A highway bridge—A database for digital methods

1 MOTIVATION

With the advent of digital twins, building information models (BIM), and structural health monitoring (SHM) systems, the bridge maintenance management is entering a new era in Germany. The key to leveraging the existing tools to their full potential is to combine them, and to create all-in-one digital platforms that organize existing knowledge using BIM, incorporate real-time measurements from SHM, and give feedback to the structural model and designer. In addition to structural engineers, bridge operators, contractors, and other stakeholders should be guaranteed access through universal data formats and intuitive visualizations. This will avoid information loss, speed up standard processes, allow for an automated condition assessment in between inspections, and enable a prediction (and possibly deceleration) of degradation processes. To pave the way for future research in industry and academia, HSU/UniBw H has decided to instrument a German highway bridge with comprehensive monitoring systems to create a finite element model and to digitize all available information using BIM. All data will be made available and, therefore, offer a benchmark study for coupling joints of internal tendons and external tendons among other features.

2 BRIDGE DESCRIPTION

The bridge is part of the German federal highway system (the Autobahn 7) and was built in 1972 (see Figure 1). It has a length of 245 m, a width of 22.95 m, and a clear height of 11.6 m. The deck is divided into seven spans, where the end spans measure 30.0 m and the central spans 37.0 m in length. The bridge is divided into two substructures, the East and the West viaduct, through a gap. Both superstructures consist of double-web plate girders, prestressed in the longitudinal and the transverse directions. There are 14–15 tendons per beam in the longitudinal direction. The bridge was originally designed for a traffic load corresponding to Bridge Class 60, as per the German standard DIN1072 (Edition 1967).1 Cracks were first observed at the coupling joints during inspection in 1995. Since 2005, the existing cracks have been monitored and documented closely during on-site inspections. In 2015, the bridge was reinforced with external tendons along the main girders. During the reassessments, the load-bearing capacity could be proven for the load case LM1 as per DIN EN 1991-2 (EC, DIN EN 1991-2/NA), given the external prestressing tendons.2

3 MONITORING SYSTEM

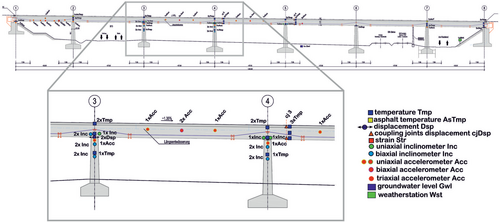

The monitoring system aims to monitor various materials or structural, geotechnical, and environmental variables. Particular attention is put on the monitoring of coupling joints, through local displacement sensors (see Table 1). Simultaneously, the stiffness and carrying capacity of both the superstructure and the piers are under constant scrutiny, employing modal properties, deflection, inclination, and strain as key indicators. Therefore, acceleration sensors are placed in two central spans and in the end spans where relevant modal modes have their maxima. Inclination sensors are installed in the same spans at points of zero moments where the highest inclinations are expected.

| Measurement quantity | Count channels | Frequency | |

|---|---|---|---|

| A | Strain | 26 | 200 Hz |

| B | Vibration | 81 | 200 Hz |

| C | Inclination | 48 | 100 Hz |

| D | Displacement | 36 | 100 Hz |

| E | Material temperature | 85 | 1 Hz |

| F | pH value | 28 | Daily |

| Chloride concentration | 56 | Daily | |

| Concrete resistance | 42 | Daily | |

| Electrochemical potential | 56 | Daily | |

| Temperature | 14 | Daily | |

| G | Weather station | 2 | 1/10 Hz |

| Groundwater level | 2 | 1/600 Hz | |

| H | Traffic loads (B-WIM) | In progress | |

| I | Tachymetric (measuring bolts) | 32 | Quarterly |

- Abbreviation: B-WIM, bridge weigh-in-motion system.

Due to initial signs of alteration, the system closely monitors the external prestressing tendons, which were installed in 2015, for losses in prestress and strand cracking. Five uniaxial and triaxial acceleration sensors are used to monitor the modal parameters of two external tendons in the end span. In addition, their bearing forces on the steel saddles are determined using strain gauges.

The functionality of bearings is another vital facet monitored, with a specific focus on bearing displacements. Hence, displacement sensors are installed at movable bearings at both abutment (Axes 1 and 8) and one row of piers (Axis 6). Furthermore, the condition of concrete and reinforcement is meticulously assessed, considering factors such as carbonation, chloride ingress, and corrosion.

Beyond these measured parameters, the monitoring system aligns with broader measurement objectives. Environmental parameters play a pivotal role in the assessment, necessitating the measurement of weather data such as wind direction, wind speed, sunlight, precipitation, and air temperature. The temperature distribution or gradient across the bridge cross-section is also systematically recorded.

The system delves into the complexities of traffic loads, encompassing a comprehensive bridge weigh-in-motion system (B-WIM) that includes determining the number of vehicles, axle load, axle count, axle spacing, and the total mass of vehicles. Moreover, groundwater levels are being monitored, recognizing the interplay between this factor and the structural integrity of the bridge.

In essence, this integrated monitoring approach aims to provide a holistic understanding of the bridge's behavior, considering both specific localized parameters and the broader environmental context (Figure 2).

4 OUTLOOK

The digital bridge management platform is both a challenge and an opportunity for novel machine-learning based algorithms and statistical methods for the reliability assessment in SHM and structural analysis. Moreover, different digital structural representations are showcased that incorporate measurements and diagnostic data, and valuable data for research on soil–structure interaction is generated. Currently, there are no universally accepted solutions that combine all these aspects in one platform. The DTEC-SHM project aims to address these challenges in a collaborative effort with leading groups from industry, academia, and federal institutions. The project team is open to sharing the data and finite element models upon request, and welcomes any other form of collaboration that goes beyond.

ACKNOWLEDGMENTS

This research is funded by dtec.bw—Digitalization and Technology Research Center of the Bundeswehr which we gratefully acknowledge. We would also like to express our gratitude to the following companies for the collaboration throughout this project: iSEA tec GmbH, REVOTEC zt gmbh, Duramon, and A+S Consult GmbH. We dedicate our very special thanks to Autobahn GmbH Nord for their guidance and commitment to the project. Open Access funding enabled and organized by Projekt DEAL.

Biographies

Sylvia Kessler

Chair of Engineering Materials and Building Preservation, Helmut Schmidt University/University of the Federal Armed Forces Hamburg

Hamburg, Germany

Alexander Mendler

Department of Materials Engineering, Chair of Non-destructive Testing, Technical University of Munich, TUM School of Engineering and Design

Munich, Germany

Alina Klemm

Chair of Steel Construction, Helmut Schmidt University/University of the Federal Armed Forces Hamburg, Hamburg, Germany

Yogi Jaelani

Chair of Engineering Materials and Building Preservation, Helmut Schmidt University/University of the Federal Armed Forces Hamburg

Hamburg, Germany

Martin Köhncke

Chair of Engineering Materials and Building Preservation, Helmut Schmidt University/University of the Federal Armed Forces Hamburg

Hamburg, Germany

Max Gündel

Chair of Steel Construction, Helmut Schmidt University/University of the Federal Armed Forces Hamburg

Hamburg, Germany

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.