Advancements in Self-Compacting Concrete Reinforced With Basalt Fiber: A Comprehensive Review

Funding: The work was supported by the Vellore Institute of Technology, Vellore, for providing the necessary resources to ensure the completion of this paper; however, no funding was provided for the same.

ABSTRACT

In recent years, the incorporation of fibers into self-compacting concrete has garnered significant attention in addressing various issues. Among the different types, basalt fiber stands out due to its excellent mechanical properties, high tensile strength, and resistance to alkali and acidic environments. This review paper addresses the impact of basalt fiber on fresh, mechanical, microstructural, and durability properties of self-compacting concrete. It's been noted that a significant amount of research is still being conducted on using basalt fiber. This work states the basalt fiber's chemical compositions, which are crucial in its applications. Based on the literature, it has been cited that the optimum dosage of the fiber is different for the compression and tensile loads on the concrete specimens. This work actively explores basalt fiber's potential in various concrete applications. The discussion emphasizes the chemical composition and optimal dosage of basalt fiber in self-compacting concrete and underscores the importance of further research in this area. Finally, this paper recommends other studies to understand the keen effect of basalt fiber in self-compacting concrete.

1 Introduction

Self-Compacting Concrete (SCC) has become a globally attractive material due to its practical applications that offer unique advantages. It can flow and consolidate on its own, making it ideal for practical situations with small member cross-sections, densely and congested reinforced sections, and more. However, challenges such as reduced mechanical properties and susceptibility to cracking have prompted research into enhancing its performance. Additionally, like regular concrete, SCC is brittle, and SCC requires more binder and powder content than regular concrete. As a result, the demand for cement is higher, making it a less eco-friendly material.

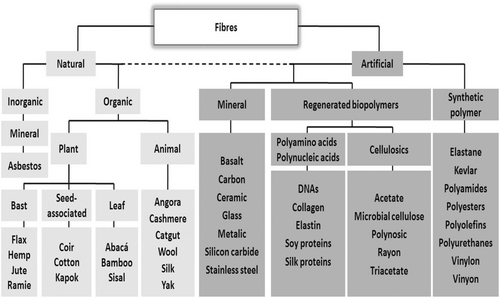

To reduce the negative adverse environmental effects without compromising the demands of the construction industry, researchers introduced materials that possess binding properties and are collectively known as supplementary cementitious materials (SCMs). Extensive work was conducted to assess the compatibility of the materials in concrete and tackle the obstacles by using SCM. Improvements in fresh, mechanical, and durability aspects were noticeable. However, these materials are not significant in providing the ductile nature of SCC. This phenomenon has been achieved using different types of fibers (Figure 1), namely steel fiber, carbon fiber, glass fiber, polypropylene fiber, etc. In addition to fibers, certain waste materials can be processed into fibers and construction materials to substitute coarse and fine aggregates. One such material is PET, which is derived from plastic waste. The disposal of plastic waste poses environmental hazards, yet it can be repurposed for construction activities to mitigate ecological impacts. Plastic waste can be incinerated and molded into various forms. Incorporating such molded waste materials into concrete enhances its properties and renders it environmentally friendly [2]. Further, most of these fibers are artificial, and their manufacturing necessitates additives and leaves chemicals in the environment, resulting in environmental deterioration.

In the present day, it is crucial to adopt a sustainable approach that encompasses the entire lifecycle of materials, from their creation to their disposal. Due to this, there is a growing shift toward using natural fibers in various industries, including construction practices. The use of basalt fiber in SCC has been the subject of relatively few studies. Given the eco-friendly concept, natural fibers are preferred as they are more environmentally friendly and compatible with the cement matrix [3]. Some natural fibers tend to absorb water, which can further decrease water availability in the cement matrix. Among these, basalt fiber stands out with its higher chemical and thermal resistance and good strength [4]. A study on the impact of basalt fiber in a UHPC matrix with waste glass powder revealed a substantial enhancement in the mechanical properties of the UHPC with the fiber [5]. This study observed the compatibility of basalt fiber with waste materials. Hence, developing the efficient concrete material which could be named as green concrete. This eco-friendly material holds great promise for use in concrete, aiming to produce fiber-reinforced concrete, polymers, and similar materials.

According to the sources cited in this article, this investigation provides credible data regarding the impact of basalt fiber in SCC. In the next section (Section 2) of this paper provides an overview of the extraction process of basalt fiber is provided, shedding light on its production and properties. The influence of incorporating basalt fiber on the fresh properties of self-compacted concrete and a detailed analysis of its impact on workability and flowability are discussed in Section 3. Following this, the hardened properties of SCC reinforced with basalt fiber are compared and examined for their influence on strength, durability, corrosion, and resistance to cracking. The last section briefs the microstructural analysis of such concrete.

This paper provides insightful data regarding basalt fiber reinforcement in concrete composites. A comprehensive literature review has been conducted, analyzing and presenting the manufacturing process of basalt fiber and its impact on concrete composites. At the outset, this provides knowledge on the optimum dosage of basalt fiber for concrete composites and the effect of the basalt fiber's properties on the performance of concrete composites. Thus, these findings pertain to the impact on fresh properties, mechanical properties, and the durability aspect of the SCC reinforced with basalt fiber. The potential use of basalt fiber in structural performance has been examined and described in the current work.

2 Basalt Fiber

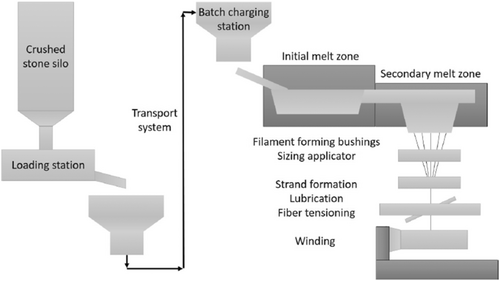

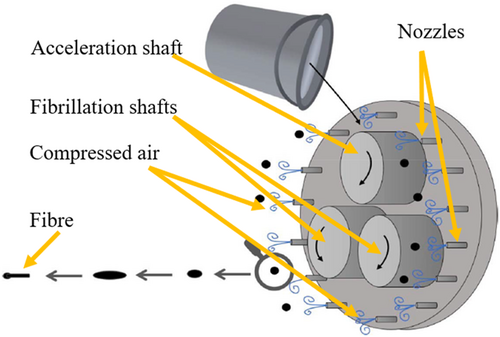

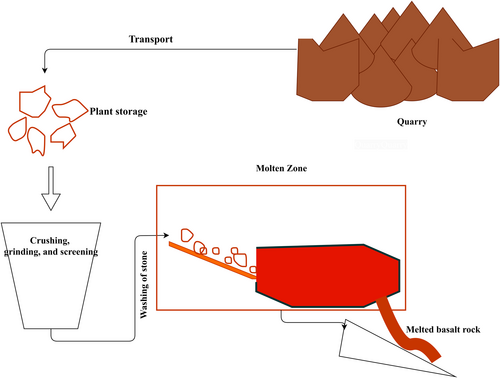

Basalt fiber, an essential inorganic material, [3] is extracted from basalt, a readily available rock obtained by volcanic activity that is abundantly available and possesses valuable petrological properties. Basalt rocks are initially crushed, washed, and melted in a furnace between 12,000°C and 15,000°C. This is followed by the extraction of filaments from the molten phase under hydrostatic pressure through the platinum-rhodium bushing. This method ensures precise and efficient filament production. The size of the filament depends on the filament extraction rate and temperature of the furnace. The continuous fiber can be extracted by following the Spinneret method (Figure 2), and short fibers are developed using the Junkers method (Figure 3) [4]. The continuous fibers can be cut to get the chopped basalt fibers [6]. Both methods follow the same procedure till extraction (Figure 4). The resulting basalt fiber has properties suitable for construction activities. Researchers studied the properties to assess its compatibility and adaptability in the cement matrix to withstand practical situations. A study was undertaken to investigate the impact of sizing on the mechanical properties of basalt fibers. The findings revealed that sized basalt fibers exhibit superior mechanical capabilities compared to unsized fiber [6]. Nevertheless, the tensile strength of each basalt fiber is influenced by manufacturing flaws. To address this issue, a study was undertaken to optimize the coupling agents used in the fiber production process [7].

Here are the qualities of basalt fibers that have been studied for their potential usage in concrete: density of 2.8 g/cm3, elastic modulus of 89 GPa, tensile strength of 2.8 GPa, elongation to fracture of 3.15%, specific modulus of 31.7 GPa/g/cm3, and specific tensile strength [8] of 1.0 GPa/g/cm3. Zeyad A [9] studied the effect of various fibers on the fresh properties and flexural toughness of SCC with the following basalt fiber characteristics: length 30 mm, diameter ranging from 0.015 to 0.050 mm, and tensile strength ranging from 550 to 750 MPa. Specific gravity ranges from 2.65 to 2.68 and the melting temperature is 1450°C. Oddly, research [10] has been conducted using basalt fibers with a tensile strength of 3100 MPa and a tensile modulus of 90 GPa. These fibers have a diameter of 13 μm, a length of 6.35% ± 10%, and a tensile modulus of 90 GPa. A work used 0.18 μm diameter fibers measuring 25 mm in length. The fibers had a density ranging from 4100 to 4840 g/cm3, a tensile strength of 3200 MPa, an elastic modulus of 100–110 MPa, and an aspect ratio of 138.89 [11]. Basalt fiber exhibits variations in its properties due to differences in dimension, and the mechanical properties of those are provided in Table 1, which was taken from the literature.

| Diameter [μm] | Length [mm] | Elastic tensile stiffness [GPa] | Tensile strength [MPa] | Elongation break (%) | Reference |

|---|---|---|---|---|---|

| 12.3 ± 1.1 | 15.0 | 66.0 ± 5.0 | 1826.0 ± 617.0 | — | [4] |

| 12.3 ± 1.1 | 30.0 | 64.0 ± 4.0 | 1586.0 ± 433.0 | — | |

| 12.3 ± 1.1 | 40.0 | 67.0 ± 4.0 | 2044.0 ± 244.0 | — | |

| 20.6 ± 2.2 | 15.0 | 103.0 ± 11.0 | 2277.0 ± 392.0 | — | |

| 20.6 ± 2.2 | 30.0 | 82.0 ± 19.0 | 1297.0 ± 667.0 | — | |

| 20.6 ± 2.2 | 40.0 | 90.0 ± 5.0 | 1295.0 ± 510.0 | — | |

| 14.2 ± 1.4 | — | 61.9 ± 3.5 | 2016.0 ± 434.0 | — | |

| 12.7 ± 1.5 | — | 62.0 ± 3.6 | 1608.0 ± 350.0 | — | |

| 14.1 ± 2.9 | — | 53.2 ± 7.4 | 1811.0 ± 331.0 | — | |

| 10.1 | — | 91.9 | 2880.0 | — | |

| 10.5 | — | 87.5 | 1760.0 | — | |

| 9.5 | — | 86.1 | 3470.0 | — | |

| 12.2 | — | 66.8 | 731.8 | — | |

| 6.3 | — | 71.9 | 840.3 | — | |

| 14.8 | — | 34.6 | 656.3 | — | |

| 10.6 | 20.0 | 76.0 | 992.4 | — | |

| 13–17 | 25 | — | 4840 | 3.15 | [12] |

| 16 ± 0.5 | 24 ± 2 | — | 3200 | 3.50 | [13] |

| 13 | 6–12 | — | 2000 | 3.00 | [14] |

| 15 | 18 | — | — | — | [15] |

| 16 | 6, 12, 18 | — | 3000 | 3.22 | [16] |

| — | — | — | 2800–3100 | 3.15 | [17] |

| 180 | 25 | — | — | — | [18] |

| 22 | 50 | — | 1380 | — | [19] |

| 10–20 | — | — | 4000–4500 | 3.15 | [20] |

| 13 | 6 ± 1.5 | — | 3500 | 3.2 | [21] |

| 16 | 24 | — | 2800 | 3.15 | [22] |

| 13–20 | 24 | — | 4000–4500 | 3.15 | [23] |

| 13 | 6.35% ± 10% | — | — | — | [24] |

| 11–18 | 24 | — | — | — | [25] |

| 14 ± 2 | 3, 6, 12, 24 | — | — | — | [26] |

| 16 | 12 | — | — | — | [27] |

The data in Table 1 indicates that the basalt fiber utilized in the studies exhibits variability in its physical qualities. This study aims to correlate the diameters of basalt fiber with its strength parameters. This endeavor showed that the variation in fiber strength does not correspond to the differences in length, diameter, or aspect ratio. Nonetheless, the data indicates that the elongation at break is nearly consistent regardless of the basalt fiber size. Furthermore, most studies employed macro fibers with a maximum length of 40 mm, whereas a limited number reported micro fibers with a minimum length of 3 mm. All these studies revealed varying tensile strength values for basalt fiber. Generally, reducing fiber length may increase tensile strength; however, this is contingent upon several elements, such as aspect ratio, diameter, loading rate, etc. On the contrary, a study [11] used different fiber lengths, i.e., micro fibers, and projected the same tensile strength. Nonetheless, regarding basalt fiber, there is an observed uncertainty in its strength, as certain microfibers demonstrated strengths three to four times lower than those of macro-sized fibers. Yet the characteristics of the basalt fiber were related to those of the other fiber types. Regardless of the circumstances, research was rapidly advancing to enhance the incorporation of basalt fiber in cement composites and structural applications. However, the basalt fiber utilized in various experiments exhibits distinct characteristics. All the aforementioned issues pertain to identifying the appropriate fiber characteristics based on the fiber's physical attributes for reinforcing fiber in concrete composites.

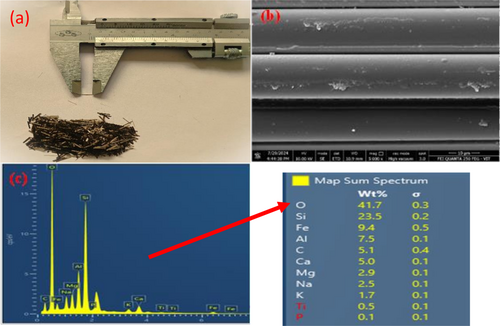

From Table 1, it is clearly understood that fiber specifications vary due to the diverse chemical compositions from the geological circumstances of the parent rock. The research conducted by Gutnikov team [28] corroborates this, and basalt primarily consists of silica oxides and other chemical oxides like Al2O3, Fe2O3, CaO, MgO, Na2O, K2O, and TiO2 [6]. Basalt fiber is classified into alkaline, mild, and acidic categories based on the silica content available, which is less than 43%, between 43% and 46%, and greater than 46%, respectively [3]. A compilation of artworks utilizing basalt rock's chemical constituents has been tabulated (Table 2). Figure 5a shows the physical appearance of basalt fiber. Consistent with the existing literature, this study demonstrates comparable results regarding the texture and composition of chemicals in the basalt fiber, as depicted in Figure 5b,c.

| Chemical compositions | References | |||

|---|---|---|---|---|

| [29] | [30] | [31] | [23] | |

| SiO2 | 54.7 | 43.3–47 | 42.43–55.69 | 54.44 |

| ZrO2 | — | — | — | — |

| Na2O | — | < 5 | 2.38–3.79 | 4.44 |

| CaO | 7.0 | 10–12 | 7.43–8.88 | 8.1 |

| TiO2 | 0.8 | < 5 | 1.10–2.55 | 0.87 |

| K2O | 1.6 | < 5 | 1.06–2.33 | 1.48 |

| MgO | 5.1 | 8–11 | 4.06–9.45 | 3.80 |

| Fe2O3 | 7.6 | < 5 | 10.80–11.68 | 7.42 |

| Al2O3 | 20.9 | 11–13 | 14.21–17.97 | 16.65 |

| FeO | — | — | — | 2.29 |

| NaO | 2.4 | — | — | — |

3 Fresh Properties

Fibers are known to reduce the workability of the mixes. Thus, it is essential to work with fresh properties of the concrete mixes reinforced with fiber. Similar to the other fiber types, basalt fiber also reduces workability as the dosage of basalt fiber increases by up to 1.0%, making the matrix stiff and cohesive [13]. A study concluded that adding basalt fiber to concrete mixes decreased the workability [20]. The workability of the basalt fiber concrete mixes has been assessed using an Abrams cone. It noted that adding fiber reduces the slump from 80 mm (control mix) to 55 mm [15]. The research was performed [10] to evaluate the workability of the self-compacted concrete made using 40% pozzolana material along with the basalt fiber with a mixing time of 80 min. This work identified a significant drop in workability, which could be due to the fiber's surface area. Zeyad [9] studied the effect of various fibers on the fresh properties of SCC and observed that basalt fiber has a less negative impact on workability than fibers from other sources. The work [23] on the fresh properties of the basalt fiber-reinforced SCC showed that the workability of the mixes containing basalt fiber decreased due to the fiber's surface area and friction between fiber and cement particles. A study used fibers such as steel and basalt fibers in SCC. It was noted that hybrid mixes showed a significant loss of workability compared to mixes with single fibers [25]. The workability test revealed important findings on SCC-reinforced basalt fiber with and without pozzolanic material; [32] results indicated a decrement in workability in both cases. However, pozzolanic material preserves the workability of the mixes better. A similar trend has been noted with two different pozzolanic materials as binary mixes, which reduce the effect of fiber on lowering the workability in mixes [18]. Saif et al. [33]. studied the impact of blended materials on the characteristics of ultra-high strength fiber-reinforced SCC exposed to extreme temperatures. This research maintained the required workability with different fillers, pozzolanic materials, and fibers and used varied superplasticizer dosages. The work focused on preserving the slump of the concrete mix incorporated with the varying lengths in basalt fiber and mentioned that the size and the amount of fiber affect the workability of the mixes and that superplasticizer dosage should be increased to achieve the desired slump [26].

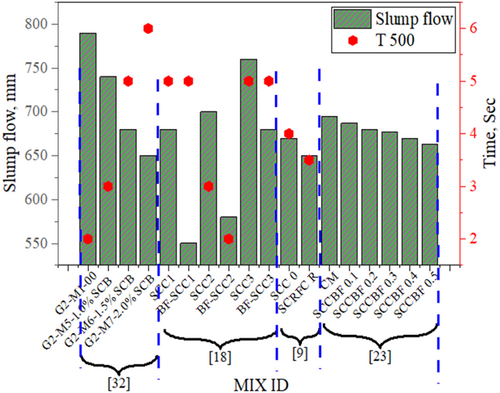

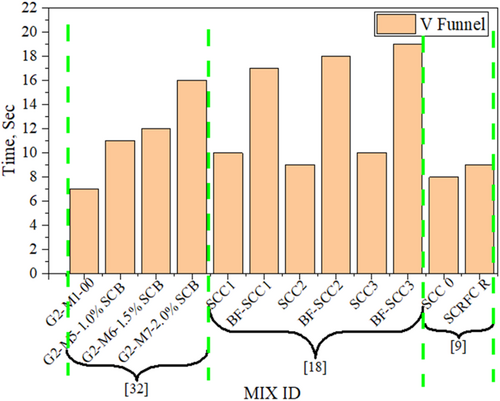

Figure 6 illustrates the phenomenon of maintaining workability in concrete mixtures. It illustrates compositions of SCC reinforced with basalt fiber. Four literature studies were analyzed and illustrated in Figure 6, which revealed that increased fiber intake correlates with reduced slump flow. Nevertheless, the research conducted by Saif et al., including pozzolanic materials, demonstrated superior flow compared to prior studies. Similarly, the V-funnel results showed that the presence of pozzolanic materials reduces the flow time, as presented in Figure 7. As predicted, it is noteworthy that incorporating the high-range water reducers and superplasticiser, together with the sustainable materials, maintains the workability of SCC reinforced with basalt fiber.

4 Hardened Properties

4.1 Mechanical Properties

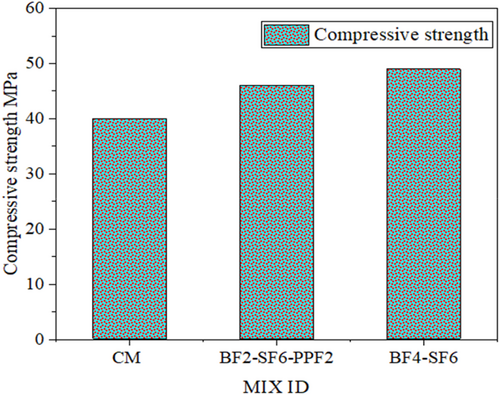

Investigations have been carried out on the mechanical properties of concrete mixtures augmented with basalt fiber, as detailed in Table 3. Krithika et al. [13] investigated the influence of basalt fiber on concrete and found that the compressive strength significantly improved with an optimal fiber replacement of 0.5%. Xue et al. [16] studied mixtures with varying water binder ratios (0.3, 0.32, 0.34). They stated that a reduction in the water binder ratio combined with a basalt fiber concentration of 0.2% demonstrated superior performance compared to other mixtures. Hijah et al. [10] examined the effect of basalt fiber on SCC with fly ash replacement and observed that the strength enhanced up to 1% of fiber replacement, and a further increase in dosage reduced the strength. A study examined the application of various types of fibers, in conjunction with basalt fiber, in SCC. The basalt fiber results were similar to those achieved with other fibers [9]. A study was executed to examine the effect of basalt fiber length on concrete [14] and dosage of basalt fiber on the mechanical characteristics of concrete [26]. This study found that the inclusion of basalt fiber led to an improvement in the concrete's mechanical properties.

| Description | Reference | |||

|---|---|---|---|---|

| [13] | [15] | [10] | [23] | |

| Optimum % of fiber for CS | 0.5 | 1.5 | 1 + 40FA | 0.3 |

| CS | 48.50 | 35 | 66.7 | 52.86 |

| % Increment of CS | ˜23 | 4.45 | ˜20 | 8.43 |

| Optimum % of fiber for STS | 0.75 | 1.5 | 1 + 40FA | 0.3 |

| STS | 4.52 | 3.6 | 3.97 | 4.46 |

| % Increment of STS | 53 | 22.58 | 17 | 20.83 |

| Optimum % of fiber for FS | 0.5 | 1.5 | — | 0.4 |

| FS | 6.67 | 7.2 | — | 7.06 |

| % Increment of FS | 44 | 57 | — | 13.61 |

- Abbreviations: ˜, approximately; CS, compressive strength in MPa; FS, flexural strength in MPa; STS, split tensile strength in MPa.

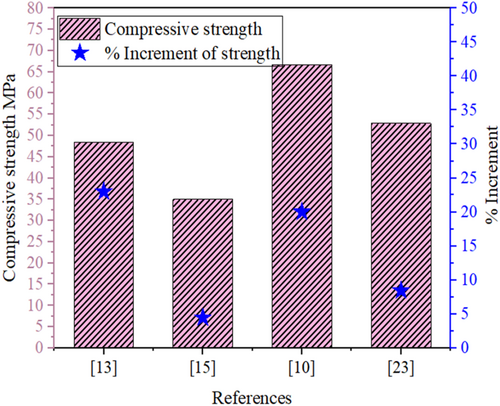

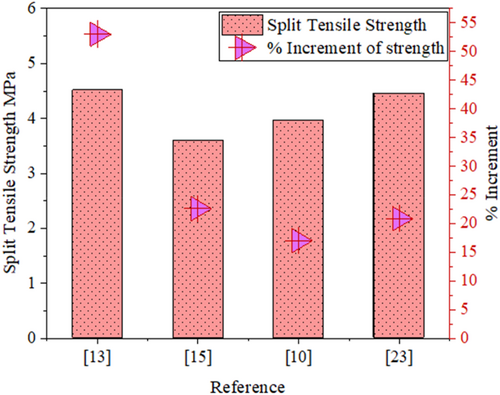

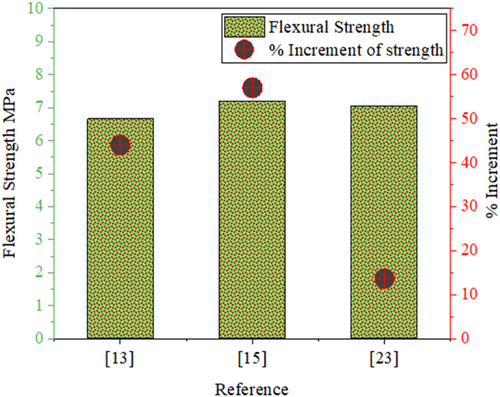

Table 3 indicates that the ideal range for basalt fiber dosage in concrete is between 0.5% and 1.5% and plots were presented in Figures 8-10. However, many variables affect this dosage, like the fiber's hybridization, SCM categories, water-to-binder ratio, and physical characteristics. All tests should be run using the same conditions to determine the precise ideal fiber dosage and the ideal range in real-world circumstances.

Figures 8-10 present the compressive, split tensile, and flexural strengths taken from the previous studies as given in Table 3. All these plots represent the strength value and percentage increment of strength on the left and right ordinates, respectively. On the abscissa, the optimum dosage obtained by the respective studies was mentioned. The plots indicate a considerable increase in strength with adding basalt fiber. Each study observed significant improvements in all three strengths but at varying fiber dosages. Due to the variation in target strength and other factors between those studies, it would be inappropriate to compare them. However, when evaluating the fiber dose alone, the most significant increment occurred between 0.5% and 15% fiber in concrete. Out of this range, the highest increment occurred at 0.5% and 0.75% of fiber.

4.2 Impact Resistance Test

The energy that the concrete specimen can withstand before failing is referred to as impact resistance. Typically, this is accomplished by employing the drop weight method (Figure 11), which repeatedly allows the weight to fall onto the specimen, causing an impact. Research was conducted to assess the concrete's resilience to impact. The study revealed that 0.75% of basalt fiber demonstrated excellent resistance to impact loading, as it required a more significant number of blows to develop first and ultimate cracks [13]. Vedhasakthi and Chithra [23] examine the strength and microstructural properties of basalt fiber integrated in SCC and note that 0.4% of the basalt fiber withstood more blows, absorbed more energy, and showed a post-crack efficiency of around 43%.

4.3 Durability Properties

The experimental investigation [33] noted that the blended mixes with high filler content exhibited good resistance to the sorptivity and absorption in ambient and elevated temperatures like 200°C and 300°C. Moreover, this effect was excellent in ternary blending compared to binary. This could be due to the filling ability of the materials in the ternary blended mixes.

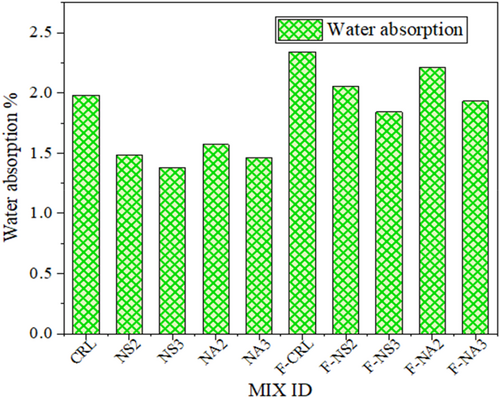

The work focused on the absorption of the concrete mixed with different types of nanomaterials (nano alumina and nano silica) along with the fiber. Ansari rad et al. [14] evaluated the addition of SCC-reinforced basalt fiber modified with hybrid nanomaterials (nano alumina and nano silica), which increased the sorptivity compared to the mixes without fibers. Also, the mix without nanomaterials and fibers exhibited lower absorption than the mix with fiber and without nanomaterials, as presented in Figure 12. This is due to the accumulation of fibers forming cavities that facilitate water transport into the concrete core. Ashteyat et al. [27] studied the effect of different fibers in SCC. This study involved determining the impact of freeze–thaw cycles, and the samples were tested under compression. The study has been performed with the hybrid fiber dosage in the concrete. The utilized fibers were steel, basalt fiber, and polypropylene fibers. The amalgamation of all three fibers in one mixture, while the other mixture comprises basalt fiber and steel fiber. In their investigation, the steel fiber content in both mixtures remained fixed, but the dosage of basalt fiber was varied at 20% and 40%. The blend comprises 20% basalt fiber and 20% polypropylene fiber inside a three-fiber combination and another mix with 40% basalt fiber and 60% steel fiber. The results are illustrated in Figure 13. The findings indicate that the presence of fibers diminishes the negative impact of freeze–thaw cycles on the compressive strength of concrete. Furthermore, it is significant that the mixture containing 40% basalt fiber demonstrated superior compressive strength compared to the 20% replacement. This implies that basalt fiber exhibits superior resistance compared to polypropylene fiber when combined with steel fiber. Observing carefully, as the steel fiber dosage remained constant in both mixtures, we can conclude that the augmentation of basalt fiber from 20% to 40% enhances the strength of concrete when subjected to freeze–thaw cycles. Also, the samples having basalt fiber exhibited more resistance to cracking and furthermore, adding fibers reduces the water absorption compared to the control sample.

Incorporating basalt fiber into the concrete enhances the durability features previously discussed in the literature. Further research and development is necessary to understand the behavior of SCC reinforced with basalt fiber in aggressive environments.

5 Ultrasonic Pulse Velocity Test (UPV)

UPV is a nondestructive test that evaluates the quality of concrete and other parameters. This section provides the works that evaluated the concrete quality incorporated with basalt fiber along with and without Supporting Information.

The literature demonstrates that incorporating basalt fiber into the cement matrix improves its quality. However, it has been established that adding fibers into concrete loosens the cement matrix. This happens as often the matrix becomes cluttered with fiber content or sometimes when fibers swarm and agglomerate. This alters the relations to forecast other properties of the concrete. Considering this, a study with 2% basalt fiber with Supporting Information was conducted to assess the quality of the concrete and surpassed the limit to maintain the required quality [18]. A study examined basalt fiber-reinforced concrete, using temperature as a variable, and assessed its uniformity. The results exhibited the uniformity of the concrete and demonstrated superior concrete quality [33]. A study noted that the basalt fiber-reinforced concrete specimen showed a 5.1 km/s velocity, demonstrating superior quality [22]. This above study was supported by the work conducted by Althoey et al., which noted almost similar results [34].

All these studies illustrate that basalt fiber combined with various SCMs preserves the uniformity and quality of the concrete. This also indicates that the distribution of basalt fiber within the matrix is practical, thereby facilitating the correlation between NDT and other concrete parameters.

6 Microstructural Analysis—Scanning Electron Microscopy (SEM)

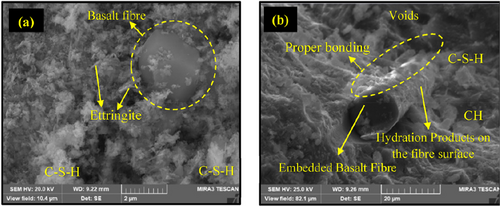

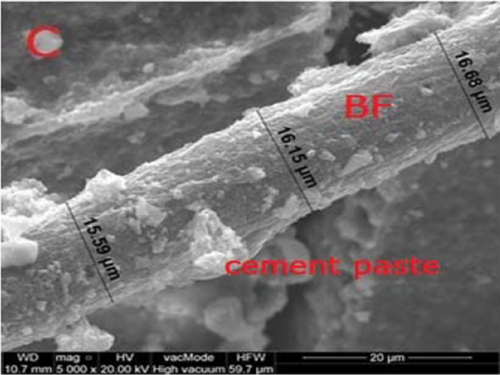

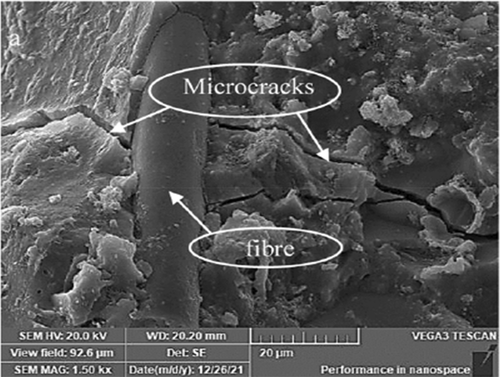

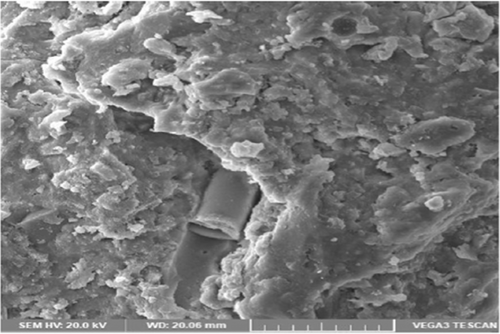

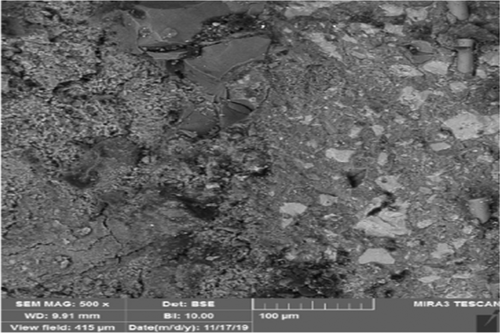

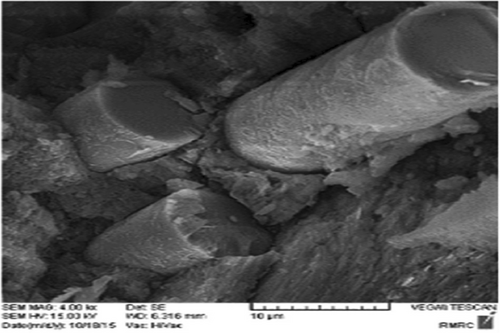

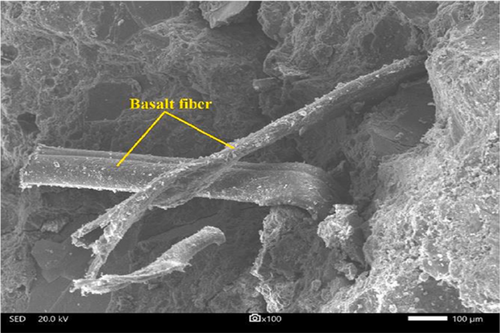

SEM depicts the surface morphology of the material along with elemental analysis. Limited studies were done for morphological studies. SEM image illustrates that the CSH gel surrounded the surface of the basalt fiber, [13] indicating a solid bond between the fiber and the matrix [22, 35]. Other literature agreed with the above statement and noted the presence of hydration products (Figures 14 and 15) on the surface of basalt fibers [23, 25]. Basalt fiber transformed a single crack into multiple cracks spanning from one side to the other, indicating a change in crack propagation and intensity, [33] clearly illustrated in Figure 16. It is visible from Figure 17 that the cement matrix that was superimposed on the basalt fiber ensured a well-bonding nature, which in turn improved the mechanical properties of the concrete material.

According to the studies, the micrographs of the concrete specimens show that the fracture zone of the basalt fiber-reinforced concrete sample has been broken up into fragments. This is because no basalt fiber (centre portion to provide a bridging effect) is present at the zone, and the edge of the basalt fiber in the matrix is visible in SEM images. The occurrence of this phenomenon is made evident in Figures 17-19. Barnat-Hunek et al. [25] studied the microstructural properties of hybrid (basalt and steel) fiber-reinforced SCC with perlite aggregate. They noted that adding fibers increased the porosity of the concrete matrix. The study also found that the free water in contact with the smooth, glassy fiber texture was responsible for the low bond between the paste and the basalt fiber. This study's literature indicates that the fibers attempt to consolidate the matrix under load, thereby enhancing the mechanical properties of concrete reinforced with basalt fibers, which successfully endure the load. Notably, one study illustrated the fracture of the basalt fiber at its tip within the matrix [35]. Figure 20 indicates that the fiber attempts to adhere to the matrix, but due to the applied load, the fiber detaches from the matrix. The fracture in the fiber could be due to the excellent bonding nature of the fiber to the cement matrix.

There is a clear research gap in understanding the morphology of basalt fiber-reinforced concrete. More studies are required to understand the behavior and validate the strength and durability expectations of SCC incorporated with basalt fiber.

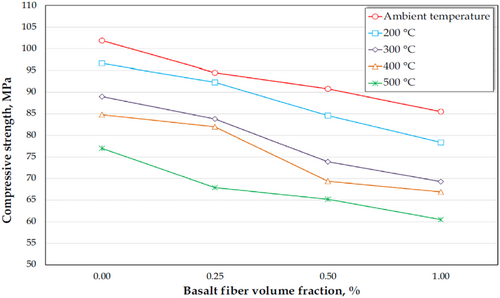

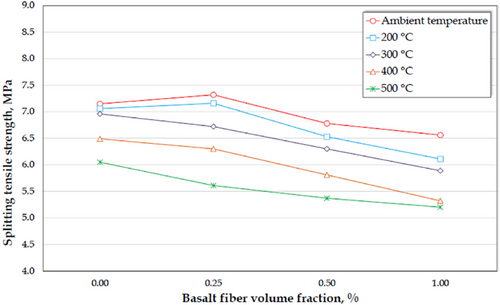

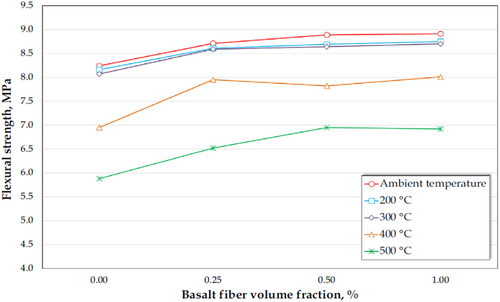

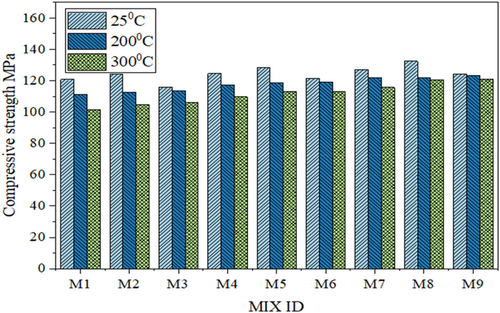

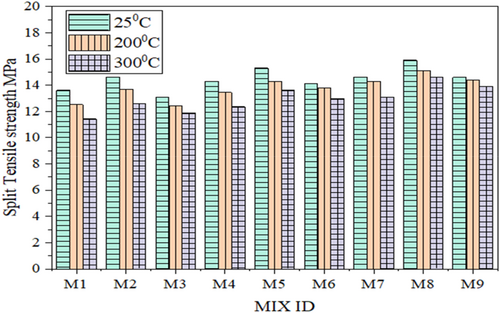

7 Elevated Temperature

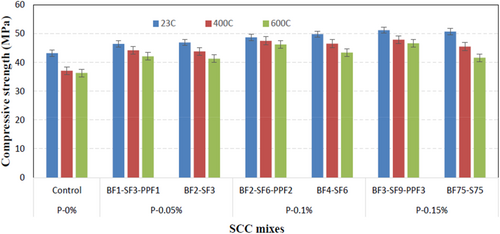

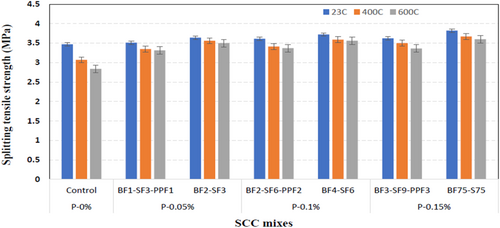

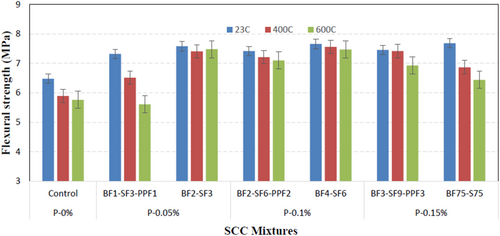

Basalt fibers exhibit good resistance to fire, leading the researchers to work on concrete encountered with high temperatures. A few works have been performed in this area and were mentioned in this section. In 2021, work was reported on concrete exposed to elevated temperatures containing basalt fiber [36]. Their work mentions that the compression, split tensile, and flexure tests were carried out on cylindrical and prism specimens after the concrete was exposed to a temperature of 500°C. Figure 21 presents the temperature exposure of samples. Figures 22-24 have been extracted from the research of Haido et al. and utilized to derive inferences from their findings. Those plots represent the concrete's compression, split tensile and flexural strength reinforced with the basalt fiber under ambient conditions, 200°, 300°, 400°, and 500°. From these plots, it has been noted that the results were uncertain due to the presence of the fiber in the self-compacting matrix. Upon examining Figure 22, it is evident that the strength diminishes immediately upon incorporating the fiber at ambient temperature, and this pattern persists at elevated temperatures. Moreover, observing the graph's pattern, the rate of strength reduction exhibited distinct behavior in relation to the increase in temperature and the rise in fiber content. This may result from insufficient bonding inside the matrix at elevated temperatures. Analysis of the graphs for split tensile strength (Figure 23) and flexural strength (Figure 24) indicates a marginal improvement in strength values at 0.25% and 1.0% fiber dosages for split tensile and flexural strengths, respectively. This pattern has been noted across all temperatures to which the samples were exposed. Therefore, it can be concluded that incorporating basalt fiber into the self-compacting matrix exhibits distinct behavior compared to other fibers. Two years later, a study examined the impact of temperature on basalt fiber with various supplementary cementitious materials (SCMs) in concrete with strengths of 125 and 150 MPa at temperatures of 200°C and 300°C. This experiment utilized pozzolanic materials as a substitute for cement while the concrete was consistently reinforced with basalt fiber. The behavior was analyzed by plotting the results as graphs, displayed in Figures 25 and 26. Figures 25 and 26 illustrate the compressive strength and split tensile strength of the mixtures at different temperatures. The strength diminished as a result of the temperature increase. Nevertheless, the mixtures, including sustainable materials, demonstrated resilience to elevated temperatures. This may result from the synergistic interaction between sustainable materials and basalt fiber. Another investigation was conducted to investigate the utilization of agricultural waste in nano sizes as a substitute for cement, together with the inclusion of basalt fiber [22]. The compression test was conducted on the specimens at 300° and 600°. This study maintained the same basalt fiber while observing its impact in conjunction with the nanomaterials. The performance of the basalt fiber with micro rice straw ash surpassed that of all other materials. An akin experiment was conducted by maintaining a consistent dosage of basalt fiber while varying the nano agri-waste products. The samples were then tested for compression at 150°, 300°, 450°, and 600°. The findings demonstrated that the combination of nanowaste straw ash and basalt fiber exhibited superior resistance to high temperatures than the other combinations [34].

A study was done on the mechanical properties [27] of the concrete specimens exposed to 400°C and 600°C. This study employs a hybrid combination of fibers to analyze their synergistic effects under normal and elevated temperatures. The combinations include basalt, steel, and polypropylene fibers as one group and basalt and steel fibers as another. These combinations were tested with varying dosages, and the performance of the concrete mixes was evaluated. The results, illustrated in Figures 27-29, indicate that as the fiber dosage increases, the resistance to elevated temperatures and the corresponding residual strength also improve. Consequently, incorporating hybrid fibers in the concrete significantly enhances its resistance to elevated temperatures. The results demonstrated that the synergistic impact of including both basalt and steel fibers yielded superior resistance.

8 Applications of Basalt Fiber in Structural Components

This section outlines the potential of basalt fiber as a composite material for the structure under structural performance. Research was conducted to utilize basalt fiber as a substitute for steel in reinforced concrete constructions. This is due to basalt fiber's resilience to corrosion and heat effects. Basalt fibers were utilized not only as a structural component but also in the production of filaments from waste materials. For brevity, not all studies were included; a study by Monaldo et al. [4] has been referenced regarding this specific topic, while the remaining papers are presented in this research.

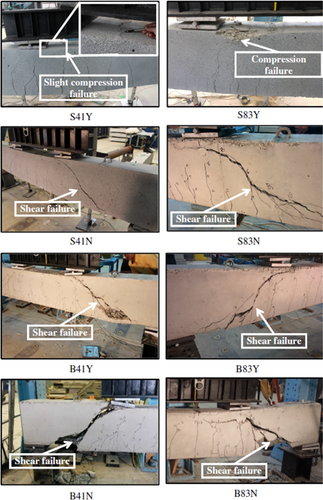

A study by Duic et al. [37] indicates that BFRP-reinforced concrete beams have sufficient deformability by CSA S6-14 standards; nonetheless, they demonstrate increased flexural and shear cracking compared to steel-reinforced beams due to their reduced stiffness. Shear failure predominates in the design of BFRP beams, as shown in Figure 30, even with the incorporation of stirrups, due to inadequate anchorage and the inability to bend BFRP stirrups. Figure 30 indicates that beams reinforced with basalt fiber displayed more shear cracks than those reinforced with steel (S-series represents steel and B series represents basalt fiber as reinforcing bars). Thus, shear reinforcement is essential since the concrete's contribution to shear (Vc) in BFRP beams is 30%–40% lower than in steel-reinforced beams. Despite these challenges, BFRP remains a feasible corrosion-resistant alternative to steel, provided that the limitations of shear reinforcement are addressed through improved design methodologies and advancements in material technology.

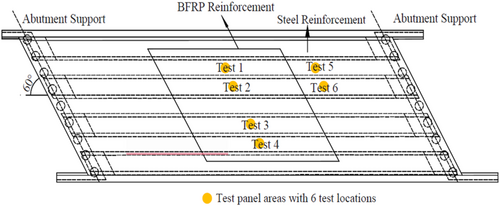

Like the previously mentioned work, another work has been done on the basalt fiber-reinforced polymer in SCC in slabs to evaluate the arching action of the slab [38]. An experimental setup has been shown in Figures 31 and 32. The research demonstrates that BFRP-reinforced slabs possess structural strength akin to that of steel-reinforced slabs when constructed with a corresponding reinforcement ratio, underscoring their efficacy in practical applications. In terms of deflection, BFRP-reinforced slabs are unaffected by the reinforcement material, confirming their appropriateness for bridge applications. Furthermore, BFRP-reinforced slabs effectively endured a 40-ton wheel load, with crack widths much below the ACI 440.1R-22 threshold, demonstrating exceptional structural integrity and serviceability. Thus, it can be concluded that the arching action remarkably enhances the load-bearing capacity of BFRP-reinforced concrete deck slabs, enabling the use of lower reinforcement ratios without compromising structural performance.

A study focused on developing the prediction of flexural strength of the reinforced concrete under normal and aggressive environments by using different models of ANN. The study used two reinforcing materials: steel and basalt. A three-point bending procedure has been adopted on 500 × 100 × 100 mm reinforced beams with steel and basalt bars. The test results were noted and used to train the Artificial Neural Network (ANN) models. The comparison of artificial neural network (ANN) models showed that all three training algorithms, Levenberg–Marquardt (LM), Bayesian Regularization (BR), and Scaled Conjugate Gradient (SC), had good predictive abilities, with R-values ranging from 0.95 to 0.99. The ANN model based on LM was the most accurate in predicting the flexural capacity of BFRP-SCGC beams, and the ANN model based on SC gave better predictions for steel-reinforced SCGC beams. Thus, the obtained predictions were compared with existing ACI 440.1R-15 guidelines, and this effort led to the conclusion that the guidelines overestimated the moment capacity of BFRP-SCGC beams. Therefore, some corrections have to be included to reduce the overestimation in the codal provision [39].

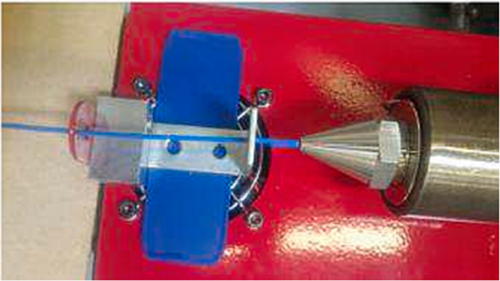

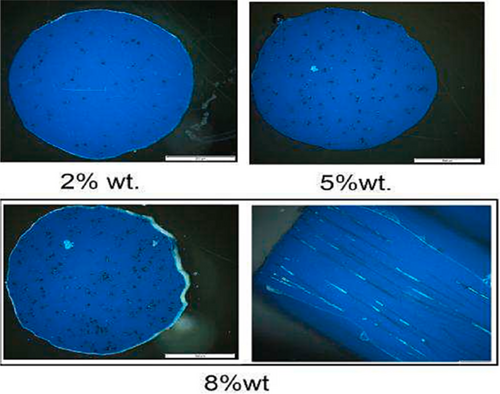

A study performed by Ghabezi et al. [40] used short basalt fibers as an additive to manufacture waste polypropylene as filaments. To obtain the filaments, the 3D printing technique has been adopted and drawn the filaments as mentioned in Figure 33. While extracting the filaments, the work stated that there was a difficulty in printing the filaments at the higher dosages of the basalt fiber due to the clogging of the nozzle. Nonetheless, at the 5% dosage of basalt fiber, no such difficulties were observed. The samples with fiber weight fractions of 5% and 8% demonstrated strengths of 888.36 ± 41.56 MPa and 970.77 ± 48.72 MPa, reflecting increment rates of 44.26% and 57.64%, respectively. The maximum tensile strength of the filaments was recorded at 38.19 ± 2.38 MPa with 5% basalt fiber, exhibiting an increase of approximately 20%. Moreover, microscopy has been employed to examine the distribution and orientation of basalt fibers inside the filaments. The findings illustrate (as depicted in Figure 34) that the fibers are aligned with the filament, and the orientation of the fibers follows the filament direction, thereby increasing the qualities of the filament. Consequently, basalt fiber has the potential for use in 3D printable materials, as clogging is not observed at lower dosages. Additional research is required to completely implement this technology before its application in the practical realm.

9 Conclusions

- Sustainable building materials preserved the workability of the concrete, which has been decreased by incorporating the basalt fiber.

- The maximum increments in compression strength, split tensile strength, and flexural strengths noted were 23%, 53%, and 44%, respectively. However, these rates are at different fiber dosages due to the fibers' bridging effect. This indicates that the fiber volume fraction affects the mechanical properties.

- Concrete reinforced with basalt fiber in the range of 0.4%–0.75% exhibited excellent energy absorption and imparted the resistance to withstand the impact loads.

- Micrographs (SEM images) depict that the bond between Basalt fiber and cement matrix is strong and reduces the size of the cracks from macro to micro and also develops the bridging effects between the micro cracks in the cement matrix thereby enhancing the material's load-bearing capability.

- Based on the study, it is worthwhile to note that the amount of fiber required to endure higher temperatures is comparable to that needed under ambient conditions.

10 Recommendations

- Currently, research is concentrated on the consistent dosage of basalt fiber with different amounts of sustainable materials; nevertheless, it is advised to determine the ideal fiber dosage while maintaining a constant amount of sustainable materials. Results about the ideal dosage of sustainable materials have been available ever since.

- Insufficient attention has been given to predicting the different parameters (strength concerning age, strength between destructive and non-destructive testing). It is necessary to pay attention to the parameter predictions.

- According to the literature, these fibers tend to make concrete slightly porous; therefore, sophisticated and non-destructive testing methods such as computed tomographic (CT scan) scanning must be used to understand the pore structure of the concrete.

- More research is needed to determine how fiber size affects the concrete's ability to withstand impacts.

- Thermogravimetric (TGA) and scanning electron microscopy studies are needed to understand further how concrete reinforced with basalt fiber behaves at higher temperatures.

- Research should be done on the concrete's alkali-silica reaction with basalt fiber.

- To improve the precision of structural predictions and to provide a more thorough and data-driven strategy for the design of long-term FRP-reinforced concrete buildings, researchers in the future should look at combining ANN models with current design formulations.

Author Contributions

M. Kiran Prabha and K. Vishnu Vardhan: conceptualization, methodology, investigation, formal analysis, writing – original draft. A. S. Santhi and G. Mohan Ganesh: supervision, conceptualization, writing – review and editing.

Conflicts of Interest

The authors declare no conflicts of interest.