of Pearson, and principal component (PCA) analysis was carried out between the different quantitative variables using XLSTAT (version 17).

3 RESULTS AND DISCUSSION

3.1 Chemical composition of L. siceraria defatted seed flour

The proximate composition of DLSSF was evaluated, and the results are presented in Table 1. The defatted flour contains mainly protein (63.17 g/100 g DM) with 12.64 ± 0.46% of albumin, 55.06 ± 3.18% of globulin, 2.89 ± 0.41% of prolamin, and 21.29 ± 0.41% of glutelin (Noumo et al., 2022), which is characteristic of many cucurbits defatted seed cakes and flours (Achu et al., 2013; Noumo et al., 2017). Thus, DLSSF has good potential as a source of protein for human nutrition and food processing. The total sugar content of DLSSF (25.73 g/100 g DM) is higher than those reported by Achu et al. (2013) on defatted seed flour of five species of Cucurbitaceae from different regions of Cameroon. This difference could be due to the difference in variety or harvesting period. Thus, thanks to the low sugar and high protein content with all essential amino acids (Noumo et al., 2022), DLSSF as a fat-free flour has a good potential to improve the nutritional quality of foods like low-fat meat products by increasing their protein content and decreasing the energetic value. DLSSF has high ash content (6.22 g/100 g DM) as reported in Cucurbita seeds collected in Nigeria (6.42% and 7.45%; Blessing et al., 2011) and is also a source of crude fiber (4.12 g/100 g DM) and secondary metabolites (Table 1) like vitamin C (75.87 mg/100 g DM), polyphenols (637.3 mg/100 g DM), and phytates (820.2 μg/100 g DM). The presence of these compounds provides a bioactive potential to DLSSF; it can thus be used in food formulation as a source of antioxidant compounds to inhibit oxidative reactions in the food products or to promote the health of the consumers (Noumo et al., 2022).

| Parameters | |

|---|---|

| Dry matter (DM) (%) | 92.15 ± 1.01 |

| Protein (g/100 g DM) | 63.17 ± 2.13 |

| Total sugar (g/100 g DM) | 25.73 ± 0.18 |

| Ash (g/100 g DM) | 6.22 ± 0.67 |

| Total polyphenol (mg/100 g DM) | 637.3 ± 21.1 |

| Vitamin C (mg/100 g DM) | 75.87 ± 3.31 |

| Crude fibers (g/100 g DM) | 4.12 ± 0.31 |

| Phytates (μg/100 g DM) | 820.3 ± 56.1 |

- Note: The results are expressed as means ± SD.

3.2 Chemical composition, caloric values, and pH of the patty

The results for proximate composition and caloric values of different samples of patty formulated with or without paste of DLSSF are shown in Table 2. The moisture content of samples is significantly affected by the moisture content of DLSSF paste and fat substitutions rate (p ≤ 0.05). In general, there is a positive and strong correlation (p ≤ 0.05) between fat substitution rate and moisture content of the sample (r = 0.80). The moisture content increased with the fat substitution rate from 57.59% for the control (P0) to 68.99% for the sample with fat substituted at 100% by the paste of DLSSF containing 72% of water (P100:72). The increase in moisture content of beef patty with fat substitution rate may be due to the high moisture content of DLSSF paste and the water holding capacity of DLSSF (Rehab et al., 2011) and the high thermal stability of the gel obtained from DLSSF (Noumo et al., 2017). The increase in moisture content in meat products was also observed using different species of Cucurbitaceae (Cucurbita maxima) seed flour paste as a fat substitute in beef patty (Noumo et al., 2016) and using wheat fibers as a fat replacer in pork patty (Barretto et al., 2015).

| Samples | Moisture | Proteins | Lipids | Ash | Total sugars | Calorie |

|---|---|---|---|---|---|---|

| P0 | 57.59 ± 0.69a | 18.05 ± 0.43a | 21.24 ± 0.55f | 2.42 ± 0.02a | 1.70 ± 0.94ab | 270.5 |

| P25:60 | 62.88 ± 1.22b | 18.34 ± 0.35a | 13.82 ± 1.43e | 2.77 ± 0.17b | 2.21 ± 0.87bc | 206.9 |

| P50:60 | 65.22 ± 2.13bc | 20.14 ± 1.83ab | 10.15 ± 1.20d | 2.78 ± 0.18b | 2.71 ± 0.85bc | 183.2 |

| P75:60 | 67.59 ± 1.01cd | 21.97 ± 0.91bc | 5.89 ± 0.60c | 3.49 ± 0.86bc | 1.06 ± 0.85a | 145.6 |

| P100:60 | 68.77 ± 0.18d | 21.56 ± 0.59bc | 2.40 ± 0.34a | 3.17 ± 0.03c | 3.83 ± 0.62c | 123.6 |

| P25:72 | 64.12 ± 0.14c | 17.76 ± 0.25a | 15.16 ± 0.68e | 3.09 ± 0.69ab | 2.35 ± 0.84bc | 217.3 |

| P50:72 | 66.65 ± 0.76cd | 18.30 ± 0.65a | 9.29 ± 0.01d | 3.06 ± 0.05c | 3.39 ± 0.20c | 170.7 |

| P75:72 | 67.33 ± 1.93cde | 17.45 ± 1.53a | 6.48 ± 0.10c | 3.23 ± 0.17c | 4.43 ± 1.69cd | 146.2 |

| P100:72 | 68.99 ± 2.73cde | 20.92 ± 0.71bc | 3.20 ± 0.21b | 3.00 ± 0.65ab | 2.85 ± 0.80bc | 124.3 |

- Notes: The results are expressed as means ± SD. Values with different letters within a column are significantly different (p ≤ 0.05); P0: control; P25:60, P50:60, P75:60, and P100:60 samples containing defatted L. siceraria seed flour paste with 60% of moisture content used to replace fat at 25%, 50%, 75%, and 100%, respectively; P25:72, P50:72, P75:72, P100:72: samples containing defatted L. siceraria seed flour paste with 72% of moisture content used to replace fat at 25%, 50%, 75%, and 100%, respectively.

The substitution of fat with DLSSF pastes significantly (p ≤ 0.05) increases the protein content the of patty from 18.05 g/100 g WM (P0) to 21.97 g/100 g WM for the sample with fat substituted at 75% by the paste of DLSSF containing 60% of water (P75:60). This is due to the higher protein content in DLSSF paste than the replaced fat. However, at the same substitution rate, the protein content of the samples is not significantly (p ≤ 0.05) affected by the moisture content of DLSSF paste. Thus, unlike many substances (starchy products (Rehab et al., 2011), fibers (Cengiz & Gokoglu, 2007), gums (Kumar et al., 2007)) also used as fat replacers in meat products, DLSSF can improve the nutritive quality of beef patty by increasing the protein content. Similar results were reported in beef sausage using hull-less barley (Sanaa, 2015) and C. maxima defatted seed flour as a fat replacer (Noumo et al., 2016).

The lipid content of the different samples of beef patty presented in Table 2 is significantly (p ≤ 0.05) affected by the fat substitution and hydration rates of the DLSSF pastes. The fat content of the patty is negatively correlated to the fat substitution rate (r = −0.92) and the moisture content of the patty (−0.56). There is a general decrease in the lipid content of the patty from 21.24 g/100 g WM (P0) to 2.40 g/100 g WM for the sample with fat substituted at 100% by the paste of DLSSF containing 60% of water (P100:60). This change is due to the fat-free nature of DLSSF used as a fat replacer.

The ash content globally increases (p ≤ 0.05) with the fat substitution rate from 2.42 g/100 g WM (P0) to 3.49 g/100 g WM (P75:60) due to the high ash content of DLSSF (6.22 g/g DM). The increase in ash content in beef patties was noticed using potato flakes as a fat replacer (Rehab et al., 2011). There is a slight variation of total sugar content from 1.06 g/100 g WM (P75:60) to 4.43 g/100 g WM (P75:72). This may be due to the low sugar content in DLSSF, the dilution effect of water during the preparation of the paste, and the low proportion (less than 10% of the flour) of the DLSSF in the product formula. Moreover, the low value obtained in P75:60 could be due to variation in the leaching out of soluble sugar in water lost or Maillard reaction during cooking.

The calorific value (Table 2) of samples was calculated using the 4.02, 9, and 4 kcal/g coefficient for protein, fat, and carbohydrate, respectively. The caloric value of the cooked patty decreases significantly with the fat substitution rate (p ≤ 0.05), lying between 270.5 kcal/100 g WM (P0) and 123.6 kcal/100 g WM (P100:60) due to the contribution of fat to the total calorie of the beef patty. Indeed, the fat content of the samples is strongly correlated (r = 0.97) to the caloric value of the samples, and the contribution of fat to the caloric value of the patty decreases with fat substitution rate from 70.66% (P0) to 17.48% (P100:60). Thus, the use of DLSSF paste as a fat replacer reduces not only the fat intake but also the total calorie absorption by consuming beef patty and could prevent the occurrence of obesity for the consumers. Similar results were reported using sodium alginate as a fat replacer in pork patty (Kumar et al., 2007) and hydrated wheat bran and hydrated hull-less barley (Sanaa, 2015) as fat replacers.

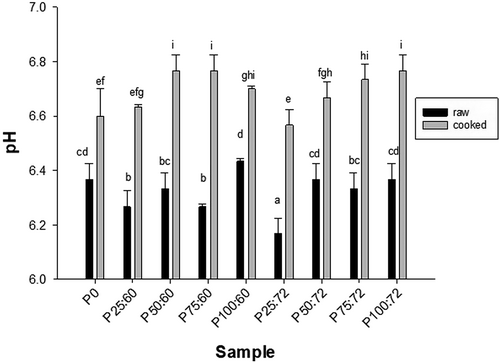

The effect of fat substitution rate and moisture content of DLSSF paste on the pH of raw and cooked beef patty is presented in Figure 1. The pH of the raw sample is influenced significantly (p ≤ 0.05) by the fat substitution rate. There is a low and positive correlation between the fat substitution rate and the pH of the patty (r = 0.54). In general, the pH of the raw sample increased with the fat substitution rate from 6.17 (P25:72) to 6.43 (P100:60), probably due to the higher pH value of DLSSF (6.37). The increase in pH of the raw patty with fat substitution can improve water retention capacity and sensory parameters of beef patty like juiciness and mouthfeel (Naga & Prabhakar, 2011). Similar results have been reported by several authors using plant protein as fat substitutes in meat products (Al-Juhaimi et al., 2016; Arun et al., 2008). After cooking, the pH of the sample increases in general, compared to the raw sample (Figure 1), and is also significantly influenced and positively correlated (r = 0.71) to the fat substitution rate. The pH of cooked samples ranges between 6.57 (P0) and 6.77 (P100:72). The reaction between organic acid and nitrogen-free carboxylic groups at high temperatures (Lewis et al., 1949), the evaporation of short chains of organic acids (Gąsecka et al., 2020) produced during the aging of meat (Stephan et al., 1997), or the thermal oxidation of some compounds like ascorbic acid (Yin et al., 2022), while cooking the patty may justify the increase in pH of the cooked samples.

3.3 Effect of DLSSF paste on the cooking yield, water activity, moisture, and fat retention of the patty

The cooking yield increases in general from 92.6% (P0) to 94. 259% (P50:60) (Table 3) and is significantly affected by the moisture content of DLSSF paste and fat substitution rate (p ≤ 0.05). The increase in yield with fat substitution rate can be attributed to the increase in the moisture content the of patty through the high water retention capacity and the stabilization of emulsion by DLSSF during cooking and the ability of DLSSF to form a heat-stable gel (Noumo et al., 2017) holding water and fat. However, the samples formulated with DLSSF hydrated at 60% have few variations in cooking yield; this could be due to their low moisture content with addition of small proportion of DLSSF paste with few variations in moisture retention affecting less the global weight of the sample. Indeed, 25% and 50% of fat substitution represent 5 and 10 total mass variations, respectively. Similar results were also reported using sodium alginate as a fat replacer in pork patty (Kumar et al., 2007) and wheat bran and hydrated hull-less barley as a fat replacer in beef sausage (Sanaa, 2015).

| Samples | Parameters | ||

|---|---|---|---|

| Cooking yield (%) | Moisture retention (%) | Fat retention (%) | |

| P0 | 92.64 ± 0.33abcd | 88.63 ± 1.74a | 81.77 ± 1.21d |

| P25:60 | 93.31 ± 0.63bcd | 91.79 ± 3.67ab | 92.50 ± 0.19e |

| P50:60 | 94.256 ± 0.28d | 90.92 ± 4.01ab | 88.04 ± 2.67e |

| P75:60 | 93.32 ± 1.47bcd | 93.01 ± 0.82b | 73.50 ± 2.50bc |

| P100:60 | 94.18 ± 1.13cd | 96.89 ± 1.65c | 65.11 ± 2.99a |

| P25:72 | 92.37 ± 0.63ab | 91.63 ± 0.67ab | 85.67 ± 3.13de |

| P50:72 | 92.22 ± 1.19ab | 92.55 ± 3.63abc | 88.28 ± 2.69e |

| P75:72 | 92.48 ± 0.15abc | 90.96 ± 2.50ab | 76.65 ± 3.59c |

| P100:72 | 91.60 ± 1.72a | 89.79 ± 2.58ab | 71.59 ± 2.92b |

- Notes: The results are expressed as means ± SD. Values with different letters within a column are significantly different (p ≤ 0.05); P0: control; P25:60, P50:60, P75:60, and P100:60 samples containing defatted L. siceraria seed flour paste with 60% of moisture content used to replace fat at 25%, 50%, 75%, and 100% respectively; P25:72, P50:72, P75:72, P100:72: samples containing defatted L. siceraria seed flour paste with 72% of moisture content used to replace fat at 25%, 50%, 75%, and 100%, respectively.

The effect of fat substitution on moisture and fat retention was evaluated and the results are presented in Table 3. Moisture and fat retentions are important for the texture, the juiciness, and the mouse feel of the cooked product. The moisture retention of the samples is significantly (p ≤ 0.05) affected by the moisture content of the flour paste and increases from 88.63% for the control (P0) to 96.889% (P100:60). The increase in moisture retention may be attributed to the formation of a heat-stable gel in which water is physically entrapped in the protein matrix resulting in less water release, as the moisture holding capacity of DLSSF increases during cooking (Noumo et al., 2017). Similar results were reported by Wan Rosli et al. (2011) after the incorporation of oyster mushrooms in the chicken patty, by Rehab et al. (2011) using potato flakes as a fat replacer in the beef patty, and by Al-Juhaimi et al. (2016) in beef burger containing moringa seed proteins. However, lower values of moisture retention were reported by Anwar et al. (2011) (51%–53%) using soy proteins in the beef burger, which may be due to the differences in functional properties like gelling and moisture holding capacities.

The fat retention rate of cooked beef patties (Table 3) is significantly (p ≤ 0.05) affected by the fat substitution rate. Above 50% of the fat substitution rate, the fat retention of the cooked patty decreases and may be due to the low stability of the batter obtained when the fat substitution rate is more than 50%. Indeed, the modification of the water/fat ratio in emulsions like patty may lead to the modification of the stability of the batter as it is a multiphase system. When there is a high level of water but little fat present (i.e., in a low-fat product), water separation may occur during thermal treatment of the product (Naga et al., 2009), leading to fluids loss. Similar results were obtained by Serdaroglu (2006) during the formulation of a low-fat beef patty using oat flour as a fat replacer. However, different results were obtained by Kumar et al. (2007) using sodium alginate as a fat replacer in pork patty. This may be due to the different mechanisms involved in fat retention. Gums like alginate hold fat in meat products by physical entrapment; thus, their effect on fat retention may be proportional to their content. However, proteins, the main component of the DLSSF, can improve fat retention through physical entrapment (Damodaran, 2017) or stabilization of the emulsion as emulsifiers (Verma et al., 2015), requiring a certain proportion of water/fat for their optimal activity.

3.4 Effect of fat substitution on color and texture parameters of cooked patties

The effect of DLSSF pastes as fat replacers on optical properties (lightness L*, redness a*, and yellowness b*) of the cooked patty was analyzed, and the results are presented in Table 4. The fat substitution rate significantly (p ≤ 0.05) influences the color parameters of the patty samples. Generally, there is an increase of L* values from 48.61 (P0) to 53.66 (P50:60). The increase of L* value with fat substitution may be related to the wither color of the DLSSF and the partial swelling of the flour granule during cooking as reported in gilthead sea bream patties containing corn flour (Makri & Douvi, 2014). Indeed, the core temperature during the cooking of the patty (72°C) is lower than the gelation temperature of the defatted seed flour (85.45°C) (Noumo et al., 2017). The increase in brightness could also be due to the dilution of the meat pigment (Rehab et al., 2011) using DLSSF paste. An increase in lightness was also reported in beef burgers containing moringa seed flour (Al-Juhaimi et al., 2016).

| Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Color | Texture | ||||||

| Samples | Lightness (L*) | Redness (a*) | Yellowness (b*) | Hardness (N) | Cohesiveness | Springiness index | Chewiness |

| P0 | 48.61 ± 1.40a | 8.14 ± 0.23c | 17.55 ± 0.67a | 116.60 ± 1.66cd a | 0.26 ± 0.03a | 0.68 ± 0.01bc | 13.01 ± 0.57bc |

| P25:60 | 52.87 ± 0.93bc | 7.20 ± 0.42ab | 18.12 ± 0.53a | 120.18 ± 2.88d | 0.36 ± 0.02b | 0.71 ± 0.03a | 18.64 ± 0.70b |

| P50:60 | 53.66 ± 0.51c | 7.38 ± 0.40abc | 20.15 ± 0.12cd | 118.51 ± 3.76d | 0.37 ± 0.01b | 0.75 ± 0.02cde | 19.11 ± 1.76cde |

| P75:60 | 53.52 ± 0.49c | 7.09 ± 0.25abc | 20.49 ± 0.22cd | 116.67 ± 1.83cd | 0.38 ± 0.02b | 0.80 ± 0.02b | 17.35 ± 1.18b |

| P100:60 | 53.28 ± 0.52bc | 7.45 ± 0.17d | 19.48 ± 0.40b | 114.26 ± 2.91c | 0.37 ± 0.01b | 0.77 ± 0.01e | 15.55 ± 0.64e |

| P25:72 | 51.85 ± 0.35ab | 7.69 ± 0.64bc | 20.61 ± 0.16d | 110.46 ± 3.36c | 0.37 ± 0.01b | 0.69 ± 0.03b | 15.37 ± 0.46b |

| P50:72 | 52.04 ± 1.37bc | 7.10 ± 0.15ab | 19.86 ± 0.35bc | 103.17 ± 2.18bc | 0.40 ± 0.02c | 0.72 ± 0.02cd | 19.78 ± 0.01cd |

| P75:72 | 52.58 ± 0.42bc | 7.03 ± 0.51ab | 20.20 ± 0.24cd | 87.20 ± 3.99a | 0.39 ± 0.01bc | 0.74 ± 0.03de | 14.77 ± 0.09de |

| P100:72 | 51.53 ± 0.27b | 6.69 ± 0.91a | 20.28 ± 0.30cd | 78.49 ± 0.48a | 0.39 ± 0.01b | 0.75 ± 0.01a | 11.73 ± 1.13a |

- Notes: The results are expressed as means ± SD. Values with different letters within a column are significantly different (p ≤ 0.05); P0: control; P25:60, P50:60, P75:60, and P100:60 samples containing defatted L. siceraria seed flour paste with 60% of moisture content used to replace fat at 25%, 50%, 75%, and 100%, respectively; P25:72, P50:72, P75:72, P100:72: samples containing defatted L. siceraria seed flour paste with 72% of moisture content used to replace fat at 25%, 50%, 75%, and 100%, respectively.

In general, there is a slight decrease in a* values (redness) with a fat substitution rate from 8.14 (P0) to 6.69 (P100:72). The reduction of redness of the samples by replacing fat with hydrated DLSSF may be due to the dilution of myoglobin concentration (Al-Juhaimi et al., 2016) or to the development of other compounds (deoxymyoglobin, oxymyoglobin, sulfomyoglobin, metmyoglobin, nitrosylhemochrome, metmyoglobin-NO2, etc.) during cooking of the samples containing DLSSF paste, induced by non-heme iron in DLSSF (Schwartz et al., 2017). This may justify the increase in b* value with fat substitution rate (p ≤ 0.05) from 17.55 (P0) to 20.61 (P25:72). Similar results were reported in beef burgers containing moringa seed flour (Al-Juhaimi et al., 2016).

During the heating of meat products, meat proteins are denaturized, which causes various changes in the structure of the meat (Radoslav et al., 2014) and can be affected by the presence of non-meat ingredients introduced during formulation (Ramadhan et al., 2011). Between the different properties, the texture is a key quality attribute used in the fresh and processed meat industry to assess product quality and acceptability. The texture profile analysis (TPA) is widely used for texture parameters (hardness, springiness, cohesiveness, and chewiness) assessment in food. The effect of fat substitution rate and moisture content of DLSSF pastes on texture parameters is presented in Table 4. Generally, all textural attributes investigated are influenced by the fat substitution rate and the moisture content of the DLSSF paste.

The hardness of beef patty is significantly (p ≤ 0.05) and negatively correlated to the fat substitution rate (r = −0.63) and moisture content (r = −0.72) of DLSSF paste. The hardness decreases from 116.6 N (P0) to 78.49 N (P100:72) with fat substitution rate and could be attributed to the higher moisture content of DLSSF paste compared to the replaced fat and the high moisture retention capacity of the DLSSF (Noumo et al., 2017) used an as fat replacer. Thus, high degree of hydration increases the softness of the product. In fact, when fat content is reduced by increasing the proportion of added water while keeping the amount of protein content constant, low-fat products become tender and soft (Kumar & Sharma, 2004). Moreover, the addition of non-meat ingredients in meat products may dilute meat protein and modify their aptitude to form gel during cooking with a subsequent reduction of the hardness of the cooked products (Barretto et al., 2015). Moreover, the decrease in hardness may be due to the replacement of beef kidney fat known as hard fat (Feiner, 2006). However, an increase in hardness was reported using dry soy protein concentrate and citrus fiber as a fat replacer in frankfurter-type sausages (Cengiz & Gokoglu, 2007) and could be due to the low moisture content of the sample with the addition of these fat replacers.

In general, the springiness index of beef patty increases with the level of fat substitution from 0.70 for control (P0) to 0.80 for the sample with fat substituted at 75% by the DLSSF paste containing 60% of moisture (P75:60). The addition of DLSSF paste in beef patty as fat replacers also increases the cohesiveness of samples. Beef patty formulated with 50% of fat substitution (P50:72) recorded the highest values of cohesiveness (0.40), whereas the control recorded the lowest value (0.26). The moisture content of the paste also affected significantly (p ≤ 0.05) the cohesiveness of the samples; the patties formulated with the paste containing 72% of moisture recorded higher values for cohesiveness. The fat substitution rate and the moisture content of the pastes significantly affected the chewiness of the patty. The chewiness decreases with the increase of moisture content of DLSSF paste, and the sample with fat substituted at 50% by the paste containing 72% of moisture (P50:72) recorded the highest value of chewiness value (19.78). The increase in springiness and cohesiveness may be due to the gelling and binding nature (Kumar & Sharma, 2004) of the DLSSF or the improvement of the protein network of the gel during cooking by the development of disulfide bonds between seed flour proteins and myofibrillar proteins. Indeed, L. siceraria seed flour proteins contain cysteine (Noumo et al., 2022), which can undergo polymerization via sulfhydryl–disulfide interchange reactions during heating with meat protein, facilitated by the presence of nitrated salt (Pegg & Shahidi, 2000), and form a continuous covalent network upon cooling (Andiç et al., 2010). Furthermore, DLSSF can form heat-stable gel stabilized by sulfur bonds (Noumo et al., 2017), resulting in a multiple gel complex formation in the cooked patty, with the proteins from DLSSF producing a second gel structure that acts as a filler for the primary meat protein gel network to stabilize meat emulsion system (Darkos et al., 2007). Similar results have been reported by Arun et al. (2008) using soybean paste in goat meat nuggets and by Andiç et al. (2010) in meat patty containing whey and skimmed milk powders.

3.5 Sensory properties

The effect of fat substitution on sensory attributes and acceptability of the patty samples is presented in Table 5. The substitution of fat with DLSSF paste affects the sensory attributes of the beef patty. The hardness of the samples decreases with the reduction of fat content from 7.06 (P0) to 5.34 (P100:72). This result is similar to those obtained with instrumental measurement (TPA) with a positive correlation between both values of hardness (r = 0.69). However, the low value of the correlation between the instrumental value and the sensory scores of the hardness could be due to the subjective nature of sensory evaluation, with score depending on the sensitivity of the panelist, and the homogeneity of the product. Indeed, instrumental measurements can detect few variations in homogeneity than sensory evaluation. The reduction of the hardness of samples with the increase of fat substitution rate is probably due to the subsequent increase in moisture content of samples while replacing fat with DLSSF paste and the reduction of hard saturated fat proportion with the replacement of the kidney fat.

| Samples | Flavor | Hardness | Saltiness | Juiciness | Color | Acceptance |

|---|---|---|---|---|---|---|

| P0 | 5.73a | 7.06cde | 5.02a | 5.26a | 5.70ab | 5.30a |

| P25:60 | 6.15b | 6.34bcd | 5.92cd | 6.39bc | 6.23b | 6.48abc |

| P50:60 | 7.29cd | 7.15de | 5.46ab | 7.68de | 6.86cde | 6.99bc |

| P75:60 | 7.19c | 7.38def | 5.52bc | 7.01cd | 7.36e | 7.39cd |

| P100:60 | 7.01bc | 7.18de | 5.92bcd | 7.88de | 7.31e | 8.23d |

| P25:72 | 6.19b | 6.37bcd | 5.44ab | 6.54b | 6.43bc | 5.90ab |

| P50:72 | 7.43cd | 5.84ab | 6.01cd | 7.07cde | 6.29b | 6.71b |

| P75:72 | 7.65d | 5.60ab | 5.63bcd | 7.72de | 6.84cde | 7.14bc |

| P100:72 | 7.56d | 5.34a | 6.14d | 8.31e | 7.10de | 7.96cd |

- Notes: The results are expressed as means ± SD. Values with different letters within a column are significantly different (p ≤ 0.05); P0: control; P25:60, P50:60, P75:60, P100:60 samples containing defatted L. siceraria seed flour paste with 60% of moisture content used to replace fat at 25%, 50%, 75%, and 100%, respectively; P25:72, P50:72, P75:72, P100:72: samples containing defatted L. siceraria seed flour paste with 72% of moisture content used to replace fat at 25%, 50%, 75% and 100%, respectively.

The sensory analysis also revealed that there is a general increase in the score of the color of the patty with the increase of fat substitution from 5.70 (P0) to 7.36 (P75:60). This may be due to the use of the whitish DLSSF paste to replace yellowish kidney fat, resulting in a lighter product with few effects on the pink color of the cured meat, or to the improvement of color homogeneity of the low-fat patties even with the same color intensity. This may justify the differences between values obtained with instrumental measurement and sensory evaluation.

The substitution of fat with DLSSF improves the juiciness (5.26 for P0 to 8.31 for P100:72) and the flavor (5.73 for P0 to 7.65 for P75:72) of the beef patty. The juiciness is positively correlated to the moisture content of the samples. The improvement of flavor could be due to the reduction of the content of hard fat (kidney fact) rich in stearic acid (about 20%) with an intense and negative effect on meat flavor (Feiner, 2006). Moreover, L. siceraria seed flour proteins are important sources of glutamate/glutamine (Noumo et al., 2022), a precursor of the monosodium glutamate, one of the umami substances that contribute to the delicious mouthwatering taste of cooked meat and meat products (Lindsay, 2017). Moreover, cysteine present in the L. siceraria seed flour proteins is the precursor of some important compounds of cooked meat and meat products flavor like thiophenes, dithiolanones, alkyl-sulfides, mercapto-ketones, and furans formed mainly in the presence of other sources of carbonyl compounds (pentoses) (Madruga, 1997).

The substitution of fat with DLSSF paste increases the general acceptance of patty from 5.30 for P0 to 8.23 for P100:60. The sensory panelists rated the samples P100:72, P75:60, and P100:60 as the best samples. The correlation analysis revealed that panelists' assessment of the overall acceptability of the patty is strongly influenced by its color (r = 0.56), flavor (r = 0.71), and juiciness (r = 0.89).

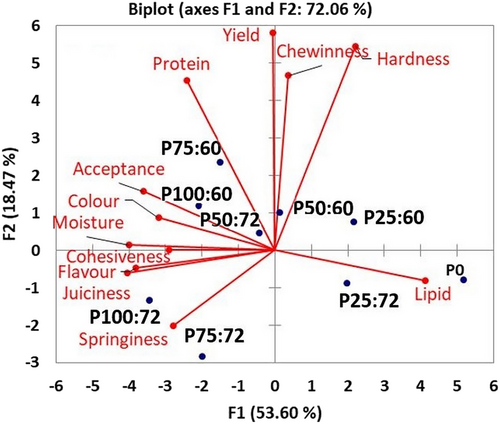

To study the relationship between the different sensory, physicochemical, and technological attributes of the samples, the PCA was conducted (Figure 2). Principal components 1 and 2 explained, respectively, 53.68% and 18.47% of the variability among the samples. The control (P0) is characterized by the highest fat content, and the increase of fat substitution rate increases the moisture and protein contents of the patty as well as juiciness, flavor, general acceptability, cooking yield, and cohesiveness. The sample P100:60 is the most accepted.

4 CONCLUSION

DLSSF contains mainly protein; the hydrated paste of DLSSF used as a fat replacer improves the cooking yield, the protein content, and physical and sensory properties of beef patty without off-flavor. DLSSF used as a fat replacer in the production of low-fat beef patty decreases the fat content and energetic values of the beef patty. For the best improvement of nutritive, technological, and sensory properties of beef patty, the kidney fat must be replaced at 75%–100% by the DLSSF with 60% of water.

ACKNOWLEDGMENTS

Noumo Ngangmou Thierry gratefully acknowledges The World Academy of Sciences (TWAS), Italy, and the Council of Scientific and Industrial Research (CSIR), India, for the award of TWAS-CSIR Sandwich Postgraduate Fellowship (grant number 3240287326).

CONFLICT OF INTEREST STATEMENT

The authors declare no conflict of interest for this article.