The effect of aging and first heater temperature on the physical properties of polybutylene terephthalate textured yarn

Abstract

In this study, the effect of aging and first heater temperature on the physical properties of polybutylene terephthalate false-twist textured yarn including mechanical properties (tenacity, breaking elongation) and crimp properties (crimp contraction, crimp modulus, and crimp stability) are studied. The as-spun fibers were produced at melt spinning temperature of 257°C and winding speed of 2850 m/min. The as-spun yarns were subjected to draw-texturing processes in 160°C-200°C with interval of 10°C. Fiber structure and physical properties of yarn samples were measured and evaluated. The results showed that as the first heater temperature increases, the value of tenacity and crimp properties of yarns increases while the breaking elongation and shrinkage values decrease. In addition, properties of aging yarns textured after 80 days was stable and this a positive point. It also showed the storage advantage of polybutylene terephthalate textured yarns in comparison with PP and PET. In addition, the storage of POY yarn had no effect on the properties of the textured yarn at 190°C.

1 INTRODUCTION

Polybutylene terephthalate (PBT) is a class of polyester that exists in two crystalline forms with convertible mechanical stresses to each other: transformation from the α-phase to the β-phase by elongation and inversely by stress decrease.1 As a fiber, it is so elastic and has excellent resilience and recovery from small deformations. Due to low humidity adsorption (0.4%), it dries so fast. It does not need to be dyed under pressure like PET.2

The most important parameters that considerably influence the structure and properties of textured yarn are texturing speed, heater temperature, draw ratio, and disk speed to yarn (D/Y).3 The heat applied by the first heater to the yarn in the texturing zone has a significant effect on the shrinkage of the textured yarn. The applied heat in the first heater also has a significant effect on texturing performance with regard to yarn breaks, dye uptake, and textured broken filaments.4 Abbasi et al. investigated the effect of first heater temperature on the physical properties of Polyamide 6 false-twist textured yarn.5 Canoglu et al. studied the effect of first heater temperature on the physical properties of textured PET yarn.6 Karakaş et al. investigated the effect of first heater temperature during the tension-texturing process on the structural parameters, viz. crystalline orientation, crystal size, and birefringence of textured PET yarn.7 Karakaş et al. investigated the effects of the texturing parameters on physical and structural properties of Polyamide 6.6 Yarns.8

Aging is a natural process in materials, especially for polymers, when the properties of polymer change over time.9 In the polymeric materials, especially fibers, several types of aging such as physical, photochemical, chemical, and mechanical can be take placed which affect the properties and structures.10

Studies have also been performed to determine the effect of aging on the physical properties of various fibers, including PET, PP, and PA6 and PA66 textured yarns.5, 11-13 Aging is an important issue that can be accompanied by decrease and sometimes an increase in physical and chemical properties. Some examples of changing properties over aging in textiles are the change of physical properties, color-ability, dimensions, substrate, inflation, weight, and so on.5 So far, the effect of aging on the physical and structural properties of PBT fibers has not been studied. In addition, there is no useful report on the effect of the first heater temperature on the structural and physical properties of PBT.

The purpose of this article is to investigate the effect of aging and first heater temperature on the structure and physical properties of PBT false-twist textured yarn. POY yarn was textured in an industrial false-twist texturing machine. Physical properties of textured yarn were measured every 20 day. The textured yarn was analyzed and the degree of crystallinity, orientation, physical properties, and elastic recovery were investigated. Moreover, to ensure the results of experiments, the effect of POY yarn aging (after 50 days) on the physical properties of textured yarn was also investigated.

2 EXPERIMENTAL

2.1 Materials and Machines

PBT chips having an intrinsic viscosity of 0.87 dL/g were dried at 140°C for 4 hours. The Barmag Extruder (Germany) spinning machine with a 48-hole spinneret, a spinning temperature of 257°C, and a winding speed of 2850 m/min was used. An industrial Barmag FK6V-1000 false-twist texturing machine (Germany) was also used for producing textured yarns. The process speed was 550 m/min. Also, five different texturing temperatures of 160°C, 170°C, 180°C, 190°C, and 200°C were investigated. Other texturing conditions were maintained constant. The draw ratio and D/Y were 1.59 and 1.9, respectively. Disk-friction type texturing unit was used. The disk configuration was 1 + 5 + 1.

3 CHARACTERIZATION METHODS

3.1 Linear density

Linear density of all samples was determined by measuring the weight of 90 m length of yarns.

3.2 Mechanical properties

Breaking elongation and tenacity of the yarn was measured using SIGMA500 machine. The gauge length for as spun yarns was 25 cm and for textured yarns was 4°m with 500 mm/min cross head speed.

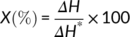

3.3 Shrinkage

(1)

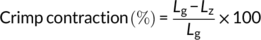

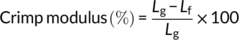

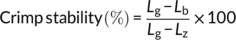

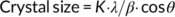

(1)3.4 Crimp properties

(2)

(2) (3)

(3) (4)

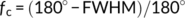

(4)3.5 Differential scanning calorimetry

(5)

(5)3.6 X-ray diffraction

X-ray diffraction (XRD) analysis was carried out using Philips X'Pert-MPD instrument with CuKα radiation (λ = 1.54 A°) which operated at voltage of 40 Kv and current of 40 mA with angle diffraction of (2θ) between 2 and 70°.

(6)

(6) (7)

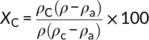

(7)3.7 Density

(8)

(8)3.8 Birefringence

Birefringence was measured on a Ziess polarizing microscope (Germany) with a 30th order tilting compensator.

3.9 Statistical analysis

Data from each test was reported as mean values ± SD. Meanwhile, statistical analysis of data was done using two-way ANOVA and independent samples t test. A P-value of <.05 was defined for significant difference between the various samples.

3.10 Instantaneous elastic recovery

(9)

(9)4 RESULTS AND DISCUSSION

4.1 Thermal analysis

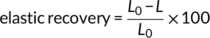

Table 1 shows the thermal behavior of samples, and Figure 1 presents the differential scanning calorimetry thermographs.

| Samples | Maximum of the melting peak (°C) | Heat of fusion of melting (J/g) | Crystallinity (%) |

|---|---|---|---|

| POY | 224.64 | −48.66 | 33.55 |

| T-160 | 225.96 | −53.77 | 37.08 |

| T-170 | 226.66 | −52.77 | 36.39 |

| T-180 | 226.14 | −46.68 | 32.19 |

| T-190 | 226.04 | −45.85 | 31.62 |

| T-200 | 226.90 | −45.61 | 31.46 |

| AT-190 | 226.66 | −45.83 | 31.60 |

- Note: AT-190: aged POY and then textured yarns at 190°C.

- Abbreviation: DSC, differential scanning calorimetry.

As it can be seen in Table 1, by increasing first heater temperature from 160°C to 200°C, the percentage of crystallinity of textured yarn was reduced. The crystallization of textured yarn at temperatures of 160°C and 170°C is more than POY yarn. However, the crystallinity of textured yarn in 180°C, 190°C, and 200°C was slightly less than POY yarn. In the case of aged and then textured POY yarn, it seems that the percentage of crystallinity is almost equal to yarn without aging and textured at 190°C. POY is subjected to externally applied forces and internal stress during draw texturizing process. The externally applied forces are tensile force and yarn twisting forces mean torsional and bending that these forces will not allow crystallinity to develop the same as the case of heat stability of filaments. This is because simple tension will assist in the formation of a lattice, while bending and torsion will tend to distort the lattice.7

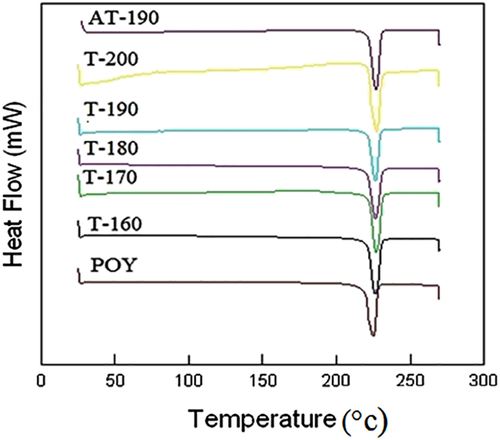

4.2 X-ray diffraction

X-ray diffraction patterns of samples are illustrated in Figure 2. The reflections observed at 2θ = 9.2°,17.2°, 23.25°, and 25.2° are corresponded to the reflections from the (001), (010), (100), and (1-11) planes, for the α form, respectively.17, 18 The XRD results of the samples are listed in Table 2. As it can be observed, there is a decrease in percentage of crystallinity, crystallite size, and crystalline orientation function ƒc in (010) and (100) planes after texturizing of POY yarn with aging and without aging.

| Crystallinity (%) | Crystallite size (nm) | ƒc | |||

|---|---|---|---|---|---|

| (010) | (100) | (010) | (100) | ||

| POY | 33.28 | 8.2 | 6.3 | 0.994 | 0.992 |

| T-190 | 31.22 | 6.7 | 4.06 | 0.992 | 0.988 |

| AT-190 | 31.35 | 6.6 | 4.06 | 0.993 | 0.988 |

- Note: AT-190: aged POY and then textured yarns at 190°C.

By comparing the aged and then textured POY yarn at 190°C and nonaged and then textured POY yarn at 190°C, it is clear that the percentage of crystallinity, crystallite size, and crytstalline orientation function are not significantly changed.

The PBT crystallization behavior is slightly different from the behavior reported for PET and nylon. The X-ray diffraction studies reported about PET showed that the crystal orientation function and size of crystal increased with increasing temperature of the yarn (155°C-185°C). Caracas et al.8 reported that the crystalline orientation factor (fc) and the crystallite size of the nylon 66 yarn increases with an increase in the temperature of the texturizing up to 200°C, and then decreases at temperatures of 210°C and 220°C. In fact, with the increase in temperature, the forces of the intermolecular will be weakened, so the flexibility of the macromolecules and the movement of the structural elements increases. As the hardness of filament decreases, the regularization of the crystals becomes easier.

On the other hand, one of the factors affecting the quality textured filament yarn is the degree of crystallization of feed yarn.

In general, orientation and crystallization depend on the previous history of the yarn. If the crystallization or orientation is high enough, they will not increase in the textured and may even decrease. Because perpendicular force on the yarn axis can decrease the crystallization due to the presence of excessive force.19 The suitable temperature for crystallization is Tc, while the stabilization temperature (first heater temperature) is usually 10-15° below the softening temperature (TS). At the stabilization temperature, the instability of the secondary bonds is higher than formation of a crystalline orientation. Therefore, considering that the crystallization rate of this polymer is high and POY yarn has a high crystallinity (33.55) and sufficiently crystallized before it is textured, and in texturizing in the case of under super-temperature conditions (higher than TC) and under tension, the crystallization can not increase and it has been decreasing.

4.3 Density

The obtained results illustrated that POY fibers and textured yarns had a density of 1.31 and 1.32 g/cm3, respectively. They also had crystallinity of 28% and 35%, respectively. No accurate data were obtained for the textured yarn at different temperatures at the first heater, due to the low precision of the method and the low difference between the density results.

4.4 Orientation

Karakas et al.8 implied that the birefringence is a criterion of orientation and increases with increasing the temperature of heater. The POY and textured fibers had a diameter of about 0.021 mm and 0.015 mm, respectively, therefore the diameter of the POY fiber was more than that of textured fibers. POY fibers had a birefringence of 0.06. The textured fibers had birefringence of 0.08°C, 0.084°C, 0.088°C, 0.09°C, and 0.093 at 160°C, 170°C, 180°C, 190°C, and 200°C, respectively.

4.5 Effect of aging and first heater temperature on physical properties of textured PBT yarn

The physical properties of POY and textured samples are listed in Table 3.

| Sample | Linear density (den) | Tenacity (g/den) | Elongation (%) | Shrinkage (%) | Crimp contraction (%) | Crimp stability (%) | Crimp modulus (%) |

|---|---|---|---|---|---|---|---|

| POY | 225 ± 0.31 | 2.64 ± 0.02 | 105 ± 0.85 | 2 ± 0.34 | - | - | - |

| T-160 | 144.5 ± 0.33 | 3.3 ± 0.02 | 20.03 ± 0.74 | 12.87 ± 0.09 | 20.97 ± 0.39 | 75.3 ± 0.52 | 10.66 ± 0.21 |

| T-170 | 144.8 ± 0.13 | 3.32 ± 0.03 | 19.6 ± 0.69 | 12.11 ± 0.11 | 25.46 ± 0.12 | 79.68 ± 1.72 | 13.04 ± 0.19 |

| T-180 | 144.6 ± 0.21 | 3.35 ± 0.05 | 19.18 ± 0.53 | 11.72 ± 0.06 | 30.71 ± 0.33 | 83.91 ± 1.52 | 16.19 ± 0.25 |

| T-190 | 144.8 ± 0.17 | 3.37 ± 0.03 | 18.98 ± 0.83 | 11.09 ± 0.06 | 35.61 ± 0.73 | 88.20 ± 2.57 | 19.57 ± 0.68 |

| T-200 | 144.60 ± 0.23 | 3.43 ± 0.06 | 18.61 ± 0.43 | 10.14 ± 0.05 | 38.42 ± 0.65 | 89.76 ± 0.57 | 21.47 ± 0.35 |

| AT-190 | 144.2 ± 0.13 | 3.36 ± 0.06 | 19.91 ± 0.49 | 11.08 ± 0.09 | 34.96 ± 0.54 | 88.90 ± 1.74 | 18.47 ± 0.68 |

- Note: AT-190: aged POY and then textured yarns at 190°C.

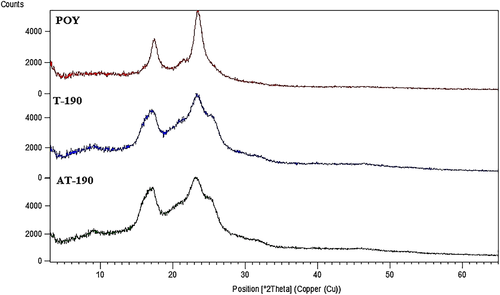

The tenacity of textured yarns at various temperatures of first heater for 80 days is depicted in Figure 3. The tenacity increases by increasing the first heater temperature. Two-way ANOVA analysis showed that an increase in temperature had a significant effect on the yarn tenacity.

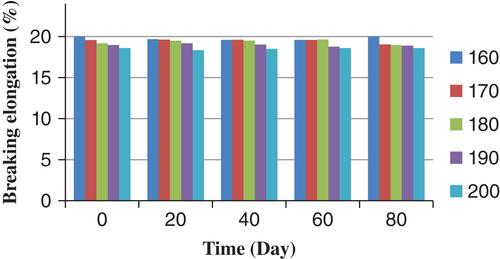

The variation of breaking-elongation in textured yarns at various temperatures of first heater during aging is shown in Figure 4. It can be seen that the breaking-elongation decreases significantly by increasing the temperature of first heater from 160°C to 200°C. In addition, the two-way ANOVA showed that an increment in temperature had significant effect on the breaking elongation.

The most significant factor for determining the fibers tenacity is orientation which can be obtained by birefringence.20

Caracas8 showed that, the breaking elongation of the yarn produced from the nylon 66 fibers was decreased and the tenacity was increased, by increasing the temperature of first heater to 200°C. However, at the temperatures of 210°C and 220°C the yarn tenacity was decreased.

Canoglu,6 implied that the temperature of first heater in the false twist texturing had a slight effect on the tenacity and elongation of the yarn. He also showed that by increasing temperature of first heater, the tenacity of the polyester yarn increases, which is due to increased crystallinity in the yarn. On the other hand, the elongation was decreased due to the dryness of the polyester yarn.

Texturizing the POY yarn and increasing the first heater temperature lead to an increment in the birefringence or orientation of yarn, which results in higher tenacity and lower breaking elongation of the textured yarn at five different temperatures than POY yarns. Also by increasing the temperature of first heater, the tenacity was increased, however the elongation was decreased.

In addition, two-way analysis of ANOVA showed that the aging had no significant effect on the tenacity and braking elongation of the yarn.

Popovic study13 showed that the tenacity and breaking elongation of the textured nylon yarn of 66 even after 12 months of maintenance were in the allowed range. Abbasi5 implied that the tensile properties of nylon 6 were relatively constant.

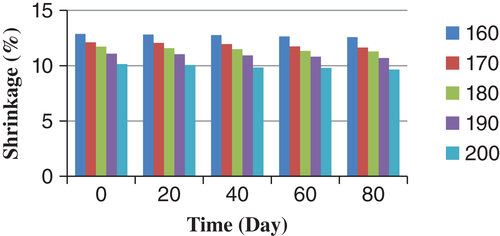

The effect of aging of the textured yarns at different temperatures of the heater, on yarn shrinkage, is shown in Figure 5. The shrinkage of the yarn was decreased by the temperature of first heater. The results of two-way ANOVA showed that the effect of temperature on yarn shrinkage was significant. The temperature of 160°C had the highest value (12.86) of shrinkage while the temperature of 200°C had the lowest (10.41). The shrinkage depends on the residual stress in the fibers. Therefore, by decreasing these tensions, the residual shrinkage in the fibers decreases. As the temperature increases, the internal stress of the fiber is released and the relaxation of the fiber would be better. As a result, there would be no tension inside the fiber to be released so that it can shrink it. Also, due to the fact that the orientation of the entire structure has increased by increasing the temperature of the texturizing operation, the shrinkage of the fiber has also decreased. The shrinkage of textured yarn is also higher than the POY fibers (Table 3), which indicates an increase in orientation in noncrystalline regions. Canoglu's studies6 also showed that by increasing the temperature of first heater, the amount of PET yarn shrinkage decreases.

In addition, two-way ANOVA analysis showed that aging had a significant effect on yarn shrinkage. Over time, the shrinkage was decreased and the maximum changes were about 4%, and the reduction was not important for applications. Popovic studies13 showed that there was no change in the shrinkage of nylon 66 after 12 months of maintenance, indicating that the yarn structure was stable after texturizing.

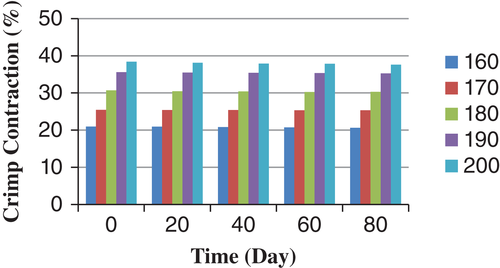

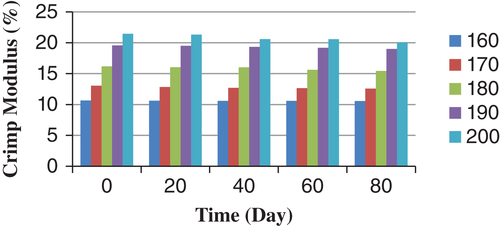

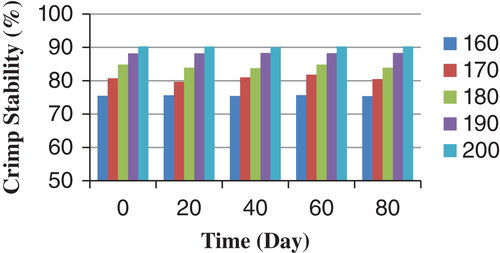

The crimp properties of the textured yarns at various temperatures of first heater and aging time of 80 days are depicted in Figures 6-8. An increment in heater temperature significantly increased the crimp contraction, crimp modulus, and crimp stability. The effect of aging on the variations of in crimp properties was significant.

Creating a deformation in the false twist texturing results in secondary bonds to be in an unstable state. The stabilization is in fact the sustainability of secondary bonds in a new position. Heating the polymer leads to more mobility of the chains in the molecular structure, and hence the stabilization would be faster and easier.21 Studies reported on PET6 and nylon8 also showed that the crimp properties of a textured yarn increases by increasing the temperature of the first heater.

It was also observed that the crimp and the crimp modulus had a decreasing trend over time. The maximum changes were about 4%, which does not matter in practical terms. The aging had no significant effect on wave stability. In the case of polypropylene (PP)11 and PET,12 the aging of the textured yarns results in a significant reduction in crimp contraction and crimp moduluse, while in the polyamide,5 the crimp properties remain relatively constant during the time.

Also, the t test showed that there was a no significant difference between the mechanical and crimp properties of the POY yarn while the textured yarn at 190°C and POY without time and then texture at 190°C.

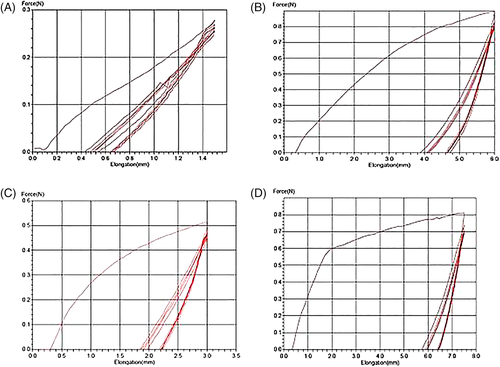

4.6 Instantaneous elastic recovery

As it is obvious in Table 4 and Figure 9, by increasing the elongation, the instantaneous elastic recovery of the PBT filament was decreased in the first and fifth cycles. As the elongation increased higher than 25%, the fibers were broken. There are four flexible methylene groups in the PBT macromolecular unit chain which has a zigzagged molecular chain. Therefore a PBT filament is more flexible than PET and hence has a better elastic recovery than PET.16 Accordingly, no significant difference was observed in the obtained results, by comparing the aged-texturized and nonaged-texturized POY yarn in temperature of 190°C.

| T-190 | AT-190 | |||

|---|---|---|---|---|

| Elongation (%) | First stretch cycle | Fifth stretch cycle | First stretch cycle | Fifth stretch cycle |

| 25 | 84.33 | 80.13 | 84.67 | 79.56 |

| 20 | 88.56 | 85.02 | 89.23 | 85.22 |

| 10 | 95.78 | 94.63 | 95.5 | 93.82 |

| 5 | 98.30 | 97.32 | 98.34 | 97.69 |

- Abbreviation: PBT, polybutylene terephthalate.

5 CONCLUSIONS

The results showed that with increasing first heater temperature from 160°C to 200°C, the tensile and crimp properties of textured yarn were improved. Crimp properties of textured yarn at the heater temperature of 200°C represented the highest values. No significant difference was observed in the obtained results, by comparing the aged-texturized and nonaged-texturized POY yarn.

Some fluctuation in the physical properties of texturized yarns was observed during 80 days, but it was within the allowed range. Moreover, the PBT filament had a high instantaneous elastic recovery and aging of the POY yarn had no effect on the instantaneous elastic recovery of the PBT filament.

According to the polymer's TS, this fiber can be texturized at a lower temperature than PET with good crimp properties. The optimum temperature for texturizing of this fiber is 160°C and for higher crimp properties, these fibers can also be texturized without reducing the mechanical properties up to 200°C.

Today, DTY polybutylene terephthalate yarn is a rival for nylon and is used to produce socks and knitted fabrics. Therefore, it is a geed idea that by increasing the temperature, increase the crimp properties, while the DTY yarn is not damaged.

ACKNOWLEDGMENTS

The work was supported by University of Guilan, Rasht, Iran. Also the authors would like to thanks Nafis Nakh Corp., Iran, for Their Sincere assistance to provide the draw-texturing machine and the PBT materials used in this study.