Smart mechanoluminescent phosphors: A review of zinc sulfide-based materials for advanced mechano-optical applications

Zefeng Huang, Xu Li, and Tianlong Liang contributed equally to this work.

Abstract

The quest for mechanoluminescence (ML) in zinc sulfide (ZnS) spans more than a century, initially sparked by observations of natural minerals. There has been a resurgence in research into ML materials in recent decades, driven by advances in optoelectronic technologies and a deeper understanding of their luminescent properties under mechanical stress. ZnS, in particular, has garnered attention owing to its remarkable ability to sustain luminescence after more than 100,000 mechanical stimulations, positioning it as a standout candidate for optoelectronic applications. In contrast to conventional photoluminescent and electroluminescent light sources, ZnS composite elastomers have emerged as flexible, stretchable self-powered light sources with considerable practical implications. This review introduces the development history, ML mechanisms, prototype ML devices, ZnS-based ML material preparation methods, and their diverse applications spanning environmental mechanical-to-optical energy conversion, E-signatures, anti-counterfeiting, wearable information sensing devices, advanced battery-free displays, biomedical imaging, and optical fiber sensors for human–computer interactions, among others. By integrating insights from ML-optics, mechanics, and flexible optoelectronics, and by summarizing pertinent perspectives on current scientific challenges, application technology hurdles, and potential solutions for emerging scientific frontiers, this review aims to furnish fundamental guidance and conceptual frameworks for the design, advancement, and cutting-edge application of novel mechanoluminescent materials.

1 INTRODUCTION

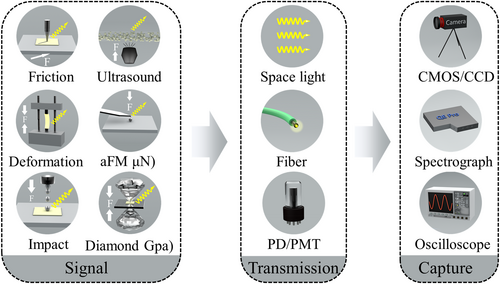

Effective retrieval and detection of information are fundamental steps for research progress, of which the acquisition and processing of mechanical information hold particular significance, requiring the use of various types of mechanical sensors, such as piezoelectric,1 electromagnetic,2 and optical fiber-based sensors.3, 4 In recent years, a new category of smart photonic devices based on mechanoluminescent (ML) materials has garnered considerable attention. Compared to traditional sensors, ML devices could operate independently of complex external circuits or batteries, without external energization or illumination, offering distinct benefits in the development of innovative intelligent systems designed for stress/strain sensing and passive display imaging. At the core of such sensors lie ML materials, which emit light directly upon deformation, fracture, or external forces.5 Unlike photoluminescent (PL), electroluminescent (EL) and other stimulus-responsive materials.6-8 ML materials can be triggered by various mechanical stimuli, including frictional forces, pressure, tensile forces, and ultrasound. In recent years, numerous inorganic ML materials have been reported, including oxides (such as SrAl2O4,5 Sr2MgSi2O7,9 Ga2O3,10 LiNbO3,11 NaNbO3,12 Sr3Sn2O7,13 LiGa5O8,14 LiYGeO4,15, 16 and SrGa12O19),17 sulfides (such as ZnS18-25 and MGa2S4 (M = Ca, Sr, Zn)),26 oxysulfides (such as CaZnOS27, 28 and X2O2S29, 30), fluorides (such as MgF2 31 and CaF2 32), and their heterojunctions (such as ZnS-CaZnOS,33-36 ZnO-ZnF2,37 and LiNbO3-NaNbO3 38). These materials emit electromagnetic waves ranging from visible to infrared wavelengths directly when subjected to mechanical stress. Among these materials, zinc sulfide (ZnS) stands out for maintaining good ML brightness even after 100,000 cycles of mechanical excitation.24

With its outstanding ML performance, ZnS has been re-igniting enormous research enthusiasm.39 Accordingly, this paper aims to furnish a comprehensive review encompassing the development history, underlying mechanisms, and application prospects of ZnS ML materials in advanced stress sensors and stretchable optoelectronics, while also shedding light on the challenges in this field.

1.1 Research history

The historical development of ZnS as a luminescent material has a fascinating timeline indeed. Théodore Sidot's initial discovery in 1866 marked the beginning of its documented history,40 his research findings being further developed by the renowned luminescence researcher A. E. Becquerel.41 The earliest research on ZnS ML dates back to 1904 when Wallace Goold Levison discovered that grayish chunks of sphalerite would emit colored light and composite luminescence when rubbed with fingertips, matches, fingernails, or steel brushes.42, 43 The ML intensity was substantial enough to be evident from several meters away. The cause of composite luminescence was attributed to various impurities in the mineral, marking the first report of natural sphalerite ZnS exhibiting ML properties.18

Curie and Porst pointed out that ML could originate from the cleavage of crystals when subjected to external stress. Later, in 1964, Alzetta et al. contradicted this interpretation.44 They studied the ML properties of ZnS powder suspensions in various liquids under hydrostatic compression and discovered that ML was independent of the medium, whether insulating or conducting. Moreover, they proposed that the energy required to excite electrons to the excited state in ML materials originates from phonons produced when the vibrational equilibrium of the crystals shift to a higher energy level owing to pressure changes. Chudacek noted that ZnS ML was directly proportional to the time variation of applied pressure, suggesting that it might be a phenomenon of a destructive nature.45, 46 In summary, early ZnS ML research focused on the phenomena and discussion of ML fundamentals.47 However, practical applications of ML materials were limited, primarily owing to challenges such as inadequate sample preparation techniques, lack of sensitive photon detection equipment, and the limited luminescence brightness of early synthesized ML materials. These factors collectively hindered progress in ZnS ML research during that time.48-55

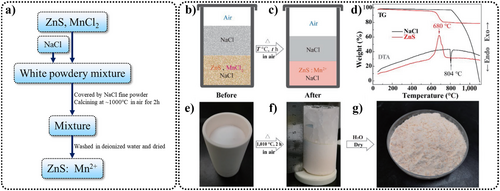

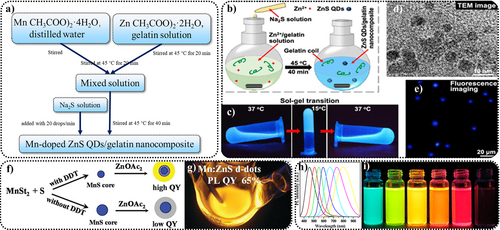

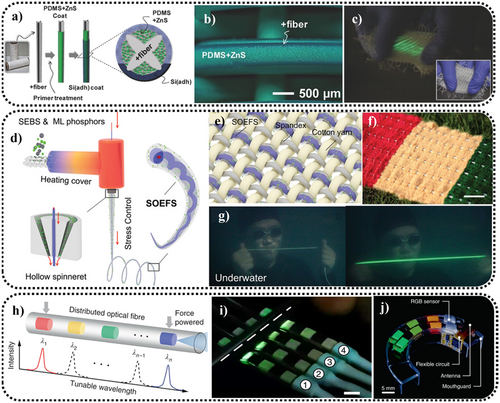

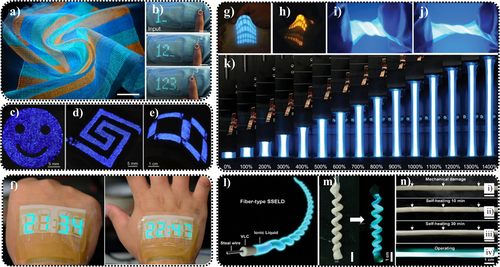

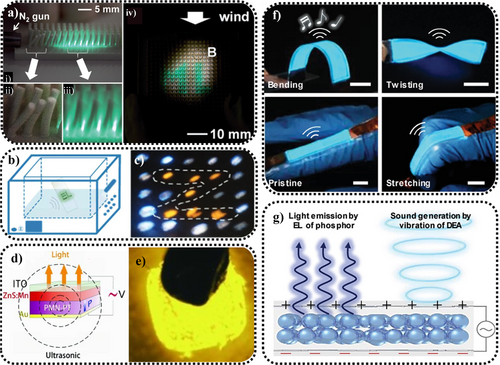

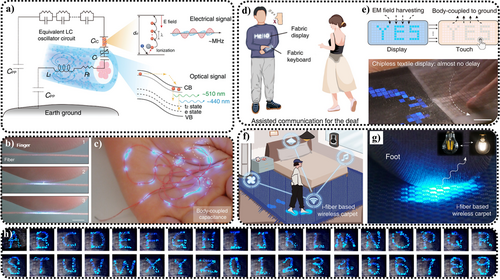

It was not until 1999 when Xu et al. proposed an effective sample preparation method and potential application of ZnS ML films for stress sensing as artificial skin that a new wave of ML research was sparked.23 They found that, under the same preparation conditions, the ML intensity of nanoscale ZnS:Mn2+ artificial skin exceeded that of the bulk solid by an order of magnitude, thanks to the high orientation of ZnS:Mn2+ thin films and the nano-sized particles embedded within. In 2013, Jeong et al. reported a kind of elastomer composite—that is, ZnS:Cu@polydimethylsiloxane (PDMS)—with a brightness of up to 120 cd · m−2 under moderate external forces (the pressure ranging from kilopascals to megapascals), and found that considerable levels of ML were capable of withstanding over 105 repeatable mechanical stress cycles.24 Moreover, they suggested that ZnS could produce tunable light emission with different luminescent dopants (such as Cu+/2+ and Cu+/2+/Mn2+), under specific experimental conditions.56 ZnS:PDMS ML composite materials could also be fabricated into wind-driven ML devices, capable of emitting light with different color temperatures (including warm, neutral, and cool white), allowing for energy-efficient lighting and image displays (Figure 1).63

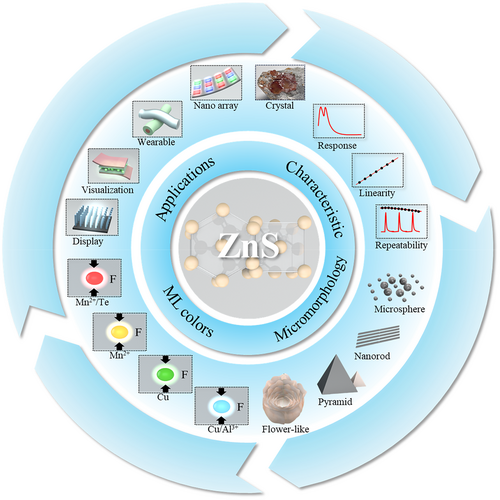

Characteristic, micromorphology, ML colors and application of ZnS particles. Characteristics: photograph of crystal; bimodal ML response44; linearity44; and repeatability.24 Micromorphology: microsphere57; nanorod58; pyramid shape59; and flower-like shape.60 ML colors: ZnS:Cu/Al3+ (blue)61; ZnS:Cu (green)24; ZnS:Mn2+ (orange)23, 52; and ZnS:Mn2+/Te (red).62 Applications: Outdoor display. Reproduced with permission from Ref.63 Copyright 2014, The Royal Society of Chemistry; Pressure visualization. Reproduced with permission from Ref. [25]. Copyright 2015, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim; Wearable fabric. Reproduced with permission from Ref. [64]. Copyright 2021, The Author(s), under exclusive license to Springer Nature Limited part of Springer Nature; Nano array.65 Reproduced with permission from Ref. [65]. Copyright 2023, Royal Society of Chemistry. ML, mechanoluminescence; ZnS, zinc sulfide.

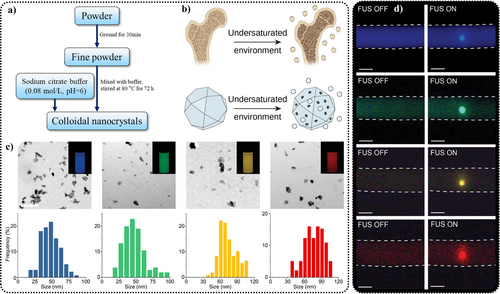

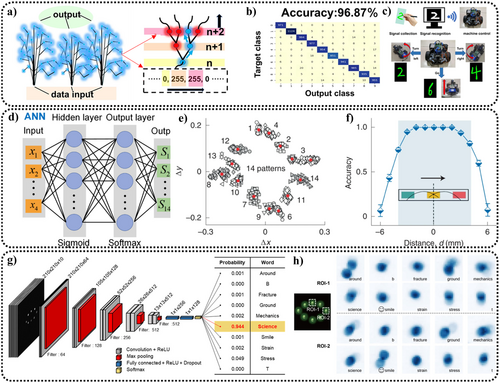

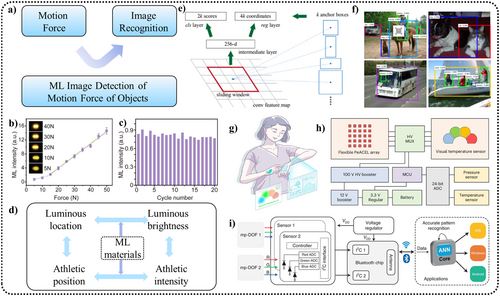

Since 2015, researchers have focused on optimizing ZnS ML performance for fine applications in different fields. For example, Wang et al. fabricated hand-writable ZnS:Mn2+ films for electronic signatures25; Qian et al. improved the deformability and ML intensity by incorporating SiO2 into ZnS:Mn2+ and ZnS:Cu66; Peng et al. increased the brightness to 2.2 times that of commercial ZnS:Mn2+ by heterogeneous compounding of ZnS:Mn2+ with CaZnOS:Mn2+, and explored the ZnS:Mn2+ bi-phase homojunction structure to enhance its ML capabilities33; Hong et al. prepared nanoscale ZnS:Ag+/Co2+ ML particles for optogenetic therapy, showcasing the diverse applications of ML materials in biomedical fields67; Hou et al. developed bite guards for human–machine interaction based on ZnS particles and introduced artificial neural networks (ANNs) to optimize data quality21; Mukhina et al. clarified the differences in the ML mechanisms of ZnS particles under low and high pressure conditions68; and Zheng et al. investigated the spectral properties of ZnS/CaZnOS:Mn2+ under extreme conditions, suitable for temperature detection under extremely high pressures.34 These studies collectively showcase the multifaceted applications and advances in ML research, ranging from material synthesis to biomedical applications and environmental sensing.

2 CRYSTAL STRUCTURE, DEFORMATION, AND LUMINESCENCE CHARACTERISTICS

The microstructure of crystals and doping ions play a crucial role in determining the luminescence properties of doped ZnS crystals, which, in turn, can further affect their application scenarios. Additionally, their relatively wide bandgap allows for the modulation of luminescence wavelengths and characteristics by doping with various element ions with matching ionic radii.

2.1 Crystal structure

ZnS is not only a typical material for ML applications but also a typical II–VI group semiconductor. Pure ZnS is an n-type semiconductor, although p-type semiconductors can also be obtained by doping ions such as Ag,69 Tm,70 and N.71, 72 At 300 K, the residual electron density in ZnS is approximately 104 cm−3, considerably higher than the expected value produced by thermal ionization in wide-bandgap materials. This suggests that it is a compensating semiconductor characterized by a significantly higher concentration of donor (D) defects compared to acceptor (A) defects.73 In the absence of an external field, the majority of these donors are occupied by electrons and thus remain neutral, while a smaller proportion of ionized donors () offsets the charged acceptors (), thereby ensuring the charge neutrality of the material.68

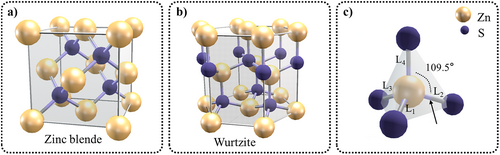

ZnS exhibits two common allotropes—that is, the hexagonal wurtzite structure (WZ, α phase, non-centrosymmetry) and the cubic zinc blende structure (ZB, β phase, centrosymmetry) (Figure 2). These two structures share a similar single cell. The phase transition temperature from β phase to α phase in undoped bulk ZnS is around 1020°C.74 In the ZB-ZnS structure, tetrahedrally coordinated zinc and sulfur atoms stack in an ABCABC pattern, belonging to the cubic phase and face-centered cubic structure with central symmetry. The lattice parameters are a = b = c = 5.41 Å, Z = 4, and the space group is F-43m, making it an isotropic crystal with a bandgap width of 3.72 eV. In the WZ-ZnS structure, the same elements stack in an ABABAB pattern, belonging to the hexagonal phase and close-packed hexagonal structure. Its lattice parameters are a = b = 3.82 Å, c = 6.26 Å, Z = 2, and the space group is P63mc, making it an anisotropic crystal with a bandgap width of 3.77 eV.75 Additionally, owing to its non-centrosymmetric structure, ZnS exhibits several piezoelectric properties with a piezoelectric constant of 8 pm · V−1.76

Crystal structure of ZnS: (a) zinc blende; (b) wurtzite ZnS; and (c) a single cell. For bond angles, they are 109.5° in both ZB and WZ structures. For bond lengths, in ZB it is L1 = L2 = L3 = L4 = 2.33 Å, and in WZ it is L1 = L2 = L3 = 2.33 Å and L4 = 2.34 Å. WZ, wurtzite structure; ZB, zinc blende structure; ZnS, zinc sulfide.

The size of ZnS particles can affect its bandgap and phase transition temperature. Compared to bulk materials, ZnS nanomaterials have a wider bandgap owing to the quantum size confinement effect of low-dimensional nanostructures.77 Qadri et al. found that reducing the particle size of ZnS crystals to the nanoscale lowers the phase transition temperature.74 In their experiments, the mixture of α and β phases in nano ZnS began to appear at temperatures as low as 350°C, much lower than the typical 1020°C. Additionally, with increasing annealing temperature, the particle size increased considerably, ranging from 2.8 to 243 Å.74

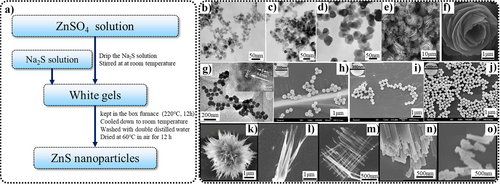

Apart from particle size, the phase transition of ZnS crystals is also related to pressure,78 temperature,79 doping,79 and preparation details.80 For example, Wang et al. proposed that the irreversible phase transition from the WZ phase to the ZB phase occurred at pressures >14 GPa in ZnS:Mn2+/Eu3+.78 Feng et al. mentioned that thorough ball milling of raw materials before sintering could reduce the required temperature for obtaining WZ-structured ZnS.80 Wang et al. explored the influence of the proportion of Mn2+ in the ZnS host on the phase transition.79 They synthesized nanorod-shaped ZnS systems via the hydrothermal method and explored the correlation between the β-phase proportion and the intensity of ML and PL. By adjusting the concentration of Mn2+ doping and the annealing temperature, it was possible to control the ratio of the two phases. Moreover, they indicated that the sample did not exhibit ML properties at calcination temperatures below the required levels.

2.2 Deformation properties related to microstructure

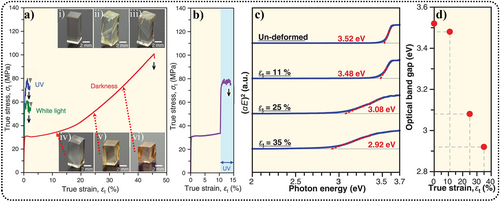

Oshima et al. discovered that ZnS single crystals could exhibit extraordinary plastic deformation effects at room temperature (297 K) in a completely dark environment, achieving a strain of εt = 45%, without undergoing fracture.81 However, when exposed to ordinary light or 365-nm ultraviolet light, the sample quickly fractured after exceeding its plastic deformation point (Figure 3a,b). This phenomenon could be attributed to the fact that the inorganic semiconductors were typically hard and brittle. During deformation, the optical bandgap of the crystal decreased from 3.52 to 2.92 eV (Figure 3c,d), and the crystal changed in color from colorless to gradually becoming orange. This suggested that the optical gap depended on the magnitude of deformation, owing to the introduction of dislocations in the deformed sample. Dislocation core regions in the crystal could have different energy band structures compared to the dislocation-free regions.82

Characterization of plastic deformation. (a) Stress–strain curves of ZnS single crystals under various lighting conditions: UV light (365 nm) (blue line), white light (green line), and complete darkness (red line). (i) An undeformed specimen. (ii, iii) Specimens subjected to deformation under white light and UV light. (iv–vi) Specimens experiencing extensive deformation in complete darkness, reaching (iv) εt = 11%, (v) εt = 25%, and (vi) εt = 35%. (b) Stress-strain curve obtained from deformation at εt = 10% in complete darkness, followed by further deformation under UV light. (c) Absorption characteristics comparison between an unaltered specimen and specimens deformed up to εt = 11%, 25%, and 35% under complete darkness. E, photon energy; α, absorption coefficient. (d) Change in the optical bandgap corresponding to varying deformation strain. Reproduced with permission from Ref. [81]. Copyright 2018, The American Association for the Advancement of Science. ZnS, zinc sulfide.

Further microstructural characterization elucidated the detailed processes involved. Based on the X-ray diffraction (XRD) results, the initially undeformed ZnS crystals exhibited approximately 50% twinning formation (Figure 4a–e).83 As plastic deformation reached around 10% strain, accompanied by changes in the crystal domain volume—that is, the disappearance of twinning—further strain increases in darkness resulted in almost constant crystal domain volume. During the initial stages of plastic deformation, the movement of the crystal domain boundaries and the associated changes in the crystal domain volume were caused by the slip of inter-domain boundary dislocations. During the later stages of plastic deformation, the crystal domain volume remained constant, and an increase in the number of paired partial dislocations was evident as the plastic strain increased (Figure 4f–h). The transition in dislocation behavior could originate from an increase in the crystal domain volume—that is, the disappearance of twinning—leading to the formation of paired partial dislocations.

(a) Schematic representation of the XRD experiments. (b, c) XRD data obtained from an initially pristine, undeformed ZnS crystal. The inset in (c) offers a real-space view of the twin formation. (d, e) The crystal orientations of Domain 1 and Domain 2, corresponding to the green and blue square indices in (b), respectively. (f–h) Bright-field scanning transmission electron microscopy images captured from the 〈111〉 direction for both undeformed and deformed ZnS (εt = 11%, 25%) in darkness, respectively. The schematic representations below indicate dislocations with distinct Burgers vectors, with arrows representing the Burgers vectors of b = 1/6<112>. (i–l) Bright-field TEM images observed from the [110] direction under different conditions: deformation in darkness: εt = 0%, 11%, and 25%; deformation under light: εt = 3%. (m, n) HRTEM images corresponding to (i and k), respectively. (o, p) Diffraction patterns acquired from the zone axis [110] for the undeformed and deformed ZnS (εt = 25%). The green hexagons represent the diffraction pattern of a ZB structure when viewed along [110]. Reproduced with permission from Ref. [83]. Copyright 2023, Acta Materialia Inc. Published by Elsevier Ltd. HRTEM, high-resolution transmission electron microscope; TEM, transmission electron microscopy; XRD, X-ray diffraction; ZB, zinc-blende; ZnS, zinc sulfide.

To validate the changes more directly in the domain volume of Domain 1 and Domain 2 (Figure 4b,c) measured by XRD during plastic deformation, transmission electron microscopy (TEM) observations of both undeformed and deformed specimens were conducted. In darkness, TEM images showed the volumes of either domain (Domain1 or Domain2) tended to increase as the plastic strain increased (Figure 4i–k). Moreover, the high-resolution transmission electron microscopy images and XRD results identified the two-type domains having a twin relationship (Figure 4m,n). Additionally, diffraction patterns were captured from the zone axis [110] for both undeformed and deformed sample (εt = 25%). The diffraction analysis of the undeformed sample revealed twin formations on {111}, while one of the two patterns from the zincblende structure, which had varying crystal orientations, nearly vanished following plastic deformation at εt = 25%. It is evident that the volume ratios of the observed black- and white-contrast areas in the TEM images (Vol.(b)/Vol.(w)) of the undeformed specimen are almost equal to 1, which deviate considerably (reaching approximately 1/6) in the specimen deformed up to εt = 25% (Figure 4o,p). By contrast, under light conditions, Figure 4l shows that a TEM image captured from an area displaying slip lines in the specimen, which was deformed up to εt = 3% under UV light illumination. It is worth mentioning that the Vol.(b)/Vol.(w) differs considerably from the others, approaching roughly 1/4 (Figure 4l).

In conclusion, it is evident that the crystal domain volume changed locally, indicating that local deformation was caused by the motion of boundary dislocations, similar to the initial deformation stages in darkness. The mobility of dislocations interacting with photoexcited charge carriers depends enormously on dislocation characteristics—that is, the atomic species in the dislocation core and the dislocation direction. The dependence of dislocation characteristics on their mobility can lead to non-uniform plastic deformation under light conditions.

When subjected to external forces, the WZ-crystal structure is prone to deformation, leading to the separation of positive and negative polarization charge centers and the generation of a polarization field. This field drives trapped electrons within crystal defects to move to the conduction band, thereby forming electron–hole pairs. The energy released from this process is transferred to the luminescent centers through non-radiative recombination, resulting in luminescence. Although the ZB-crystal structure is a centrosymmetric crystal and typically lacks piezoelectricity—often considered essential for solid materials to exhibit ML—several studies have indicated that piezoelectricity may not be indispensable. For instance, Ma et al. reported that Mn2+-doped ZB crystals also exhibited self-recoverable ML (RML) characteristics. They proposed that this phenomenon was attributed to the transfer of electronic energy to luminescent centers during the process of chemical bond reconstruction, leading to the emission of excited light.84 This topic will be discussed in detail in Chapter 3.

2.3 ML and mechanical quenching (MQ)

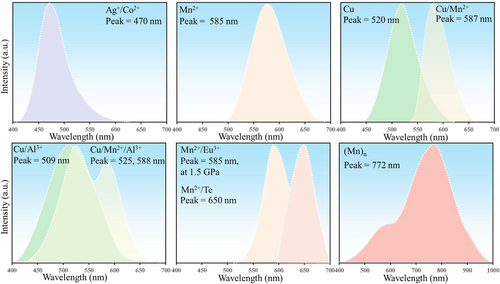

The intense ML in ZnS typically requires doping to occur. Undoped ZnS crystals exhibit weak PL and EL and exhibit little ML owing to the absence of impurity energy levels. Commonly used doping ions that can act as luminescent centers include Mn2+,63, 66, 85-87 Cu+,21 Cu2+,56, 88-90 Cu/Cl,86 Mn2+/Te,62, 91 Mn2+/Li+,92 Mn2+/Cu,56 Ag+/Co2+,93 Cu/Al3+,61, 86 and Cu/Mn2+/Al3+ (Figure 5, Table 1).61 The emissions in the visible light band are bright and clearly visible, especially the blue-light emission (which is unrivaled in brightness compared to other ML materials), thereby enabling the realization of white-light ML emission by combining three colors.63, 100 These advantages have also enabled ZnS to rapidly achieve widespread commercial use in the field of ML.

| Phosphor material | Dopants | λML [nm] | Condition | Refs. |

|---|---|---|---|---|

| α-ZnS/PDMS | Mn2+ | 585 | 1050°C/2 h | [86] |

| α-ZnS/Au/PMN-PT | Mn2+ | 590, 684, 772, 868 | Laser deposition | [95] |

| β-ZnS | Mn2+ | 590 | 900°C/2 h | [84] |

| Bi-phase-ZnS/PDMS | Mn2+ | 590 | 1010°C/2 h | [84] |

| ZnS/PDMS | Cu+ | 475 | Purchase (from LONCO) | [21] |

| α-ZnS (bulk crystals) | Cu/Cl | 517 | Thermal evaporation | [86] |

| α-ZnS/PDMS | Cu | ∼517 | Purchase (GG45, from Osram Sylvania Inc.) | [63, 89] |

| β-ZnS/PDMS | Cu | 520 | Purchase (GGS42, from Osram Sylvania Inc.) | [24] |

| Bi-phase-ZnS/PDMS | Cu | 513 | Purchase (D512c, Shanghai Keyan Optoelectronic Technology Co., Ltd.) | [96] |

| α-ZnS/PVDF | Cu/Mn2+ | 593 | Purchase | [97] |

| β-ZnS/PDMS | Cu/Mn2+ | 587 | Purchase (GGS12, from Osram Sylvania Inc.) | [56] |

| β-ZnS | Cu/Mn2+ | 580 | 1050°C/3 h | [98] |

| α-ZnS/Fe-Co-Ni/PDMS | Cu/Al3+ | 509 | Purchase | [61] |

| α-ZnS/Fe-Co-Ni/PDMS | Cu/Mn2+/Al3+ | 525, 588 | Purchase | [61] |

| α-ZnS | Mn2+/Te | 650 | 1150°C/12 h | [62] |

| β-ZnS (nanoparticles) | Mn2+/Te | 650 | 850°C/10 h | [91] |

| α-ZnS | Mn2+/Li+ | 580 | 1050°C/3 h | [92, 98] |

| α-ZnS | Mn2+/Eu3+ | 585 | 1126.85°C/3 h | [78] |

| α-ZnS (nanoparticles) | Ag+/Co2+ | 470 | 800°C/3 h | [93] |

| ZnS/PDMS:DCJTB | - | 600 | - | [99] |

- Note: The symbol “-” indicates that this case is either not applicable or not mentioned in the article.

- Abbreviations: α-ZnS, the WZ phase; β-ZnS, the ZB phase; DCJTB, 4-(dicyanomethylene)-2-t-butyl-6-(1,1,7,7-tetramethyljulolidyl-9-enyl)-4H-pyran; PMN-PT, Pb(Mg1/3Nb2/3)O3-xPbTiO3; WZ, wurtzite structure; ZB, zinc blende structure.

Metal ions typically replace Zn atoms in the ZnS crystal lattice and serve as luminescent centers, whereas Cl− ions fill defect levels within the ZnS crystal, thereby considerably altering the local piezoelectric constants around luminescent ions and making it easier to produce ML under pressure owing to piezoelectrically-induced detrapping of the charge carriers.86, 101, 102 Currently, the strongest luminescence intensity among ZnS materials is associated with the doping of Mn2+ ions, which has a luminescence peak at 585 nm (attributed to electron transitions from the 4T1-6A1 level of Mn2+).23 Another common dopant element is Cu. Although it has exhibited blue, green, and orange ML emissions, as shown in Hou et al.'s research (ZnS:Cu+@ Al2O3 exhibits an ML peak at 475 nm, ZnS:Cu2+@Al2O3 at 525 nm, and ZnS:Cu2+/Mn2+@Al2O3 at 595 nm),21 its valence state and mechanism remain controversial.63 First, Cu+ and/or Cu2+ could be involved in the ML process.103 Second, the extraction process causing the blue emission remains unclear.24 The PL spectra show that ZnS:Cu has two emission bands (blue and green).104 The green emission originates from the transition from the shallow defect state to the t2 state of Cu.104 The blue emission has been attributed to various factors—such as the association with the e state,105, 106 the transition from the CB edge of ZnS to the acceptor-like t2 state of Cu,104 or native defect states,107 as Peng et al. determined that undoped samples also exhibited blue emission near 450 nm.107 The introduction of Al could also have a more complex effect on the ML of ZnS:Cu. For example, the overall ML color of ZnS:Cu/Al3+ changes from green to blue light under high-frequency forces.108 Additionally, it has been reported that coating the surface of ZnS:Cu with Al2O3 is necessary to exhibit ML properties.109

Beyond doping, ML can also be influenced by the phase of ZnS (Table 1). Generally, the WZ phase (which forms at high temperatures), displays a stronger ML intensity owing to its non-centrosymmetric crystal structure. However, for ZnS, the total energy difference between the WZ and ZB phases is minimal, making it a polymorphic material prone to stacking faults and mixed phase formation (WZ–ZB).110 This propensity can lead to variations in experimental results, as the precise proportion of the phases within samples is often insufficiently analyzed. Consequently, the interaction between the two phases in ML behavior does not merely reflect a straightforward sum of their individual contributions but involves a more intricate coupling mechanism.68, 110-112 This complexity suggests that the interplay between phases in ML requires additional detailed study to fully understand its dynamics and implications.

Here, we list several results of the relationship between the phase and ML from past research, as shown in Table 1. It is evident that ML has been reported in both WZ and ZB phases for ZnS:Mn2+,84, 86 ZnS:Cu,24, 89 ZnS:Cu/Mn2+,56, 98 and ZnS:Mn2+/Te.62, 91 Specifically, doping and particle size are also factors that can influence the existence of ML. For example, bulk crystals of WZ-ZnS:Cu/Cl exhibit plastico-ML (PML) instead of elastico-ML (EML); microcrystals of WZ-ZnS:Cu/Al3+ exhibit considerable EML. Finally, in nanocrystals, WZ-ZnS:Ag+/Co2+ exhibits UV-RML.93

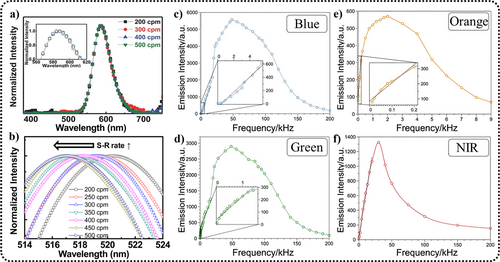

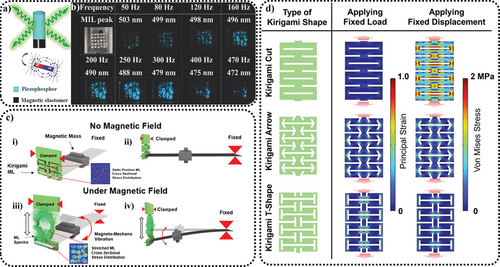

The ML spectra of ZnS can be influenced by the frequency and magnitude of the applied stress. This has been validated by multiple research groups, although the methods they used to vary the stress frequency and magnitude differ. Here, we list some of the conclusions observed. Through the high-pressure testing system (specifically mentioned in Section 5.3), Zheng et al. applied high pressure to ZnS:Mn2+/Eu3+ and found that under an applied stress frequency of 0.5 GPa · s−1, increasing the stress from 2 to 3.6 GPa results in the ML peak shifting from 585 to 615 nm.78 High-frequency mechanical (or electrical) signals typically cause the spectrum to shift toward blue, the extent of this influence differing according to the doping ions. For instance, with a stretching–releasing testing system, jeong et al. found that the ML peak of ZnS:Cu/Mn2+ remains virtually unchanged when the stretching–releasing circle per minute (S–R cpm) increases from 200 to 500 (Figure 6a). Moreover, its EL peaks do not shift when the electrical frequency increases from 80 Hz to 10 kHz (a sinusoidal voltage, 170 V).56 However, under another doping condition, ZnS:Cu, it exhibits a 3-nm blue shift under the same frequency of S–R cpm (Figure 6b),24 and its EL peak changes from 508 to 460 nm as the electrical frequency increases from 50 Hz to 20 kHz at a fixed applied voltage of 100 V.113 Subsequently, Zhou et al. were able to observe spectral changes under high-frequency mechanical signals (in the kHz range) by applying high-frequency electrical voltages to piezoelectric materials, revealing the influence of high-frequency forces on the spectrum.108 For ZnS:Cu/Al3+, with rectangular wave voltage with fixed strength of 165 V, an initial increase in frequency led to enhanced ML in both the blue and green bands, with the blue band showing a more substantial increase, surpassing the green band in intensity at 3.3 kHz, with both bands beginning to quench at 48 kHz (Figure 6c,d). For ZnS:Mn2+, with rectangular wave voltage with fixed strength of 200 V, an increase in frequency initially led to enhanced ML in the orange band, peaking at 4 kHz and almost disappearing at 9 kHz; moreover, as the frequency continued to increase, near infrared (NIR) ML began to dominate, peaking around 30 kHz, and began to quench with further frequency increases (Figure 6e,f).

Frequency response of the EML spectral shape and intensity. (a) ZnS:Cu/Mn2+; Reproduced with permission from Ref. [56]. Copyright 2013, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (b) ZnS:Cu; Reproduced with permission from Ref. [24]. Copyright 2013, American Institute of Physics. (c, d) ZnS:Cu/Al3+ (blue and green light); (e, f) ZnS:Mn2+ (orange and NIR light). For samples (c–f), the voltage waveform applied to the piezoelectric materials is a rectangular wave with an amplitude of 200 V. Reproduced with permission from Ref. [108]. Copyright 2022, Wiley-VCH GmbH. EML, elastico-ML; NIR, near infrared.

Upon analysis, it was concluded that the blue shift in the ZnS:Cu/Al3+ spectrum was due to increased electron–hole recombination rates for both Vs (S vacancies)-CuZn (Cu replacing Zn) (blue light) and AlZn (Al replacing Zn)-CuZn (green light) pairs; whereas for ZnS:Mn2+, the blue shift was caused by high-frequency signals promoting the formation of (Mn)n clusters (n = 2–6) and the energy transfer from excited Mn2+ ions to (Mn)n clusters.95, 108 Finally, the saturation and subsequent quenching of ML in both cases could be attributed to the carrier recombination rate failing to match the excitation frequency.

The ML of ZnS possesses an exceptionally low threshold. However, this threshold can be influenced by several factors, including the doping ions,86 particle size,86 surface morphology,114 crystal structure,68, 110 testing conditions (whether compounded with a matrix, the rate of load application), and the structure of the fabricated devices.115, 116 Consequently, variations in threshold values are evident across different studies. Here, data observed in several seminal studies are summarized. In the research conducted by Chandra et al.,86 it was mentioned that for ZnS powder, smaller particles led to a lower threshold. For example, ZnS:Mn2+ bulk crystals (diameter: 1.2 mm, length: 3 mm) exhibited an EML threshold of 20 MPa, whereas its microcrystals had an EML threshold of 1 MPa. In the case of ZnS:Cu/Cl, the bulk crystals (2 × 2 × 4 mm3) only exhibited PML with a threshold of 30 MPa, whereas microcrystals exhibited EML with a threshold of 1.5 MPa. On the one hand, bulk crystals are less prone to deformation and have fewer internal defects near impurity centers, which can lead to a higher ML threshold and a lack of EML in ZnS:Cu/Cl. On the other hand, the introduction of Cl ions into ZnS:Cu results in the filling of negative ion vacancies by the Cl− ions.117 Consequently, the number of local dipoles is reduced, leading to the disappearance of EML.117 Wei et al. fabricated thin-film structures of ZnS:Cu using polymethyl methacrylate (PMMA) and fluorinated ethylene propylene (FEP), measured the ML through friction and discovered that the ML threshold could be even lower than 10 kPa. They attributed this extremely sensitive ML to triboelectroluminescence (TIEL).115 In the study by Mukhina et al.,68 it was found that some ZnS:Mn2+ microcrystals had a threshold below 1 MPa, with a few microcrystals exhibiting a threshold of just 233 ± 60 kPa. It is noteworthy that in their experiment, 44 samples of ZnS:Mn2+/PDMS were tested, with the ZnS:Mn2+ having a diameter of 4.6 μm, various surface structures, and a load application rate of 0.125 μm · ms−1. They attributed the exceptionally low thresholds observed in certain particles to the enhancement of the local piezoelectric field resulting from the WZ–ZB phases. Subsequent research by Wang et al. proposed a similar viewpoint, suggesting that ZB-ZnS stacking faults in WZ-ZnS crystals caused band bending, which reduced the gap between shallow donors and the conduction band, thereby enabling the material to generate ML under minimal stress excitation.110 In this model, the variability in threshold values among different ZnS particles could be explained by the differing relative proportions of the WZ and ZB phases, leading to varying degrees of conduction band bending and, consequently, different ML thresholds.

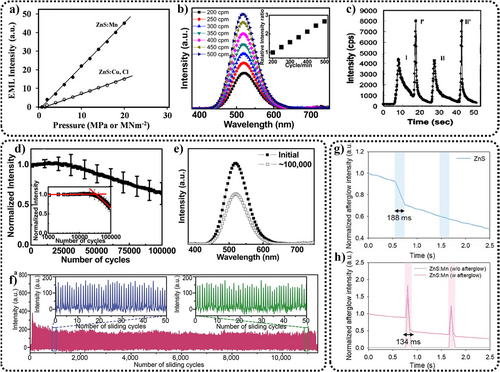

ZnS ML also exhibits linear and quadratic characteristics. Linearity refers to the fact that the emitted ML intensity is proportional to the magnitude of (P-Pth)2.118 Overall responses can be fitted with linear functions, with the slope and intercept of this function varying depending on factors such as the doping and testing conditions (Figure 7a).86 Considering that ML responds to the strain rate—that is, dynamic forces are needed to trigger ML—the response curve can also be influenced by the strain rate (the amount of deformation per unit time). For instance, Jeong et al. observed considerable differences in ML intensity when applying stress at strain rates ranging from 200 to 500 cpm (Figure 7b).24 However, controlling the strain rates, especially under rapid force impact, can be challenging. Hence, current research commonly employs the stress magnitude as the independent variable for the response function. Additionally, the quadratic characteristic imply that during the EML process, a second ML peak emerges after releasing the applied pressure (Figure 7c),44 which is more intense than the light emitted during pressure application.23 This could be due to higher strain rates upon the release of pressure.86 However, the generation and appearance of this secondary ML peak are notably quicker, posing a challenge for its precise capture and characterization.

(a) Relationship between EML intensity and pressure of ZnS:Mn and ZnS:Cu/Cl (pressing rate = 10 MPa · ms−1). Reproduced with permission from Ref. [86]. Copyright 2016, Elsevier B.V. (b) Relationship between ML intensity and strain rate (S–R cpm) of ZnS:Cu/PDMS. Reproduced with permission from Ref. [24]. Copyright 2013, American Institute of Physics. (c) ML response of ZnS:Mn nanoparticles (coated on quartz plate, compression stress = 500 N, compression stress rate = 0.10 mm · min−1). Reproduced with permission from Ref. [23]. Copyright 1999, American Institute of Physics. (d) The ML intensity variation of ZnS:Cu film during 100,000 stretching–releasing cycles, (e) Comparison of the ML intensity of ZnS:Cu film in the initial state and after 100,000 stretching–releasing cycles. Reproduced with permission from Ref. [24]. Copyright 2013, American Institute of Physics. (f) The ML intensity variation of ZnS:Mn2+ films during 10,000 bending cycles. Reproduced with permission from Ref. [25]. Copyright 2015, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (g, h) The MQ phenomenon in PVDF-HFP/ZnS and PVDF-HFP/ZnS:Mn2+ patches under mechanical force. Prior to the experiment, both samples were exposed to UV light for 5 s, with blue and red regions indicating the repeated application of the same pressure (10 MPa). The gray line in (h) represents the ML of PVDF-HFP/ZnS:Mn2+ patches without afterglow (under the same mechanical force condition but being left for 30 min after UV pre-radiation) The ML intensity observed was comparatively lower than that seen with afterglow. Reproduced with permission from Ref. [119]. Copyright 2024, Wiley-VCH GmbH. EML, elastico-ML; ML, mechanoluminescence; MQ, mechanical quenching; PDMS, polydimethylsiloxane; PVDF-HFP, polyvinylidene fluoride-hexafluoropropylene; ZnS, zinc sulfide.

The rise and fall times of ZnS ML are typically in the microsecond range, but results can vary owing to different testing methods. In Chen et al.'s research, the material was mixed with epoxy resin, and a force signal was applied using the drop-ball method. They measured the ML lifetime of ZnS:Mn2+ to be approximately 0.97 ms, with the ML intensity curve undergoing a rapid increase to a peak at approximately 35 μs, followed by a slow decay over several milliseconds.120 In Zhou et al.'s study, the material was compounded using a UV-curable adhesive matrix, and a high-frequency force signal was applied using a piezoelectric material.108 They found that the rise and fall times were both related to the frequency of the applied force. When the excitation frequency was below 12 kHz, the rise and fall times were 9.7 and 35.1 μs, respectively. As the excitation frequency increased, the decay process was interrupted by the strain release, and the fall time was no longer calculated. The rise time began to gradually decrease only when the excitation frequency exceeded 30 kHz, reaching 7.2 and 5.8 μs at 40 and 50 kHz, respectively.108

The repeatability of ML is also crucial for its application. Initially, Xu et al. conducted sliding-stress tests on crystal thin films of ZnS.23 Later, Jeong,24 Wang,25 Wei,115 Peng,33, 35, 84, 121 and others performed repeatability tests under sliding/stretching/bending conditions on films compounded with ZnS powder (Figure 7d–f), confirming its excellent repeatability.24

It is worth mentioning that ZnS exhibits an effect opposite to ML—known as MQ119—which refers to the phenomenon where the afterglow (AL) of the material diminishes after being subjected to stress (Figure 7g,h). The principle behind this phenomenon shares certain similarities with ML, the main difference lying in the stress-induced piezoelectric field driving electrons to recombine with holes at non-radiative centers. Observing MQ requires pre-charging the material with UV light to generate AL. Upon applying stress, a momentary ML occurs, followed by a weaker AL at the stressed sites compared to unstressed ones, indicative of MQ. Pre-charging also leads to stronger ML compared to when not pre-charged, although the enhancement diminishes with the continued application of stress. This characteristic is very similar to the ML of SrAl2O4:Eu2+,5 suggesting that ZnS's MQ can be seen as having dual modes of generation—that is, mechanical energy converted to light energy and mechanical energy inducing the release of stored energy in the form of light, with the latter being less pronounced.

It is important to note that MQ is more easily observed in undoped ZnS,119 but the introduction of Mn doping induces ML in the material, reducing the AL, which in turn makes the MQ effect more likely to be overlooked.

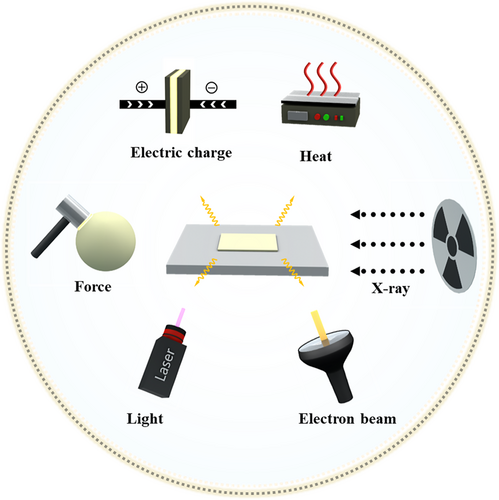

2.4 Multi-stimuli responsive luminescence

ZnS exhibits multimode luminescent characteristics beyond ML, including PL, EL, thermoluminescence (TL), X-ray-induced luminescence (XIL), and cathodoluminescence (CL) (Figure 8). These luminescence modes share close ties with ML, their spectra being consistent with that of ML, so playing an important role in understanding the underlying mechanism within ML.

Multimodal luminescence of zinc sulfide.

PL refers to the phenomenon in which luminescent materials emit light after absorbing photons (electromagnetic radiation). If the emitted light has a shorter wavelength than the excitation light, it is called down-conversion or down-shifting luminescence; conversely, if the emitted light has a longer wavelength, it is known as up-conversion luminescence or anti-Stokes photoluminescence, which requires the simultaneous absorption of two or more photons. Down-shifting luminescence is more common in ZnS-based fluorescent materials and can be observed in various main group, transition metal, and lanthanide ion-doped ZnS materials, such as Mn2+,23 Co2+,122, 123 Cu+/2+,21, 24 Sb3+,124-126 Pb2+,127-130 Al3+,126, 131-133 Sn2+,126, 134, 135 Bi3+,136 Ag2+,100 Au+,137-139 and Ln2+/3+ = Eu2+/3+, Sm3+, Tb3+, Er3+,140, 141 among others. Their spectra essentially cover the visible light range. Additionally, up-conversion luminescence can be observed in ZnS nanocrystals doped with various lanthanide ions, such as Er3+,142 Yb3+,143 and Ho3+,144 among others. The Zn2+ and S2− ions in ZnS are also prone to defects during the synthesis process, introducing intrinsic defects and trap levels for capturing electrons and holes, characteristics that contribute to the versatile luminescent properties of ZnS materials.

Similar to PL, when a material emits light owing to X-ray radiation, it is referred to as XIL. X-rays can induce phenomena such as the photoelectric effect and Compton scattering, and pair production of electron–hole pairs within the atomic lattice of the luminescent material, generating a large number of hot electrons and deep holes. These low-energy charge carriers gradually migrate to luminescent centers, leading to luminescence emission. Materials exhibiting XIL properties are also called scintillators. As the excitation mechanisms for XIL and PL are similar, their spectra are also similar, such as the XIL spectrum of ZnS:Cu/Co nanoparticles,145 which falls in the range of 400–650 nm with a peak at 510 nm, closely matching the PL spectrum.

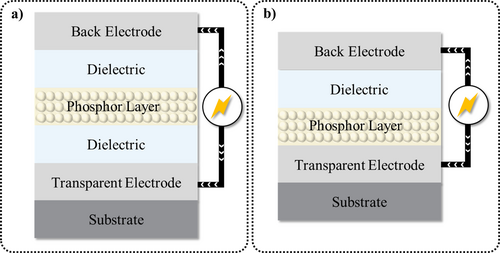

Moreover, ZnS exhibits excellent EL properties, with ZnS:Cu demonstrating superior performance when subjected to an external alternating current (AC) electric field. This phenomenon was first discovered in 1936 when Destriau dispersed the ZnS:Cu phosphor in castor oil.146, 147 Usually, it is necessary to formulate a multi-layer structure to achieve ZnS alternating current electroluminescent (ACEL). The core phosphor layer is either the ZnS powder itself (using the deposition method) or a composite of ZnS, dielectric particles (e.g., BaTiO3 148), and matrix (e.g., resin,148 polyvinylidene fluoride [PVDF],149 or PDMS150). Structurally, ACEL devices can be classified according to their dielectric layers into two types—that is, symmetric and asymmetric structures (Figure 9).

Schematic illustrations of symmetric (a) and asymmetric (b) structures.

In symmetric structures, the electron and hole generation layers can be inserted between the phosphor layer and dielectric to facilitate carrier generation. In simpler asymmetric structures, holes and electrons can be injected alternately from the same electrode in different electric field directions.151

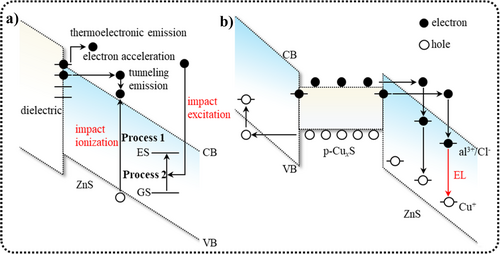

The dielectric layer and CuxS needles play important roles in the process of ZnS ACEL. Under the influence of an AC electric field, defects at the interface or within the phosphor layer are activated as charge carriers and subsequently injected into the phosphor layer. As shown in Figure 10a, the dielectric directly contacts ZnS, creating substantial interfacial states with energy levels distributed within the forbidden band gap of the semiconductor. These activated hot electrons are injected into the conduction band through tunneling and/or field-enhanced thermal excitation of trapped electrons (Figure 10a). Conversely, the CuxS needles not only facilitate the formation of Schottky barriers between CuxS and the ZnS semiconductor but also intensify the local electric field by one to two orders of magnitude. This intense local electric field causes electrons and holes to be injected from both ends of the CuxS needles through tunneling (Figure 10b).

(a) Energy band diagram when a dielectric material and a semiconductor are in contact. (b) Energy band diagram of the simultaneous injection of electrons and holes from the opposite ends of a CuxS needle into the surrounding ZnS:Cu/Cl lattice. CB, conduction band; ES, excited state; GS, ground state; VB, valence band. Reproduced with permission from Ref. [147]. Copyright 2021, Author(s).

After carrier injection, theories that explain the subsequent light emission include the impact ionization and impact excitation theories. In the impact ionization theory, high electric fields accelerate thermal electrons to collide with the phosphor lattice, generating electron–hole pairs (Process 1, Figure 10a). These pairs are subsequently captured by donors and acceptors. The recombination of these electrons and holes then produces light emission, or electron–hole pairs transfer their energy to doping ions (such as Mn2+), causing electron transitions to excited states and subsequent light emission upon returning to the ground state. In the impact excitation theory, thermal electrons directly collide with local luminescent centers, exciting ground state electrons to higher energy levels (Process 2, Figure 10a), producing light emission upon their return to the ground state.

TL is a phenomenon where a material emits electromagnetic or ionizing radiation (previously absorbed and stored as photon energy within the lattice defects) when heated. This process is also known as thermally stimulated luminescence. The sources of radiation energy that can be absorbed include visible light, X-rays, β-particles, or α-particle radiation, among others. The TL intensity of ZnS material increases as the crystal size decreases because smaller particle sizes result in increased surface states or defect sites that can trap carriers.152 When heated, more charge carriers are released, combining with holes, and the energy is transferred to the luminescent centers, resulting in enhanced light emission. Additionally, reducing the particle size can increase the overlap between electron and hole wave functions, potentially accelerating the rate of charge carrier recombination, and further enhancing luminescence.152 It is worth noting that the ZnS TL peak does not vary substantially with decreasing particle size, which could be because the trap depth of surface states is insensitive to particle size.153

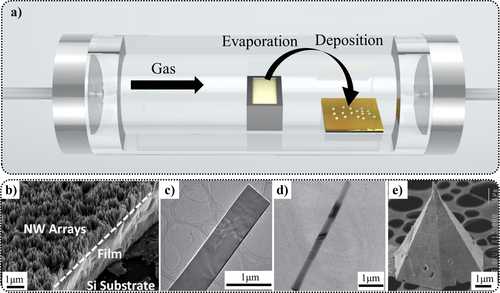

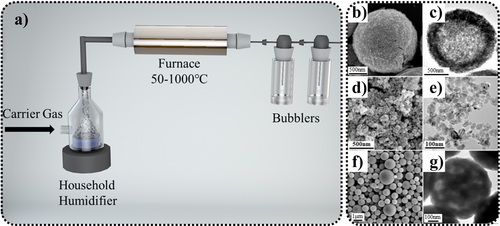

CL is the phenomenon where luminescent materials emit light when excited by a high-energy electron beam, thus offering higher spatial resolution (up to several nanometers) and applicability to wide-bandgap semiconductors compared to other luminescent methods. CL imaging is a powerful tool for visualizing the spatial distribution of excitons, defects, and other phenomena within a material, thereby facilitating detailed analyses of the crystal lattice and band structure. For the same material, different morphologies, doping ions, and temperature variations can result in different CL spectra.154 Generally, ZB-ZnS exhibits strong and stable 337-nm ultraviolet emission in CL spectra at room temperature.59 Liu et al. studied the morphology, doping, and temperature dependence of one-dimensional ZnS nanostructures in CL.58 Chen et al. successfully synthesized pyramid-structured ZB-ZnS using thermal evaporation, and its CL spectra exhibited strong and stable 337-nm ultraviolet emission, indicating high crystallinity.59 This emission could be attributed to band emission from the ZB structure. Moreover, compared to other structures—such as nanobelts, nanowires, and nanorods—pyramid-structured ZB-ZnS exhibited a lower turn-on field, higher field-enhancement factor, and high stability with low fluctuation of field-emission current, suggesting its potential suitability for optoelectronic applications.59

3 ML CLASSIFICATION AND MECHANISM

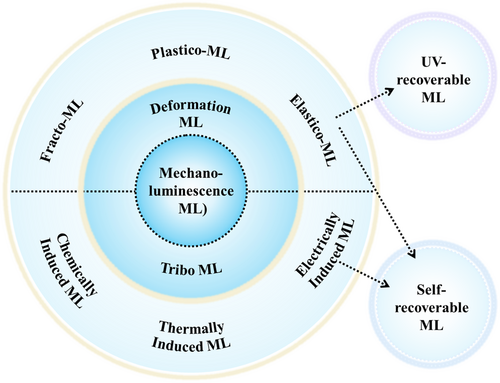

Based on the force application method during the ML process, the ML mechanism can be broadly categorized into deformation ML (DML) and tribo-ML (TML). For DML, depending on the extent of deformation caused by the applied force, it can be further divided into three luminescence mechanisms—that is, EML (elastic deformation), PML (plastic deformation), and fracto-ML (FML, fracture of the crystal lattice). For TML, it encompasses various luminescence mechanisms induced by triboelectrification and electroluminescence between solid ML particles and other materials. These mechanisms include electrically induced ML, chemically induced ML, and thermally induced ML.24

Figure 11 shows the classification and relationships of these ML mechanisms.155 EML and TML materials are considered to be the most promising ML materials for practical applications owing to their self-recoverable luminescence properties. For example, ZnS:Mn2+ exhibits only a slight decrease in luminescence intensity after 100,000 repeated stretches.24 Conversely, other materials may exhibit RML but require recharging with additional energy (such as UV light), termed UV-RML. A prime example is SrAl2O4:Eu2+/Dy3+, where ML entails the emission of photons in response to disturbances from external fields such as electric or force fields. The intrinsic mechanism involves the easy release of electrons in a metastable state under external stimuli.5

Classification of ML mechanisms. Reproduced with permission from Ref. [155]. Copyright 2021, Elsevier Ltd. ML, mechanoluminescence.

In some research reports, TML is used interchangeably with ML. This is because TML used to be referred to as ML in earlier research.156 To avoid confusion, this paper uses ML to refer broadly to all luminescent phenomena induced by mechanical force, while TML is used to specifically indicate ML induced by friction. Moreover, it is necessary to clarify the specific differences between DML and TML: DML is solely induced by the deformation of the ML material and is independent of the material's properties causing the deformation. Consequently, DML is a physical process, such as luminescence from the fracture of sugar cubes. TML, on the contrary, is related to the interface properties of different materials when they come into contact with deformation, leading to effects like charge generation, heat generation, or chemical reactions.24

Although the classification of ML into two main categories and six subcategories is widely accepted,157 it remains challenging to confirm the specific types of ML involved in the actual processes of all materials and further divide them into their different mechanistic categories. This complexity can also lead to a variety of mechanisms to account for the ML in ZnS. The classical model remains the piezoelectric model, with many new models being improvements based on it. Additional models have proposed various mechanisms, some of which offered explanations for the generation of the piezoelectric field. If the field was generated through dislocations, then it was a dislocation model; if explained through WZ–ZB-phase heterostructures to account for high piezoelectric fields under small pressures, it led to spatial models; if generated through triboelectricity, then it resulted in a triboelectric model. That said, the covalent bond breaking model is somewhat unique. Owing to the non-centrosymmetric structure which lacks piezoelectric effects, this model involves the breaking and reformation of Zn-S covalent bonds and a series of subsequent processes to explain the ML of β-ZnS.

However, no single model can uniformly explain the ML of ZnS in all scenarios (including doping, and grain size, etc.). First, the material can be doped with a rich variety of ions, each potentially having a different pathway and method of internal electron generation and transfer under force. Second, it can be challenging to synthesize purely WZ- or ZB-phase ZnS; the two phases tend to coexist to varying degrees in samples used for testing. The extent of this coexistence and its impact on the mechanistic process require further exploration, with most current models only explaining the ML process of a single phase and lacking in-depth investigation into the impact of bi-phase ZnS. Moreover, tests are often performed on ZnS and organic compounds (for example, ZnS/PDMS). Under the same type of mechanical stimulation (stretching, compression, and friction, etc.), multiple subsequent processes (such as heat generation, deformation, and electric field formation), can occur within the material. Finally, with existing techniques, it can be difficult to directly detect the specific behavior within a material; instead, inferences are made through the material's intrinsic properties, delayed lifetime images, and PL spectra. Consequently, further analysis of mechanisms still requires the development and refinement of experimental facilities and protocols.

3.1 Piezoelectric effect model

The piezoelectric effect model is the most common model used to explain ZnS ML in different doping situations, such as Mn2+,117 (Mn)n,108 Cu,117 Cu/Mn2+,77 Mn2+/Te,91 and UV-RML in ZnS:Ag+/Co2+.93 This model suggests that ML in ZnS is intimately linked to the excitation–deexcitation process of the built-in electric field and luminescent centers during deformation, which is also supported by the consistency observed in the PL, EL, and ML spectra. Regarding the transfer of mechanical energy from ZnS crystals to luminescent centers during the EML process, Chandra et al. noted that when the crystal underwent elastic deformation, the piezoelectric constant near the impurity center increased considerably compared to other positions in the crystal.102 Consequently, with the non-centrosymmetric structure of ZnS, a strong piezoelectric field is generated in the crystal's vicinity, leading to a reduction in trap depth within the crystal. This reduction allows trapped electrons to escape the confines of the traps and move into the conduction band. Some of these escaped electrons recombine with holes, releasing energy that can be transferred to the luminescent center, which then emits energy in the form of light waves. Moreover, the self-recovery characteristic of EML can be achieved through the recapture of carriers drifting in the presence of the piezoelectric field.117 Chandra coined this ML excitation model the “piezoelectrically-induced trap-depth reduction model,” which was also suitable for ML of ZnS crystals of different sizes (bulk crystals, microcrystals, and nanocrystals).94, 158, 159 However, ML is only applicable when the force varies with time rather than being static.102, 160

This model is typically used to explain the orange ML emission of ZnS:Mn2+.94 Although there are partial distinctions in other situations, the main triggering factor is usually the piezoelectric field induced by pressure. For ZnS:(Mn)n, the NIR ML is due to the energy transfer from excited Mn2+ ions to (Mn)n clusters under high-frequency mechanical excitation.108 For ZnS:Cu, the luminescent center is Cu rather than Mn2+.117 For ZnS:Cu/Mn2+, Cu and Mn2+ together act as luminescence centers.77 For ZnS:Mn2+/Te, the EML process involves energy transfer from Mn2+ to Te, where the transition of Te from 3T1 to 1A1 emits red light.161 For ZnS:Ag+/Co2+, UV light excites electrons, which are captured by Co2+ and remain in a metastable state. Pressure-induced piezoelectric fields release electrons from Co2+, transferring energy to Ag+, causing a transition that emits photons with a wavelength of 470 nm.93 Based on the principles of light-emitting diodes, heterojunction structures can considerably enhance the EML intensity of crystals.

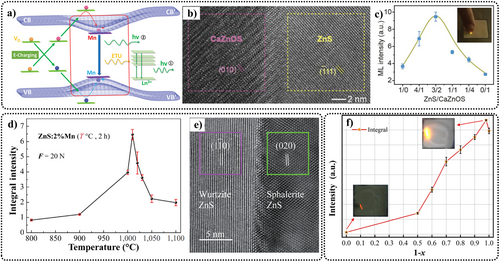

Peng et al. combined p-type CaZnOS and n-type ZnS to create a p-CaZnOS/n-ZnS:Mn2+ piezoelectrically-induced luminescent heterojunction crystal. When an external force is applied, the built-in piezoelectric field causes a band offset between the ZnS/CaZnOS heterojunction, increasing the efficiency of electrons escaping from traps into the conduction band and forming electron–hole pairs (Figure 12a,b).

(a) Band bending between heterojunction regions caused by the built-in piezoelectric field. (b) High-resolution TEM image of a heterojunction in a ZnS/CaZnOS particle and a bi-phase junction cut from the edge of a ZnS particle (1020°C, 2 h). (c) Integrated intensity over the 500–750 nm range from ZnS/CaZnOS heterostructures under mechanical excitation at 35 N as a function of ZnS to CaZnOS molar ratios. Inset: Photograph of the sample with the optimal composition under mechanical excitation using a finger. Reproduced with permission from Ref. [33]. Copyright 2020, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (d) The ML integrated intensity of ZnS:2% Mn2+ at different temperatures. The sample is in a pure ZB phase at 900°C, and a bi-phase at 1010°C. The sample with the strongest ML is sintered at 1010°C for 2 h, during which ZnS is in a bi-phase state. (e) A bi-phase junction cut from the edge of a ZnS particle (1020°C, 2 h). Reproduced with permission from Ref. [111]. Copyright 2022, Tsinghua University Press. (f) Integrated intensity over the 500–750 nm range from (3ZnS/2CaZnOS)1-xSrZnOSx:2% Mn2+ heterostructures under mechanical excitation at 30 N as a function of the 3ZnS/2CaZnOS ratio. Insets: ML photographs of the strongest and weakest luminescence. Reproduced with permission from Ref. [162]. Copyright 2023, The Author(s). Published by Elsevier Ltd. ML, mechanoluminescence; TEM, transmission electron microscopy; ZB, zinc blende structure; ZnS, zinc sulfide.

This enhances carrier mobility, thereby substantially increasing the EML intensity. Consequently, the ZnS/CaZnOS heterojunction structure exhibits highly reproducible EML, with an intensity 2.2 times higher than that of commercial ZnS:Mn2+ and 3.5 times higher than that of the classical quaternary EML material CaZnOS:Mn2+. It can emit visible light under a 1 N fingertip force excitation (Figure 12c). Additionally, full-spectrum tunable luminescence has been achieved covering the visible and NIR spectrum by incorporating Mn and lanthanide ions Ln3+ (such as Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, and Yb) into the structure. Based on the heterojunction principle, bi-phase homojunction ZnS:Mn2+ crystals (WZ and ZB phases) have also been synthesized, which exhibited EML intensities 3–6 times higher than pure WZ-phase ZnS:Mn2+(Figure 12d,e). Furthermore, they reported ML enhancement in SrZnOS using the ZnS/CaZnOS heterojunction, resulting in an EML intensity approximately 60 times higher than SrZnOS:Mn2+ (Figure 12f). Additionally, the ZnO/ZnF2 heterojunction they constructed also considerably enhanced the EML intensity of ZnO:Mn2+.33, 37, 162

3.2 Models related to dislocation motion

Covalent bond breakage-reformation model

The covalent bond breakage-reformation model can be used to explain the ML in β-ZnS:Mn2+. The majority of centrosymmetric crystal structures do not exhibit ML characteristics, because crystals with a center of symmetry undergo uniform deformation when subjected to stress, and the center of positive and negative charge mass remains overlapping, resulting in no polarization and, therefore, no piezoelectric effect. Whereas some centrosymmetric crystals may occasionally display ML, their ML is either caused by the piezoelectric phase of defects or is unrelated to piezoelectric effects, such as luminescence caused by the charge impact on gas molecules within the crystal and defect motion.163

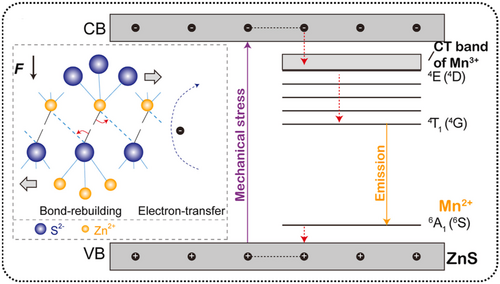

Ma et al. proposed this improved plastic DML model to explain the self-RML in β-ZnS:Mn2+.84 When an external force is applied, defects within the crystal move, causing partial covalent bonds between Zn and S to break. This results in the redistribution of s and p electrons, leading to a considerable number of Zn2+ ions acquiring extra electrons. These extra electrons can be considered to be intermediate states for rebuilding covalent bonds, with an abundance of Zn dangling bonds in the Zn 4s orbital (CB) with extra electrons and extra holes in the S 3p orbital (VB). These conditions are sufficient to excite ML.

They also employed a carrier capture model to explain how carrier energy is transferred to Mn2+. To be specific, Mn2+ is involved in the recombination of electron–hole pairs. When an electron–hole pair migrates near Mn2+, Mn2+ sequentially captures the holes from the valence band and the electrons from the conduction band. This completes the energy transfer from the exciton (electron–hole pair) to Mn2+, resulting in Mn2+ being in an excited state. This process differs from the common pathway where Mn2+ directly transitions from the ground state to the excited state. In this model, there is a brief process of Mn3+ generation, similar to Mn2+ acting as a recombination center for electron–hole pairs.164 Thus, it exhibits high luminescence efficiency. After the ML process is completed, the broken covalent bonds are reformed, allowing ZnS to exhibit good ML repeatability. This explains why the samples with the highest PL and ML do not necessarily have the same Mn2+ doping concentrations (Figure 13).

Schematic diagrams of self-recoverable mechanoluminescence mechanisms in β-ZnS:Mn2+. Reproduced with permission from Ref. [84]. Copyright 2020, Elsevier B.V.

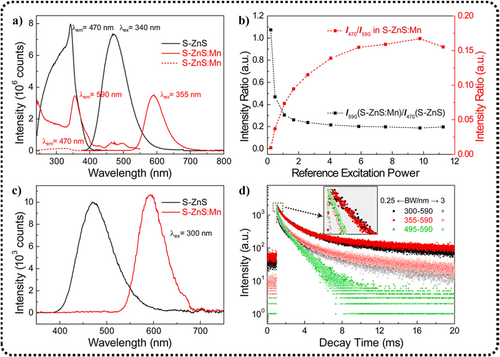

The mechanism can be explained through the emission and excitation spectra of β-ZnS and β-ZnS: Mn2+ (Figure 14a). In further experiments, they observed that the β-ZnS sample exhibited a broad UV excitation band at 470 nm, composed of excitonic transitions (ZnS:VB→CB) (I) and a defect-related excitation band centered at 340 nm (II). When monitoring the emission at 590 nm, corresponding to Mn2+, the excitation band of β-ZnS:Mn2+ included excitonic transitions (I), charge transfer transitions (Mn2+ 3d→CB), and a series of d-d transitions centered at 355 nm (II) (Mn2+:6A1(6S)→4E (4D), 4T2 (4D), (4A1,4E) (4G), 4T2 (4G), or 4T1 (4G)) (III).165

(a) Excitation and emission spectra of S-ZnS and S-ZnS:Mn2+, where S-ZnS is equal to β-ZnS. (b) The relationships between the peak intensity ratios and excitation power. The red dotted line is I470/I590 in S-ZnS:Mn2+. The black dotted line is I590, S-ZnS: Mn/I470, S-ZnS. (c) PL comparison of S-ZnS and S-ZnS:Mn2+ under low excitation power. (d) The luminescence decay curves of 590-nm emission in S-ZnS:Mn2+ under different excitation (300, 355, and 495 nm) with a bandwidth of 0.25 or 3 nm. Inset is the magnification of the selected initial decay. Reproduced with permission from Ref. [84]. Copyright 2020, Elsevier B.V. PL, photoluminescent; ZnS, zinc sulfide.

Two notable facts about β-ZnS:Mn2+ are the disappearing blue emission band under 355-nm excitation and the absence of the defect-related excitation band when monitoring at 470 nm. These observations suggest the presence of an efficient energy transfer process from the defect centers to Mn2+. Considering that ML may not be as efficient as PL in mechanical-to-optical energy conversion, under the condition of a fixed excitation wavelength at 300 nm, by further reducing the excitation power, the intensity ratio of blue to yellow emission (I470/I590) decreases (Figure 14b). At low excitation intensity (approximately 2% of the initial excitation), the blue emission band eventually disappears, resulting in the PL spectrum being similar to the ML spectrum (Figure 14c). Although the blue band caused by defects in β-ZnS and the yellow band caused by Mn2+ in β-ZnS:Mn2+ can be separately excited by 300-nm ultraviolet light, at relatively low excitation power, the efficiency of ultraviolet-to-yellow energy conversion is substantially improved. Consequently, they suggest that the RML process in β-ZnS:Mn2+ is similar to the inter-band excitation PL process involving Mn2+ under weak excitation, rather than being primarily influenced by any point defects.

To describe the luminescence mechanism, they further studied the luminescence decay behavior in β-ZnS:Mn. By adjusting the bandwidth to change the laser intensity (0.25 and 3 nm), they compared the luminescence decay curves (Figure 14d). Ignoring the later slow decay, after magnifying the initial decay curves (see inset in Figure 14d), they found that under weak excitation of band I or band II, the decay curves completely overlapped. The longer decay lifetimes compared to band III can be attributed to additional trapping and detrapping processes between the defect levels and the CB. Under strong excitation of band I or band II, accelerated decay of the 590-nm emission was evident owing to increased non-radiative electron–hole recombination. In conclusion, the above spectral results validated the rationality of their proposed ML model.

ML spatial models

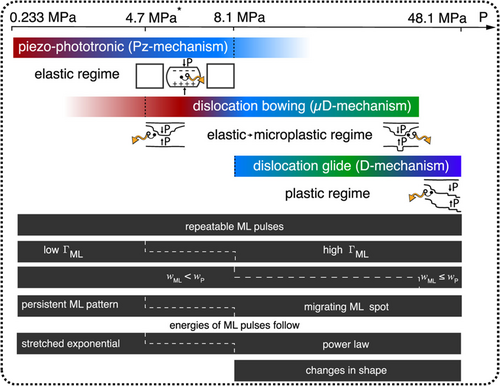

To fill the research gaps, Mukhina et al. revealed the existence of three different ML mechanisms in single ZnS particles under low stress (<8.1 MPa).68 They referred to these mechanisms as the ML induced by stacking faults exciton fields (Pz mechanism), ML induced by fully or quasi-reversible fault bending (μD mechanism), and ML induced by irreversible fault slip at higher pressures (D mechanism) (Figure 15). When the stress was below 8.1 MPa, ML generation was dominated by the Pz mechanism, and the μD mechanism also came into play. By contrast, at pressures above 8.1 MPa, charged fault motion became the primary source of excitation. This model could explain the EML in ZnS:Mn2+ at extremely low pressures (≈233 kPa). The mechanism relies on the local enhancement of the piezoelectric field produced by the stacking faults' interfaces of WZ and ZB phases along the c-axis direction of the ZnS crystal, where some interfaces lack electrons, enhancing the local piezoelectric field generated when an external stress is applied.68

ML mechanisms at different pressure ranges with corresponding properties. ΓML, wML, and wP denote the ML emission rate, width of the ML pulse, and width of the pressure pulse, respectively. *Provisional limit of the microplastic regime defined by the lowest pressure at which the μD-component is observed in experiments. Reproduced with permission from Ref. [68]. Copyright 2021, American Chemical Society. ML, mechanoluminescence.

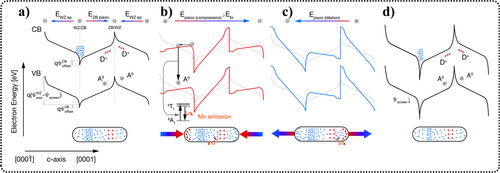

Assuming that the EML of ZnS requires a sufficiently large electric field for excitation, in cases where the electric field intensity from the piezoelectric effect is insufficient, alternative sources of enhanced electric fields need to be identified. Previously, it was believed that the EML of ZnS originated solely from the piezoelectric effect of the pure WZ phase.68 However, Mukhina et al. observed the phenomena of WZ–ZB phase alternation in ZnS and proposed that such microstructural heterogeneity could generate a sufficiently strong intrinsic electric field. This, when stressed, could induce intense EML. In the faulted structure depicted in Figure 16, ZB is inserted into the WZ, forming a WZ–ZB–WZ structure.

ML mechanisms for a structural unit WZ/ZB/WZ, under different conditions: (a) without external stress, (b) compressed, (c) dilated, and (d) after multiple emission cycles. Red pluses and blue minuses denote polarization charges induced by electric fields and localized states. Blue and empty red circles illustrate free electrons and holes, respectively. Gray dotted lines in panels (b–d) depict band structures prior to pressure application. Reproduced with permission from Ref. [68]. Copyright 2021, American Chemical Society. ML, mechanoluminescence; WZ, wurtzite structure; ZB, zinc blende structure.

In Figure 16a, owing to the absence of inversion symmetry along the c-axis, an electric field (EWZsp) is generated within the WZ phase. Owing to the reverse piezoelectric effect, the insertion of the ZB phase produces an electric field (EZBpiezo) in the opposite direction. Consequently, an intrinsic sawtooth potential (Ψsaw) is generated, causing free carriers (electrons) to drift toward the positive pole, leaving behind vacant D+ and A0 energy levels to compensate for the intrinsic field. The most likely candidates for the A0 center are the shallow hole states in S vacancies, which are involved in defect-related ZnS luminescence at room temperature.

During compression (Figure 16b), a unipolar piezoelectric field pervades the entire particle. It aligns with the intrinsic field direction in the ZB phase and opposes the intrinsic field direction in the WZ phase. Consequently, the overall internal fields rearrange, resulting in a change in Ψbi. The most important alteration occurs at the WZ/ZB interface owing to intrinsic compensation, leading to electron depletion. Here, the potential profile (Ψpiezo) induced by the piezoelectric effect cannot be screened by free electrons, and the bands of the WZ and ZB phases could contain relative potential jumps reminiscent of a piezoelectric p–n junction.173, 174 Hence, the increase in the local barrier owing to this phenomenon could exceed what is predicted by the intrinsic piezoelectric coefficients of WZ-ZnS. If the piezoelectric field induced by mechanical deformation along the c-axis surpasses the intrinsic field (Epiezo ≥ Ebi), free electrons are liberated from the potential wells at the WZ/ZB interface and can acquire sufficient kinetic energy to reach the conduction band floor of the WZ phase, subsequently recombining with holes at the A0 center (see Figure 16b). The energy released when accelerated electrons recombine with holes can potentially be transferred non-radiatively to nearby isoelectronic Mn2+,175 subsequently exciting and radiating photons at 585 nm, resulting in instantaneous ML.

This mechanism can also be used to explain the second ML peak with the condition that Epiezo < Ebi, which is typically attributed to ML produced when ZnS recovers after deformation. At the moment of stress application, holes trapped in the A0 center (owing to intrinsic compensation) can be captured by the potential wells (generated by piezoelectric-induced potential jumps). Concurrently, certain donor centers in the ZB phase can be reoccupied by electrons at the outset of piezoelectric polarization. After the pressure is released, these potential jumps vanish, and holes are released into the valence band. Subsequently, holes can be captured by nearby Mn2+ ions with an attractive hole, and Mn2+ ions can be excited through various resonant energy transfer pathways— such as the energy of recombination between electrons (at the D0 center) and trapped holes (at nearby Mn2+ ions), or the energy of excitons X (formed when the electrons are released from the D0 center owing to recompensation) bound to the Mn2+. During the expansion process of ZnS:Mn2+ microparticles, as depicted in Figure 16c, ML excitation is similar to the compression process described above, except for the reversed roles of the ZB and WZ phases.

Throughout the entire mechanism, when the applied force is removed, the crystal structure can fully or partially recover, but irreversible changes occur at the electron level, including the generation and migration of charge carriers and their recombination within the crystal. However, the behavior of the actual systems is more complicated than that. The ML process depletes electrons engaged in compensating the intrinsic field, resulting in a reduction in Ψscreen (Figure 16d). During the subsequent pressure cycle, the potential jumps generated become more substantial, facilitating the escape of electrons from the potential wells at the WZ/ZB interface. Moreover, the depletion of charge carriers leads to a reduction in charge at the WZ/ZB interface, which can be regarded as partial dislocations, and the decrease in dislocation charge further increases the mobility of charges.176 Consequently, it can be concluded that each elastic ML excitation cycle increases the chance of elastic or microplastic events occurring at the WZ/ZB interface during the next pressure cycle, followed by the appearance of μD components. Over time, this process depletes the internal reservoir of charge carriers, ultimately resulting in the cessation of ML.

In the aforementioned ML process, Mn2+ ions can be excited by the energy transferred through non-radiative recombination of electron–hole pairs to some extent, which is consistent with the mechanism predicted by EML. Additionally, they can also directly participate in the process of hole–electron recombination, emitting light during the recombination–decomposition process. Therefore, the spatial models of ML can be mutually validated using the previously proposed mechanisms.

Movement of dislocations model

This model can account for the PML observed in ZnS:Cu/Cl,86 ZnS:Mn,86 ZnS:Ag/Cl,177 and ZnS:Au/Cl.177 Compared to the piezoelectric effect model, this model suggests that the electric field causing defect-bound electrons to escape into the conduction band is not produced by the piezoelectric effect, but rather by the movement of charged dislocations. Using ZnS:Cu/Cl as an example, when ZnS crystals are subject to plastic deformation, the movement of charged dislocations within generates an enormous internal electrostatic field reaching up to 106 V · m−1,178 which causes the bending of the conduction and valence bands. Consequently, defect-trapped electrons tunnel into the conduction band and recombine with holes in CuZn. The energy released from this recombination excites Cu ions, leading to the emission of light following the de-excitation of these excited Cu ions.86

3.3 Triboelectroluminescence

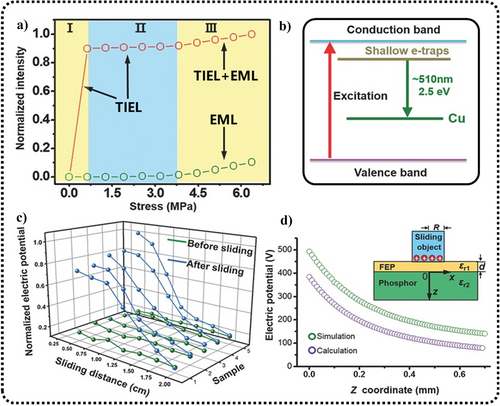

This model posits that the ML is primarily EL induced by triboelectrification, and has been employed to clarify the ML of ZnS:Cu/PMMA/FEP under low pressure (<10 kPa), which also cannot be explained using the traditional piezoelectric effect model.115 When different materials come into frictional contact with ZnS, frictional charges can be generated on the surface. These charges are easily transferred into the interior of the ZnS crystal, leading to the excitation of ZnS phosphors and the generation of EL. Wei et al. conducted an in-depth analysis of the luminescent process of ZnS:Cu and found that it could be categorized into three stages.115 When the applied pressure was <3.8 MPa, the sample exhibited only TIEL. In detail, the ML of ZnS:Cu thin films could be divided into three phases (Figure 17a). During phase I, the applied pressure was low, and the TIEL increased rapidly, with a sensitivity of approximately 0.04 MPa. During phase II, the stress was further increased to 3.8 MPa, but the TIEL no longer increased owing to the saturation of the tribocharge density. During phase III, the pressure exceeded 3.8 MPa, and EML began to occur (dominated by the piezoelectric effect model), further enhancing the overall ML intensity.

(a) Luminescence intensity of the TIEL/EML in different stress regions as well as the single EML. (b) Energy band structure of the ZnS EL. (c) Changes in surface electric potential of the electrification layer, mapped along the sliding trajectory pre- and post-sliding. (d) Computed and simulated profiles of electric potential across the luminescent layer's thickness. The inset shows the 2D structural diagram. Reproduced with permission from Ref. [115]. Copyright 2016, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. EL, electroluminescent; EML, elastico-ML; TIEL, triboelectroluminescence; ZnS, zinc sulfide.

The overall mechanism can be explained as follows: electrons excited by friction fall into shallow electron trap states and then transition to Cu impurity states, resulting in luminescence at a wavelength of 510 nm (Figure 17b). Figure 17c shows that with the onset of sliding, the density of frictional charges on the moving object's surface rapidly reaches a saturation value related to the material. During the early stages of sliding, owing to the accumulation of frictional charges, the surface potential increases considerably, indicating substantial charge transfer at the contacting surfaces. Subsequently, with continued sliding, the surface potential decreases sharply and eventually becomes indistinguishable from the background after sliding 2 cm, indicating that no more frictional charges are formed on the electrified layer. Figure 17d shows the potential along the thickness direction of the luminescent layer underneath the charged sliding object, represented along the z-axis in the inset of Figure 17d.

The ML of ZnS:Mn2+ could also be associated with triboelectric charges. Wang et al. fabricated a triboelectric nanogenerator (TENG) based on ZnS:Mn2+/PDMS.179 They discovered that when the applied pressure was sufficient to induce ML, there was a substantial decrease in both the current and voltage of the TENG, accompanied by a reduction in the triboelectric charges on the PDMS surface. Conversely, when the pressure was too low to generate ML, the triboelectric charges would accumulate without dissipating. Using this TENG to attract foam microspheres, they observed that, compared to specific regions of PDMS composite films without ZnS:Mn2+ phosphors, the ZnS:Mn2+ luminescent layer lost its attraction for foam microspheres after ML, which perhaps suggests that electrical charges contribute to the ML process in ZnS.

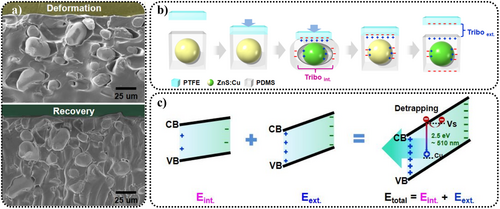

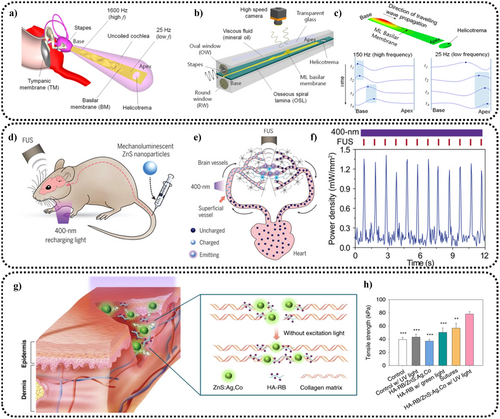

Park et al. analyzed the TIEL during the stretching–releasing process of ZnS:Cu/PDMS.166 When ZnS:Cu was combined with PDMS, air entered at the interface, forming natural pores. During the stretching–releasing process, the deformation of PDMS caused the pores to enlarge and then recover (Figure 18a), with friction occurring at the interface between ZnS:Cu and PDMS, causing TIEL. In these experiments, the force was applied indirectly via polytetrafluorethylene (PTFE). The specific ZnS:Cu/PDMS/PTFE structure could generate both internal and external electric fields during the stretching–releasing cycle (Figure 18b,c), enhancing the overall intensity of TIEL. Additionally, the primary reason for choosing PDMS and PTFE as substrates was their ability to generate a higher friction-induced output voltage.

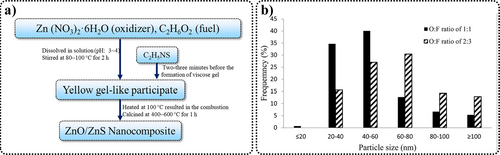

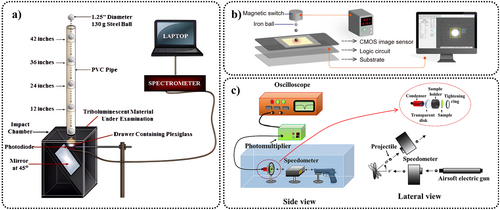

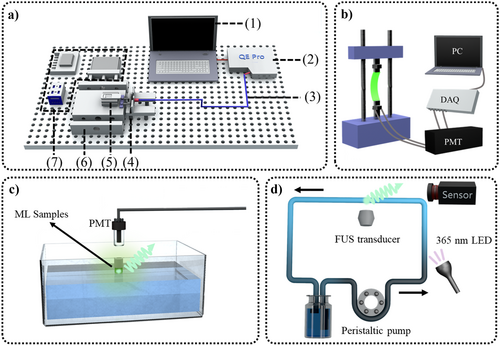

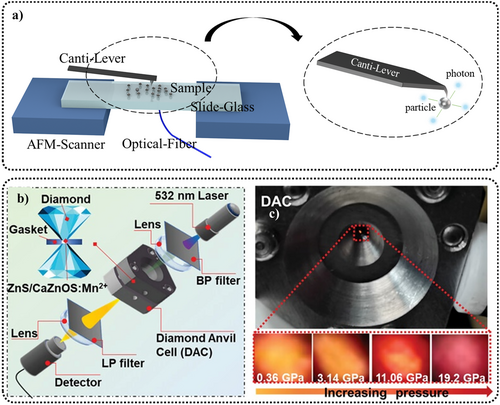

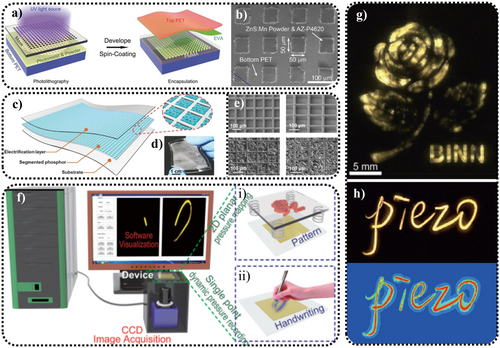

(a) The generation and recovery of pores between ZnS:Cu and PDMS under external forces. (b) Diagrams of the generation of internal and external frictional electric fields during the contact–separation between ZnS:Cu/PDMS and PTFE. When an external force is applied through PTFE, friction charges are generated between ZnS and PDMS, inducing TIEL. When the external force is removed and PTFE separates from PDMS, friction charges are generated, inducing TIEL. (c) Band diagram of the TIEL of ZnS:Cu. The electric field (Einternal + Eexternal) causes band tilting, resulting in electrons in Vs being released and recombining with holes in AlZn, leading to light emission. Reproduced with permission from Ref. [166]. Copyright 2021, American Chemical Society. PDMS, polydimethylsiloxane; PTFE, polytetrafluoroethylene; TIEL, triboelectroluminescence; ZnS, zinc sulfide.