PID Parameter Optimization of Temperature Control for Plastic Extruder Based on ISA-PSO Algorithm

Abstract

In order to improve the control accuracy of the temperature control system for the plastic extruder and better achieve optimal control between the parameter settings and the temperature of the plastic extruder, an intelligent algorithm combining improved simulated annealing (ISA) algorithm and particle swarm optimization (PSO) algorithm is studied. This algorithm is utilized to achieve automatic optimization of the PID parameters of the temperature control system, thereby making parameter optimization faster and more accurate. The benchmark test function was employed to evaluate the performance of the improved PSO (IPSO) algorithm, genetic algorithm improved PSO (GA-PSO), simulated annealing PSO (SA-PSO), and ISA-PSO. The results demonstrated that the ISA-PSO algorithm possesses stronger global optimization capability and superior convergence performance. Finally, MATLAB simulation and experimental test results indicate that, compared to the control effects of IPSO, GA-PSO, and SA-PSO, the PID controller optimized by the ISA-PSO algorithm exhibits better accuracy and robustness. The temperature fluctuation of the charging barrel is significantly reduced, with the maximum value of the absolute temperature deviation being only 0.6°C and the average value of the absolute temperature deviation being approximately 0.35°C. This effectively enhances the accuracy and robustness of the temperature control system for the plastic extruder.

1. Introduction

Plastic products are widely used in industrial and agricultural production, transportation, building materials, and other fields due to their abundant raw materials, low prices, easy processing, and other characteristics [1]. The plastic extruder is the primary equipment for the production and processing of plastic products [2], and its temperature is the prerequisite condition for promoting the plasticization of molding materials and the flow of plastic melt. The precision of temperature control directly determines the quality and performance of plastic products [3]. Therefore, rapidly and accurately controlling the temperature of the plastic extruder has become a key research focus in the plastic extrusion molding process.

Currently, plastic extruders exhibit characteristics such as large inertia, time delay, and nonlinearity in temperature control of plastic melts during operation, which reduces the system’s ability to quickly adjust and steady-state accuracy, making the control effect achieved by standard PID methods not ideal. For the characteristics of the temperature control system, some researchers have made adaptions. For example, Yang et al. [4] constructed an improved genetic algorithm (IGA) and used it to optimize the PID controller parameters of the control loop for the variable air volume air conditioning system. Compared with the conventional PID method, the IGA PID control system has a certain improvement in control accuracy, response speed, and robustness. Jiang [5] introduced the fuzzy neural network (FNN) algorithm into PID parameter tuning and verified the superiority of the FNN PID algorithm through example simulation in the intelligent control of the plastic extruder. In order to improve the control performance and anti-interference ability of the airborne optoelectronic platform, Wang et al. [6] improved the particle swarm optimization (PSO) algorithm from the two aspects of speed and inertia and adjusted the parameters of the PID controller with the PSO algorithm. The simulation results show that the PSO algorithm has a faster rate of convergence and the control performance of the system has been greatly improved. Zhang et al. [7], Shi et al. [8], Zhan and Su [9], He et al. [10], and Ali et al. [11] used the improved sparrow search algorithm (ISSA), improved PSO (IPSO) algorithms, etc., to optimize PID parameters. The introduction of the above individual algorithms has a certain positive effect on the tuning of PID control parameters, but there are still some aspects that need to be improved, such as the number of neurons and hidden layers of neural network which is difficult to determine, and PSO is prone to premature convergence and local optimality. Zhu et al. [12] used the GA-PSO hybrid method to optimize the initial weights of the BP neural network and achieved good control results in the water and fertilizer control system. However, the GA algorithm is difficult to encode the network weights, and its performance is greatly affected by the selection of genetic operators. Shao et al. [13] used the SA-PSO algorithm to optimize the PID parameters of a quadcopter unmanned aerial vehicle control system. The results showed that the algorithm effectively improved the disadvantage of the PSO algorithm being prone to local optima and enhanced the optimization speed and disturbance resistance. The SA algorithm does not require encoding like the GA algorithm and does not require genetic operator selection, but its search space is greatly affected by the cooling function. Therefore, selecting an appropriate cooling function is particularly important.

With the development of artificial intelligence technology, machine learning methods represented by deep learning have been successfully applied in many fields [14, 15]. Wang et al. [16] utilized deep Q-networks and PID algorithms to achieve effective tracking of moving targets, with stronger robustness and generalization. Yang et al. [17] improved the traditional PID controller based on the deep deterministic policy gradient (DDPG) algorithm to adapt to different road conditions and vehicle acceleration and deceleration situations. Although deep learning has shown its own advantages in the field of control, there are still problems such as low sample efficiency, unstable training, and difficulty in balancing exploration and utilization.

- 1.

By improving the cooling function and adding storage elements, the performance of the SA algorithm can be enhanced. The integration of ISA algorithm and PSO algorithm improves the problem of PSO easily getting stuck in local optima, while enhancing the convergence speed and accuracy of particle optimization at the end.

- 2.

Applying this algorithm to the temperature control of plastic extruders not only solves the problem of PID controller lag in the temperature control system but also improves the accuracy and speed of PID parameter automatic optimization, achieving precise temperature control of plastic extruders.

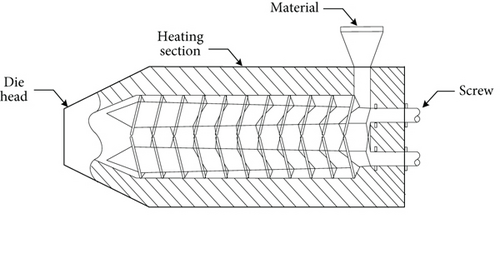

2. Temperature Control System for Plastic Extruder

The plastic extruder is mainly composed of transmission unit, extrusion unit, and heating and cooling unit. The structure schematic diagram of its charging barrel is shown in Figure 1. During the working process of the plastic extruder, the heater makes the temperature of the charging barrel rise, and the raw material is transformed from particles to melts. The melts are evenly stirred by the screw in the charging barrel and extruded by the die head, and then processed into plastic products after cooling, trimming, and winding.

3. SA-PSO Algorithm and Its Improvement

3.1. PSO Algorithm

Even if the value adjusted by using the above method is adopted, the PSO is still easy to fall into the local extremum, so other optimization algorithms need to be adopted to make the PSO jump out of the local optimal.

3.2. SA and Its Improvement

SA algorithm randomly searches to obtain the global optimal solution of the objective function by giving probabilistic jumping in the search process. However, this algorithm also has some shortcomings such as slow convergence speed and difficult parameter adjustment [22, 23]. According to the characteristics of temperature control for the plastic extruder, this study proposes an improved SA algorithm based on the standard SA algorithm.

3.2.1. Improved Cooling Function

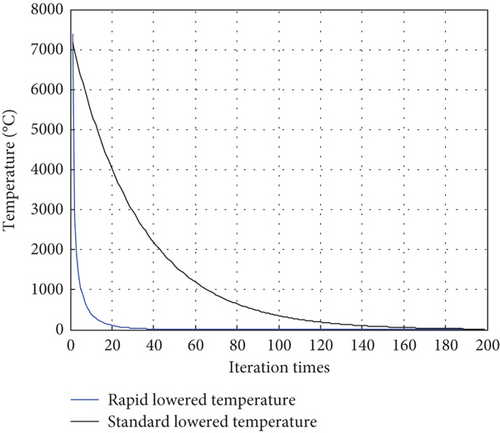

The cooling function is one of the main elements in the SA algorithm, which affects the search space of the algorithm. The temperature can make the algorithm conduct global search or local search.

The above two cooling function curves are shown in Figure 2. From the graph, it can be seen that both cooling functions will decrease the quality of the solution.

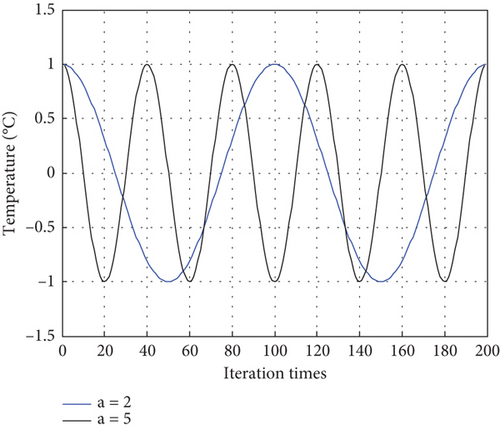

The function curves for different values of α are shown in Figure 3.

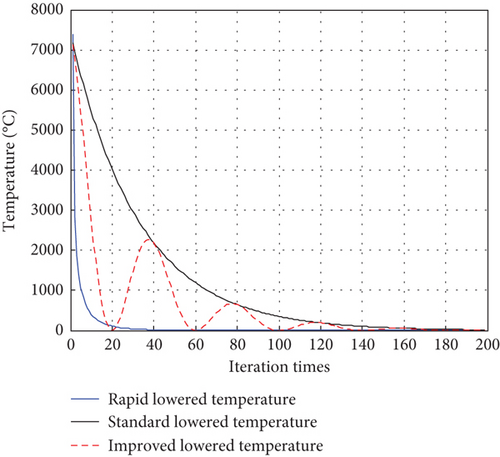

In order to verify the effect of the improved cooling function, standard cooling, rapid cooling, and the cooling function in this paper are selected for comparison, and the cooling curve is shown in Figure 4.

As can be seen from Figure 4, the cooling function in this paper combines the advantages of standard cooling and rapid cooling and adds the tempering process to enhance the global search and local search capabilities of the algorithm. At the same time, the cooling speed and tempering process can be adjusted by adjusting the tempering cycle coefficient.

3.2.2. Add Storage Segment

In the iterative process of the algorithm, the principle of acceptance criteria may lead to abandoning the optimal solution. Therefore, the memory matrix M and the memory function F are added in the iterative process. At the beginning, the memory matrix M has only element i0, and F = f(i0). Each time the new solution j is accepted, F and f(j) are compared. If f(j) < F, then F = f(j), and j is accepted, F will be stored in the memory matrix M. If f(j) > F, then F remains unchanged, and j is accepted, F will not be released into the memory matrix M. After the iteration is completed, the final optimal solution is compared with the historical optimal solution in the memory matrix M to determine the optimal one as the final optimal solution, thereby ensuring that the final solution is in the best state.

Through the above improvements on the traditional SA algorithm, the improved SA algorithm realizes fast cooling in the initial stage and stable cooling in the later stage and includes the tempering process and the memory function, which improves the search accuracy and operation efficiency of the algorithm.

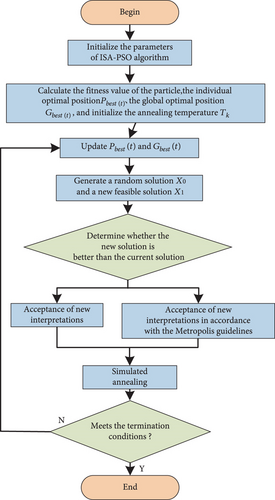

3.2.3. ISA-PSO Algorithm

The PSO algorithm is simple to implement and has strong global search ability. However, during the optimization process, it tends to focus on the current optimal solution, which can lead to getting stuck in local optima. On the other hand, the ISA algorithm is characterized by its heuristic and random search properties, with probabilistic jumping in the search process that helps escape local optima. Taking into account the characteristics of both algorithms comprehensively, this paper proposes the ISA-PSO algorithm, and its flowchart and pseudocode are shown in Figure 5 and Algorithm 1.

-

Algorithm 1: ISA-PSO algorithm pseudocode.

-

Algorithm: ISA-PSO

-

Input: Initialize the basic parameters of PSO and ISA algorithm, including the Number M, Dimensions D, Iteration times N, Weight factors ωmax and ωmin, Velocity boundary Vmax and Vmin, and ISA algorithm constants k

-

Output: Global optimal solution Gbest(t)

-

1 Initialize the basic parameters of PSO and ISA algorithm

-

2 For i = 1 to M do

-

3 Initialize position xi, vi randomly within range

-

4 Calculate fitness value f(xi)

-

5 Set Pbest(t) = xi

-

6 end For

-

7 Gbest(t) = min{Pbest}

-

8 For t = 1 to N do

-

9 For i = 1 to M do

-

10 Calculate the initial annealing temperature T0

-

11 E = f(xi) − f(xi+1)

-

12 if E < 0 or random(0, 1) ≤ Pi then

-

13 Gbest(t) = xi+1

-

14 elseGbest(t) = xi

-

15 end if

-

16 Update xi and vi

-

17 Update Pbest and Gbest

-

18 end For

-

19 Update Temperature T

-

20 t = t + 1

-

21 end For

The specific steps are as follows:

Step 1: Initialize the position and velocity of each particle in the population.

Step 2: Calculate the fitness value of each particle, and save the individual optimal position in Pbest(t) and the global optimal position in Gbest(t).

Step 3: Determine the initial annealing temperature T0.

Step 4: Perform ISA algorithm iteration for Pbest(t) of each particle, perform optimal operation, and update Pbest(t) of each particle and Gbest(t) of the population.

Step 5: Conduct cooling operation according to Equation (5).

Step 6: When the algorithm meets the termination conditions, stop searching, and output the results. Otherwise, return to Step 4 to continue searching.

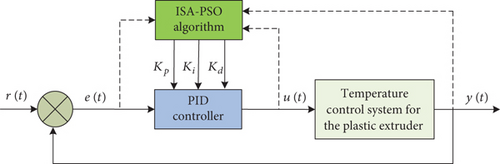

3.3. PID Controller Design of ISA-PSO Algorithm

Using the ISA-PSO algorithm, the individual and global extreme values of the searcher are continuously calculated and updated through the fitness function value, ultimately finding the optimal solution for the three parameters Kp, Ki, and Kd to ensure the optimal performance of the temperature control system. The system control structure is shown in Figure 6.

4. System Simulation Test and Experiment

4.1. Algorithm Performance Testing

Before applying the ISA-PSO algorithm to practical engineering, the performance of the algorithm is tested based on four benchmark test functions [25]. Among them, the sphere function is a typical single-peak function with only one extreme point; Rosenbrock has a global minimum point, but it is a pathological function, and it is difficult for the general algorithm to converge to this extreme point; Rastrigin and Griewank are multipeak functions with multiple local minimum points in the solution space. The function expression and parameter range of each test function are shown in Table 1.

| Function name | Displayed formula | Parameter range |

|---|---|---|

| Sphere | [−100, 100] | |

| Rosenbrock | [−30, 30] | |

| Rastrigin | [−5.12, 5.12] | |

| Griewank | [−600, 600] |

IPSO algorithm [26], GA-PSO [12] algorithm, SA-PSO [13] algorithm, and ISA-PSO algorithm are used as comparison objects for the experiment. The simulation software was MATLAB 2018b, and the computer configuration was Intel Core i7-7700HQ CPU @ 2.80 GHz, the memory is 8 GB, and the operating system is Windows 10. In order to ensure fairness, the parameter settings of each PSO algorithm are basically the same, with the number of particles set to 50 and the number of iterations set to 100. In order to reduce the impact of the randomness of the algorithms on the test results, each algorithm is run independently for each test function for 30 times. The mean and standard deviation based on the error are used to evaluate the convergence accuracy: The mean reflects the optimization ability of the algorithm, while the standard deviation reflects the stability of the algorithm. The running results are shown in Table 2.

| Test function | Algorithm | Average value | Standard deviation |

|---|---|---|---|

| Sphere | IPSO | 1.22e−02 | 2.92e−02 |

| GA-PSO | 1.22e+02 | 2.47e+02 | |

| SA-PSO | 8.71e−04 | 1.89e−04 | |

| ISA-PSO | 4.65e−08 | 2.07e−08 | |

| Rosenbrock | IPSO | 2.79e−01 | 4.94e−01 |

| GA-PSO | 1.36e+00 | 2.57e+00 | |

| SA-PSO | 1.42e−02 | 2.41e−02 | |

| ISA-PSO | 6.85e−06 | 3.04e−06 | |

| Rastrigin | IPSO | 1.91e+01 | 2.05e+01 |

| GA-PSO | 7.48e+02 | 1.28e+02 | |

| SA-PSO | 1.46e+00 | 1.62e+01 | |

| ISA-PSO | 8.63e−02 | 6.59e−02 | |

| Griewank | IPSO | 2.77e−01 | 2.06e−01 |

| GA-PSO | 1.92e+00 | 1.15e+00 | |

| SA-PSO | 2.55e−02 | 2.54e−02 | |

| ISA-PSO | 1.24e−03 | 5.54e−03 | |

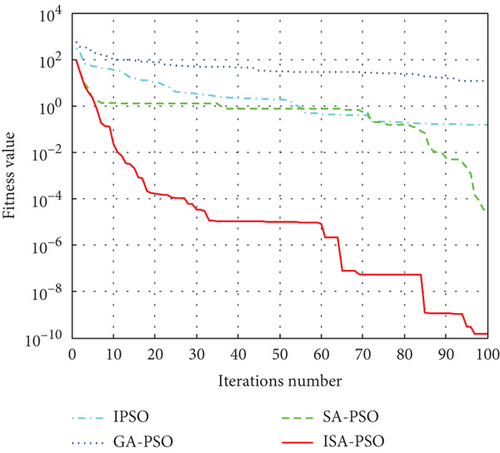

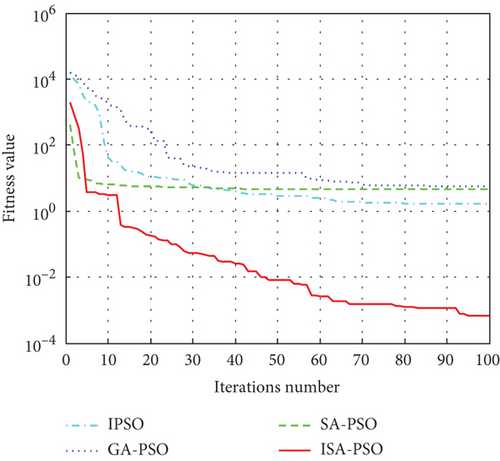

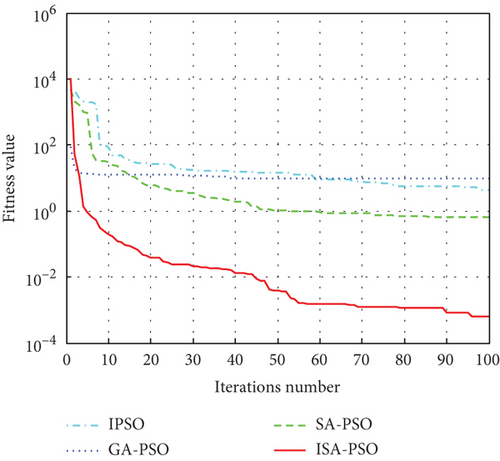

As can be seen from Table 2, in the process of optimizing four functions, the optimization performance of ISA-PSO algorithm is superior to the other three algorithms, and the optimization accuracy has been improved by one to four orders of magnitude. The above indicates that ISA-PSO algorithm can effectively overcome the disadvantage of PSO algorithm being prone to falling into local optima, and the optimization ability and efficiency have been effectively improved. In the multipeak complex test function Rastrigin and Griewank, the ISA-PSO algorithm has higher convergence accuracy and more stable iteration results than the other three algorithms, indicating that the ISA-PSO algorithm has stronger global optimization ability and better robustness. So both in single-peak and multipeak functions, the proposed ISA-PSO hybrid algorithm exhibits superior optimization performance compared to the other three algorithms. The convergence of IPSO algorithm, GA-PSO algorithm, SA-PSO algorithm, and ISA-PSO algorithm in solving the test function is shown in Figure 7.

From Figure 7, it can be seen that compared with IPSO algorithm, GA-PSO algorithm, and SA-PSO algorithm, ISA-PSO algorithm can find the solution of the test function quickly and has better convergence performance.

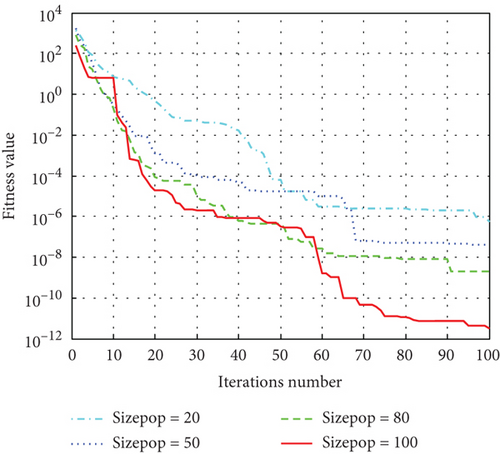

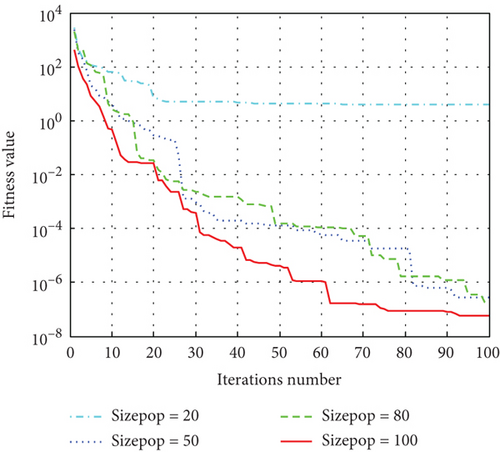

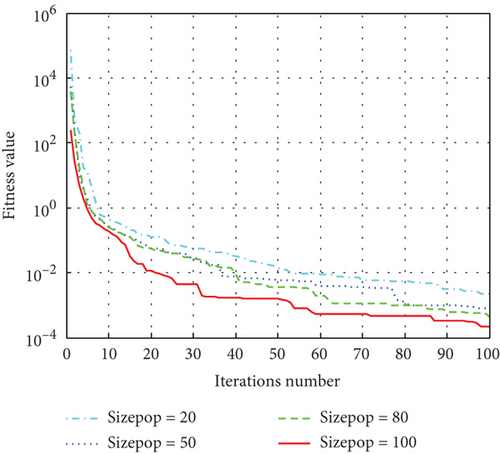

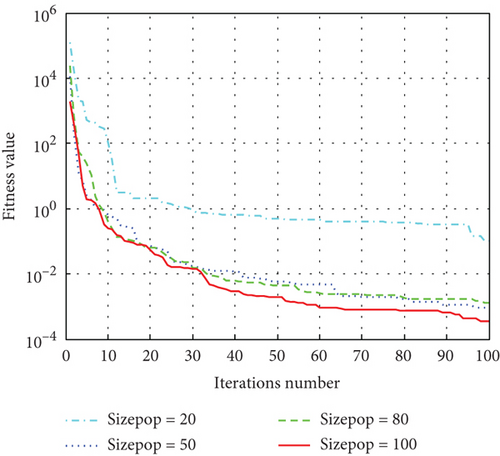

To further evaluate the performance of the ISA-PSO algorithm, different population sizes were used to test the optimization efficiency of the algorithm. Set the population size to 20, 50, 80, and 100, respectively, and use the ISA-PSO algorithm to optimize and solve the four functions. The simulation results are shown in Figure 8.

From the Figure 8, it can be seen that ISA-PSO algorithms with different population sizes converge after about 80 iterations. The higher the population size, the more concentrated the convergence curve of the algorithm, indicating that the stability of the algorithm is also higher. Comparing Figures 8a, 8b, 8c, and 8d, it is found that the maximum convergence algebra of the algorithm decreases with the increase of the population size. However, the larger the population size, the longer the convergence time of the algorithm. If the population size is too small, it will reduce the diversity of the population, and there is a risk of falling into local optima. If the problem requires high convergence time for the algorithm, it tends to choose a smaller population size.

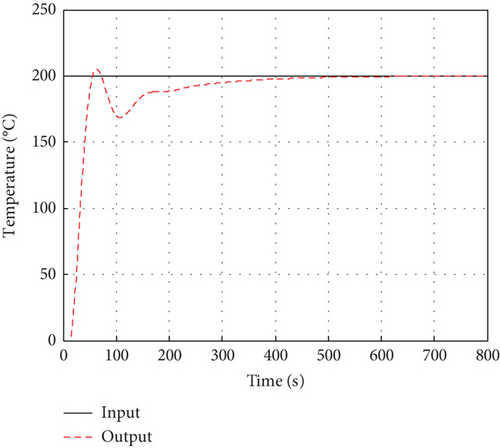

4.2. Simulation Test

Under the control of the traditional PID method, the temperature change curve of the charging barrel is shown in Figure 9, which is mainly divided into heating stage and insulation stage. The temperature rises rapidly in the heating stage and slowly after approaching the set temperature. The system does not have good adjustment ability for environmental changes, and the adjustment time is long. During this period, the system cannot meet the production quality requirements. In order to improve the system performance, it is necessary to continuously adjust the parameters Kp, Ki, and Kd based on experience. The adjustment process is complex, and the accuracy is not high. In addition, the parameters need to be readjusted every time when the production is adjusted, which increases the time and cost of production and maintenance. Therefore, it is necessary to use optimization algorithm to optimize PID parameters.

The simulation experiments were carried out in MATLAB software. After multiple tests, the maximum number of iteration in the PSO algorithm was 100, the particle swarm size was 50, the maximum inertia weight was 0.9, and the minimum inertia weight was 0.1.

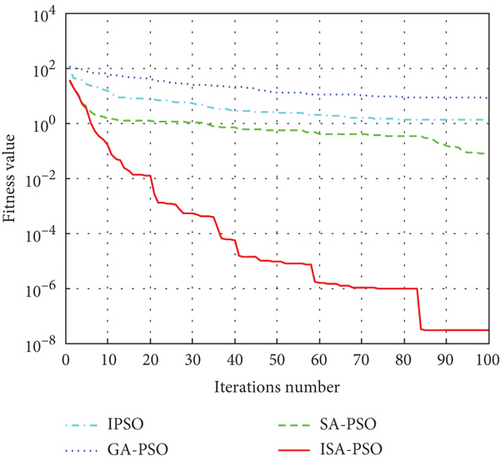

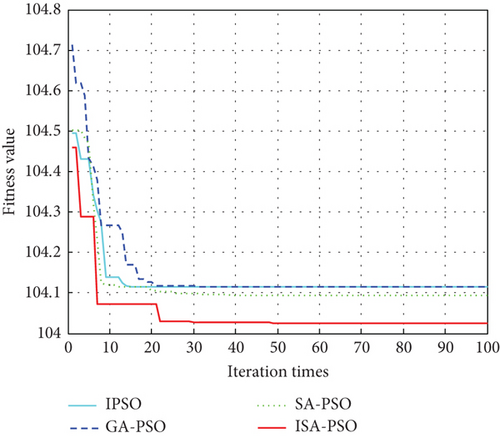

The simulation results of the IPSO, GA-PSO, SA-PSO, and ISA-PSO are compared and analyzed, and the change curves of fitness value are shown in Figure 10. The four algorithms all achieve fast convergence within the number of iteration, but the convergence speed and accuracy of the ISA-PSO algorithm are obviously more advantageous.

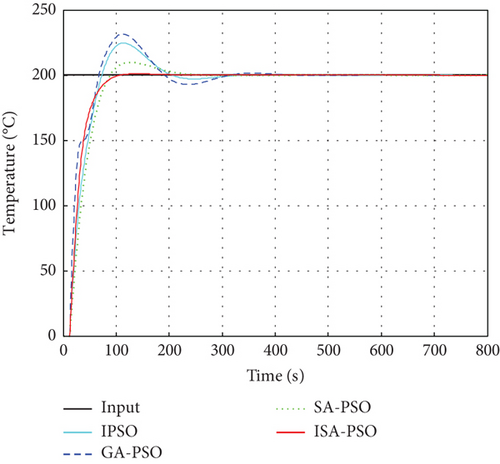

Given the step signal for the temperature control system, the steady-state value of the system is set as 200°C according to the actual working condition of the temperature control system for the plastic extruder. The parameters Kp, Ki, and Kd optimized by the three algorithms are, respectively, brought into the control system, and the simulation results are shown in Figure 11.

As can be seen from Figure 11, all four algorithms optimized controllers can make the system achieve stable output results: GA-PSO and IPSO algorithms make the control system output response about 15.79% and 12.31% dynamic overshooting, respectively, and reach a stable state in about 280 s; SA-PSO algorithm reduces the dynamic overshooting of the control system output response to about 4.91% and reaches a stable state in about 211 s; and ISA-PSO algorithm can reduce the overshoot response of the control system to only 0.54%, and it can reach a stable state in about 93 s without any shaking phenomenon, greatly improving the output response speed and accuracy of the control system. The performance indicators under different algorithms are shown in Table 3.

| Control algorithm | Rise time t/s | Overshoot σ /% | Settling time t/s |

|---|---|---|---|

| IPSO | 61.34 | 12.31% | 268.58 |

| GA-PSO | 59.47 | 15.79% | 294.13 |

| SA-PSO | 69.35 | 4.91% | 211.46 |

| ISA-PSO | 56.12 | 0.54% | 93.88 |

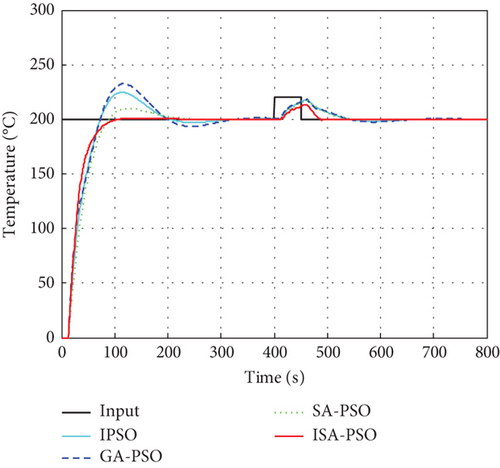

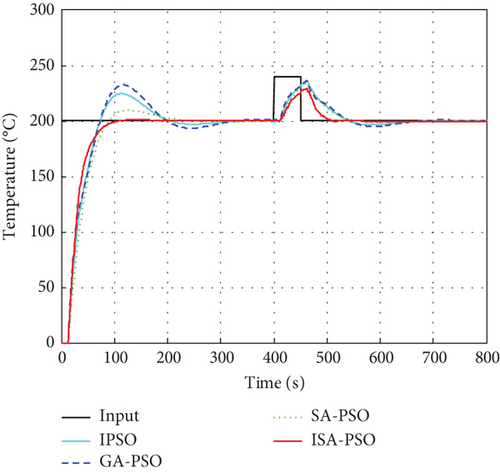

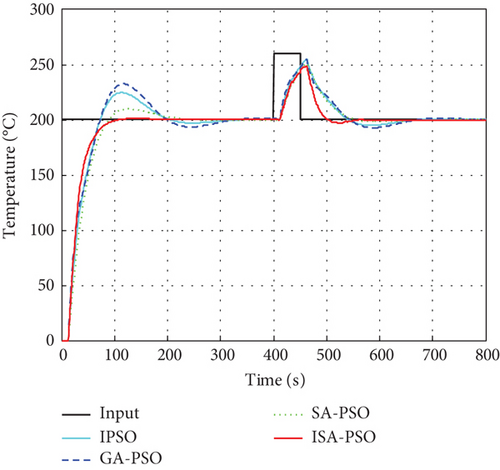

To further verify the improved anti-interference performance of the ISA-PSO algorithm optimized control system, interference signals with pulse width of 50 s and amplitudes of 10%, 20%, and 30% of the set values were added to the system input at t = 400 s, as shown in Figure 12.

From Figure 12a, it can be seen that the control systems optimized by the four algorithms will produce certain oscillations after being disturbed, resulting in dynamic overshoot in the system output. However, the dynamic overshoot generated by the ISA-PSO algorithm is the smallest among the four methods and can stabilize the system output in 90.27 s. From Figure 12b, it can be seen that under 20% interference, the control effect of the ISA-PSO algorithm optimized control system is still better than the other three algorithms, and the system output can be stabilized in 102.42 s. From Figure 12c, it can be seen that as the amplitude of the interference signal increases, the control effect of the ISA-PSO algorithm oscillates, and the adjustment time further increases. After 136.12 s, the system output tends to stabilize, but the control effect is still the best. The specific performance indicators are shown in Table 4. The above results indicate that the control system optimized by the ISA-SPO algorithm has stronger robustness, which presents a good control effect on the temperature control of plastic extruders.

| Disturbance signal | Control algorithm | Overshoot σ /% | Settling time t/s |

|---|---|---|---|

| 10% | IPSO | 9.21% | 118.25 |

| GA-PSO | 9.88% | 129.53 | |

| SA-PSO | 8.61% | 124.18 | |

| ISA-PSO | 6.77% | 90.27 | |

| 20% | IPSO | 18.41% | 223.87 |

| GA-PSO | 18.21% | 239.51 | |

| SA-PSO | 17.22% | 138.05 | |

| ISA-PSO | 14.55% | 102.42 | |

| 30% | IPSO | 27.61% | 237.78 |

| GA-PSO | 27.82% | 248.93 | |

| SA-PSO | 25.82% | 173.44 | |

| ISA-PSO | 24.32% | 136.12 | |

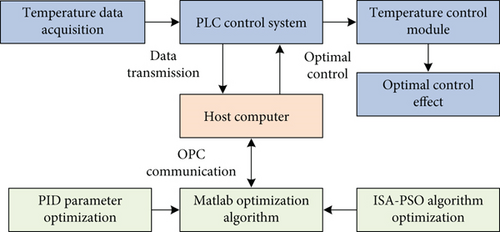

4.3. Algorithm Experiment Test

In order to further verify the effectiveness of the ISA-PSO algorithm, an intelligent PID control platform was established, which could collect the charging barrel temperature by using thermocouple sensor and transmit the collected temperature signal to the acquisition module of the PLC through the transmitter. The PLC controller changes the output signal through the intelligent algorithm according to the difference between the sampling value and the set value of the temperature, thus realizing the control of the charging barrel temperature. The hardware structure diagram of the control system is shown in Figure 13.

The experimental verification of the selected plastic extruder in the paper was carried out. The charging barrel temperature of the plastic extruder was set at 200.0°C. The temperature was, respectively, controlled by the IPSO algorithm, the GA-PSO algorithm, the SA-PSO algorithm, and the ISA-PSO algorithm. The charging barrel temperature was collected at regular intervals for real-time detection, recording, and comparison. The results are shown in Table 5.

| IPSO algorithm | GA-PSO algorithm | SA-PSO algorithm | ISA-PSO algorithm | ||||

|---|---|---|---|---|---|---|---|

| Actual value | Absolute deviation | Actual value | Absolute deviation | Actual value | Absolute deviation | Actual value | Absolute deviation |

| 201.6 | 1.6 | 202.6 | 2.6 | 200.6 | 0.6 | 200.1 | 0.1 |

| 200.8 | 0.8 | 202.9 | 2.9 | 201.6 | 1.6 | 200.4 | 0.4 |

| 201.7 | 1.7 | 198.6 | 1.4 | 200.4 | 0.4 | 199.7 | 0.3 |

| 202.8 | 2.8 | 196.4 | 3.6 | 199.3 | 0.7 | 199.5 | 0.5 |

| 203.8 | 3.8 | 198.9 | 1.1 | 198.5 | 1.5 | 199.7 | 0.3 |

| 202.8 | 2.8 | 203.4 | 3.4 | 198.9 | 1.1 | 200.6 | 0.6 |

| 201.6 | 1.6 | 202.4 | 2.4 | 200.5 | 0.5 | 200.4 | 0.4 |

| 198.6 | 1.6 | 201.8 | 1.8 | 201.8 | 1.8 | 200.3 | 0.3 |

| 198.3 | 1.7 | 198.6 | 1.4 | 201.7 | 1.7 | 199.7 | 0.3 |

| 198.6 | 1.4 | 198.3 | 1.7 | 200.5 | 0.5 | 200.3 | 0.3 |

| Average value | 1.98 | Average value | 2.23 | Average value | 1.04 | Average value | 0.35 |

It can be seen from Table 5 that the charging barrel temperature in the GA-PSO and IPSO algorithms fluctuates greatly, the maximum value of the absolute temperature deviation is 3.8°C, and the average value of the absolute temperature deviation is about 2°C. In the SA-PSO algorithm, the temperature fluctuation is slightly improved, and the maximum value and the average value of the absolute temperature deviation are 1.8°C and 1.04°C, respectively. In the ISA-PSO algorithm, the temperature fluctuation becomes significantly smaller, and the maximum value and the average value of the absolute temperature deviation are 0.6 °C and 0.35°C, respectively. This indicates that the temperature control effect of the ISA-PSO algorithm is relatively ideal, which can significantly improve the accuracy of temperature control. For a complete list of symbols and abbreviations, refer to Appendix A.

5. Conclusion

- 1.

The ISA-PSO algorithm effectively combines the strengths of both the ISA and PSO algorithms. This integration enhances the accuracy and timeliness of the PID controller. The proposed method has been validated through simulations in MATLAB and experimental platforms.

- 2.

The simulation results of the ISA-PSO algorithm were compared with IPSO algorithm, GA-PSO algorithm, and SA-PSO algorithm. The findings indicate that the ISA-PSO algorithm effectively leverages the benefits of ISA and PSO algorithms, significantly improving the optimization process in terms of speed and accuracy. The optimized PID controller can reduce the overshoot response of the plastic extruder temperature control system to only 0.54%, and it can reach a stable state in about 93 s without any shaking phenomenon, which is at least 118 s faster than the other three methods. Under interference, the overshoot was lower than the other three methods, and the adjustment time was shortened by at least 30 s. This reduction effectively mitigates the impact of interference on the control system, further enhances the system’s robustness, and enables precise temperature control of plastic extruders, demonstrating practical value.

- 3.

With the continuous advancement of intelligent algorithms, the accuracy and stability of PID control systems based on these algorithms can be expected to improve. This will enable better adaptation to diverse application scenarios, further enhancing the performance and reliability of plastic extruder temperature control systems.

In summary, the ISA-PSO algorithm offers significant improvements in PID parameter optimization for plastic extruder temperature control systems, demonstrating superior performance in terms of speed, accuracy, and robustness compared to other algorithms. This approach holds promise for practical applications in the field of plastic extrusion. With the emergence of innovative technologies such as artificial intelligence, cloud computing, and big data, future work will consider using machine learning algorithms to tune the PID parameters of control systems, utilizing the powerful self-learning characteristics of machine learning algorithms to reduce the dependence on system models during the optimization process, thereby achieving better control effects in the optimization control of more complex systems.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This work was supported by the Key Problems in Science and Technology of Henan Provincial (232102210049, 242102240114, and 252102240115) and the Key Discipline of Henan Province (Electronic Information).

Acknowledgments

This work was supported by the Key Problems in Science and Technology of Henan Provincial (232102210049, 242102240114, and 252102240115) and the Key Discipline of Henan Province (Electronic Information).

Appendix A

| Serial number | Symbols and acronyms | Elaboration |

|---|---|---|

| 1 | PSO | Particle swarm optimization |

| 2 | SA | Simulated annealing |

| 3 | IPSO | Improved particle swarm optimization |

| 4 | ISA | Improved simulated annealing |

| 5 | GA-PSO | Genetic algorithm improved particle swarm optimization |

| 6 | SA-PSO | Simulated annealing particle swarm optimization |

| 7 | ISA-PSO | Improved simulated annealing particle swarm optimization |

| 8 | IGA | Improved genetic algorithm |

| 9 | FNN | Fuzzy neural network |

| 10 | ISSA | Improved sparrow search algorithm |

| 11 | DDPG | Deep deterministic policy gradient |

| 12 | Equation (1) | G(s) is the transfer function of the second order system, K represents the gain coefficient, τ represents the delay time, and T1 and T2 are the undetermined coefficients |

| 13 | Equation (2) | f represents the fitness value of the current particles; fmin and favg are the minimum fitness value and the average fitness value of all current particles, respectively; ωmax represents the maximum of the weighting factor ω; and ωmin represents the minimum of the weighting factor ω |

| 14 | Equations (3)–(4) | T1, T2 represents the temperature after transformation, T0 represents the initial annealing temperature, λ represents cooling coefficient, and k represents the number of iteration |

| 15 | Equations (5)–(8) | α represents the adjustment coefficient of tempering cycle and gapiter represents the number of floating intervals |

| 16 | Equation (9) | f(i) represents the current objective function value and f(i + 1) represents the new objective function value |

| 17 | Equation (10) | r(t) is the input value, y(t) is the output value, and e(t) is the deviation |

| 18 | Equation (11) | Kp is the proportionality coefficient, Ki is the integral time constant, and Kd is the differential time constant |

| 19 | Equation (12) | S is the number of searchers in the population |

Open Research

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.