Challenges and Emerging Trends in Hydrogen Energy Industrialization: From Hydrogen Evolution Reaction to Storage, Transportation, and Utilization

Abstract

Green hydrogen (H2) emerges as a sustainable alternative to fossil fuels, offering a clean method to store renewable energy through water electrolysis with high energy content and zero carbon emissions. While research largely focuses on specific aspects such as hydrogen evolution reaction (HER), seawater HER electrocatalysts, and electrolyzer development, these studies often overlook the broader hydrogen economy from an integrated industry chain perspective. This review bridges that gap by providing a comprehensive analysis of hydrogen energy industrialization, covering advancements in HER, seawater HER, and electrolyzers, all aim at enabling industrial-scale H2 production. It further explores innovations and challenges in hydrogen storage and transportation, as well as real-world projects spanning the green hydrogen supply chain. Additionally, life cycle assessment studies validate the environmental benefits of using renewable energy sources for green H2 production. Furthermore, this review highlights advancements in counter-oxygen evolution reactions and organic oxidation reactions, alongside strategies to mitigate competing chlorine evolution reactions. Through this comprehensive examination, this review aims to inform readers of the latest developments in hydrogen energy industrialization, explore its growth potential, and provide new insights to propel the hydrogen economy forward.

1 Introduction

Since the advent of the Industrial Revolution, the progress of human society has heavily relied on an abundant energy supply. Fossil fuels, with their vast and accessible reserves, have long been the energy source of choice, with consumption surging dramatically since 1800.[1] As of 2022, the global annual consumption of coal, oil, and natural gas exceeds 1.3 × 105 TWh, accounting for a significant portion of 82.98% of the world's energy usage.[2] Regrettably, the rampant use of fossil fuels not only intensifies the greenhouse effect through the massive release of greenhouse gases such as carbon dioxide (CO2) but also contributes to water pollution from leaks during fossil fuel exploitation and air pollution from the emission of harmful gases and particulates during combustion. Collectively, these environmental impacts exacerbate global climate change, with far-reaching effects on human societies, including disruptions to livelihoods and economic productivity.[3-5]

Given the non-renewable and polluting nature of fossil fuels, the pursuit of renewable and eco-friendly energy sources has become an urgent global priority. Encouragingly, recent decades have seen rapid advancements in clean energy technologies, such as biofuels, hydro, wind, and solar energy, all of which are poised to claim an increasing share of global energy consumption.[2] However, a notable limitation associated with these renewable energies is their decentralized and intermittent nature, posing significant challenges for the storage and transportation of generated electricity.[6] This challenge emphasizes the importance of a stable energy carrier capable of storing electricity in the form of chemical energy. Hydrogen, with its high heat value, efficient energy conversion, and zero carbon emissions, emerges as an ideal energy carrier for the transportation, storage, and utilization of electricity produced from various clean energy sources.[7-9] Unlike grey and blue hydrogen derived from fossil fuels, green hydrogen—produced using renewable energy—has gained widespread acceptance and popularity worldwide.[10, 11] A prominent example is the UK government's launch of its hydrogen strategy in August 2021, aimed at delivering cleaner hydrogen energy to support economic and daily activities. This plan involves delivering 5 GW of H2 production by 2030 to align with the UK's net-zero commitments.[12] The strategy benefits significantly from the UK's rich offshore wind energy, which provides abundant electricity for producing green H2 through electrolysis, a comprehensive blueprint of the hydrogen economy outlines the planning from H2 production to storage, transportation, and utilization across various sectors. These include its use as a primary heat source for industries, an industrial raw material, a means of central city heating, and as fuel for transportation. Clearly, hydrogen energy is positioned as a central pillar of the future energy system, with the global green hydrogen movement gaining significant momentum. Nearly all major nations are actively engaging in the hydrogen economy, solidifying hydrogen's role as a robust medium for harnessing renewable energy and replacing polluting fossil fuels. In short, hydrogen represents a powerful solution to transition away from fossil fuels and maximize the potential of renewable energy sources.

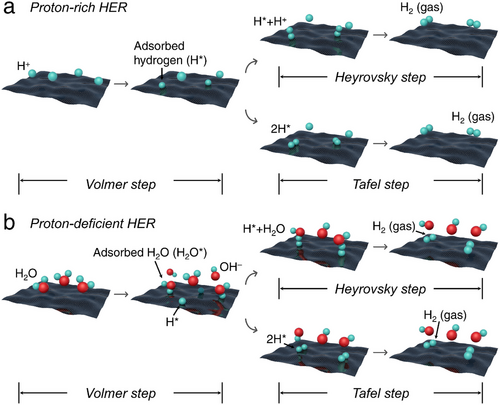

Obviously, achieving high HER performance under proton-deficient conditions depends not only on optimizing the hydrogen bond strength but also on accelerating the rate of water dissociation. Therefore, it is crucial to focus on the strategic design of electrocatalysts specifically tailored to enhance water adsorption and dissociation while ensuring efficient hydrogen ad/desorption capabilities.

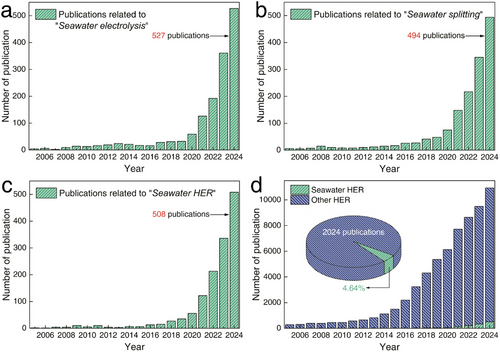

In the context of HER from water electrolysis, optimal electrocatalytic conditions typically require fresh water. However, freshwater constitutes a mere 2.5% of Earth's total water resources, with nearly two-thirds of this valuable freshwater trapped in glaciers or otherwise inaccessible through conventional means.[15] Given this scarcity, the growing hydrogen economy, particularly the production of green H2, which depends heavily on substantial volumes of water, is poised to place significant demand on freshwater resources. Conversely, Earth's vast seawater reserves, combined with abundant offshore wind and solar energy, present a promising solution for seawater-based HER.[16] Coastal regions around the globe are well-positioned to harness renewable electricity and seawater for green H2 production. Notably, coastal arid zones with plentiful photovoltaic resources, such as the Middle East, South Africa, the west coast of the Americas, and Australia, along with areas endowed with substantial wind energy like the north coast of Europe, the south coast of Alaska, the tip of South America, Greenland, and several coastal zones in Australia and Asia, are particularly suited for hydrogen production from seawater. As illustrated in Figure 2a–c, research on seawater electrolysis, seawater splitting, and seawater HER has steadily increased over the past two decades, demonstrating its growing significance for the future. However, despite this progress, studies specifically focusing on seawater HER still represent a small fraction of overall HER research. As of 2024, seawater HER studies account for only 4.64% of total HER publications (Figure 2d). This highlights the urgent need for further development in this area. Utilizing seawater as a resource for H2 production is a crucial step toward realizing a sustainable and clean energy future.

Despite the many challenges faced in the early stages of developing H2 production, storage, and transport systems, significant technological and material breakthroughs are steadily advancing the industrialization of hydrogen energy. In the area of electrocatalyst design for water and seawater electrolysis, existing reviews have typically categorized their discussion based on electrocatalytic materials such as Pt-, Ru-, and Mo-based electrocatalysts, or transition metal oxides, nitrides, chalcogenides, and phosphides. Additionally, other classifications have been made based on modification techniques like doping, alloying, defect inclusion, and interface engineering. However, most of these discussions have focused solely on catalytic activity or performance at low current densities, frequently overlooking the cost-effectiveness and practicality required for scaling H2 production to industrial levels.

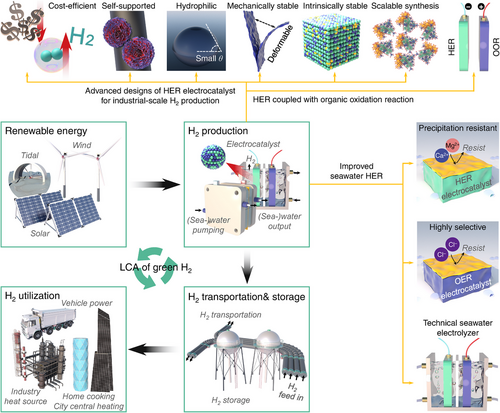

Hence, as shown in Figure 3, this review brings together the most recent and progressive studies on green H2 production, with a particular emphasis on HER and seawater HER electrocatalysis. It highlights the critical need for developing cost-effective, self-supported, hydrophilic, mechanically robust, and electrochemically stable electrocatalysts to facilitate both water and seawater electrolysis at an industrial scale. Emphasis is placed on integrating high catalytic activity with physical and electrochemical stability while ensuring the scalability of fabrication processes to meet the demands of industrial-scale H2 production. The review also emphasizes the advancements in HER coupled with organic oxidation reactions, which replace traditional anodic oxygen evolution reaction (OER) electrocatalysis with organic oxidation processes to improve overall efficiency. Additionally, it addresses specific strategies to enhance HER and OER activity and stability in actual seawater conditions, such as designing internal channels, surface ion-sieving layers, and Lewis acid layers on electrocatalysts. Furthermore, the review explores the design of electrolyzers, particularly their internal membranes, with a focus on meeting the increased demands of H2 production at scale. For the first time, it advances the discussion of electrocatalysts and electrolyzers, particularly for seawater applications, from the perspective of industrial-scale H2 production. By prioritizing realistic utility and scalability, this review provides a new perspective aimed at bridging the gap between laboratory research and industrial implementation.

In addition to green H2 production, this review highlights recent advancements in H2 storage and transportation, demonstrating novel material developments and innovative methods employed across various countries. Moreover, it presents comparative analyses and discussions on the H2 industrial chain and market potential, based on current enterprises and projects. The aim is to provide readers with diverse perspectives and insights on H2 industrialization, promoting further development in this field. Finally, the LCA studies are coordinated to validate the environmental benefits of using renewable energies to produce green H2, promoting further development in the field of H2 industrialization (Figure 3). Through this comprehensive review, we anticipate the establishment of a foundational link in the understanding among laboratories, industry, and the broader community toward advancing future green H2 technologies.

2 Challenges and Progresses of H2 Production

2.1 Challenges of HER Electrocatalysts

2.1.1 Cost-Efficiency of HER Electrocatalysts

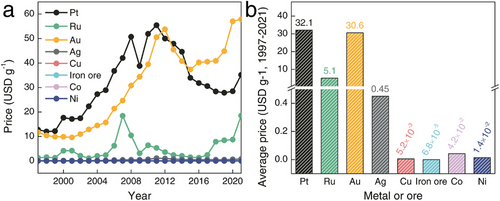

To date, the efficient catalysis of the HER typically relies on platinum-group metals, such as Pt and Ru, due to their ideal metal–H bond strengths of ≈62 and 65 kcal mol−1 for Pt–H and Ru–H, respectively. These strengths facilitate a balance between hydrogen adsorption and desorption, enabling a kinetically rapid HER.[17, 18] However, as indicated in Figure 4a,b and reported by the National Minerals Information Center, the average price of Pt over the last 20 years has exceeded that of Au and is 71.3 times higher than that of Ag. Compared to more common metals like Cu, Fe, Co, and Ni, elements of Pt and Ru entail significantly higher costs, which poses a strong financial burden on the development of HER electrocatalysis.[19-25] Therefore, in the mass production and development of industrial-scale electrocatalysts, strategies to reduce or replace platinum-group metals are crucial to lower the costs associated with H2 production.

2.1.2 Scalable and Stable H2 Production

Undoubtedly, in addition to HER activity, the durability of an electrocatalyst that can operate under industrial-scale current densities (higher than 500 mA cm−2) is essential for the industrialization of HER. While the performance of HER electrocatalysts can initially be evaluated by the strength of the metal–H bond at low current densities, at higher currents, factors such as interfacial charge transfer resistance, coverage rate of intermediates, electrocatalytic durability, and H2 bubble release kinetics must also be considered.[26-29] For example, sluggish electron transfer often occurs on layered transition metal dichalcogenides (TMDs) due to large interlayer potential barriers,[30] or increased electrocatalytic impedance can arise in assembled electrocatalysts that require post-coating with binders and conductive agents.[31] Typically, advanced electrocatalysts exhibit Tafel slopes of ≈30 mV dec−1 at low current densities; however, these slopes often rise above 120 mV dec−1 at higher densities, limited by real-world proton diffusion and adsorption characteristics.[14, 32] Additionally, subsequent inefficient H2 desorption at these higher current densities can block electrocatalytic active sites, impeding electron and mass transfer during HER.[33, 34] Furthermore, under high HER current densities, the elevated reaction potentials and rapid H2 bubble formation can cause the electrocatalyst layers to detach from their substrates due to weak adhesion, a common issue in conventionally assembled electrocatalysts.[35, 36] Overall, developing an electrocatalyst capable of withstanding the demanding conditions of industrial-scale H2 production remains a significant challenge.

2.2 Advanced Designs of HER Electrocatalysts

2.2.1 Cost-Efficient Electrocatalysts

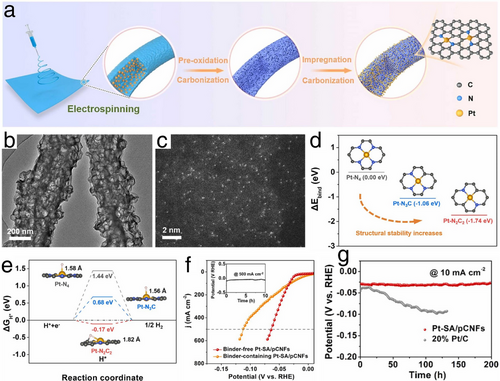

Considering the superior activity of Pt-based electrocatalysts, efforts to reduce the cost of HER have initially focused on the development of Pt nanocluster or single-atom electrocatalysts. These strategies aim to achieve high HER performance by maximizing active surface areas while minimizing the quantity of Pt used. For instance, Han et al. developed a novel Pt single atom electrocatalyst supported on N-doped porous carbon nanofibers (Pt-SA/pCNFs), employing electrospinning followed by carbonization to form the nanofibers, and impregnation followed by pyrolysis to synthesize Pt-SA/pCNFs, as depicted in Figure 5a.[37] In the Pt-SA/pCNFs, the porous structure of the N-doped carbon nanofibers, shown in the transmission electron microscope (TEM) image in Figure 5b, imparted significant hydrophilicity, enhancing the HER electrocatalysis. As presented in Figure 5c, the high-angle annual dark-field scanning transmission electron microscopy (HAADF-STEM) image illustrated that the Pt single atoms were anchored through strong interactions from tailored N and C, forming a stable Pt─N2C2 configuration, which led to exceptional Pt atomic utilization and electrocatalytic activity. Additionally, the density functional theory (DFT) results depicted in Figure 5d,e highlight a small negative binding energy at the Pt─N2C2 site and near-zero Gibbs free energy of hydrogen intermediate (ΔGH ⃰) for the Pt-SA/pCNFs, indicating robust structural stability and HER activity. Remarkably, in a 0.5 m H2SO4 electrolyte, the Pt-SA/pCNFs electrocatalyst achieved an exceptionally low overpotential of 64 mV at a high current density of 500 mA cm−2, maintaining stability with minimal decay over 200-h at 10 mA cm−2 and 10-h at 500 mA cm−2 (Figure 5f,g). These results suggested a promising potential for large-scale H2 production using the Pt-SA/pCNFs electrocatalyst.

According to the statistical analysis previously presented in Figure 4, the cost of Pt significantly exceeds that of other metals such as Ru, Cu, Fe, Co, and Ni. Consequently, the long-term development of HER technologies based on Pt is not sustainable. In response, researchers have explored numerous transition metal-based HER electrocatalysts as alternatives to Pt, benefiting from their lower cost and adjustable HER activity through doping or alloying processes.

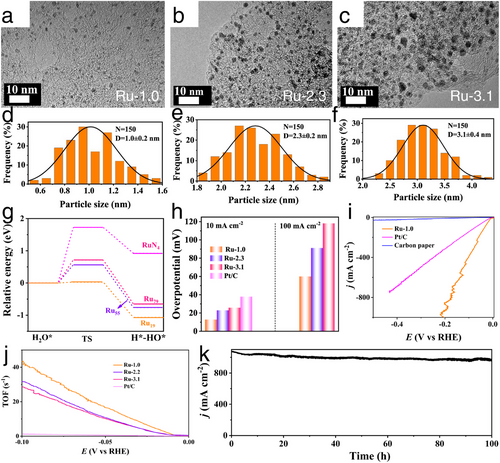

In terms of single transition metal-based HER electrocatalysts, as presented in Figure 6a–f, Hu et al. designed the Ru nanocrystals ranging from nanoparticles to sub-nanoclusters and single atoms through a calcination process in H2/Ar flow.[38] In this work, the diameter of Ru directly influenced the d-band center of fabricated Ru nanocrystals, with the smallest Ru clusters exhibiting an upshifted d-band center that provided enhanced water dissociation capability compared to Ru nanoparticles and single atoms, thereby improving HER activity, especially under proton-deficient conditions (Figure 6g). Additionally, the cluster morphology of Ru increased the specific surface area and significantly boosted the number of active HER sites. Consequently, Ru clusters demonstrated superior alkaline HER activity, achieving a very low overpotential of 13 mV at a current density of 10 mA cm−2 and a high turnover frequency (TOF) of 43.3 s−1 at a potential of 100 mV (Figure 6h,j). Remarkably, as shown in Figure 6i,k, Ru clusters could achieve a large current density of 1000 mA cm−2 at just overpotential of 196 mV when a mass of Ru loading on electrode reached to 1 mg cm−2, along with maintaining stability over 100-h at this high current density without significant degradation. These exceptional HER performances demonstrated the potential for industrial-scale H2 production using cost-effective Ru-based electrocatalysts.

To further enhance the cost-efficiency of HER using transition metals, TMDs and transition metal phosphides (TMPs) have gained tremendous attention recently. The layered structure of TMDs, with abundant exposed edge sites, is typically considered rich in active sites for HER electrocatalysis.[39] Concurrently, the more electrically conductive TMPs feature numerous triangular prism structures that can expose additional crystal planes and potential HER active sites.[40] Based on this understanding, through a colloidal reaction, Kwak et al. synthesized the Nb1–xVxSe2 nanosheets across the full compositional range of x.[41] At x = 0.3, the Nb1–xVxSe2 nanosheets exhibited the lowest overpotentials of 236 and 298 mV at current densities of 10 and 100 mA cm−2 respectively, with a Tafel slope of 72 mV dec−1. The chronoamperometry stability test at current densities of 10 and 20 mA cm−2 showed no noticeable current reduction after the long-term stability test, and even after 5000 linear sweep voltammetry (LSV) cycles, the overpotentials of Nb1 − xVxSe2 nanosheets remained at 238 and 302 mV at current densities of 10 and 100 mA cm−2 respectively, with only negligible decay.

2.2.2 Self-Supported Electrocatalysts

To facilitate industrial-scale H2 production with robust durability, managing disruptions from rapid H2 bubble evolution is crucially dependent on the adhesive strength of electrocatalysts applied to electrodes. However, in cases involving large current densities and extensive H2 bubble formation, the electrocatalyst layer, often combined with a binder and conducting agent, can easily detach due to insufficient adhesion. This detachment not only buries active sites but also leads to increased impedance in HER.[31] To address this challenge, researchers have developed various self-supported electrocatalysts, designed to prevent peeling and secondary aggregation through the in situ growth of electrocatalysts on substrates. These substrates, equipped with active electrocatalysts, can then be directly utilized as working electrodes in HER electrocatalysis.

As demonstrated in Figure 7a, Ni et al. successfully in situ constructed a hierarchically self-supported HER electrode, through the integration of Cu nanowires, NiFe nanosheets, and Pt3Ir alloy nanoparticles (Cu NWs@NiFe-Pt3Ir).[42] DFT calculations confirmed that the coupling between NiFe and Pt3Ir significantly enhanced the HER kinetics by facilitating electron consumption at the electrode–electrolyte interface (Figure 7b–d). Additionally, as shown in Figure 7e,f, incorporating Ir atoms into the Pt3Ir structure lowered the d-band center energy level of the Pt 5d orbital, optimizing H* adsorption and desorption during HER electrocatalysis. Leveraging its hierarchical structure with numerous active sites and the in situ contact structure, the Cu NWs@NiFe-Pt3Ir electrode achieved exceptionally low HER overpotentials of only 210 and 239 mV to reach industrial-scale current densities of 500 and 1000 mA cm−2 in 1 m KOH, as evidenced by the corresponding TEM images and HER activities displayed in Figure 7g,h. In terms of electrochemical stability, as shown in Figure 7i, the Cu NWs@NiFe-Pt3Ir self-supported electrocatalyst consistently produced H2 for 7 days, even under a substantial current density of 500 mA cm−2, with an inappreciable potential increase of only 8 mV. This expertly designed self-supported electrode demonstrated outstanding HER activity and durability at an industrial scale.

Furthermore, through a straightforward electrospinning strategy optimized with pyrolysis temperature and precursor mass ratios, Ouyang et al. effectively developed in situ grown and self-supported Mo2C@carbon nanofibers (Mo2C@C NF) film demonstrating exceptional HER electrocatalytic performance.[43] This self-supported electrocatalyst avoided the occlusion of active sites and enhanced the diffusion of electrons and reaction intermediates during HER electrocatalysis. Consequently, the Mo2C@C NF achieved a low overpotential of 86 mV at a current density of 10 mA cm−2 and a minimal Tafel slope of 43 mV dec−1 in 1 m KOH. Thanks to its robust construction from in situ growth, the Mo2C@C NF displayed outstanding electrocatalytic stability in alkaline HER, maintaining stability for 340-h and 100-h at current densities of 20 and 50 mA cm−2, respectively. Similarly, Liu et al. developed a mechanically stable, all-metal, and highly efficient CuMo6S8/Cu electrode through an in situ reaction between MoS2 and Cu.[44] The resulting electrocatalyst demonstrated robust interfacial binding between the active CuMo6S8 and support Cu while exhibiting weak adhesion between the CuMo6S8/Cu interface and H2 bubbles. This unique combination effectively prevented electrocatalyst detachment and enhanced reaction kinetics at industrial-scale current densities. As a result, in a 1 m KOH electrolyte, the self-supported CuMo6S8/Cu electrocatalyst achieved a remarkably low overpotential of 334 mV and demonstrated stable operation for over 100 h at a high current density of 2500 mA cm−2.

2.2.3 Hydrophilic Electrocatalysts

Obviously, a well-designed self-supported electrocatalyst with robust durability can effectively resist the bubble disturbance to maintain steady H2 generation. However, during industrial-scale HER with rapid H2 bubble generation, the diffusion and adsorption of intermediates (e.g., protons, H*, and H2O*) are also significantly impacted by the kinetics of H2 bubble release during the HER processes. In practice, when H2 bubbles extensively cover the surface of the electrocatalyst, the occupied air zones seriously obstruct the diffusion of water molecules and protons to the electrocatalytic active sites at the interface between the electrocatalyst surface and the electrolyte.[45] Additionally, these occupied air zones can cause an inhomogeneous current distribution on the electrocatalyst surface, increase the HER overpotentials in areas not covered by H2 bubbles, and ultimately lead to premature degradation of the electrocatalyst durability.[46] Therefore, to facilitate the rapid release of H2 bubbles, designing HER electrocatalysts with more hydrophilic (i.e., aerophobic) surfaces is advantageous. This design ensures that the electrolyte, rather than the H2 bubbles, preferentially contacts the electrocatalyst surface, thereby enhancing the exchange efficiency of intermediates during HER electrocatalysis.

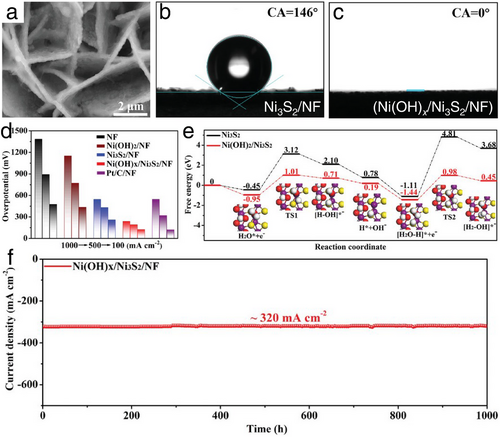

The highlighted work from He et al. introduced a free-standing heterostructure electrocatalyst,[47] consisting of microporous Ni(OH)x/Ni3S2 on Ni foam (Ni(OH)x/Ni3S2/NF presented in the scanning electron microscopy (SEM) image in Figure 8a. As demonstrated in Figure 8b,c, compared to the pristine Ni3S2/NF (water contact angle of 146°), this well-designed heterostructure electrocatalyst exhibited a water contact angle of 0°, indicating an absolute hydrophilic property. This exceptional wettability ensured a high utilization rate of active sites on the Ni(OH)x/Ni3S2/NF electrode and supported continuous H2 production even under long-term, high-current-density HER electrocatalysis. Leveraging its microporous and self-supported structures, the Ni(OH)x/Ni3S2/NF exhibited remarkable HER activity and stability in 1 m KOH electrolyte, achieving overpotentials of just 126, 193, and 238 mV to reach substantial current densities of 100, 500, and 1000 mA cm−2, respectively (Figure 8d). These impressive HER activities were further corroborated by DFT calculations (Figure 8e), which indicated that easy H2O dissociation and reduced H* adsorption significantly enhance HER kinetics. Additionally, a 1000-h long-term durability test conducted under a high current density of ≈320 mA cm−2 showed no significant decay (Figure 8f). These results surpassed those of commercial Pt/C electrocatalysts, positioning this as a leading HER performer among recently reported state-of-the-art non-noble metal electrocatalysts.

Further study focusing on the hydrophilic modification of HER electrodes is highlighted in Sun's study.[48] Through a combination of hydrothermal and chemical etching processes, crystalline nickel tellurium nanorods enclosed by amorphous rhodium hydroxide (a-Rh(OH)3/NiTe) were produced. Notably, the resulting a-Rh(OH)3/NiTe demonstrated a significantly enhanced hydrophilic property, exhibiting a water contact angle of ≈0°. This superhydrophilic surface of a-Rh(OH)3/NiTe ensured close contact between the electrocatalyst and the electrolyte during HER processes, facilitating accelerated electrocatalytic kinetics through rapid electron and mass exchange. Attributed to these superiorities, the a-Rh(OH)3/NiTe achieved exceptionally low HER overpotentials of only 51, 109, and 64 mV in 1 m KOH, 1 m PBS, and 0.5 m H2SO4 to reach a current density of 100 mA cm−2, alongside robust electrochemical stability. Moreover, Luo et al. synthesized molybdenum disulfide microspheres modified with molybdenum carbide nanoparticles (MoS2/Mo2C) through a combination of hydrothermal and chemical vapor deposition processes.[49] The unique structure of the microspheres, composed of numerous aligned MoS2 nanosheets, generates a strong capillary force that efficiently pumps the electrolyte onto the MoS2/Mo2C surface. This significantly reduces gas–solid adhesion and facilitates the rapid detachment of H2 bubbles, as evidenced by the nearly zero contact angle when using a 1 m KOH droplet. Furthermore, the presence of a large number of exposed active Mo2C nanoparticles at the edges of the MoS2 nanosheets enhances catalytic performance. The resulting MoS2/Mo2C electrocatalyst demonstrates remarkably low overpotentials of 227 and 220 mV at a high current density of 1000 mA cm−2 in acidic and alkaline conditions, respectively. Additionally, it exhibits excellent electrochemical stability in both catalytic media.

2.2.4 Mechanically Stable Electrocatalysts

During industrial-scale HER, the rapid formation and detachment of large volumes of H2 bubbles typically exert significant force on the electrocatalysts, often leading to the deformation of electrocatalysts and degradation of HER performance. In such cases, the flexibility and adaptability of the electrocatalysts become crucial in alleviating the tension and vibration generated by the release of H2 bubbles.[50]

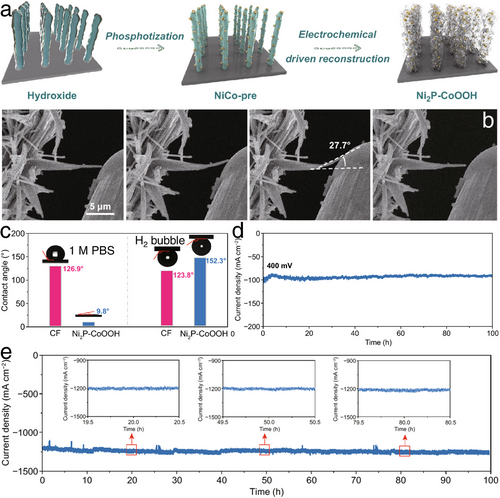

Zhang et al. designed a 2D CoOOH sheet-encapsulated Ni2P (Ni2P–CoOOH) tubular array electrocatalytic system,[51] where the 2D stacked structure acted as an adaptive material to buffer the impact of H2 bubble rupture and evolution by releasing stress (Figure 9a). As shown in Figure 9b, during the bending deformation and restoration processes, the single nanotube of Ni2P–CoOOH demonstrated remarkable flexibility, withstanding a maximum bending angle of up to 27.7° and fully recovering once the external force was removed. Moreover, the porous structure of Ni2P–CoOOH, as evidenced by the contact angle results in Figure 9c, enhanced electrolyte contact with the electrode surface and facilitated H2 bubble detachment. As a result, the well-engineered Ni2P–CoOOH system demonstrated outstanding long-term HER stability, operating for over 100 h at current densities of 2000, 1200, and 100 mA cm⁻2 in alkaline, neutral water, and seawater, respectively (Figure 9d,e). These results signify a promising transition from laboratory-scale to industrial-scale water electrolysis. Similarly, Wang et al. employed dealloying and potentiostatic polarization techniques to develop a flexible, nanostructured Zr-based amorphous HER electrocatalyst.[52] During the dealloying process, sharp cracks were mitigated through potentiostatic polarization, resulting in low-stress concentration and high flexibility. The porous structure of the synthesized electrocatalyst delivered a low HER overpotential of 53 mV at a current density of 10 mA cm−2 in 1 m KOH, along with long-term stability under an industrial-scale current density of 300 mA cm−2 for 100 h.

2.2.5 Intrinsically Electrochemically Stable Electrocatalysts

By implementing in situ growth and optimizing surface morphology to facilitate rapid H2 bubble detachment, improved HER activity and stability have been achieved through stable electrocatalyst structures. These advancements can be extended to a wide range of electrocatalytic materials. Besides, a certain group of electrocatalysts possess inherent properties that withstand against electrochemical decay, such as electrocatalytically active materials protected by another fence layer, in situ self-reconstruction at the electrocatalyst surface, and dealloying processes during HER electrocatalysis.

Utilizing this concept of protective fence engineering for efficient and steady alkaline HER, Huang et al. successfully shielded highly active cobalt-doped MoS2 with a molecule-selective CoS2 barrier fence (Co─MoS2@CoS2).[53] DFT studies showed that the CoS2 barrier prevented the penetration of O2 and OH− ions species while allowing reactant H2O to pass through, thereby preventing surface poisoning of the Co─MoS2 catalyst during alkaline HER electrocatalysis. Simultaneously, the CoS2 barrier also helped to prevent the oxidation or dissolution of active Co─MoS2 into the electrolyte in the form of MoO42− and SO32−. These engineered modifications to Co─MoS2@CoS2 enhanced both HER activity and stability without compromise. In terms of electrochemical stability, Co─MoS2@CoS2 maintained a long-term 120-h test with negligible activity decay at a constant potential of 100 mV. These enhanced HER performances after the protective fence engineering undoubtedly provided a viable blueprint for developing highly active and long-term stable HER electrocatalysts.

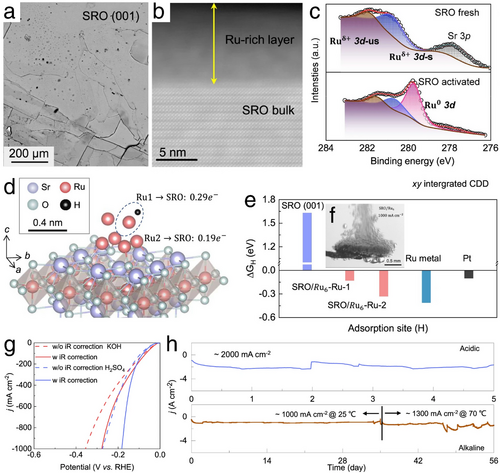

Similarly, in terms of the electrochemical stability enhancements, Zhang's work demonstrated a notable enhancement in electrochemical stability through an in situ self-reconstruction phenomenon on the surface of the designed electrocatalyst.[29] Investigating Sr2RuO4 bulk single crystals during a high current density HER test revealed the in situ formation of ferromagnetic Ru clusters on the surface of Sr2RuO4, evidenced by numerous micro-scale Ru islands as shown in Figure 10a,b, with the formation of Ru clusters confirmed by using X-ray photoelectron spectroscopy (XPS) test (Figure 10c). This in situ exsolution of Ru from Sr2RuO4, subsequently re-incorporated into the Sr2RuO4 bulk crystal, not only improved the cohesion between the Ru clusters and the Sr2RuO4 substrate but also ensured overall electrocatalyst stability and uniform distribution of Ru clusters, which is advantageous for HER activity due to accelerated kinetics in the electron mobility. The corresponding electron redistribution and improved electrocatalytic activity were validated via DFT calculations, as depicted in Figure 10d. Here, the Ru atoms at the top of the Ru6 clusters are identified as HER active sites, exhibiting a ΔGH ⃰ value comparable to that of a Pt catalyst (Figure 10e), and significantly lower than that of the original Sr2RuO4. Remarkably, the in situ self-reconstructed Ru clusters on Sr2RuO4 also formed highly porous and hierarchical structures that facilitated the growth and detachment of H2 bubbles (Figure 10f), simultaneously enhancing mass transfer efficiency and the mechanical stability of the electrocatalyst, particularly at industrial-scale current densities. Ultimately, as demonstrated in Figure 10g,h, the reconstructed Ru6/Sr2RuO4 achieved ultra-low overpotentials of 182 and 278 mV to reach exceptionally high current densities of 1000 mA cm−2 in 0.5 m H2SO4 and 1 m KOH, respectively. Coupled with robust electrochemical stability, continuous testing over 56 days at initial temperatures of 25 °C followed by 70 °C, at a high current density of 1000 mA cm−2, demonstrated the impressive HER performance of this well-reconstructed Ru6/Sr2RuO4 electrocatalyst. These remarkable results confirmed the viability of using this advanced electrocatalyst for industrial-scale H2 production through HER electrocatalysis.

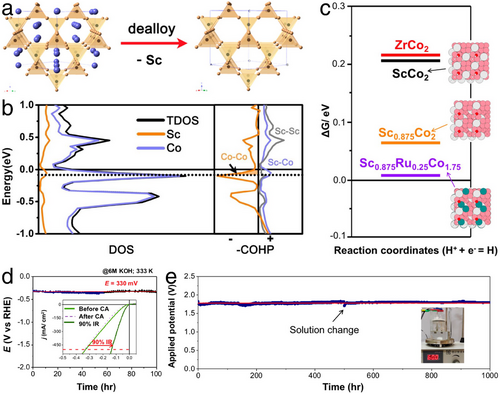

Furthermore, leveraging the dealloying processes as illustrated in Figure 11a, Ji et al. developed optimal HER electrocatalysts using ScRu0.25Co1.75, characterized by zeolite-like metal frameworks.[54] Initially, the minor presence of Ru in ScRu0.25Co1.75 did not alter the dealloying behavior, which involved stripping Sc metal from the center of tunnel structures, thereby forming voids or vacancies in the ScRu0.25Co1.75 structure and significantly increasing the electrocatalytically active surface areas. Further, as shown in Figure 11b, the total density of state (TDOS) indicated a slight downward shift in Fermi level (EFermi) for Sc0.875Co2 (partially Sc stripped) compared to pristine ScCo2. Yet, combined with the crystal orbital Hamilton population (COHP) results presented in Figure 11b, this downshift led to a depopulation of the antibonding states of the Co─Co bond, thereby strengthening the Co–Co connection in Sc0.875Co2. These structural changes, brought about by dealloying engineering, significantly enhanced the electrocatalytic stability of ScRu0.25Co1.75. Additionally, the depopulation of the antibonding states of the Co─Co bond improved the Co─H bond in Sc0.875Co2, potentially increasing H* adsorption following Sc stripping to enhance HER electrocatalysis (Figure 11c). As a result, under industrial HER conditions in 6 m KOH at 60 °C, ScRu0.25Co1.75 achieved an overpotential of only 132 mV to reach a high current density of 500 mA cm−2 (Figure 11d) and demonstrated 1000-h long-term stable H2 production (Figure 11e). These enhanced properties of ScRu0.25Co1.75, derived from the dealloying processes during HER electrocatalysis, demonstrated its potential for industrial-scale H2 production.

2.2.6 Large-Scale Synthesis of Electrocatalysts

For industrial-scale H2 production, an ideal HER electrocatalyst should be easily manufactured in large quantities, avoiding complex or low-yield initial laboratory synthesis methods such as high-temperature annealing in various atmospheres.[55] In recent years, large-scale synthesis of diverse electrocatalysts in ambient conditions has remained popular, utilizing representative methods such as room-temperature immersion synthesis, centrifugal spinning fabrication, and ball-milling manufacturing.

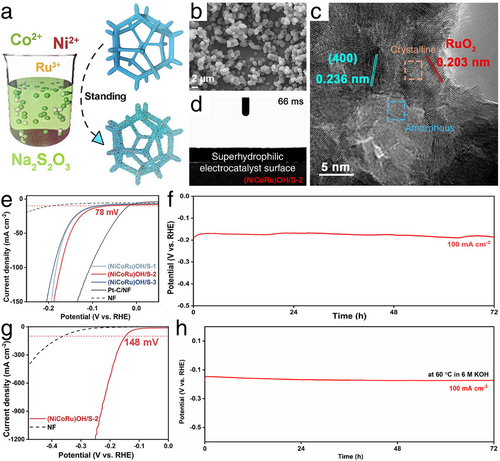

The classic room temperature immersion synthesis by Yang et al. developed a well-designed NiCoRu hydroxide/sulfide heterostructure on Ni foam (i.e., (NiCoRu)OH/S).[56] As illustrated in Figure 12a, the (NiCoRu)OH/S electrocatalyst can be readily produced through industrial-scalable room temperature soaking for in situ growth on Ni foam. According to the characterized results shown in Figure 12b, after four days of room temperature immersion, abundant (NiCoRu)OH/S nanoparticles were distributed on the Ni foam substrate, significantly increasing the specific surface areas and enhancing electron and mass transfer during HER electrocatalysis to accelerate the final HER kinetics. Additionally, the coexistence of crystalline and amorphous planes in (NiCoRu)OH/S exposed numerous active sites (Figure 12c), further facilitating electron transfer. Coupled with the confirmed superhydrophilic properties shown in Figure 12d and intrinsic HER activity from the multiple chemical states of the trimetallic compound, the (NiCoRu)OH/S-2 sample treated with optimal immersion time demonstrated remarkable HER activity with a low overpotential of 78 mV at a current density of 10 mA cm−2 and maintained 72-h robust electrochemical durability tested at a constant current density of 100 mA cm−2 in 1 m KOH (Figure 12e,f). Even under industrial operation conditions in 6 m KOH at 60 °C, (NiCoRu)OH/S-2 required overpotentials of only 148 and 250 mV to reach high current densities of 100 and 1200 mA cm−2, respectively, maintaining 72-h robust durability at a constant current density of 100 mA cm−2 (Figure 12g,h). Beyond excellent HER performance, (NiCoRu)OH/S-2 also served as an effective OER electrocatalyst, showing outstanding OER activity and stability even under industrial conditions. This sophisticated heterostructure electrocatalyst, (NiCoRu)OH/S, holds promise as a ready-to-use bifunctional electrode, poised to advance the industrialization of HER technologies.

Compared to electrospinning, which has low throughputs and requires high voltage, centrifugal spinning technology generally achieves higher throughputs. Typical centrifugal spinning equipment with two nozzles can produce ≈50 g h−1, a rate nearly two orders of magnitude higher than that of laboratory-scale electrospinning. Utilizing an in-house developed centrifugal spinning setup, Mukkavilli et al. produced TaOxN1 − x fibers through ammonolysis of as-spun ([Ta(OEt)5]2)/polyvinylpyrrolidone (PVP) fiber mats.[57] Consequently, the TaOxN1 − x fibers demonstrated superior HER activity compared to Ta2O5. This centrifugal spinning method undoubtedly provides a universal scalable approach for producing other up-scaled electrocatalysts in the future. Moreover, as a prominent solvent-free mechanochemical technique, the high-energy ball milling approach is straightforward and highly scalable, suitable for producing large quantities of electrocatalysts. In this context, Hu et al. utilized graphene quantum dots (GQDs) as exfoliation agents to synthesize and functionalize nearly atom-layered MoS2 nanosheets (ALMS).[58] Impressively, the produced ALMS measured ≈4 nm and could be uniformly dispersed in isopropanol, forming a stable colloidal solution due to the sulfonation process facilitated by GQDs, demonstrating that the scaled-up-fabricated ALMS can be reliably stored. Without requiring organic solvents, catalysts, substrates, or the harsh conditions of vacuum systems, the synthesis yield of ALMS reached 63% with efficient recovery and recycling of GQDs as an exfoliation agent, ensuring a reliable and scalable production of electrocatalysts for industrial HER needs. Finally, the produced ALMS exhibited considerable HER activity and outstanding electrochemical durability even after a 200-h long-term stability test in 0.5 m H2SO4 solution. The development of this stable 2D nanomaterial electrocatalyst provides a feasible route for producing electrocatalysts on a large scale, aiming to meet the increasing demands for HER industrialization.

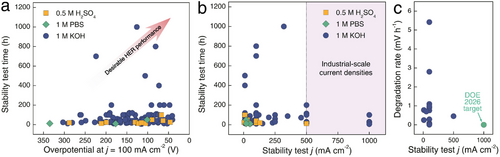

To provide a clear understanding of the current state of green H2 production, we have summarized the advanced designs of HER electrocatalysts in Table 1 with taking into account various key properties of the reviewed electrocatalysts, such as cost-effectiveness, self-supporting structures, hydrophilicity, mechanical stability, intrinsic electrochemical stability, and scalable designs to satisfy the high demands of HER electrocatalyst for enabling industrial-scale H2 production. In addition, we further analyzed hundreds of studies closely related to the topic of high-performance HER in recent three years. Specifically, an industrial-scale current density normally should exceed 500 mA cm−2, also along with a long-term stable utilization. However, as shown in Figure 13a and Table S1 (Supporting Information), although most HER studies have demonstrated progressively lower overpotentials even at a current density of 100 mA cm−2, electrochemical stability remains largely limited to low current densities and short testing durations (Figure 13b). Additionally, the analyzed degradation rate of voltage presented in Figure 13c still falls significantly short of the DOE 2026 target, both in terms of operating current density and the average voltage degradation rate. These results clearly indicate that the development of scalable and stable electrocatalysts is an essential future direction for generating green H2. Furthermore, to achieve scalable and stable H2 production, it is essential to integrate the key qualities discussed in this chapter—such as cost efficiency, self-supporting architecture, hydrophilicity, mechanical robustness, and intrinsic electrochemical stability—into a single, all-in-one electrocatalyst for ensuring efficient and long-term stable water electrolysis. Ultimately, this well-designed electrocatalyst should be a scalable synthesis to meet the large demands of industrial H2 production.

| Electrocatalyst property | Electrocatalyst | Activity | Stability | Electrolyte |

|---|---|---|---|---|

| Cost-efficient | Pt-SA/pCNFs[37] | 64 mV at j of 500 mA cm−2 | 200-h at j of 10 mA cm−2 | 0.5 m H2SO4 |

| 10-h at j of 500 mA cm−2 | ||||

| Ru clusters[38] | 13 mV at j of 10 mA cm−2 | 100-h at j of 1000 mA cm−2 | 1 m KOH | |

| 196 mV at j of 1000 mA cm−2 | ||||

| Self-supported | Cu NWs@NiFe-Pt3Ir[42] | 210 mV at j of 500 mA cm−2 | 168-h at j of 500 mA cm−2 | 1 m KOH |

| 239 mV at j of 1000 mA cm−2 | ||||

| Mo2C@C NF[43] | 86 mV at j of 10 mA cm−2 | 340-h at j of 20 mA cm−2 | 1 m KOH | |

| 100-h at j of 50 mA cm−2 | ||||

| CuMo6S8/Cu[44] | 334 mV at j of 2500 mA cm−2 | 100-h at j of 2500 mA cm−2 | 1 m KOH | |

| Hydrophilic | Ni(OH)x/Ni3S2/NF[47] | 126 mV at j of 100 mA cm−2 | 1000-h at j of 320 mA cm−2 | 1 m KOH |

| 193 mV at j of 500 mA cm−2 | ||||

| 238 mV at j of 1000 mA cm−2 | ||||

| a-Rh(OH)3/NiTe[48] | 51 mV at j of 100 mA cm−2 | 75-h at j of 10 mA cm−2 | 1 m KOH | |

| 109 mV at j of 100 mA cm−2 | / | 1 M PBS | ||

| 64 mV at j of 100 mA cm−2 | 56-h at j of 10 mA cm−2 | 0.5 m H2SO4 | ||

| MoS2/Mo2C[49] | 227 mV at j of 1000 mA cm−2 | 24-h at j of 200 mA cm−2 | 1 m KOH | |

| 220 mV at j of 1000 mA cm−2 | 24-h at j of 200 mA cm−2 | 0.5 m H2SO4 | ||

| Mechanically stable | Ni2P–CoOOH[51] | / | 100-h at j of 2000 mA cm−2 | 1 m KOH |

| 20 mV at j of 10 mA cm−2 | 100-h at j of 1200 mA cm−2 | 1 m PBS | ||

| 194 mV at j of 10 mA cm−2 | 100-h at j of 100 mA cm−2 | Seawater | ||

| Zr-based amorphous alloy ribbons[52] | 53 mV at j of 10 mA cm−2 | 100-h at j of 300 mA cm−2 | 1 m KOH | |

| Electrochemically stable | Co─MoS2@CoS2[53] | 105 mV at j of 10 mA cm−2 | 120-h at j of 100 mA cm−2 | 1 m KOH |

| Ru6/Sr2RuO4[29] | 278 mV at j of 1000 mA cm−2 | 1344-h at j of 1000–1300 mA cm−2 (25 + 70 °C) | 1 m KOH | |

| 182 mV at j of 1000 mA cm−2 | 120-h at j of 2000 mA cm−2 | 0.5 m H2SO4 | ||

| ScRu0.25Co1.75[54] | 132 mV at j of 500 mA cm−2 | 1000-h at j of 500 mA cm−2 (60 °C) | 6 m KOH | |

| Large-scale synthesis | (NiCoRu)OH/S[56] | 78 mV at j of 10 mA cm−2 | 72-h at j of 100 mA cm−2 | 1 m KOH |

| 148 mV at j of 100 mA cm−2 | 72-h at j of 100 mA cm−2 (60 °C) | 6 m KOH | ||

| 250 mV at j of 1200 mA cm−2 | ||||

| ALMS[58] | 270 mV at j of 10 mA cm−2 | 200-h at j of 10 mA cm−2 | 0.5 m H2SO4 |

2.3 HER Coupled with Organic Oxidation Reactions

In the previous chapter, we thoroughly reviewed recent studies on electrocatalyst designs aimed at enhancing HER performance. However, we also recognize that the counterpart anodic OER, involving a sluggish four-electron process, significantly impacts the overall efficiency of water splitting during practical H2 production. In recent years, there has been a growing focus on organic oxidation reactions as alternatives to OER in water splitting, with small organic molecules such as alcohols, aldehydes, or amines being particularly favored. Integrating these organic oxidation reactions with HER electrocatalysis can effectively reduce the overall voltage required for hybrid water splitting due to more favorable thermodynamic and kinetic processes at the anode, thereby indirectly lowering the barriers to H2 production. Additionally, this approach allows for the generation of high-value-added chemicals.[59-61] Consequently, we provide brief reviews of the latest breakthroughs in organic oxidation reaction studies to broaden understanding of HER developments across various related fields.

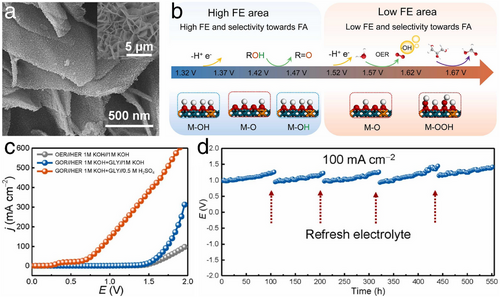

Among these studies, the glycerol oxidation reaction is simpler to be proceeded than traditional water oxidation (i.e., OER). At the anode, not only does the glycerol oxidation reaction reduce the overpotential compared to OER in overall water splitting, but the resulting formic acid (FA) can also be utilized as a high-energy-density fuel for direct formic acid fuel cells. Building on this concept, Song et al. developed an amorphous layered double hydroxide (LDH) enriched with active oxygen sites.[62] As shown in Figure 14a, self-supported amorphous NiFe-LDH (A-NiFe-LDH) nanosheets were developed on Ni foam through an electrochemical amorphization process of crystallized NiFe-LDH. Notably, the hydroxy groups in the host layer of A-NiFe-LDH can be easily deprotonated, particularly at an ultralow voltage, leading to the generation of active oxygens. These active oxygens are beneficial for oxidizing glycerol molecules while suppressing the OER (Figure 14b). This high selectivity toward FA using A-NiFe-LDH can effectively complement cathodic HER electrocatalysis. Consequently, a hybrid electrolyzer comprising an alkaline anode chamber and an acid cathode chamber was designed. This setup achieved low cell voltages of 0.9 and 1.72 V to reach high current densities of 100 and 500 mA cm−2, respectively (Figure 14c). Furthermore, as shown in Figure 14d, this hybrid cell operated for over 500-h with minimal decay at a current density of 100 mA cm−2, upon refreshing the electrolyte at both anode and cathode. Throughout these processes, not only was the typically sluggish OER circumvented by replacing it with the glycerol oxidation reaction, but both desirable H2 and high-value-added FA were also acquired.

Furthermore, Xu et al. have merged methanol oxidation reaction with HER to co-generate value-added formate and H2 using NiIr-based metal–organic framework (MOF) nanosheets in situ arrayed on Ni foam (NiIr-MOF/NF).[63] This bifunctional electrocatalyst served as a self-supported electrode at both anode and cathode, capable of oxidizing methanol while concurrently facilitating H2 production. The electrochemical performance of this hybrid water-splitting system demonstrated that the anodic and cathodic Faradaic efficiencies for formate and H2 were both nearly close to 100% (with no O2 bubble evolution at the anode,). Remarkably, the entire cell operated at a voltage of only 1.39 V to achieve a current density of 10 mA cm−2 in 1 m KOH containing 4 m methanol. Conversely, in a conventional water-splitting setup using pure 1 m KOH, the NiIr-MOF/NF requires a higher cell voltage of 1.56 V to reach the same current density. These results significantly enhanced the energy conversion efficiency in a combined electrocatalysis system of methanol oxidation and HER, producing valuable chemicals and clean hydrogen energy simultaneously.

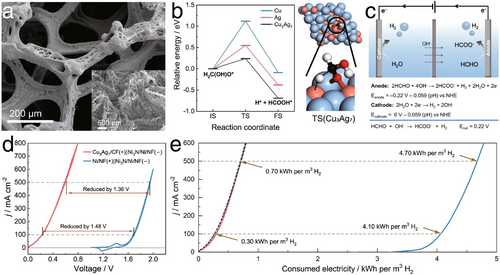

In addition to alcohols, aldehydes have also shown great potential for oxidation processes that can replace traditional water oxidation in OER. Specifically, Li et al. developed a Cu3Ag7 electrocatalyst capable of generating formate and releasing H2 at the anode,[64] utilizing formaldehyde as the organic molecule (i.e. formaldehyde oxidation reaction, Figure 15a). According to DFT analyses depicted in Figure 15b, the intermediate H2C(OH)O* was stabilized on Cu3Ag7 during the hydration of formaldehyde, resulting in a reduced C─H cleavage barrier. When paired with cathodic HER in alkaline conditions (Figure 15c,d), the electrocatalyst achieved remarkably low cell voltages of only 0.22 and 0.60 V for current densities of 100 and 500 mA cm−2, respectively, accompanied by a notable 200% Faradaic efficiency for H2 generation (attributed to both anodic formaldehyde oxidation and cathodic HER). As shown in Figure 15e, the energy consumption for H2 production in this hybrid electrolyzer was significantly lower, only 0.3 and 0.7 kWh m−3 at current densities of 100 and 500 mA cm−2, compared to the energy requirements of conventional water splitting, which are 4.1 and 4.7 kWh m−3, respectively. This demonstrated a substantial reduction in energy demand, emphasizing the efficacy of using aldehyde oxidation reactions as an alternative in electrocatalytic systems.

Similarly, utilizing the successful synthesis of a porous CuAg electrocatalyst through a galvanic replacement method (CuAgglv/Cu), Liu et al. employed biomass-derived furfural as the organic molecule to enhance the anodic reaction in a hybrid water-splitting system combined with cathodic HER, facilitating the production of green H2 at both electrodes.[65] Notably, the oxidation product at the anode, 2-furoic acid, is a crucial raw material for polyethylene furanoate, widely used in the production of edible bottles. This integration of furfural oxidation and HER not only achieved low cell voltages for bipolar H2 production but also generated high-value chemicals from readily available furfural (annually produced at ≈0.43 million tons from inedible lignocellulose). Experimental results demonstrate that increasing the potential from 0.2 to 0.4 V during electrocatalytic oxidative dehydrogenation mitigated the Cannizzaro reaction, thereby inhibiting the formation of furfuryl alcohol. The likely presence of a gem-diol intermediate in both the oxidative dehydrogenation and Cannizzaro reactions of furfural promoted the dissociation of C─H to form 2-furoic acid and H2 on the Cu surface. Utilizing the roughened surface characteristics of CuAgglv/Cu, which enhanced electron and mass transfer, the combined hybrid water-splitting system produced H2 at both anode and cathode with total Faradaic efficiencies of ≈200%, requiring only 0.4 and 0.6 V to reach current densities of 248 and 390 mA cm−2, respectively. This design not only eliminated the potential safety hazards of mixing H2 and O2 as in traditional water-splitting but also ensured pure H2 generation. Moreover, it reduced energy consumption and yielded extra high-value-added chemicals, with an estimated H2 production cost ≈2.51 USD kg−1, making it competitive with the “Green H2” objectives set by the United States Department of Energy (US DOE).[66, 67]

Urea, a well-known amine, can also support water splitting by acting as the fuel for anodic urea oxidation reactions, providing an alternative to the sluggish OER. Employing a sequential hydrothermal-phosphorization-hydrothermal approach, Chen et al. developed a porous Ni foam-supported bimetal phosphide (NiCoPx) nanowire array decorated with ultrathin NiFeCo-MOF nanosheets (NiCoPx@NiFeCo-MOF/NF) for urea-assisted hybrid water splitting.[68] DFT calculations highlighted optimized adsorption energy for COO* of −0.452 eV on the Ni sites within the NiFeCo-MOF, enhancing the generation of intermediates during the urea oxidation reaction. Simultaneously, another part of the NiCoPx exhibited an advantageous ΔGH* value, improving HER efficiency. The well-designed hierarchical structure of NiCoPx@NiFeCo-MOF/NF also enriched the active sites and facilitated electron and mass transfer during the hybrid water-splitting process. As a result, this urea-assisted hybrid water splitting system required a low cell voltage of only 1.54 V to achieve a substantial current density of 100 mA cm−2 in 1 m KOH containing 0.5 m urea solution.

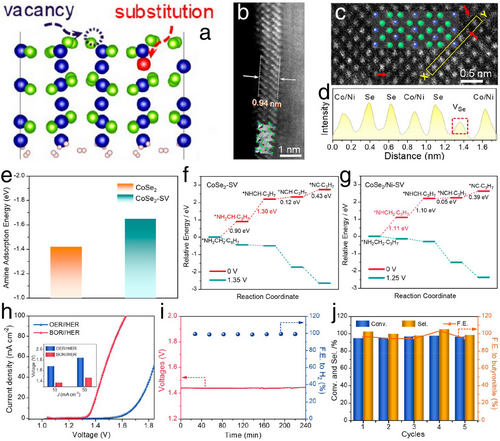

Furthermore, Zeng et al. presented advanced electrocatalysts by developing Se-vacancy and Ni-substitution-employed atomically thin CoSe2 sub-nanometer belts (CoSe2/Ni–SVs SBs) to drive the butylamine oxidation reaction, aiming to replace the conventional anodic OER (Figure 16a–d).[69] Notably, butylamine, a relatively obscure amine species in electrocatalysis, when oxidized, produces butyronitrile, a compound with substantial commercial applications in dye-sensitized solar cells and the chemical and pharmaceutical industries.[70, 71] Additionally, DFT calculations (Figure 16e) revealed that the presence of Se vacancies enhanced the adsorption of N atoms, identifying these sites as strong Lewis acids. Also, Ni substitution in CoSe2/Ni–SVs SBs enhanced the thermodynamics of the dehydrogenation reaction (Figure 16f,g). Consequently, in a hybrid water splitting setup using 1 m KOH and 0.02 m butylamine, CoSe2/Ni–SVs SBs achieved impressively low cell voltages of 1.37 and 1.47 V at current densities of 10 and 50 mA cm−2, respectively, for the anodic oxidation of butylamine and cathodic HER using CoP (Figure 16h). These voltages were 320 and 360 mV lower, respectively than those in conventional water splitting with anodic OER and cathodic HER. Further illustrating the catalytic efficiency, the system demonstrated the absolute selectivity toward butyronitrile with Faradaic efficiencies of 96.7% for butyronitrile and 98.9% for H2 production, maintaining these high rates and efficiencies over five consecutive electrochemical cycles (Figure 16i,j). Thus, utilizing CoSe2/Ni–SVs SBs in hybrid water splitting not only reduced cell voltage but also simultaneously produced H2 and commercially valuable byproducts, presenting a significant improvement over conventional water splitting methods.

In brief, both glycerol and methanol oxidation reactions exhibit significantly lower overpotentials compared to the OER. For instance, glycerol oxidation achieves an overpotential of 0.9 V at a current density of 100 mA cm−2 using A-NiFe-LDH,[62] while methanol oxidation reaches 1.39 V at 10 mA cm−2 using NiIr-MOF/NF.[63] Additionally, the reaction products, such as FA and formate, are high-value-added chemicals. However, glycerol oxidation typically requires a continuous supply of biodiesel by-products, while methanol oxidation depends on the large-scale, renewable production of methanol. Aldehyde oxidation reactions demonstrate ultralow overpotentials and low energy consumption (e.g., 0.22 V at j of 100 mA cm−1 and 0.3 kWh m−3 H2 using Cu3Ag7),[64] but industrial applications are limited due to the toxicity and storage safety concerns of aldehydes like formaldehyde. Meanwhile, urea and amine oxidation reactions exhibit relatively higher overpotentials (e.g., 1.54 V at j of 100 mA cm−1 using NiCoPx@NiFeCo-MOF/NF,[68] and 1.37 V at j of 10 mA cm−2 using CoSe2/Ni–SVs SBs,[69] respectively). However, the resources for these reactions, such as urea-containing wastewater and biomass-derived amines, are readily available, and their products (CO2, N2, and butyronitrile) have extensive industrial applications. Given the ample resource availability and mature technologies (e.g., biodiesel production and wastewater treatment), glycerol and urea oxidation reactions are likely to be rapidly implemented as viable alternatives to OER in water electrolysis. The potential of methanol oxidation reactions is also expected to grow as green methanol production technologies advance. Furthermore, aldehyde and amine oxidation reactions hold considerable potential due to the high-value-added nature of their products. However, achieving this potential will require breakthroughs in ensuring resource safety and improving product separation techniques.

3 Challenges and Progresses of Seawater HER

3.1 Typical Obstacles of Seawater HER

The HER industrialization using seawater presents many benefits. However, seawater HER also faces several challenges due to the complex composition of seawater, including sediment, microplastics, microorganisms, dissolved gases, and complex ion species. Additionally, the physical and chemical properties of seawater can vary significantly based on geographic location and seasonal changes.[72-74] Therefore, a viable approach to seawater HER must address these complexities by ensuring consistent H2 production, high reaction selectivity, and robust corrosion resistance in electrocatalysts.

3.1.1 Precipitations of Seawater HER Electrocatalysts

Admittedly, sediments, microplastics, and microorganisms present in seawater can be readily filtered out prior to seawater HER. However, the removal of many ions (e.g., F−, Cl−, Br−, Na+, Mg2+, K+, Ca2+, Cu2+, Sr2+, Cd2+, HCO3−, CO32− and SO42−, with concentrations detailed in Table 2) poses a challenge, as they cannot be easily eliminated through simple filtration.[75] On one hand, during seawater, HER, the concentration of OH− increases (manifested as a pH increase) alongside H2 evolution at the cathode. This results in the precipitation of Ca(OH)2 and Mg(OH)2, which can cover the electrocatalyst surface, obstructing the active HER sites and ultimately reducing the durability of seawater electrocatalysts. On the other hand, due to the reduction potential at the cathode, ions such as Cu2+ and Cd2+ can undergo reduction to metallic forms under specific potentials instead of contributing to HER. These competitive reactions can similarly block the HER active sites and affect the stability of electrocatalysts during seawater HER.[77, 78] Currently, the addition of buffer electrolytes to stabilize the pH of seawater is a popular method to mitigate these issues.[79] However, this approach also increases costs, hindering the scalability of industrial-scale seawater HER. Consequently, developing seawater electrolyzers that can effectively separate sediments from the cathode surface represents a promising direction. This innovation aims to enable the direct use of seawater for H2 production without additional concerns.

| Dissolved species in seawater | Concentration [ppm] |

|---|---|

| Cl− | 19 500–22 000 |

| Na+ | 10 770–14 039 |

| Mg2+, MgSO4, MgCO3 | 1290–1490 |

| SO42−, NaSO4+ | 905–3200 |

| K+ | 380–469 |

| Ca2+ | 378–421 |

| Br− | 67 |

| HCO3−, CO32− | 28 |

| Cu2+ | 5.3 × 10−5–2.8 × 10−4 |

| Cd2+ | 1.8 × 10−5–9.7 × 10−5 |

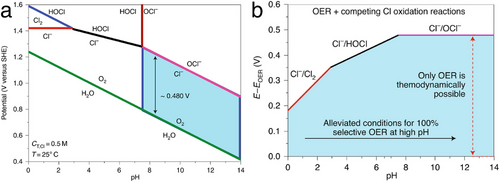

3.1.2 Competitive Anodic Chlorine Evolution

These results indicate that ClER can be circumvented by using a high-performance electrocatalyst that achieves an OER overpotential of less than ≈180 mV in acidic conditions, or less than ≈480 mV in alkaline conditions. Obviously, the latter case is generally more feasible to implement. Nonetheless, achieving industrial-scale current densities at an overpotential under 480 mV presents a significant challenge. Extensive research is needed to enhance activity and simultaneously stabilize the pH to prevent the precipitation of Ca(OH)2 and Mg(OH)2 during the electrocatalytic production of H2 from seawater.

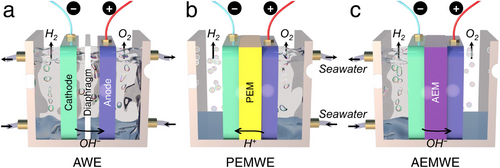

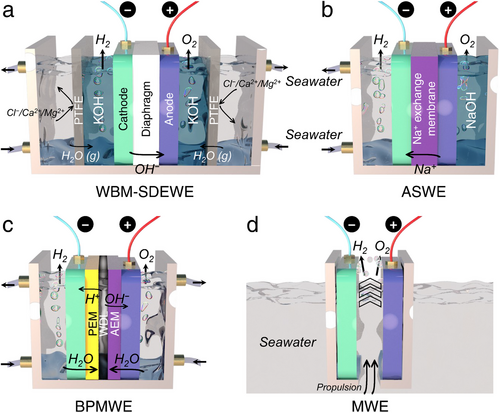

3.1.3 Conventional Electrolyzers for Seawater HER

Given the shift toward using readily available and inexpensive seawater in industrial HER electrocatalysis, conventional water electrolyzers must be adapted to address the specific challenges posed by seawater splitting. Briefly, in this sub-section, we provide an overview of typical traditional electrolyzers, including alkaline water electrolyzers (AWE), proton exchange membrane water electrolyzers (PEMWE), and anion exchange membrane water electrolyzers (AEMWE). The discussion aims to clarify which advantages of these systems should be preserved and which shortcomings or unsuitable aspects need modification for effective seawater electrolysis.

As depicted in Figure 18a, the AWE is a well-established electrolyzer used for water splitting, utilizing a porous diaphragm to separate the cathode and anode. This diaphragm allows the conduction of OH− ions from the cathode to the anode while keeping the produced H2 and O2 gases separate. Notably, when operating an alkaline seawater splitting, non-noble metal-based electrocatalysts can be used, which offer considerable overpotential and stability compared to acidic conditions.[86] As previously mentioned, in OH−-rich environments typical of seawater electrolysis, competitive ClER can be effectively suppressed, enhancing OER performance while maintaining the overpotential below 480 mV. Additionally, the alkaline environment in AWE can precipitate Ca2+ and Mg2+ ions, reducing sediment coverage of Ca(OH)2 and Mg(OH)2 on the cathodic electrode surface, making AWE technology suitable for large-scale seawater electrolysis. However, the porous diaphragm often leads to higher ohmic losses with low working current densities (below 400 mA cm−2) and the inevitable risk of H2 and O2 crossover, which increases the potential for explosions during H2 production.[87, 88] Moreover, the diaphragm can become clogged by ions and impurities in seawater, reducing the efficiency of seawater splitting. Maintaining concentrated alkaline conditions in the AWE system also incurs additional costs for H2 production. The strengths and weaknesses of AWE are detailed and compared with PEMWE and AEMWE in Table 3.

| Electrolyzers | Advantages | Disadvantages |

|---|---|---|

| AWE | Non-noble metal based-electrocatalysts available | Limited electrolysis efficiency |

| OER favorable than ClER | Explosion risks (gas crossover) | |

| Ca2+ and Mg2+ pre-precipitation to avoid the cathodic block | Extra cost on alkaline seawater | |

| PEMWE | No precipitation at the cathode | Competitive ClER than OER |

| High electrolysis efficiency | Stability challenges of PEM and related accessories | |

| Low energy consumption | Competitive Na+ transfer through PEM instead of H+ | |

| Extra-pure H2 generation | High cost on noble metal-based electrocatalysts and other anticorrosive accessories | |

| AEMWE | Non-noble metal based-electrocatalysts available | Limited electrolysis efficiency |

| OER favorable (suppressed ClER) | Stability challenges of AEM | |

| Low cost on AEMWE construction | Serious precipitation at the cathode |

The PEMWE similarly consists of cathode and anode electrocatalysts (predominantly Ir and Pt-based materials) and employs an acidic membrane (i.e., PEM) made from materials like Nafion as a solid electrolyte. This configuration enables the migration of protons from the anode to the cathode, leading to the generation of H2.[89] In PEMWE, seawater is exclusively introduced at the anode, effectively preventing the formation of Ca(OH)2 and Mg(OH)2 precipitates on the cathode surface (Figure 18b). The electrolysis process in PEMWE features faster kinetics compared to AWE due to the high proton conductivity and reduced ohmic loss in the PEM, allowing PEMWE to achieve current densities exceeding 2000 mA cm−2, thus lowering energy consumption for H2 production. Additionally, thanks to minimal H2 and O2 crossover, the purity of the H2 produced (over 99.999%) is significantly higher than that from AWE, also reducing explosion risks during seawater splitting.[90] However, the acidic environment within the PEMWE system makes the ClER more competitive than the OER at the anode. The resultant Cl2 and oxychlorides can severely damage the PEM, electrodes, and bipolar plates in the PEMWE system, degrading overall seawater electrolysis performance and shortening the lifetime of the PEMWE. Furthermore, the high concentration of Na+ in seawater often competes with H+ for passage through the PEM, leading to H+ accumulation at the anode, increasing the Nernst overpotential, and resulting in unstable PEMWE operation. Besides, the use of noble metal-based electrocatalysts and anti-corrosive Ti-based bipolar plates also significantly elevates the fabrication and operational costs of PEMWE (Table 3).[91]

The AEMWE combines elements of both AWE and PEMWE, incorporating cathode and anode electrocatalysts separated by a solid electrolyte of nonporous polymer membrane, known as AEM (Figure 18c). Similar to AWE, AEMWE operates in an alkaline environment, with the AEM facilitating the movement of OH⁻ from the cathode to the anode. Compared to the Nafion-based PEM used in PEMWE, AEM is generally more cost-effective. Introducing seawater exclusively at the cathode reduces the risk of ClER at the anode, which is enriched with OH⁻ rather than Cl⁻. This makes it possible to replace the typically expensive anti-corrosive Ti-based bipolar plates with more affordable stainless steel. Furthermore, the alkaline environment enables the use of non-noble metal-based electrocatalysts, significantly lowering the overall cost of AEMWE.[92] However, despite integrating some advantages of AWE and PEMWE, AEMWE faces challenges. The electrochemical stability of the AEM against Cl− corrosion is suboptimal, and its transport of OH− is slower compared to H+ transport in PEM, resulting in much lower efficiency during seawater electrolysis than PEMWE.[93, 94] Simultaneously, due to the direct supply of seawater to the cathode, the precipitation issue of Ca(OH)2 and Mg(OH)2 during cathodic HER is serious, which covers the cathodic electrode, blocks active sites on the electrocatalyst, and ultimately impedes overall seawater splitting efficiency in AEMWE (Table 3). Meanwhile, in terms of economic competitiveness, the well-established AWE technology is projected to grow at a compound annual growth rate of 6.5% from 2021 to 2028, with the market size expected to reach 180.03 million dollars by 2028 and an H2 production capacity exceeding 3880 Nm3 h−1.[95] However, one of the primary obstacles to further commercialization of AWE remains its high capital expenditure. On the other hand, AEMWE, as an emerging H2 production technology, shows the potential in overcoming the cost-effectiveness limitations of AWE. Although its current H2 production capacity is ≈210 Nm3 h−1, the investment cost remains relatively high at over 2000 USD kW−1, even surpassing that of AWE, which ranges from 500 to 1700 USD kW−1.[96] In brief, the cost-efficiency and investment trends of AEMWE indicate a promising direction for future research and development.

3.2 Improvements of Seawater HER

As highlighted in previous studies, to meet the demands for industrial-scale green H2 production, particularly under conditions of high current densities typically exceeding 500 mA cm−2 and during prolonged HER processes, significant efforts have been directed toward developing cost-efficient and durable HER electrocatalysts capable of large-scale synthesis. These investigations have undoubtedly paved numerous pathways toward developing exceptionally performing HER electrocatalysts, significantly advancing the industrialization of HER. In addition, recent years have seen the emergence of seawater HER as an advanced step in HER industrialization (Figure 2d), aimed at conserving scarce freshwater resources and maximizing the use of abundant seawater and coastal renewable energies, such as offshore wind and solar power. Assuredly, an electrocatalyst designed for freshwater HER typically performs effectively in seawater HER too. Consequently, with the rapid advancements in HER electrocatalyst design, applications for seawater HER have also expanded, leveraging the same HER mechanisms. Despite potential challenges such as precipitations and competitive ClER in seawater HER processes, this review further explores the progress in developing adapted seawater HER electrocatalysts and electrolyzers.

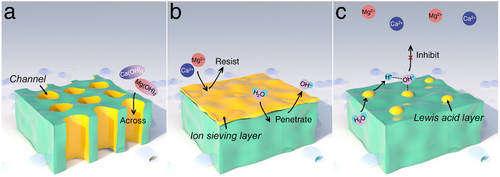

3.2.1 Precipitation Resistant Seawater HER Electrocatalysts

During seawater HER electrocatalysis, the consumption of protons from H2O increases the local concentration of OH− near the cathode, leading to a rise in pH and the formation of precipitates such as Ca(OH)2 and Mg(OH)2 on the active surface of the electrocatalyst. To address this issue, designs for cathodic seawater HER electrocatalysts should focus on self-cleaning of sediments, blocking Ca2+/Mg2+ ions, or maintaining local seawater pH. Based on this understanding, as schematically illustrated in Figure 19a, researchers are developing electrocatalysts with porous or channel-incorporated structures to minimize the retention of precipitates on the surface, allowing precipitates to be carried away with the electrolyte flow. Additionally, Figure 19b shows an HER electrocatalyst coated with an ion-sieving layer that blocks Ca2+ and Mg2+ ions from seawater while permitting the penetration of H2O and OH−, thereby facilitating the seawater HER process. This approach fundamentally reduces the impact of sedimentary corrosion through physical resistance. Moreover, as depicted in Figure 19c, the application of a Lewis acid layer on the electrocatalyst surface is becoming popular. This layer captures the produced OH− from water dissociation, preventing its diffusion into the bulk seawater and the formation of insoluble precipitates. Although these strategies are theoretically sound, practical applications to fully realize these concepts are still in developmental stages.

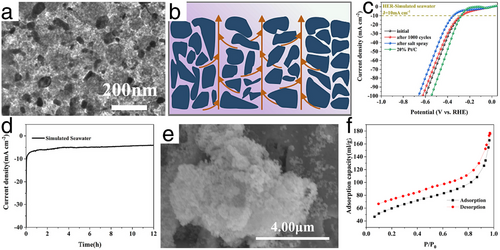

Drawing inspiration from the natural channel structure in plants, Li et al. developed a Mo2C composite electrocatalyst in situ grown on corn straw biochar using a cold isostatic pressure method (Mo2C/B (CIP)), as illustrated in Figure 20a.[97] The schematic in Figure 20b shows that the Mo2C/B (CIP) benefited from an abundance of mesoporous and vertically wide channels, facilitating timely electron exchange and the release of H2 bubbles. Although the formation of precipitates such as Ca(OH)2 and Mg(OH)2 was still inevitable, the natural porous and channel structures in Mo2C/B (CIP) effectively alleviated congestion caused by these precipitates, enabling rapid mass transfer of H2 bubbles and seawater electrolyte through its low-tortuosity channels. As shown in Figure 20c,d, this well-designed seawater HER electrocatalyst demonstrated a notably low overpotential of 251 mV to achieve a current density of 10 mA cm−2 in simulated seawater. Remarkably stable performance was also maintained even after the 12-h seawater HER test, with the specific surface area of Mo2C/B (CIP) maintained at 206.7 m2 g−1, demonstrating its resistance to Ca(OH)2 and Mg(OH)2 precipitations during seawater HER electrocatalysis, as depicted in Figure 20e,f.

In a similar pursuit for sediment resistance during seawater HER, Liu et al. developed a novel Ni foam electrode coated with a Ni(OH)2 nanofiltration membrane (Ni(OH)2–NF), as detailed in Figure 21a.[98] This positively charged Ni(OH)2 membrane with nanometer-scale cracks effectively prevented Ca2+ or Mg2+ from reaching the HER electrocatalyst surface, while permitting the passage of reactants or intermediates such as H2O and OH− during seawater HER processes, as shown in Figure 21b,c. When compared to the bare Ni foam electrode, the Ni(OH)2–NF electrode achieved a dramatic reduction in precipitations by 98.3%, maintaining stable operation for 100-h in a Mg(OH)2-saturated seawater solution, as shown in Figure 21d,e. In the context of a flow-type direct seawater electrolyzer, as depicted in Figure 21f, the system utilizing the Ni(OH)2–Pt–NF electrode (cathodic HER) alongside a Cr2O3–IrRuO2–Ti electrode (anodic OER) exhibited superior resistance to seawater HER precipitations compared to a conventional water splitting system with a Pt–NF cathodic electrode. After a 100-h seawater HER stability test, the sediment accumulation on the Ni(OH)2–Pt–NF electrode was just 0.82 mg cm−2, significantly lower than the 10.06 mg cm−2 on the Pt–NF electrode without the Ni(OH)2 nanofiltration coating, as presented in Figure 21g.

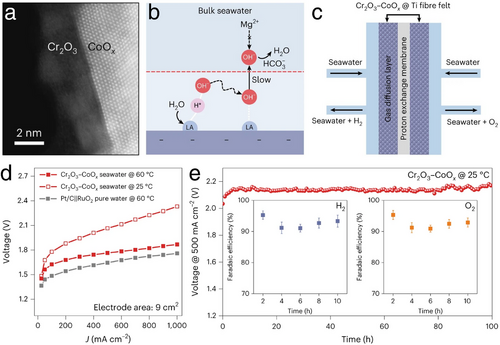

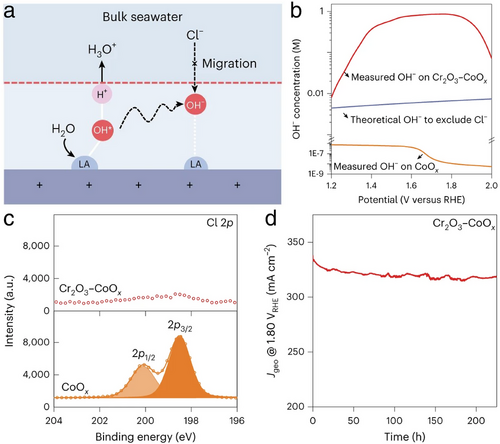

In a notable study aimed at mitigating corrosion from the precipitation of Ca(OH)2 and Mg(OH)2 during seawater HER, Guo et al. implemented a Lewis acid layer on their electrocatalyst design.[99] This novel seawater HER electrocatalyst featured CoOx grown on carbon fibers and encapsulated with a durable Lewis acid layer of Cr2O3, chosen for its electrochemical stability and extremely low pKa value of 2.05, as shown in Figure 22a. This layer effectively captured OH– ions generated during water dissociation in the seawater HER process, thus preventing their diffusion into the seawater and inhibiting the formation of Ca(OH)2 and Mg(OH)2 precipitations on the electrode surface, as illustrated in Figure 22b. Performance results detailed in Figure 22c–e demonstrate that the Cr2O3–CoOx electrocatalyst achieved a low operational cell voltage of only 1.87 V to reach an industrial-scale current density of 1000 mA cm−2 at 60 °C. It also maintained stable performance at a current density of 500 mA cm−2 over 100 h, with high Faradaic efficiencies for H2 (≈93%) and O2 (≈92%) generation in a flow-type seawater electrolyzer using real seawater. This sophisticated design not only effectively supported direct seawater electrolysis but also adapted to industrial-scale current densities and stability requirements.

3.2.2 Highly Selective Anodic Electrocatalysts

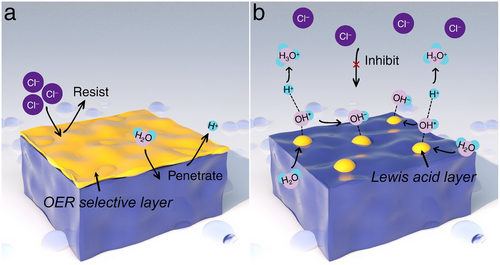

Chloride (Cl−), the predominant anion in seawater (ranging from 19 500 to 22 000 ppm as detailed in Table 2), often undergoes competitive ClER processes at the anode, typically generating corrosive Cl2 gas. While the strategic design of anodic OER electrocatalysts to circumvent ClER indirectly benefits seawater HER activities, minimizing Cl2 damage is crucial for extending the operational life of industrial seawater electrolyzers. As mentioned previously, to achieve industrial-scale current densities in acidic conditions without Cl2 evolution, the applied overpotential must remain below 180 mV, a challenging target seldom met in current research. However, in alkaline conditions, an overpotential up to 480 mV is permissible, which significantly reduces the concern on the competitive ClER. Thus, in view of these obstacles and potential opportunities, and also essential for a comprehensive evaluation of seawater HER progress, recent studies have focused on developing functional seawater OER electrocatalysts, such as those depicted in Figure 23a,b. These include developing an OER-selective layer that blocks Cl− while allowing H2O and H+ to pass through during seawater OER or establishing a localized alkaline environment using a Lewis acid layer on the electrocatalyst surface. This setup creates a stable electrical double layer rich in OH− and H3O+, which effectively prevents localized Cl− migration from the bulk seawater to the electrocatalyst surface, thereby inhibiting competitive ClER at the anodic side of seawater splitting.

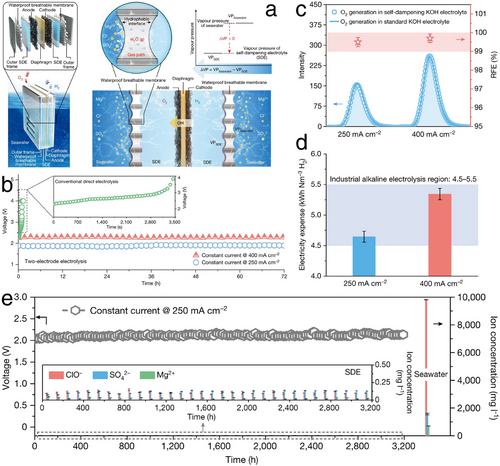

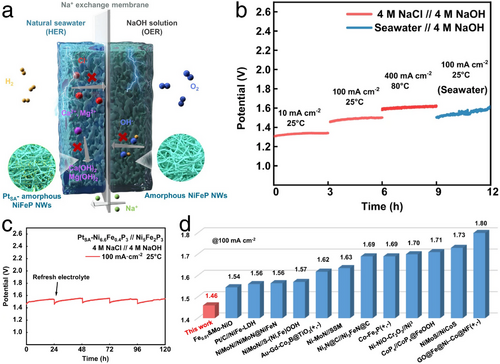

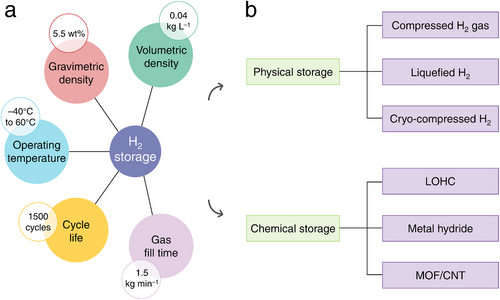

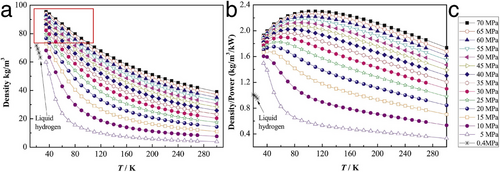

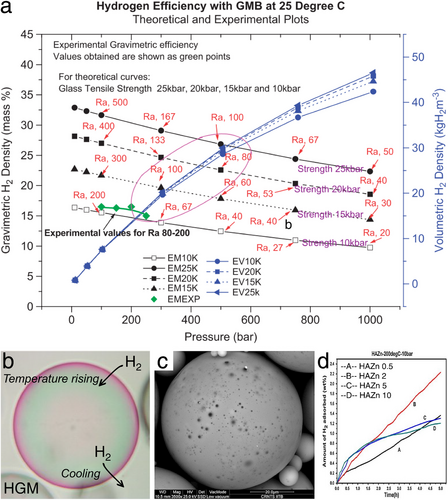

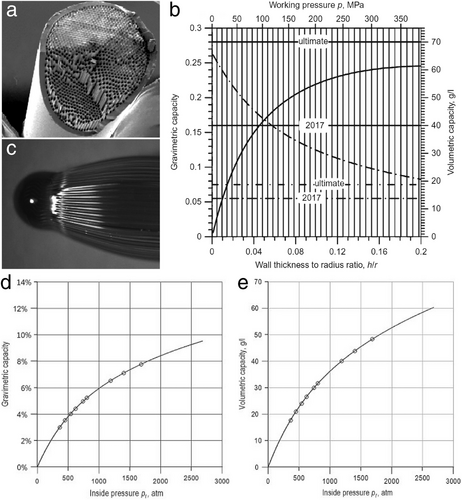

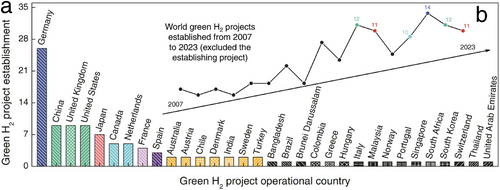

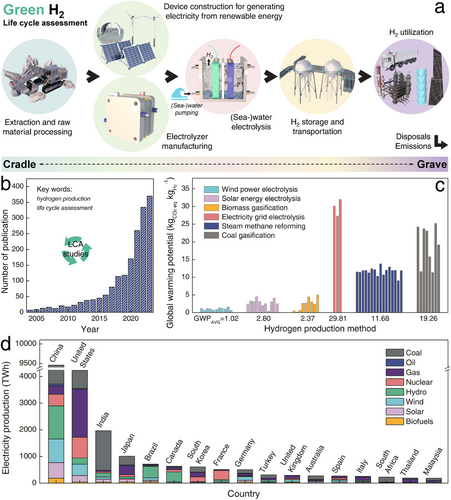

In a noteworthy development, Tan et al. engineered an in situ sulfate passivating layer on a Ni foam-supported Ni2Fe-LDH/FeNi2S4 heterostructure (Ni2Fe-LDH/FeNi2S4/NF) during repeated CV scans for OER electrocatalysis.[100] This heterostructure, featuring numerous bimetallic hydroxide/sulfide interfaces, enhanced the adsorption of oxygen intermediates, thereby accelerating OER. Intriguingly, the Cl−-repellent sulfate layer formed in situ on the electrocatalyst surface further extended its application in seawater OER. Following the establishment of this sulfate film, the Ni2Fe-LDH/FeNi2S4/NF demonstrated exceptional performance in alkaline simulated seawater electrolyte, achieving an ultralow OER overpotential of 250 mV at a current density of 100 mA cm−2. The enhanced long-term stability observed post-film formation surpassed the performance of the uncoated Ni2Fe-LDH/FeNi2S4/NF, demonstrating highly increased resistance to Cl− thanks to the post-formed sulfate passivating layer, effectively inhibiting Cl2 evolution in seawater splitting. Similarly, using a two-step approach involving hydrothermal synthesis and electrochemical activation, Kang et al. enhanced the performance of the RuMoNi electrocatalyst for seawater OER.[101] During electrochemical reconstruction, in situ generated MoO42−, formed through the leaching of Mo from the RuMoNi electrocatalyst, effectively repels Cl⁻ from the electrocatalyst surface. This reversible dissolution and precipitation of NiMoO4 results in the formation of a selective MoO42− layer, stabilizing the RuMoNi electrocatalyst for at least 3000 h, even under an industrial-scale current density of 500 mA cm−2, with a minimal voltage degradation rate of 0.64 µV h−1. Remarkably, the system exhibits ≈100% selectivity for alkaline seawater OER. Furthermore, the AEM electrolyzer employing the RuMoNi electrocatalyst achieved seawater electrolysis at a high current density of 1000 mA cm−2 with an applied voltage of just 1.72 V, delivering an energy conversion efficiency of 77.9%. As a result, the calculated cost per gallon of gasoline-equivalent for the produced hydrogen is 0.85 dollars, significantly lower than the DOE 2026 target of 2 dollars. Fan et al. developed the CoFe-Ci@GQD seawater electrolysis electrocatalyst by strategically combining several innovative features.[102] They constructed CoFe-based host layers to enhance OER activity, introduced CO32− into the interlayer to create narrow interlayer spacing and repel Cl⁻ ions, and anchored graphene quantum dots (GQDs) on the catalyst surface to generate Coulomb repulsion, preventing Cl⁻ from accessing surface active sites. Benefiting from these superior characteristics, CoFe-Ci@GQD demonstrated remarkable durability, achieving over 2800 h of alkaline seawater OER operation even at an industrial-scale current density of 1250 mA cm−2. Additionally, the CoFe-Ci@GQD electrocatalyst was integrated as both HER and OER components in a photovoltaic–electrolysis device, achieving a record solar-to-hydrogen efficiency of 18.1% for overall seawater splitting, along with excellent stability for up to 200 h under a high current of 440 mA. These outstanding performances undoubtedly reinforce the potential of green H2 as a sustainable energy solution for the future.