Tensile Properties of Kenaf Fiber Bundle

Abstract

Tensile tests of kenaf fiber with different characteristics were carried out and their potential application to the reinforcement of FRP was conducted. Specifically, the effect of stem diameter and length on the mechanical properties of kenaf fiber of different types was investigated. In addition, after converting kenaf fibers into pulp, the cellulose content ratios and extent of polymerization within the fibers were measured to investigate their influence on the tensile strength of the fibers. The tensile strength of kenaf fiber was observed to increase with the length of the stem. Moreover, at approximately 48%, the ratio of cellulose contained in kenaf fiber was found to be stable regardless of the length and diameter of the kenaf stem. Cellulose DP in kenaf fibers was observed to change depending on the tensile strength of the fiber and longer kenaf fibers were found to have relatively higher tensile strengths and cellulose DP.

1. Introduction

Recent years have witnessed the rapid development of technologies and an increase in the standard of living of people. However, these developments have their disadvantages; we are running out of fossil fuels and there is insufficient space for our waste. There is thus no longer doubt that it is becoming increasingly difficult to live sustainably in the global environment. Solutions to these problems involve the development of appropriate waste treatment processes and methods for recycling waste as soon as possible. One of such solution is the development of a recycling society. Plastic materials are used in various fields for many reasons, including their lightweight, high specific strength, good processing ability, and the ease by which they can be mass-product. One of the major causes underlying the lack of space for waste disposal is that plastics consisting of materials that degrade very slowly naturally are buried in landfills. One solution to this problem is the development of biodegradable plastics [1], which would be decomposed into water and carbon dioxide by micro-organisms in the soil. Such biodegradable plastics would have a very small load on the environment. Since the carbon dioxide liberated during biodegradation is absorbed by plants during photosynthesis, the over all balance with respect to carbon dioxide remains zero. Biodegradable composite materials [2–4] can be used in the manufacture of such plastics and it is believed that nonpetroleum-based natural fibers will play a major role in solving the aforementioned problems.

In fiber reinforced plastics (FRPs), the strength of the combined fibers has a marked effect on the characteristics of the resulting composite materials. Consequently, it is thus necessary to determine the strength distributions of natural plant fibers in order to develop practical applications for biodegradable composite materials. Furthermore, differences in the growth conditions and characteristics of plants could affect the strength characteristics of different fibers. While natural fibers are considered to consist of cellulose, lignin, hemicellulose, and so forth [5], it is generally believed that it is the strength of cellulose that affects the strength of the fiber.

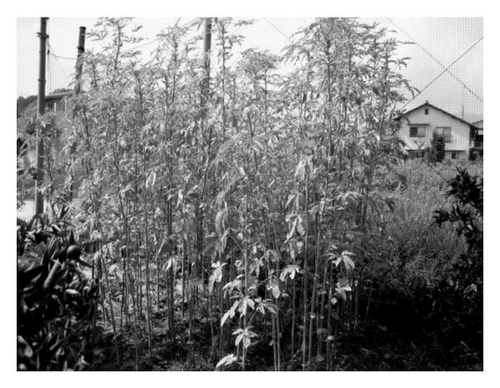

Given these characteristics, this study focused on kenaf [6–8], a natural fiber. Kenaf (Hibiscus cannabinus L.) is an herbaceous annual plant that can be grown under a wide range of weather condition. It grows to more than 4 m within 6 months even in moderate conditions. In this research, kenaf plants were cultivated and measured a length and a diameter of their stem. Next fiber bundles were extracted by retting. The tensile strength of fiber bundles from different dimensions was assessed. In addition, the effect stem diameter and length on the strength of kenaf fiber were also examined. Single fibers were extracted from fiber bundles to examine the extent of cellulose DP and cellulose-content ratios, and the extent to which cellulose DP was related to tensile strength was also examined.

2. Experimental Procedures

2.1. Selection of Kenaf

Thirty kenaf plants were selected for this experiment. The kenaf plants consisted of plants that were similar in length with stem diameters that varied, or that varied in length but had different stem diameters. In this experiment, kenaf specimens that were similar in length (approximately 3 600 mm) but that had different diameters (25 mm, 32 mm, and 43 mm) were selected, and specimens with similar diameters (approximately 32 mm), and different lengths (2 670 mm, 3 640 mm, 4 120 mm). Table 1 shows the stem diameter and length of each kenaf plant.

| Number | Diameter of stalk (mm) | The total length of stalk (mm) |

|---|---|---|

| 1 | 32 | 3640 |

| 2 | 43 | 3440 |

| 3 | 32 | 2670 |

| 4 | 32 | 4120 |

| 5 | 25 | 3610 |

Fibers were extracted from selected kenaf specimens using a process referred to as retting. In this process, plants are soaked in water and microorganisms begin digesting the epidermis, and in so doing, they expose the fibers. Retting term is 60 days, and any chemicals were not use.

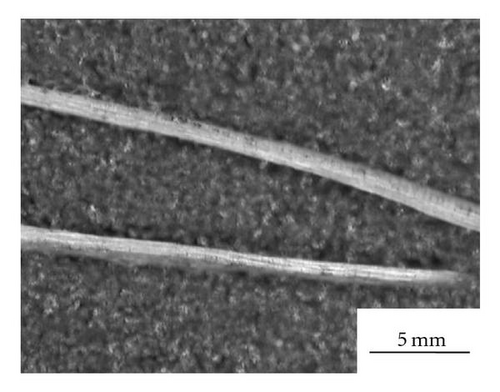

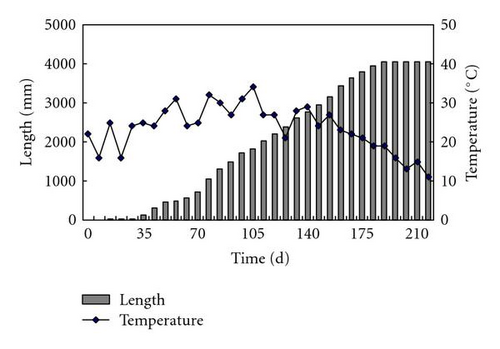

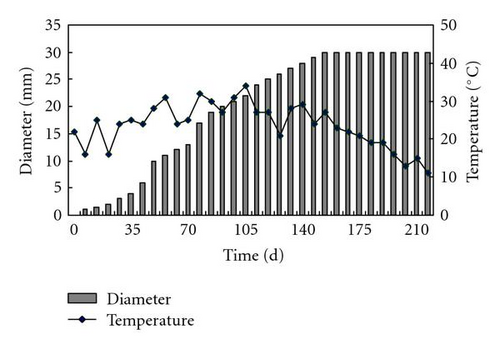

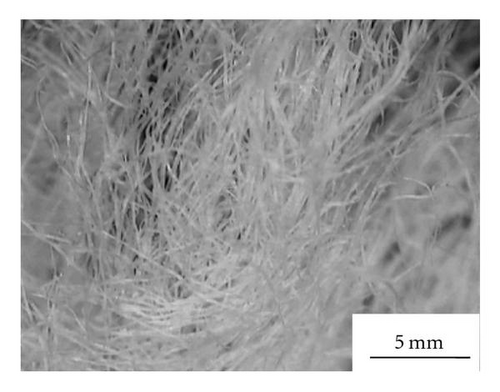

Figure 1 shows a photograph of the kenaf tested. Figure 2 shows the fiber bundles that were obtained, and Figures 3 and 4 show the growth of the kenaf plants. Kenaf has a woody base from which numerous fibers can be extracted. Kenaf also grows faster than numerous other plants. As shown in Figure 1, it grows to around 4 000 mm in height in half a year. In addition, as indicated in Figure 2, fiber bundles measuring 100 to 300 μm in diameter could be harvested (Figure 1). As can be seen in Figure 3, kenaf grows until the 180 days where after growth decreases and the plant remains at approximately the same height. Stem diameter, as shown in Figure 4, reaches approximately 30 mm in approximately 150 days and then remains approximately the same thereafter.

2.2. Preparing the Tensile Specimen

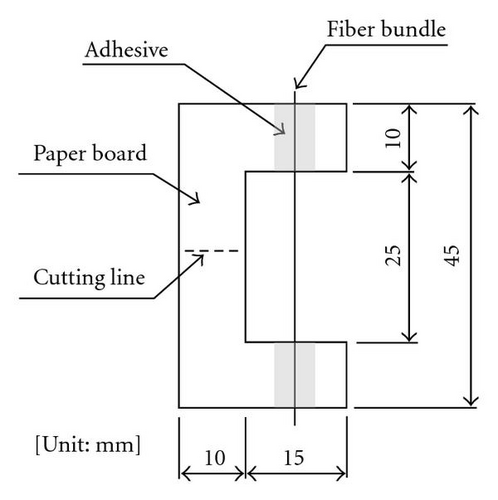

Paper board was prepared for our tensile test, referring to JIS R 7601 : 1986 testing methods for carbon fibers. Figure 5 shows made tensile specimen. To measure the cross-sectional area of fibers, the diameter of each fiber at ten different positions was measured, using a large, precision projector (Model PP-55C of Topcon Corporation, Japan), and obtained the average of these measurements.

2.3. Methods of the Tensile Test

The tensile specimens were attached onto the testing machine (Aikoh engineering co., Ltd., model 1301D) so that the fibers were positioned vertically. Then, to conduct the tensile test, the paper board was cut along cutting lines and a strainrate of 0.04 per min was applied to the fibers. The test was performed 15 times under the same conditions in order to obtain the tensile strength of each fiber at a 95% confidence interval.

2.4. Measurement of Cellulose Content Ratios

The technique employed to obtain pulp from kenaf fibers is referred to as Kraft pulping [9], which removes lignin using caustic soda and sodium sulfide. In the pulping process, the kenaf fibers are placed into an aqueous solution of water, caustic soda (NaOH), and sodium sulfide, with the sulfidity ((Na2S/(NaOH + Na2S)) × 100%) of 30% and an alkali additive ratio of 15%.

The pulping temperature was 110°C for 6 hours. Following this process, the kenaf fiber bundles were placed into a mixer with water, which was stirred for 5 minutes before the kenaf pulp was extracted by filtering (Figure 6). The photograph shows fiber bundles from Figure 2 being separated into single fibers. Using the masses measured before and after pulping, the cellulose content ratios using the following formula could be calculated as follows:

2.5. Measuring the Degree of Polymerization

The kenaf fibers were then obtained from kenaf pulp after dissolving in a solution of cuprammonium. Then, using an Ubbelohde-type viscometer (SU-6830 of Sibata Scientific Technology Ltd. Japan), the viscosity of the solution was measured and the degree of polymerization using the following formulae [10] was determined. For these viscosity measurements, the quantity of pulp dissolved into the solution was 30 mg to 70 mg:

3. Results and Discussions

3.1. The Structure of Kenaf

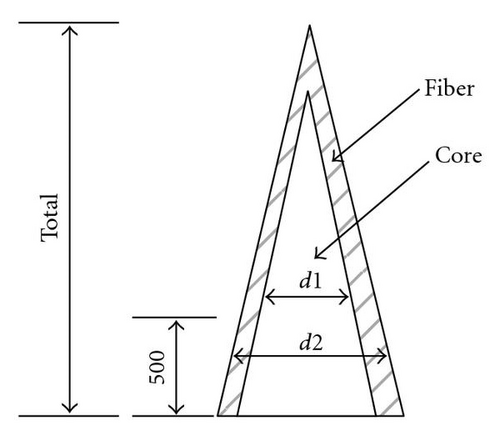

Kenaf has bast fiber on and around its stem, and the fibers used in this study are extracted from this bast. To use kenaf as a reinforced composite material, there is need to quantify how much fiber can be extracted from a single kenaf. Figure 7 shows a kenaf model. However, d1 is the diameter of the stem itself, and d2 is the entire diameter, including the fibers. Furthermore, Figure 8 shows a cross-section of kenaf, the stem of which has bundles of fibers around it.

Using one of the kenaf samples thus prepared, several sections of the two stem diameters were examined; one with and the other without the fibers (Table 2). The diameter of the kenaf decreases as one moves from the root to the highest end. The kenaf was then cut into sections measuring 500 mm each, beginning with where the trunk came into contact with the soil. Using the diameter of the stem from the center with and without the fibers and the length of kenaf, the volume ratio of the fibers for each kenaf specimen were obtained. The volume ratio of fibers was approximately 28% (n = 10). Table 3 shows data for three of these specimens. While individual kenaf specimens differed with respect to stem diameter and length, the fiber volume ratio remained almost the same at around 28%.

| The total length of stalk (mm) | Part | Diameter of stalk (mm) | Diameter of stalk (mm) |

|---|---|---|---|

| (a) | 29.0 | 26.4 | |

| (b) | 21.7 | 18.9 | |

| (c) | 18.1 | 15.5 | |

| (d) | 16.4 | 14 | |

| 4040 | (e) | 14.8 | 13.2 |

| (f) | 12.5 | 11.1 | |

| (g) | 11.5 | 9.3 | |

| (h) | 8.5 | 7.3 | |

| Top | 3.5 | 3.2 |

| The total length of stalk (mm) | Diameter of stalk (mm) | Diameter of core (mm) | Percentage of the filbers (%) | |

|---|---|---|---|---|

| 1 | 4110 | 37.1 | 31.1 | 27.9 |

| 2 | 4180 | 29.1 | 22.7 | 27.0 |

| 3 | 3650 | 37.0 | 32.0 | 28.3 |

3.2. Effect of Stem Diameter on the Tensile Properties of Kenaf Fibers

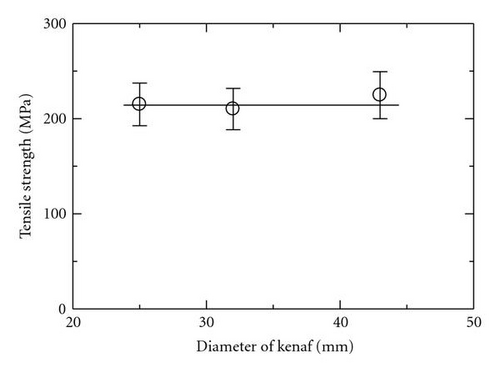

To determine effect of the stem diameter of kenaf on the strength characteristics of the fiber, tensile tests of three groups of kenaf fibers extracted from three different kenaf specimens of similar length, but with different stem diameters were conducted (Table 1 number 1, number 2, and number 5). All of the fibers used in this test were extracted from the sections close to the roots. As can be seen in Figure 9, the tensile strength from the different kenaf plants was similar, irrespective of stem diameter indicating that different stem diameters do not significantly affect fiber strength.

3.3. Effect of Stem Length on Kenaf Fiber Strength

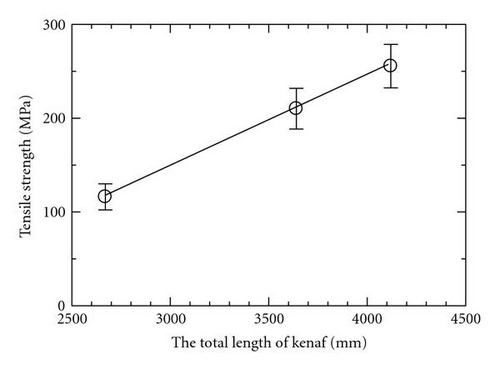

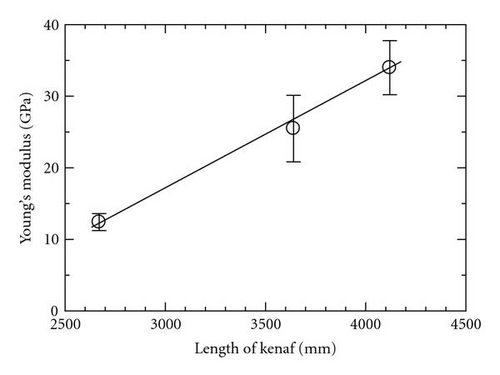

To determine the effect of the stem length on the fiber strength characteristics of kenaf, tensile tests were conducted on three groups of kenaf fibers extracted from three different kenaf specimens with similar stem diameters but with different lengths (Table 1 number 1, number 3, and number 4). As can be seen in Figure 10, longer kenaf had greater tensile strengths, indicating that fibers extracted from taller kenaf are stronger. Figure 11 shows the relationship between kenaf length and the elastic modulus of their fibers. As with tensile strength, elastic modulus also increased with the height of the kenaf.

3.4. Cellulose Content Ratios of Kenaf Fibers

To determine how the cellulose ratio affects tensile strength of kenaf fibers, the cellulose content ratios of fibers from kenaf of different lengths were measured. The fibers were all pulped under the same conditions, extracted from the resulting pulp, and the fiber masses were compared before and after pulping to determine pulp content ratios (Table 4). Cellulose content ratios were found to be similar (approximately 48%) for kenaf of different length, indicating that the cellulose content ratio remains similar across kenaf plants with different dimensions and fiber strengths.

| Number | Mass before making to pulp g | Mass after making to pulp g | Cellulose content mass% |

|---|---|---|---|

| 1 | 1.226 | 49.0 | |

| 3 | 2.5 | 1.216 | 48.6 |

| 4 | 1.191 | 47.6 |

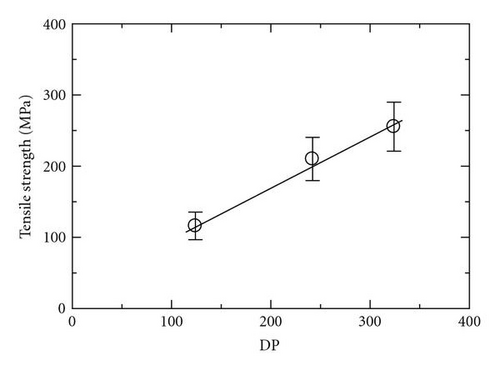

3.5. Measurement of Cellulose DP

To investigate the relationship between the tensile strength of kenaf fiber and the degree of cellulose DP, the extent of cellulose DP extracted from kenaf fibers, was determined (Figure 12). As shown in this figure, the tensile strength was highest in kenaf fiber with a higher cellulose DP. These results are similar to the results obtained for kenaf length and the tensile strength of fiber (Figure 10) and show that the extent of cellulose DP is positively related to kenaf height and tensile strength.

4. Conclusion

With a view to using kenaf fibers for reinforcement of FRP, this study conducted tensile strength tests of fibers extracted from several kenaf plants with different characteristics, in order to determine how stem diameter and length affect the mechanical characteristics of fibers. Kenaf pulp was also produced from plant fibers and the cellulose content and degree of cellulose polymerization were measured. The relationship between the extent of polymerization and fiber tensile strength were measured and the following results were obtained.

Stem thickness of kenaf is not constant. Stems decrease in thickness in an upward direction. Moreover, the volume ratio of fibers in the whole kenaf is constant at approximately 28%, irrespective of stem diameter and length.

Furthermore, kenaf fiber strength was observed to increase as kenaf increase in height, regardless of stem diameter.

At around 48%, the cellulose content ratio of kenaf fibers was similar between samples, irrespective of kenaf stem diameter and length.

The cellulose DP in kenaf fibers affected tensile strength, with taller plants having fibers with greater tensile strength, and by inference, higher cellulose DP.