Effect of high-range water reducer and W/C ratio on the fresh and mechanical properties of fiber-reinforced natural zeolite SCC

Abstract

The present study aims to investigate how the use of high-range water reducer (HRWR) and variations in water/cement (W/C) ratio affect the properties of self-consolidating concrete (SCC) while taking into account different proportions of polypropylene fibers (PF) and natural zeolite (NZ). A total of 28 samples were cast and analyzed. PF fractions ranging from 0% to 1.5% by weight were added, along with a substitution of 10% NZ for cement (50 kg/m3). Four W/C ratios (0.30, 0.35, 0.40, and 0.45) were tested, in addition to seven HRWR contents ranging from 5 to 6.5 kg/m3. Various tests were conducted to assess slump, T500, V-funnel, L-box, modulus of elasticity, and compressive, tensile, and flexural strengths. Novel models were developed to predict the properties of hardened concrete based on W/C, HRWR, PF, and NZ content. Findings indicated that optimal performance of PF-reinforced SCC with NZ was achieved when up to 0.75% PF was combined with an HRWR content equivalent to 1.25% of the cement fraction and NZ ratio. Furthermore, the proposed models offer accurate predictions of both fresh and hardened-state properties of PF-reinforced SCC with NZ based on W/C and HRWR ratios.

1 INTRODUCTION

Recently, self-consolidating concrete (SCC) has gained widespread usage in member manufacturing due to its ease of movement among dense reinforcement bars and complex molds, resulting in the attainment of uniform and homogeneous concrete.1-4 Additionally, the effort to combat discrimination in concrete casting serves as another motivation for the adoption of SCC.5, 6 Various materials such as natural zeolite (NZ), metakaolin, and fly ash (FA) have been employed as cement substitutes in SCC production.7-9 However, the use of high proportions of fine materials in SCC production has led to increased shrinkage cracking. To mitigate this issue, fibers have been recommended to reduce shrinkage and crack propagation.10-21 NZ, being a globally available binder, is utilized for its ion-exchange properties.22, 23 Consequently, numerous studies have been conducted to explore the impact of NZ on concrete properties. Zaroudi et al.24 investigated the properties of polypropylene fibers (PF)-reinforced SCC incorporating NZ. Their findings demonstrated that the highest compressive and splitting tensile strengths were achieved when 10% of cement was replaced with NZ and 0.5% PF was added. Furthermore, Shahmansouri et al.25 developed novel models using artificial neural networks (ANN) to predict the compressive and splitting tensile strengths of NZ concrete. Their approach, coupled with a well-organized presentation of laboratory findings, proves advantageous for practical applications. In another study, Shahmansouri et al.26 utilized gene expression programming to predict the compressive strength and electrical resistivity of concrete incorporating NZ. Jokar et al.27 investigated the performance of concrete incorporating various rubber and NZ proportions. They found that incorporating NZ led to improvements in mechanical properties, with optimal results achieved at 5% rubber and 15% and 10% NZ for extreme compressive and flexural strengths, respectively. Ramesh et al.28 employed NZ and a pozzolan in the production of structural concrete. Their findings demonstrated enhanced performance across all properties with the addition of NZ, with further enhancements observed when a pozzolan was also included.

Markiv et al.29 evaluated the mechanical properties of concrete incorporating NZ. Their study involved substituting 10% of cement with NZ. Furthermore, the slump of NZ-incorporated concrete required higher superplasticizer content due to the increased surface area of NZ compared with cement. Nagrockiene and Girskas30 determined the optimal NZ content for achieving superior concrete properties. Their experiments revealed that replacing up to 10% of cement with NZ improved compressive strength by 15% and reduced water absorption by 2.3 times compared with the control mix. Graybeal and Stone31 utilized NZ and waste materials to produce high-strength concrete. The inclusion of NZ enhanced concrete durability and mechanical performance by filling pores and reducing absorbency and permeability without compromising target properties. They noted a lack of research on NZ concrete with various water/cement (W/C) ratios and recommended further investigation into the influence of W/C on NZ concrete performance. Naseroleslami and Chari32 assessed how varying incorporation ratios of both NZ and silica fume (SF) affected the properties of SCC. Their findings revealed that the use of both NZ and SF led to a decrease in the fresh-state properties of SCC, as observed in workability, T500, V-funnel, and L-box tests. Additionally, while the incorporation of both NZ and SF had little effect on electrical resistivity, water absorption, and chloride diffusivity, it significantly influenced the permeability of SCC. Recently, Chang et al.33 investigated the influence of pozzolanic reactions on the carbonation and resistance of concrete containing both steel slag and NZ. Regarding carbonation, the inclusion of 15% NZ alongside steel slag resulted in a 10.2% increase in carbonation depth compared with the mix without NZ. Azad et al.34 examined the effects of NZ and pumice powders on the physical properties of porous concrete. While pumice powders enhanced physical behavior, NZ showed greater potential in improving porous concrete's performance in wastewater quality improvement. Additionally, Sabet et al.35 studied the durability and physical characteristics of high-performance SCC incorporating different proportions of NZ, SF, and FA. Overall, the use of these materials generally enhanced the properties of SCC mixtures. However, SF was found to be somewhat more effective than NZ or FA in enhancing durability characteristics, although NZ was deemed more economically beneficial. Nasr et al.36 evaluated the effect of nano-silica on SCC performance with varying NZ contents. Laboratory results indicated that the mechanical properties of SCC improved with increasing NZ and nano-silica contents as cement replacements. Furthermore, the incorporation of NZ and nano-silica increased electrical resistivity and reduced the absorbency of SCC. Samimi et al.37 investigated the acid attack durability of SCC incorporating pumice powder and NZ. Their study revealed that the optimal replacement levels of cement with pumice powder and NZ, yielding maximum acid attack resistance in SCC, were 10% and 15%, respectively. In another study, Samimi et al.38 examined the impact of pumice powder and NZ on the compressive strength and chloride diffusion of high-performance SCC. Their findings showed that the higher pozzolanic activity of NZ improved compressive strength, electrical resistivity, and resistance to chloride migration more effectively than the incorporation of pumice powder. Additionally, replacing cement with 15% pumice or 10% NZ in high-performance SCC proved to be cost-effective for all mechanical properties.

Water absorption plays a crucial role in the transfer of water within concrete, impacting its durability due to pore structure effects and moisture migration. Concrete strength is a primary concern for performance, and achieving adequate compaction and vibration is essential for enhancing durability. Therefore, SCC is widely used in densely reinforced concrete structures with challenging casting conditions, particularly in high-rise buildings, where permeability is crucial. Consequently, SCC's adoption extends the lifespan of concrete compared with traditional vibrated concrete. Ahmad et al.39 conducted an experimental study where sand was replaced with quarry dust at varying percentages (10%, 20%, 30%, and 40%), along with the addition of 0.9% superplasticizer. The study revealed that increasing quarry dust content improved compressive strength and workability by up to 30%, but excessive dust adversely affected these properties. In another research, Johnsirani et al.40 conducted experimental research on SCC using fine aggregate instead of quarry dust at varying proportions (0%, 25%, 50%, 75%, and 100%), along with the addition of mineral admixtures like FA and SF, and chemical admixtures like high-range water reducer (HRWR). The hardened properties of SCC, such as splitting tensile and compressive strengths, indicated that the SCC_25% mixture exhibits higher strength, approximately 34.62 and 2.36 MPa, respectively. It is not recommended to entirely replace sand with quarry dust, as this significantly reduces the splitting tensile and compressive strengths of SCC. Vanjare41 introduced glass particles into SCC at 5%, 10%, and 15%. Results showed that traits like segregation resistance, filling ability, and passing ability are compromised with the addition of glass powder to SCC mixtures. Bradu and Florea42 investigated water absorption in SCC with added FA. The results revealed that the type of cement, W/C ratio, and inclusion of FA all influenced the water absorption of SCC, with significant improvements observed with the addition of FA. Previous studies39-46 have established a strong correlation between water absorption and voids within concrete, where voids act as pathways for fluid movement, thereby increasing absorption. FA, when incorporated into SCC, resulted in higher water absorption values compared with other materials. Additionally, cement plays a crucial role in water absorption, as research suggests that the compressive strength of SCC increases as water absorption decreases. In a separate investigation, Chari et al.47 evaluated the effect of temperature on the moisture transfer coefficient of cement-based mortars. They tested 12 mortar combinations, six of which had varying W/C ratios and six containing either NZ or SF, across temperatures ranging from 20 to 60°C. Using a combined experimental and numerical approach, they determined moisture transfer coefficient values for both soaking and drying phases. Results indicated that temperature significantly influenced the moisture transfer coefficient during moisture loss, contrasting with the effect of water absorption.

Bozorgmehr Nia et al.48 investigated the influence of NZ as a substitute for cement on the properties of SCC. Different proportions of NZ (0%–20% by weight of cement) were incorporated into SCC mixes with varying water/binder ratios. The study evaluated new attributes using slump flow, visual stability index, T500, V-funnel, and L-box tests. Variations in compressive strength and slump flow over time were also considered. Additionally, the study assessed compressive strength, splitting tensile strength, ultrasonic pulse velocity, and initial and ultimate absorption characteristics. Results indicated that NZ could effectively enhance SCC performance in terms of viscosity, flowability, and passing ability. However, mixes containing higher percentages of NZ experienced greater slump flow loss, and flowability decreased for all combinations over time. The impact of NZ on compressive and splitting tensile strengths of SCC mixes was correlated with the W/C ratio. Moreover, mixes with slump flow exceeding 550 mm at longer mixing times exhibited increased compressive strength. Ultrasonic pulse velocity measurements revealed the minimal impact of NZ on pulse velocity readings at high compressive strength. As NZ-containing SCC matured, its absorption properties significantly decreased compared with control SCC. In another study, Bozorgmehr Nia and Chari49 investigated the effects of NZ and limestone powder on the rheological and mechanical properties of SCC. Initially, six mortar mixes with varying W/C ratios were prepared to determine the optimal W/C ratio for SCC properties. Subsequently, a W/C ratio of 0.45 was selected, and the influence of NZ and limestone powder on the fluidity, viscosity, and stability of SCCs was examined. The study also evaluated the compressive and tensile strengths of the mixes at 28 days. Results indicated that NZ and limestone powder enhanced the flowability of the mixes, with NZ increasing viscosity while limestone powder had a negligible effect on viscosity. Furthermore, the addition of limestone powder to cementitious mixes led to a slight increase in compressive strength.

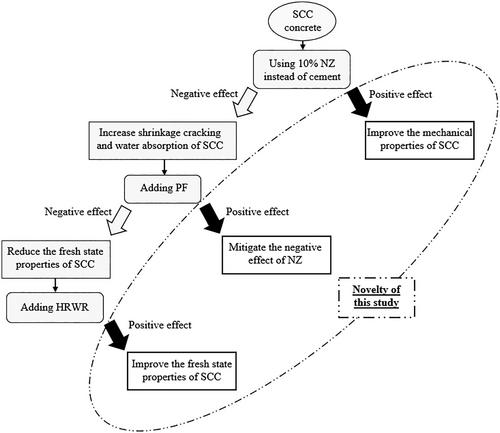

As previously discussed, numerous research studies have focused on assessing the durability and mechanical properties of concrete incorporating various raw materials as partial substitutes for cement. NZ has gained widespread use due to its cost-effectiveness and superior ability to enhance the behavior of SCC compared with metakaolin, FA, and slag. Previous research has identified the optimal replacement ratio of NZ for cement as 10%, resulting in optimal fresh and hardened-state characteristics of SCC.30, 37, 38 Therefore, in this study, 10% NZ was chosen as the cement replacement. Additionally, it has been observed that the inclusion of NZ increases shrinkage cracking and water demand in SCC due to its advanced surface area.24, 50, 51 Consequently, PF was added to mixes with varying contents to mitigate the adverse effects of NZ. Furthermore, the influence of HRWR was evaluated to reduce water demand resulting from the use of NZ and PF, thereby enhancing the durability of SCC. Thus, the current research also examined the impact of the W/C ratio on the performance of NZ-incorporated SCC. Finally, novel regression models were developed to predict the modulus of elasticity, splitting tensile and flexural strengths of PF-reinforced SCC incorporating various proportions of NZ, W/C, and HRWR. The novelty of this study is depicted in Figure 1.

2 MATERIAL PROPERTIES AND SAMPLES' CHARACTERISTICS

2.1 Cement and NZ

For the production of SCC mixes, cement type II was utilized following ASTM C150.52 Additionally, NZ was employed as a substitute for cement. The chemical compositions of the cement and NZ utilized are detailed in Table 1. To evaluate the chemical properties of the materials, XRF analysis using Spectro X-Lab 2000 was conducted. Furthermore, Table 2 outlines the physical properties of both cement and NZ.53-57

| Cement | NZ | ||

|---|---|---|---|

| CaO | 59.36% | SiO2 | 77.04% |

| SiO2 | 25.23% | Al2O3 | 13.20% |

| Al2O3 | 7.22% | K2O | 6.42% |

| Fe2O2 | 1.80% | FeO | 0.66% |

| MgO | 2.20% | CaO | 0.75% |

| SO3 | 2.80% | MgO | 0.53% |

| K2O | 0.76% | Na2O | 1.30% |

| Na2O | 0.02% | CeO2 | 0.05% |

| Cl | 0.59% | Sc2O3 | 0.03% |

| TiO2 | 0.02% | Nd2O3 | 0.02% |

| Fineness index | 405 m2/kg | Fineness index | 390 m2/kg |

- Abbreviation: NZ, natural zeolite.

| Physical features | Rate | |

|---|---|---|

| Cement | NZ | |

| Early setting time (min) | 160 | 75 |

| Ending setting time (min) | 215 | 160 |

| Specific gravity (gr/cm3) | 3.19 | 2.27 |

| SSA (cm2/g) | 2895 | 1495 |

| Autoclave expansion (%) | 0.72 | 0.35 |

- Abbreviations: NZ, natural zeolite; SSA, specific surface area.

2.2 Aggregates

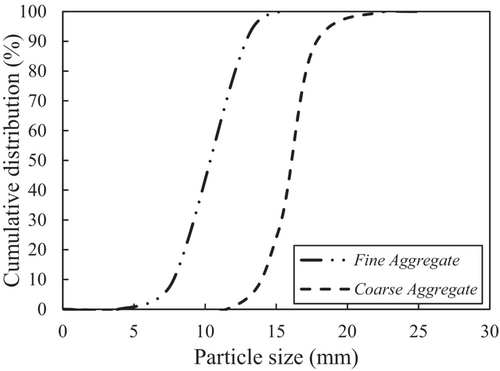

Furthermore, the fine aggregates exhibited water absorption, specific gravity, and fineness modulus values of 2.65%, 2.5%, and 2.5, respectively. The particle size distribution of both fine and coarse aggregates is illustrated in Figure 2.57 Additionally, NZ are hydrated, crystalline microporous aluminosilicates, characterized by structures containing channels and/or cavities of molecular dimensions with a diameter of 1.7 nm.

2.3 Water and HRWR

Tap water was employed in the production of SCC mixtures following ASTM C1602.59 Additionally, an HRWR, detailed in Table 3, was incorporated to mitigate water demand when PF or NZ was utilized and to enhance the rheological properties of the SCC mixtures.

| Type | Density (g/cm3) | Solid content (%) | pH value | Chloride content (%) | Alkali content (Na2O) (%) |

|---|---|---|---|---|---|

| Polycarboxylic ether-based | 1.085 | 37.28 | 3.79 | <0.1 | <10 |

2.4 Fibers

PF were introduced into the production of SCC mixes, as depicted in Figure 3. These fibers are white, measuring 24 mm in length and approximately 18 ± 4 μm in diameter. They possess a tensile resistance of 365 MPa, a density of 850 kg/m3, and a melting point of 170°C.

2.5 Concrete mixes

Twenty-eight SCC mixtures were produced as per ACI 237R-07,60 as detailed in Table 4. Each mixture included 10% NZ as a partial replacement for cement. Additionally, PF were added at varying volumes: 0%, 0.25%, 0.5%, 0.75%, 1.0%, 1.25%, and 1.5%. Furthermore, to examine the impact of water content, four W/C ratios were considered: 0.3, 0.35, 0.4, and 0.45. To enhance the rheological properties of the mixtures containing PF and NZ, the effect of HRWR admixture was investigated at seven different dosages: 5, 5.25, 5.5, 5.75, 6, 6.25, and 6.5 kg/m3, corresponding to 1.25% of cement content plus NZ ratio, based on previous research.24, 61-64

| Group | Specimen | Cement (kg/m3) | NZ (kg/m3) | Water (kg/m3) | W/C | Sand (kg/m3) | Gravel (kg/m3) | HRWR (kg/m3) | PF (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| SCC1 | 0.3W-5R-0P | 450 | 50 | 165 | 0.30 | 959 | 772 | 5.00 | 0.00 |

| 0.3W-5.25R-0.25P | 450 | 50 | 165 | 0.30 | 959 | 772 | 5.25 | 2.12 | |

| 0.3W-5.5R-0.5P | 450 | 50 | 165 | 0.30 | 959 | 772 | 5.50 | 4.25 | |

| 0.3W-5.75R-0.75P | 450 | 50 | 165 | 0.30 | 959 | 772 | 5.75 | 6.37 | |

| 0.3W-6R-1.0P | 450 | 50 | 165 | 0.30 | 959 | 772 | 6.00 | 8.50 | |

| 0.3W-6.25R-1.25P | 450 | 50 | 165 | 0.30 | 959 | 772 | 6.25 | 10.62 | |

| 0.3W-6.5R-1.5P | 450 | 50 | 165 | 0.30 | 959 | 772 | 6.50 | 12.75 | |

| SCC2 | 0.35W-5R-0P | 450 | 50 | 175 | 0.35 | 959 | 772 | 5.00 | 0.00 |

| 0.35W-5.25R-0.25P | 450 | 50 | 175 | 0.35 | 959 | 772 | 5.25 | 2.12 | |

| 0.35W-5.5R-0.5P | 450 | 50 | 175 | 0.35 | 959 | 772 | 5.50 | 4.25 | |

| 0.35W-5.75R-0.75P | 450 | 50 | 175 | 0.35 | 959 | 772 | 5.75 | 6.37 | |

| 0.35W-6R-1.0P | 450 | 50 | 175 | 0.35 | 959 | 772 | 6.00 | 8.50 | |

| 0.35W-6.25R-1.25P | 450 | 50 | 175 | 0.35 | 959 | 772 | 6.25 | 10.62 | |

| 0.35W-6.5R-1.5P | 450 | 50 | 175 | 0.35 | 959 | 772 | 6.50 | 12.75 | |

| SCC3 | 0.4W-5R-0P | 450 | 50 | 200 | 0.40 | 959 | 772 | 5.00 | 0.00 |

| 0.4W-5.25R-0.25P | 450 | 50 | 200 | 0.40 | 959 | 772 | 5.25 | 2.12 | |

| 0.4W-5.5R-0.5P | 450 | 50 | 200 | 0.40 | 959 | 772 | 5.50 | 4.25 | |

| 0.4W-5.75R-0.75P | 450 | 50 | 200 | 0.40 | 959 | 772 | 5.75 | 6.37 | |

| 0.4W-6R-1.0P | 450 | 50 | 200 | 0.40 | 959 | 772 | 6.00 | 8.50 | |

| 0.4W-6.25R-1.25P | 450 | 50 | 200 | 0.40 | 959 | 772 | 6.25 | 10.62 | |

| 0.4W-6.5R-1.5P | 450 | 50 | 200 | 0.40 | 959 | 772 | 6.50 | 12.75 | |

| SCC4 | 0.45W-5R-0P | 450 | 50 | 225 | 0.45 | 959 | 772 | 5.00 | 0.00 |

| 0.45W-5.25R-0.25P | 450 | 50 | 225 | 0.45 | 959 | 772 | 5.25 | 2.12 | |

| 0.45W-5.5R-0.5P | 450 | 50 | 225 | 0.45 | 959 | 772 | 5.50 | 4.25 | |

| 0.45W-5.75R-0.75P | 450 | 50 | 225 | 0.45 | 959 | 772 | 5.75 | 6.37 | |

| 0.45W-6R-1.0P | 450 | 50 | 225 | 0.45 | 959 | 772 | 6.00 | 8.50 | |

| 0.45W-6.25R-1.25P | 450 | 50 | 225 | 0.45 | 959 | 772 | 6.25 | 10.62 | |

| 0.45W-6.5R-1.5P | 450 | 50 | 225 | 0.45 | 959 | 772 | 6.50 | 12.75 |

- Abbreviations: HRWR, high-range water reducer; NZ, natural zeolite; PF, polypropylene fibers; SCC, self-consolidating concrete.

3 FRESH-STATE PROPERTIES

3.1 Slump and T500

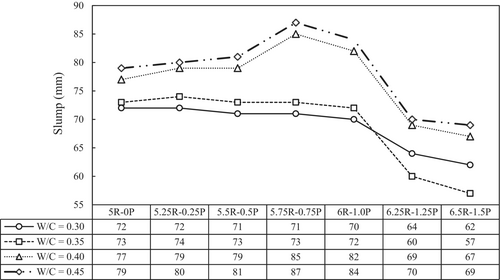

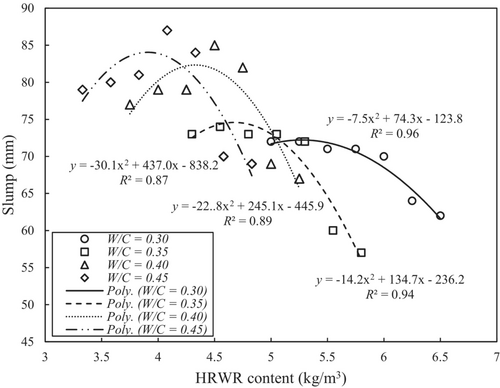

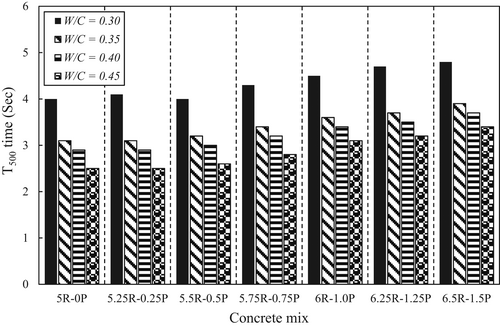

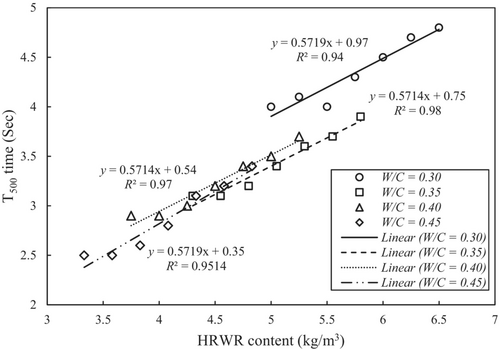

In this section, two important parameters of flowability and T500 were carried out to evaluate the workability of mixes.65 The slump test serves as a measure of concrete's fluidity and workability, while also providing a secondary evaluation of its uniformity and toughness. Additionally, the T500 test gauges flow speed and viscosity, indicating the time it takes for the fluid paste to form a 500-mm diameter circle on the workability flow plate after raising the cone. Figure 4 displays the workability results for various mixes. Notably, for mixes with a low W/C ratio (≤0.35), there is no significant difference in workability when using up to 1.0% PF and HRWR up to 6 kg/m3. However, prior studies have shown a considerable slump reduction when PF is utilized.11, 28, 66, 67 Hence, as the content of HRWR increased, the slump of SCC remained nearly constant even with up to 1% PF utilization. However, surpassing the 1% threshold of PF incorporation resulted in a slump reduction, likely due to PF's property increasing water demand. Alberti et al.68 indicated that the swelling of PF fraction escalated water demand, consequently decreasing the slump. Workability of SCC decreased by 10 and 16 mm, respectively, when incorporating 1.5% PF with 6.5 HRWR, and the W/C ratios were 0.3 and 0.35. Conversely, in mixes with W/C ≥ 0.4, HRWR's influence was more significant, likely due to heightened chloride and H2O reaction with increased water content. The workability of SCC showed gradual enhancement with the addition of up to 0.75% PF alongside up to 5.75 kg/m3 HRWR. Consequently, in PF-reinforced NZ SCC, workability improved by 10% and 11%, respectively, when 5.75 kg/m3 HRWR was applied in producing 0.75% PF-reinforced SCC with W/C ratios of 0.4 and 0.45. However, the slump decreased when PF exceeded 0.75%. These findings suggest that to maintain suitable workability when incorporating over 1% PF, it is advisable to increase HRWR content more than PF. The decline in workability beyond 1% PF utilization, coupled with increased water and HRWR contents, is primarily attributed to the densification of mixes alongside heightened water demand.

3.2 V-funnel and L-box

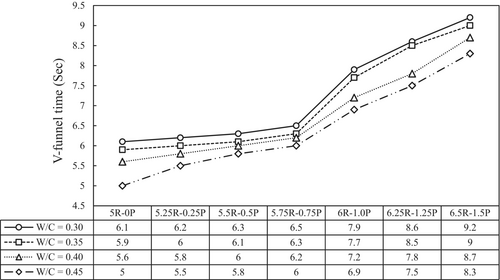

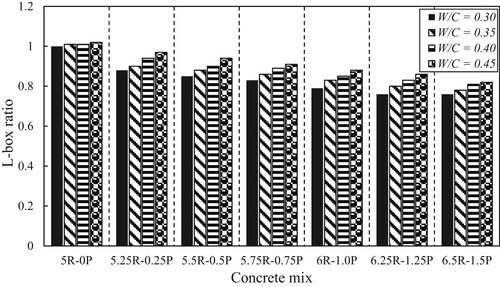

To evaluate the rheological behavior of mixes and the uniformity of concrete, the L-box test was utilized, with the L-box ratio calculated as the H2/H1 ratio.69 An optimal H2/H1 value should be 1. Additionally, the V-funnel test was conducted to assess the viscosity and deformation of samples in their fresh state.70 This test measures the time taken for 12 L of concrete to flow through the funnel's entrance. It is worth noting that the ideal satisfactory value for SCC from this test is 12 s, as per EFNARC guidelines.71 Consequently, the results are depicted in Figure 8.

According to Figure 8, increasing the HRWR fraction in tandem with higher PF contents effectively prevented a significant increase in V-funnel time, with only a slight increase observed when up to 0.75% PF was added alongside 5.75 kg/m3 HRWR. However, previous studies have indicated a notable amplification in V-funnel time for SCC with low PF contents, below 1%.28, 67 Gencel et al.72 have noted that PF induces a partial blocking effect, leading to a substantial increase in V-funnel time. Therefore, employing an HRWR content equivalent to 1.25% of the cement and NZ ratio could be beneficial when PF content is limited to 1% by volume. Additionally, it was observed that when utilizing up to 1% PF with corresponding HRWR, there is minimal variation in V-funnel time among NZ SCC with different W/C ratios; however, with increased W/C ratio, this time slightly decreased. Alternatively, when high PF contents were added, both the increased water demand and the formation of a denser mix led to a significant increase in V-funnel time beyond 1% PF addition. Thus, it is recommended to increase HRWR content beyond 1.25% of the cement plus NZ fraction. This increase can be attributed to the limited coalescence of coarse aggregate and fibers. Even with a higher W/C ratio and additional HRWR, discrimination resistance decreased and deformability increased. In a previous study, Hosseinpoor et al.22 noted that this unusual increase in deformability does not necessarily decrease the flow period, suggesting inadequate cohesion among the matrix, aggregate, and fibers. Consequently, PF overflowed and obstructed the flue outlet. The findings of the V-funnel test are largely consistent with those of Alberti et al.68 Figure 9 illustrates the L-box fraction of the SCC specimens, revealing no difference between the L-box fraction of the control mix and that of mixes with various W/C ratios. Furthermore, the ratio decreased with increasing PF content due to PF's water demand and its effect on densifying the mixes. Previous studies have reported that swelling fiber fractions result in a significant reduction in the L-box ratio.11, 68, 73 Nevertheless, the inclusion of HRWR prevented a significant reduction in the L-box ratio and helped maintain adequate deformability of SCC. Conversely, the H2/H1 ratio increased with higher W/C fractions; however, the differences among the L-box ratios of various mixes diminished as the PF content increased.

4 HARDENED-STATE PERFORMANCE

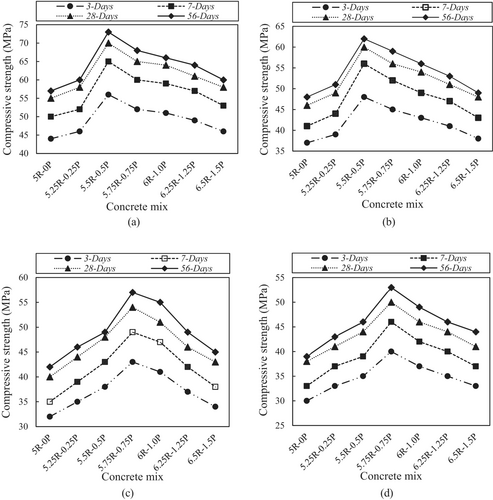

4.1 Compressive strength

To assess the compressive strength, three 150 × 300 mm samples were made and measured under a hydraulic setup.74 Figure 10 shows the average results of three measured samples for each mix. The compressive strength of specimens improved by increasing the curing age while the impact of the curing time on the compressive resistance declined between 28 and 56 days, because hydration effects stood on the boundary, counting amorphous calcium silicate hydrates gel, ettringite with an extended form, and plate-like calcium hydroxide crystals, overlain with each other, resulting from the insufficient hydration reaction at early hydration. Afterwards, additional hydration response befalls and the places among cement paste and aggregates are occupied with poorly glassy calcium silicate hydrates, which helps to surge the coherency and accordingly, the resistance of the interfacial transition zone as curing age increases.75 Therefore, the compressive strength increased with curing time, as anticipated. Furthermore, for mixes containing low PF content, the addition of 0.25% PF along with the corresponding HRWR slightly elevated the compressive strength by an average of 4.6% and 4.5% for W/C ratios of 0.3 and 0.35, respectively. However, the highest compressive strength was achieved when 0.5% PF was combined with 5.5 kg/m3 HRWR, resulting in an average improvement of 28% and 31.75% for W/C ratios of 0.3 and 0.35, respectively (refer to Figure 10a,b). The primary reason for enhancing compressive strength through the use of 0.5% PF could be attributed to the increased cohesiveness between the cement matrix and particles, thereby enhancing the tensile strength of the concrete matrix. Consequently, as the PF content increased, the compressive strength decreased with increasing HRWR content.

The decrease in compressive strength observed with higher PF contents may be attributed to increased water absorption by the fibers. This results in heightened porosity within the hardened concrete samples, weakening their internal structure. Therefore, it may be beneficial to increase the HRWR content beyond the sum of 1.25% cement and NZ ratio when using low PF contents. Conversely, there was a significant decline in compressive strength with an increase in the W/C ratio (refer to Figure 10c,d). The optimal PF content for obtaining the highest compressive strength was found to be 0.75%, with the W/C ratio increased to 0.4 and 0.45. However, compressive strength decreased with PF content exceeding 0.75% thereafter. These results confirm the impact of PF's high-water absorption, as evidenced by the maximum compressive strength achieved with the incorporation of 0.75% PF, swelling the W/C fraction. The compressive strength increased by an average of 29.5% and 25.8% for W/C ratios of 0.4 and 0.45, respectively. Similar trends in the influence of fibers on compressive strength have been reported previously. Zaroudi et al.24 confirmed that the compressive strength of SCC with NZ improved with the addition of up to 0.75% polyolefin fibers, and then declined. Aslani and Nejadi76 demonstrated that the maximum compressive strength of plain SCC was achieved with the addition of 0.55% PF, but declined with higher PF contents. Nehdi and Ladanchuk77 suggested that the optimal PF content for maximizing compressive strength in SCC was 0.5%, decreasing by approximately 19% with the use of 1% PF.

4.2 Splitting tensile strength

This test was carried out on 150 mm × 300 mm specimens as per ASTM C469.74 Figure 11 provides the impact of HRWR on the splitting tensile strength of PF-reinforced SCC with various W/C fractions.

The tensile strength of the specimens increased with curing age, while a rise in W/C resulted in a significant decline. Furthermore, the tensile strength experienced a sharp increase with the incorporation of 0.5% PF, followed by a gradual decrease with higher PF contents when a W/C ratio of up to 0.35 was used (refer to Figure 11a,b). This increase in tensile strength attributed to the use of PF may be due to the enhancement of the matrix's tensile strength, thereby limiting tensile cracking in concrete. Conversely, the increase in water demand resulting from using more than 0.5% PF is the primary cause of the reduction in tensile strength, leading to the formation of a porous structure in the hardened specimens. Thus, for NZ SCC samples with a W/C ratio of 0.3, the addition of 0.5% PF improved the splitting tensile strength by approximately 58%, 57%, 55%, and 54% at 3, 7, 28, and 56 days after curing, respectively. Thus, as the W/C ratio increased, there was a greater demand for water by the fibers, resulting in an overall decline in tensile strength compared with mixes with W/C ratios of 0.3 and 0.35 (Figure 11c,d). Additionally, this property experienced a significant decline with the addition of more than 0.75% PF. Consequently, the tensile strength decreased by an average of 85.9% and 84.8% for W/C ratios of 0.4 and 0.45, respectively. Zaroudi et al.24 reported that the maximum tensile strength of SCC was achieved with the incorporation of 0.5% polyolefin fibers. In another study, Mohseni et al.78 demonstrated a 40% increase in tensile strength with the inclusion of 0.5% PF in mixes. Moreover, Khayat and Long50 showed that 0.5% PF improved the tensile strength of SCC by 11% at 28 days after curing. Therefore, the observed changes in tensile strength closely align with those reported in previous investigations without NZ and with a constant HRWR content.

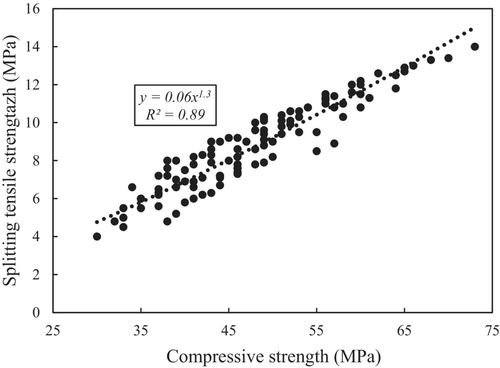

Furthermore, the findings are compared with models proposed in previous studies for predicting the splitting tensile strength of SCC mixes in relation to compressive strength, as provided in Table 5.

Using these equations, the splitting tensile strength of various mixes was calculated using different models, as outlined in Table 6. It was observed that all previous models tend to underestimate the splitting tensile strength of SCC when PF and NZ are incorporated into mixes with varying W/C ratios and HRWR contents, particularly when the W/C ratio is below 0.4. Furthermore, for specimens with a W/C ratio of 0.45, the model developed by Bae Martinez-Lopez and Escalante-Garcia83 with an average deviation of 28%, provided a more accurate prediction compared with others. Consequently, these existing models prove inadequate in estimating the splitting tensile strength of PF-reinforced SCC with NZ, necessitating the development of a new model for this purpose.

| Group | Specimen | Curing age (days) | This study | Xu et al.79 | Arioglu et al.80 | Ramadoss et al.81 | ACI 318–1082 | Bae Martinez-Lopez and Escalante-Garcia83 | Bae Martinez-Lopez and Escalante-Garcia83 |

|---|---|---|---|---|---|---|---|---|---|

| SCC1 | 0.3W-5R-0P | 3 | 7.1 | 4.9 | 4.2 | 4 | 3.7 | 4.9 | 5.7 |

| 0.3W-5.25R-0.25P | 8.6 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | ||

| 0.3W-5.5R-0.5P | 11.2 | 5.9 | 4.9 | 4.6 | 4.2 | 5.5 | 6.7 | ||

| 0.3W-5.75R-0.75P | 10.6 | 5.6 | 4.7 | 4.4 | 4 | 5.3 | 6.4 | ||

| 0.3W-6R-1.0P | 10.4 | 5.5 | 4.6 | 4.4 | 4 | 5.3 | 6.3 | ||

| 0.3W-6.25R-1.25P | 9.4 | 5.3 | 4.5 | 4.3 | 3.9 | 5.2 | 6.1 | ||

| 0.3W-6.5R-1.5P | 9.2 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | ||

| SCC2 | 0.35W-5R-0P | 6.2 | 4.2 | 3.8 | 3.7 | 3.4 | 4.5 | 5 | |

| 0.35W-5.25R-0.25P | 8 | 4.4 | 3.9 | 3.8 | 3.5 | 4.6 | 5.2 | ||

| 0.35W-5.5R-0.5P | 10 | 5.2 | 4.5 | 4.2 | 3.9 | 5.1 | 6 | ||

| 0.35W-5.75R-0.75P | 9.2 | 4.9 | 4.3 | 4.1 | 3.8 | 5 | 5.7 | ||

| 0.35W-6R-1.0P | 9 | 4.8 | 4.2 | 4 | 3.7 | 4.9 | 5.6 | ||

| 0.35W-6.25R-1.25P | 8.2 | 4.6 | 4 | 3.9 | 3.6 | 4.8 | 5.4 | ||

| 0.35W-6.5R-1.5P | 8 | 4.3 | 3.9 | 3.7 | 3.5 | 4.6 | 5.1 | ||

| SCC3 | 0.4W-5R-0P | 4.8 | 3.7 | 3.5 | 3.4 | 3.2 | 4.2 | 4.5 | |

| 0.4W-5.25R-0.25P | 6 | 4 | 3.7 | 3.6 | 3.3 | 4.4 | 4.8 | ||

| 0.4W-5.5R-0.5P | 7.2 | 4.3 | 3.9 | 3.7 | 3.5 | 4.6 | 5.1 | ||

| 0.4W-5.75R-0.75P | 9 | 4.8 | 4.2 | 4 | 3.7 | 4.9 | 5.6 | ||

| 0.4W-6R-1.0P | 7.8 | 4.6 | 4 | 3.9 | 3.6 | 4.8 | 5.4 | ||

| 0.4W-6.25R-1.25P | 7.2 | 4.2 | 3.8 | 3.7 | 3.4 | 4.5 | 5 | ||

| 0.4W-6.5R-1.5P | 6.6 | 3.9 | 3.6 | 3.5 | 3.3 | 4.4 | 4.7 | ||

| SCC4 | 0.45W-5R-0P | 4 | 3.5 | 3.3 | 3.3 | 3.1 | 4.1 | 4.3 | |

| 0.45W-5.25R-0.25P | 5 | 3.8 | 3.5 | 3.4 | 3.2 | 4.3 | 4.6 | ||

| 0.45W-5.5R-0.5P | 6 | 4 | 3.7 | 3.6 | 3.3 | 4.4 | 4.8 | ||

| 0.45W-5.75R-0.75P | 7.5 | 4.5 | 4 | 3.8 | 3.5 | 4.7 | 5.3 | ||

| 0.45W-6R-1.0P | 6.5 | 4.2 | 3.8 | 3.7 | 3.4 | 4.5 | 5 | ||

| 0.45W-6.25R-1.25P | 6 | 4 | 3.7 | 3.6 | 3.3 | 4.4 | 4.8 | ||

| 0.45W-6.5R-1.5P | 5.5 | 3.8 | 3.5 | 3.4 | 3.2 | 4.3 | 4.6 | ||

| SCC1 | 0.3W-5R-0P | 7 | 8.2 | 5.4 | 4.6 | 4.3 | 4 | 5.2 | 6.2 |

| 0.3W-5.25R-0.25P | 9.9 | 5.6 | 4.7 | 4.4 | 4 | 5.3 | 6.4 | ||

| 0.3W-5.5R-0.5P | 12.9 | 6.7 | 5.4 | 5 | 4.5 | 5.9 | 7.4 | ||

| 0.3W-5.75R-0.75P | 12.2 | 6.3 | 5.1 | 4.8 | 4.3 | 5.7 | 7 | ||

| 0.3W-6R-1.0P | 12 | 6.2 | 5.1 | 4.8 | 4.3 | 5.6 | 6.9 | ||

| 0.3W-6.25R-1.25P | 10.8 | 6 | 5 | 4.7 | 4.2 | 5.6 | 6.8 | ||

| 0.3W-6.5R-1.5P | 10.6 | 5.7 | 4.8 | 4.5 | 4.1 | 5.4 | 6.4 | ||

| SCC2 | 0.35W-5R-0P | 6.9 | 4.6 | 4 | 3.9 | 3.6 | 4.8 | 5.4 | |

| 0.35W-5.25R-0.25P | 9 | 4.9 | 4.2 | 4 | 3.7 | 4.9 | 5.7 | ||

| 0.35W-5.5R-0.5P | 11.5 | 5.9 | 4.9 | 4.6 | 4.2 | 5.5 | 6.7 | ||

| 0.35W-5.75R-0.75P | 10.1 | 5.6 | 4.7 | 4.4 | 4 | 5.3 | 6.4 | ||

| 0.35W-6R-1.0P | 10.2 | 5.3 | 4.5 | 4.3 | 3.9 | 5.2 | 6.1 | ||

| 0.35W-6.25R-1.25P | 9 | 5.1 | 4.4 | 4.2 | 3.8 | 5.1 | 5.9 | ||

| 0.35W-6.5R-1.5P | 8.6 | 4.8 | 4.2 | 4 | 3.7 | 4.9 | 5.6 | ||

| SCC3 | 0.4W-5R-0P | 5.5 | 4 | 3.7 | 3.6 | 3.3 | 4.4 | 4.8 | |

| 0.4W-5.25R-0.25P | 7 | 4.4 | 3.9 | 3.8 | 3.5 | 4.6 | 5.2 | ||

| 0.4W-5.5R-0.5P | 8.3 | 4.8 | 4.2 | 4 | 3.7 | 4.9 | 5.6 | ||

| 0.4W-5.75R-0.75P | 10.3 | 5.3 | 4.5 | 4.3 | 3.9 | 5.2 | 6.1 | ||

| 0.4W-6R-1.0P | 9 | 5.1 | 4.4 | 4.2 | 3.8 | 5.1 | 5.9 | ||

| 0.4W-6.25R-1.25P | 8.3 | 4.7 | 4.1 | 3.9 | 3.6 | 4.8 | 5.5 | ||

| 0.4W-6.5R-1.5P | 7.6 | 4.3 | 3.9 | 3.7 | 3.5 | 4.6 | 5.1 | ||

| SCC4 | 0.45W-5R-0P | 4.5 | 3.8 | 3.5 | 3.4 | 3.2 | 4.3 | 4.6 | |

| 0.45W-5.25R-0.25P | 5.6 | 4.2 | 3.8 | 3.7 | 3.4 | 4.5 | 5 | ||

| 0.45W-5.5R-0.5P | 6.6 | 4.4 | 3.9 | 3.8 | 3.5 | 4.6 | 5.2 | ||

| 0.45W-5.75R-0.75P | 8.2 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | ||

| 0.45W-6R-1.0P | 7.1 | 4.7 | 4.1 | 3.9 | 3.6 | 4.8 | 5.5 | ||

| 0.45W-6.25R-1.25P | 6.9 | 4.5 | 4 | 3.8 | 3.5 | 4.7 | 5.3 | ||

| 0.45W-6.5R-1.5P | 6.3 | 4.2 | 3.8 | 3.7 | 3.4 | 4.5 | 5 | ||

| SCC1 | 0.3W-5R-0P | 28 | 8.5 | 5.8 | 4.9 | 4.6 | 4.2 | 5.5 | 6.6 |

| 0.3W-5.25R-0.25P | 10.3 | 6.1 | 5 | 4.7 | 4.3 | 5.6 | 6.9 | ||

| 0.3W-5.5R-0.5P | 13.4 | 7.1 | 5.7 | 5.2 | 4.7 | 6.1 | 7.8 | ||

| 0.3W-5.75R-0.75P | 12.7 | 6.7 | 5.4 | 5 | 4.5 | 5.9 | 7.4 | ||

| 0.3W-6R-1.0P | 12.5 | 6.6 | 5.4 | 5 | 4.5 | 5.9 | 7.4 | ||

| 0.3W-6.25R-1.25P | 11.3 | 6.4 | 5.2 | 4.8 | 4.4 | 5.7 | 7.1 | ||

| 0.3W-6.5R-1.5P | 11 | 6.1 | 5 | 4.7 | 4.3 | 5.6 | 6.9 | ||

| SCC2 | 0.35W-5R-0P | 7.4 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | |

| 0.35W-5.25R-0.25P | 9.6 | 5.3 | 4.5 | 4.3 | 3.9 | 5.2 | 6.1 | ||

| 0.35W-5.5R-0.5P | 12 | 6.3 | 5.1 | 4.8 | 4.3 | 5.7 | 7 | ||

| 0.35W-5.75R-0.75P | 11 | 5.9 | 4.9 | 4.6 | 4.2 | 5.5 | 6.7 | ||

| 0.35W-6R-1.0P | 10.8 | 5.8 | 4.8 | 4.5 | 4.1 | 5.4 | 6.5 | ||

| 0.35W-6.25R-1.25P | 9.8 | 5.5 | 4.6 | 4.4 | 4 | 5.3 | 6.3 | ||

| 0.35W-6.5R-1.5P | 9.6 | 5.2 | 4.5 | 4.2 | 3.9 | 5.1 | 6 | ||

| SCC3 | 0.4W-5R-0P | 5.8 | 4.5 | 4 | 3.8 | 3.5 | 4.7 | 5.3 | |

| 0.4W-5.25R-0.25P | 7.2 | 4.9 | 4.2 | 4 | 3.7 | 4.9 | 5.7 | ||

| 0.4W-5.5R-0.5P | 8.6 | 5.2 | 4.5 | 4.2 | 3.9 | 5.1 | 6 | ||

| 0.4W-5.75R-0.75P | 10.8 | 5.8 | 4.8 | 4.5 | 4.1 | 5.4 | 6.5 | ||

| 0.4W-6R-1.0P | 9.4 | 5.5 | 4.6 | 4.4 | 4 | 5.3 | 6.3 | ||

| 0.4W-6.25R-1.25P | 8.6 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | ||

| 0.4W-6.5R-1.5P | 7.9 | 4.8 | 4.2 | 4 | 3.7 | 4.9 | 5.6 | ||

| SCC4 | 0.45W-5R-0P | 4.8 | 4.3 | 3.9 | 3.7 | 3.5 | 4.6 | 5.1 | |

| 0.45W-5.25R-0.25P | 6 | 4.6 | 4 | 3.9 | 3.6 | 4.8 | 5.4 | ||

| 0.45W-5.5R-0.5P | 7.2 | 4.9 | 4.2 | 4 | 3.7 | 4.9 | 5.7 | ||

| 0.45W-5.75R-0.75P | 9 | 5.4 | 4.6 | 4.3 | 4 | 5.2 | 6.2 | ||

| 0.45W-6R-1.0P | 7.8 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | ||

| 0.45W-6.25R-1.25P | 7.2 | 4.9 | 4.2 | 4 | 3.7 | 4.9 | 5.7 | ||

| 0.45W-6.5R-1.5P | 6.6 | 4.6 | 4 | 3.9 | 3.6 | 4.8 | 5.4 | ||

| SCC1 | 0.3W-5R-0P | 56 | 8.9 | 6 | 5 | 4.7 | 4.2 | 5.6 | 6.8 |

| 0.3W-5.25R-0.25P | 10.8 | 6.3 | 5.1 | 4.8 | 4.3 | 5.7 | 7 | ||

| 0.3W-5.5R-0.5P | 14 | 7.4 | 5.8 | 5.4 | 4.8 | 6.2 | 8.1 | ||

| 0.3W-5.75R-0.75P | 13.3 | 7 | 5.6 | 5.2 | 4.6 | 6 | 7.7 | ||

| 0.3W-6R-1.0P | 13 | 6.8 | 5.5 | 5.1 | 4.5 | 5.9 | 7.5 | ||

| 0.3W-6.25R-1.25P | 11.8 | 6.6 | 5.4 | 5 | 4.5 | 5.9 | 7.4 | ||

| 0.3W-6.5R-1.5P | 11.5 | 6.3 | 5.1 | 4.8 | 4.3 | 5.7 | 7 | ||

| SCC2 | 0.35W-5R-0P | 7.8 | 5.2 | 4.5 | 4.2 | 3.9 | 5.1 | 6 | |

| 0.35W-5.25R-0.25P | 10.1 | 5.5 | 4.6 | 4.4 | 4 | 5.3 | 6.3 | ||

| 0.35W-5.5R-0.5P | 12.6 | 6.5 | 5.3 | 4.9 | 4.4 | 5.8 | 7.2 | ||

| 0.35W-5.75R-0.75P | 11.6 | 6.2 | 5.1 | 4.8 | 4.3 | 5.6 | 6.9 | ||

| 0.35W-6R-1.0P | 11.3 | 5.9 | 4.9 | 4.6 | 4.2 | 5.5 | 6.7 | ||

| 0.35W-6.25R-1.25P | 10.3 | 5.7 | 4.8 | 4.5 | 4.1 | 5.4 | 6.4 | ||

| 0.35W-6.5R-1.5P | 10.1 | 5.3 | 4.5 | 4.3 | 3.9 | 5.2 | 6.1 | ||

| SCC3 | 0.4W-5R-0P | 6.2 | 4.7 | 4.1 | 3.9 | 3.6 | 4.8 | 5.5 | |

| 0.4W-5.25R-0.25P | 7.6 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | ||

| 0.4W-5.5R-0.5P | 9.1 | 5.3 | 4.5 | 4.3 | 3.9 | 5.2 | 6.1 | ||

| 0.4W-5.75R-0.75P | 11.4 | 6 | 5 | 4.7 | 4.2 | 5.6 | 6.8 | ||

| 0.4W-6R-1.0P | 9.5 | 5.8 | 4.9 | 4.6 | 4.2 | 5.5 | 6.6 | ||

| 0.4W-6.25R-1.25P | 8.8 | 5.3 | 4.5 | 4.3 | 3.9 | 5.2 | 6.1 | ||

| 0.4W-6.5R-1.5P | 8 | 4.9 | 4.3 | 4.1 | 3.8 | 5 | 5.7 | ||

| SCC4 | 0.45W-5R-0P | 5.2 | 4.4 | 3.9 | 3.8 | 3.5 | 4.6 | 5.2 | |

| 0.45W-5.25R-0.25P | 6.3 | 4.8 | 4.2 | 4 | 3.7 | 4.9 | 5.6 | ||

| 0.45W-5.5R-0.5P | 7.6 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | ||

| 0.45W-5.75R-0.75P | 9.5 | 5.7 | 4.8 | 4.5 | 4.1 | 5.4 | 6.4 | ||

| 0.45W-6R-1.0P | 7.9 | 5.3 | 4.5 | 4.3 | 3.9 | 5.2 | 6.1 | ||

| 0.45W-6.25R-1.25P | 7.3 | 5 | 4.4 | 4.1 | 3.8 | 5 | 5.8 | ||

| 0.45W-6.5R-1.5P | 6.7 | 4.9 | 4.2 | 4 | 3.7 | 4.9 | 5.7 |

- Abbreviation: SCC, self-consolidating concrete.

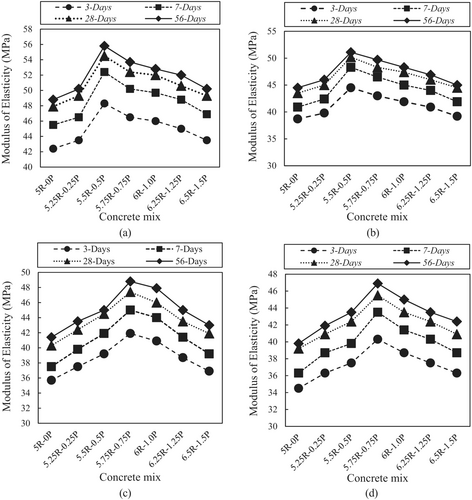

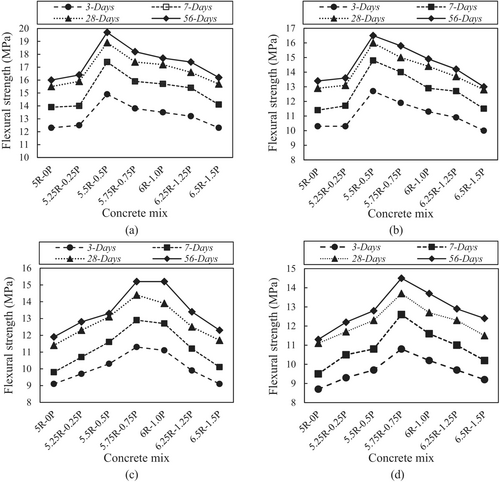

4.3 Modulus of elasticity

To determine the modulus of elasticity, three 150 mm × 300 mm samples were situated in a ring that included a strain gauge with correctness of 0.002 mm.74 Formerly, the stress–strain curves of samples were generated, and the preliminary tangent angle of these curves was chosen as the value of the modulus of elasticity. The results are presented in Figure 13.

Furthermore, the modulus of elasticity results was compared with those of previous models listed in Table 7,31, 84-86 and the obtained results are presented in Table 8. According to these results, the previously proposed models significantly underestimated the modulus of elasticity of PPF-reinforced SCC with NZ, particularly when 0.5% or 0.75% PPF was utilized. Therefore, the proposed models by Alsalman et al.,84 Graybeal and Stone,31 ACI 363–10,82 and NS 3473,86 which exhibited average differences of 35%, 42%, 31%, 52%, and 29%, respectively, are not suitable tools for estimating the modulus of elasticity of PPF-reinforced SCC.

| Group | Specimen | Curing age (days) | This study | Alsalman et al.84 | Graybeal and Stone31 | Graybeal and Stone31 | ACI 363-1085 | NS 347386 |

|---|---|---|---|---|---|---|---|---|

| SCC1 | 0.3W-5R-0P | 3 | 42.4 | 31.6 | 27 | 25.5 | 28.9 | 29.6 |

| 0.3W-5.25R-0.25P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | ||

| 0.3W-5.5R-0.5P | 48.3 | 34.5 | 30.4 | 28.7 | 31.7 | 31.8 | ||

| 0.3W-5.75R-0.75P | 46.5 | 33.6 | 29.3 | 27.7 | 30.8 | 31.1 | ||

| 0.3W-6R-1.0P | 46 | 33.4 | 29.1 | 27.4 | 30.6 | 30.9 | ||

| 0.3W-6.25R-1.25P | 45 | 32.9 | 28.5 | 26.9 | 30.1 | 30.5 | ||

| 0.3W-6.5R-1.5P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | ||

| SCC2 | 0.35W-5R-0P | 38.7 | 29.7 | 24.8 | 23.4 | 27.1 | 28.1 | |

| 0.35W-5.25R-0.25P | 39.8 | 30.3 | 25.4 | 24 | 27.6 | 28.5 | ||

| 0.35W-5.5R-0.5P | 44.5 | 32.6 | 28.2 | 26.6 | 29.9 | 30.3 | ||

| 0.35W-5.75R-0.75P | 43 | 31.9 | 27.3 | 25.8 | 29.2 | 29.8 | ||

| 0.35W-6R-1.0P | 41.9 | 31.4 | 26.7 | 25.2 | 28.7 | 29.4 | ||

| 0.35W-6.25R-1.25P | 40.9 | 30.8 | 26.1 | 24.6 | 28.2 | 28.9 | ||

| 0.35W-6.5R-1.5P | 39.2 | 30 | 25.1 | 23.7 | 27.4 | 28.3 | ||

| SCC3 | 0.4W-5R-0P | 35.7 | 28.2 | 23 | 21.7 | 25.7 | 26.9 | |

| 0.4W-5.25R-0.25P | 37.5 | 29.1 | 24.1 | 22.7 | 26.5 | 27.6 | ||

| 0.4W-5.5R-0.5P | 39.2 | 30 | 25.1 | 23.7 | 27.4 | 28.3 | ||

| 0.4W-5.75R-0.75P | 41.9 | 31.4 | 26.7 | 25.2 | 28.7 | 29.4 | ||

| 0.4W-6R-1.0P | 40.9 | 30.8 | 26.1 | 24.6 | 28.2 | 28.9 | ||

| 0.4W-6.25R-1.25P | 38.7 | 29.7 | 24.8 | 23.4 | 27.1 | 28.1 | ||

| 0.4W-6.5R-1.5P | 36.9 | 28.8 | 23.7 | 22.4 | 26.3 | 27.4 | ||

| SCC4 | 0.45W-5R-0P | 34.5 | 27.6 | 22.3 | 21 | 25.1 | 26.4 | |

| 0.45W-5.25R-0.25P | 36.3 | 28.5 | 23.4 | 22.1 | 26 | 27.1 | ||

| 0.45W-5.5R-0.5P | 37.5 | 29.1 | 24.1 | 22.7 | 26.5 | 27.6 | ||

| 0.45W-5.75R-0.75P | 40.3 | 30.6 | 25.7 | 24.3 | 27.9 | 28.7 | ||

| 0.45W-6R-1.0P | 38.7 | 29.7 | 24.8 | 23.4 | 27.1 | 28.1 | ||

| 0.45W-6.25R-1.25P | 37.5 | 29.1 | 24.1 | 22.7 | 26.5 | 27.6 | ||

| 0.45W-6.5R-1.5P | 36.3 | 28.5 | 23.4 | 22.1 | 26 | 27.1 | ||

| SCC1 | 0.3W-5R-0P | 7 | 45.5 | 33.1 | 28.8 | 27.2 | 30.4 | 30.7 |

| 0.3W-5.25R-0.25P | 46.5 | 33.6 | 29.3 | 27.7 | 30.8 | 31.1 | ||

| 0.3W-5.5R-0.5P | 52.4 | 36.4 | 32.8 | 31 | 33.7 | 33.2 | ||

| 0.3W-5.75R-0.75P | 50.2 | 35.4 | 31.5 | 29.7 | 32.6 | 32.4 | ||

| 0.3W-6R-1.0P | 49.7 | 35.2 | 31.3 | 29.5 | 32.4 | 32.3 | ||

| 0.3W-6.25R-1.25P | 48.8 | 34.7 | 30.7 | 29 | 32 | 32 | ||

| 0.3W-6.5R-1.5P | 46.9 | 33.8 | 29.6 | 28 | 31.1 | 31.3 | ||

| SCC2 | 0.35W-5R-0P | 40.9 | 30.8 | 26.1 | 24.6 | 28.2 | 28.9 | |

| 0.35W-5.25R-0.25P | 42.4 | 31.6 | 27 | 25.5 | 28.9 | 29.6 | ||

| 0.35W-5.5R-0.5P | 48.3 | 34.5 | 30.4 | 28.7 | 31.7 | 31.8 | ||

| 0.35W-5.75R-0.75P | 46.5 | 33.6 | 29.3 | 27.7 | 30.8 | 31.1 | ||

| 0.35W-6R-1.0P | 45 | 32.9 | 28.5 | 26.9 | 30.1 | 30.5 | ||

| 0.35W-6.25R-1.25P | 44 | 32.4 | 27.9 | 26.3 | 29.7 | 30.2 | ||

| 0.35W-6.5R-1.5P | 41.9 | 31.4 | 26.7 | 25.2 | 28.7 | 29.4 | ||

| SCC3 | 0.4W-5R-0P | 37.5 | 29.1 | 24.1 | 22.7 | 26.5 | 27.6 | |

| 0.4W-5.25R-0.25P | 39.8 | 30.3 | 25.4 | 24 | 27.6 | 28.5 | ||

| 0.4W-5.5R-0.5P | 41.9 | 31.4 | 26.7 | 25.2 | 28.7 | 29.4 | ||

| 0.4W-5.75R-0.75P | 45 | 32.9 | 28.5 | 26.9 | 30.1 | 30.5 | ||

| 0.4W-6R-1.0P | 44 | 32.4 | 27.9 | 26.3 | 29.7 | 30.2 | ||

| 0.4W-6.25R-1.25P | 41.4 | 31.1 | 26.4 | 24.9 | 28.4 | 29.2 | ||

| 0.4W-6.5R-1.5P | 39.2 | 30 | 25.1 | 23.7 | 27.4 | 28.3 | ||

| SCC4 | 0.45W-5R-0P | 36.3 | 28.5 | 23.4 | 22.1 | 26 | 27.1 | |

| 0.45W-5.25R-0.25P | 38.7 | 29.7 | 24.8 | 23.4 | 27.1 | 28.1 | ||

| 0.45W-5.5R-0.5P | 39.8 | 30.3 | 25.4 | 24 | 27.6 | 28.5 | ||

| 0.45W-5.75R-0.75P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | ||

| 0.45W-6R-1.0P | 41.4 | 31.1 | 26.4 | 24.9 | 28.4 | 29.2 | ||

| 0.45W-6.25R-1.25P | 40.3 | 30.6 | 25.7 | 24.3 | 27.9 | 28.7 | ||

| 0.45W-6.5R-1.5P | 38.7 | 29.7 | 24.8 | 23.4 | 27.1 | 28.1 | ||

| SCC1 | 0.3W-5R-0P | 28 | 47.9 | 34.3 | 30.2 | 28.5 | 31.5 | 31.6 |

| 0.3W-5.25R-0.25P | 49.3 | 34.9 | 31 | 29.2 | 32.2 | 32.1 | ||

| 0.3W-5.5R-0.5P | 54.5 | 37.4 | 34 | 32.1 | 34.7 | 34 | ||

| 0.3W-5.75R-0.75P | 52.4 | 36.4 | 32.8 | 31 | 33.7 | 33.2 | ||

| 0.3W-6R-1.0P | 52 | 36.2 | 32.6 | 30.7 | 33.5 | 33.1 | ||

| 0.3W-6.25R-1.25P | 50.6 | 35.6 | 31.8 | 30 | 32.8 | 32.6 | ||

| 0.3W-6.5R-1.5P | 49.3 | 34.9 | 31 | 29.2 | 32.2 | 32.1 | ||

| SCC2 | 0.35W-5R-0P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | |

| 0.35W-5.25R-0.25P | 45 | 32.9 | 28.5 | 26.9 | 30.1 | 30.5 | ||

| 0.35W-5.5R-0.5P | 50.2 | 35.4 | 31.5 | 29.7 | 32.6 | 32.4 | ||

| 0.35W-5.75R-0.75P | 48.3 | 34.5 | 30.4 | 28.7 | 31.7 | 31.8 | ||

| 0.35W-6R-1.0P | 47.4 | 34.1 | 29.9 | 28.2 | 31.3 | 31.4 | ||

| 0.35W-6.25R-1.25P | 46 | 33.4 | 29.1 | 27.4 | 30.6 | 30.9 | ||

| 0.35W-6.5R-1.5P | 44.5 | 32.6 | 28.2 | 26.6 | 29.9 | 30.3 | ||

| SCC3 | 0.4W-5R-0P | 40.3 | 30.6 | 25.7 | 24.3 | 27.9 | 28.7 | |

| 0.4W-5.25R-0.25P | 42.4 | 31.6 | 27 | 25.5 | 28.9 | 29.6 | ||

| 0.4W-5.5R-0.5P | 44.5 | 32.6 | 28.2 | 26.6 | 29.9 | 30.3 | ||

| 0.4W-5.75R-0.75P | 47.4 | 34.1 | 29.9 | 28.2 | 31.3 | 31.4 | ||

| 0.4W-6R-1.0P | 46 | 33.4 | 29.1 | 27.4 | 30.6 | 30.9 | ||

| 0.4W-6.25R-1.25P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | ||

| 0.4W-6.5R-1.5P | 41.9 | 31.4 | 26.7 | 25.2 | 28.7 | 29.4 | ||

| SCC4 | 0.45W-5R-0P | 39.2 | 30 | 25.1 | 23.7 | 27.4 | 28.3 | |

| 0.45W-5.25R-0.25P | 40.9 | 30.8 | 26.1 | 24.6 | 28.2 | 28.9 | ||

| 0.45W-5.5R-0.5P | 42.4 | 31.6 | 27 | 25.5 | 28.9 | 29.6 | ||

| 0.45W-5.75R-0.75P | 45.5 | 33.1 | 28.8 | 27.2 | 30.4 | 30.7 | ||

| 0.45W-6R-1.0P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | ||

| 0.45W-6.25R-1.25P | 42.4 | 31.6 | 27 | 25.5 | 28.9 | 29.6 | ||

| 0.45W-6.5R-1.5P | 40.9 | 30.8 | 26.1 | 24.6 | 28.2 | 28.9 | ||

| SCC1 | 0.3W-5R-0P | 56 | 48.8 | 34.7 | 30.7 | 29 | 32 | 32 |

| 0.3W-5.25R-0.25P | 50.2 | 35.4 | 31.5 | 29.7 | 32.6 | 32.4 | ||

| 0.3W-5.5R-0.5P | 55.8 | 38 | 34.8 | 32.8 | 35.3 | 34.4 | ||

| 0.3W-5.75R-0.75P | 53.7 | 37 | 33.6 | 31.7 | 34.3 | 33.7 | ||

| 0.3W-6R-1.0P | 52.8 | 36.6 | 33.1 | 31.2 | 33.9 | 33.4 | ||

| 0.3W-6.25R-1.25P | 52 | 36.2 | 32.6 | 30.7 | 33.5 | 33.1 | ||

| 0.3W-6.5R-1.5P | 50.2 | 35.4 | 31.5 | 29.7 | 32.6 | 32.4 | ||

| SCC2 | 0.35W-5R-0P | 44.5 | 32.6 | 28.2 | 26.6 | 29.9 | 30.3 | |

| 0.35W-5.25R-0.25P | 46 | 33.4 | 29.1 | 27.4 | 30.6 | 30.9 | ||

| 0.35W-5.5R-0.5P | 51.1 | 35.8 | 32 | 30.2 | 33 | 32.8 | ||

| 0.35W-5.75R-0.75P | 49.7 | 35.2 | 31.3 | 29.5 | 32.4 | 32.3 | ||

| 0.35W-6R-1.0P | 48.3 | 34.5 | 30.4 | 28.7 | 31.7 | 31.8 | ||

| 0.35W-6.25R-1.25P | 46.9 | 33.8 | 29.6 | 28 | 31.1 | 31.3 | ||

| 0.35W-6.5R-1.5P | 45 | 32.9 | 28.5 | 26.9 | 30.1 | 30.5 | ||

| SCC3 | 0.4W-5R-0P | 41.4 | 31.1 | 26.4 | 24.9 | 28.4 | 29.2 | |

| 0.4W-5.25R-0.25P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | ||

| 0.4W-5.5R-0.5P | 45 | 32.9 | 28.5 | 26.9 | 30.1 | 30.5 | ||

| 0.4W-5.75R-0.75P | 48.8 | 34.7 | 30.7 | 29 | 32 | 32 | ||

| 0.4W-6R-1.0P | 47.9 | 34.3 | 30.2 | 28.5 | 31.5 | 31.6 | ||

| 0.4W-6.25R-1.25P | 45 | 32.9 | 28.5 | 26.9 | 30.1 | 30.5 | ||

| 0.4W-6.5R-1.5P | 43 | 31.9 | 27.3 | 25.8 | 29.2 | 29.8 | ||

| SCC4 | 0.45W-5R-0P | 39.8 | 30.3 | 25.4 | 24 | 27.6 | 28.5 | |

| 0.45W-5.25R-0.25P | 41.9 | 31.4 | 26.7 | 25.2 | 28.7 | 29.4 | ||

| 0.45W-5.5R-0.5P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | ||

| 0.45W-5.75R-0.75P | 46.9 | 33.8 | 29.6 | 28 | 31.1 | 31.3 | ||

| 0.45W-6R-1.0P | 45 | 32.9 | 28.5 | 26.9 | 30.1 | 30.5 | ||

| 0.45W-6.25R-1.25P | 43.5 | 32.1 | 27.6 | 26 | 29.4 | 30 | ||

| 0.45W-6.5R-1.5P | 42.4 | 31.6 | 27 | 25.5 | 28.9 | 29.6 |

- Abbreviation: SCC, self-consolidating concrete.

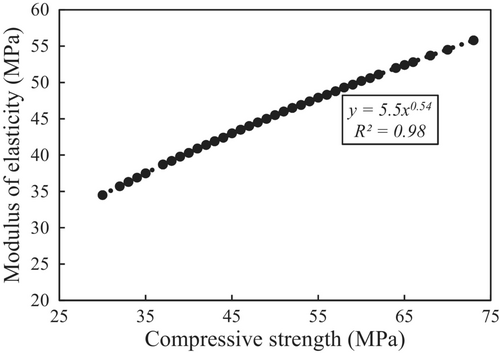

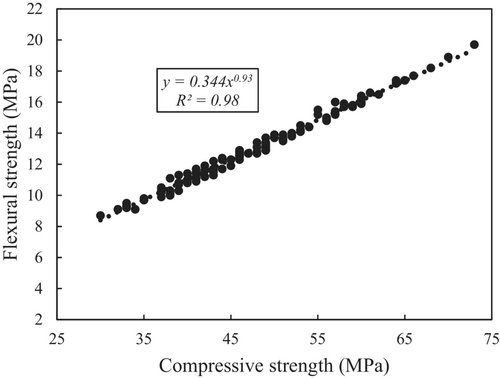

4.4 Flexural strength

The influence of the W/C ratio and HRWR on the flexural strength of PF-reinforced SCC with NZ was investigated. For this purpose, three samples measuring 500 mm × 100 mm × 100 mm were fabricated from each mixture and subjected to testing using a bending test.87 The average results of three tests for each sample were measured to determine the flexural strength of the mixtures, as depicted in Figure 15 for various W/C ratios. Consistent with previous findings on the enhancement of PF on the compressive and tensile strengths of SCC, flexural strength was improved due to the increased compressive and tensile strengths. In fact, when a sample is subjected to a flexural load, the top and bottom cross-sectional regions of the sample experience compressive and tensile stresses. Consequently, a similar trend of improvement was observed in the flexural strength of SCC with NZ, with the maximum value observed for 0.5% PF when the W/C ratio is 0.3 or 0.35, and 0.75% PF when the W/C ratio is 0.4 or 0.45. Therefore, employing an HRWR content equal to the sum of 1.25% cement and NZ ratio resulted in maximum flexural strength when low PF contents were utilized. Consequently, the highest flexural strength was achieved when 0.5% PF was combined with 5.5 kg/m3 HRWR, resulting in an average improvement of 22.5% and 25% for W/C ratios of 0.3 and 0.35, respectively. However, increasing the PF content above 0.5% for W/C ratios ≤0.35 and above 0.75% for 0.35 < W/C ratios ≤ 0.45 led to a decrease in the flexural strength of SCC with NZ. This declining trend associated with increasing PF content could be attributed to the water demand of PF, which increases the hardened state porosity of the specimens.

Moreover, Table 9 lists previous models proposed to predict the flexural strength of concrete based on compressive strength.84, 87-90 Additionally, Table 10 presents a comparison between the experimental results and those of previous models. It is evident that there is a significant disparity between the experimental findings and those predicted by previous models, with the latter underestimating the flexural strength of PPF-reinforced SCC with optimal NZ content, particularly when the W/C ratio is 0.3. Consequently, a new model is proposed, as illustrated in Figure 16 and Equation 7, to estimate the flexural strength of PPF-reinforced SCC with NZ, accounting for various W/C ratios and HRWR contents.

| Group | Specimen | Curing age (days) | This study | ACI 318–1485 | CSAA23.3-0488 | EN 1-189 | NZS 310190 | Kim91 |

|---|---|---|---|---|---|---|---|---|

| SCC1 | 0.3W-5R-0P | 3 | 12.3 | 4.1 | 4 | 5.4 | 4 | 4.6 |

| 0.3W-5.25R-0.25P | 12.5 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | ||

| 0.3W-5.5R-0.5P | 14.9 | 4.6 | 4.5 | 6.4 | 4.5 | 5.5 | ||

| 0.3W-5.75R-0.75P | 13.8 | 4.5 | 4.3 | 6.1 | 4.3 | 5.2 | ||

| 0.3W-6R-1.0P | 13.5 | 4.4 | 4.3 | 6 | 4.3 | 5.2 | ||

| 0.3W-6.25R-1.25P | 13.2 | 4.3 | 4.2 | 5.8 | 4.2 | 5 | ||

| 0.3W-6.5R-1.5P | 12.3 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | ||

| SCC2 | 0.35W-5R-0P | 10.3 | 3.8 | 3.6 | 4.8 | 3.6 | 4.1 | |

| 0.35W-5.25R-0.25P | 10.3 | 3.9 | 3.7 | 5 | 3.7 | 4.2 | ||

| 0.35W-5.5R-0.5P | 12.7 | 4.3 | 4.2 | 5.7 | 4.2 | 4.9 | ||

| 0.35W-5.75R-0.75P | 11.9 | 4.2 | 4 | 5.5 | 4 | 4.7 | ||

| 0.35W-6R-1.0P | 11.3 | 4.1 | 3.9 | 5.3 | 3.9 | 4.5 | ||

| 0.35W-6.25R-1.25P | 10.9 | 4 | 3.8 | 5.2 | 3.8 | 4.4 | ||

| 0.35W-6.5R-1.5P | 10 | 3.8 | 3.7 | 4.9 | 3.7 | 4.1 | ||

| SCC3 | 0.4W-5R-0P | 9.1 | 3.5 | 3.4 | 4.4 | 3.4 | 3.6 | |

| 0.4W-5.25R-0.25P | 9.7 | 3.7 | 3.5 | 4.7 | 3.5 | 3.9 | ||

| 0.4W-5.5R-0.5P | 10.3 | 3.8 | 3.7 | 4.9 | 3.7 | 4.1 | ||

| 0.4W-5.75R-0.75P | 11.3 | 4.1 | 3.9 | 5.3 | 3.9 | 4.5 | ||

| 0.4W-6R-1.0P | 11.1 | 4 | 3.8 | 5.2 | 3.8 | 4.4 | ||

| 0.4W-6.25R-1.25P | 9.9 | 3.8 | 3.6 | 4.8 | 3.6 | 4.1 | ||

| 0.4W-6.5R-1.5P | 9.1 | 3.6 | 3.5 | 4.6 | 3.5 | 3.8 | ||

| SCC4 | 0.45W-5R-0P | 8.7 | 3.4 | 3.3 | 4.2 | 3.3 | 3.5 | |

| 0.45W-5.25R-0.25P | 9.3 | 3.6 | 3.4 | 4.5 | 3.4 | 3.7 | ||

| 0.45W-5.5R-0.5P | 9.7 | 3.7 | 3.5 | 4.7 | 3.5 | 3.9 | ||

| 0.45W-5.75R-0.75P | 10.8 | 3.9 | 3.8 | 5.1 | 3.8 | 4.3 | ||

| 0.45W-6R-1.0P | 10.2 | 3.8 | 3.6 | 4.8 | 3.6 | 4.1 | ||

| 0.45W-6.25R-1.25P | 9.7 | 3.7 | 3.5 | 4.7 | 3.5 | 3.9 | ||

| 0.45W-6.5R-1.5P | 9.2 | 3.6 | 3.4 | 4.5 | 3.4 | 3.7 | ||

| SCC1 | 0.3W-5R-0P | 7 | 13.9 | 4.4 | 4.2 | 5.9 | 4.2 | 5.1 |

| 0.3W-5.25R-0.25P | 14 | 4.5 | 4.3 | 6.1 | 4.3 | 5.2 | ||

| 0.3W-5.5R-0.5P | 17.4 | 5 | 4.8 | 7 | 4.8 | 6.2 | ||

| 0.3W-5.75R-0.75P | 15.9 | 4.8 | 4.6 | 6.7 | 4.6 | 5.8 | ||

| 0.3W-6R-1.0P | 15.7 | 4.8 | 4.6 | 6.6 | 4.6 | 5.7 | ||

| 0.3W-6.25R-1.25P | 15.4 | 4.7 | 4.5 | 6.4 | 4.5 | 5.6 | ||

| 0.3W-6.5R-1.5P | 14.1 | 4.5 | 4.4 | 6.1 | 4.4 | 5.3 | ||

| SCC2 | 0.35W-5R-0P | 11.4 | 4 | 3.8 | 5.2 | 3.8 | 4.4 | |

| 0.35W-5.25R-0.25P | 11.7 | 4.1 | 4 | 5.4 | 4 | 4.6 | ||

| 0.35W-5.5R-0.5P | 14.8 | 4.6 | 4.5 | 6.4 | 4.5 | 5.5 | ||

| 0.35W-5.75R-0.75P | 14 | 4.5 | 4.3 | 6.1 | 4.3 | 5.2 | ||

| 0.35W-6R-1.0P | 12.9 | 4.3 | 4.2 | 5.8 | 4.2 | 5 | ||

| 0.35W-6.25R-1.25P | 12.7 | 4.3 | 4.1 | 5.7 | 4.1 | 4.8 | ||

| 0.35W-6.5R-1.5P | 11.5 | 4.1 | 3.9 | 5.3 | 3.9 | 4.5 | ||

| SCC3 | 0.4W-5R-0P | 9.8 | 3.7 | 3.5 | 4.7 | 3.5 | 3.9 | |

| 0.4W-5.25R-0.25P | 10.7 | 3.9 | 3.7 | 5 | 3.7 | 4.2 | ||

| 0.4W-5.5R-0.5P | 11.6 | 4.1 | 3.9 | 5.3 | 3.9 | 4.5 | ||

| 0.4W-5.75R-0.75P | 12.9 | 4.3 | 4.2 | 5.8 | 4.2 | 5 | ||

| 0.4W-6R-1.0P | 12.7 | 4.3 | 4.1 | 5.7 | 4.1 | 4.8 | ||

| 0.4W-6.25R-1.25P | 11.2 | 4 | 3.9 | 5.3 | 3.9 | 4.5 | ||

| 0.4W-6.5R-1.5P | 10.1 | 3.8 | 3.7 | 4.9 | 3.7 | 4.1 | ||

| SCC4 | 0.45W-5R-0P | 9.5 | 3.6 | 3.4 | 4.5 | 3.4 | 3.7 | |

| 0.45W-5.25R-0.25P | 10.5 | 3.8 | 3.6 | 4.8 | 3.6 | 4.1 | ||

| 0.45W-5.5R-0.5P | 10.8 | 3.9 | 3.7 | 5 | 3.7 | 4.2 | ||

| 0.45W-5.75R-0.75P | 12.6 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | ||

| 0.45W-6R-1.0P | 11.6 | 4 | 3.9 | 5.3 | 3.9 | 4.5 | ||

| 0.45W-6.25R-1.25P | 11 | 3.9 | 3.8 | 5.1 | 3.8 | 4.3 | ||

| 0.45W-6.5R-1.5P | 10.2 | 3.8 | 3.6 | 4.8 | 3.6 | 4.1 | ||

| SCC1 | 0.3W-5R-0P | 28 | 15.5 | 4.6 | 4.4 | 6.3 | 4.4 | 5.5 |

| 0.3W-5.25R-0.25P | 15.9 | 4.7 | 4.6 | 6.5 | 4.6 | 5.7 | ||

| 0.3W-5.5R-0.5P | 18.9 | 5.2 | 5 | 7.4 | 5 | 6.5 | ||

| 0.3W-5.75R-0.75P | 17.4 | 5 | 4.8 | 7 | 4.8 | 6.2 | ||

| 0.3W-6R-1.0P | 17.2 | 5 | 4.8 | 7 | 4.8 | 6.1 | ||

| 0.3W-6.25R-1.25P | 16.6 | 4.8 | 4.7 | 6.7 | 4.7 | 5.9 | ||

| 0.3W-6.5R-1.5P | 15.7 | 4.7 | 4.6 | 6.5 | 4.6 | 5.7 | ||

| SCC2 | 0.35W-5R-0P | 12.9 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | |

| 0.35W-5.25R-0.25P | 13.1 | 4.3 | 4.2 | 5.8 | 4.2 | 5 | ||

| 0.35W-5.5R-0.5P | 16 | 4.8 | 4.6 | 6.7 | 4.6 | 5.8 | ||

| 0.35W-5.75R-0.75P | 15 | 4.6 | 4.5 | 6.4 | 4.5 | 5.5 | ||

| 0.35W-6R-1.0P | 14.4 | 4.6 | 4.4 | 6.2 | 4.4 | 5.4 | ||

| 0.35W-6.25R-1.25P | 13.7 | 4.4 | 4.3 | 6 | 4.3 | 5.2 | ||

| 0.35W-6.5R-1.5P | 12.8 | 4.3 | 4.2 | 5.7 | 4.2 | 4.9 | ||

| SCC3 | 0.4W-5R-0P | 11.4 | 3.9 | 3.8 | 5.1 | 3.8 | 4.3 | |

| 0.4W-5.25R-0.25P | 12.3 | 4.1 | 4 | 5.4 | 4 | 4.6 | ||

| 0.4W-5.5R-0.5P | 13.1 | 4.3 | 4.2 | 5.7 | 4.2 | 4.9 | ||

| 0.4W-5.75R-0.75P | 14.4 | 4.6 | 4.4 | 6.2 | 4.4 | 5.4 | ||

| 0.4W-6R-1.0P | 13.9 | 4.4 | 4.3 | 6 | 4.3 | 5.2 | ||

| 0.4W-6.25R-1.25P | 12.5 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | ||

| 0.4W-6.5R-1.5P | 11.7 | 4.1 | 3.9 | 5.3 | 3.9 | 4.5 | ||

| SCC4 | 0.45W-5R-0P | 11.1 | 3.8 | 3.7 | 4.9 | 3.7 | 4.1 | |

| 0.45W-5.25R-0.25P | 11.7 | 4 | 3.8 | 5.2 | 3.8 | 4.4 | ||

| 0.45W-5.5R-0.5P | 12.3 | 4.1 | 4 | 5.4 | 4 | 4.6 | ||

| 0.45W-5.75R-0.75P | 13.7 | 4.4 | 4.2 | 5.9 | 4.2 | 5.1 | ||

| 0.45W-6R-1.0P | 12.7 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | ||

| 0.45W-6.25R-1.25P | 12.3 | 4.1 | 4 | 5.4 | 4 | 4.6 | ||

| 0.45W-6.5R-1.5P | 11.5 | 4 | 3.8 | 5.2 | 3.8 | 4.4 | ||

| SCC1 | 0.3W-5R-0P | 56 | 16 | 4.7 | 4.5 | 6.4 | 4.5 | 5.6 |

| 0.3W-5.25R-0.25P | 16.4 | 4.8 | 4.6 | 6.7 | 4.6 | 5.8 | ||

| 0.3W-5.5R-0.5P | 19.7 | 5.3 | 5.1 | 7.6 | 5.1 | 6.7 | ||

| 0.3W-5.75R-0.75P | 18.2 | 5.1 | 4.9 | 7.2 | 4.9 | 6.4 | ||

| 0.3W-6R-1.0P | 17.7 | 5 | 4.9 | 7.1 | 4.9 | 6.3 | ||

| 0.3W-6.25R-1.25P | 17.4 | 5 | 4.8 | 7 | 4.8 | 6.1 | ||

| 0.3W-6.5R-1.5P | 16.2 | 4.8 | 4.6 | 6.7 | 4.6 | 5.8 | ||

| SCC2 | 0.35W-5R-0P | 13.4 | 4.3 | 4.2 | 5.7 | 4.2 | 4.9 | |

| 0.35W-5.25R-0.25P | 13.6 | 4.4 | 4.3 | 6 | 4.3 | 5.2 | ||

| 0.35W-5.5R-0.5P | 16.5 | 4.9 | 4.7 | 6.8 | 4.7 | 6 | ||

| 0.35W-5.75R-0.75P | 15.8 | 4.8 | 4.6 | 6.6 | 4.6 | 5.7 | ||

| 0.35W-6R-1.0P | 14.9 | 4.6 | 4.5 | 6.4 | 4.5 | 5.5 | ||

| 0.35W-6.25R-1.25P | 14.2 | 4.5 | 4.4 | 6.1 | 4.4 | 5.3 | ||

| 0.35W-6.5R-1.5P | 13 | 4.3 | 4.2 | 5.8 | 4.2 | 5 | ||

| SCC3 | 0.4W-5R-0P | 11.9 | 4 | 3.9 | 5.3 | 3.9 | 4.5 | |

| 0.4W-5.25R-0.25P | 12.8 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | ||

| 0.4W-5.5R-0.5P | 13.3 | 4.3 | 4.2 | 5.8 | 4.2 | 5 | ||

| 0.4W-5.75R-0.75P | 15.2 | 4.7 | 4.5 | 6.4 | 4.5 | 5.6 | ||

| 0.4W-6R-1.0P | 15.2 | 4.6 | 4.4 | 6.3 | 4.4 | 5.5 | ||

| 0.4W-6.25R-1.25P | 13.4 | 4.3 | 4.2 | 5.8 | 4.2 | 5 | ||

| 0.4W-6.5R-1.5P | 12.3 | 4.2 | 4 | 5.5 | 4 | 4.7 | ||

| SCC4 | 0.45W-5R-0P | 11.3 | 3.9 | 3.7 | 5 | 3.7 | 4.2 | |

| 0.45W-5.25R-0.25P | 12.2 | 4.1 | 3.9 | 5.3 | 3.9 | 4.5 | ||

| 0.45W-5.5R-0.5P | 12.8 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | ||

| 0.45W-5.75R-0.75P | 14.5 | 4.5 | 4.4 | 6.1 | 4.4 | 5.3 | ||

| 0.45W-6R-1.0P | 13.7 | 4.3 | 4.2 | 5.8 | 4.2 | 5 | ||

| 0.45W-6.25R-1.25P | 12.9 | 4.2 | 4.1 | 5.6 | 4.1 | 4.8 | ||

| 0.45W-6.5R-1.5P | 12.4 | 4.1 | 4 | 5.4 | 4 | 4.6 |

- Abbreviation: SCC, self-consolidating concrete.

5 CONCLUSIONS

- In terms of fresh-state properties of PF-reinforced SCC with NZ (slump, T500, V-funnel, and L-box ratio), using an HRWR content equal to the sum of 1.25% cement and NZ content avoided a reduction in workability of SCC when up to 1% PF were used, even though previous studies showed that increasing the PF content led to reducing the workability of SCC;

- Increasing the W/C ratio decreased the modulus of elasticity, compressive, flexural and splitting tensile strengths of SCC with NZ; however, these properties improved with an increase in the curing age, as expected. In addition, using an HRWR content equal to the sum of 1.25% cement content and NZ ratio avoided a reduction in mechanical properties of PF-reinforced NZ SCC when up to 0.5% PF were used with up to 0.35 W/C ratio or 0.75% PF were used with up to 0.45% W/C. Also, it is recommended that more HRWR than the sum of 1.25% cement content and NZ ratio is used when more than 0.75% PPF are used;

- Previous models proposed by standards and investigations were unable to predict the mechanical properties of PF-reinforced SCC with NZ and underestimated the properties of specimens by a substantial difference;

- The models proposed in this study show a good agreement with experimental results and are recommended in order to predict the fresh- and hardened-state properties (splitting tensile strength, flexural strength and modulus of elasticity) of PF-reinforced SCC with NZ, based on W/C ratio and HRWR content, relative to the compressive strength.

ACKNOWLEDGMENT

Open access publishing facilitated by Western Sydney University, as part of the Wiley - Western Sydney University agreement via the Council of Australian University Librarians.

Biographies

Dr. Arash K. Pour got his Ph.D. in Civil Engineering from the University of Texas at El Paso (UTEP), USA, in 2023. Also, he has been the reviewer for different publishers in civil engineering research area. His main research area is sustainable concrete structures and recycled cementitious concrete mixtures, finite element method simulation, advance concrete technology, etc. Email: [email protected].

Dr. Amir Shirkhani is a Research Fellow in Structural and Earthquake Engineering at the University of Tabriz. His current research works are on structural vibration control, energy dissipation systems, structural optimization, seismic hazard levels, innovative structural systems, performance-based earthquake engineering, seismic loss assessment, cost–benefit analysis, seismic rehabilitation and retrofit, endurance time method, reinforced concrete, environmental impacts, and artificial neural networks. Email: [email protected].

Dr. Ehsan Noroozinejad Farsangi is a Senior Researcher at the Urban Transformations Research Centre, where he specializes in Smart Resilient Construction and Infrastructure. With a wealth of experience, Dr. Noroozinejad previously held a prestigious position at UBC Smart Structures in Canada before joining the UTRC. As the director of the Resilient Structures Research Group, Dr. Noroozinejad has spearheaded groundbreaking advancements in the field of structural engineering alongside an esteemed team of international researchers. Dr. Noroozinejad's prolific and influential academic career is underscored by the publication of over 150 high-impact journal papers, 7 books in collaboration with esteemed publishers, and various patents. Email: [email protected].

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.