Evaluating Coal–Jatropha curcas Composite Briquettes as Sustainable Fuel Alternatives

Abstract

Coal is a major fuel source but raises environmental concerns. This study investigated the feasibility of utilizing a composite briquette sustainable fuel produced from subbituminous coal and Jatropha curcas biomass. Briquettes were prepared with varying weight ratios of coal to J. curcas biomass (90:0–0:90) using corn starch as a binder. The influence of this ratio on the briquettes’ properties was comprehensively evaluated through proximate analysis, ultimate analysis, scanning electron microscopy (SEM), and X-ray fluorescence (XRF) analysis. The results revealed that increasing the J. curcas content in the briquettes gradually decreased the moisture content, ash content, and fixed carbon content while increasing the volatile matter content. The elemental composition analysis showed a decreasing trend in carbon and sulfur content with increasing J. curcas, while nitrogen and oxygen content increased. The gross calorific value (GCV) exhibited a significant positive correlation with the coal content, reaching a maximum value of 28.29 MJ/kg for briquettes specially composed of J. curcas biomass. These findings suggest that coal–J. curcas briquettes offer a promising alternative fuel source with tailorable properties depending on the desired balance between burning characteristics and calorific value. Further research could explore the combustion behavior and emission profiles of these briquettes to assess their environmental impact.

1. Introduction

As global energy demands continue to rise, the search for sustainable and environmentally friendly energy sources has become increasingly urgent. Traditional fossil fuels, particularly coal, have been the backbone of energy production for decades due to their high energy content and availability [1]. However, the environmental impact of coal, including greenhouse gas emissions and air pollution, has necessitated the exploration of cleaner energy alternatives [2]. Biomass-coal blending offers an effective solution by reducing the environmental impact of coal without immediately retiring the infrastructure tied to it. Biomass, a renewable and carbon-neutral energy source, helps lower sulfur dioxide (SO2) and greenhouse gas emissions when mixed with coal, making the blend a more environmentally friendly option [3–5]. This approach allows for a gradual transition to renewable energy, supporting energy security while scaling up cleaner technologies [6, 7].

In the literature, numerous studies have reported that by blending coal with biomass, it is possible to create composite briquettes that leverage the high calorific value of coal while benefiting from the cleaner combustion properties of biomass [5]. For instance, Balraj et al. [8] produced biomass-coal briquettes without a binder, using bagasse, groundnut shell, woodchips, and coal-fine waste in three particle sizes (50, 134.3, 199.7 μm). Proximate analysis showed low ash, high volatile matter, and reasonable fixed carbon in the biomass waste. Adeleke et al. [9] analyzed ashes from bio-coal briquettes made with lean-grade coal and torrefied woody biomass using coal tar pitch and molasses as binders. XRD identified quartz as the dominant mineral, with silicon dioxide (SiO2) (57%–58%), aluminum oxide (Al2O3) (19%–21%), and iron oxide (Fe2O3) (8%–9%) as major oxides. The study concluded that adding torrefied biomass (≤15%) and blended binder had negligible impact on the ash properties of the bio-coal briquettes. Khan et al. [10] used central composite design (CCD) and response surface methodology (RSM) to study the impact of coal and biomass quantities and types on coal briquette calorific value. They found all factors significantly influenced calorific value, with pomegranate biomass yielding higher values than olive biomass. The optimal formulation (180 g coal, 54 g pomegranate biomass) achieved a calorific value of 6728 kJ/kg. In another study, Khan et al. [11] investigated biomass-coal blends using coal from Darra Adam Khel, Cherat, Harnoi, and Daola in KPK, Pakistan, along with Parthenium weed biomass. The results revealed that higher biomass ratios decreased net calorific values, reduced sulfur content, notably in Darra coal, increased volatile matter uniformly, and lowered ash content, though moisture content rose due to difficulties in drying Parthenium weed biomass. Ajith Kumar et al. [12] studied biomass and charcoal briquettes with and without binders as alternative fuels. Using wood waste and charcoal, with starch as a binder, they measured calorific value, moisture, ash, and volatile matter. Pure charcoal had a higher calorific value compared to briquettes with binders or biomass. Binders reduced ash, moisture, and volatile matter, potentially minimizing corrosion effects.

Mursito, Widodo, and Arifin [13] manufactured bio-coal briquettes from a blend of low-quality coal and biomass waste, using a bio-activator solution for fermentation before pressing. The coal from Caringin–Garut Regency had high sulfur (6.57 wt%) and low calorific value, while Bayah–Lebak Regency coal had lower sulfur (0.51 wt%) and higher calorific value. Biomass, in the form of fermented cow dung (Bio-Kohe), had a calorific value of 4192 kcal/kg and 1.56 wt% sulfur. Fermentation with Garant + 1 wt%/vol molasses (0.2 L/kg) reduced sulfur content in the blend to 1.00–1.14 wt%, meeting quality standards for noncarbonized bio-coal briquettes. Organic sulfur in the briquettes decreased by 38%–58% compared to raw coal, which was mainly pyritic and sulfate. Adeleke et al. [14] studied hybrid fuel briquettes (HFBs) made from 97% coal and 3% torrefied biomass, using pitch and molasses binders in various ratios. Fourier transform infrared (FTIR) spectrophotometer analysis identified aromatic C═C bonds and phenolic OH groups in the HFB. Tumbling strength (TSI + 3 mm) decreased significantly after curing and exposure to 1200°C. Reactivity indices (RIs) ranged from 48% to 56%, indicating high reactivity. HFB shows potential as carbonaceous material for direct reduced iron production via rotary kilns.

Nikiforov et al. [15] studied bio-coal briquettes using biomass (sunflower husks and leaves) and industrial waste (coal and coke dust). They varied biomass from 20% to 70%, using fine (<2 mm) and coarse (<6 mm) fractions, pressed at 25 MPa without binders. As per the results, fine fraction briquettes burned longer with lower rates than coarse ones. Increasing coal dust prolonged burning times and reduced rates. Optimal mixes included 70% sunflower husk and 30% coal dust from Karazhyra and 60% sunflower husk and 40% coal dust from Shubarkul, showing potential as alternative fuels. Ganesan and Vedagiri [16] explored biomass briquette production using deoiled cashew nut shells, comparing them with coal, charcoal, and areca plate waste briquettes. Deoiled cashew nut shells offer a calorific value of 4804 kcal/kg. They utilized agricultural waste and sawdust as binders. These briquettes exhibit properties suitable for industrial and domestic applications. Li et al. [17] developed bio-coal briquettes by blending bituminous coal with corn straw, sewage sludge, and cow dung. They found these briquettes ignited and burned more easily than coal, with higher combustion efficiencies and rates. Bio-coal briquettes emitted significantly less CO2 and CH4 (31%–47% and 41%–51% reduction, respectively) compared to bituminous coal, along with lower CO and NO emissions. Adeleke et al. [18] blended torrefied Melina wood (3%–20%) with lean-grade coal fines (80%–97%) using pitch as a binder to produce composite briquettes. Scanning electron microscopy (SEM) and FTIR identified microstructural features and functional groups. Briquettes with <10% torrefied biomass showed excellent water resistance (>95%). Those with 97% coal fines and 3% torrefied biomass exhibited the highest strengths and improved carbon content. These briquettes, up to 20% torrefied biomass, are suitable as versatile fuel sources.

Jatropha curcas, a nonedible oilseed plant, has emerged as a promising biomass source. Its high oil content, rapid growth, and ability to thrive in marginal soils make it an attractive candidate for bioenergy production [19]. The by-products of Jatropha oil extraction, such as seed husks and shells, can be utilized as biomass feedstock for briquette production, providing an efficient way to utilize agricultural waste [20]. By blending coal with Jatropha biomass, it is possible to create composite briquettes that leverage the high calorific value of coal while benefiting from the cleaner combustion properties of biomass. For instance, Suryaningsih, Resitasari, and Nurhilal [21] studied bio-briquettes from rice husk and Jatropha seed waste. They tested 80:20 and 50:50 charcoal mixtures with 8% and 12% newspaper pulp as an adhesive. The optimal briquette, a 50:50 mix with 8% adhesive, had the best calorific value at 5650 cal/g. Key characteristics included 3.85% moisture, 43.87% volatile matter, 23.78% ash, and 28.50% fixed carbon. Jatropha seed charcoal significantly increased the calorific value of rice husk from 3350 to 5650 cal/g. Cuaresma et al. [22] evaluated Jatropha wastes for charcoal briquettes using 100% husk, 50% husk, 50% pressed cake, and 100% pressed cake. Briquettes were bonded with 10%, 14%, and 18% cassava or corn starch. Pressed cake briquettes with 10% binder were superior, while the 50/50 mix was promising but less effective. Husk briquettes failed to meet standards due to high volatile matter and ash content. Fadele et al. [23] investigated using Jatropha seed shells (JSSs) and Eucalyptus camaldulensis wood shavings (EcWSs) with Acacia senegal as a binder to produce briquettes. The optimal ratio (75:25) and binder quantity (60 g) yielded briquettes with improved properties: density 0.70 kg/m3, moisture content 10.88%, water resistance 98.11%, and shatter index 99.86%. This study shows that JSS and EcWSs are effective organic waste for briquette production, with mixing ratios significantly influencing briquette quality. Steinbrück et al. [24] investigated using biomass steam processing (BSP) to convert jatropha crop and seed residues into high-quality bio-coal. This method significantly increased the energy density of the residues, resulting in an estimated marketable energy yield of 90 GJ per hectare per year for a 5-year-old jatropha plantation, compared to 30 GJ per year when only jatropha oil is marketed.

This study focuses on the development and characterization of briquettes composed of Darra Adamkhel (Region of Khyber Pakhtunkhwa, Pakistan) coal (subbituminous coal) and J. curcas biomass. Darra Adamkhel coal is particularly famous for its high-energy content, making it a valuable energy resource [25]. However, its use is often accompanied by substantial emissions of sulfur, nitrogen oxides (NOxs), and particulate matter [10, 25]. On the other hand, J. curcas biomass, a renewable resource, has a lower sulfur content and provides a sustainable alternative to pure coal usage [26]. While previous research has explored the use of J. curcas waste after oil extraction, its potential as biomass without prior oil extraction has not been fully explored in the existing literature. Furthermore, the blending of J. curcas biomass with subbituminous coal remains largely uninvestigated. Therefore, this study aims to address these research gaps by evaluating the potential of blending subbituminous coal with J. curcas biomass. Our findings provide original insights into the combustion properties and emissions profile of this unique coal-biomass blend, highlighting its potential as a sustainable fuel alternative in the context of local energy resources.

2. Materials and Methods

2.1. Materials

Coal of the subbituminous type, which is available in the commercial mine Darra, located in Khyber Pakhtunkhawa, Pakistan, was procured for the present examination. The coal sample was then crushed using a jaw crusher (Armfield, UK) to form powder, as shown in Figure 1a. The particle size distribution was determined by sieving (using Retsch D-42759 HAAN/Germany), and samples with particle sizes between 200 and 100 μm were used based on previous studies [27, 28]. J. curcas sample was obtained from the Kohat region of Khyber Pakhtunkhwa district, Pakistan, were they are available abundantly. Through sun-drying, the moisture content was reduced to less than the 10 wt% target, with the process strictly adhering to the established practices for biomass feedstock drying. It is crushed using a grinder (Silver Crest powder grinder 400 G), as shown in Figure 1b, and the sieving method with a particle size range of 300–100 μm was used as suggested in previous studies for biomasses [29, 30]. The coal and J. curcas powder are mixed in specified ratios (as tabulated in Table 1) using corn starch as an additive at a constant 10 wt% [22, 31] and stirred gently at room temperature for 1.5 h. Then, the coal briquettes were produced using a press machine at a constant pressure of 15 MPa, as shown in Figure 1c.

| Sample | Powdered coal (wt%) | Jatropha curcas (wt%) | Corn starch (wt%) |

|---|---|---|---|

| 1 | 90 | 0 | 10 |

| 2 | 85 | 5 | 10 |

| 3 | 75 | 15 | 10 |

| 4 | 65 | 25 | 10 |

| 5 | 55 | 35 | 10 |

| 6 | 45 | 45 | 10 |

| 7 | 35 | 55 | 10 |

| 8 | 25 | 65 | 10 |

| 9 | 15 | 75 | 10 |

| 10 | 5 | 85 | 10 |

| 11 | 0 | 90 | 10 |

2.2. Methods

The coal briquettes were subjected to proximate analysis, ultimate analysis, density, SEM, X-ray fluorescence (XRF), and gross calorific value (GCV). Proximate analysis of biomass-coal briquettes provides critical information about their moisture, ash, volatile matter, and fixed carbon content. The ASTM standards were adopted to measure these quantities, that is, ASTM D3302/D3302M [32] for moisture content, ASTM D3174 [33] for ash content, ASTM D3175 [34] for volatile matter and [35] for fixed carbon content. These parameters are important for predicting the combustion behavior and efficiency of the briquettes. Lower moisture content generally leads to higher combustion efficiency [36], while higher volatile matter content can enhance ignition and combustion stability [37]. The ash content influences the residue left after combustion and can impact the overall fuel efficiency [38]. Ultimate analysis, on the other hand, determines the elemental composition of the briquettes, including carbon, hydrogen, nitrogen, sulfur, and oxygen, and was determined using ASTM D3176-15 [39]. Understanding the elemental composition is essential for predicting the emissions profile and energy content of the briquettes, which are critical for assessing their environmental impact and suitability as a fuel source [36].

GCV of the briquettes was determined to assess their energy content, which is a critical factor in evaluating their suitability as a fuel source. GCV represents the total amount of heat released when a specific amount of fuel is completely combusted, including the latent heat of the vaporization of water. The calorific value of the coal was measured by the standard bomb calorimetry method using ASTM D5865/D5865M [40]. To measure GCV, the briquette samples were crushed to uniform particle size (1–2 mm), weighed (~1 g), and combusted in an oxygen bomb calorimeter (CA-4PJ, Shimadzu) under controlled conditions. The oxygen bomb was charged with pure oxygen at a pressure of ~25 atm and placed in the calorimeter’s water jacket containing a known quantity of water. The temperature rise of the water was monitored to calculate the heat released during combustion, with corrections for heat losses and the latent heat of vaporization applied to determine the GCV in MJ/kg.

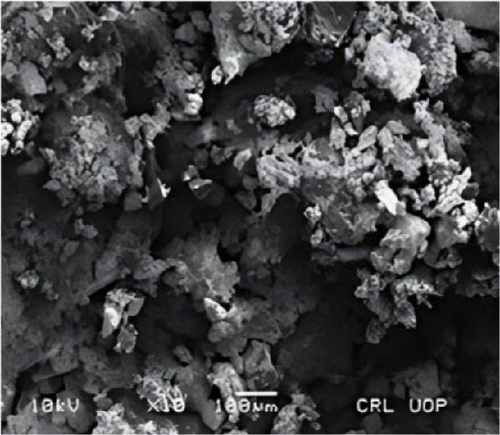

Briquettes made from biomass-coal are characterized microstructurally by SEM analysis. This is essential for determining surface morphology and particle interactions within briquettes. A number of studies indicate that biomass and coal particles are likely to have a significant impact on briquette strength and combustion behavior depending on their distribution and bonding [37]. SEM analysis was performed on Superscan SSX-550 SEM (Shimadzu Corporation). The samples were fractured to expose internal surfaces, mounted on aluminum stubs with conductive carbon tape, and coated with a thin layer of carbon using a sputter coater to enhance conductivity. The samples were then analyzed using a high-resolution SEM at an accelerating voltage of 10 kV to capture detailed images of surface features such as porosity, particle distribution, and bonding between coal and biomass particles.

A nondestructive analysis method, XRF, is used for determining biomass-coal briquettes’ elemental composition. An XRF analyzer provides accurate and precise information on the major and trace elements that are present in briquettes. An advantage of this method is that it can identify elements that may have hazardous effects on the environment. This technique provides a thorough analysis of the elements in briquettes, which is critical for understanding their environmental impact, especially in regard to ash disposal and soil contamination. In the present study, XRF is performed on Benchtop XRF analyzers (Fisher Scientific ARL QUANT’X EDXRF Spectrometer). Briquettes were pulverized to a fine powder (≤75 µm) using a ball mill and loaded directly into the spectrometer’s chamber. The XRF analyzer, calibrated with certified reference materials, and the concentrations of key elements such as carbon, oxygen, sulfur, and trace metals, which are vital for understanding the fuel’s environmental impact, were identified.

3. Results and Discussions

3.1. Proximate Analysis

The proximate analysis of various coal and J. curcas mixtures, as tabulated in Table 2, provides the progressive impact of these fuels on key combustion parameters such as total moisture, ash content, volatile matter, GCV, and fixed carbon content, as well as the structural changes observed through SEM analysis.

| Sample | Powdered coal (%) | Jatropha curcas (%) | Total moisture (%) | Ash content (%) | Volatile matter (%) | Gross calorific value (GCV) (MJ/kg) | Fixed carbon (%) |

|---|---|---|---|---|---|---|---|

| 1 | 90 | 0 | 2.07 | 13.88 | 12.67 | 23.31 | 68.41 |

| 2 | 85 | 5 | 3.37 | 12.61 | 13.45 | 23.94 | 62.77 |

| 3 | 75 | 15 | 3.71 | 11.97 | 15.01 | 24.43 | 61.14 |

| 4 | 65 | 25 | 4.02 | 11.56 | 16.96 | 24.85 | 60.75 |

| 5 | 55 | 35 | 5.23 | 10.78 | 18.07 | 25.23 | 55.16 |

| 6 | 45 | 45 | 6.01 | 10.02 | 20.11 | 25.92 | 52.77 |

| 7 | 35 | 55 | 6.78 | 9.92 | 22.54 | 26.38 | 49.1 |

| 8 | 25 | 65 | 6.91 | 9.22 | 29.81 | 26.85 | 42.11 |

| 9 | 15 | 75 | 7.22 | 8.91 | 39.77 | 27.32 | 39.12 |

| 10 | 5 | 85 | 7.81 | 7.88 | 48.7 | 27.95 | 34.94 |

| 11 | 0 | 90 | 8.33 | 7 | 59.61 | 28.29 | 24.71 |

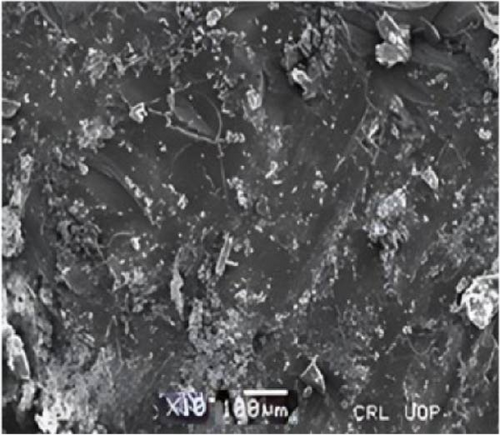

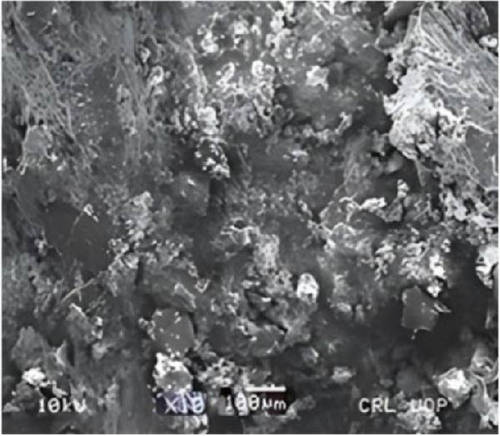

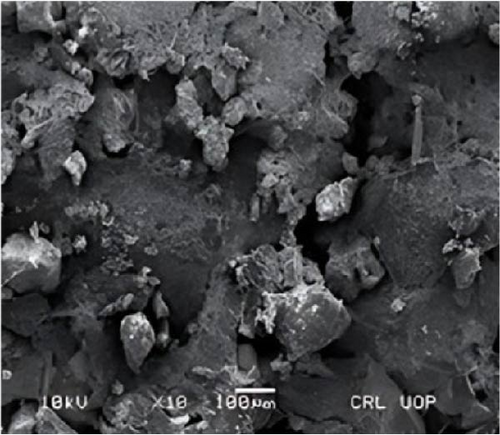

Sample 1, consisting of 90% coal and 0% J. curcas, represents pure coal with a low moisture content of 2.07% and a high fixed carbon content of 68.41%. It has a high ash content of 13.88% and a relatively low volatile matter of 12.67%, resulting in a GCV of 23.31 MJ/kg. Figure 2a shows an SEM image of pure coal, revealing a dense and compact structure with relatively smooth surfaces and fewer porosities. This dense structure is indicative of high fixed carbon content, contributing to the coal’s high energy density but also leading to higher ash residues and lower reactivity compared to biomass fuels. Introducing 5% J. curcas (Sample 2) slightly increases the moisture content to 3.37% and volatile matter to 13.45%, while reducing the ash content to 12.61%. The GCV improves to 23.94 MJ/kg, indicating that even small amounts of Jatropha can enhance energy content. The addition of 5% J. curcas introduces slight surface roughness and increased porosity as evident from Figure 2b. This change corresponds with the minor increase in volatile matter and moisture, suggesting that the Jatropha particles are less dense and more porous than coal particles.

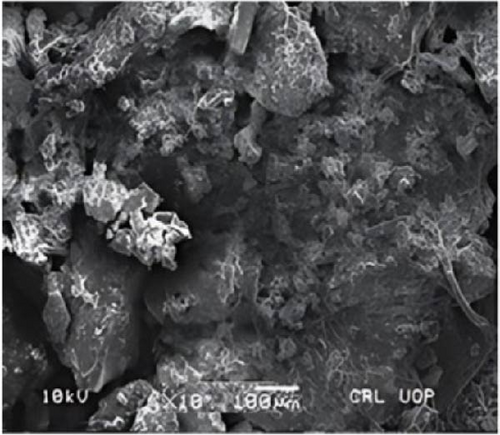

With 15% J. curcas (Sample 3), the trends continue: moisture content increases to 3.71%, volatile matter to 15.01%, and GCV to 24.43 MJ/kg, while ash content decreases to 11.97%. This blend offers a balance between the properties of coal and biomass, improving combustion efficiency. At 25% J. curcas (Sample 4), the GCV rises to 24.85 MJ/kg, with further reductions in ash content to 11.56% and increases in volatile matter to 16.96%. SEM analysis in Figure 2c of this blend shows a greater number of voids and surface irregularities compared to lower Jatropha blends. The increased porosity and surface texture contribute to better combustion efficiency and reduced environmental pollutants. The porosity observed supports the higher volatile matter and reduced ash content, indicating enhanced reactivity.

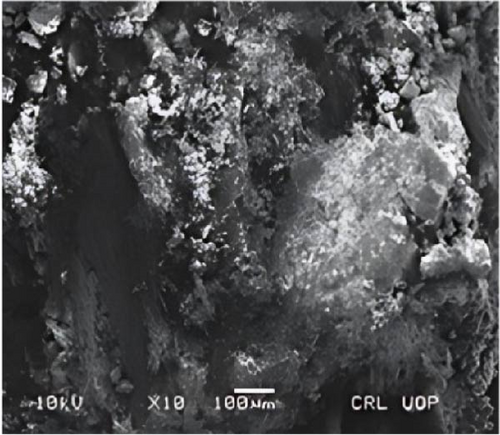

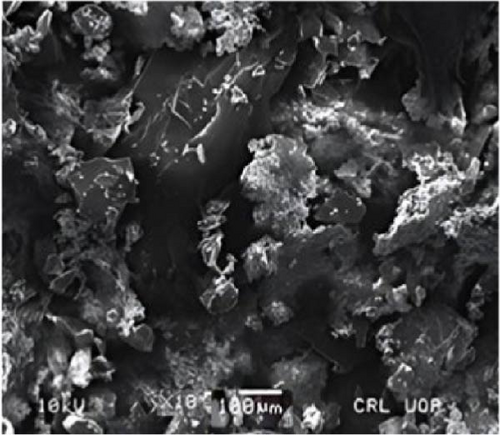

Increasing J. curcas to 35% (Sample 5) results in a higher moisture content of 5.23%, volatile matter of 18.07%, and a GCV of 25.23 MJ/kg, while ash content drops to 10.78%. This shows the potential of Jatropha to improve energy content when blended with coal. At a 45% blend (Sample 6), the benefits of J. curcas become more pronounced, with a GCV increase to 25.92 MJ/kg and a decrease in ash content to 10.02%. The higher volatile matter of 20.11% enhances combustion efficiency. The SEM analysis of this 45% blend in Figure 2d shows a significantly porous structure with increased surface irregularities. The greater proportion of J. curcas contributes to this high porosity and surface roughness, which supports the enhanced combustion efficiency observed in the proximate analysis.

With 55% J. curcas (Sample 7), the mixture continues to show improved energy content (GCV of 26.38 MJ/kg) and reduced ash (9.92%), although moisture content rises to 6.78%, which might require additional drying processes for optimal combustion. At 65% J. curcas (Sample 8), the GCV increases dramatically to 26.85 MJ/kg, and the volatile matter rises to 29.03%. SEM images in Figure 2e show a very high level of porosity and surface irregularities. The presence of J. curcas particles results in a highly reactive fuel with an increased surface area, contributing to the significant rise in GCV and improved combustion efficiency. The reduced ash content also suggests fewer operational issues in combustion systems.

A 75% J. curcas blend (Sample 9) shows a remarkable increase in GCV to 27.32 MJ/kg and volatile matter to 39.77%, highlighting its potential as a high-energy fuel. The moisture content, however, increases to 7.22%, necessitating moisture management for efficient combustion. With 85% J. curcas (Sample 10), the blend achieves a very high GCV of 27.95 MJ/kg, with volatile matter constituting almost half the content at 48.7%. The ash content drops to 7.88%, improving the overall environmental footprint. The SEM images in Figure 2f show an extremely porous and rough surface texture, with J. curcas particles dominating. This structure contributes to the very high GCV and volatile matter, indicating excellent reactivity and energy output.

Pure J. curcas (Sample 11) offers the highest GCV (28.29 MJ/kg) and volatile matter (59.61%) among all samples, making it an excellent high-energy biomass fuel. The low ash content of 7% and high reactivity make it a clean-burning option, although the higher moisture content of 8.33% could necessitate drying before use. Pure J. curcas shows the highest level of porosity and surface irregularity, as revealed by SEM analysis in Figure 2g. This structure, combined with the high volatile matter and low ash content, makes it an ideal high-energy biomass fuel. As per previous studies, the cellulose and hemicellulose in Jatropha contribute to its high volatile matter and, therefore, have high GCV values [20, 41, 42]. However, hemicellulose also contributes to moisture retention, which increases the fuel’s moisture content (as evident from proximate analysis) and necessitates predrying in high Jatropha blends [43]. On the other hand, the presence of lignin provides sustained energy release and reduces ash residue [44].

In summary, blending coal with J. curcas significantly enhances fuel properties, particularly increasing the GCV and volatile matter while reducing ash content. These improvements suggest that J. curcas is a feasible biomass fuel that can enhance the efficiency and environmental performance of coal-fired systems. However, the higher moisture content in J. curcas must be managed to fully realize these benefits.

3.2. Ultimate Analysis

The ultimate analysis of various coal and J. curcas mixtures, as presented in Table 3, shows how the fuel blend’s elemental composition influences its combustion properties and environmental impact. The increase in the percentage of coal in the blend primarily leads to higher carbon content, as seen in Sample 1 (90% coal), where carbon makes up 88.7% of the composition. This high carbon content is indicative of coal’s energy density, which is beneficial for producing substantial energy. However, coal also introduces challenges, particularly with sulfur content, which is 2.77% in Sample 1. Sulfur is primarily present in coal as pyritic sulfur (FeS2), and when combusted, it forms SO2, a major contributor to air pollution and acid rain [45]. Therefore, coal’s high sulfur content is a concern for its environmental impact. Additionally, coal has relatively low nitrogen levels, which is beneficial for reducing NOx emissions during combustion, as lower nitrogen content typically results in lower NOx formation [46].

| Sample | Powdered coal (%) | Jatropha curcas (%) | %N | %C | %H | %S | %O |

|---|---|---|---|---|---|---|---|

| 1 | 90 | 0 | 1.201 | 88.7 | 4.35 | 2.77 | 22.51 |

| 2 | 85 | 5 | 1.51 | 85.8 | 4.76 | 2.67 | 22.03 |

| 3 | 75 | 15 | 1.861 | 82 | 5.515 | 2.11 | 21.99 |

| 4 | 65 | 25 | 1.9 | 75.8 | 5.23 | 1.95 | 21.88 |

| 5 | 55 | 35 | 1.99 | 65.3 | 5.79 | 1.88 | 21.67 |

| 6 | 45 | 45 | 2.01 | 61.6 | 6.71 | 1.78 | 20.14 |

| 7 | 35 | 55 | 2.22 | 58.8 | 7.37 | 1.23 | 19.89 |

| 8 | 25 | 65 | 2.31 | 49.1 | 8.11 | 0.94 | 19.46 |

| 9 | 15 | 75 | 2.51 | 45.7 | 9.62 | 0.501 | 19.22 |

| 10 | 5 | 85 | 2.76 | 41.9 | 10.4 | 0.094 | 18.98 |

| 11 | 0 | 90 | 2.99 | 37.4 | 11.21 | 0.061 | 18.77 |

As the proportion of J. curcas biomass increases in the blends, the elemental composition shifts in a way that enhances both combustion efficiency and the environmental profile of the fuel. J. curcas biomass is rich in hydrogen due to its organic, volatile nature, and increasing its content in coal biomass briquette results in an increase in hydrogen levels, as depicted in Table 3. For instance, in Sample 2 (5% Jatropha), the hydrogen content increases to 4.76%, compared to 4.35% in Sample 1, while a significant increase is observed for J. curcas briquette, that is, 11.21%. Higher hydrogen content promotes better combustion efficiency, as hydrogen is more reactive and combusts at lower temperatures, improving reactivity and ignition speed [47]. This may be attributed to the low-density and porous structure of J. curcas, allowing for better oxygen penetration and faster combustion.

Another important trend is the reduction in sulfur as the biomass percentage increases. For instance, in Sample 11 (90% J. curcas), the sulfur content drops dramatically to 0.061% from 2.77% for coal at 90%. The low sulfur content in biomass reduces the formation of SO2 during combustion, making the biomass blends more environmentally friendly. This reduction in sulfur is a key advantage, as SO2 emissions are a major pollutant, and the switch to a higher biomass blend contributes to a significant reduction in sulfur-related pollution [3, 48]. The lower sulfur content, combined with higher hydrogen levels, not only makes the blend more efficient but also significantly improves its environmental footprint.

The presence of J. curcas also influences the nitrogen content of the blend. Nitrogen content increases with higher biomass content, as Jatropha contains organic nitrogen compounds. For example, in Sample 11, nitrogen rises to 2.99%, compared to 1.201% in Sample 1. While this increase in nitrogen can result in higher NOx emissions during combustion [48], the overall impact on the environment is still less detrimental compared to coal due to the lower sulfur content and improved combustion efficiency from higher hydrogen levels.

The oxygen content also varies depending on the coal-biomass ratio, but its influence is less pronounced than that of carbon, sulfur, and hydrogen. Coal, being rich in carbon, has a higher tendency to form stable organic compounds with lower oxygen content compared to biomass [4, 49]. However, as the proportion of J. curcas increases, the oxygen content of the blend rises slightly due to the presence of oxygenated functional groups in the biomass (such as cellulose and hemicellulose) [20]. This is reflected in the small decrease in oxygen content as the coal proportion increases, with Sample 1 (90% coal) showing 22.51% oxygen, which decreases slightly in biomass blends, that is, 18.77% for 90% biomass.

In conclusion, blending coal with J. curcas improves the fuel’s combustion efficiency and reduces sulfur emissions. Although the fixed carbon content decreases, the significant rise in hydrogen and volatile matter enhances the fuel’s energy density as the proportion of J. curcas increases. The reduction in sulfur content, particularly in blends with higher J. curcas percentages, indicates better environmental performance, while the higher hydrogen content improves combustibility. However, managing the increased moisture content in J. curcas is crucial for optimizing combustion efficiency and overall fuel performance.

3.3. XRF Analysis

The XRF analysis of coal-biomass briquettes, detailed in Table 4, reveals the elemental composition of 11 samples. The analysis focused on key oxides, including SiO2, Al2O3, Fe2O3, potassium oxide (K2O), magnesium oxide (MgO), calcium oxide (CaO), sodium oxide (Na2O), titanium dioxide (TiO2), and the loss on ignition (LOI) values.

| Samples | SiO2 | Al2O3 | Fe2O3 | K2O | MgO | CaO | Na2O | TiO2 (ppm) | LOI |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 50.1 | 14.4 | 7.2 | 2.14 | 2.3 | 5.95 | 0.781 | 0.0045 | 9 |

| 2 | 50.7 | 14.71 | 7.21 | 5.31 | 3.91 | 6.71 | 0.8 | 0.0046 | 9.15 |

| 3 | 50.91 | 14.81 | 7.29 | 5.41 | 2.19 | 8.71 | 0.82 | 0.0048 | 9.21 |

| 4 | 45.91 | 13.97 | 8.61 | 7.81 | 4.7 | 8.97 | 0.85 | 0.005 | 8.24 |

| 5 | 31.61 | 11 | 7.01 | 22.4 | 8.21 | 9.51 | 0.86 | 0.0051 | 9.15 |

| 6 | 18.61 | 7.38 | 6.81 | 31.38 | 8.41 | 13.81 | 0.89 | 0.0053 | 10.71 |

| 7 | 15.61 | 6.91 | 5.44 | 32.19 | 8.85 | 14.1 | 0.91 | 0.0058 | 11.9 |

| 8 | 14.07 | 5.41 | 4.31 | 38.53 | 8.97 | 14.19 | 0.94 | 0.0061 | 13.02 |

| 9 | 11.97 | 4.45 | 3.66 | 40.89 | 9.02 | 14.29 | 0.97 | 0.0063 | 14.61 |

| 10 | 8.61 | 3.81 | 2.7 | 42.81 | 9.07 | 14.31 | 1 | 0.0064 | 14.81 |

| 11 | 5.99 | 1.5 | 0.78 | 45.81 | 9.14 | 14.71 | 1.02 | 0.0067 | 15 |

The SiO2 content shows a noticeable decrease across the samples, starting from 50.1% in Sample 1 and dropping to 5.99% in Sample 11. This trend indicates a higher presence of silica in coal-dominant samples and a reduction as biomass content increases. Al2O3 also follows a similar decreasing pattern, starting at 14.4% in Sample 1 and reducing to 1.5% in Sample 11, highlighting the reduced aluminum content in higher biomass compositions. Fe2O3 levels fluctuate slightly but generally decrease from 7.2% in Sample 1%–0.78% in Sample 11. This reduction suggests a lower iron content in biomass compared to coal. Conversely, K2O exhibits a significant increase, from 2.14% in Sample 1%–45.81% in Sample 11. This substantial rise indicates that biomass, particularly J. curcas, contributes a higher potassium content to the briquettes. MgO and CaO levels also increase with higher biomass content. MgO starts at 2.3% in Sample 1 and reaches 9.14% in Sample 11, while CaO rises from 5.95% in Sample 1%–14.71% in Sample 11. These increases suggest that biomass contributes more magnesium and calcium compared to coal, which may enhance certain combustion properties. Na2O shows a steady but slight increase across the samples, from 0.781% in Sample 1%–1.02% in Sample 11. TiO2 content, measured in ppm, also rises modestly, indicating a higher presence in biomass-dominant samples. The LOI values, which indicate the amount of weight loss after burning, generally increase with higher biomass content, from 9% in Sample 1%–15% in Sample 11. This increase in LOI suggests that biomass has more volatile matter, which is consistent with its higher organic content compared to coal.

The XRF analysis shows a clear compositional shift from coal to biomass. Coal-dominant samples have higher SiO2, Al2O3, and Fe2O3, whereas biomass-dominant samples have higher K2O, MgO, CaO, and LOI values. This shift reflects the differing elemental compositions of coal and biomass, with the latter contributing more alkali and alkaline earth metals, which can influence the combustion characteristics and ash properties of the briquettes. The results provide key insights for optimizing briquette formulations to achieve desired fuel properties and performance.

3.4. Limitations

There are several limitations to this study that need to be addressed in order to provide a balanced perspective. This study focused on J. curcas as the only biomass component, limiting its generalizability to other biomass types with differing combustion and emission characteristics. As this study was conducted at a laboratory scale, its findings may not directly translate to industrial applications due to differences in processing, storage, and combustion dynamics. Although the study highlighted increased moisture content in biomass-rich briquettes, its effect on ignition and heat release was not discussed in detail. A number of important aspects, including life cycle assessment (LCA), cost–benefit analysis, and optimization of blending ratios, were not examined. Furthermore, slagging, fouling, and reuse potential were not evaluated, nor were briquette durability and storage stability under different environmental conditions. In future research, these gaps could be filled to improve coal-biomass briquettes’ practical and economic viability.

3.5. Practical Implications

Several practical implications arise from this study on coal-biomass briquettes using subbituminous coal and J. curcas. The increase in GCV associated with biomass content suggests the possibility of using biomass as a high-energy alternative to pure coal, improving energy efficiency in power generation and industrial heating applications [50, 51]. As a result of the lower sulfur content of biomass-rich briquettes, they comply with environmental regulations, reducing emissions of SO2 and promoting cleaner energy production [52]. In addition, the higher volatile matter facilitates quicker combustion, which is appropriate for processes requiring rapid energy release [53]. The use of locally available biomass such as Jatropha encourages energy diversification, enhances local economies, and reduces the need for imported coal [54, 55]. The incorporation of agricultural residues into briquette production also contributes to waste management and circular economies [56]. Through this framework, policymakers will be able to design fuel blends that balance energy efficiency, environmental benefits, and application-specific requirements, creating incentives for renewable energy integration and cleaner energy deployment.

4. Conclusions

In this study, coal-biomass briquettes are made from subbituminous coal and J. curcas were evaluated to enhance energy output and reduce environmental impact. Results showed that blending coal with J. curcas significantly increased GCV, with the highest energy yield observed at 90% J. curcas (28.29 MJ/kg) compared to pure coal (23.31 MJ/kg). As biomass content increased, moisture and volatile matter increased as well, potentially affecting combustion efficiency. Carbon and sulfur levels also decreased, leading to lower SO2 emissions. A compositional shift has been confirmed by microstructural and elemental analyses, with coal-rich samples exhibiting higher SiO2, Al2O3, and Fe2O3, whereas biomass-rich samples are enriched in K2O, MgO, and CaO. These findings suggest that coal-biomass briquettes are a promising solution for sustainable energy production, offering a balance between high energy yield and reduced environmental pollutants.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

There is no separate funding body or organization to declare.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.