Influence of soft block and film thickness on confined morphology of poly(ether-mb-amide) multiblock copolymers

Funding information: No. 21574140, Crystalline Transition and Transamidation Reaction Mechanism in Long Chain Polyamides and Their Alloys; No. U1510207, The basic scientific problems in functionalization and stabilization of coal-based thermoplastic polymer materials, Grant/Award Numbers: 21574140, U1510207

Abstract

This work investigated the confined morphology within ultrathin films of a family of poly(ether-mb-amide) multiblock copolymer (PEAc) samples, which contains long-chain carbon polyamide 1012 (PA1012) and poly(tetramethylene oxide) (PTMO). As a weakly segregated system, the PA1012-rich phase could break out the microdomains forged by the phase separation in the melt and big spherulites were observed after cooling. The PTMO segments and the film thickness were the key factors in determining the crystalline structure and morphology. As the content of PTMO component increased, an obvious morphological evolution was observed in the atomic force microscopy test. The morphological evolution was related to the increase of segregation strength and the dilution effect. The evolution of PA1012 crystalline structure along with the decreasing of film thickness resulted from the slow diffusion rate of crystallizable chains, the higher glass transition temperature, and the lower number of nuclei induced by the considerably thin film thickness.

1 INTRODUCTION

Constituted by soft segments (SS) and hard segments (HS), the multiblock copolymers usually show very different glass transition temperature (Tg) and/or melting temperature (Tm). The physical cross-linking sites between HS (such as hydrogen bonding) and the elasticity of the SS, making those materials thermoplastic elastomer tunable morphology and properties.1-3 A microphase separation morphology could be usually observed in a multiblock copolymer contains two kinds of intrinsic incompatible segments.4 As a result, the multiblock copolymers had attracted a lot of attention in the past few decades because of their outstanding mechanical properties and applications.5-7

The semicrystalline copolymers exhibited a complex morphology because the final microstructures could diverse largely due to the existence of two driving forces: microphase separation and crystallization. As path-dependent processes, those two factors could generate versatile structural transformation.8-11 Generally, the microphase separation starts firstly in the melt state, which favors the formation of nanodomains. Then the crystallization of HS could either be confined within the microphase separated nanodomains or destroy the previous nanodomains (also called break out) to form big lamellae or even spherulites, depending on its intrinsic properties and environmental factors (such as heat or force).12 The morphology of semicrystalline multiblock copolymers was rather complicated due to the intrinsic and environmental factors, affecting their bulk properties significantly.13

The polyamide functional group was proved to be an excellent motif for thermoplastic elastomer because their strong hydrogen bonding promotes the formation of strong physically cross-linking.14 The commercial poly(ether-mb-amide) copolymer (PEAc) materials under trademark as PEBAX were widely used and studied. Those materials had a broad range of applications due to their adjustable performance range.15-17

It was well known that film thickness was a crucial factor when deciding the nucleation and growth rate if the crystallization occurs within thin or ultrathin films.18-22 Generally, the definition of the ultrathin film was the film whose thickness was smaller than 100 nm. The ultrathin film provides a confined environment for the crystallization. As the film thickness decreases, the evolution of morphology and crystal orientation can be observed within crystalline polymers. The spherulitic morphology, which was usually observed in bulk crystallization, may no longer exist if the crystallization occurs within ultrathin film. Dendritic or seaweed-like crystals with flat-on lamellae become preferred morphologies.19, 23-31

In our previous work, a new family of segmented PEAc materials consists of polyamide1012 (PA1012) and polytetramethylene oxide (PTMO) were manufactured and named as PA1012-mb-PTMO.32, 33 Ander uniaxial elongation, the weight content of PTMO segments determined whether the deformation mechanism follow the Gaussian model or not. The strain induced crystallization of PTMO phases deviation was the main reason for the deviation. Moreover, PA1012-mb-PTMO copolymers were also used for high-performance elastic filament fibers.34, 35 The PA1012-mb-PTMO elastic filament fibers exhibited large elongation at break, low initial modulus, and excellent elastic recovery, within a strain of 200%.36, 37 The double crystallization behavior of PA1012-mb-PTMO samples were thoroughly investigated.38

The crystallization of PEAc materials was considerably sophisticated due to the effect of SS and microphase separation. When the crystallization happened within an ultrathin film, the dimensional confinement should be bringing more complexity to this system. As a continuation, this study was mainly focused on the confined crystallization of PA1012-mb-PTMO ultrathin film. With the findings of morphological observation, the effect of microphase separation, the soft component, and the film thickness on the crystallization of PA1012 phase were studied. The amorphous PTMO segments bring confinement effect for PA1012 HS by dilution and microphase separation. The morphological evolution of PA1012 phase was revealed with the deceasing of film thickness. This research would be very important for the film preparation and application of this multiblock copolymer materials.

2 EXPERIMENTAL SECTION

2.1 Materials and sample preparation

A series of lab-made PEAc materials with the same dicarboxylic-terminated PA1012 (DTPA1012) segment and varied poly(tetramethylene oxide) (PTMO) segments were utilized in this work. The chain structure of all PA1012-mb-PTMO samples was described in our last paper.38 The exact compositions of sample copolymers and the oligomeric molecular weights were listed in Table 1. All the samples were named as A960Gxxxx, where subscripts mean the oligomeric molecular weight of PA1012 segments and PTMO segments.

| Name | WPTMO | Mn (×104) | Mw (×104) | PDI |

|---|---|---|---|---|

| A960G650 | 0.40 | 1.93 | 4.54 | 2.35 |

| A960G1000 | 0.51 | 1.81 | 2.59 | 1.43 |

| A960G2000 | 0.68 | 2.76 | 4.82 | 1.75 |

| A960G3000 | 0.76 | 3.53 | 6.52 | 1.85 |

- Note: The WPTMO value indicates the exactly weight content of PTMO calculated by nuclear magnetic resonance. The samples were N-trifluoroacetylated by trifluoroacetic anhydride (purchased from Sigma-Aldrich) to measure the molecular weight by Gel Permeation Chromatography.39-41

- Abbreviation: PTMO, poly(tetramethylene oxide).

All the copolymers were purified by the dissolution-precipitation process and then were dried at 60°C under vacuum for 24 hours before experiment.

For the preparation of thin film, a thin carbon layer was evaporated forming on the surface of newly cleaved mica substrates. The PA1012-mb-PTMO samples were dissolved in dimethylacetamide (DMAc) and then spin-coated onto the surface of carbon-covered mica. And then all films with a thickness range of 10 to 200 nm were obtained by changing the concentrations of the solution and the spin speeds. The temperature of the spin coater was maintained at 120°C during the process.

The nonisothermal treatment was performed in a Linkam THMS600E hot stage under dry nitrogen gas atmosphere. All the samples were heated from ambient temperature to 220°C at a rate of 30°C/min and held 5 minutes to eliminate the thermal histories, then cooled to room temperature with a rate of 10°C/min.

2.2 Characterization

The crystalline morphologies of PA1012-mb-PTMO thin films were measured by tapping mode atomic force microscopy (AFM, Bruker multimode 8) on a mica substrate. Tapping MPP-rotated cantilevers with silicon probes (name: RTESPA, order MPP-11120-10, 40 N/m, 300 kHz, rotated tip, Al reflective coating) were used in the characterization. The amplitude set point was adjusted above 250 mV to obtain clear height and phase images. The film thickness could be obtained by measuring the height difference between sample film and substrate under AFM.

The microscopic study was carried out on a JEOL (JEM-2200FS) transmission electron microscope (TEM), operating at an accelerating voltage of 200 kV. For TEM characterization, the spin-coated PA1012-mb-PTMO thin films on mica were transferred onto a carbon-coated copper grid through deionized water and dried under ambient conditions.

3 RESULTS AND DISCUSSION

The chain structure, phase behavior, and thermal behavior were elaborated in our last article.38 According to the report, the PA1012-mb-PTMO samples we employed here were weakly microphase separated systems with clearly defined segmented structures. The thermal characterization showed two crystalline phases with two distinct crystallization temperatures, but only the crystalline structures of PA1012-rich phase retained at room temperature.

3.1 Crystalline morphology

Atomic force microscopy phase micrographs of PA1012-mb-PTMO thin films spin-coated on mica substrates were shown in Figure S1. In this situation, all the samples do not experienced the nonisothermal treatment. So no obvious crystalline structures were observed because the crystallization of PA1012 segments did not occur. Many spherical aggregates with a size of several microns could be observed in A960G650 and A960G1000 (Figure S1A,B). It should be pointed out that the images become more ambiguous as the WPTMO increases, resulting from the massive amorphous PTMO segments cover the film surface.

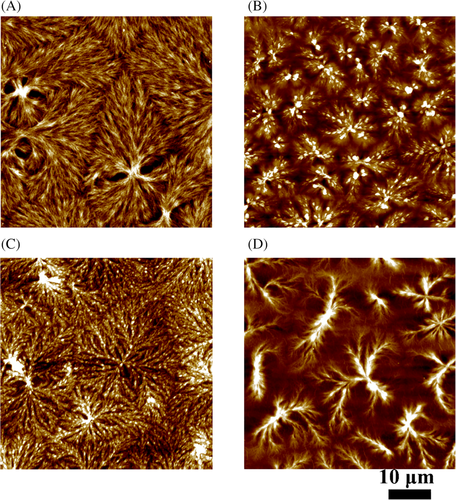

Atomic force microscopy height images of PA1012-mb-PTMO thin films with a thickness of 200 nm could be found in our latest paper (Figure 1).38 During the cooling process, the PA1012-rich phase formed edge-on orientated lamellae and grew into “2D” spherulites with about tens of microns' diameters via “breaking-out.”12 The diversity in the morphological features of PA1012 within copolymer thin films was attributed to the SSs.

Depending on the WPTMO values, the morphological features of the PA crystals were considerably diversed. When WPTMO value was rather low (Figure 1A,B), PA1012 spherulites with compact structure and clear boundaries were observed. As for A960G3000, the final spherulites connected and no visible borders could be distinguished (Figure 1C). This transition was related to the influence of the amorphous PTMO segments.

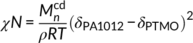

The calculations of segregation strength were summarized in Table 2. Even though the calculation was not accurate, the increase in segregation strength along with WPTMO was observed. The results indicated that the formation of big crystalline structures must experience a bigger barrier when the WPTMO value was higher. So the confined morphology of PA1012 phase along with the increase of WPTMO were observed.

| Samples | σPA1012a (J/cm3)0.5 | σPTMO (J/cm3)0.5 | χ | N | χN |

|---|---|---|---|---|---|

| A960G650 | 23.24 | 17.39 | 1.38 | 8.05 | 11.11 |

| A960G1000 | 23.24 | 17.39 | 1.38 | 9.80 | 13.52 |

| A960G2000 | 23.24 | 17.39 | 1.38 | 14.80 | 20.42 |

| A960G3000 | 23.24 | 17.39 | 1.38 | 19.80 | 27.32 |

- a Theoretical value based on group contribution method reported by Van Krevelen.

- Abbreviation: PEAc, poly(ether-mb-amide) multiblock copolymer; PTMO, poly(tetramethylene oxide).

The dilution effect was the other factor when deciding the crystalline morphologies. As a weakly segregated system, the dilution effect was reported to be the reason for the reduction in the number of crystallizable segments.43 As WPTMO value increases, the density of crystallizable PA1012 segments was gradually reduced. Figure 1D shows that densely packed spherulites of PA1012 were no longer existed due to the dilution of amorphous PTMO chains. Owing to the microphase separation and the dilution effect, the amorphous PTMO segments impact greatly on the crystallization of PA1012 crystalline structures.

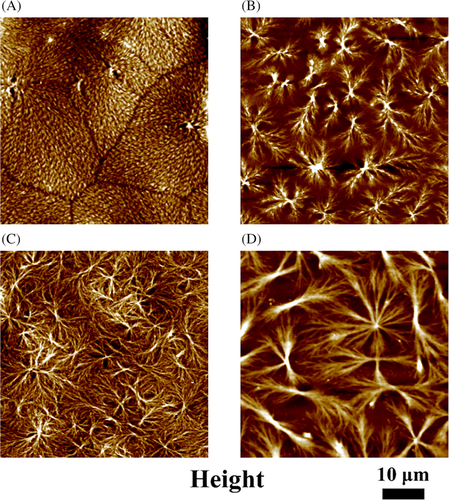

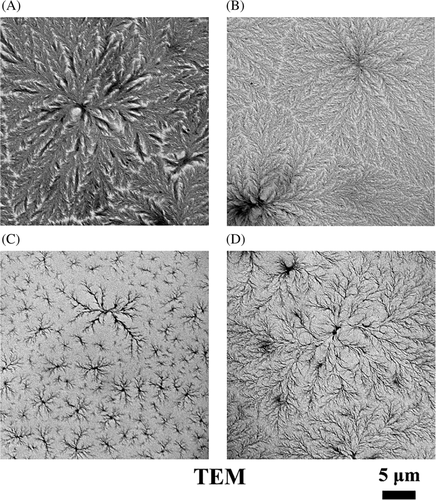

The crystalline structures of four block copolymer samples were shown in Figure 2 with the film thickness of 100 nm. As for the A960G650 (the sample with the lowest WPTMO ratio), the PA1012 segments still grew a “spherulitic” crystalline structures. When the WPTMO value was higher (Figure 2B,C), the PA1012 crystals become less regular, more “sheaf-like” structure formed. The sheaf-like lamellae started to penetrate or pass neighboring domains, leading to a morphology of spherulites with unclear boundaries. As for the copolymer with the highest WPTMO value (Figure 2D), the PA1012 lamellae could not grow to a typical spherulite during the nonisothermal crystallization process, but to a morphology of dendritic crystals (Figure 2D). As we have discussed in the former part, the PTMO component have already confines the crystallization of PA1012 phase. And the confinements became more severe due to the smaller film thickness. Researchers had found that the dendritic or seaweed-like crystals were the common morphology when the crystallization was strongly confined within the thin films or ultrathin films.28, 44-46 In this case, the PA1012 component within A960G3000 exhibited a strongly confined morphology because of the amorphous PTMO domain and the film thickness.

Transmission electron microscope was employed here to provide another evidence for the morphological evolution. Figure 3 exhibited the TEM images of PA1012-mb-PTMO thin films with a thickness range from 100 to 150 nm. The densely packed PA1012 lamellae could develop to big spherulites with “eye structure” on both sides when WPTMO value was rather low (Figure 3A,B). As shown in Figure 3C,D, only loosely packed dendritic lamellae aggregates could be obtained. The PTMO component dependence of morphology was similar to the AFM observation (Figure 2), but more detailed lamella structure could be distinguished.

3.2 Influence of film thickness and confinement effect

Film thickness played a crucial role in crystallization within thin or ultrathin films. Sample A960G2000 with a rather high WPTMO value was selected for further investigation. The surface morphology of A960G2000 thin/ultrathin films with a thickness range of 15 to 200 nm was investigated by AFM.

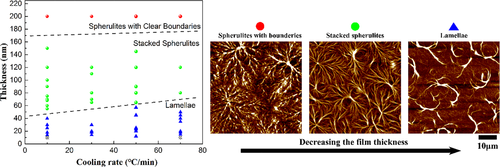

As shown in Figure 4, the impact of film thickness on morphological features was observed. When the film thickness was 200 nm, the PA1012 component within A960G2000 could form compact, space-filling spherulites with clear boundary. As for the PA1012 crystals within ultrathin film, the PA1012 lamellae aggregates begin to stack with each other and no visible border can be identified with a thickness of 100 nm. Then only curved PA1012 lamellae were observed when the film thickness was smaller than 50 nm. Lamellae aggregates became isolated with each other and their number reduce sharply when the film thickness was 40 nm. Compared Figure 4D with Figure 4E, a little deceasing in film thickness leaded to a considerable reduction in the number of crystals. Researchers have found that the decline in the number of active nuclei occurs with the decrease of the film thickness.19, 47, 48 Further reduction in thickness led to the smaller lamellae, and finally, only tiny lamellae could be formed when the thickness was 15 nm. The mechanism would be discussed following.

Atomic force microscopy images of A960G2000 ultrathin films with different film thicknesses were collected, in which the morphology diagram was plotted against film thickness, as shown in Figure 5. Under the thickness range from 200 to 10 nm, several cooling rates were chosen to provide various thermal processes, which was set as the x-axis of the diagram. Both the thinner film thickness and higher cooling rate resulted in the morphological evolution. The crystalline morphologies fall into three types: spherulites with well-defined boundaries, stacked spherulites and lamellae, depending on the film thickness and cooling rate. However, it should be pointed out that the boundaries of the preferred morphology were hard to verify. The morphology diagram was utilized as a reference for the preferred morphology.

Figure 6 showed the deterioration of crystal structure with decreasing film thickness, from spherulites with clear boundaries to stacked spherulites and then to curved lamellae at different thermal histories. When A960G2000 ultrathin films were applied higher cooling rates, a similar morphological transition was observed, while the onset of morphological deterioration occurs on higher thickness.

When polymer crystallized within an ultrathin film (<100 nm), it was believed that the film thickness was the foremost factor in dictating the crystalline morphology.18-22 As several literatures reported, the thickness would take no evident effect on converting the morphologies until it increased to 100 nm.28, 44-46 In our systems, the transition around 100 nm manifests itself by the interpenetration of spherulites, and that was the point when the effect of film thickness became visible.

The second critical thickness was around the average size of the polymer in a random coil conformation, and the severely confined seaweed-like or dendritic crystals with flat-on orientated lamellae were commonly morphology.35-37 In this thickness region, the crystallization was strongly confined and the diffusion rate would take the place of nucleation to control the crystallization process. In the PA1012-mb-PTMO system, only curved lamellae aggregates with edge-on oriented lamellae were observed even though the film thickness was only 15 nm. It was close to the long period of the PA1012-mb-PTMO (~17 nm). Moreover, no crystalline structure can be found when film thickness decreases to 10 nm. When diffusion controls crystallization process within the ultrathin film, seaweeds, or dendrites were predominant morphology.23-27 The absence of flat-on oriented lamellae may resulted from the fast crystallization rate of polyamide. When the film thickness was lower than 15 nm, no crystalline structure can be observed due to the low crystallinity of this copolymer.

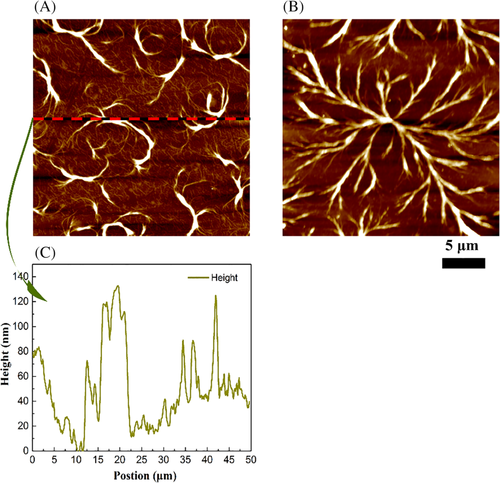

Besides, the formation mechanism of the curved PA1012 lamellae aggregates was discussed (Figure 4E). The altering of the width of the crystallized hard domain was noted. The lamellae were more densely packed in the center of spherulites, and became loosely stacked at spherulite edges where they curvedly penetrate amorphous domains. It was supposed that the curved lamellae commonly found in A960G2000 films with a low thickness were intermediate status during the growth of crystals. Isothermal crystallization was utilized to provide more evidence, as shown in Figure 6B. After experienced isothermal crystallization at 138°C for 1 hour, the PA1012 lamellae could develop to a more spherulite-like structure. However, the PA1012 lamellae still cannot growing to well-developed spherulite as we observe in the thicker film (like Figure 2) due to the confinements bring by amorphous segments and film thickness. Dendritic lamellae aggregates were observed after the isothermal crystallization.

Generally, the film thickness will slow down the crystallization rate by three aspects: the increase in the glass transition temperature, the reduction in chain mobility, and the decline in the number of active nuclei.12 In the former part, we observed the sharp reduction in the number of crystals when the film was thinner. As shown in Figure 6A,B, the curved lamellar morphology was ascribed to the effect of film thickness. The mobility of the crystallizable chain was seriously confined, while the increase of Tg narrows down the temperature region for crystallization. So it was impossible for the lamellae to densely pack during the cooling process because of the limited crystallization rate. Then the curved lamellae were frozen as an intermediate status, as we observed in Figure 6A.

On the other hand, Figure 6A,B also showed that the PA1012 lamellae aggregates were separately distributed in the amorphous matrix. Meanwhile, Figure 6C revealed a rather big altitude difference (dozens of nanometers) between lamellae and the substrate, just like a sea-island phase separated structure with raised lamellae immersed in amorphous domains. Some researchers reported that lamellae might stick out of the ultrathin film, as a result of the slow diffusion rate. And the height difference could be more distinct if the lamellar orientation was edge-on.49-51 As for our systems (Figure 6A,B), the altitude difference between edge-on orientated lamellae and the substrate was bigger than the film thickness. It meant that the diffusion rate was considerably low due to the confinement brought by the film thickness.

4 CONCLUSIONS

In this work, the crystallization morphology and corresponding formation mechanism of a novel series PA1012-mb-PTMO copolymers within thin/ultrathin film were discussed. The copolymers were found to be a weakly segregated system, and the PA1012 segments could break through the microphase domains formed by microphase separation during crystallization. The AFM results showed that the SS and the film thickness could strongly influence the crystallization morphology of PA1012 component. The evolution of PA1012 crystalline structure as the WPTMO increased or film thickness decreased. The SS brought confinements to the crystallization by microphase separation and dilution effect. Curved edge-on oriented lamellae were observed within A960G2000 ultrathin film when the film thickness was rather thinner. The impact of thickness was mainly embodied in three aspects: reduction in active nuclei, the decrease of chain diffusion rate and the increase in Tg.

ACKNOWLEDGMENTS

This research work was supported by the National Natural Science Foundation of China (NSFC, Grant No. 21574140 and U1510207). And we would like to thank Cui Su for helpful discussions. Wensheng Bu and Xuexin Liu are gratefully acknowledged for experimental and technical assistance.