Direct Tensile Testing of Free-Standing Ultrathin Polymer Films on Liquid Surface at High Temperature

Abstract

The fragile nature of ultrathin polymer films poses a challenge for precise mechanical property measurements in a free-standing state, despite their critical importance for the fabrication and performance of advanced electronic devices under thermal loading. Here, a novel high-temperature tensile testing method for free-standing ultrathin polymer films using a film on heated liquid (FOHL) platform is proposed. Glycerol is chosen for the thermally stable liquid platform for its high surface tension, high boiling point, miscibility with water, and chemical stability. A defect healing process of the specimen on the heated liquid effectively eliminates preexisting defects of the brittle polymer sample, enabling precise tensile property measurements at elevated temperatures. The methodology is validated through experiments on polystyrene (PS) films of varying thicknesses (50–400 nm) at elevated temperatures of 25–100 °C, demonstrating the influence of temperature and thickness on tensile properties. Decreasing elastic modulus with increasing temperature and decreasing thickness of ultrathin PS films is accurately measured. The proposed method provides a reliable method todirectly evaluate the tensile properties of ultrathin films in high-temperature conditions.

1 Introduction

Mechanical properties of ultrathin polymer films are of critical importance for reliable fabrication and usage of various thin electronic devices that undergo frequent thermal loading during fabrication or operation. As advanced electronic technologies develop, the devices are gradually becoming miniaturized and integrated, and ultrathin polymer films are used as key materials for organic light emitting diode (OLED),[1] thin film transistor (TFT),[2] environmental barriers in packaging,[3] and various thin films encapsulation (TFE).[4] In particular, the mechanical stability prediction of the devices is made through accurate measurement of the mechanical property of thin film materials constituting the device.[5-7] There has been a continuous effort to characterize tensile properties of thin films at room temperatures, including micro/nano-indentation,[8, 9] small scale testing using micro-electro mechanical systems,[10, 11] and film buckling-based method.[12-14] Recently, the polymer thin films constituting these device are usually exposed to a high-temperature environment, and the mechanical properties of the thin film tend to change greatly in the high-temperature environment.[15, 16] Therefore, it is critical to accurately measure the mechanical properties of polymer thin films under high-temperature conditions to predict the devices performance in high-temperature environments and ensure their reliability and durability.

Despite their importance, it is challenging to measure the tensile properties of the ultrathin polymer films due to difficult fabrication in a defect-free state due to their fragile nature. Some studies have conducted research on the tensile behavior of the thin films at high temperature by using indirect comparison measurement methods,[14] and analytical methods related to thermodynamic model of polymer thin films.[17] Torres et al. developed an elastic modulus measurement method of polymer thin films using wrinkling on an elastic substrate, but the limitations were that the thin films were confined by a solid substrate and the measurement method was an indirect measurement method by a compressive test.[14] Since the conventional test methods for polymer thin films are practically not applicable for direct tensile testing at high temperature, experimental demonstration has not yet been introduced.

The tensile testing should be conducted for a free-standing thin film that is not deposited or confined to a solid substrate. The substrate confinement effect on thin films results in inconsistent measurements of mechanical properties.[18, 19] In particular, the thinner the thickness of the film deposited on the substrate, the higher the fraction of the surface layer of the thin film. This increased surface effect results in inaccurate mechanical property measurements compared to films of bulk scale thickness.[20] Thus, tensile testing of free-standing thin films should be performed to eliminate interfacial effects by the substrate that can cause inconsistent measurement results.[21] In addition, a variable temperature setup should be adopted so that in-situ heating is guaranteed. A measurement setup that can track changes in the mechanical properties of a specimen while controlling the temperature over a wide range of temperatures.[22, 23] However, it has been very difficult to develop a method for accurately measuring the tensile properties of thin films experimentally in an elevated temperature condition with an in-situ heating system.[17]

In order to overcome the inaccurate measurement of the mechanical properties of the films due to the confinement effect of the film substrate, Kim et al. developed a tensile testing method with the free-standing state of the film by utilizing a water platform.[24] As a result, the tensile properties of various previously unknown free-standing films such as nanocarbon composite electrode[25] and active layer of polymer solar cells (PSCs)[26] have been reported. Novel methods have been developed to measure thermomechanical properties such as the coefficient of thermal expansion (CTE) and glass transition temperature (Tg),[27-29] as well as stress relaxation of thin films on heated water surface.[30] However, no experimental studies have been reported for direct tensile testing of freestanding ultrathin films at high temperature.

In this research, a direct measurement method that enables accurate in-situ measurement of the mechanical properties of ultrathin polymer films at an elevated temperature is demonstrated. The platform for setting up high-temperature tensile testing for ultrathin polymer films should be selected as a thermally stable platform, and we constructed the tensile testing system by adopting a film on heated liquid (FOHL) configuration.[27] A thermally stable heated liquid platform should satisfy the conditions of no internal flow generation by thermal heating that can cause damage to the thin film, and it should be miscible with water to ensure the transfer of the free-standing films onto the water surface. A transfer method capable of successfully transferring various thin films onto the thermally stable liquid surface was developed, and a setup based on a heated liquid platform capable of measuring the tensile properties of polymer and metal thin films in elevated temperature conditions was established. We first characterized the high-temperature tensile behavior of polystyrene (PS) ultrathin films with thickness below 100 nm. Glycerol was selected as the optimal FOHL platform by considering its high-surface tension (≈60 mN m−1), high-boiling temperature (≈290 °C), miscibility with water, and chemical stability.[31] Tensile properties of free-standing ultrathin PS films with thickness ranging from 50 to 400 nm was measured at elevated temperature ranging from 25–100 °C without the substrate confinement effect. The temperature and thickness dependence of Young's modulus was accurately evaluated using the direct tensile test on heated glycerol surface. The method we propose to accurately evaluate the tensile properties of free-standing ultrathin films in elevated temperature conditions can reveal the high-temperature tensile properties of various thin films that are not well known.

2 Results and Discussion

2.1 Tensile Testing System for Ultrathin Film on Heated Liquid Platform

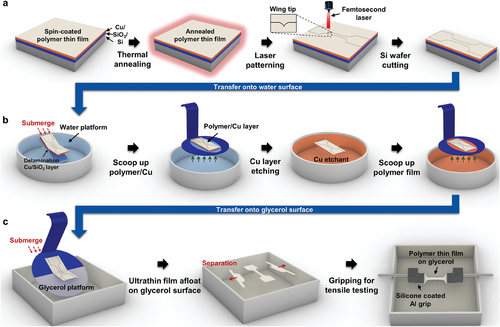

Ultrathin polymer films are prone to being damaged or fractured by impact when transferred to a specific platform in a free-standing state. A method that transfers a free-standing target ultrathin polymer film onto a thermally stable liquid platform without significant mechanical degradation is shown in Figure 1. The target ultrathin polymer film is deposited on a 1µm-thick Cu sacrificial layer (Cu/SiO2/Si) with a root mean square (RMS) roughness of 4.02 ± 0.64 nm (mean ± SD, n = 3), with a standard error (SE) of 0.37 nm, as shown in Figure S2 (Supporting Information). This level of roughness may have negligible influence the mechanical properties of the PS films, which exhibited a lower RMS roughness of 1.29± 0.83 nm (mean ± SD, n = 3), with a standard error (SE) of 0.48 nm. The target film is then thermally annealed and patterned into a dog-bone shape to apply uniform stress around the middle of the specimen when tensile force is applied (Figure 1a). This patterning process utilizes a femtosecond laser, which minimizes defects near the edges of the specimen because the pulse duration (230 fs) is very short. In addition, the wing-tips are additionally processed on the target film, which is a pattern for the digital image correlation (DIC) device to recognize the strain change of the target film in a noncontact manner. The prepared specimen is submerged in DI water to induce delamination between the Cu and SiO2 layer due to weak adhesion[32] so that target thin film/Cu bilayer is transferred onto the water surface (Figure 1b). To selectively etch the Cu layer, the target thin film/Cu bilayer is scooped up from DI water to 0.05 m of (NH4)2S2O8(aq) (ammonium persulfate aqueous solution) surface. The target film scooped up from the (NH4)2S2O8(aq) surface is transferred to a DI water platform and then to the thermally stable liquid platform. The scooping and transferring to the thermally stable liquid platform are conducted three times to ensure no water residue is left on the target film. The target film in a free-standing state on a thermally stable platform, with parts except for the dog-bone shape removed (Figure S1, Supporting Information), is gripped by van der Waals force to a 5 mm-thick layer of polydimethylsiloxane (PDMS)-coated aluminum grip (Figure 1c). Each grip is attached to a load cell and a linear actuator, to measure tensile force and to control displacement, respectively. The PDMS-coated aluminum grips approach the target film perpendicularly, allowing the film to bond to the grips without defects. The van der Waals adhesion between the PDMS coating and the specimen surface provides strong adhesion without the need for adhesives, external forces, or mechanical fastening. This method ensures easy handling and prevents slippage or delamination during tensile testing, allowing for reliable tensile property measurements of the target film. To confirm the structural integrity of samples after the multiple transfer processes, vision inspection by differential interference contrast camera was conducted before each testing. Any micro-cracks would be clearly visible through the camera, as shown in Figure S1 (Supporting Information). We also checked that the PS thin films recovered elastically within the elastic deformation region during tensile testing. Had the films been deformed beyond the elastic region during the transfer processes, they would have fractured. Therefore, we conclude that the thin films did not fracture during the transfer process due to the high-surface tension (60–70 mN m−1) of the liquids—water, Cu etchant, and glycerol—that effectively minimized deformation of the films throughout the transfer. It is also noted that the bending strain should be negligible when considering the nano-scale thickness of the tensile specimen.

Schematic of the total setup for direct tensile testing of ultrathin polymer films at elevated temperature conditions was shown in Figure 2a. The tensile testing liquid platform utilizes thermally stable liquid and the FOHL measurement method is applied. The FOHL platform is placed onto the brass hot plate which can heat the liquid and target film. It is necessary to select the appropriate liquid platform that can stably perform tensile testing on the target free-standing ultrathin film in a high-temperature condition. The characteristics that should be satisfied for an appropriate tensile testing liquid platform for ultrathin film in elevated temperature conditions are high-surface tension, high-boiling temperature, miscibility with water, and chemical inertness. Glycerol can be used as a FOHL platform that satisfies all these characteristics, and detailed information of selecting the liquid is descripted in “Selecting a thermally stable high-temperature tensile testing liquid platform” part.

For accurate strain measurement, the DIC method[33] was adopted, using a charge-coupled device (CCD) camera on top of the specimen center. The wing tip of the target film was patterned by a femtosecond laser as a tracking pattern, which is recognized and assigned as the strain gauge (P1, P1') (Figure 2b). The temperature of the heated liquid platform was measured by a thermometer at the surface, where the temperature is assumed to be the same with that of thin film specimen due to sufficiently thin thickness of the film. The strain change of the target film was measured by the distance change between wing tips, and the tensile load was measured by a load cell simultaneously during the tensile testing at elevated temperature conditions. In conclusion, the setup established can accurately measure the tensile properties of the free-standing ultrathin film in elevated temperature conditions by an in-situ method was established.

2.2 Selecting a Thermally Stable Liquid Platform for High-Temperature Tensile Testing

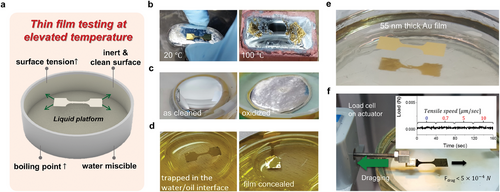

It is necessary to select the appropriate liquid platform that can stably perform tensile testing of target free-standing ultrathin film on a high-temperature condition. The most important properties for being an appropriate tensile testing liquid platform for ultrathin film in elevated temperature conditions are high boiling temperature with thermal stability, high surface tension, high boiling temperature, miscibility with water, and chemical inertness (Figure 3a). Table S1 (Supporting Information) summarizes liquids (water, sunflower oil, liquid gallium, and glycerol) that can be utilized as a tensile testing platform in elevated temperature conditions and their physical properties.[31, 34-41] As the first candidate, liquid gallium was selected due to its high boiling temperature of ≈2200 °C and its unique property of being liquid at room temperature. For experimental convenience, a gold thin film was used to verify the usability of our tensile testing system as a heated liquid. As seen in Figure 3b, the phase change from solid to liquid could be utilized by scooping a 55 nm-thick Au thin film specimen afloat on water using a solid gallium block. After melting the gallium to liquid, however, two major problems were found regarding material compatibility and surface oxide problem. First, the liquid gallium dissolves some noble metals such as gold or platinum by diffusion. We confirmed that the 55 nm-thick Au thin film was dissolved on the surface of liquid gallium. Second, due to its high reactivity with oxygen, the surface layer becomes oxidized in several seconds, by forming several nanometer-thick layers of gallium oxide (Ga2O3).[42] Although it could be removed when strong acid (HCl) or base (NaOH) solution was applied, the liquid gallium oxidizes right after the oxide removal reaction (Figure 3c). Sunflower oil was also considered as a platform for tensile testing of free-standing ultrathin film in elevated temperature conditions because sunflower oil has a high boiling point over 200 °C and comparable surface tension (33.5 mN m−1) with that of water. However, the tensile testing liquid platform should be water-miscible since the target free-standing film is transferred to a water or water-based etchants platform. We confirmed that the 55nm Au thin film could not be transferred onto the sunflower oil surface because the sunflower oil is not mixed with water, and we determined that sunflower oil was difficult to use as the tensile testing platform (Figure 3d). As a result, glycerol was selected as the most suitable platform to utilize as the FOHL platform of tensile testing ultrathin film in elevated temperature conditions. Since the boiling point of glycerol is high enough (≈290 °C), little internal liquid flow and no bubbles are generated in the glycerol platform, and mechanical degradation does not occur to the free-standing target thin film during tensile testing in a high-temperature condition. Vaporization occurred when the temperature exceeds ≈120 °C, but it does not disturb the thin film on the surface. Considering the fact that the majority of polymers show glass transition at a temperature less than 120 °C, we conclude that glycerol is a proper testing platform for polymer film under elevated temperatures. The surface tension of glycerol is ≈60 mN m−1 at room temperature which is almost similar to that of water. Importantly, glycerol has three hydroxyl groups that make glycerol very miscible in water. Ultrathin gold films with a thickness of 55 nm were successfully transferred onto the glycerol surface (Figure 3e). In addition, during the measurement of tensile properties of polymer film under elevated temperature, the interfacial work by surface tension at the polymer film-glycerol interface is considered negligible.[43-45]

Compared to the breakage force (≈0.05 N) and breakage strain (≈1.5%) of the 100 nm gold film,[24] the drag force (Ffriction) and strain change (ɛfilm) due to friction between the glycerol surface and the film are negligible. Also, the lower the pulling speed, the smaller the frictional effect of the glycerol platform. In addition, since the dynamic viscosity of the glycerol exponentially decreases as temperature increases,[40] it is certain that no significant frictional force acts at the interface between the thin film and glycerol surface during high-temperature tensile testing. In the case of polymer thin film, the elastic modulus (for example, PS film with a 390 nm thickness: ≈3.9 GPa at RT condition) is generally lower than that of metal film, but strain change due to the drag force is also negligible compared to breakage strain (for example, PS film with 390 nm thickness: 1.1% at RT condition). In conclusion, our tensile testing setup has the ability to accurately measure tensile properties of the free-standing films in high-temperature conditions.

2.3 Measurement of Tensile Properties of the PS Thin Film at High Temperature

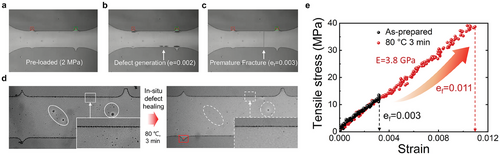

PS thin film is used as a key material for improving the mechanical properties of next-generation devices, and this device has a high risk of being exposed to a thermal environment during operation. Therefore, it is very important to accurately measure the tensile properties of the film in a high-temperature condition to predict the thermal stability of the devices. However, in the case of ultrathin polymer films, there is a high possibility of defect generation in the specimen during the fabrication process due to their brittle nature. In addition, the dog-bone patterning process of the specimen using a femtosecond laser is a method to maximize the edge quality, but there is a limit to the precision of thin film patterning due to the nm-scale thickness of the specimen, and edge defects are usually found at the initially rugged edge of the specimen. Our developed tensile testing setup can prevent the mechanical degradation that causes difficulties in measuring the precise properties of ultrathin film specimens. Figure 4a shows images from the CCD camera for an ultrathin PS film specimen with a thickness of 190 nm under a small pre-load of 2 MPa. During tensile testing, macro defect was generated from an edge side at elongation of 0.002 (Figure 4b), and resulted in premature fracture (Figure 4c). Utilizing our proposed tensile testing setup, thermal annealing can be performed on the polymer thin-film specimens prior to tensile testing to solve the premature fracture problem. The thermal heating condition was determined to be 80 °C for 3 min, where the polymer surface relaxes its structural conformation near its glass transition temperature (Tg) which is ≈100 °C.[30]

The thermal heating process thermally reconfigures the defective parts of the specimen. With the simple thermal heating process as mentioned above, the edge of the specimen becomes smoother, the side edge quality improves, and the pinhole existing in the specimen is healed (Figure 4d). As a result, stress concentration around the edge and pinhole is prevented during the tensile process. Figure 4e indicates that elongation at fracture (ef) of the PS thin film increases from 0.003 to 0.011, confirming that more accurate tensile properties can be measured by defect healing during the tensile testing of the PS thin film through the prior thermal heating process.

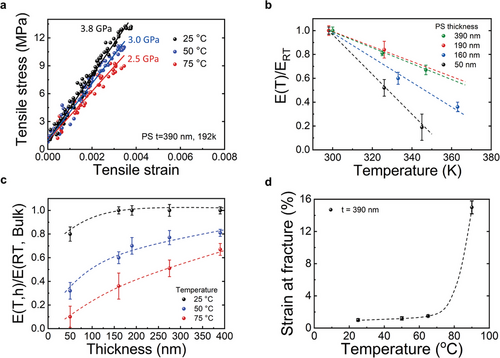

As the thickness of PS film decreases, its fragility increases significantly, it was very challenging to accurately measure the tensile properties of free-standing ultrathin PS film in a high-temperature condition. We have solved this problem by utilizing the tensile testing setup we developed. The elastic modulus of a 390 nm-thick free-standing PS film with molecular weight of 192 K with different temperatures of 25, 50, and 75 °C was measured (Figure 5a). Tensile testing was conducted within the strain range of 0–0.003. The stress does not start from 0 MPa due to the initial pre-loading necessary to eliminate slack in the system and ensure proper contact between the sample and the testing apparatus. At room temperature, the measured elastic modulus was 3.8 GPa. As temperature increased to 52 and 75 °C, the measured elastic modulus decreased to 3.0 and 2.5 GPa, respectively. The elastic modulus of PS thin films tends to decrease as they are exposed to high-temperature conditions because the interaction between PS molecules becomes weakened.[15, 16] In order to investigate the elastic modulus dependence on both thickness and temperature, modulus measurements at different temperature were conducted for PS thin films with various thicknesses from 50 to 390 nm (Figure 5b). It was found that the decreasing rate of modulus for increasing temperature was much larger for thinner thin film materials. The reason is that as the thickness decreases, the portion of the surface soft layer of the thin films becomes larger, and the interaction between the PS molecules weakens as the temperature increases. The weakened chain interactions inside films result in lower Tg as the film thickness reduces. Thus, the reduction in thickness leads to a greater rate of decrease in the Young's modulus due to lower Tg as the temperature increases.[47] Figure 5c shows the thickness dependence at different temperatures. It was also observed that the modulus decreasing rate for decreasing film thickness was larger at higher temperature. Interestingly, the elongation of the PS film with 390 nm thickness tended to increase significantly as the temperature increased (Figure 5d). This is because the elongation to reach the maximum stress increases due to the decrease in the elastic modulus. Previously, these temperature or thickness effects on the elastic modulus have only been conducted using an analytical model or FEM simulation. Using our setup with an in-situ heating system, the accurate tensile properties of free-standing thin films in elevated temperature conditions that have not been previously reported will be simply acquired experimentally.

3 Conclusion

Direct measurement of tensile properties of polystyrene ultrathin film with the thickness of 50 nm at the temperature of 25–75 °C was first presented using the film on heated liquid (FOHL) configuration with controllable temperature. A method to minimize defect or fracture issue of side edge defects of the specimen was developed by a femto-second laser patterning, which was further improved by a short-term thermal heating process at 80 °C before the tensile testing. Ultrathin polymer thin films were successfully transferred to glycerol surface without breaking. It was confirmed that negligible dynamic friction was applied while the thin film slid onto the heated liquid surface through theoretical calculation and experimental measurement of drag force. Digital image correlation was adopted for tensile strain measurement which was conducted by rubber-based tensile gripping method. As a result, the dependence of elastic modulus of PS thin films on both thickness and temperature was accurately investigated. The decreasing rate of modulus with increasing temperature was found to be much greater for thinner films, due to the larger portion of surface soft layer. It was also observed that the modulus decreasing rate for decreasing film thickness was greater at higher temperature. Our experimental method will provide the guidelines for advanced device design requiring high-temperature durability by understanding free-standing polymer thin films with large aspect ratios, which are within the range of practical thin film utility.

4 Experimental Section

Preparation of the Ultrathin Films

Polystyrene (PS) (Mw ≈192 000 Da, Sigma–Aldrich Chemistry, USA), designated as PS192K, was used to fabricate ultrathin PS films. The PS was diluted with toluene solvent for various PS weight fractions (0.5, 1, 2, 3, and 4 wt %) in order to fabricate PS thin films with different thicknesses ranging from 50 to 390 nm. The Cu (1 µm)/SiO2 (300 nm)/Si (525 µm) substrate was cut into small pieces (15 × 15 mm2), and oxygen plasma treatment was performed using a plasma instrument (CUTE, FEMTO Science, Korea). The PS/toluene solution was spin coated at speed of 3000 rpm for 60 s. These supported films were thermally annealed in a vacuum oven at 160 °C for 12 h. The heating and cooling rate was controlled so as not to exceed 1 °C min−1. This was done to remove the residual stress on the specimens formed during the spin coating. To pattern the dog-bone shape of the PS thin film, a femtosecond laser (PHAROS) was used under the same conditions as for gold thin film patterning. The thickness of the PS films was measured using atomic force microscopy (AFM) (XE-100, Park Systems, Korea).

A gold thin film was fabricated to select an appropriate liquid platform to be used in tensile testing of free-standing thin film under elevated temperature, and for drag force testing of the liquid platform. The gold film with a 55 nm thickness was deposited on a 15 × 15 mm2 size Cu (1 µm)/SiO2 (300 nm)/Si (525 µm) substrate using evaporation. To make the Cu sacrificial layer surface clean and reactive, oxygen plasma treatment was performed using a plasma instrument (CUTE, FEMTO Science) before depositing the gold film. To pattern the dog-bone shape of the gold thin film, femtosecond laser (PHAROS) was used with a 230 fs pulse duration, 100 kHz repetition rate, and 15 mW output power.

Measurement of Tensile Properties of Thin Films

A strain gauge (P1, P1') was assigned according to the wing tips of the dog-bone patterned target thin film using DIC. The glycerol platform was heated using a brass hot plate and the temperature change was tracked using a thermometer. In the case of polymer thin film, thermal heating was performed to a temperature below Tg of the target film in a short time (≈3 min) for defect healing. Strain change measurement using DIC, tensile load measurement using an ultra-small capacity load cell (LTS-50GA, Kyowa Japan), and real-time platform temperature measurement using a thermometer are simultaneously conducted in an in-situ heating system to accurate measure the tensile properties of the target free-standing thin film at an elevated temperature condition. To ensure statistical reliability, at least five tensile tests were conducted for each condition.

Acknowledgements

T.-I.L. and J.H.K. contributed equally to this work. This work was supported by the National Research Foundation of Korea (NRF) grant (No. RS-2024-00423772, RS-2023-00247545, RS-2023-00239657, 2022R1A2C3009087, RS-2024-00406240) This study was also supported by the Technology Innovation Program (Public-private joint investment semiconductor R&D program (K-CHIPS) to foster high-quality human resources) (RS-2024-00403256, RS-2023-00236091 (grant 1415187584)) funded by the Ministry of Trade, Industry & Energy of Korea (MOTIE).

Conflict of Interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.