Potential regulatory approaches on the environmental impacts of photovoltaics: Expected improvements and impacts on technological innovation

Abstract

This work assesses the opportunities for technological development and innovation that may be imposed or created by environmental policy. Working within the legislative framework of European Union (EU) sustainable product policies, a study of the feasibility of four specific policy instruments (Ecodesign Directive, Energy Labelling, Green Public Procurement and the EU Ecolabel) to photovoltaic products (modules, inverters and systems) led to the identification of key performance metrics and design features. Starting from an analysis of the environmental hotspots of photovoltaic products throughout the whole life cycle (from raw material extraction to their end of life and disposal), a number of areas of attention for innovation are identified and a policy approach is proposed to tackle these aspects in regulatory terms by means, in particular, of requirements within the legal framework of the Ecodesign Directive.

1 INTRODUCTION

As announced in the ‘European Green Deal’,1 the decarbonisation of the European Union (EU) energy system is critical in order to reach climate objectives in 2030 and 2050. To this extent, a power sector must be developed that is based largely on renewable energy sources (RES), complemented by the rapid phasing out of coal and by the decarbonising of natural gas. In particular, the 2018 Renewable Energy Directive2 establishes a binding renewable energy share for the EU for 2030 of at least 32%, and currently, there is momentum for increasing the EU's greenhouse gas (GHG) emission reductions target for 2030 to at least 50% and towards 55%. A recent analysis of the different decarbonisation scenarios in regard to how to reach these GHG reduction targets concluded that the cumulative photovoltaic (PV) capacity in the EU and the United Kingdom would need to increase to 455–605 GW.3 Being sure that newly installed PV products in the EU are environmentally friendly and do not create new future burdens on the environment is therefore of primary importance, given the role that this technology is expected to have in the decarbonisation of the EU energy system. Regulatory measures in the field of sustainable product policy could be instrumental to this extent, to ensure the environmental sustainability of PVs by improving their environmental performance as well as their energy yield, in turn reducing the overall life cycle environmental footprint of the products deployed in the field.

To date, EU sustainable product policy4 addresses different aspects associated with the life cycle of products (and services, to a lesser extent) such as product design, materials, manufacturing, use, end of life and the related use of energy, water, chemicals and other resources. This policy is currently articulated in a number of policy instruments with which the market can be driven towards the production and consumption of more sustainable products. These policy instruments, as summarised in Table 1, include Ecodesign,5 Energy Labelling,6 Green Public Procurement7 (GPP) and the EU Ecolabel.8

| Policy instrument | Nature of the provisions | Scope | Life cycle stage | Verification |

|---|---|---|---|---|

| Ecodesign | Mandatory | Products |

The EU Ecodesign Directive allows for setting minimum environmental requirements on every stage of the life cycle of products. Most product requirements adopted so far are in fact related to the use and end-of-life phases, traditionally on aspects related to energy efficiency. Requirements on material efficiency are systematically present in recent (i.e., as of 2019) Ecodesign Regulations. Annex V of the Directive also allows for a management system for design through manufacturing to be used for conformity assessment. |

Market surveillance is carried out at Member State level. |

| Energy label | Mandatory | Products, packages of products | Energy labels help customers to make purchasing choices based on the provision of accurate, relevant and comparable information on the specific energy consumption of products, to facilitate those consuming less energy during use. | Market surveillance is carried out at Member State level. |

| EU Ecolabel | Voluntary | Can be products or services | The ecolabel helps consumers to make purchasing choices based on the verified compliance of products with stringent ecological criteria. Criteria can be set on any life cycle stage and can include manufacturing sites as well as tested product performance. | Member State competent bodies verify compliance evidence and award the label. |

| Green Public Procurement (GPP) | Voluntary | Can be products or services | Criteria can be set on any life cycle stage and can include manufacturing sites as well as tested product performance. The criteria must always relate to the subject matter. | Verification is through evidence from tenderers provided during the procurement process. |

In terms of mandatory instruments, the Ecodesign Directive5 requires manufacturers placing products on the EU market to improve their environmental performance by meeting mandatory minimum energy efficiency requirements, as well as other obligatory environmental requirements such as water consumption, emission levels or material efficiency aspects. The Energy Labelling Regulation6 provides consumers with a straightforward informative tool to make a better purchase choice, by grading products according to a well-known A-G/green-to-red seven class label.

In terms of voluntary instruments, the EU Ecolabel8 was established as a tool to encourage businesses to develop products with a reduced environmental impact throughout their whole life cycle and to help consumers find the best environmentally performing products in their category. GPP7 criteria are proposed to identify environmentally friendly goods, services and works; their voluntary use by EU public authorities is intended to stimulate demand for more sustainable goods and services, which otherwise would be difficult to bring onto the market.

The two voluntary instruments can be applied to both products and services, the latter being relevant for the PV sector. Specifically in the case of PV products, an important aim of introducing the GPP criteria would be to use the wider potential public sector influence, in particular at regional and local level, by providing guidance and criteria on the procurement of new solar PV systems, or by establishing frameworks for reverse auctions as well as usage rights and power purchase agreements for public assets (lands, roofs) to be exploited for RES electricity generation. The potential to combine the use of reverse auctions with associated procurement criteria to meet solar home PV deployment targets could be particularly important as this has proved a difficult market segment to influence. Service-based business models for circular economy have, moreover, the potential to minimise the environmental impact of production and consumption9 and may play an important role in the solar sector, especially in the residential segment.

Other pieces of EU legislation can be identified that are of relevance for the PV products, such as, for example, the Renewable Energy Directive, the Waste Electrical and Electronic Equipment Directive, the Energy Performance of Buildings Directive and the Construction Products Regulation. Although the possibilities for policy synergies can be identified, here however, the focus of the analysis is narrowed down to the four policy instruments that are aimed at improving the sustainability of the PV products.

The importance of a sustainable product policy framework at EU level has been stressed within a very recent policy document, the Circular Economy Action Plan 2020,10 with the aim to (i) make products fit for a climate-neutral, resource-efficient and circular economy; (ii) reduce waste; and (iii) ensure that the performance of front runners in sustainability progressively becomes the norm. Such a policy approach attributes a pivotal role to the Ecodesign Directive5: Ecodesign requirements on repairability, refurbishment capability and spare parts availability and on recyclability are now systematically present in Ecodesign Regulations, since the publication of a set of new/revised regulations in 2019 on a range of products supplied from business to consumer (such as washing machines or refrigerators) and from business to business (such as servers). * In most cases, the specific formulation of the requirements relates to, on one side, the availability of spare parts, the access to repair and maintenance information and the removability of components and, on the other side, the supply of information regarding presence/content of specific materials or substances.

The legislative framework based on the synergy between the Ecodesign Directive and the Energy Labelling Regulation6 has been up to now of paramount importance, as it both improves the energy efficiency of products and removes the worst-performing ones from the market, with positive effects on consumer expenditure for energy bills and on extra revenues for industry, wholesale and retail sectors. In quantitative terms, this framework is by 2020 estimated to deliver energy savings higher than the annual primary energy consumption of Italy.11 In addition, by 2030, further savings are expected, in the order of the annual primary energy consumption of Sweden.11

Concerning the impacts on research and development and technological innovation, a 2014 study12 concluded that there is a rather direct relationship between the stringency of the requirements and the innovation impact: observing that for products where the Ecodesign implementing regulations define ambitious requirements in relation to the market, the innovation impact was strong. As an example, Ecodesign implementing measures for motor pumps have fostered process innovation and a radical restructuring of the production lines.12, 13 These findings are supported by the technological progress in module design and performance reported in the Chinese market as a result of requirements imposed on the performance of modules under the Top Runner product policy programme.14

Finally, the Ecodesign and Energy Labelling framework benefits from a broad support from industrial stakeholders, as well as consumer and environmental organisations. This is because when regulatory measures are being prepared by the European Commission, a transparent and extensive consultation process is systematically vcarried out,15 giving to any stakeholder the chance to interact and send feedback during the lawmaking process.

The prospects for growth of the PV market have been underestimated in the past. The reality today is that global PV-installed capacity exceeded 627 GW at the end of 2019, 22% of which is installed in the EU (130.67 GW), and is projected to reach ~10 TW by 2050.17, 18 However, according to more ambitious projections, 10 TW could be already installed by 2030 and 30 to 70 TW by 2050.19

Silicon wafer-based PV technologies still dominate the PV market nowadays with a market share of around 95% of the global PV module production in 2019.20 Their records efficiencies are 26.7% to 23.4% for single-junction technologies. Thin-film technologies cover the remaining market share, with lower efficiencies than silicon-based ones—for example, up to 21% for CdTe.20

Life cycle assessment (LCA) can be used to evaluate the benefit of PV products over their full lifetime and it is extensively used to compare the environmental impact of PV technologies—with the IEA LCA guidelines for PV being one of the best examples of sectoral guidance on how to do this.21 A number of simplified methods for analysing the life cycle of PV technology have received attention. Energy return of investment (EROI) and energy payback time (EPBT) are methods for relating the energy yield of PV systems to their embodied impacts and have been extensively debated in literature. The values for the EROI vary in literature from 8.7 to 34.2 times the input energy, whereas the EPBT ranges from 1 to 4.1 years, the lowest value corresponding to CdTe modules and the highest to monocrystalline silicon modules22. The variation in embodied energy among different types of PV modules and systems has been found to be greater than the variation in efficiency and performance ratio (PR). This fact suggests that the relative ranking of the EROI or EPBT of different PV technologies today and in the future depends primarily on their embodied energy and not on their efficiency.20

While the technology costs have been decreasing in the last decade to reach 0.25 €/W for silicon module technologies,19 the future prospects for growth pose significant challenges for PV technology that could be potentially addressed by policy mechanisms for these products. An important challenge is on the supply risk as there are metals closely linked to PV technologies within the 27 materials identified in the EU as critical raw materials.23, 24 There is moreover a need to ensure the entry of products in the EU market with a minimum quality. With the rapid increase in the manufacturing of PV modules in the Far East during the period 2000 to 2010, quality issues linked to the scale up of manufacturing and the rapid entry of new products into the market have been cited. Moreover, these issues can be substantiated by results from factory inspections as well as, for example, the more recent testing of the stability of PERx-type modules entering the market.25 In view of the massive projected deployment of PV technology, strategies to minimise the waste that is projected to arise by 2050 (78 million tonnes of raw materials26) are also vital and suggest the need for an increase in the circularity of both the module and the inverter—with concepts such as repairability, recyclability and dismantleability having been proposed. Durability under different climatic conditions in order to minimise failures and maintain long-term yield, as well as increased repairability in the field to extend the lifetime, are issues that could be tackled by harmonised EU policy.

This paper elaborates on the findings of a study on the environmental impact of PV products that has been carried out by the Joint Research Centre of the European Commission, the ‘Preparatory study for solar PV modules, inverters and systems’27 (referred to as ‘the JRC study’ in the remainder of the text), focusing in particular on the approach and results obtained on the assessment of the available technologies and the policy scenario analysis. The assessment made was preceded by a detailed desktop research (based on data gathering and expert judgement) including the development of an understanding of the market segmentation, user behaviour and technical improvement options. The JRC study was primarily aimed at providing the necessary analysis of three product groups, that is, solar PV modules, inverters and systems, to inform and help policymakers in developing, when relevant and feasible, minimum Ecodesign requirements, an Energy Label, EU Ecolabel criteria and GPP criteria.

The aim of this paper is to contribute to the knowledge base by assessing the opportunities for technological development and innovation that may be imposed or created by environmental policy, with specific regard to PV products. Starting from an analysis of the environmental hotspots of PVs throughout the whole life cycle (from the raw material extraction to their end of life and disposal), it identifies a number of areas of attention for innovation, and a policy approach to tackle these aspects in regulatory terms is proposed—by means, in particular, of requirements in the legal framework of the EU Ecodesign Directive.

This paper is organised in four sections. Section 2 outlines the methodological approach chosen, from the perspective of both the policy and the environmental analysis. Section 3 presents and discusses the results of the research undertaken, and finally, Section 4 summarises the main findings and possible implications.

2 RESEARCH METHODOLOGY

2.1 Ecodesign-based specific methodology

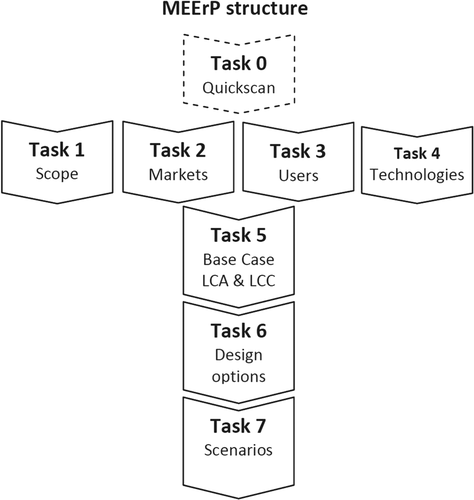

The development of Ecodesign and Energy Labelling requirements is underpinned by preparatory studies that provide the evidence base for policy decisions. The standard preparatory studies on Ecodesign and Energy Labelling are conducted by means of the ‘Methodology for the Ecodesign of Energy-Related Products’ (MEErP),28 which consists of a techno–economic–environmental assessment of the product group under analysis. The MEErP is structured28 in seven tasks, as illustrated in Figure 1. This structured analysis provides policymakers with a comprehensive set of cross-cutting data and findings, amongst which is provided an analysis of the product functionality, of market figures and trends, of user behaviour, of the environmental impacts over the product life cycle and of the ‘design option’ with the least life cycle cost (LLCC). On this basis, Ecodesign requirements (possibly accompanied by an Energy Labelling scheme) are determined, and the impacts at EU level associated with the policy measures including these requirements are estimated.

- The BC represents the average product on the market in terms of resource efficiency, emissions and functional performance.

- The BAT point represents the best commercially available product with the lowest resource use and/or emissions.

-

The BNAT point represents an experimentally proven technology that outperforms the BAT, but is not yet brought to market; for example, it is still at the stage of field tests or official approval.

The MEErP guidance also notes that:

- BNAT technologies could be accelerated to market by incentive programmes once they have been evaluated as such in an Ecodesign preparatory study and

- the BNAT level (of performance) can be an indicator for future new energy classes.

Under Task 4, the ‘bill of materials’ data, based on how the design options are manufactured and using which materials, are collected. These data are then entered into a streamlined LCA tool, the ‘EcoReport tool’. In Tasks 5 and 6, the design options are analysed environmentally and techno-economically, and then, the competing solutions are ranked on the basis of their LLCC, together with an assessment of the environmental and resource impacts related to the product group under analysis (again, via the ‘EcoReport tool’). The level of stringency of the (potential) Ecodesign requirements for a certain product group is determined in line with the features of the design option, which represents the LLCC. Task 7 uses the analysis of the six previous tasks to suggest potential policy measures, typically based on Ecodesign requirements and/or on Energy Labelling.

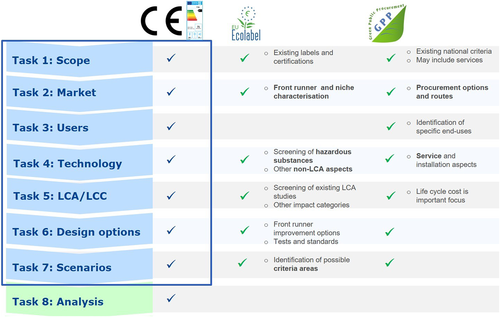

Given that a combined approach between the analysis on Ecodesign/Energy Labelling, GPP and the EU Ecolabel was requested for the JRC study,27 additional methodological considerations were introduced. This resulted in the adoption of a tailor-made methodology in the JRC study, which was largely built on the MEErP to which specific steps aimed at supporting the policymaking process for GPP and the EU Ecolabel were added. Figure 2 displays the eight tasks of this tailor-made methodology, as well as the specific steps, task by task, for GPP and the EU Ecolabel (the outcomes for the Ecodesign/Energy Labelling are those from the standard MEErP). For example, when developing the EU Ecolabel, the Task 1 scope had to include a review of existing certification and labelling schemes.

This approach resulted in a comprehensive analysis of the technical features, as well as of the economic and environmental impacts and of the various design options under analysis, conducted in parallel on three different products groups (PV modules, inverters and systems). For each of these products, the JRC study also outlined potential requirements within the framework of the aforementioned policy instruments.

2.2 LCA methods

The environmental and economic improvement on the BCs of PV module, inverter and system design improvement options was assessed—as detailed in Section 2.3—and was undertaken using the EcoReport tool. The EcoReport tool was developed as part of the MEErP methodology and is used in all Ecodesign preparatory studies. The tool provides for a streamlined LCA of a product, together with a life cycle cost assessment.

The identification of potential criteria for EU Ecolabel and GPP was made through the use of existing LCA evidence, including the product environmental footprint (PEF) pilot for PV products.29 A systematic review of the available LCA literature was conducted, as an extension of Task 5 of the JRC study. It included a screening of the parameters used, information on impact categories and impact assessment, assumptions, data quality, results and their interpretation.

- 1 kWh of DC power output under predefined climatic and installation conditions defined for 1 year averaged over a service life of 30 years;

- 1 kWh of AC power output from a reference PV system (excluding the efficiency of the inverter) under predefined climatic and installation conditions for 1 year averaged over a service life of 10 years; and

- 1 kWh of AC power output supplied under fixed climatic conditions for 1 year (with reference to IEC 61853 part 4) averaged over a service life of 30 years.

The results from the EcoReport tool are scaled accordingly to those functional units. The majority of the new PV modules entering the market nowadays have power warranties of up to 30 years, and for PV inverters, there are manufacturer warranties of up to 10 years. These figures have been analysed in detail in the JRC study, and they have been discussed with stakeholders. These service lives therefore represent a notional period for the purpose of the modelling, with the intention that products with extended life spans, slower performance degradation or lower failure rates would be differentiated in the results.

- raw materials use and manufacturing,

- distribution,

- use phase, and

- end-of-life phase.

Emission and resource use have been expressed as results for each of the different impact categories that are required by the MEErP methodology.

2.3 Technical analysis

The main assumptions and proxies for the lifetime and performance of the modules, inverters and systems that were used as the basis for conducting the technical analysis are listed in Tables 2 and 3. These were derived from the analysis conducted in the JRC study and the consultation process. The BCs were selected to represent the residential, commercial and industrial market segments, which were identified from the Task 2 market analysis in the JRC study.

| Base case 1 | Base case 2 | Base case 3 | |

|---|---|---|---|

| Module type | Multicrystalline Si back surface field (BSF) | Multicrystalline Si BSF | Multicrystalline Si BSF |

| Market segment | Residential | Commercial | Utility |

| Inverter type | String 1 phase inverter 2500W | String 3 phase inverter 20 kW | Central inverter 1500kW 3 strings of 500 kW |

| Mounting | Roof | Roof | Ground |

| Rated capacity DC (modules based) | 3 kW | 24.4 kW | 1.875 MW |

| Module lifetime | 30 years | 30 years | 30 years |

| Inverter lifetime | 10 years | 10 years | 30 years (the components of the inverter are progressively repaired and replaced along their lifetime) |

| System lifetime | 30 years | 30 years | 30 years |

| Climate condition | Reference EU location | Reference EU location | Reference EU location |

| Reference yield before PR (year 1) | 1331 kWh/kWp | 1331 kWh/kWp | 1331 kWh/kWp |

| Performance ratio | 0.75 | 0.825 | 0.825 |

| AC:DC ratio | 0.83 | 0.83 | 0.80 |

| Performance degradation rate of the modules (% per year) | 0.70% | 0.70% | 0.70% |

| Failure rate (%/year) module inverter |

0.005–0.1 10 |

0.005–0.1 Below 10 |

0.005–0.1 Below 10 |

| Availability | TBD | 98% | 98% |

| Base case 1 | Base case 2 | Base case 3 | Unit | |

|---|---|---|---|---|

| System | 3 | 24.4 | 1875 | kWp |

| Inverter | 2.5 | 20 | 1500 | kW |

| Inverter:module DC capacity | 1:1.20 | 1:1.20 | 1:1.25 | |

| Life span system | 30 | 30 | 30 | Years |

| Life span inverter | 10 | 10 | 30 | Years |

| Inverter units in the LC | 3 | 3 | 1 (replacement of parts) | Unit |

| Electricity output system | 81 | 662 | 50 862 | MWh |

| Inverter units per FU (1kWh) | 3.69E-05 | 4.53E-06 | 1.97E-08 | Inverters per kWh |

Module technology is advancing quite rapidly, and during the progress of the JRC study, it was considered important to recognise the existence of technological improvements of the BC, which dated back to 2016. For example, the product projected by the industrial association VDMA in their annual PV sector roadmap34 to have a majority share of the market was forecast to change from multicrystalline back surface field (BSF) to passivated emitter and rear cell (so called PERC) monocrystalline by 2020. Table 4 presents an overview of the composite new BC for 2020, which was compiled from a range of sources and expert inputs.

| Production step | Selected improvement measures | |

|---|---|---|

| Optimised PERC Si 2020 (optimised process and materials) | Further optimisations in BoM (BAT 2025) | |

| Wafer production | Monocrystalline with diamond wire sawing with larger wafer size than >156 × 156 mm2, 170-μm wafer thickness and 75 μm of kerf loss | Wafer production with larger wafer size than >156 × 156 mm2 and wafer thickness of 120 μm and 50 μm of kerf loss with recycling (30% recycled content of kerf) |

| Semi-conductor preparation (e.g., passivation) | PERC p-type mono wafer | PERC on p-type mono-Si wafer |

| Cell metallisation | Reduced Ag to 80 mg/cell | Reduced Ag (70 mg/cell) and Pb-free cell metallization paste with <0.1% module weight |

| Cell stringing | Full cells and 5BB interconnection | Half-cell, busbarless cells with copper interconnection with Pb-free soldering |

| Cell encapsulation | Reduced front glass thickness 3.2 mm |

Front glass non-fluorinated backsheet Glass with AR and anti-soiling coating and <2.5-mm thickness |

| Module power | 281.6 Wp for 60-cell modules | 313.6 Wp for 60-cell modules |

| Degradation rate | 0.6% | 0.5% |

| Performance warranty | 25 years (modelled for 30 years) | 30 years |

| Factory quality inspection | Infrared + electroluminescence/lock in thermography – <1.5% factory reject rate assumed |

Infrared + high-resolution electroluminescence/lock in thermographyLeTID/potential induced degradation assessment<0,5% factory reject rate assumed |

After a screening of the market and technologies, design options were selected for PV modules, inverters and systems. Table 5 shows the design options for solar PV modules, albeit not categorised by market segment, as they can be used in residential, commercial or utility sectors. From the 12 design options selected, 8 of them were considered as possible BAT candidates and there were 4 BNAT technologies. Initial design options representing the BNAT were identified alongside the BAT. Because BNAT is important for the technological evolution of PVs, the findings are discussed under a separate heading in Section 3.

| Design options | Description |

|---|---|

| Option 1: Optimised PERC Si 2020 | Optimized PERC modules as of today (2020) (see further details in Table 4) |

| Option 2: BAT PERC 2019 | The 2019 best mono-Si PERC cells with also thinner wafers |

| Option 3: BAT PERCbi 2019 (bifacial) | Bifacial PERC cells with a glass backsheet |

| Option 4: CdTe | Thin-film CdTe |

| Option 5: CIGS | Thin-film CIGS |

| Option 6: SHJ | Silicon heterojunction |

| Option 7: BAT PERC 2025 | BAT PERC 2019 with further improvements in the BOM (see further details in Table 4) |

| Option 8: BNAT PERCbi 2025 incl. Wafer recycling |

PERC bifacial cells (PERC 2019) + BNAT option for wafer recycling Recycle wafers for new cells (BNAT): it would require additional process steps (e.g., etching or backsheet removal). Only feasible in a closed loop circular economy model, where modules return to their original manufacturer for recycling. Other options for cell recycling exist as well (e.g., refurbishing secondhand modules with less invasive steps such as inspection, glass cleaning and coating, replace the bypass diode, etc.). These can extend the in situ cell lifetime beyond a reference 30 years |

| Option 9: Interdigitated back contact (IBC) | Both contact polarities are on the rear side that significantly reduces shading losses providing the highest commercial modules efficiencies. |

| Option 10: BNAT perovskite thin film | Expected to be a disruptive technology because of its potential of very low-cost production and its suitable band gap for tandem formation |

| Option 11: BNAT perovskite/Si-tandem | The start-up Oxford PV demonstrated efficiencies over 22% outperforming single junction. |

| Option 12: BNAT kerfless silicon | Kerfless wafer production eliminates the need for the slicing of silicon blocks or ingots to obtain the wafer substrate. |

- Note. The options selected for further analyses are highlighted in grey.

For inverters, 13 design options were selected, with 11 of them considered to represent technology that is available presently, being therefore BAT candidates and 1 being BNAT (Table 6).

| Design options | Description |

|---|---|

| Residential | |

| Option 1: More efficient | This design option represents the potential for improvement on the euro efficiency of the base case |

| Option 2: Longer lifetime | This design option represents the potential for extension of the design lifetime of the base case |

| Option 3: Repair (repaired) | This design option represents the extent to which a product is designed for repair along its lifetime |

| Option 4: Monitor/smart | This design option represents the potential for monitoring to diagnose and react to faults related to firmware or hardware. It can help additionally the consumer to adjust their demand to increase self-consumption |

| Option 5: Module level inverter (MLI) | This design option represents the installation of module level inverters that may increase yield in mismatch conditions |

| Option 6: Hybrid storage worst performer (peak shaving) |

These design options represent the installation of inverter with integrated storage to either • provide peak shaving in feed in • increase hourly and quarterly self-consumption |

| Option 7: Hybrid storage best performer (load following) | |

| Commercial | |

| Option 8: More efficient | This design option represents the potential for improvement on the euro efficiency of the base case |

| Option 9: Repair (repaired) | This design option represents the extent to which a product is designed for repair along its lifetime |

| Option 10: Wide band gap inverter (WBG) | This design option represents the installation of inverters which transistors are completely based on new semiconductor materials with a wide band gap |

| Utility | |

| Option 11: More efficient | This design option represents the potential for improvement on the system level efficiency of the base case |

| Option 12: More efficient plus combiner strings | This design option represents the potential for improvement on the euro efficiency of the base case |

| Option 13: Wide band gap inverter (WBG) | This design option represents the installation of inverters which transistors are completely based on new semiconductor materials with a wide band gap |

- Note. The options selected for further analyses are highlighted in grey.

For solar PV systems, 13 and 9 design options were selected for the residential and commercial/utility segments, respectively (see further details in the JRC study27). The PV system options considered largely consist of combinations (or ‘packages’) of the module and inverter technology design options together with options that focus on improvements in system performance as a whole. For example, for the residential segment, one system option could consist of the optimised PERC 2020 + the best performing inverter, thus combining the best module with the inverter with longer life and including a smart monitoring system.

2.4 Policy options analysis

- Ecodesign (ED) requirements on modules and inverters: mandatory requirements could be set that would apply to individual modules and inverters placed on the EU market.

- Energy Labelling (EL) requirements for residential PV systems: mandatory requirements could be set that would apply to either the weighted efficiency of a package consisting of a module type and an accompanying inverter type or, alternatively, the calculated energy yield of a whole PV installation.

- EU Ecolabel criteria set: a voluntary criteria set could be established that would apply to a combination of a package placed on the EU market and the related system design and installation service offered to consumers.

- GPP criteria: a voluntary criteria set could be established that would apply to the process of procuring a solar PV system, from contractor selection through to decommissioning.

- Combined policy options: it was considered to combine the mandatory and voluntary options that were evaluated, given that each of them can act in a different way to achieve improvements in the market.

- ‘Combined option 1’ (ED + EL + GPP) would be led by implementation of the two mandatory instruments, namely, Ecodesign and Energy Labelling, to be complemented by voluntary GPP criteria.

- ‘Combined option 2’ (ED + GPP + EU Ecolabel) would be led by implementation of the two voluntary instruments, namely, the EU Ecolabel and GPP, backed by the mandatory instrument Ecodesign.

3 RESULTS AND DISCUSSION

3.1 Environmental hotspots, impacts on technology innovation and potential policy approaches

3.1.1 LCA hotspot identification

The results for the environmental profile of the PV module BC are presented in Table 7. They were found to be dominated by the production stage for all the impact categories that are evaluated in the EcoReport tool.

| Indicators (from EcoReport) | Base case | Optimized PERC 2020 | BAT PERC 2019 | BAT PERCbi 2019 | CdTe | CIGS | SHJ | BAT PERC 2025 | BNAT PERCbi 2025 + recycled wafer |

|---|---|---|---|---|---|---|---|---|---|

| Total energy (GER) | 100% | 94% | 84% | 83% | 28% | 76% | 87% | 70% | 60% |

| Water | 100% | 131% | 118% | 117% | 10% | 24% | 65% | 166% | 95% |

| Waste, non-haz./landfill | 100% | 115% | 104% | 104% | 14% | 27% | 109% | 82% | 69% |

| Waste, hazardous/incinerated | 100% | 38% | 34% | 33% | 5% | 8% | 38% | 33% | 18% |

| Greenhouse gases in GWP100 | 100% | 96% | 87% | 86% | 28% | 76% | 90% | 72% | 63% |

| Acidification, emissions | 100% | 95% | 86% | 85% | 28% | 64% | 93% | 76% | 64% |

| Volatile organic compounds (VOCs) | 100% | 83% | 74% | 74% | 8% | 13% | 85% | 70% | 69% |

| Persistent organic pollutants (POP) | 100% | 94% | 84% | 84% | 17% | 45% | 102% | 67% | 61% |

| Heavy metals to air | 100% | 91% | 81% | 81% | 19% | 33% | 112% | 84% | 56% |

| PAHs | 100% | 79% | 71% | 71% | 5% | 66% | 79% | 63% | 57% |

| Particulate matter (PM, dust) | 100% | 89% | 79% | 79% | 60% | 81% | 87% | 73% | 70% |

| Heavy metals to water | 100% | 83% | 74% | 74% | 4% | 26% | 111% | 58% | 54% |

| Eutrophication | 100% | 102% | 92% | 92% | 13% | 45% | 121% | 66% | 67% |

Based on the results of the technical and environmental analysis of the BCs against the 14 impact categories that MEErP considers, global warming potential (GWP) (CO2eq) and the related primary energy (MJ) were selected as significant parameters that can be optimised. The environmental performance of the ‘design options’ was analysed using the lead indicator of primary energy (GER in MJ) because this was deemed to be in line with the objectives of Ecodesign, which is to identify improvement options associated with the energy use of the product and its associated manufacturing processes, as opposed to emissions from associated grid infrastructure. Secondary environmental indicators were also identified based on their relevance to the solar PV life cycle—namely, polycyclic aromatic hydrocarbons (PAHs), volatile organic compounds and heavy metals to air and water (see further details in the JRC study27).

The design options were, for each subproduct and market segment, ranked in descending order of impact and cost, with a view to identify those with the lowest life cycle environmental impact and cost to users over the notional service life for each product.

- Modules: in the residential market segment, the CIGS thin-film design, and for the commercial and utility segments, the CdTe thin-film design were the BAT. Composite design improvements based on PERx cell architectures have the potential to deliver a comparable performance to the CIGS design for the GER results. This is particularly the case if BNAT options such as kerfless wafers and design for recycling were to be implemented.

- Inverters: in the residential market segment, the longer life and repairable options were the BAT, with both achieving a significant margin of 54%–61% improvement upon the BC. In the commercial segment, the repairable option comes out as the BAT, showing a 52% improvement. In the utility segment, there appears to be very limited margin to identify a BAT based on the design options modelled.

- PV systems: in the residential market segment, options that include a long life inverter or an inverter designed for repair, as well as options that have had the system PR optimised—either from a design or an operation and maintenance perspective—were identified as BAT.

A sensitivity analysis of the influence of the electricity grid mix in difference global regions was also made, as suggested by other authors.35 This analysis showed that a variance of up to 38% can be seen in the results when using life cycle GWP, suggesting that GWP could also be used to screen for the geographical influence of electricity and fuel infrastructure.

Table 8 gives a more detailed insight into the production stage and shows the relative contribution of the different materials to a certain impact category. The heavy metals (Sn, Pb, Cu) used for interconnections are listed separately.

The PV cell herein is mainly silicon but also contains some other materials such as silver for electrodes (contained in the metallisation paste of the electrodes). The PV cell gives the greatest contribution across the majority of the impact categories considered in MEErP. The aluminium frame contributes greatly for PAH and HMw and to a lesser extent for GWP, persistent organic pollutant (POP), and particulate matter (PM). Also notable is the consumption of water in relation to the glass fibre in the junction box (Table 8).

| Weight | GER | Water (proc. + cool) | Haz. waste | Non-haz. waste | GWP | AD | VOC | POP | HMa | PAH | PM | HMw | EUP | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Photovoltaic cell | 4% | 72% | 0% | 98% | 91% | 79% | 80% | 70% | 77% | 91% | 12% | 76% | 35% | 86% |

| Interconnection—tin | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 1% | 0% | 0% | 0% | 1% | 0% | 0% |

| Interconnection—lead | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Interconnection—copper | 1% | 0% | 0% | 0% | 0% | 0% | 2% | 0% | 1% | 1% | 0% | 0% | 6% | 0% |

| Encapsulation—ethylvinylacetate | 7% | 3% | 0% | 0% | 1% | 1% | 0% | 9% | 0% | 1% | 0% | 0% | 0% | 3% |

| Backsheet—PVF | 1% | 1% | 0% | 0% | 1% | 1% | 1% | 2% | 1% | 1% | 0% | 0% | 0% | 2% |

| Backsheet—PET | 3% | 1% | 13% | 0% | 0% | 1% | 1% | 2% | 0% | 0% | 0% | 1% | 0% | 0% |

| Pottant and sealing | 1% | 0% | 0% | 0% | 0% | 0% | 0% | 1% | 0% | 0% | 0% | 0% | 1% | 0% |

| Aluminium frame | 16% | 15% | 0% | 0% | 4% | 11% | 9% | 1% | 19% | 2% | 87% | 17% | 46% | 0% |

| Solar glass | 66% | 6% | 0% | 0% | 4% | 6% | 6% | 15% | 2% | 4% | 0% | 3% | 2% | 6% |

| Junction box—diode | 0% | 0% | 2% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Junction box—HDPE | 0% | 0% | 1% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Junction box—glass fibre | 2% | 1% | 84% | 1% | 0% | 1% | 1% | 0% | 0% | 0% | 0% | 1% | 9% | 1% |

- Note. In columns are the environmental categories: GER (gross energy requirement), haz./non haz. waste (hazardous/non-hazardous waste), GWP (global warming potential), AD (abiotic depletion), VOCs (volatile organic compounds), POP (persistent organic pollutants), HMa (heavy metals to air), PAH (polycyclic aromatic hydrocarbon), PM (particulate matter), HMw (heavy metals to water), EUP (eutrophication potential).

- Contribution to impact category 25% < X < 50%.

- Contribution to impact category 10% < X < 25%.

- Contribution to impact category X > 10%.

- [Colour table can be viewed at wileyonlinelibrary.com]

3.1.2 Links between environmental impacts, technological innovation and policy

Based on the LCA review on PVs that was conducted in the JRC study, the environmental hotspots together with the life cycle stages where they assume an importance were identified. To tackle these hotspots and to translate them into possible technical requirements to support improvements, a number of focus areas in the PV production processes were identified. These areas together with the translation of the LCA evidence into possible Ecodesign measures are summarised in Table 9. Among the four policy instruments under analysis (Ecodesign Directive, Energy Labelling, GPP and the EU Ecolabel), the focus has been placed on Ecodesign mainly for the reason that, as highlighted in the introduction, this policy instrument had proved to be an effective legislative tool for the setting of material efficiency requirements. Bearing in mind its compulsory nature (i.e., where there are product-specific Ecodesign Regulations, all products placed on the EU market have to be compliant with the requirements laid down in those regulations), this is expected to be the (most) effective legislative approach to decrease the environmental impacts highlighted by the life cycle hotspot analysis.

| Life cycle stages | Where environmental hotspots have been identified | Focus areas of attention for innovation | How can this be translated into the Ecodesign policy? |

|---|---|---|---|

| Production stage | (Silicon wafer production and raw material supply chain) The production of solar and metallurgical grade silicon leading into block, ingot and wafer production |

• The recycling of processing waste • The potential for silicon wafer and film semi-conductor designs that are material efficient • Life cycle primary energy (GER) or GWP (global warming potential) as a reported parameter |

• Information requirements on GER and GWP |

| Operational life (use stage) | The optimisation of system design and yield, taking into account the climatic response and degradation rate of the module design and the overall design of the PV system. |

• Energy yield of modules as a parameter • Design/testing to minimise long-term degradation • System design optimisation taking into account defined derate factors |

• Requirements on life time electricity yield for modules and on the efficiency for inverters • Requirements on durability and/or on degradation rate |

| Repair (use stage) | The service lifespan and replacement cycles of inverters and modules. |

• Ease of accessing/replacing key inverter components on-site, • Ease of accessing/replacing bypass diode and junction box of modules |

• Requirements on repairability |

| Dismantling (end of life stage) | The ease of dismantling modules to access semi-conductor material at the end of life. |

• Ease of separating the encapsulation of a module • Recycling or reuse of semi-conductor materials |

• Requirements on recyclability (ability to dismantle and material content) |

Reporting of life cycle GER and GWP information

A requirement could be imposed on PV module manufacturers to report GER and/or GWP for the PV module at the moment of its placing on the market. This requirement would represent a first step in establishing a consistent basis for comparing the life cycle impacts of the products. It could in turn provide data in support of life cycle criteria for the EU Ecolabel and/or GPP, as well as for construction projects.

Requirements on lifetime electricity yield/efficiency

For PV modules, a requirement could consist of an obligation for manufacturers to report the lifetime electricity yield, in which the module energy output (yield) (kWh/kWp) is calculated according to IEC 61853-336 for each of the three ‘European reference climatic profiles’, as identified in the framework of a dedicated research work37 that was aimed to support the JRC study with the most suitable testing and calculation methods for the functional parameters. Given that the testing according to IEC 61853-3 is a relatively new performance measurement (it was introduced in 2018), it is not yet considered possible to establish thresholds that could form the basis for mandatory minimum requirements. In order for thresholds to be set, more data gathering on the EU market distribution of the lifetime electricity yield of modules would be needed.

For inverters, a requirement could be for a minimum euro efficiency starting at 94% and increasing in time to 96%, as measured according to EN 50530.38

Requirements on durability

To increase the lifetime of the PV modules, one requirement could consist of imposing compliance with the testing sequence required for design qualification under IEC 61215.39 This could be further extended to require factory quality controls and auditing according to IEC TS 62941 and the IECRE OD405 series, although further analysis on the legal feasibility in the framework of the Ecodesign Directive would be needed. As a matter of fact, Ecodesign Regulations apply to products at the moment of their placing on the market and market surveillance can be effected typically by testing specific product characteristics, whereas factory controls, which are important to assure that the tested design quality is replicated in large-scale production, foresee monitoring and auditing activities at the level of the manufacturing process.

A second requirement could be the declaration of the lifetime performance degradation rate. The manufacturer would have to declare the average linear degradation rate expected over a notional service of 30 years, derived on the basis of field data in agreement with a specific protocol37 (which specifies the minimum consecutive years of data coverage, as well as requirements on the geographical location and on the type of installation, such as ground mounted or roof mounted). In the absence of this declaration, default data would be used.

For inverters, each model could be certified to have passed the product test sequence required for design qualification under IEC 6209340—clearly stating whether the product is for indoor or outdoor applications. However, similar to the case of modules, to ensure implementation of the design features upon mass production, the qualification would need to be complemented by factory inspections of product quality.

Requirements on reparability

A first category of Ecodesign requirements on repairability typically consists of (compulsory) information requirements.

Concerning PV modules, manufacturers could be required to report information both on the possibility to access and replace the bypass diodes in the junction box and on the possibility to replace the whole junction box of the module.

As for inverters, the requirement could consist of the identification by the manufacturer of the circuit boards that can be replaced on site if the inverter is below 30 kW. For inverters with a capacity larger than 30 kW, the manufacturers could be required to provide the list of parts that may be replaced and the timing of preventative measures to achieve a declared intended design technical lifetime (as required in IEC TS 6315741).

The recently published EN 45554 standard,42 which provides generic methods to assess the ability to repair, reuse and upgrade of energy-related products in scope to the Ecodesign Directive, could pave the way for a second category of semi-quantitative or quantitative requirements on reparability. This could be attained by defining product-specific indexes aggregating/normalising/weighting scores related to single parameters such as (i) the availability of information on maintenance, repair and upgrade; (ii) the typology of fasteners/connectors; (iii) the typology of tools necessary for repair; and (iv) the minimum technical skill of the person who performs the repair.

Requirements on recyclability

To increase the recyclability of PV modules, one requirement could consist of reporting on the potential to separate and recover the semi-conductor from the frame, glass, encapsulants and backsheet. The design measures to prevent breakage and enable a clean separation of the glass, contacts and internal layers during the dismantling operations should be clearly detailed. Moreover, and following identification of relevant critical raw materials and other materials that either represent hotspots for environmental impact or a potential future supply risk, the manufacturer should declare the content in grammes of a set of materials in the product (antimony, cadmium, gallium, indium, lead, silicon metal, silver and tellurium). Consequently, despite being categorised according to the LCA results as BAT technologies in terms their GER results, for thin-film technologies, proper recovery and recycling is an important aspect that has to be taken into account due to the toxicity of the semi-conductor materials.43 For the encapsulant and backsheet, the type of polymers used (including if it is fluorinated or contains fluorinated additives) and the content in grammes could also be declared by the manufacturer.

As for inverters, and following identification of relevant critical raw materials and other materials that either represent hotspots for environmental impact or a potential future supply risk, the manufacturer could be required to declare the content in grammes of listed materials present in the product as a whole and in the replaceable circuit boards (lead, cadmium, silicon carbide, silver, indium, gallium and tantalum).

3.1.3 Future prospects for technological improvements

As part of the MEErP methodology, a series of BNAT for modules and inverters technologies were identified that could tackle the environmental problems summarised in Table 9 and offer further, in some cases substantial, potential improvements in performance relative to the BCs in the upcoming years.

PV modules

-

commercially available, with limited production lines at present:

- ○

TOPCon passivated contact silicon cells

- ○

silicon modules redesigned for recyclability

- ○

inverters based on wide bandwidth semi-conductors

- ○

-

pre-production scale:

- ○

epitaxial or ‘kerfless’ silicon wafer production

- ○

tandem perovskite:silicon wafer cells

- ○

-

prototype stage:

- ○

back contact (IBC) silicon heterojunction cells

- ○

- Silicon wafer material and energy efficiency

The production of silicon wafers by alternative processes that are more efficient in their use of energy and silicon, such as epitaxial growth or ‘lift-off’ processes, are currently identified as BNAT, although modules based on this type of wafer production have previously entered the market as BAT in the period 1999–2014.44 This type of wafer could potentially be introduced into multisilicon module production lines, which in 2016 accounted for around 65% of the crystalline portion of the market, which at the present time is expanded from BSF cells to also now includes some PERx cell variants (PERC/PERL on p-type material). However, this portion is projected to decline to around 10% by 2030, when only multicrystaline PERC/PERL cells may remain, so the scope to bring process efficiency gains into the market may be constrained unless the associated modules are more competitively priced.

- Crystalline module redesign for recycling

The near BAT 'design for recyclability' silicon module is noteworthy given the need to consider the end of life scenarios for a rapidly increasing module stock. Currently, the majority of module designs present various technical difficulties and challenges at the moment of seeking to dismantle them to recovery materials for recycling.45 Once the junction box and aluminium frame (if present) have been removed, the main difficulty is to separate the encapsulated components as well as the soldered connections and tabbing of the cells. This requires destructive thermal and mechanical processes to be used, which result in low-grade, cross-contaminated material recovery.

Thin-film module designs to some extent simplify the dismantling process, and processes have been developed at commercial scale that achieve a high recovery of the semi-conductor material.46 Alternative crystalline wafer module designs have been developed to a pre-commercial stage that have eliminated the polymer encapsulants and laminates as well as the metal soldering that can hinder dismantling.47 The same pilot production modules have been certified to have passed IEC 61215 design approval,39 indicating that the design and material changes do not appear to have compromised the durability of the encapsulation—although this is still to be more rigorously tested in the field.

PV inverters

For inverters, BNAT are inverter designs based on wider band gap semi-conductors (MOSFET). Although some products entered the commercial-scale PV market segment in 2018—suggesting that they could eventually be candidates for BAT—their application field is as yet limited. Moreover, information is still lacking on the potential benefits and trade-offs in relation to changes in the bill of materials and their performance under higher temperature conditions. Given the significance of thermally induced failures in inverters, more research is needed in this area.

4 CONCLUSIONS

A preparatory study on the environmental impact of PV products has been carried out by the Joint Research Centre. Based on the conclusions, a consistent focus on the yield, long-term performance and circularity of PV modules, inverters and systems could be ensured by (mandatory) legal instruments, acting at both component and system level. Stemming from the conclusions of the JRC study, the research work hereby presented demonstrates how technological innovation could be fostered by regulatory measures on the environmental impacts of the PV products that are underpinned by a thorough analysis of the market, potential BAT and BNAT technologies and LCA analysis of hotspots of environmental impact. Further research work could be devoted to a more extensive and structured analysis of the applicability, limits and interactions of the four policy instruments as applied to the specific case study of PVs, with the aim of identifying the optimal mix of regulatory measures to decrease the environmental impacts of the products.

- silicon wafer and film semi-conductor designs that further improve performance under variable climatic conditions and that are material efficient;

- module design to minimise long-term material and performance degradation and to ensure durability in the field;

- module and inverter design for ease of disassembly to facilitate access to/replacement of key components; and

- module and inverter design for ease of dismantling to facilitate the recovery of components and raw materials.

- composite combinations of BAT manufactured features and material components, and

- BNAT products with new overall designs, manufactured features and material components.

ACKNOWLEDGEMENTS

The authors acknowledge the support of VITO (the Flemish Institute for Technological Research), for part of the work hereby presented, in particular to Paul Van Tichelen and Karolien Peeters. We would also like to thank Eszter Voroshazi from Imec for providing support along the work.

DISCLAIMER

The views expressed in the article are personal and do not necessarily reflect an official position of the European Commission. Neither the European Union institutions and bodies nor any person acting on their behalf may be held responsible for the use which may be made of the information contained therein.