A Hybrid Fault Diagnosis Model for Rolling Bearing With Optimized VMD and Fuzzy Dispersion Entropy

Abstract

The vibration signal of rolling beating is nonlinear and nonstationary, which makes feature extraction difficult for fault diagnosis. To improve the efficiency of feature extraction and fault diagnosis, a hybrid model based on optimized variational mode decomposition (VMD), fuzzy dispersion entropy (FDE), and a support vector machine (SVM) is proposed. Firstly, a parameter optimization method using the sparrow search algorithm (SSA) was applied to VMD to improve the decomposition ability. Subsequently, a feature vector based on the FDE was proposed as a fault-diagnosis feature. Finally, SVM was applied with the proposed feature vector for the fault diagnosis of rolling bearings. The simulation and experimental study results indicate that the proposed method can obtain useful features for fault diagnosis, particularly in short-length samples and noise conditions. The proposed method performed well in the fault diagnosis for different fault types and degrees of rolling bearings.

1. Introduction

Rolling bearings play an important role in a wide range of applications, such as vehicles, pumps, and motors. They often operate under variable working conditions with long-term working hours, which may cause rolling bearing failures to occur [1]. In general, rolling bearing failures can cause a larger range of failures, which can lead to serious accidents. Therefore, it is necessary to conduct fault detection and diagnosis for rolling bearings to ensure their safety and stability.

The fault diagnosis of rolling bearings primarily involves vibration signals [2], sound signals [3], and infrared thermal imaging [4]. Because the vibration signal includes rich information and is convenient to collect, it is most widely used for fault diagnosis. The features of a vibration signal usually change when the state is unstable or a fault occurs [5]. Thus, the feature extraction of vibration signals is the core issue of fault diagnosis in rolling bearings. The fault diagnosis features of vibration signals in existing research can be divided into two main categories: time and frequency features and entropy features [6, 7].

As time and frequency features can reflect the vibration signal directly and have a significant physical description, they have received considerable attention. Many time and frequency signal processing methods have been proposed, such as the fast Fourier transform (FFT), short-time Fourier transform (STFT), wavelet transform (WT), and Wigner–Ville distribution (WVD) [8–11]. However, these methods have some limitations in terms of processing nonlinear and nonstationary signals; for example, FFT cannot directly reflect the characteristics of data frequency variation over time, and the selection of the wavelet basis and filtering function has a significant influence on the WT [12]. Empirical mode decomposition (EMD) can decompose nonlinear and nonstationary signals into several intrinsic mode functions (IMFs), which are suitable for the signal processing of rolling bearings [13]. Ensemble empirical mode decomposition (EEMD) increases the randomness of the signal by adding noise to the original signal, resulting in a stronger decomposition ability [14]. EEMD solves the problem of mode mixing in EMD. However, both EMD and EEMD are sensitive to noise, which can result in inaccurate IMF components. Variational mode decomposition (VMD) is a signal processing method evolving from EMD that can avoid endpoint effects and fake component problems, and it has strong antinoise capability [15].

Entropy reflects the complexity of vibration signals [16]. The entropy value of the vibration signal changes when the running state of the rolling bearing changes [17]. Many researchers have applied entropy as a feature in the fault diagnosis of rolling bearings. The approximate entropy (AE) can reflect the similarity degree of patterns in a time series and can be applied to the classification of fault characteristics; its effectiveness is limited to extremely short sequences or extremely noisy data [18]. However, the computational complexity of AE is high, and the calculation results are influenced by the parameter selection. Sample entropy (SE) is similar to AE in that it reflects the probability of new patterns appearing in a time series and measures their complexity [19]. The advantage of the SE is that the calculation result is independent of the data length. Similar to AE, the selection of calculation parameters also influences the entropy value. Permutation entropy (PE) can determine the complexity and orderliness of a system by calculating the probability of different arrangement patterns appearing [20]. However, PE is sensitive to noise and has a high computational cost. Dispersion entropy (DE) overcomes some disadvantages of other entropies [21]. It has a fast calculation speed and is less affected by mutation signals, which has made it widely used in the fault diagnosis of rolling bearings in recent years [22–24]. Fuzzy dispersion entropy (FDE) is a new entropy concept proposed in 2022 by Mostafa et al. It is less sensitive to signal data length and has better noise resistance [25, 26].

In this study, a novel hybrid fault diagnosis model is proposed. Parameter optimization of VMD and feature extraction based on FDE are proposed to obtain fault diagnosis features. A support vector machine (SVM) is applied for fault classification.

The remainder of this paper is organized as follows. The theoretical background and the proposed methods are introduced in Section 2. In Section 3, a simulation is presented to analyze the ability of different signal processing methods in a rotating system. In Section 4, the experiments conducted to verify the advantages of the proposed method are presented. Finally, conclusions are presented in Section 5.

2. Theoretical Background and Methods

2.1. FDE

DE is an index that reflects the degree of signal irregularity. As DE can effectively reflect the changes in signal amplitude and frequency at the same time and has less calculation time, it has been widely used in fault diagnosis by many researchers. However, in the DE calculation process, the round function makes the DE value sensitive to the data length, noise, and parameter selection [25]. To solve these problems, FDE is proposed. The FDE value of a time series x = [x1, x2, ⋯, xN] with a data length N is calculated as follows:

Then, every is assigned to one or two classes by the fuzzy membership function.

The number of dispersion pattern is cm.

2.2. VMD

2.3. The Proposed Method

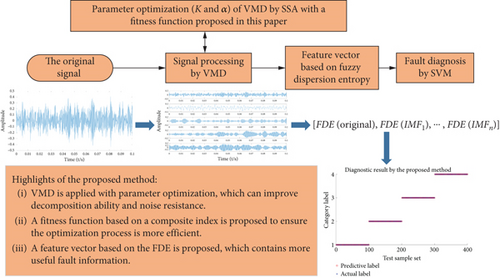

In this paper, a VMD with parameter optimization is proposed to obtain multiple modals of different frequency centers and decrease the influence of noise simultaneously. A feature vector, which is formed by FDE, was also proposed for the SVM for fault diagnosis. The flowchart of the proposed method is shown in Figure 1. The detailed process and the highlights of the proposed method are introduced in Sections 2.3.1 and 2.3.2.

2.3.1. Parameter Optimization of VMD

VMD exhibits outstanding performance in nonstationary signal processing. However, the number of extracted modal K and modal frequency bandwidth control parameters α must be assigned primarily. If K is set too large or too small, it will cause overdecomposition or a lack of decomposition. Parameter α will cause missing frequency band information if α is set too large. This results in increased frequency band information redundancy and computational complexity if α is set too small.

To obtain suitable parameters for VMD, reasonable evaluation indicators must be proposed. In this study, two factors were considered as the optimal parameters for VMD.

Firstly, the FDE represents the complexity and fluctuation of the time-domain signal. The IMFs acquired by suitable VMD parameters are more regular and have less noise, and the FDE of the IMFs is smaller. Therefore, the FDE can be utilized as an indicator to evaluate the performance of VMD processing.

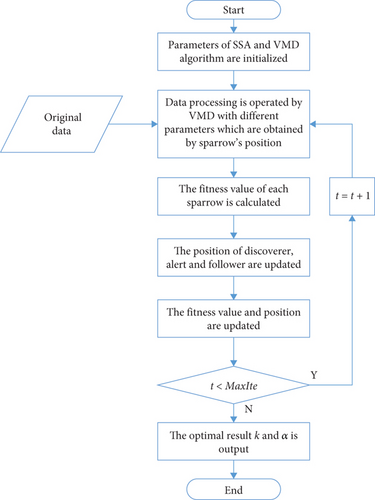

In this study, the sparrow search algorithm (SSA) was utilized to obtain the optimized parameters of the VMD using the fitness function proposed above. The SSA is a swarm intelligence optimization algorithm known for its fast calculation speed and good robustness [27]. The steps of the parameter optimization of VMD by SSA are as follows:

Step 1: initialize the algorithm parameters. The parameters include the number of sparrows nPop, the maximum number of iterations MaxIte, safety value ST, and dimensions and boundaries of the optimization problems. The positions of the sparrows were initialized.

Step 2: obtain the values of K and α for each sparrow according to the position. The original data were processed using VMD with different K and α values. And the fitness is calculated with the IMFs according to Equation (15). The fitness is then sorted to find the individual with the current best fitness and its current best position.

Step 4: The fitness of each sparrow was compared before and after the position update, and a better position was selected. Then, the position of the sparrow with the best fitness is updated.

Step 5: The position of the sparrow with the best fitness is output until the maximum number of iterations is reached. Otherwise, Steps 3 and 4 were repeated.

The flowchart of the parameter optimization of the VMD by SSA is shown in Figure 2.

2.3.2. Feature Extraction Based on FDE

- I.

The FDE of the original vibration signal FDE(original) was calculated to reflect the characteristics of the original signal.

- II.

The vibration datasets u1(t), u2(t), ⋯, um(t) in different running states are decomposed by VMD. Because different datasets have different optimal parameters Ku1, Ku2, ⋯, Kum, the number of IMFs of different datasets is not consistent. To ensure consistent dimensionality of the feature vectors, the former K = min{Ku1, Ku2, ⋯, Kum} modal is selected to form the fault feature.

- III.

The FDE of each IMF of the vibration signal was calculated. The feature vector based on the FDE can be described as follows:

3. Simulation Analysis

Because of the nonlinear and nonstationary characteristics of the rolling bearing signals, it is difficult to extract the fault features using a normal signal processing method.

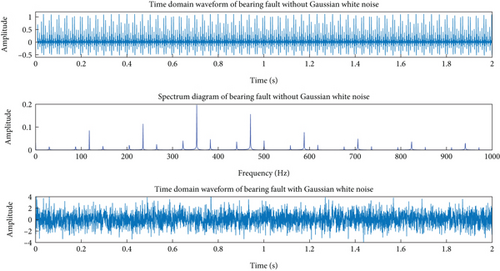

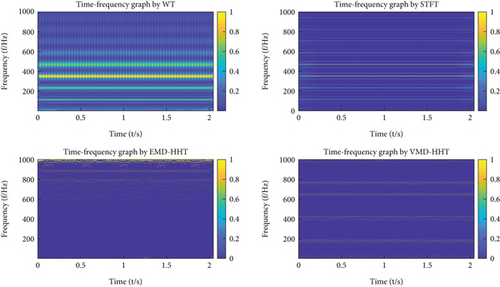

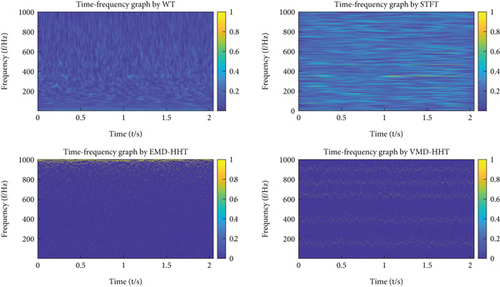

In this section, a rolling bearing fault model is used to simulate the fault signal of the inner race fault. The WT, STFT, EMD, and VMD are applied to test the ability of the time-frequency analysis, which will also verify the signal processing method proposed in this paper.

The simulated vibration signals in the time domain and frequency domain are shown in Figure 3.

The WT, STFT, EMD, and VMD are applied to obtain the time-frequency spectrogram, where EMD and VMD are combined with Hilbert-Huang transform (HHT) to obtain the time-frequency spectrogram. The results are shown in Figures 4 and 5.

As shown in Figures 4 and 5, the WT and STFT can obtain the resonance frequency and other multiplier frequencies well when there is no noise interference. However, the characteristic frequencies can hardly be obtained by the WT and STFT when the original signals contain strong noise. EMD-HHT can obtain some characteristic frequencies when there is no noise interference, but modal mixing appears when the original signal is doped with noise. The VMD-HHT method can still obtain the frequency characteristics when the signal is dropped with noise. These results indicate that VMD has a strong ability to suppress noise.

The performance of the VMD method was influenced by the preset parameters. The proposed parameter optimization method was applied to the vibration signal with noise to obtain suitable parameters for the VMD. The optimization results were K = 9 and α = 613. The center frequencies by VMD with optimization parameters are compared to the center frequencies by VMD with default parameters (where K = 5 and α = 2000), as shown in Table 1.

| Parameters | Center frequencies of IMFs (Hz) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| K = 5, α = 2000 | 92.70 | 226.38 | 359.31 | 610.80 | 811.08 | ||||

| K = 9, α = 613 | 51.81 | 152.96 | 260.78 | 362.56 | 480.30 | 584.85 | 712.40 | 834.12 | 953.04 |

It can be observed that the center frequencies of the IMFs decomposed by the optimization parameters are close to the characteristic frequencies of the vibration signal without noise, as shown in Figure 3. The results indicate that the proposed parameter optimization methods can obtain suitable parameters for VMD, which can help VMD get better performance.

4. Experiment Study

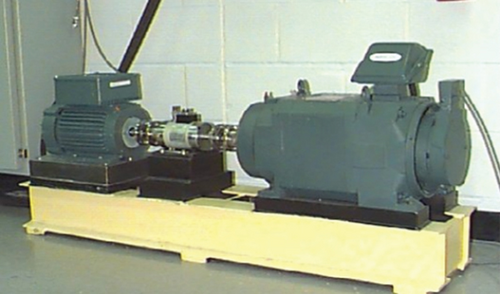

To verify the performance of the proposed method for fault diagnosis, a public bearing dataset from the Bearing Data Centre of the Case Western Reserve University was used [28]. The original datasets can be accessed from https://engineering.case.edu/bearingdatacenter/download-data-file. The experimental platform includes a 2 hp reliance electric motor and data collection device, as shown in Figure 6. The acceleration data of the motor bearing were measured, and the collected dataset contained vibration data under different operating conditions. The signal sampling frequency was 12 kHz, and the rotating speed of the motor was 1772 rpm. The algorithms in this study were run on an Intel i7-6700HQ 2.6 GHz in MATLAB 2022a.

4.1. Fault Diagnosis for Different Fault Types

4.1.1. Analysis of the Influence of Sample Data Length

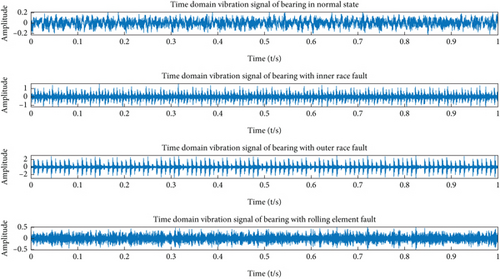

The vibration datasets used in this section contained four different operating conditions: normal, inner race fault, outer race fault, and rolling element fault. The time-domain vibration data are shown in Figure 7. Vibration datasets with different sample lengths were studied to verify the performance of the proposed method, and the sample length was set to 256 points and 1024 points. Because the SVM was applied for classification, the dataset was divided into training and testing sets. The detailed parameters of the vibration datasets are listed in Table 2.

| Operating conditions | Sample length | Sample number | Training sample number | Test sample number | Label |

|---|---|---|---|---|---|

| Normal | 256 data points or 1024 data points | 100 | 50 | 50 | 1 |

| Inner race fault | 50 | 50 | 2 | ||

| Outer race fault | 50 | 50 | 3 | ||

| Rolling fault | 50 | 50 | 4 |

The VMD parameters were optimized using the proposed method, and the results were [K = 4, α = 367]. VMD with default parameters [K = 5, α = 2000] was used for future feature calculations of AE, SE, DE, and FDE. These methods were then compared with the proposed method. The detailed parameter settings of the proposed method and comparison methods were referenced to some similar research [21, 25, 29, 30] and are listed in Table 3.

| Method | VMD parameters | Special entropy parameters | Common entropy parameters |

|---|---|---|---|

| VMD+AE | K = 5, α = 2000 | Threshold value is 0.15 | Embedding value is 2 |

| VMD+SE | Threshold value is 0.15 | ||

| VMD+DE | Number of classes is 6 | ||

| VMD+FDE | Number of classes is 6 | ||

| Proposed method | K = 4, α = 367 | Number of classes is 6 |

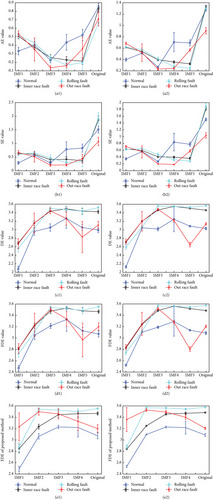

Fault diagnosis features were extracted using different methods with data lengths of 256 and 1024 points. The feature contains the entropy of the original vibration signal and the entropy IMFs decomposed by VMD. The mean values and SD of the entropy obtained using different methods are shown in Figure 8.

To achieve better diagnostic results, fault diagnosis using entropy values as a fault feature requires significant differences in the entropy values under different operating conditions. As shown in Figure 8, the DE and FDE of the original signal with 1024 data points exhibit significant differences under different operating conditions. However, distinguishability decreased when the data length was reduced to 256. This cannot lead to a better diagnostic result, depending only on the entropy value of the original signal. It can be observed that the entropy of the IMFs by VMD provides more feature information for fault diagnosis. The results indicated that the feature structure proposed in this study can improve the efficiency of fault diagnosis.

As shown in Figure 8, the entropy values of the method proposed in this study have the best differentiation under different operating states, and the standard deviation is small, which is favorable for fault diagnosis. These results indicate that the feature extraction method proposed in this study is effective.

SVM was applied for fault diagnosis based on the above extraction features. The diagnostic accuracy and average calculation time per sample of each method are listed in Table 4.

| Method | 1024 point length | 256 point length | ||

|---|---|---|---|---|

| Accuracy | Time cost per sample | Accuracy | Time cost per sample | |

| VMD+AE+SVM | 99.00% | 0.845 s | 93.50% | 0.169 s |

| VMD+SE+SVM | 99.00% | 0.830 s | 90.00% | 0.166 s |

| VMD+DE+SVM | 100% | 0.476 s | 97.50% | 0.129 s |

| VMD+FDE+SVM | 100% | 0.488 s | 98.00% | 0.131 s |

| Proposed method | 100% | 0.670 s | 100% | 0.165 s |

The results presented in Table 4 demonstrate that when the sample data length is 1024 points, the diagnostic accuracy of the various methods is comparatively high, with the DE-based, FDE-based, and proposed methods achieving 100% accuracy. However, the diagnostic efficiency of certain methods decreased when the sample length was reduced to 256 data points. Notably, the efficiency of SE-based fault diagnosis decreased to 90%. However, the diagnostic accuracy of the proposed method remained 100%, which indicates that the proposed method is effective for a short sample length. The calculation times of the proposed method and the comparison methods were approximately equivalent, and the calculation time of the method proposed in this study was acceptable.

4.1.2. Analysis of the Influence of Noise

The influence of noise on the proposed method is analysed in this section. The noise was added to the original vibration signal, and the SNR was set to 5 dB. The sample data length was set to 256 points, and the remaining parameters of the dataset and fault diagnosis methods were set according to Tables 2 and 3.

Fault diagnosis features were extracted using different methods. The feature contains the entropy of the original vibration signal and the entropy IMFs decomposed by VMD. Then the features were applied to SVM for fault diagnosis. The mean values and SD of the entropy obtained by the different methods and the confusion diagrams of the fault diagnosis result are shown in Figure 9.

As shown in Figure 9, the features extracted by the proposed method under different operating conditions have more significant discriminability than the features extracted by the other methods. The diagnostic correctness rate of the method proposed in this study reached 95.5%, while the diagnostic correctness rates of the other methods were lower than 87%. The above results demonstrate that the proposed method can achieve good diagnosis results under noise interference.

4.2. Fault Diagnosis for a Single Fault With Different Degrees

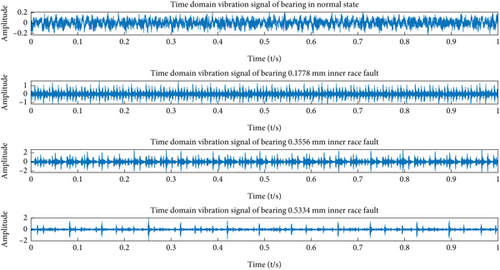

The fault diagnosis for a single fault with different degrees was also presented to verify the proposed fault diagnosis method. The vibration data of the drive end included the normal operation condition and three inner-race fault conditions of 0.1778, 0.3556, and 0.5334 mm. The time-domain vibration data under different conditions are shown in Figure 10. The dataset was built for the analysis in this section according to the parameters listed in Table 5.

| Operating conditions | Sample length | Sample number | Training sample number | Test sample number | Label |

|---|---|---|---|---|---|

| Normal | 1024 data points | 100 | 50 | 50 | 1 |

| 0.1778 mm inner race fault | 50 | 50 | 2 | ||

| 0.3556 mm inner race fault | 50 | 50 | 3 | ||

| 0.5334 mm inner race fault | 50 | 50 | 4 |

The VMD parameters were optimized using the proposed method, and the results were [K = 6, α = 703]. VMD with default parameters [K = 5, α = 2000] was used for future feature calculations of AE, SE, DE, and FDE. These methods were then compared with the proposed method. The rest of the parameters of the proposed method and comparison methods were set according to Table 3.

The original vibration data were applied directly. Fault diagnosis features were extracted using different methods. The feature contains the entropy of the original vibration signal and the entropy IMFs decomposed by VMD. Then, the features were applied to SVM for fault diagnosis. The mean values and SD of the entropy obtained by the different methods and confusion diagrams of the fault diagnosis results are shown in Figure 11.

As shown in Figure 11, the features extracted by all methods exhibited good differentiation under different operating conditions. The proposed method and comparison methods performed well for both the normal state and the 0.1778 inner race fault state; only one misdiagnosis occurred in the AE-based method. Most misdiagnoses occurred in the 0.3556 mm inner race fault and 0.5334 mm inner race fault states. The proposed method achieved better diagnosis results in this part; only two misdiagnoses occurred, and the accuracy rate of the fault diagnosis reached 99%. The results demonstrate that the proposed method has good diagnostic ability.

A dataset with additional noise was used for fault diagnosis. The noise was added to the original vibration signal, and the SNR was set to 5 dB. The mean values and SD of the entropy obtained by the different methods and confusion diagrams of the fault diagnosis results are shown in Figure 12.

As shown in Figure 12, the differentiation of the four operating condition features decreased for all the methods under noise interference, and the features extracted based on DE and FDE performed better than AE and SE. Most misdiagnoses still occurred in the 0.3556 mm inner race fault and 0.5334 mm inner race fault states. The proposed method obtained the highest fault-diagnosis accuracy of 94%. The results indicate that the proposed method has a good fault diagnosis ability under noise interference.

All the above experimental study results indicate that the proposed fault diagnosis method has good performance for the fault diagnosis of rolling bearings. In addition, the proposed method exhibits a better fault diagnosis effect when the sample data length is short and mixed with noise.

5. Conclusions

- a.

The proposed feature extraction method based on VMD with parameter optimization and FDE is efficient for fault diagnosis of rolling bearings.

- b.

The proposed feature extraction method can obtain useful features for fault diagnosis, particularly in short-length samples and noise conditions.

- c.

The proposed method performed well in fault diagnosis for different fault types and degrees.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This work is supported by the Suqian Sci&Tech Program (Grant No. H202410) and the National Natural Science Foundation of China (NSFC) (51709121).

Acknowledgments

This work is supported by the Suqian Sci&Tech Program (Grant No. H202410) and the National Natural Science Foundation of China (NSFC) (51709121).

Open Research

Data Availability Statement

The data that support the findings of this study are available upon request from the corresponding author.