Stretch-induced stable-metastable crystal transformation of PVDF/graphene composites

Funding information National Natural Science Foundation of China, Grant/Award Numbers: 21374077, 51673147, 51573131

Abstract

Deformation-induced crystalline structure transformation of poly(vinylidene fluoride) (PVDF)/graphene composites from stable α-crystal to metastable β-crystal at different temperatures was investigated by means of in situ synchrotron radiation wide-angle and small-angle X-ray scattering (SAXS). The obtained results of lamellar and crystalline structures during tensile deformation shown that the α-β crystal transformation relies on the evolution of orientation and there is a threshold value (∼0.5) of orientation function for structure transformation. The mechanism of α-β crystal transformation was interpreted based on an indirect approach via the intermediate state of tensile deformation-induced fragmentation and recrystallization process. The fragmentation and recrystallization process was verified by the analysis of four-point and then six-point SAXS patterns. The formation of β-phase at 160°C was confirmed as a “recrystallization (α-crystal -) β-phase transformation.” The loaded appropriate stress guarantees the stable-metastable phase transformation of PVDF. While at 30°C, the adequate stress concentrated on the crystal phase results in formation of β-crystal from the initial recrystallization. The addition of graphene is beneficial to enhance the mechanical property of PVDF at both 30°C and 60°C, but the compatibility of PVDF/graphene composites does not favor high temperature such as deformation at 160°C.

1 INTRODUCTION

As an applied semicrystalline polymer, poly(vinylidene fluoride) (PVDF) has been both extensively and intensively investigated, due to its attractive pyroelectric and piezoelectric properties in addition to its flexibility, thermal stability, excellent processability, and chemical resistance, when being polarized.1-4 The outstanding mechanical properties characterize PVDF's uses as an engineering material, while the good chemical resistance makes it an excellent candidate in coating and membrane applications.5-7 The properties are intensively affected by the crystalline structures in PVDF, which exhibits pronounced polymorphic crystalline forms, depending on crystallization conditions.8 PVDF can crystallize into at least four distinct crystals, known as α, β, γ, and δ.9, 10 The α-crystal is the most stable form in PVDF.11 Unlike the situations in isotactic polypropylene and isotactic polybutene-1, the transformation in PVDF is from a stable crystal (α) into a metastable crystal (β). Therefore, sufficient energy is necessary to ensure the transformation. This interesting feature promotes us to deeply analyze the mechanism of phase transformation in PVDF.

The crystalline phases differ from each other due to the relative orientation of the molecules in the crystalline structure and due to the sequential ordering of the torsion angles.12 Of all the known modifications, α- and β-crystals are most common. When crystallized from the melts at normal or rapid cooling conditions, one can obtain the nonpolar α-crystal, which is mostly kinetically favored, having two trans-gauche (TGTG′) chains packed antiparallel in a unit cell.2, 13 The β-crystal is the one that has attracted the most attention due to its extensive pyroelectric and piezoelectric applications.14-16 It has all TTTT conformation and polymer chains in this crystal are perpendicular to the direction of this dipole but all dipoles along the chain are parallel to the ones of the crystals.9 The dipole moments of β-crystal gives PVDF a much higher polarity compared with other phases.

β-crystal can be obtained by different techniques,17, 18 among which the mechanical stretching of α-crystal is the most important one.19-22 Numerous publications reported characterization and understanding of the mechanically induced structure-transformation.23, 24 Necking, defect, and heterogeneous stress are considered to play important roles in the structure transformation. Sencadas et al.15 uniaxially stretched α-crystal of PVDF at different temperatures at draw ratios from 1 to 5 and found that the structure transformation is accompanied by a decrease of crystallinity about 10% for the optimum transformed samples. Besides, the α-β transformation that occurs by stretching can be further optimized by applying a poling field. Ye et al.9 pointed out that during stretching deformation, new coordination of fluoride atoms with the adjacent hydrogen atoms is formed and induces the conversion from normal crystalline structure (α-crystal) to electroactive ferroelectric structure (β-crystal). The relative content of β-crystal is intensively enhanced after stretching and reaches a peak composition of 93%.

A semicrystalline polymer is normally schematically presented as crystalline lamellae embedded in amorphous phase and its mechanical behavior is closely linked to the deformation processes of each constituent and their interactions.25 In situ measurements combining structure and property become essential for understanding structure and mechanical property relationship of the materials.26 Small- and wide-angle X-ray scattering (SAXS and WAXS) techniques can be carried out in situ during the deformation on samples with morphologies similar to bulk material.27 Indeed in situ drawing on synchrotron radiation X-ray scattering measurements provides rich structure-property information for many semicrystalline polymers such as PVDF.28-31 In such a way, Castagnet et al.32 adopted WAXS and SAXS techniques to specify the cavitation phenomenon occurring in α-crystal PVDF homopolymer when stretching it at room temperature. They found that the crystalline phase of the PVDF remains unchanged for elongations up to about 40%. At higher elongations, crystalline lamellae rupture, orienting perpendicularly to the drawing direction. And, microfibrils are formed with quite extended voids between them, without any crystalline structure transformation observed. Also by means of WAXS and SAXS measurements, Wu et al.33 suggested that the application of stress at room temperature creates defects during the shearing of α-crystal in PVDF fiber and thus facilitates the transformation of α-crystal to β-crystal. Recently, the deformation-induced structure transformation upon tensile deformation has been studied by Defebvin et al.34 The authors pointed out that α-β crystalline structure transformation which could be found in the temperature range from T g to T m occurs during the formation of fibrillar structure induced by necking.

The process and mechanism of α-β crystalline structure transformation in PVDF is an attractive issue that the formation of β-phase should be learnt thoroughly. To date, the processes of α-β crystalline structure transformation in literatures are still not totally consistent and always lack of detailed information. In our previous research35 based on the tensile deformation of pure PVDF at different temperatures, the crystalline and lamellar structure evolution during deformation has been explored, and the α-β phase transformation was found at both low (60°C) and high temperature (140°C). However, the mechanism of α-β phase transformation was not addressed intensively. Besides, it is difficult to obtain nice tensile curve for pure PVDF sample at 30°C as the rupture of the material occurred randomly. Therefore, in this article, we investigated PVDF/graphene composites, aiming to understand the α-β crystalline structure transformation in considerable detail when being subjected to uniaxial tensile deformation at different temperatures. Due to the versatile excellent properties, graphene incorporated composites of PVDF possess property optimization.36, 37 The main experimental techniques were WAXS and SAXS using synchrotron. The mechanism of α-β crystalline structure transformation is confirmed as that deformation induced fragmentation and recrystallization under certain stress would cause the formation of β-crystal. At 160°C, the transformation efficiency is getting lower and the β-crystal is transformed from imperfect newly formed α-crystal during deformation.

2 METHODS

2.1 Sample preparation

PVDF (Solef 6008, Mw of 2.55 × 105, polymer dispersity index of 1.9) was purchased from Solvay S. A., Brussels, Belgium. The melting point (177°C) was determined by differential scanning calorimeter (TA-Q20) with a heating rate of 10°C/min. Graphene (SE1231, specific surface area of 90-150 m2/g, particle size [D50] of 10 μm) was provided by The Sixth Element Materials Technology Co., Ltd (Changzhou, China).

PVDF granules were melt mixed with graphene at 230°C via the chamber of XSS-300 torque rheometer span at 32 rpm. The load of graphene in the composites was 0.1 wt% (based on the weight of PVDF). The PVDF/graphene plates with a thickness 0.5 mm were obtained by compression molding. To ensure that deformation occurred in the path of the X-ray beam, dumbbell-shaped samples were obtained with an overall length of 26 mm, a length between the shoulders of 3 mm and a neck width of 1.5 mm.

2.2 Characterization measurements and analysis

In situ X-ray scattering measurements were carried out at beamline 1W2A of the Beijing Synchrotron Radiation Facility (Beijing, China). The wavelength of the radiation source was 0.154 nm. The WAXS and SAXS measurements were performed with sample-to-detector distances of 130.5 and 1590 mm, respectively. A charge-coupled device detector was used to record the synchrotron X-ray patterns. A Linkam TST 350 tensile hot stage (Linkam Scientific Instruments, Ltd., Epsom, UK) equipped with a 200 N load cell was adopted for the uniaxial tensile deformation of the samples during the in situ experiments. The tensile hot stage was controlled via a computer through Linksys 32 system control software. The tensile experiments were performed at four temperatures (30°C, 60°C, 120°C, and 160°C) and the drawing speed was fixed at 10 μm/s.

The long period (L, distance between the adjacent lamellae along the stretching direction) was calculated from the Bragg equation of L = 2π/qmax, where qmax corresponds to the peak position calculated from the one-dimensional (1D) SAXS profiles.

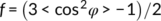

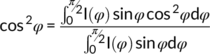

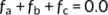

(1)

(1) (2)

(2) (3)

(3) (4)

(4)

3 RESULTS AND DISCUSSION

3.1 Mechanical property

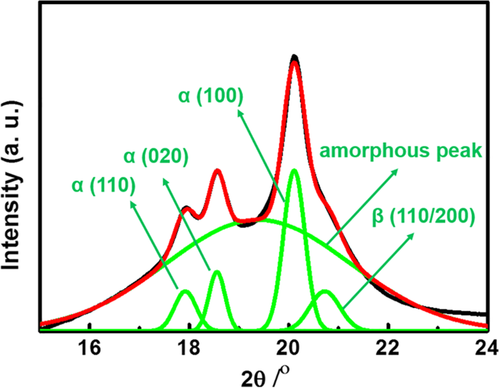

Nominal stress-strain curves on specimens are shown in Figure 2A at different drawing temperatures, exhibiting a strong influence of the temperature on the tensile behavior. The four curves exhibit the region with high slope, the region with negative slope, and strain hardening regions with moderate slope, representing the elastic, yielding, and plastic deformations, respectively.40 The yield stress and Young's modulus show a decrease with increasing drawing temperature and the strain hardening response appears more pronounced at higher temperatures. The Young's modulus and modulus of strain hardening as a function of temperature obtained from Figure 2A are shown in Figure 2B. On the contrary to Young's modulus, the modulus of strain hardening before fracture increases with increasing temperatures. The deformation performances around different regions show different temperature dependences. This interesting phenomenon brings us to detailed investigations on structure evolutions of PVDF/graphene composites at different temperatures. Thus, in situ WAXS and SAXS measurements are necessary to be adopted, aiming to detect the detailed structural information during the different regions.

Sencadas et al.15 reported that obtaining the permanently deformed PVDF samples is not possible for temperatures below 80°C. As mentioned above, our tentative experiment also indicated that it is difficult to obtained fine tensile curve for pure PVDF sample at 30°C. In this article, the S-S curve of PVDF/graphene composites obtained at 30°C is feasible due to the graphene as nanofiller. Correspondingly, the yield stress (∼35 MPa) of PVDF/graphene at 60°C is higher than that of a pure PVDF sample (∼29 MPa). The mechanical property of PVDF could be enhanced effectively by the adopted graphene in this experiment.

3.2 In situ WAXS and SAXS

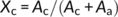

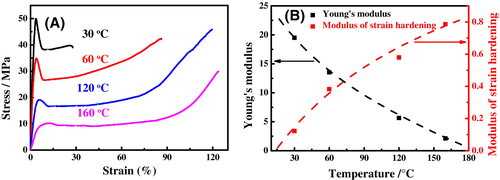

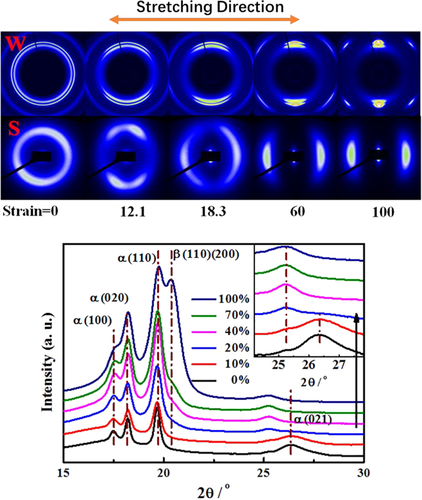

The following results refer to those obtained at a temperature of 30°C. Characteristic WAXS and SAXS patterns recorded at different strains and the integrated intensity profiles calculated from the WAXS patterns during the deformation are depicted in Figure 3. Before deforming, the SAXS patterns exhibit isotropic scattering from the stacks of randomly oriented chain-fold lamellae. In the initial WAXS pattern, several isotropic diffraction rings are detected. The peaks at diffraction angles of 17.8°, 18.4°, 20.0°, and 26.7° correspond to (100), (020), (110), and (021) crystal plane of α-crystal,12, 41, 42 as shown in Figure 3 (bottom). It is observed that the undeformed sample is total α-PVDF.

As strain increased, a rising streak in the center of SAXS pattern appeared. After yield region, the SAXS patterns are dominated by the intense streak which is perpendicular to the stretching direction. This streak is probably due to stress-induced microvoids and/or strain-induced crystalline fibrils arising during deformation until the sample ruptures.10, 33, 43 Castagnet et al.32 found that at room temperature, the growth and the nucleation of cavities in PVDF (α-crystal) are created in the equatorial zones of spherulites before reaching the yield point and cavities in other areas are responsible for softening behavior. Also in Figure 3 (top), the orientation signal in WAXS pattern is observed at large strain. The mechanical properties of a semicrystalline polymer intensively depend on the anisotropy in chain alignment and crystal forms.44 The details of crystal orientation induced by deformation will be discussed in the later section. During deformation, a new peak appears at 2θ = 20.68°, which corresponded to β (110/200) peak.12, 41, 42 The WAXS curves in Figure 3 (bottom) indicate that β-crystal forms and stretching induces the crystal transformation from α- to β-crystal.

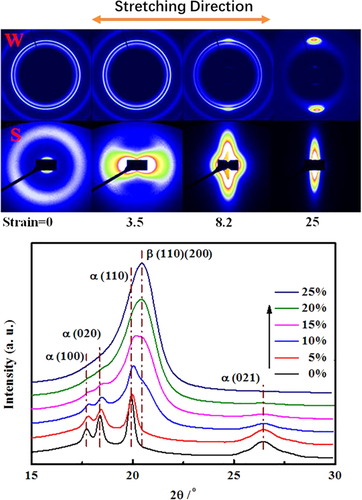

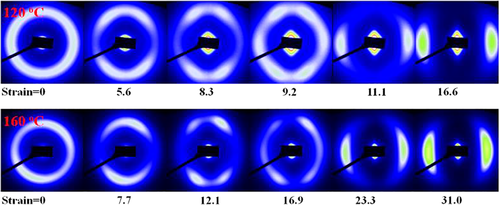

At 160°C, the selected WAXS and SAXS patterns during deformation are illustrated in Figure 4 (top). The SAXS patterns change gradually from a ring to a four-point pattern around yield region, suggesting that partial lamellar structure is fragmentized into pieces.45 Those fragmented lamellae are tilted against the stretching direction and/or has a checkerboard arrangement to minimize the stress concentration at the lamellar structure.40 Upon further deformation, the additional two arcs could be observed along the stretching direction in the SAXS patterns, indicating that the crystalline lamellae exist with the lamellar planes perpendicular to the stretching direction. The details of four-point SAXS data are important and will be discussed intensively in the later section. At this temperature, the voids induced by deformation are probably limited by the increasing mobility of chains.

As seen in Figure 4 (bottom), in the undeformed state the sample is also predominantly in α-crystal. Up on the deformation, the crystals become oriented and the diagnostic (110/200) peak of β-crystal develops. It is worth noting that the content of β-crystal keeps quite low before the strain of 80%. At 160°C, the α-β crystalline structure transformation efficiency is not as high as that at 30°C.

The insert of Figure 4 (bottom) indicates that, as strain increases, there is a small peak appears at about 25.3° which is not found at 30°C. The peak here corresponds to the layer-to-layer distance (d-spacing) of about 0.35 nm, which was close to the d-spacing (0.335 nm) of natural graphite.46, 47 In addition, at high temperature, the mechanical property of tensile sample and pure PVDF is with little difference, unlike the obvious improvement at low temperature as mentioned above. The structure information obtained by WAXS and the inconspicuous mechanical influence indicate that the compatibility of PVDF/graphene composites decreases at high temperature and the graphene is aggregated and/or separated from PVDF matrix.

3.3 Structure transformation and orientation function

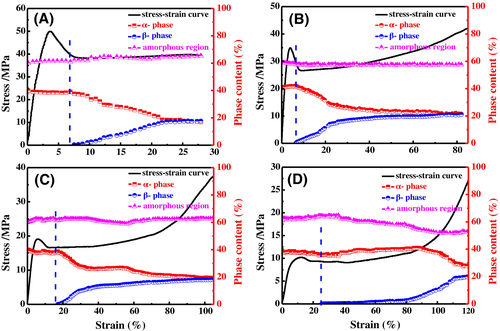

Representative examples of the crystalline content and evolution of α- and β-crystals during deformation at the four drawing temperatures are reported in Figure 5. The evolution of phase contents indicates that stretching assists in the transformation from α- to β-crystal and mixed α- and β-crystal are found to coexist after the presence of β-crystal. According to literature,25 the β-crystal develops at the expenses of pristine α-crystal crystals during the formation of fragments and fibrils rather than from the amorphous region, whose amount keeps almost unaltered.

At 30°C, before yield region, no diffraction signal from β-crystal can be detected, indicating that the structure transformation does not initiate yet. The β-crystal appears exactly after the region with negative slope. The end of negative slope is essentially the finish of mechanical yield, suggesting that the beginning of α-β crystalline structure transformation or formation of β-phase corresponds to the yield of α-crystal crystals. After that, the content of β-crystal grows distinctly along with strain, and approaches a maximum value about 20% till fracture. At 60°C, the onset and increase of α-β crystalline structure transformation are similar to 30°C, and the content of β-phase increases quite slowly after a strain of 22%. Deformations at higher temperatures show a relatively low efficiency of structure transformation. As stretching at 160°C, the content of β-crystal keeps low at the starting stage. At the stain of 80%, the content is just about 3%. After the strain of 80%, α-β crystalline structure transformation is accelerated intensively. The α-β crystalline structure transformation of stretched PVDF is normally affected by stretching temperature and rate.41 Sencadas et al.15 reported that the maximum value of the β-crystal content is obtained at 80°C with stretch ratio of 5 (while 80°C is the lowest temperature in this publication). Also they pointed out that higher stretching temperature increases chain orientation but the structure transformation is less efficient. It is generally accepted that, at high stretching temperature, the introduced stress becomes relative lower due to the high chain mobility, resulting in a lower α-β crystalline structure transformation.9, 24

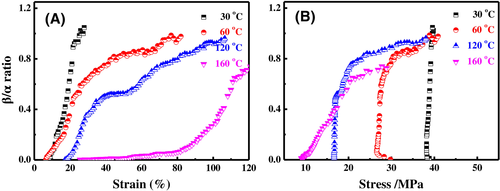

To investigate the role of strain and stress in the structure transformation, the degree of transformation (β/α ratio) as a function of strain and stress is reported in Figure 6A,B, respectively. Figure 6A shows that the transformation proceeds at relatively short strain range at 30°C. As temperature increases, the role of strain in the transformation is getting more important. At 160°C, the extremely slow growth of β/α ratio between strains of 22% to 80% could be observed. As shown in Figure 6B, the conversion from α- to β-crystal at 30°C increases without changing of stress. In the case of 160°C increasing stress promotes the growth of β/α ratio gradually. At the medium temperatures (60°C and 120°C), the β/α ratios increase immediately at first. While to reach a higher β/α ratio, extra stress is required. As deduced from the results in Figure 6, the data of conversion against strain and stress demonstrate that certain stress is necessary to trigger and enhance the α-β crystalline structure transformation. Especially, high β/α ratio is obtained only by applying sufficient stress on the sample. At high stretching temperature, the stress introduced by stretching is not high enough to make the α-crystals reorganize into β-crystal, so the α-β crystalline structure transformation is limited. As mentioned above, the phase transformation of PVDF is the transformation from a stable phase into a metastable one. Sufficient stress during deformation plays possibly an important role to provide the energy of phase transformation. Meanwhile, the stress concentration induced by defect and/or material structure is much higher than the value obtained from the strain-stress curve, providing the real driving force for the phase transformation.

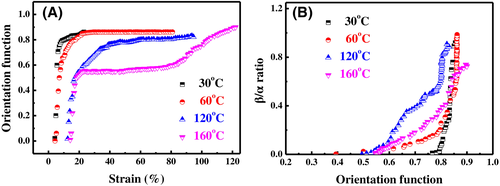

With WAXS techniques, one can study the orientation of the crystallites in semicrystalline polymers based upon the azimuthal intensity distribution along the scattering circles.48 The results for the orientation functions of the α-crystal are given in Figure 7A. At 30°C, the orientation starts after yield region and reaches a high value rapidly. Increasing temperature weakens the increase of orientation. At 160°C, the growth of orientation function gets slowed down after a strain of 20%, and gets enhanced again after a strain of 80%. Coincidently, the temperature-dependent orientation function (Figure 7A) is similar to the variation of the β/α ratio (Figure 6A) in both origin and evolution. For quantitative comparison, variation of the β/α ratio as a function of orientation function is given in Figure 7B, giving a strong correlation between the two sets of data. The result indicates that a conversion from α- to β-crystal is because of alignment induced by stretching9 and the α-β crystalline structure transformation relies on the evolution of orientation. Mohammadi et al.12 concluded that the uniaxial stress applied to PVDF films results in longitudinal deformation of chains in the crystals and induces a higher β-crystal contribution. They found that higher content of β-crystal is always found in sample with higher orientation. In Figure 7B, it is noted that there is a threshold for the onset of structure transformation. The structure transformation will not initiate until the orientation function reaches about 0.5, suggesting that considerably orientation is necessary for the chains with ability for being involved in structure transformation. Or, the β-crystal forms from the well orientated chains directly. One thing should be considered is that the orientation is possibly not a reason for the α-β crystalline structure transformation, but a symbiotic result of the applied stress. Here, the threshold of 0.5 implies a threshold of applied stress in essence. The destabilizing of α-crystal and maintaining the β-crystal is necessary to initiate the stable-metastable transformation. The threshold here indicates the necessary energy (or stress) in α-β phase transformation of PVDF.

3.4 Recrystallization and lamellar evolution

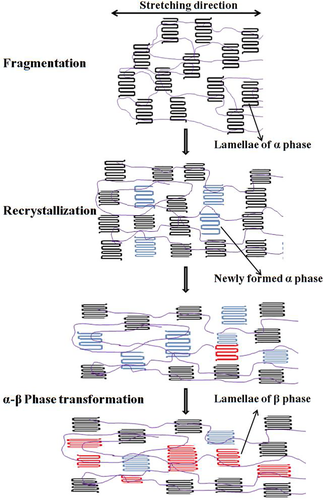

SAXS which is applicable to system exhibiting fluctuations in electron density49 provides rich information for semicrystalline polymers. The four-point pattern as mentioned previously has been reported by literatures.34, 42 Kamal et al.40 examined the lamellar and crystal structural evolution of poly(ε-caprolactone) during tensile deformation at room temperature by using SAXS and WAXS techniques and four-point scatterings and subsequently mixed six-point scatterings were observed in the SAXS patterns. According to the detailed analysis of the characteristic of the four- and six-point pattern, the melting of the pristine chain-folded lamellae and recrystallization of the chain extended fibrillar crystals during deformation was proved. In our article, a change from oblate to four-point and then to six-point patterns exhibited by the SAXS patterns is also found at 120°C and 160°C, as shown in Figure 8. The four-point pattern indicates that the lamellae in the early stages are fragmentized into pieces, and those fragmented lamellae are tilted against the stretching direction and/or had a checkerboard arrangement. This observation can be explained by assuming that lamellae which are inclined with respect to the macroscopic orientation direction are able to experience an slip, keeping some correlation within the stacks, while lamellae with their normal parallel and perpendicular to the drawing direction are frustrated, resulting in a loss of SAXS intensity.45 The subsequent formation of chain extended fibrillar crystals results in another two scattering maxima along the stretching direction. During the process of fragmentation, the chains escaped from the initial chain-folded lamellae becomes extended and crystallized into newly formed chain extended fibrillar crystals oriented along the drawing direction adding a two-point pattern.40

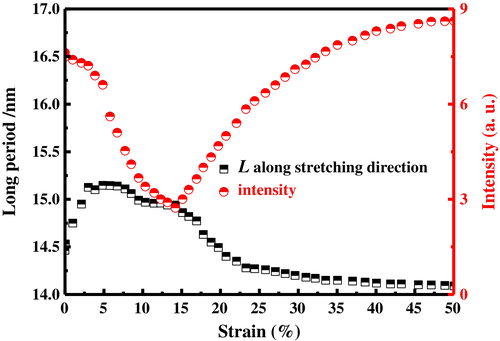

Information about changes in the lamellar structure during deformation can be extracted from the SAXS patterns.29, 31 The long period (L) is equal to the average thickness of a lamella together with one interlamellar amorphous layer measured along the lamellar normal. The L values from stretching direction were evaluated by the Bragg's law (L = 2π/qmax). For a closer look on the long period, attention is also drawn to a notable feature being the scattering intensity variation during stretching. In general, the scattering power is closely linked to the amount of the dispersed phase and the density difference between the dispersed phases and the matrix.27 Illustrated by the case of 160°C, the scattering intensity as a measure of the scattering power along stretching direction and the long period are shown in Figure 9.

Initially, there is an increase from around 14.5 to 15.3 nm in the long period, which corresponds to the increase of both lamellar and amorphous layers thickness, for that the crystallinity keeps almost unchanged (Figure 5D). Subsequently, a decrease in the long period is observed. The decrease is due to the beginning of yield region (fragmentation occurs), and the drop is accelerated at a strain of 14%. Coincidentally, scattering intensity decreases with the strain and then reaches a minimum value at a strain of about 14%. At strain >14%, the developed two-point scatterings along the stretching direction are separated from the four-point patterns, mainly resulting in the scattering intensity increase.40 The decrease in long period after strain of 14% is in line with the assumption of a fragmentation and recrystallization process occurring during tensile deformation.45 Fragmentation at 160°C reduces the growth of long period by separation of lamellae, and the additional recrystallization accelerates the decrease of long period along the stretching direction. After the strain of 22%, the decrease of long period along stretching direction gets mitigated again. It is worth noting that the four-point pattern also disappears at a strain of about 22%, indicating that the existing lamellar fragments are almost completely melted down (or highly disordered) or get full orientated. Recrystallization becomes the main role to reduce the long period in the condition of stretching. These results support that the disaggregation and recrystallization processes correspond to the four-point and additional two-point in SAXS patterns of PVDF, respectively.

As mentioned previously, the α-β crystalline structure transformation at 160°C also occurs at a strain of 22% and the yield region ends around this strain as well. Therefore, the almost melting of fragments and the steadily increasing of crystals induced by recrystallization promotes the formation of β-crystal. The β/α ratio at 160°C stays around a quite low level in a large strain range as discussed in Figure 6A, suggesting that the β-crystal is not directly formed from the recrystallization. According to literatures12, 33 which pointed that the amount of β-structure must be increased at the expense of the α-phase, the formation of β-phase at 160°C could be confirmed as a “recrystallization (α-crystal) -β-phase transformation.” Deformation of semicrystalline polymers under stretching leads to the orientation of chains and even the breakage of crystals.23 The α-crystal lamellae induced by recrystallization from the melting of lamellar fragments is chain extended fibrillar crystals which are imperfect. When the applied stress on the newly formed α-crystal reaches a certain value, the chains orientation gets enhanced. As a symbiotic result under stress, the α-β crystalline structure transformation occurs accordingly. The structure evolution discussed above is depicted in Figure 10. For convenience and intuitively, only lamellae of each phase along stretching direction are shown.

The low stress due to the high chain mobility slows down the structural evolution of PVDF at 160°C, providing a possibility to illustrate the detailed process and mechanism of α-β crystalline structure transformation. Although the α-β crystalline structure transformation is attributed to the reorganization and recrystallization of imperfect lamellae,12 structure transformation at 160°C does not take place as soon as fibrils are pulled out from the lamellae. The lamellar fragments which are also imperfect and the direct formation from recrystallization are both not the pathway to the formation of β-phase at 160°C. The β-phase originates from the recrystallization (α-crystal) under certain stress is confirmed by the structural evidence in this article. The detailed process could disturb the stable state of α-phase and provided extra energy to ensure the progressing of formation of metastable phase (β-phase). However, at 30°C, the onset of α-β crystalline structure transformation is also around the end of yield region, suggesting that the β-crystal is also from recrystallization. In the case of 30°C, the β-crystal grows rapidly along with increasing strain and the growth is independent of stress (Figure 6A,B), indicating that the stress has been above the certain threshold once the crystals meet the requirement to form β-crystal. It is difficult to figure out that whether it directly forms through recrystallization or there is still a transitory conversion from α- to β-crystal after recrystallization. Indeed, in the condition with sufficient stress, the two processes are potentially the same one.

4 CONCLUSIONS

The lamellar and crystal structural evolutions of PVDF/graphene bends at 30°C, 60°C, 120°C, and 160°C were investigated as a function of strain using scanning synchrotron WAXS and SAXS experiments. Graphene as nanofiller is beneficial to enhance the mechanical property of PVDF at 30°C and 60°C. At 160°C, the compatibility of PVDF/graphene composites decreases during deformation. The transformation from α-crystal to β-crystal is observed by uniaxial tensile deformation at all the four drawing temperatures, and the transformation is suppressed by the increase of temperature. The α-β crystalline structure transformation relies on the evolution of orientation. The mechanism that the formation of β-crystal is from deformation induced fragmentation and recrystallization under certain stress is clearly proved by structural evidence. The detailed process of α-β crystalline structure transformation at 160°C is illustrated in this article. During deformation, the stress-induced lamellar fragments are gradually recrystallized into defective α-crystal after yield region. The newly formed α-crystal is getting oriented continuously by the applied stress. When the stress exceeds a certain value, the stable α-phase is disturbed and sufficient energy to form metastable β-phase is provided, resulting in the conversion from newly formed α-crystal to β-crystal.

ACKNOWLEDGMENT

This work is supported by the National Natural Science Foundation of China (51573131, 51673147, and 21374077).

CONFLICT OF INTEREST

The authors declare no competing conflict of interest.