Efficient integration of deep neural networks in sequential multiscale simulations

Abstract

Multiscale computations involving finite elements are often unfeasible due to their substantial computational costs arising from numerous microstructure evaluations. This necessitates the utilization of suitable surrogate models, which can be rapidly evaluated. In this work, we apply a purely data-based deep neural network as a surrogate model for the microstructure evaluation. More precisely, the surrogate model predicts the homogenized stresses, which are typically obtained by the solution of (initial) boundary-value problems of a microstructure and subsequent homogenization. Furthermore, the required consistent tangent matrix is computed by leveraging reverse mode automatic differentiation. To improve data efficiency and ensure high prediction quality, the well-known Sobolev training is chosen for creating the surrogate model. This surrogate model is seamlessly integrated into a Fortran-based finite element code using an open-source library. As a result, this integration, combined with just-in-time compilation, leads to a speed-up of more than 6000× , as demonstrated in the example of a plate with a hole examined in this work. Furthermore, the surrogate model proves to be applicable even in load-step size controlled simulations, where it overcomes certain load-step size limitations associated with the microstructure computations.

1 INTRODUCTION

Multiscale computations often rely on finite elements for spatial discretization on both macro- and microscale, as explained, for example, in the literature [1]. However, the evaluation of heterogeneous microstructures, frequently represented using representative volume elements (RVEs), is a computationally expensive task. This evaluation typically involves solving boundary value problems (BVPs) or initial BVPs, especially when dealing with inelastic or viscous constitutive behavior, followed by a subsequent homogenization step. Recently, neural network-based surrogate models have become invaluable to substantially accelerate these computations or make them even feasible, when considering three-dimensional RVEs as well as complex constitutive or multiphysical behavior.

Machine learning methods, including deep neural networks (DNNs), have already been applied in multiscale computations, as comprehensively reviewed in the literature [2]. Among other approaches, [3] choose clustering techniques in a data-driven two-scale approach for the prediction of homogenized quantities from the microscale. An adaptive switching between the evaluation of a reduced order model and a neural network is presented by literature [4] to ensure accurate predictions. Beyond simple feedforward DNNs, as applied in this work, more complex architectures are applied to multiscale problems as well, see [5-7] and the cited references. Moreover, [8] introduced a data-driven multiscale framework coupled with autonomous data mining for multiscale computations. A current trend is the incorporation of physics into neural networks, see, exemplarily, [9, 10] and the literature cited therein, which is beyond the scope of this contribution. Moreover, Sobolev training [11], as demonstrated by literature [12], has proven to enhance the accuracy of the neural network-based surrogate models and is therefore followed also in this work together with reverse mode automatic differentiation (AD).

In this contribution, we begin by briefly summarizing the use of DNN surrogate models in sequential multiscale analyses. Afterward, the architecture and training process of a straightforward data-driven DNN surrogate is explained, which can be constructed directly from RVE evaluations, specifically homogenized stress and strain quantities. We intentionally omit the evaluation of other approaches, such as those involving the local strain-energy, as carried out, for instance, in the literature [13]. Our focus in this contribution is primarily on the efficient integration into an existing finite element code, for which a simple model is sufficient. Finally, a particular application example of a plate with a hole is studied, where non-linear elastic constitutive behavior is present in the microstructure. This example considers three key aspects: first, the prediction accuracy, second, the load-step size behavior, and third, the speed-up compared to classical concurrent multiscale FE2 computations. The novelty of this work lies in the efficient integration of a Python-based DNN surrogate model into a Fortran-written finite element code while facilitating just-in-time compilation techniques, leading to a significant speed-up compared to reference FE2 computations. Furthermore, we demonstrate the applicability of a simple data-based DNN surrogate model in load-step size controlled simulations.

Regarding the notation, column vectors and matrices at the global finite element level are symbolized by bold-type italic letters and column vectors and matrices on the local (element) level using bold-type Roman letters A. Here, microscale quantities are denoted by  . Further, calligraphic letters

. Further, calligraphic letters  denote DNN surrogate models.

denote DNN surrogate models.

2 SEQUENTIAL MULTISCALE ANALYSES WITH DEEP NEURAL NETWORK SURROGATE MODEL

In multiscale analyses, the goal is to incorporate the effective constitutive behavior of a heterogeneous microstructure into a macroscale analysis. Typically, concurrent multiscale FE2 computations are carried out as follows: first, the macroscale strains  are used to impose boundary conditions on the surface of the RVE, representing the microstructure. Subsequently, a BVP is solved on the microscale, followed by a homogenization step to obtain the macroscopic stresses

are used to impose boundary conditions on the surface of the RVE, representing the microstructure. Subsequently, a BVP is solved on the microscale, followed by a homogenization step to obtain the macroscopic stresses  and the consistent tangent

and the consistent tangent  . The notation

. The notation  denotes a quantity associated with macroscale integration point j of element e. However, the solution of the microscale BVPs can be efficiently replaced by the evaluation of a surrogate model to reduce computational costs. This leads to sequential multiscale analyses because the RVE has to be evaluated beforehand. In this context, the general assumptions still hold, that is the effective constitutive behavior has to be an intrinsic material property that is not influenced by the specific macroscale BVP. Additionally, scale separation between micro- and macroscale is assumed to use first-order homogenization. Moreover, since we apply periodic displacement boundary conditions on the RVE in this work, it is assumed that no discontinuities are present, and thus, composite phases are perfectly bonded in the microstructure. Further, it should be mentioned that we restrict ourselves to problems in the small strain domain.

denotes a quantity associated with macroscale integration point j of element e. However, the solution of the microscale BVPs can be efficiently replaced by the evaluation of a surrogate model to reduce computational costs. This leads to sequential multiscale analyses because the RVE has to be evaluated beforehand. In this context, the general assumptions still hold, that is the effective constitutive behavior has to be an intrinsic material property that is not influenced by the specific macroscale BVP. Additionally, scale separation between micro- and macroscale is assumed to use first-order homogenization. Moreover, since we apply periodic displacement boundary conditions on the RVE in this work, it is assumed that no discontinuities are present, and thus, composite phases are perfectly bonded in the microstructure. Further, it should be mentioned that we restrict ourselves to problems in the small strain domain.

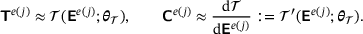

is evaluated depending on the macroscale strains

is evaluated depending on the macroscale strains  , while parametrized with the trainable parameters

, while parametrized with the trainable parameters  . The DNN outputs are the homogenized stresses

. The DNN outputs are the homogenized stresses  , which are used to employ reverse mode AD, see [14], on the surrogate model

, which are used to employ reverse mode AD, see [14], on the surrogate model  to obtain

to obtain  and predict the consistent tangent matrix

and predict the consistent tangent matrix  ,

,

(1)

(1)

In the literature [15] it was shown that employing reverse mode AD with a single neural network surrogate model to obtain  is superior to an approach that uses two separate neural networks for predicting

is superior to an approach that uses two separate neural networks for predicting  and

and  independently.

independently.

3 DEEP NEURAL NETWORK SURROGATE MODEL

In this work, we restrict ourselves to two-dimensional examples in the small strain domain, that is the macroscale strains  ,

,  , is the vector of input quantities for the surrogate model and the output quantities are

, is the vector of input quantities for the surrogate model and the output quantities are  ,

,  and

and  . Here, the strains and stresses can be arranged in column vectors since the corresponding tensors are symmetric in the small strain case. Furthermore, the coefficients of the consistent tangent matrix, which is here a symmetric 3 × 3 matrix, are compiled in a column vector as well,

. Here, the strains and stresses can be arranged in column vectors since the corresponding tensors are symmetric in the small strain case. Furthermore, the coefficients of the consistent tangent matrix, which is here a symmetric 3 × 3 matrix, are compiled in a column vector as well,  .

.

The DNN surrogate model is developed by drawing on two different frameworks, TensorFlow [16] and JAX [17]. The data for the surrogate modeling is generated by performing RVE computations with different prescribed macroscale strains that are generated by Latin hypercube sampling [18]. Thereby, particular symmetry relations of the constitutive models, which are applied in the RVE, are employed leading to an essential reduction of the required RVE computations for the data generation. We refer to [15] for further details regarding the data generation. The macroscale strains are restricted to a domain of  as maximum strain for each strain component. Further, the inputs and outputs of the model are scaled with their mean and standard deviation to obtain efficient training. There, the scaling of the consistent tangent output has to retain the relationship between consistent tangent and homogenized stress.

as maximum strain for each strain component. Further, the inputs and outputs of the model are scaled with their mean and standard deviation to obtain efficient training. There, the scaling of the consistent tangent output has to retain the relationship between consistent tangent and homogenized stress.

, the number of neurons per each hidden layer

, the number of neurons per each hidden layer  , and the activation function) on the performance of the model is investigated. A summary of the obtained results is reported in Table 1 only for three different sizes of the DNN with swish activation function, for the sake of brevity. Based on the results, we choose a DNN architecture of eight hidden layers, each with 128 neurons and employing the swish activation function. The weights and biases are initialized by drawing on the Glorot uniform algorithm [19]. The training is done with 80% of the data for training and 20% for validation, using the Adam optimizer [20]. Here, different sizes of the dataset containing 103 to 106 samples are chosen. The training is done for 4000 epochs with an exponential decay of the learning rate η, which is initially chosen to

, and the activation function) on the performance of the model is investigated. A summary of the obtained results is reported in Table 1 only for three different sizes of the DNN with swish activation function, for the sake of brevity. Based on the results, we choose a DNN architecture of eight hidden layers, each with 128 neurons and employing the swish activation function. The weights and biases are initialized by drawing on the Glorot uniform algorithm [19]. The training is done with 80% of the data for training and 20% for validation, using the Adam optimizer [20]. Here, different sizes of the dataset containing 103 to 106 samples are chosen. The training is done for 4000 epochs with an exponential decay of the learning rate η, which is initially chosen to  . The decay step is 1000 and the decay rate

. The decay step is 1000 and the decay rate  . The dataset is decomposed to obtain 100 batches and the mean squared error is selected for the loss function,

. The dataset is decomposed to obtain 100 batches and the mean squared error is selected for the loss function,

(2)

(2) and

and  denote the weighting factors for the two loss components of the predicted stresses and consistent tangent, respectively. Note that we track the validation loss during the training process and select the model parameters based on the lowest validation loss to avoid overfitting. The DNN surrogate model is implemented into the MPI-parallelized FORTRAN in-house code TASAFEM using the FORPy library [21]. It should be noted that utilizing more sophisticated DNN models, for example physics-informed NNs, see [10], could improve the performance of the model. However, here we focus more on developing an efficient framework for integrating DNN models into finite-element codes for sequential multiscale simulations by employing modern scientific computing tools such as just-in-time compilation and efficient FORTRAN-Python communication. Further, we show the applicability of our framework for load-step size controlled simulations in the following numerical example.

denote the weighting factors for the two loss components of the predicted stresses and consistent tangent, respectively. Note that we track the validation loss during the training process and select the model parameters based on the lowest validation loss to avoid overfitting. The DNN surrogate model is implemented into the MPI-parallelized FORTRAN in-house code TASAFEM using the FORPy library [21]. It should be noted that utilizing more sophisticated DNN models, for example physics-informed NNs, see [10], could improve the performance of the model. However, here we focus more on developing an efficient framework for integrating DNN models into finite-element codes for sequential multiscale simulations by employing modern scientific computing tools such as just-in-time compilation and efficient FORTRAN-Python communication. Further, we show the applicability of our framework for load-step size controlled simulations in the following numerical example. |

|

|

|

|

Training time (min.) |

|---|---|---|---|---|---|

| 32× 2 | 1.81 |

1.79 |

3.07 |

2.98 |

10.9 |

| 64× 4 | 3.74 |

4.28 |

1.29 |

1.28 |

14.5 |

| 128× 8 | 3.78 |

3.55 |

3.02 |

2.97 |

31.2 |

- Note: Results are reported for models with swish activation function. A dataset with the size of 105 is employed for training.

4 NUMERICAL EXAMPLE

The framework explained earlier, which utilizes a DNN surrogate model to predict the homogenized stress  and consistent tangent matrix

and consistent tangent matrix  , is employed to analyze the mechanical response of a two-dimensional plate with a hole subjected to shear load. Here, we focus on three aspects: the prediction quality using the DNN, the load step-size behavior in load-step controlled simulations, and the speed-up.

, is employed to analyze the mechanical response of a two-dimensional plate with a hole subjected to shear load. Here, we focus on three aspects: the prediction quality using the DNN, the load step-size behavior in load-step controlled simulations, and the speed-up.

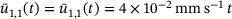

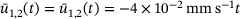

4.1 Problem setup

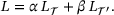

The macroscale geometry for the numerical example is shown in Figure 2A.

and

and  . The plate is discretized using eight-noded quadrilateral elements, leading to

. The plate is discretized using eight-noded quadrilateral elements, leading to  elements and

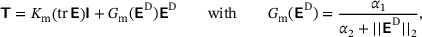

elements and  nodes. In the analysis, a plane strain state is assumed. The corresponding RVE is depicted in Figure 2B and comprises matrix material and fiber sections. The matrix material is modeled with a non-linear elasticity relation,

nodes. In the analysis, a plane strain state is assumed. The corresponding RVE is depicted in Figure 2B and comprises matrix material and fiber sections. The matrix material is modeled with a non-linear elasticity relation,

(3)

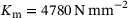

(3) and the parameters

and the parameters  and

and  are the material parameters of the matrix material.

are the material parameters of the matrix material. denotes the deviatoric strains and

denotes the deviatoric strains and  represents the Euclidean norm. In contrast, the fibers are assumed to be linear elastic with bulk modulus

represents the Euclidean norm. In contrast, the fibers are assumed to be linear elastic with bulk modulus  and shear modulus

and shear modulus  . The RVE is spatially discretized with

. The RVE is spatially discretized with  eight-noded quadrilateral elements and

eight-noded quadrilateral elements and  nodes.

nodes.

4.2 Prediction quality

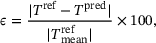

(4)

(4) is the corresponding stress quantity for a reference FE2 solution and

is the corresponding stress quantity for a reference FE2 solution and  represents the prediction from the DNN surrogate model. Since some of the stresses are zero, we use

represents the prediction from the DNN surrogate model. Since some of the stresses are zero, we use  as the mean value of the stresses in the reference solution to obtain a relative error measure. Results are summarized in Table 2 for different sizes of the training/validation dataset

as the mean value of the stresses in the reference solution to obtain a relative error measure. Results are summarized in Table 2 for different sizes of the training/validation dataset  , where

, where  and

and  indicate the mean and the standard deviation of the absolute percentage error ε over all the integration points and stress components. It can be observed that the DNN model trained on a dataset with only 103 samples can provide very accurate results with

indicate the mean and the standard deviation of the absolute percentage error ε over all the integration points and stress components. It can be observed that the DNN model trained on a dataset with only 103 samples can provide very accurate results with  and

and  of around 1%. Moreover, the error is decreased by employing a larger dataset for training and validation. In the following, we will focus on the results obtained from the DNN model trained on the dataset with

of around 1%. Moreover, the error is decreased by employing a larger dataset for training and validation. In the following, we will focus on the results obtained from the DNN model trained on the dataset with  of 105.

of 105. |

(%) (%) |

(%) (%) |

|---|---|---|

| 103 | 1.08 | 1.14 |

| 104 | 0.14 | 0.13 |

| 105 | 0.04 | 0.03 |

| 106 | 0.02 | 0.03 |

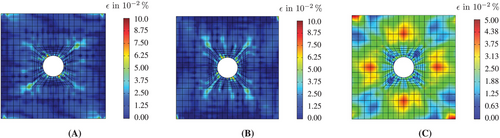

The absolute percentage errors for the predicted stresses are shown in Figure 2 for the final evaluation time of the applied load. Apparently, the DNN surrogate model is able to precisely predict the stresses in the present example, with the maximum error in the stresses being about 0.10%. As depicted in Figures 3A,B, the absolute error across a large domain is below 0.01%, with only a few integration points in the vicinity of the hole exhibiting slightly larger errors in the normal stresses. However, it is worth mentioning that the prediction of the shear stress τ12 is less accurate compared to σ11 and σ22. This discrepancy could be attributed to the geometry of the RVE and the different stiffness of the constituents, which results in higher differences in the orders of magnitude for stresses and components of the consistent tangent matrix when subjected to shear load. Similar behavior has been previously reported for different macroscale problems in the literature [15].

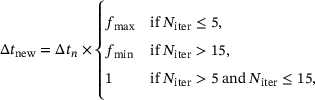

4.3 Load-step size behavior

FE2 computations usually utilize a load-step control since the initial load-step (or time-step, respectively) size is often very small to avoid convergence issues. Therefore, it is essential to investigate the performance of the DNN surrogate model in step-size controlled computations.

s is selected. The incremental application of the prescribed load, which can be interpreted as time integration, is performed using the Backward-Euler method. The system of linear equations arising in non-linear elastic finite element computations can be formally extended with

s is selected. The incremental application of the prescribed load, which can be interpreted as time integration, is performed using the Backward-Euler method. The system of linear equations arising in non-linear elastic finite element computations can be formally extended with  to obtain a system of differential-algebraic equations as it is common in computations dealing with inelastic or viscous constitutive behavior. The determination of the time-step size for the next time-step

to obtain a system of differential-algebraic equations as it is common in computations dealing with inelastic or viscous constitutive behavior. The determination of the time-step size for the next time-step  is based on the number of global Newton iterations

is based on the number of global Newton iterations  and the current time-step size

and the current time-step size  ,

,

(5)

(5) and

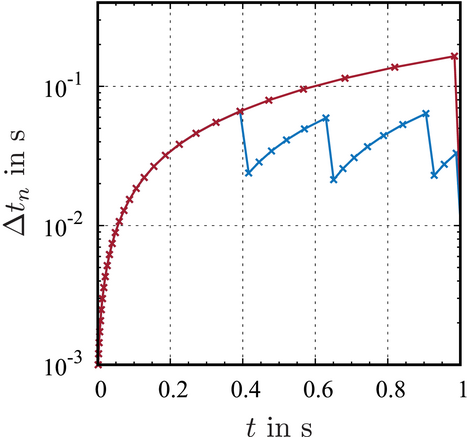

and  . The step-size behaviors for reference FE2 computation and the multiscale computation using a DNN surrogate model are shown in Figure 4.

. The step-size behaviors for reference FE2 computation and the multiscale computation using a DNN surrogate model are shown in Figure 4.

In this specific example, the initial time-step size  is suitable for both methods. Moreover, both methods exhibit a similar behavior in the first iterations. However, the reference FE2 computation shows a certain limit for the time-step size

is suitable for both methods. Moreover, both methods exhibit a similar behavior in the first iterations. However, the reference FE2 computation shows a certain limit for the time-step size  at around

at around  s, which appears due to non-convergence of the RVE computations for certain load-increments. In contrast, the evaluation of the DNN surrogate model allows a continuously increasing time-step size. Thus, the application of a DNN surrogate model for the microscale evaluations even extends the applicable time-step sizes, at least for the non-linear elastic problem studied here.

s, which appears due to non-convergence of the RVE computations for certain load-increments. In contrast, the evaluation of the DNN surrogate model allows a continuously increasing time-step size. Thus, the application of a DNN surrogate model for the microscale evaluations even extends the applicable time-step sizes, at least for the non-linear elastic problem studied here.

4.4 Speed-up

of the reference FE2 simulation by that of the multiscale simulation with DNN surrogate

of the reference FE2 simulation by that of the multiscale simulation with DNN surrogate  ,

,

(6)

(6)5 CONCLUSIONS

As it is well-known, (deep) neural network surrogate models can significantly reduce the computational expenses of multiscale computations. In this contribution, an efficient integration of such a DNN surrogate model into an existing finite element code is explained, utilizing the open-source library FORPy [21] for Fortran-Python interoperability. This integration already results in a speed-up of around 500× for the specific example of a plate with a hole. Furthermore, using just-in-time compilation has significantly increased the speed-up to around 6000× . In load-step size controlled simulations, where non-linear elastic material behavior is present in the microstructure, it is observed that the surrogate model can overcome specific step-size limitations inherent in the RVE computations. Therefore, the use of a DNN surrogate model can even extend the feasible load-step sizes for multiscale computations.

ACKNOWLEDGMENTS

Hamidreza Eivazi's research was conducted within the Research Training Group CircularLIB, supported by the Ministry of Science and Culture of Lower Saxony with funds from the program zukunft.niedersachsen of the Volkswagen Foundation.

Open access funding enabled and organized by Projekt DEAL.

: An efficient data-driven multiscale approach based on physics-constrained neural networks and automated data mining

: An efficient data-driven multiscale approach based on physics-constrained neural networks and automated data mining