Effects of sterilization temperature on the concentration of ethyl carbamate and other quality traits in Chinese rice wine

Abstract

Ethyl carbamate (EC), which is present in Chinese rice wine, has a large potential for carcinogenicity and genotoxicity. EC is produced during the process of rice wine fermentation and storage. High concentrations of precursors, as well as high temperatures, will significantly accelerate the formation of EC. The present work aims to reduce EC formation by optimizing the production process, especially the boiling procedure. With various boiling sterilization temperatures, EC accumulated to different concentrations but the lower the temperature, the less EC was formed. To preserve the quality traits of Chinese rice wine, including biological and non-biological stability, as well as the sugar component, an 80°C boiling temperature is suggested. The present study provides direction for process optimization, which combined with improved production technology and metabolic engineered yeast strains, can reduce the content of EC in Chinese rice wine. Copyright © 2014 The Institute of Brewing & Distilling

Introduction

Chinese rice wine is a famous traditional fermented alcoholic beverage with 4000 years of history 1. It is typically fermented from steamed glutinous rice with yeasts and ‘wheat Qu’ (made from raw wheat and naturally inoculated with moulds, bacteria and yeast) 2. The function of ‘wheat Qu’ is partially equivalent to that of ‘koji’ in sake, another ancient alcoholic beverage that originated in Japan 3. The quality traits of Chinese rice wine depend mainly on the raw materials, yeast strains, brewing conditions and maturation conditions. Owing to its unique aroma, subtle flavor and low alcoholicity, Chinese rice wine is widely consumed with an annual consumption of more than 2 million tons 3. However, the traditional complex fermentation process of the famous Chinese rice wine has generated attention regarding safety problems. Amongst potentially harmful by-products 4, 5, EC (ethyl carbamate), a well-known carcinogen and genotoxin widespread in fermented foods and beverages, is believed to be very harmful to human health 6, 7. A survey by Wu et al. 8 showed that Chinese rice wine contained up to 515 µg L−1 with an average of 160 µg L−1 of EC.

Based on previous research work, EC can be formed from various precursors, such as urea, citrulline and N-carbamyl compounds by the spontaneous reaction with ethanol, and urea is the most important EC precursor in Chinese rice wine 6. The rate of formation and final yield of EC are dependent upon the transfer of the carbamyl moiety in complex solutions and the presence or absence of competing acceptor molecules 9. In addition, several studies have shown that high temperature, as well as high concentrations of ethanol, urea and citrulline, will significantly accelerate the formation of EC 10, 11. Owing to the increasingly recognized harm of EC to human health, a large amount of effort has been undertaken to eliminate it, including yeast metabolic engineering 12, 13, high effective acid urease exploration 14, 15, the refining of raw materials and manufacturing process optimization 6.

During Chinese rice wine production, there is one heat treatment step, ‘the wine boiling sterilization process’, which takes place at 85–95°C followed immediately by jar filling 11. This boiling sterilization process helps raw rice wine maturation, removes volatile harmful compounds, especially aldehydes, benefits biological stability, and enhances the non-biological stability, avoiding haze formation. The boiling temperature is set according to the rice wine type. Higher temperatures (90–95°C) are used for low-sugar rice wines, while lower boiling temperatures (85–90°C) are used for rice wines with a higher sugar content, to avoid melanoidin formation from sugars and amino acids. However, the high temperature of the boiling sterilization process offers a high risk of EC accumulation. To preserve the quality traits of Chinese rice wine, an optimized boiling process for the rice wine industry was investigated in the present study, where the effects of a series of boiling temperatures (75, 80, 85, 90 and 95°C) on EC formation were tested.

Materials and methods

Chinese rice wine samples and chemicals

Raw Chinese rice wine samples were provided by Guyuelongshan (a famous Chinese rice wine manufacturer in Shaoxing, Zhejiang Province, China) as soon as fermentation ended. The rice wine samples were heated at a series of boiling temperatures (75, 80, 85, 90 and 95°C) for 30 min and then immediately cooled to 20°C.

EC and N-butyl carbamate (nBC) standards (ACS reagent) were purchased from Sigma-Aldrich (St Louis, MO, USA).

EC determination with GC/MS

The EC concentration in the heat treated rice wine samples was determined according to the method described by Wang et al. 16. Briefly, 2 mL of rice wine sample was homogenized with 400 μL of nBC (2.0 mg L−1), which was dissolved in methanol and used as the internal standard. After that, 0.3 g of sodium chloride was added to promote the vaporization of EC in the sample. The mixture was then subjected to a diatomite SPE column (CNWBOND Celite 545/Na2SO4, Shanghai ANPEL Scientific Instrument Co. Ltd) for 20 min until the liquid was adequately absorbed. Finally, the sample was eluted with 10 mL of a 5% ethyl acetate-diethyl ether solution (5 mL ethyl acetate in 95 mL diethyl ether) and then evaporated with nitrogen gas to an approximate volume of 1 mL before GC/MS analysis.

The EC determination was performed with a GC/MS system of Shimadzu QP2010Ultra using RTX-wax column (30 m × 0.25 mm × 0.25 µm, Shimadzu, Japan) with the following conditions: splitless injection with 1 μL of sample at an injection temperature of 220°C. The carrier gas was helium at a constant flow rate of 1 mL min−1. The oven temperature was programmed from 50°C (1 min) to 180°C with a heating ramp of 8°C min−1, and then to 240°C (6 min) with a heating ramp of 10°C min−1. The MS transfer line ion source temperature was 230°C. The mass spectrometer was operated in electron ionization mode at 70 eV. Analysis was performed in selected ion monitoring mode. The signals at m/z 62 were used for quantification, and the signals at m/z 62, 74 and 89 were used for confirmation.

Detection of biological stability

Ten millilitres of the rice wine sample was serially diluted (10−1, 10−2, 10−3, 10−4, 10−5) with sterilized water. From each diluted sample, 0.1 mL was spread onto the Potato Dextrose Agar medium (PDA), Luria-Bertani medium (LB) and MRS medium plates and cultured at the aforementioned temperature for 2–3 days to detect fungi, bacteria and lactic acid bacteria, respectively.

Determination of soluble proteins, haze-active proteins and polyphenols

The soluble proteins in the heated rice wine samples were expressed as total nitrogen content using the Kjeldahl method 17. Ten millilitres of rice wine sample was mixed with 1 mL of concentrated sulfuric acid and charred at 220°C for 30 min using a digestion furnace supplied by Foss Scino (Suzhou, China). Five grams of copper (II) sulfate and potassium sulfate (3:100, w/w) as catalyst were added to the mixture, and then 15 mL of sulfuric acid (98.3% w/w) for digestion at 420°C for 2 h. Nitrogen determination was with a Kjeldahl apparatus KT260 distillation unit (Foss Scino, Suzhou, China). For middle molecular weight nitrogen determination, 20 mL of rice wine sample was mixed with 20 mL of sterilized water and 1 mL of sulphuric acid (50% w/w), and then incubated at 20°C for 20 min, followed by addition of 2.5 mL of tannin (16% w/v). The treated sample was then made up to the volume of 50 mL and filtered, and 10 mL was used for the nitrogen determination as described above. For low-molecular-weight nitrogen determination, the rice wine sample was treated with a similar process, except that 15 mL of sterilized water and 2.5 mL of sodium molybdate (50% w/v) were added to the original sample.

The content of haze active proteins was expressed as the changes in turbidity after a series of tannin amounts (2.5, 5.0 and 10.0 mg L−1) were added to rice wine samples. The concentration of haze active polyphenols was expressed as the increase in turbidity with the addition of 0.4 g L−1 polyvinylpyrrolidone. The turbidity of the rice wine sample was determined by the OrionTM AQ4500 Turbidimeter (ThermoFisher Scientific, Franklin, MA, USA).

Sugar content determination

Sugar content in the rice wine samples was determined using the Lane Eynon method according to GB/T 13662-2008 of Chinese Rice Wine National Standards.

Results and discussion

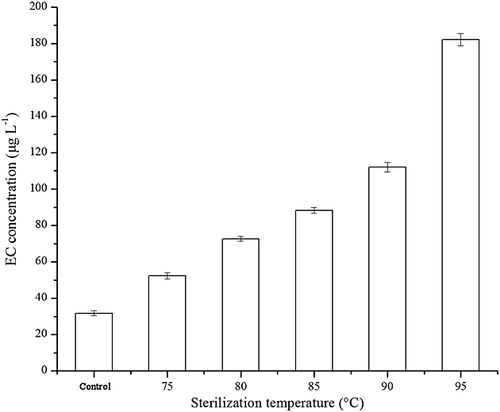

Effects of sterilization temperature on EC formation

It has been found that controlling the fermentation temperature is useful to reduce EC formation during fermentation and storage. The lower temperature could inhibit the growth of lactic acid bacteria and malolactic fermentation, leading to a 10-fold change in EC formation rate 10. Similar results could be obtained in rice wine 11. In addition to the fermentation temperature, the high temperature during wine boiling is also an important target for process optimization to reduce EC concentration. Consistent with previous studies, the data in the present study showed that the rate of EC formation increased with boiling temperature. Before boiling, the EC concentration in the raw Chinese rice wine sample was 31.7 µg L−1. After sterilization at various temperatures from 75 to 95°C, EC accumulated to various degrees, with final EC concentrations of 52.3 ± 1.62 to 182 ± 3.4 µg L−1 (Fig. 1). The lower the sterilization temperature, the less EC accumulated during the heat treatment of the Chinese rice wine. With a boiling temperature <85°C, the EC concentration in the fresh rice wine was below the health value limit of 100 µg L−1 (the limit in the Canadian Regulations), although EC will be formed further during storage of the wine. Therefore, it is suggested that the wine boiling sterilization temperature be decreased in order to reduce the EC concentration, while keeping the other quality traits of the Chinese rice wine.

Effects of sterilization temperature on biological stability

One of the significant functions of the wine boiling treatment is sterilization. Therefore, the biological stability should be evaluated when decreasing the wine boiling temperature. Before sterilization, large numbers of microorganisms were present in the raw rice wine (0.79 × 104 of bacteria and 0.60 × 104 of fungi). For bacteria, the thermal death condition is 63–100°C for 5–30 min. To kill fungi, treatment at 55–70°C for 2–15 min is required. Therefore, the boiling temperature chosen was 75–95°C with 5°C increments. As shown in Table 1, heat treatment >80°C for 30 min was lethal to all fungi and bacteria tested for with the three media. However <80°C, several species of fungi and bacteria could survive the heat treatment. Therefore, the results suggest that the wine boiling temperature should not be decreased <80°C.

| Boiling temperature (°C) | Bacteria (CFU mL−1) | Fungi (CFU mL−1) |

|---|---|---|

| Control | 0.79 × 104 | 0.60 × 104 |

| 95 | 0 | 0 |

| 90 | 0 | 0 |

| 85 | 0 | 0 |

| 80 | 0 | 0 |

| 75 | 5 | 3 |

Effects of sterilization temperature on non-biological stability

Because of the different manufacturing process of Chinese rice wine from that of other alcohol beverages, the source of haze active protein and the mechanism of haze formation are still unclear. Therefore, the best way to maintain the non-biological stability of Chinese rice wine is to maintain a suitable Lundin fraction of total proteins and to induce haze formation and natural sedimentation of haze active material by heat treatment 18. By changing the boiling temperature, there was no significant difference in the content of haze active proteins and polyphenols among the various heat-treated rice wine samples (Table 2), nor the Lundin fraction of total proteins (Table 3). Therefore, it is suggested that all of the wine boiling temperatures are suitable for removing most of the haze-active materials.

| Boiling temperature (°C) | Haze active polyphenols (EBC units) | Haze active proteins (EBC units ) |

|---|---|---|

| 95 | 0.13 ± 0.04 | 0.57 ± 0.09 |

| 90 | 0.11 ± 0.02 | 0.51 ± 0.07 |

| 85 | 0.12 ± 0.01 | 0.56 ± 0.04 |

| 80 | 0.12 ± 0.03 | 0.54 ± 0.08 |

| 75 | 0.11 ± 0.01 | 0.55 ± 0.06 |

| Boiling temperature (°C) | TNa (mg L−1) | HWNa (mg L−1/%b) | MWNa (mg L−1/%b) | LWNa (mg L−1/%b) |

|---|---|---|---|---|

| 95 | 2047 | 1068 ± 102/52.2 | 156 ± 24/7.6 | 823 ± 53/40.2 |

| 90 | 2017 | 1051 ± 97/52.1 | 150 ± 13/7.4 | 816 ± 47/40.4 |

| 85 | 2032 | 1037 ± 84/51.0 | 123 ± 8/6.1 | 872 ± 36/42.9 |

| 80 | 2047 | 1072 ± 110/52.4 | 145 ± 20/7.1 | 829 ± 34/40.5 |

| 75 | 2011 | 1025 ± 76/51.0 | 166 ± 21/8.3 | 820 ± 29/40.7 |

- a TN, total nitrogen; HWN, high-molecular-weight nitrogen; MWN, medium-molecular-weight nitrogen; LWN, low-molecular-weight nitrogen.

- b The percentage of HWN or MWN or LWN in TN.

| Boiling temperature (°C) | Sugar content (mg L−1) |

|---|---|

| 95 | 27.35 ± 2.87 |

| 90 | 27.56 ± 3.44 |

| 85 | 26.82 ± 5.01 |

| 80 | 27.42 ± 3.21 |

| 75 | 26.18 ± 4.32 |

Effects of sterilization temperature on sugar contents

The high temperature during wine boiling sterilization will also affect the sugar content, which is an important quality feature of Chinese rice wine. The results showed that the content of sugars in the Chinese rice wine samples that were heat treated at various temperatures were altered <5%, indicating that a decreased boiling temperature for EC reduction could be used (Table 4).

Conclusions

In the present work, the possibility of reducing the wine boiling temperature for EC elimination was examined by inspecting the effects of various boiling temperatures on EC concentration and on the other quality traits of Chinese rice wine. The results suggest that 80°C is the minimum boiling temperature that can keep EC formation at a comparatively lower rate without changing the sugar content or the biological and non-biological stability. Since most of the EC is generated during the processes of wine boiling, jar-filling and storage, more efforts should be engaged in the strict control of time and temperature in the above processes. Combined with improved production technology and metabolically engineered strains that produce fewer EC precursors, the EC could be reduced to a safer level in Chinese rice wines.

Acknowledgements

This research was supported by the Major State Basic Research Development Program of China (973 Program, 2012CB720802 and 2013CB733602), the National Natural Science Foundation of Jiangsu Province, China (BK20140144), the Key Program of National Natural Science Foundation of China (31130043), the Open Project of Key Laboratory of Industrial Biotechnology, Ministry of Education, Jiangnan University (KLIB-KF201308) and the Program of Introducing Talents of Discipline to Universities (111 Project, 111-2-06).