Wireless real-time monitoring of malolactic fermentation in wine barrels: the Wireless Sensor Bung system

Abstract

Background and Aims

Malolactic fermentation (MLF) is a metabolic process promoted in wine by lactic acid bacteria, which can improve wine quality. The MLF, however, must be properly monitored and handled in a timely manner as the bacteria remaining in the wine can produce off-flavours. This work describes the Wireless Sensor Bung (WSB), a system for monitoring remotely wine parameters in barrel and a methodology for monitoring MLF in real time.

Methods and Results

A wireless system to measure wine deacidification because of MLF was developed. The WSB was calibrated and tested in an experiment in a commercial cellar to assess the system performance in a barrel. The system enabled an exhaustive monitoring of wine deacidification associated with MLF.

Conclusions

The WSB system was demonstrated to be an effective tool for monitoring remotely MLF in barrel.

Significance of the Study

The WSB provides timely information on the completion of MLF, so that lactic acid bacteria can be eliminated from wine before they produce undesirable metabolites.

Introduction

The understanding of the complex transformation of grape must into wine requires the monitoring and controlling of the many steps of this process. The process of high-quality wine production is usually resource-intensive and time-consuming, and requires accurate planning to obtain the desired quality. The winemaker needs to collect as much information as possible about the whole process.

Malolactic fermentation (MLF) is a metabolic reaction that commonly occurs after the completion of alcoholic fermentation, and its principal effect is a reduction in wine acidity through the conversion of L-malic acid, a dicarboxylic acid, to L-lactic acid, a monocarboxylic acid, with production of carbon dioxide. Lactic acid bacteria, such as Oenococcus, Leuconostoc, Pediococcus and Lactobacillus spp., promote MLF, and although it is regarded as a secondary fermentation process, it plays a primary role in the production of most red wines, of some white wines from cultivars such as Chardonnay and of some sparkling wines, contributing to the complexity of the wine taste and flavour (Rodriguez et al. 1990, Laurent et al. 1994, Sauvageot and Vivier 1997), and conferring a degree of microbiological stability to the wine (Henick-Kling 1995).

Lactic acid bacteria remaining in wine after the end of MLF could cause microbiological problems (Kunkee 1991, Davis et al. 1988, Maicas et al. 1999a, Liu 2002, Ugliano et al. 2003), and promote the production of undesirable volatile compounds, such as volatile acidity, mousy taint, bitterness, geranium notes, oily and slimy texture, overt buttery characters (Murat et al. 2007, Bartowsky and Pretorius 2008) and the formation of biogenic amines (Guerrini et al. 2002, Liu 2002, Marcobal et al. 2006) that are toxic to human health (Bauza et al. 1995, Silla Santos 1996, Bodmer et al. 1999).

For these reasons, the timely determination of the completion of MLF is of primary importance so that winemakers can promptly stabilise the wine and remove or inhibit the bacterial biomass after malic acid depletion, through filtration or addition of sulfites or lysozyme (Mira de Orduña 2001). Several methods are available to monitor and identify the completion of MLF, such as paper chromatography, thin layer chromatography, high-performance liquid chromatography and enzymatic chromatography, but they require time and resources in the winery for periodic sampling of tank or barrel, and for analysis. Furthermore, in the wine-ageing area, barrels are often stacked at least five or six high, obliging the operator to work under hazardous conditions in order to sample and monitor the wine.

The aim of this work is to describe the functionalities of the Wireless Sensor Bung (WSB) system for the remote monitoring of wine parameters in barrel, and to test the efficacy of this methodology for the real-time monitoring of MLF based on the detection of variations in pH that occur during MLF.

Materials and methods

Description of the WSB system

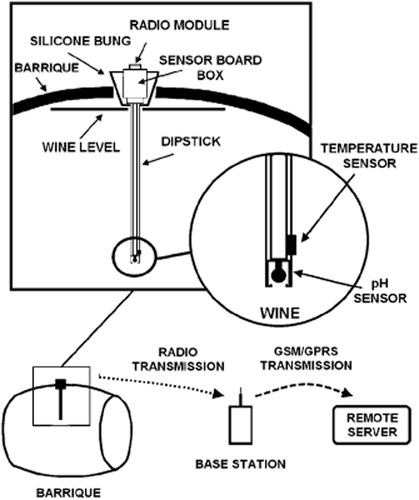

The developed WSB is constructed of a sensor node housed in the silicone bung of the barrel and a receiving base station. The sensor node is composed by a sensor probe fixed to a case that holds a sensor board with analogue and digital channels to connect sensors for data acquisition, and a radio module for wireless data transmission (Figure 1).

Schematic of the Wireless Sensor Bung system. GSM/GPRS, global system for mobile communications/general packet radio services.

The sensor probe structure is a polycarbonate dipstick (PC 1000; Quadrant Technology, Tielt, Belgium) that is physiologically inert and suitable for food contact, of 2-cm diameter and 30-cm long. Temperature and pH sensors are placed at the end of the dipstick in direct contact with wine approximately in the middle of the barrel (Figure 1).

The temperature sensor is a thermistor, with a measuring range of −40 to +80°C, resolution of 0.1°C, and accuracy of ±0.3°C between the range of 10 and 30°C.

The pH electrode sensor (PHE 1304; Omega Engineering Inc., Stamford, CT, USA) has a measuring range of pH 0–14, resolution of 0.01 pH and accuracy of ±0.02 pH. These sensors were selected as suitable options for the WSB considering signal stability, ruggedness, and low maintenance and cost.

The WSB receiving base station utilises a coordinator device with a receiving radio module, which has a bridge function between the wireless node and an existing data management infrastructure (PC, local area network or wireless local area network), and it is interfaced via USB connection directly to a PC for data storage and visualisation (Figure 1).

The software management system installed in the receiving PC allows users to interact with the node, and provides data storage and real-time visualisation. The output of the program is a text file that can be customised to user needs, with a summary of the parameters acquired, such as recording date, time, battery voltage, temperature and pH values measured by the WSB; an alarm signal (short message service) could also be received. The WSB acquires wine parameters (temperature and pH), and the data package is sent to the receiver by a radio module; the base station receives and transmits data to a remote central server with a global system for mobile communications/general packet radio services industrial modem. The WSB uses the Institute of Electrical and Electronics Engineers (IEEE) 802.15.4 communication protocol at 2.45 GHz (offset quadrature phase-shift keying modulation and bit rate of 250 kbps net) divided into 16 channels and manages data transmission conflicts using a CSMA/CA (Carrier Sense Multiple Access/Collision Avoidance) protocol.

The maximum transmission distance in an open space and in the absence of noise is about 150 m using a power of 0 dBm (1 mW) and an integrated ceramic antenna on the peripheral device (gain = 1 dB). The communication between the wireless device and base station is a star type wireless network, and the base station could potentially manage up to 250 wireless sensor nodes.

Calibration of the WSB system

A battery supply test and a laboratory calibration of the WSB sensors were realised. The battery supply test was done to check the duration of the battery life; the WSB was set with a 5 s acquisition and transmission time to evaluate the energy autonomy. The calibration procedure was done in the laboratory to verify the precision and accuracy of the WSB temperature and pH sensors.

The temperature sensor was calibrated by immersing the sensors in a Haake F3 thermostatic bath (Haake GmbH, Karlsruhe, Germany), containing a solution of 50% water and 50% ethylene glycol; a temperature reference sensor type PT100 four-wire was connected to a 3468A Multimeter HP (Hewlett-Packard Company, Palo Alto, CA, USA). The first measurement was made with the liquid of the thermostatic bath at room temperature, after which temperature was measured at different points of the scale between +10°C and +40°C.

The pH sensor was calibrated in the thermostatic bath, through sensor normalisation with the following buffer solutions: pH 2.00 ± 0.05 at 20°C, pH 3.00 ± 0.02 at 20°C, pH 3.56 ± 0.02 at 25°C and pH 4.00 ± 0.02 at 25°C (Titolchimica S.p.A., Pontecchio Polesine, Rovigo, Italy) (UNI EN ISO 9001:2008, UNI EN ISO 13485:2004 and UNI EN ISO 14001:2004). Buffer solutions for sensor calibration were chosen to approximate the normal range of wine pH values. Calibration data were acquired at 10, 15 and 20°C to evaluate the effect of temperature on the pH measurement in the liquid medium. Moreover, the WSB system was subjected to a calibration test directly in Sangiovese red wine with the laboratory reference electrode (Hamilton Electrochemical Sensor, model Flushtrode; Hamilton Company USA, Reno, NV, USA) mounted on a Lab Instruments Orion Model 720 (Lab Instruments s.r.l., Castellana Grotte, Bari, Italy). The test was conducted through titration with a strong acid solution (HCl 0.1 M) and a strong base solution (NaOH 0.1 M) from pH 2.0 to pH 4.5, and from pH 4.5 to pH 2.0, thus evaluating the data quality and response time of the sensor relative to the reference under operational conditions.

Application of the WSB system in a wine barrel

The functionality of the WSB was tested and verified in 2011 at Azienda Agricola Comparini winery, in Empoli, near Florence, Tuscany, Italy. In the wine-ageing area of the winery, a pilot system network was established with one WSB node and a base station. In this trial, the distance transmission was kept to 10 m, and the base station was placed behind a cellar wall, which separated the receiver from a clear view of the wireless node, evaluating the interference because of the cellar architecture.

The WSB node was inserted into a 225 L Bordeaux-style barrique, which is the most common barrel, containing a batch of Sangiovese red wine. An analytical certificate for the wine batch ensured that MLF had not yet taken place.

The experiment started on 13 June (day of the year (DOY) 164) and ended on 10 August (DOY 222). The WSB system was set to acquire data (temperature and pH) every 5 s. The system data acquisition was set so high during the experiment in order to test the system reliability, the linearity of data acquisition and the power consumption of the WSB system in operating mode.

To verify the WSB system performance and to compare the pH values acquired by the system during the experiment against that obtained by standard laboratory analysis, the wine was sampled periodically nine times during the progress of MLF. The wine was sampled at approximately 10:00 am each sampling day to ensure uniformity for the laboratory analysis. Each wine sample of 300 mL was taken with a glass pipette, slightly raising the bung, without releasing the sensor head from the wine, just to allow the insertion of the pipette into the hole of the barrique. The wine samples were analysed at a laboratory (Isvea s.r.l., Poggibonsi, Italy) accredited to analyse musts and wines (UNI CEI EN ISO/IEC 17025:2005 and UNI EN ISO 9001:2008). Each wine sample was subjected to the following analyses published in the Organisation Internationale de la Vigne et du Vin compendium methods (Organisation Internationale de la Vigne et du Vin 2012): lactic acid bacteria population (ref. method OIV MA-F-AS4-01 2009), L-malic acid (ref. method OIV MA-AS313-11 2009), L-lactic acid (ref. method OIV MA-AS313-07 2009) and pH value (ref. method OIV MA-AS313-15 2009).

Statistical analysis was carried out with R software (R version 2.14.1; The R Foundation for Statistical Computing, Vienna, Austria); the relationships between variables were analysed by linear regression (F-test).

Results

The calibration of the WSB temperature and pH sensors showed a high linearity with the reference sensors and the buffer solution at known pH (data not shown). The temperature sensor calibration parameters (y = 1.0289x − 0.9336; R2 = 0.999, P < 0.001) demonstrated high precision and response stability of the sensor, allowing system requirements to be met optimally. The pH sensor was calibrated with four buffer solutions at known pH, at 10, 15 and 20°C in the thermostatic bath, showing a high correlation with the data obtained from the reference sensor (y = 0.9427x + 0.1394; R2 = 0.998, P < 0.001).

The power supply test with acquisition and transmission frequency at 5-s intervals demonstrated that wine monitoring was possible for eight consecutive days. After the eighth day, the battery level lowered progressively from 3.4 V down to 2.4 V, when data acquisition and transmission were interrupted. The WSB acquired 17 280 observations per day of wine temperature and pH, and data were then averaged to achieve a daily value.

In operational configuration, four values per day of pH and temperature could be sufficient to perform an exhaustive monitoring, considering that the changes in wine chemical and physical characteristics are slow; such a setting ensures around 75 days of system efficiency in terms of power supply.

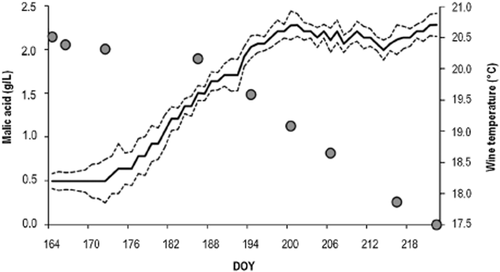

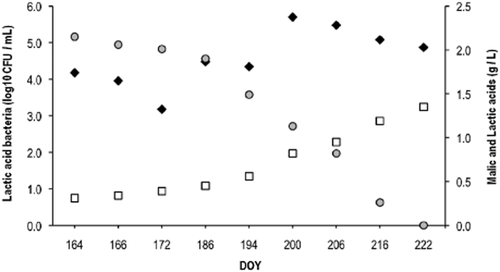

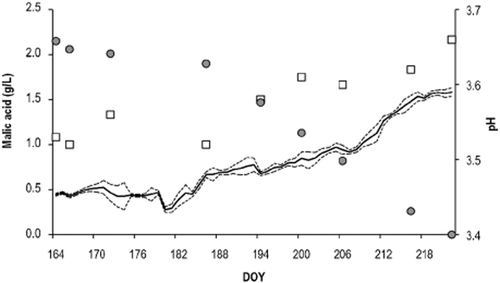

The laboratory analysis of the nine wine samples taken during the experimental period revealed that the malic acid concentration commenced to decrease at the beginning of the experiment and accelerated at the beginning of July (DOY 186), when the temperature of the wine reached 20°C ± 0.5; on DOY 222, malic acid concentration was no longer detectable (Figure 2). Moreover, the lactic acid bacteria population increased corresponding to the decrease in malic acid: bacteria concentration peaked at DOY 200, and then decreased with the reduction in malic acid and the increase in lactic acid (Figure 3). As expected, the pH increased during MLF, as confirmed by both laboratory analysis and WSB observation (Figure 4), and stabilised at the end of MLF (DOY 216–222).

Malic acid concentration (•), determined in the wine laboratory, and wine temperature (—), acquired continuously by the Wireless Sensor Bung, of the wine in barrique. Dotted lines represent the standard deviation of the daily values of the wine temperature. DOY, day of the year.

Lactic acid bacteria population (♦) and the concentration of malic acid (•) and lactic acid (□) of the wine in the barrique, determined in the wine laboratory, of the nine samples from 13 June (day of the year (DOY) 164) to 10 August (DOY 222).

Malic acid (•) concentration and wine pH measured by the wine laboratory (□) and wine pH measured by the Wireless Sensor Bung (—). Dotted lines represent the standard deviation of daily values of the wine pH during the time in barrique. DOY, day of the year.

The observed difference in absolute pH value between that of the laboratory analysis and of the WSB depended on the intrinsic calibration of the two pH sensors. The variation in pH during the experimental period showed a similar behaviour when measured with the two instruments (Figure 4).

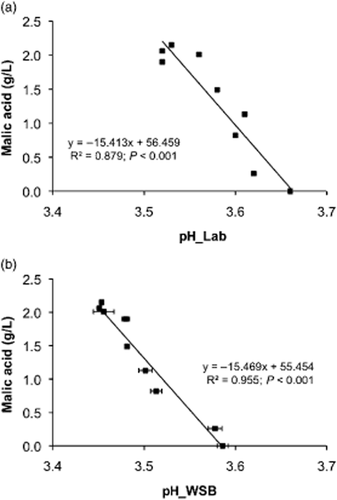

To assess the system potential in terms of MLF discrimination, the malic acid concentration data, supplied by the laboratory, were considered as an indicator of fermentation progress. These values were correlated with both pH data acquired by the wireless system and that from laboratory analysis. The correlation between the pH data and malic acid concentration was higher for the WSB acquisition than for the laboratory analysis (R2 = 0.955 and R2 = 0.879, respectively, P < 0.001) (Figure 5).

(a) Correlation of the malic acid concentration and pH measured by the wine laboratory (R2 = 0.879, P < 0.001); (b) Correlation of the malic acid concentration and pH measured by the Wireless Sensor Bung (WSB) (R2 = 0.955, P < 0.001).

System deployment has shown that the experimental conditions, in terms of transmission distance and architecture interference of the cellar walls, have allowed a regular reception of data by the WSB.

Discussion

The WSB system showed good performance in terms of data transmission, power supply management, and accuracy and stability of the data acquired. The trial in the barrique confirmed the ability of the WSB to detect and monitor MLF, providing real-time remote information about the beginning, progress and end of MLF. Continuous monitoring of wine pH during MLF by the WSB allowed the end of fermentation to be identified, thus providing timely information in order to eliminate lactic acid bacteria from the wine before they can cause the development of undesirable metabolites related to wine quality.

The importance of monitoring and tracking quality production has already been highlighted by several authors. Anastasi et al. (2009) presented a wireless sensor network that follows wine cycle production from grapes to bottle, through wireless nodes located in both the vineyard and winery. In this system, however, monitoring of wine was limited to temperature and relative humidity of the wine-ageing area, thus neglecting the winemaking process and the traceability of the same product in different barrels. Esti et al. (2004), and more recently Gamella et al. (2010) and Albanese et al. (2011) described the monitoring of oenological processes by means of electrochemical biosensors, which have shown excellent accuracy and reliability. They generally require, however, treatment of the wine sample with a buffer solution, thus making the system more complex by integrating a flow injection system not suitable for the low-cost and small-sized needs of wireless sensor networks. In this sense, the WSB device, remaining in contact with the wine throughout the duration of MLF, enables pH and temperature probes to reach equilibrium, ensuring more accurate readings with respect to spot laboratory analyses, thus minimising sampling errors as pointed out by Frisby et al. (2005).

If we consider that WSB system features could be implemented in a network for real-time monitoring of up to 250 barrels, an operational adoption of this system presents a consistent reduction of manual operations of wine sampling and could lead to a substantial reduction of laboratory analyses for monitoring MLF.

Furthermore, from a technological point of view, the presence of analogue and digital channels in the WSB hardware makes it possible to integrate other types of sensors, allowing the measurement of several oenological parameters and enabling the winemaker to monitor all stages of the winemaking process with a wireless methodology. In addition, the WSB platform implements relay channels, which could provide the automation of some manual operations by activating/deactivating processes following thresholds of a monitored parameter. An example of relay application is the dissolved oxygen or sulfur dioxide management in wine, in terms of quantity and time of gas additions. Another opportunity offered by the system is to provide a tool to ensure traceability, which is a prerequisite in the production of quality wine. This could be achieved by implementing an onboard memory for recording product information and through the development of a peripheral nodes triaxial localisation system, which could give the exact location of each barrel in the wine-ageing area.

The experiment described in this work utilises a WSB system with a 30-cm dipstick that measures wine parameters in the middle of the barrique. The system, however, could be adapted to other barrel and tank sizes by modifying the length of the dipstick.

Conclusions

The WSB has demonstrated good performance for monitoring MLF in real time. The high flexibility and possibility of customisation of the WSB offers significant opportunity to meet the needs of any type of control of the wine production chain, with the particular advantage of the versatility and low cost of wireless sensor networks.

Considering the overall costs of wine production management and control in terms of manpower, sampling and chemical analyses, the proposed system represents an attractive solution for monitoring winemaking processes.

The WSB presented here could be expanded to create a wireless sensor network to monitor several barriques simultaneously and supply real-time information on wine evolution to the winemaker for each barrel in the wine-ageing area assuring quality preservation.

Acknowledgements

The authors gratefully acknowledge Dr Marco Salvini (Advanced Microwave Engineering s.r.l., Florence, Italy) for the technical support in the development of the pilot system, Dr Agostino Cavazza (Edmund Mach Foundation – FEM, Trento, Italy) for constructive comments and suggestions during the WSB development, and to Azienda Agricola Comparini winery where the experiment took place.