Consequences of Switching From Lime to Dololime Fines Injection in Electric Arc Furnace

Funding: The authors received no specific funding for this work.

ABSTRACT

This study presents a successful solution implemented at a steelmaking plant of the company United Steel in Kuwait. The primary challenge addressed in this study involves the generation of excessive dololime fines (particles less than 10 mm) and insufficient lime fines (particles between 5 and 15 mm) at the lime and dololime plant. This size disparity presents operational challenges within the steelmaking process. An innovative strategy is implemented to overcome this disparity and optimize material utilization. The solution involves replacing lime fines injection with dololime fines injection in the electric arc furnace. The original practice employs a combination of lime fines injection with the use of lime and dololime lumps. The proposed solution replaces the lime fines injection with available dololime fines. To maintain the required mass balance, the quantity of lime lumps is increased, while dololime lump usage is reduced. The implemented strategy results in several key improvements. Lime and dololime consumption demonstrably decrease, indicating improved material efficiency. The economic benefits are significant. By eliminating the need for external briquetting of dololime fines and reducing purchased lime fines quantities, the solution generates annual cost savings of approximately USD 350,000.

1 Introduction

Electric Arc Furnaces (EAFs) are widely used in steel production due to their flexibility in handling various feedstocks like steel scrap, Direct Reduced Iron (DRI) and Hot Briquetted Iron (HBI). However, achieving high-quality carbon steel requires efficient removal of impurities. This is where lime (CaO) and dololime (CaO-MgO) injection play a crucial role [1].

Lime and dololime act as essential fluxing agents. They react with undesirable elements like silicon (Si), sulfur (S) and phosphorus (P) within the scrap, forming a liquid slag that floats on top of the molten steel. This slag is then removed, separating the impurities from the steel [2]. This enhances the durability and strength of the final product, which is critical for industries that rely on steel, such as construction, automotive, and manufacturing, supporting infrastructure development and economic growth globally.

Precise control of slag chemistry is vital for optimal steel quality. Lime provides calcium oxide (CaO), while dololime offers a combination of CaO and magnesium oxide (MgO). This allows for adjustments in slag basicity (ratio of basic oxides like CaO and MgO to acidic oxides like SiO2) to effectively remove impurities. Moreover, MgO ensures the chemical compatibility between slag and refractory, minimizing the corrosion of the latter due to the action of the former [2]. Early formation of CaO- and MgO-saturated slag is critical for process productivity. To achieve this, flux must be dissolved in the melt in a limited process time [3].

The addition of lime is essential for the proper bath chemistry and the slag foaming practice, which offers an increased energy efficiency in the EAF, since the heat from the arc is captured by the slag; a protection of the water panels and the roof from radiation and a decreased noise pollution and low nitrogen incorporation in the steel [4-7]. The lime is also essential for optimal dephosphorization during the refining of the bath. If not removed, phosphorus has detrimental effects on the mechanical properties of the steel. Therefore, highly available CaO in the slag allows the decrease of the phosphorus content of the bath through the generation of tricalcium phosphate compounds (3CaO·P2O5) which are captured by the slag [8]. The thermodynamics of the process is ruled by the content of lime in the slag; the higher the content, the better the dephosphorization, while the kinetics is controlled by the dissolution rate of lime into the slag; the finer the lime, the faster the dephosphorization [8-10]. All these parameters and the overall effectiveness of lime during steelmaking depend on lime quality, which is ruled by the original limestone used for its production [11].

The addition of magnesia, in combination with lime, controls the apparent viscosity of the slag, favoring the precipitation of MgO-containing solid phases that ensure chemical stability toward refractory corrosion [12] and enhance slag foaming, leading to a stable and long-lasting foam over the refining stage after scrap melting [13]. However, too high MgO content may lead to a diminished capacity of the slag to seize phosphorus [14]. Thus, a predominantly liquid and just MgO-saturated slag is preferred in EAF steelmaking to achieve all the above-mentioned targets [15].

Typically, lime and dololime are charged as lumps within the scrap buckets, but the number of sites where the fluxes are injected is still increasing over time. Indeed, although bulky materials are cheaper than fine fluxes, they require longer melting times and, due to a higher carbonate content in the core, they deliver fewer active fluxes to the slag [11].

- improved efficiency: maintains a more consistent slag composition, leading to better control over impurity removal and steel quality;

- energy savings: reduces heat loss compared to stopping the furnace for lime addition;

- lower emissions: minimizes dust formation and improves overall environmental performance.

- elimination/reduction of all fluxes charged through the EAF roof;

- furnace building environment improvement reducing the environmental footprint;

- low operating and maintenance costs;

- reduction of conversion costs;

- a better yield of the material being injected directly into the slag;

- metallurgical process optimization due to the faster reaction of lime and/or dolomite;

- efficient dephosphorization;

- continuous foaming slag formation with higher volume and longer endurance;

- better bath insulation with reduced temperature losses and less nitrogen pick-up;

- arc stability improvement due to earlier foamed slag formation, which creates arc stability (lower impedance) and higher active power;

- hot spot protection enhances the refractory lifetime and eliminates delays due to patching.

The efficient use of lime and better control of slag chemistry has led to significant energy savings for steelmakers.

Additional benefits include cleaner environments for shops, reduced volumes in lime-to-furnace evacuation systems, better lime yield resulting in less quicklime used during the melting process, and reduced maintenance costs compared to mechanical systems.

Additionally, advancements in injection technology enable 100% lime injection into the EAF, faster lime dissolution due to increased particle surface area, flexible slag control throughout the heat, and enhanced overall steelmaking performance [21, 22].

Dololime offers an additional advantage due to the presence of MgO. While both lime and dololime can remove sulfur, MgO can further enhance this process. Additionally, MgO contributes to improved slag viscosity, enhancing its ability to capture impurities [23].

Lime is injected in powdered form through strategically placed nozzles in the EAF walls. Optimizing factors like particle size, injection rate, and nozzle positioning is crucial for achieving efficient material utilization and effective slag formation.

1.1 Problem Statement

Kuwait Steel's lime plant offers production flexibility to meet the dynamic flux requirements of the steelmaking plant (SMP). The plant can produce both quicklime and dololime, enabling it to efficiently adjust production based on specific needs.

Three primary flux types are employed in the steelmaking process: lime lumps (> 15 mm), dololime lumps (> 10 mm), and lime fines (5–15 mm). Lime and dololime lumps are introduced through the furnace roof, while lime fines are injected through a dedicated injector system [24].

A detailed breakdown of typical flux requirements is provided in Table 1:

| Lime lumps consumption per t (kg) | 29.2 |

| Lime fines consumption per t (kg) | 8.9 |

| Dolo lumps consumption per t (kg) | 25.4 |

| Lime fines (Ladle: Tapping + Ladle furnace) (kg) | 6.2 |

| Total consumption (lime + dololime) per tonne (kg) | 69.7 |

- Dololime: a single-deck screen is employed to classify the crushed dololime into two distinct sizes: 0–10 mm and > 10 mm.

- Lime: a double-deck screen is used to achieve three separate size fractions for the crushed lime: 0–5 mm, 5–15 mm, and > 15 mm [25].

- lime powder (0–5 mm) and dololime powder (0–10 mm) are compressed into briquettes to create larger, more manageable lumps suitable for use in the EAF;

- lime fines (5–15 mm) are directly injected into the EAF for efficient material utilization;

- lime (> 15 mm) and dololime lumps (> 10 mm) are conveyed directly to the EAF for use.

| Size distribution | ||

|---|---|---|

| Lime (%) | Dololime (%) | |

| 0–5 mm | 12 | 29.92 |

| 5–15 mm | 11.25 | 22.73 |

| 15–50 mm | 76.75 | 47.35 |

Table 3 illustrates the disparity between the size distribution of lime produced at the lime plant and the lime requirements of the SMP. As the table indicates, the current production capacity is insufficient to meet the specific needs for lime fines. Consequently, the SMP must procure the remaining quantity from external suppliers, incurring higher costs.

| Percentage of lime types produced at lime plant and needed at the steel making plant | ||

|---|---|---|

| Produced at lime plant (%) | Lime needed at SMP (%) | |

| Lime fines for injection (5–15 mm) | 11.25 | 34 |

| Lime lumps (> 15 mm) & briquettes obtained from briquetting of size 0–5 mm | 88.75 | 66 |

Although Kuwait Steel operates a lime and dololime production plant, it still needs to supplement its supply of fine lime (5–15 mm) with annual purchases. This discrepancy arises from the incongruence between the size distribution of the produced lime and the specific process requirements for this size fraction at the steelmaking plant.

The annual purchase of lime fines is around 11,000 t. The annual requirement to procure approximately 11,000 t of lime fines creates an additional cost burden on steel billet production at the SMP. This highlights the need to explore potential solutions to mitigate the shortfall in internally produced fine lime.

To further utilize the dololime fines and powder (0–10 mm fraction), the plant employs a briquetting process. While this process allows for the efficient use of this material, it incurs an additional cost of approximately USD 11 per tonne of briquettes. This cost contributes to the overall production cost of steel billets.

1.2 Proposal

With the aim of minimizing the additional steel billet production costs associated with the procurement of lime fines and the briquetting of dololime fines, the substitution of lime fines injected into the furnace with dololime fines is evaluated after metallurgical considerations. To ensure process stability, the amount of lime lumps added will be increased to match the reduction in lime fines. Conversely, the quantity of dololime lumps will be decreased by an equivalent amount corresponding to the fines used for injection. Thus, the goal is to maintain the current consumption level of fluxes while optimizing the use of in-house produced lime and reducing reliance on more expensive purchased lime. Additionally, a further aim is to minimize the costs associated with dololime briquetting. The details of this proposal are presented in Table 4.

| Total actual consumption of lime and dololime: 63.5 kg/t | ||||

|---|---|---|---|---|

| Lime lumps (furnace) | Dololime lumps (furnace & ladle tapping) | Lime fines (furnace injection) | Dololime fines (furnace injection) | |

| Actual | 29.2 kg | 25.4 kg | 8.9 kg | 0 |

| Proposal | 38.1 kg | 16.5 kg | 0 | 8.9 kg |

While the proposed flux substitution strategy is outlined in Table 4, it is important to acknowledge the role of our intelligent control system, SmartArc from AMI [26]. This system dynamically adjusts all production parameters, including fluxes, based on the real-time conditions of the furnace charge mix and other relevant factors. In detail, the intelligent control system analyses the slag composition of the previous heat to adjust the quantity of fluxes for the next heat. This system leads to a further decreasing of dololime consumption after the implementation of the new proposed practice as it is documented in the further sections.

2 Method

At United Steel in Kuwait, the steelmaking process utilizes a blend of DRI and steel scrap, with the scrap percentage ranging from 25% to 75% depending on raw material availability. Previously, the process relied on a consistent 40% scrap charge, with the remaining balance being DRI. To ensure a fair comparison when evaluating the impact of the process changes, the scrap charge ratio was deliberately maintained at 40% after implementation. All other operational parameters (DRI, lime dololime, carbon qualities) were also held constant. It is important to note that the only potential source of variation now arises from the specific type of scrap used, which is inherently variable (see Figure 1 for scrap used during comparisons).

The proposed flux substitution strategy has been approved for implementation at the SMP. To ensure a smooth transition, the existing AMI lime injection profile has been adapted for the use of dololime fines, ensuring optimal material delivery within the furnace [26].

The results of 106 heats before (53 heats) and after (53 heats) the changes in the process by using dololime injection instead of lime injection are presented in terms of flux, energy, oxygen, and carbon consumptions. To objectively determine whether the switching affected these parameters, the statistical difference between the averages is used. MINITAB software is used to compute the test at a 95% confidence interval.

3 Results and Discussion

3.1 Analysis of Fluxes Consumption

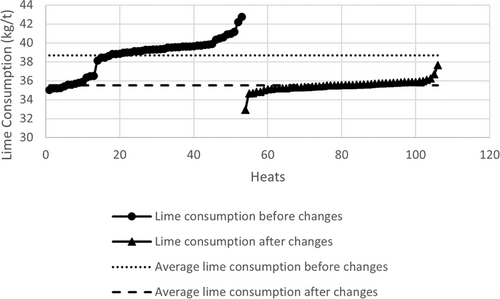

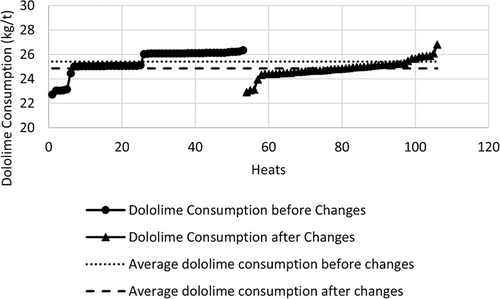

The implementation of dololime injection in place of lime fines injection resulted in a decrease in the consumption of the two materials: lime and dololime. The average lime consumption before the change was 38.7 kg/t, while after the change it decreased to 35.5 kg/t, representing a decrease of 3.2 kg/t (see Figure 2). Similarly, the average dololime consumption decreased from 25.4 kg/t to 24.8 kg/t, a decrease of 0.6 kg/t (Figure 3).

While the initial analysis shows a decrease in flux consumption after switching to dololime injection, formal hypothesis testing is crucial to establish the statistical significance of this observation.

Hypothesis testing is a method for making a choice between two mutually exclusive and collectively exhaustive alternatives. In this method, two hypotheses are made (Null Hypothesis [H0] and the Alternative Hypothesis [H1]) and only one can be true. Specifically, the H0 is represented by η1 − η2 = 0 (where η1 is the median or mean value of the monitored parameter, that is, lime, dololime, electricity, oxygen or carbon, before changes and η2 is the same monitored parameters after implemented changes) while H1 is expressed as η1 > η2. Hence, at a specified significance level (α = 0.05), the possibility of rejecting or not rejecting the Null hypothesis is tested [27].

The difference in consumption before and after the implemented changes is consistently monitored by the 95% confidence interval. If this interval includes negative values, namely comprehends zero, a statistically significant difference in consumption cannot be confirmed. Conversely, if the interval contains only positive values, there will be sufficient evidence to confirm a statistically significant difference in consumption. In other words, if the p value for the test is less than the significance level, the null hypothesis must be rejected.

Minitab employs the mean as a measure of central tendency for symmetrically distributed data, while favoring the median when faced with skewed distributions, given the median's robustness to such influences.

This testing would involve formulating a null hypothesis using Minitab, such as the standard operation utilizes a higher lime consumption compared to dololime injection. The results would then be evaluated against a predetermined significance level to determine if the observed decrease can be attributed to chance or a genuine effect of the new process.

It is clear from Tables 5 and 6 that the lime and dololime consumptions decrease with the novel changes.

| Sample size (N) | Median | Standard deviation (SD) | |

|---|---|---|---|

| Lime consumption before changes (η1) | 53 | 39.246 | 1.81 |

| Lime consumption after changes (η2) | 53 | 35.528 | 0.59 |

| Confidence Interval (CI) with 95% confidence level (Range of values within which the difference in consumption is likely to fall) | (3.320, 3.924) | ||

| p | < 0.001 | ||

| Sample size (N) | Median | SD | |

|---|---|---|---|

| Dololime consumption before changes (η1) | 53 | 26.058 | 0.95 |

| Dololime consumption after changes (η2) | 53 | 24.833 | 0.69 |

| Confidence Interval (CI) with 95% confidence level (Range of values within which the difference in consumption is likely to fall) | (0.378, 1.015) | ||

| p | < 0.001 | ||

Theoretically, lime injection should promote lower lime consumption due to enhanced intermixing and reactivity of the finer particles. However, the observations revealed a progressive increase in lime consumption during the 53 heats belonging to the lime injection practice (before changing injected material). This discrepancy can be attributed to the variability in scrap quality [28]. While the quantity of scrap charged remained consistent between the two practices, strict control over scrap composition was not feasible, particularly due to storage on sand. This factor may have led to elevated levels of SiO2 within the scrap, consequently necessitating additional lime for fluxing purposes. Additionally, the improved quality of the lime produced at our plant compared to imported lime, which can degrade during storage and shipment, contributes to the decreased lime consumption. Freshly produced lime from our plant typically exhibits a higher percentage of CaO (on average 93.3 wt%) than the imported one.

Conversely, the lower dololime consumption observed during dololime injection can be explained by the improved mixing and reactivity achieved with finer dololime particles. This is also confirmed by the reduced basicity of the slag before and after the injection campaign, which moves from 3 to 2.4 (Table 7).

| CaO | MgO | SiO2 | FeO | Al2O3 | MnO | CaO/SiO2 | |

|---|---|---|---|---|---|---|---|

| During lime injection | 35.36 | 7.99 | 11.52 | 33.54 | 3.66 | 1.44 | 3.07 |

| During dololime injection | 32.69 | 8.08 | 13.49 | 32.95 | 4.19 | 1.53 | 2.44 |

3.2 Analysis of Electrical Consumption

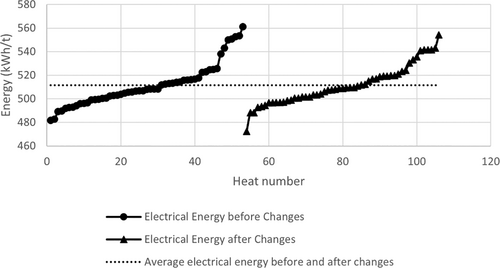

While Figure 4 visually shows no significant change in electrical consumption following the process modifications and the average electrical consumptions before and after changes are 512 kWh/t, formal hypothesis testing is essential for confirmation. As presented in Table 8, the test results clarify that the observed similarity in consumption can be attributed to chance or reflects a genuine null effect of the changes. Given that hypothesis testing indicates a negligible impact on electrical consumption, the next logical step is to investigate oxygen and carbon consumption.

| Sample size (N) | Median | SD | |

|---|---|---|---|

| Electrical Energy consumption before changes (η1) | 53 | 507.96 | 18.39 |

| Electrical Energy consumption after changes (η2) | 53 | 508.90 | 16.63 |

| Confidence Interval (CI) with 95% confidence level (Range of values within which the difference in consumption is likely to fall) | (−6.59, 5.25) | ||

| p | 0.7569 (> 0.05) | ||

Table 7 presents the average slag analysis for both practices. While theoretically higher lime consumption during lime injection (before changing injection profile) could lead to increased electrical energy demands, limitations imposed by the local authority on energy consumption necessitated an alternative approach. To mitigate this limitation, additional chemical energy was introduced through increased oxygen and carbon injection, which will be discussed in detail in the following sections.

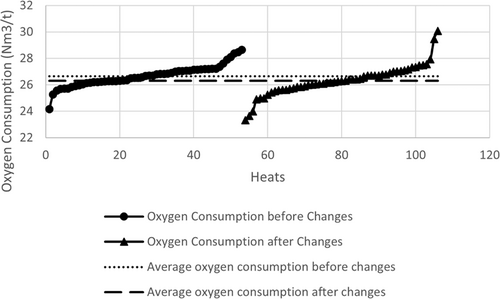

3.3 Analysis of Oxygen Consumption

Figure 5 illustrates the oxygen consumption for the standard process and the process using dololime injection. The average oxygen consumption before and after the changes was 26.7 and 26.3 Nm3/t, respectively. However, to confirm the statistical significance of this variation, hypothesis testing was employed. Normality testing confirmed that the oxygen consumption data distributions were suitable for parametric analysis. The results of the hypothesis test, presented in Table 9, indicate that it is not possible to reject the null hypothesis. Thus, the oxygen consumption between the two processes is the same.

| Sample size (N) | Mean | (SD) | |

|---|---|---|---|

| Oxygen consumption before changes (η1) | 53 | 26.663 | 0.812 |

| Oxygen consumption after changes (η2) | 53 | 26.32 | 1.16 |

| Confidence Interval (CI) with 95% confidence level (Range of values within which the difference in consumption is likely to fall) | (−0.040, 0.734) | ||

| p | 0.078 (> 0.05) | ||

However, the marginal reduction in oxygen consumption during the dololime injection can be explained by the fact that extra energy was needed during lime injection because of the extra lime used, and this was done using chemical energy.

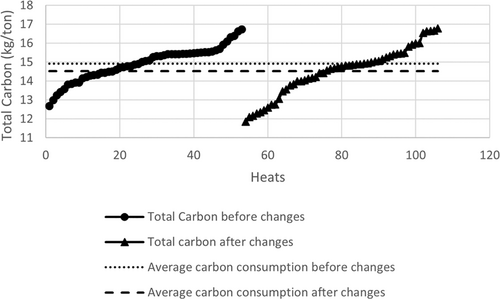

3.4 Analysis of Carbon Consumptions

Figure 6 details the analysis of total carbon consumption during the heat. Three carbon types are currently employed: charging carbon, bucket carbon, and foaming carbon injected through injectors. The pre- and post-change average total carbon consumption values were 14.9 and 14.5 kg/t, respectively. Hypothesis testing was employed to assess the statistical significance of this observed decrease. Normality testing confirmed that the carbon consumption data distributions were suitable for parametric analysis (Table 10). The hypothesis test results indicate that the null hypothesis of no difference in total carbon consumption between the two processes cannot be rejected. Thus, this statistically supports the similarity in overall carbon consumption across the two procedures, and it is enough for this study to conclude that the carbon consumption decreased or remained constant.

| Sample size (N) | Mean | (SD) | |

|---|---|---|---|

| Total Carbon consumption before changes (η1) | 53 | 14.923 | 0.895 |

| Total Carbon consumption after changes (η2) | 53 | 14.52 | 1.29 |

| Confidence Interval (CI) with 95% confidence level (Range of values within which the difference in consumption is likely to fall) | (−0.024, 0.833) | ||

| p | 0.064 (> 0.05) | ||

This small difference in carbon consumption can be explained by the fact that extra energy was needed for the extra lime used during lime injection, and this was done through chemical energy (carbon and oxygen). This is the reason why the two main chemical energy sources increase simultaneously during the control campaign before changing the injected material. In addition, by looking at the average chemical composition of the slag before and after the injection switching (Table 7), the slag obtained with dololime injection has a concentration of SiO2 and Al2O3 higher than the slag formed during lime addition. This increase in acidic species may lead to an increase in viscosity that facilitates the foaming, since it reduces the drainage rate of the CO/CO2 bubbles [29]. Thus, less powdered carbon is needed to promote, control, and maintain the foaming slag during the refining stage.

3.5 Parameters Monitored

In addition to the parameters previously discussed, a comprehensive evaluation of the process post-modification included monitoring a broader range of operational parameters. A detailed comparison of these parameters for the standard and modified processes is presented in Table 11. The analysis revealed no significant deviations from expected values, indicating that the process changes did not introduce any detrimental effects on overall process stability.

| EAF parameters | Standard process | After process changes |

|---|---|---|

| Lime dispenser idle pressure (bar) | 0.3 | 0.3 |

| Lime dispenser working pressure (bar) | 0.8 | 0.8 |

| Fines injecting flow rate (kg/min) | 45–90 | 45–90 |

| Furnace refractory condition | Normal | Normal |

| Furnace refractory side wall & banks condition | Normal | Normal |

| During fines feeding furnace performance | Normal | Normal |

4 Discussion

A comprehensive financial analysis was conducted to assess the economic benefits associated with the proposed flux substitution strategy. Table 12 summarizes the projected annual cost savings based on a production volume of 1 million tonnes per annum (tpa) billets. It is important to acknowledge that actual savings may vary depending on the production tonnage at the SMP.

| Before lime to dololime fines switch | After lime to dololime fines switch | |

|---|---|---|

| Purchase of lime fines (tpa) | 11,767 | 128 |

| Annual lime briquetting (t) | 4759 | 6505 |

| Annual dololime briquetting (t) | 12,754 | 4205 |

| Briquetting cost (11 US$/t) | 60,595 | 37,056 |

| Production of lime at lime plant (tpa) | 31,731 | 43,370 |

| Total production at lime plant (tpa) | 69,257 | 80,896 |

| Cost of fluxes (production + purchase + Briquetting) in US$ | 7,552,420 | 7,200,180 |

| Savings | 352,240 (US$) | |

The implemented process modification involved substituting lime fines injection with dololime fines injection while maintaining the overall mass balance of lime and dololime. This strategy ensured a controlled environment for evaluating the impact of the change by keeping all other operational parameters constant. As observed in the previous sections, overall consumption levels either remained consistent or decreased following the implementation. Notably, the reduction in flux consumption surpassed initial expectations, translating into greater cost savings.

5 Conclusion

This study investigated the feasibility of switching traditional lime fines injection with dololime fines injection in the electrical arc furnace at KuwaitSteel SMP. The primary objective was to evaluate the potential for dololime injection without introducing negative side effects. The analysis aimed to identify and validate any benefits associated with dololime compared to the existing practice.

- Lime consumption decreased by 3.2 kg/t.

- Dololime consumption also exhibited a slight decrease of 0.6 kg/t.

- While reductions in electrical energy, carbon, and oxygen consumption were observed, these changes were less significant.

This study successfully demonstrates the viability of substituting lime injection with dololime injection in specific scenarios, offering potential advantages for steelmakers.

Author Contributions

Bilal Elhajjar: conceptualization, investigation, writing – original draft, methodology, validation, visualization, writing – review and editing, software, formal analysis, project administration, resources, data curation. Mohamed Samir Larhrib: software, supervision. Davide Mombelli: formal analysis, writing – review and editing.

Acknowledgments

The authors would like to express their sincere gratitude to The CEO of Kuwait Steel Company, Mr. Faisal Alkhaldi, for his unwavering support and encouragement during this research. He recognized the potential of this project and provided the resources and freedom necessary for its successful completion.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.