Isogeometric cohesive zone modeling of interfaces in reinforced concrete structures

Abstract

In reinforced concrete structures, the correct representation of the bond between concrete and reinforcement is a challenging task, since different mechanisms are acting simultaneously. On the other hand, the exact description of the reinforcement's geometry is not sufficient when using Lagrange shape functions and can additionally alter the modeling of this interaction. Isogeometric analysis enables the exact representation of complex geometries, and thus, can improve the correct description of the interface mechanisms. The concrete matrix and the reinforcement are modeled using boundary representation together with Non-Uniform Rational B-Spline (NURBS) and B-splines Scaled Boundary Isogeometric Analysis (SBIGA) which is in accordance with the modeling technique in Computer Aided Design (CAD) tools. This allows for a straightforward use of the design model in the analysis process. The interaction mechanisms between reinforcement and concrete are modeled using a zero-thickness interface in combination with a thermodynamically consistent cohesive zone model that captures the decohesion, compression and sliding effects. It includes a coupled damage-plasticity dissipation for the normal and tangential direction. The model is verified using experimental results and a comparison to the standard finite element method (FEM) is carried out in order to investigate the benefits of applying isogeometric analysis for the exact representation of the reinforcement.

1 INTRODUCTION

In the interface region between the concrete matrix and reinforcement, different mechanisms are acting that also influence one another, thus, making the correct description of the bond behavior difficult. At the same time, the use of Lagrange shape functions to describe circular or elliptical geometries, as it is common for reinforcement like steel bars, leads to higher computational cost and lower accuracy. Furthermore, since the mechanisms of the interface depend on the contact area between the concrete matrix and the reinforcement, the use of an approximation of the area instead of the exact value influences the bond behavior. In the past, cohesive zone elements have been combined with isogeometric analysis in order to take advantage of the higher continuity of NURBS basis functions [1, 2]. Furthermore, isogeometric analysis allows for the use of the exact geometry in the analysis process. Since CAD tools use a boundary representation modeling technique, that is, the solid is described solely by the boundary surfaces of the solid, the description of the concrete and reinforcement using the scaled boundary method is advantageous. Here, the cohesive zone model from Chudoba et al. [3] is combined with isogeometric analysis in order to capture the exact geometry of the interface between the concrete and reinforcement and thus, the bond behavior between these two materials. The concrete matrix and reinforcement is modeled using the Scaled Boundary Isogeometric Analysis (SBIGA).

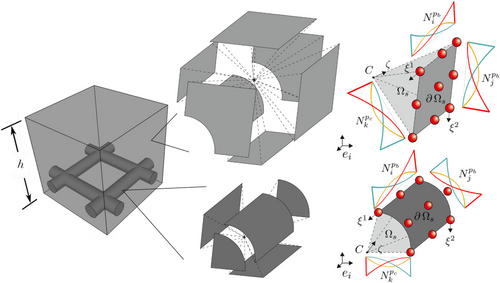

2 PARAMETRIZATION OF SOLIDS USING SBIGA

3 ISOGEOMETRIC COHESIVE ZONE MODEL

The interface between the concrete and the reinforcement is described by an isogeometric cohesive zone model.

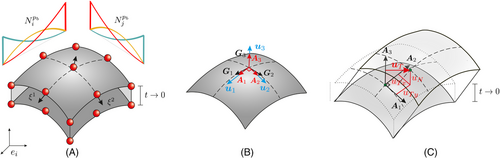

3.1 Parametrization and kinematics

3.2 Material model

4 NUMERICAL EXAMPLES

The numerical examples are used to demonstrated the capabilities of the material model.

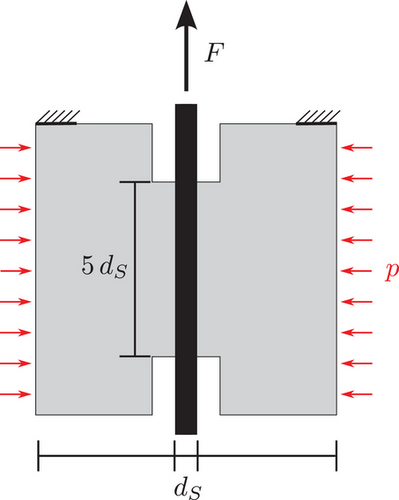

4.1 Pull-out test

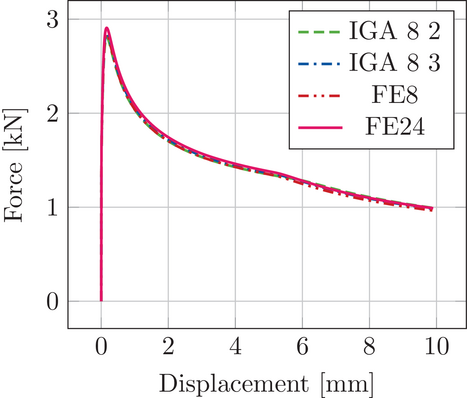

The pull-out test is intended as a first comparison of the finite element and Isogeometric Analysis (IGA) implementation of the cohesive element.

In Figure 3, the test setup is depicted. Herein, the steel bar is embedded in a concrete block. The diameter of the steel bar is (mm) and the contact length to the concrete is . For both, the concrete and steel material a linear elastic behavior is assumed. With a Young's modulus and Poisson ration of (GPa), for the steel and (GPa), for the concrete, respectively. For the cohesive element, the material parameters in tangential direction are: (MPa/mm), shear stress limit (MPa), damage energy rate scaling parameter (N/mm), damage rate exponent (-), damage accumulation exponent (-), isotropic hardening modulus (MPa/mm), kinematic hardening modulus (MPa/mm). In normal direction, the material parameters are: (MPa/mm), tensile interface strength (MPa), compressive interface strength (MPa) and (MPa), damage energy rate scaling parameter (N/mm), damage rate exponent (-), damage accumulation exponent (-). The pressure sensitivity parameter is (-).

As the test specimen is chosen such that there is barely any deformation in the concrete or the steel bar, the impact of refinement in the radial direction would not change the results. For the sake of completeness, the outer concrete is modeled with three elements in the radial direction for the Finite Element (FE) approximation, the inner concrete ring with three elements in the radial direction, and the steel bar with a three-by-three block and a surrounding lay to represent the circle. Eight elements are employed in the height direction, the area in which the steel is in contact with the concrete. For SBIGA, the outer concrete block and the steel bar were each divided into 16 patches with one element per patch, that is, eight elements in circumferential direction, two elements in height direction and one element in radial direction. The inner concrete ring was modeled using eight patches with one element per patch; thus, eight elements in circumferential direction, one element in height and radial direction.

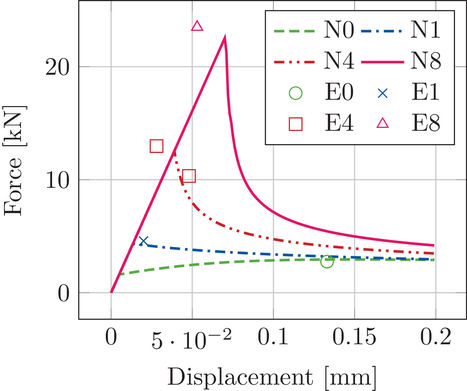

Figure 4 shows the good agreement of the IGA and FE results. In the case of IGA 8 2, with eight elements in circumferential direction of order 2, and IGA 8 3, with eight elements in circumferential direction of order 3, the results are almost identical and match with the FE results from FE8 and FE24 with 8 and 24 elements in the radial direction, respectively. This was expected, as the pull-out activates sliding in length direction of the steel bar. In this case, the IGA and FE models both approximate the geometric properties of the problem in the same way. To show the capabilities of the proposed material model, Figure 5 shows the comparison of the simulation results with the experimental data of ref. [6]. Herein, the lines are the load deflection curves of the numerical simulation and the marked points are the experimental data at the maximum loads of each individual test. The key point of this comparison is the applied pressure p to the system. The numbers indicate the pressure level: N0 means an applied pressure of (MPa), N1 of , N4 of , and N8 . The N stand for the numerical simulation and E for the experimental data. In this case the analysis is performed on material level only.

4.2 Torsion test

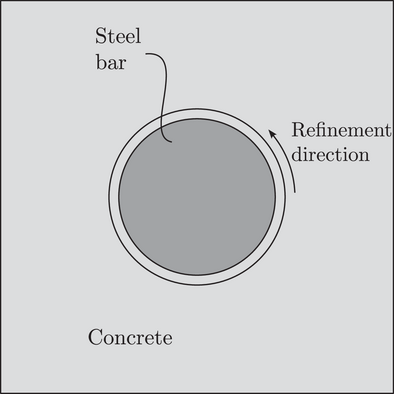

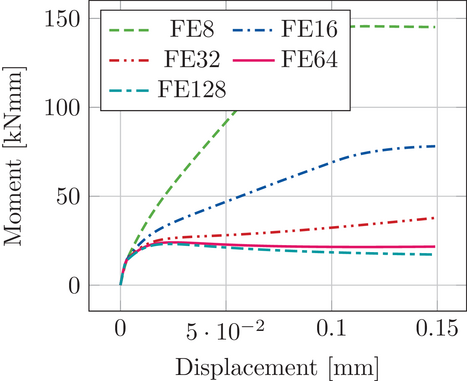

The torsion test is chosen to show the superiority of the IGA implementation of the cohesive element over the FE implementation. In this case, sliding is activated in the circumferential direction of the steel bar. As the material model is pressure dependent, only with an exact representation of the geometry, the converged results can be obtained.

The model and material parameters are the same as in the pull-out test. Only the force F is replaced by a moment M. Figure 6 shows the top-view of the system with the refinement direction of the mesh. The results of the analysis with the FE implementation of the cohesive element are shown in Figure 7. Herein, the number of elements are indicated by the numbers in the names, for example, FE8 means eight elements in circumferential direction, FE16 means 16 elements in circumferential direction and so on. A convergent behavior can be observed, but very fine meshes are needed to obtain the correct results.

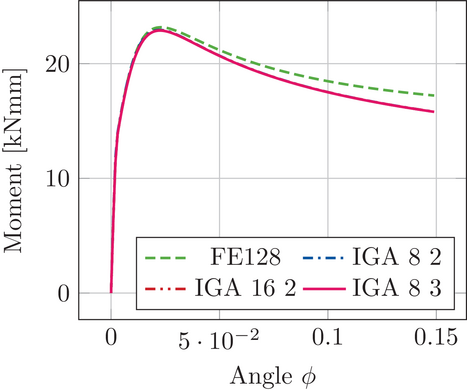

In contrast, Figure 8 shows the results of the IGA implementation of the cohesive element and compares it to the finest FE mesh (FE128). Herein, the IGA models are represented with two numbers, for example, IGA 8 2 which means eight elements in circumferential direction and an approximation order of 2 or IGA 8 3 which means eight elements in circumferential direction and an approximation order of 3 and so on. IGA 8 2 was chosen as the coarsest mesh since in SBIGA, every point of a patch has to be “visible” from the scaling center. In order to fulfill this for the inner concrete ring at least eight patches were necessary in circumferential direction. The results obtained by IGA are independent of mesh refinement and approximation order. Thus, in case of the proposed element very coarse meshes are sufficient to obtain the converged results when using IGA. Comparing the required number of equations, the IGA implementation of the cohesive element only requires 4202 equations, while the FE implementation requires 87 027 equations to get accurate results. Hence, the IGA implementation of the cohesive element is superior to the FE implementation. This example demonstrates the importance of an accurate geometry representation for the proposed material model because the results are strongly pressure dependent. Even if realistic reinforcements do not have a perfectly smooth surface, the accurate approximation drastically reduces the degrees of freedom.

5 CONCLUSIONS

In this work a cohesive zone model that considers decohesion, compression and sliding effects was combined with isogeometric analysis in order to accurately represent the bond between concrete and reinforcement. The concrete matrix and reinforcement were modeled using SBIGA, while the interface was described by an isogeometric solid element with zero thickness. The model was calibrated and validated using two examples. A comparison with the standard FEM showed that in the case were sliding occurs along the curved surface of the steel bar, the exact representation of the geometry using higher order NURBS basis functions leads to higher accuracy with less degrees of freedom. A comparison of the results from the simulation using the isogeometric cohesive zone element with experimental data from a pull-out test was made and showed good agreement. The calibration and validation of the model for carbon reinforced concrete structures within the framework of the Collaborative Research Center/Transregio 280 (SFB/TRR 280) is going to be the scope of future work. Furthermore, an incorporation of the isogeometric cohesive zone element into a scheme is planned.

ACKNOWLEDGMENTS

This research was funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation)–SFB/TRR 280. Projekt-ID: 417002380.

Open access funding enabled and organized by Projekt DEAL.