A Data-Driven-Aided Thermoelectric Equivalent Circuit Model for Accurate Temperature Prediction of Lithium-Ion Batteries

Abstract

Accurate temperature estimation models for lithium (Li)-ion batteries are critical for timely identification of and response to thermal runaway effects to ensure battery safety. In this paper, a hybrid data-driven approach incorporating thermoelectric equivalent model (TEM) is proposed to predict the temperature of Li-ion batteries under different state of health (SOH) based on measured data. The proposed TEM model consists of an electrical equivalent circuit model (EECM) and a thermal equivalent circuit modeling (TECM). The electrical model is a second-order RC equivalent circuit model, and the thermal model is a first-order thermal model, which interacts with parameters such as state of charge (SOC) and internal resistance to improve the accuracy of the model. In order to solve the problem that the model part is susceptible to measurement errors, a data-driven model using Kalman filter (KF) combined bidirectional gated recursive unit (BiGRU) and Transformer is proposed to ensure high accuracy in predicting the temperature. The output of the TEM is used as the input to the data-driven part to obtain the implied relationship between the temperature and parameters. The experimental results confirm the high accuracy of the hybrid model in estimating the battery temperature. The maximum temperature prediction error of the Li-ion battery was 0.3423°C with a predicted root mean square error (RMSE) of 0.1266 under different SOH conditions.

1. Introduction

Lithium (Li)-ion batteries serve as the principal energy storage units in electric vehicles, renowned for their high-power density, energy density, extended lifespan, and durable cycling performance [1]. However, the Li-ion batteries are vulnerable to diverse operational conditions that may result in electrical [2], thermal [3], and mechanical stresses [4]. Any form of abuse can initiate thermal runaway in Li-ion batteries, leading to heightened temperatures that pose a risk of combustion or even explosion. As shown in [5], excessively high core temperatures can induce battery explosions, especially under high discharge rates. Hence, precise and timely monitoring of Li-ion battery temperature is critical for safety. Additionally, battery temperatures influence the state of health (SOH) [6], state of charge (SOC) [7, 8], and residual capacity [9] of Li-ion batteries. Most battery management systems (BMSs) incorporate temperature monitoring functions to diagnose battery failures and manage pack balancing [10]. However, existing temperature monitoring techniques in BMSs are either overly simplistic or excessively complex. Simplified versions often compromise temperature accuracy, while more intricate approaches introduce high computational burdens and costs. Therefore, there is a need for an accurate and cost-effective temperature monitoring model [11]. Existing temperature monitoring models can be categorized into three main types: electrochemical models, thermal equivalent circuit modeling (TECM), and data-driven models.

Electrochemical models are typically developed using energy balance equations as outlined in [12] and [13] and a coherent heat generation model as described in [14]. However, electrochemical-based thermal modeling, whether using a simple one-dimensional model [15] or a complex three-dimensional thermal model [16] to represent the chemical behavior in Li-ion batteries, requires the corresponding parameters of the chemical materials inside the battery. Despite the high accuracy of electrochemical model-based methods, in practice, the complexity of the data to be acquired and the high computational cost make it difficult to achieve real-time prediction of battery temperature. The TECM does not rely on the physical basis of the Li-ion batteries but instead utilizes basic electrical components to construct a simplified circuit structure that models the temperature variations within the batteries [17]. One significant advantage of TECM over the electrochemical model is its simplicity and ease of implementation in digital controllers. In [18], an adaptive observer is introduced to monitor the internal core temperature of Li-ion batteries using a second-order TECM. The parameters of the TECM are identified through the classic least square method based on the measured surface temperature of the batteries. Then, the internal resistance of the method is characterized by its correlation with temperature variations, while a least square algorithm with a nonuniform forgetting factor is adopted to compensate for the internal resistance variations. In [19], an extended Kalman filter (EKF) is utilized to enhance the estimation of internal and surface temperatures of Li-ion batteries. This EKF-based thermal estimation and control method demonstrates superior accuracy compared to traditional approaches. Its temperature error is controlled within ±0.2°C, and the accuracy is improved at different room temperatures. In [20], an enhanced TECM model is proposed to take into account the coupling effects among battery capacity, SOC, and temperature to improve the accuracy of various state estimations. A coestimation scheme of battery capacity, SOC, and surface temperature is constructed, which is able to control the estimation error of battery core temperature and surface temperature within ±0.5 K. Besides, a lumped TECM with the consideration of heat transfer between the battery surface and surrounding medium is proposed in [21]. An adaptive core temperature estimation algorithm is also proposed to estimate both the internal temperature and thermal resistance of the Li-ion battery. It is experimentally verified that the estimation error of the core temperature remains within ±0.6°C under different ambient temperatures and discharge conditions.

The data-driven model is developed to address accuracy issues in TECMs under disturbances and the complexity inherent in electrochemical models. In [22], a data-based neural model is proposed to predict the thermal behaviors of Li-ion batteries. In [23], two types of recurrent neural networks (RNNs) are introduced: long short-term memory (LSTM)-RNN and gated recurrent unit (GRU)-RNN. These models are proposed to predict the surface temperature of 18650 Li-ion batteries during discharge across varying ambient temperatures. Based on the validation, the maximum absolute errors of LSTM-RNN and GRU-RNN are about 0.75°C and 0.71°C, respectively. A similar GRU-RNN is further used to eliminate the surface temperature variations of Li-ion batteries [24]. In [25], a hybrid model combining a physically informed neural network (PINN) with LSTM is introduced to forecast temperature variations in Li-ion batteries during DC fast charging. The results show that the root mean square error (RMSE) of the LSTM-PINN model is 0.57°C under the DC fast charging test and 0.52°C under the ramp load test. Additionally, an EKF-based approach is employed to mitigate internal temperature variations, complemented by a neural network to capture disturbances [26]. The RMSE of the proposed method was 0.32°C at −15°C and 0.21°C at 5°C. Concurrently, a fast recursive algorithm (FRA) is employed to determine the parameters of the linear neural network [27]. The results showed an RMSE of 0.081 for a small range of temperatures and 0.129 for a large range of temperature data. A hybrid data-driven method that combines an electrochemical–thermal neural network (ETNN) with an unscented Kalman filter (UKF) is proposed for estimating both SOC and state of temperature (SOT) [28]. The results show that the estimation error of SOT is 1.08°C at an ambient temperature of −10°C, while the error is less than 0.7°C at temperatures ranging from 20 to 40°C. The primary challenge with data-driven models is the requirement for extensive data measurement to ensure model accuracy.

In order to solve the problem of prediction error caused by the inability of the equivalent model to describe the internal chemical behavior of the battery in detail and the problem of high data demand faced by the data-driven method, some studies on the state prediction of Li-ion batteries have combined the equivalent model-based approach with the data-driven method. The output data of the equivalent model are used as input for the data-driven part, and then the data-driven method is used to explore the target invisible relationship between the battery parameters and the predicted quantities. Yao [29] proposes a hybrid prediction model particle swarm algorithm (PSO)-extreme learning machine (ELM)-relevance vector machine (RVM) for the remaining useful life (RUL) prediction of Li-ion batteries. The model maps the relationship with the capacity through the RVM optimized by PSO and then predicts the RUL of the batteries through the PSO-ELM. Similarly, Zhang et al. [30] proposes an forest algorithm (RF)-artificial bee colony (ABC)-general regression neural network (GRNN) model for predicting the battery RUL. The RF-ABC-GRNN model uses a random RF to screen high correlation data for the correlation between the parameters and the RUL. In addition, the smoothing parameter values in the GRNN were optimized by the ABC algorithm to improve the prediction. For the SOH of batteries, Chen et al. [31] proposed an ELM-BSASVM model. The proposed ELM-BSASVM model uses a better performance ELM for prediction in the front-end data after noise reduction of the data by wavelet basis functions. And bird swarm algorithm (BSA) in the back-end data optimizes the SOH prediction model on the input parameters of the support vector machine (SVM). Thus, high accuracy prediction of SOH for long cycle data is realized. In addition to the prediction of battery life, Talluri et al. [32] proposes a novel hybrid model based on machine learning (ML) and an improved coulomb counting method (CCM) to predict the capacity change during the battery cycling process. The method uses the real-time voltage value and the SOC data obtained from the CCM calculation as additional inputs to the ML algorithm in order to achieve a higher accuracy of capacity prediction. However, there are still fewer methods that use hybrid models for predicting the temperature of Li-ion batteries, but in fact, this hybrid model is able to well combine the advantages of current temperature prediction methods in order to achieve simpler and more accurate real-time predictions.

Based on the above discussion, this paper combines TECM and data-driven approaches to address the lack of TECM’s description of thermal behavior with data-driven difficulties in data requirements. In this paper, a thermoelectric equivalent model (TEM) is proposed which combines a TECM and an electrical equivalent circuit model (EECM). The TEM is used as an input to the data-driven part by collecting data in order to output difficult-to-access thermal-related parameters of the battery. The Kalman filter (KF)-bidirectional gated recursive unit (BiGRU)-Transformer model was also constructed. In it, the collected data were noise reduced using KF, and then the noise-reduced data were trained by BiGRU to obtain the implied relationship between each parameter and the time series, and finally, this relationship was inputted into the Transformer network for real-time prediction of temperature. To validate the accuracy of the hybrid model, experimental evaluations were performed on Li-ion batteries under different SOH conditions.

2. TECM and Parameter Identification

2.1. First-Order TECM

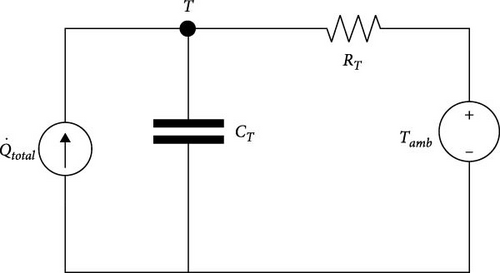

The battery thermal model can be simplified by dividing the battery into a thermal capacity and a thermal resistor. In Figure 1, Tamb represents the current ambient temperature, and RT and CT represent the overall thermal resistance and heat capacity, respectively. Assume that the overall material inside the battery is evenly distributed and that the parameters of all parts are the same. Therefore, based on Kirchhoff’s current law and Ohm’s law, the following relationship is established:

2.2. Second-Order TECM

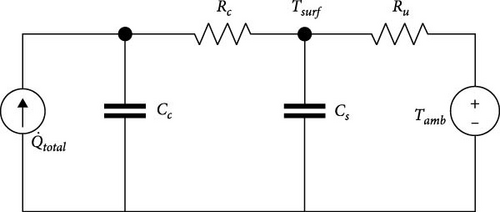

However, due to the different shapes and sizes of batteries, some batteries will have a large temperature difference between the core temperature and the surface temperature. Therefore, a second-order TECM was developed to represent two temperatures at different locations of the cell in terms of voltages at two different potentials.

In Figure 2, Tc and Ts represent the core temperature and surface temperature, respectively. The convective heat exchanges between the battery’s surface and the environment through the convective thermal resistance Ru. The heat exchanges between the core and surface through the conduction thermal resistance Rc. Cc and Cs denote the specific heat capacities of the core and surface of the battery, respectively. Here, it is assumed that the material inside the battery is uniform, implying a constant specific heat capacity at each position within the battery. The following relationship is established as follows:

2.3. Parameter Identification of Thermal Model

Traditional parameter identification methods can be divided into offline identification and online identification. The offline identification method is to obtain the model parameters in advance for identification, and the online identification method is to use real-time data for identification. TECM needs to discuss its optimal identification method because it is closely related to the material properties of the battery, which is different from the EECM whose parameters change with the change of the working conditions. In this study, the more advanced adaptive weighting factor and forgetting factor recursive least squares (VWF-VFFRLS) [33] was chosen as the online identification method; meanwhile, the coyote optimization algorithm (COA) was chosen as a typical offline identification method. The two identification methods are used to identify the TECM parameters, respectively, and analyze the applicability and accuracy difference for TECM identification.

2.3.1. VWF-VFFRLS Identification Algorithm

2.3.2. COA

COA is a bionic global optimization algorithm. Algorithm 1 draws inspiration from the life events of coyote populations, including birth, growth, death, and migration. The simplicity of implementation and fast convergence of COA make it widely used for parameter identification. For space reasons, the pseudocode for COA is listed in Table 1.

| Algorithm 1 Pseudocode of the COA. | |

|---|---|

| 1: | Initialize Np packs with Nc coyotes each |

| 2: | Verify the coyote’s adaptation. |

| 3: | while the stopping criterion is not achieved do |

| 4: | for each p pack do |

| 5: | Define the alpha coyote of the pack |

| 6: | Compute the social tendency of the pack |

| 7: | for each c coyote of the p pack do |

| 8: | Update the social condition |

| 9: | Evaluate the new social condition |

| 10: | Adaptation |

| 11: | end for |

| 12: | Selection of new individual parents。 |

| 13: | Compute the worse adapted group ω and the number of coyotes ϕ. |

| 14: | ifϕ = 1 then |

| 15: | The survives and the only coyote in ω dies. |

| 16: | elseif ϕ > 1 then |

| 17: | The survives and the oldest coyote in ω dies. |

| 18: | Else |

| 19: | The dies. |

| 20: | end if |

| 21: | end for |

| 22: | Transition between packs |

| 23: | Update the coyotes’ ages. |

| 24: | end while |

| 25: | Select the best adapted coyote |

- Abbreviation: COA, coyote optimization algorithm.

Similar to the process of online identification, after obtaining the corresponding battery data, the first-order thermal model and the second-order thermal model of the battery are identified offline. The following COA offline recognizes the first-order and second-order TECMs.

In the process of offline identification of the first-order thermal model parameters with COA, T (t) represents the real-time temperature of the battery, Tpre (t) represents the cell temperature calculated according to Equation (5). It is assumed that the target values CT and RT are known, thus iteratively. Denoting CT and RT in Equation (5) as the social status of individual mid-coyotes, the resulting COA algorithm can iterate over first-order thermal model parameters randomly generated over a set range, minimizing overall error by comparing predicted temperatures to experimentally obtained surface temperatures.

And in the offline identification process of the second-order thermal model parameters with COA, the data being identified are analogized to the social condition of a coyote individual in the COA, represented as . By comparing this calculated surface temperature with the measured temperature as Equation (8), a dataset minimizing the overall error is determined, aligning with the COA algorithm’s objective of minimizing this discrepancy. Tpre (t) can be replaced by Equation (8). It is similar to the iterative approach of the first-order thermal model, where the unknown parameters are iterated as if they were known quantities to obtain the optimal value.

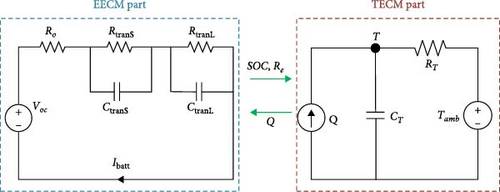

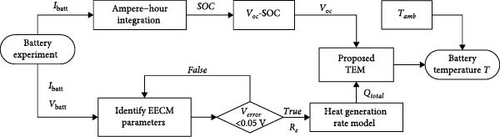

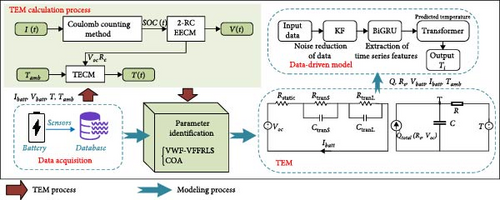

3. TECM

By identifying and simulating the TECM, it is obtained that the temperature variation of the battery in TECM is a function of the heat generation Q and the internal resistance Re. And the heat generation Q is also a function of the internal resistance Re and the open-circuit voltage Voc of the battery. Therefore, there are a large number of parameter interactions between the EECM and the TECM, and by using this feature, the values of the battery’s SOC, Re, and other parameters can be obtained in the EECM as inputs to the TECM for obtaining the value of the heat generation Q. And the TECM feeds back the temperature T obtained through simulation into the EECM to correct its parameters in order to obtain a higher recognition accuracy. Therefore, the corresponding TEM model is established through the connection between the heat generation Q in the TECM and Re and Voc in the EECM, and the real-time simulation of the battery temperature T is realized through the operating state of the battery after obtaining the identification results of the overall model. In this paper, the structure of TEM with first-order TECM and second-order RC-EECM, for example, is shown in Figure 3.

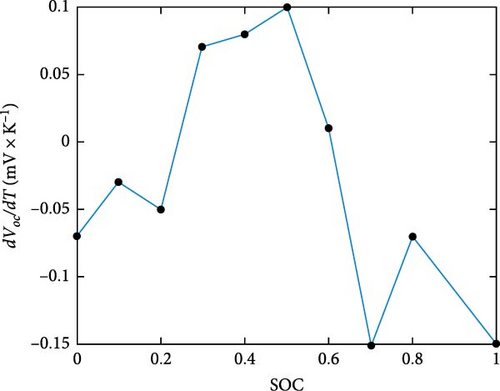

To calculate the amount of heat generation Q, it is first necessary to obtain the entropy heat coefficient dVoc/dT and the internal resistance Re in Equation (3). In TEM, the entropy heat coefficient dVoc/dT can be considered as a function of SOC. By calculation, the relationship between entropy heat coefficient dVoc/dT and SOC is shown in Figure 4. In addition, the internal resistance required in the heat calculation process can also be expressed as the sum of the EECM components Ro, RtranS, and RtranL. Therefore, the Re parameter is obtained after selecting the VWF-VFFRLS to identify the EECM part of the TEM.

In addition, the SOC–Voc curve is obtained by charging and discharging with small currents in a laboratory environment and then fitted with polynomials. Since a Voc test is time-consuming and in [36] it was shown that the curve is less affected by the aging of the battery and does not change much during the whole life cycle, a new battery with SOH = 1 is chosen for fitting the SOC–Voc curve. The resultant equation of the fitting is shown in Equation (17), where the parameters are all represented in Table 1. The SOC-VOCV relationship equation and specific parameters in the equation were derived through HPPC experiments and least squares fitting (given in Table 2).

| Fitting result | p1 | p2 | p3 | p4 | p5 | p6 |

|---|---|---|---|---|---|---|

| Value | 0.9215 | −3.283 | 3.955 | −1.248 | 0.2633 | 3.733 |

4. Model and Data-Driven Fusion Approach Modeling

4.1. Overview of the Fusion Approach Model

Based on the constructed TEM, the electrical characteristics and temperature variations of the battery are simulated under the condition that the battery operation data have been acquired. However, TEM-based temperature prediction methods are inevitably affected by small noise during the identification process or simulation. This noise makes the simulation results produce errors, especially when the battery is under complex operating conditions, and the effect of this noise will be further amplified. Therefore, in this section, the output of TEM is used as input to predict the temperature using a BiGRU-Transformer neural network based on KF optimization, to realize the temperature prediction method based on the fusion of model and data-driven in order to obtain the temperature prediction method with high accuracy and high adaptability.

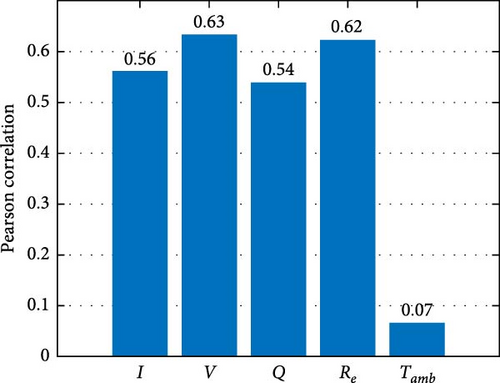

To filter the parameters with higher correlation with the battery temperature as inputs, person correlation was used to evaluate the correlation of different parameters, and the results are shown in Figure 6. Heat generation Q, internal resistance Re, battery current I, and battery voltage V were used as inputs to the data-driven part.

Furthermore, the correlation between the ambient temperature Tamb and the battery temperature change is low. However, the fact that the ambient temperature largely influences the baseline value of the battery temperature change, as well as the rate of temperature change of the battery, makes it one of the inputs to the data-driven model as well.

4.2. Relevant Theoretical Foundations

4.2.1. KF

By repeating the prediction and updating steps, the estimation of the system state is continuously optimized based on new measurements and the system model, and useful information is extracted from the noisy acquired signals, reducing the influence of noise on the signals.

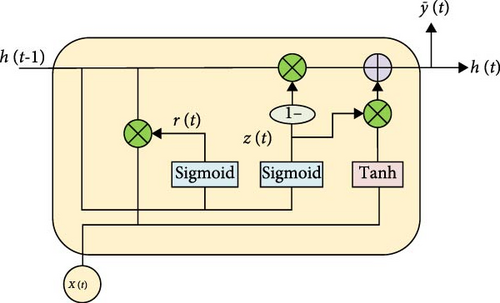

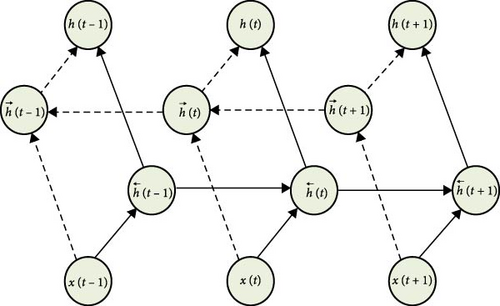

4.2.2. BiGRU Network

GRU is a variant of RNN designed to better handle long-term dependencies in sequential data and to prevent the gradient vanishing problem. The structure of GRU is given in Figure 7. Similar to LSTM, there are update gates and reset gates in GRU, which allow the network to selectively update the internal state. But the structure of GRU is simpler than that of LSTM, and GRU has the speed advantage of dealing with long time series data. The update gate and reset gate in GRU are represented as follows.

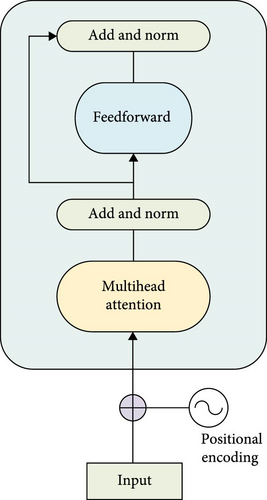

4.3. Transformer Network

Transformer is a neural network architecture with superior performance. It is generally used in natural language processing, computer vision, time series prediction, etc. Its main feature is that it is based on attention mechanism rather than recursive structures (such as RNN and LSTM). A standard Transformer is a sequence-to-sequence architecture that consists of an encoder and a decoder. The encoder is responsible for mapping the input sequence into a vector of higher dimensions, which is then fed into the decoder to generate a series of outputs. Its conventional structure is shown in Figure 9.

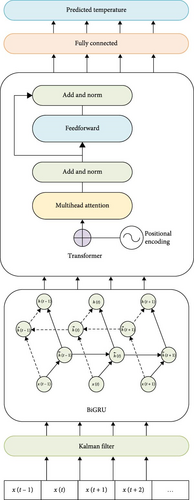

4.4. KF-BiGRU-Transformer

In the timing prediction task, the raw data are affected by the acquisition process, and the result may be is not monotonous and smooth. These data are noisily processed by KF to reduce the effect of noise on the prediction and at the same time shorten the training time. BiGRU network can use its recursive property to extract the temporal features of the data, and the Transformer network can fully explore the global features of the data by modeling the data through the multihead self-attention mechanism and FFN switching. Therefore, this paper proposes a battery temperature prediction method (KF-BiGRU-Transformer) that combines KF, BiGRU, and Transformer. The method includes a data preprocessing module, a KF module, a BiGRU module, a Transformer module, and a fully connected (FC) module, as shown in Figure 10.

The modeling framework proposed in this paper can fully utilize the advantages of the Transformer network and KF: In the process of collecting battery data, the sensor or transmission process will inevitably be affected by noise. Therefore, reducing the noise in the data before adding the KF to the BiGRU network will reduce some of the prediction arithmetic burden while enhancing the subsequent prediction accuracy and reducing the impact of noise. The equations of state and the spatial equations of the KF are established based on the TEM and perform the noise reduction process on the data acquired from the experiments. Next, the processed time series are fed into the BiGRU module, which consists of two single-layer BiGRU networks, respectively. In this case, each single-layer BiGRU passes its output to the next layer after processing by an activation function, so that each layer can learn information at different time scales. This structure helps to better capture the long-term dependencies between battery temperature and other parameters in long sequences, thus improving the information extraction ability of the model. And then, the attentional weights of the multiattention mechanism can better integrate the uncertainty information in the battery temperature data and focus on the parameter (current, voltage, heat generation, etc.) effects on the battery temperature to improve the prediction accuracy. Therefore, the features extracted from the BiGRU module are input into the Transformer module, and the data features at different locations are extracted and spliced using the multihead attention mechanism and then nonlinearly transformed through the FFN. Finally, the output of the Transformer is input into the FC layer for real-time prediction of the battery temperature. In summary, the strategy adopted in this paper can maximize the advantages of the KF, BiGRU, and Transformer network to achieve good prediction results.

4.5. Fusion Method Prediction Process

Based on the above TEM and KF-BiGRU-Transformer theories, the flow of the hybrid model and data-driven modeling approach proposed in this paper is shown in Figure 11, which includes three basic parts, that is, obtaining parameter identification of the TEM, training of the data-driven model, and testing.

First, the actual operating parameters of the battery are obtained through various types of sensors, including the voltage, current, and surface temperature of the battery as well as the ambient temperature. Then, based on the results of online and offline identification for different TECMs, the identification method with relatively higher accuracy is selected to identify the parameters of the TECMs in the TEM, and the VWF-VFFRLS is used to identify the parameters of the EECMs in the TEM. The TEM can accurately describe the dynamic temperature change during the battery operation and provide the variation of electrical characteristics of different chemical reactions inside the battery. In addition, to prevent errors in the identification results in the modeling part from affecting the results of the neural network model, the accuracy of the model is calculated by simulation before neural network training is carried out.

Second, the TEM model is used to simulate the simulation to obtain the values of some parameters that cannot be obtained by the sensors, such as the amount of heat generated Q and the internal resistance of the battery Re. Then, all recorded datasets and parameters with high correlation were obtained, and the input dataset was obtained by Pearson correlation coefficient method. The interaction between the TEM and the data-driven part is realized by this method of using the data simulated by the TEM and the actual sampled data as inputs to the KF-BiGRU-Transformer part.

Third, a neural network-based data-driven model is developed, which consists of KF to optimize the input data, BiGRU for feature extraction in the time series, and finally Transformer for temperature prediction. The model is trained using the parameters selected in Figure 6, which takes the heat generation Q, internal resistance Re, current of battery Ibatt, voltage of the battery Vbatt, and ambient temperature Tamb as inputs and the battery temperature T as output.

Finally, based on the training and validation results, the proposed model successfully realizes the online prediction of battery temperature based on the hybrid model.

In this way, the proposed model and the data-driven hybrid model cannot only have real-time high-precision prediction, but also bypass the huge arithmetic power of real-time simulation of the TEM model.

5. Experiment Validation

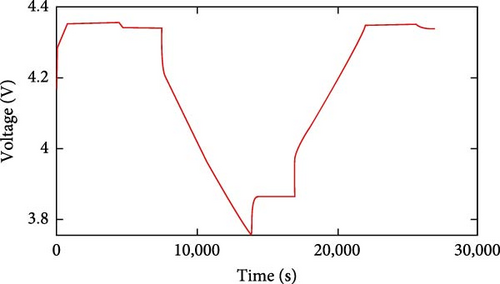

As shown in Figure 12, constant temperature charging and discharging experiments were carried out on two Pokefi SY300-1 Li-polymer batteries, where the nominal capacity of Pokefi SY300-1 was converted to an equivalent capacitance of 13860 F. Among them, Bat1 was a new battery with SOH value of 1 and Bat2 with SOH values of 0.6578, where the voltage, current, and surface temperature of the cells were recorded by a Hioki LR8450 data logger.

5.1. Experimental Data Analysis

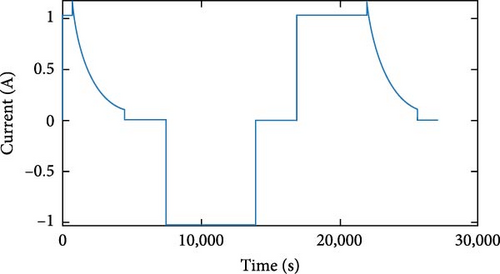

Validate the accuracy of the proposed TEM for Li batteries as well as obtain inputs for the neural network model through a series of experiments. Online and offline identification methods for determining the parameters of the battery thermal model were evaluated using complete charge and discharge data. Two batteries Bat1 and Bat2 with different SOH were selected for the experiment. The batteries all went through three stages of discharge, resting, and charging during the experimental operation. The measured output voltages and currents of the two batteries are shown in Figure 13. The charging current was set to be positive, and the discharging current was set to be negative.

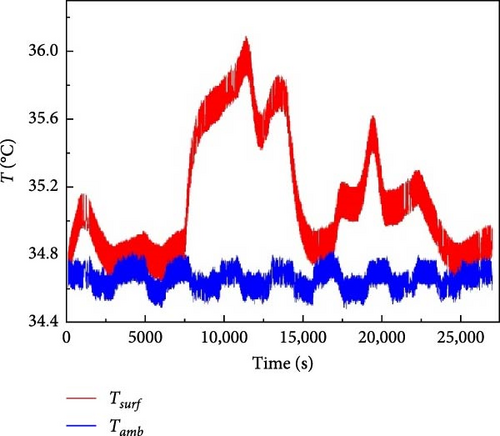

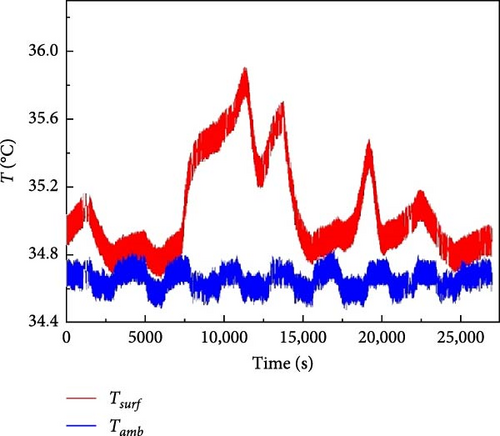

In the experiment, the surface temperature and ambient temperature of the two batteries were monitored and recorded separately, as shown in Figure 14. The laboratory temperatures were all maintained at approximately 34.7°C for the experiment. Initially, both Bat1 and Bat2 showed a small increase in battery surface temperature during the short charging phase at the beginning of the experiment. Subsequently, the surface temperatures of both batteries decreased rapidly during the resting period but eventually stabilized. And then again, during the constant current discharge phase, the batteries warmed up rapidly. At the same time, its surface temperature remains high. When the battery is discharged to the lowest operating voltage, the discharge stops. Then, a rapid decrease in the surface temperature of the battery can be observed. Subsequently, constant current charging begins. The maximum surface temperature in this stage is 35.6°C, which is lower than the temperature in the discharge stage.

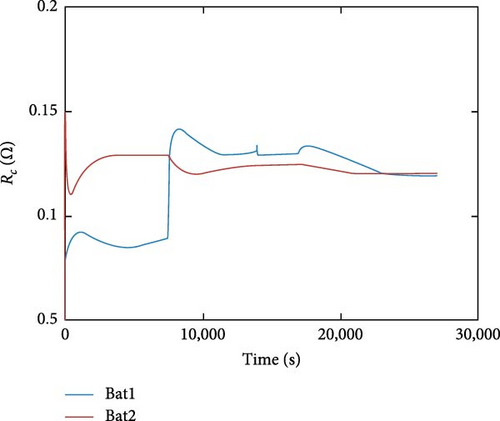

The EECM model, as part of the TEM, has the main role of providing the TECM part with the internal resistance Re and the open-circuit voltage Voc. Conversely, the temperature predicted by the TECM part also reacts back to the EECM for parameter correction. However, this paper focuses more on the parametric inputs from the EECM to the TECM. Therefore, the EECM needs to use VWF-VFFRLS identification to obtain the internal resistance of the battery Re. In the model proposed in this paper, the internal resistance Re is the sum of all the resistance values in the EECM model, and the identification results are shown in Figure 15.

The trend of the internal resistance Re of Bat1 and Bat2 with the charging and discharging process can be seen from Figure 15. As can be seen from Figure 15, the internal resistance of both batteries experienced a rapid rise at the beginning and then stabilized, but the internal resistance of Bat1 showed significant fluctuations after about 10,000 s, while the internal resistance of Bat2 was relatively smooth. This variation in internal resistance may affect the accuracy of the battery temperature prediction, and although the small value of the internal resistance Re is analyzed from a mathematical point of view and its effect on the temperature estimation does not cause an excessive shift in the results, it seriously affects the goal of high accuracy of the prediction. Therefore, in practice, the dynamic changes in internal resistance need to be considered, especially for Bat1, whose fluctuations in internal resistance may require special attention and adjustment of model parameters to accurately predict temperature changes.

5.2. Validation of Thermal Model Identification

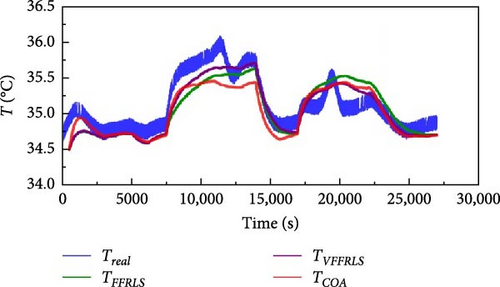

For the offline identification of the first-order thermal model with COA, the parameter settings of the algorithm are as follows: 50 coyote individuals are utilized, and the algorithm undergoes a total of 200 iterations. The iteration range for thermal resistance is defined as (0, 100), while the iteration range for heat capacity is set between (0, 1000). After iterations, the thermal resistance of the cell in the first-order thermal model is computed as 4.0619 K/W−1, and the heat capacity is determined to be 411.3769 J/K−1. At the same time, the obtained battery data are identified online by VWF-VFFRLS. To demonstrate the accuracy of VWF-VFFRLS in online identification, the simplest FFRLS is also validated here.

The first-order thermal model parameters obtained by the on-line and off-line identification methods mentioned in Section 2 are simulated and verified, respectively. The simulated temperatures resulting from these parameter sets were compared with the actual battery temperatures, as illustrated in Figure 16. It can be observed that, for the first-order thermal model, the simulated temperature changes of the battery derived from the three methods closely align with the actual temperature variations. The temperature error differences among the three methods are relatively minor. This similarity in the error values can be attributed to the simplicity of the first-order model, where many algorithms exhibit comparable accuracy due to the model’s straightforward nature.

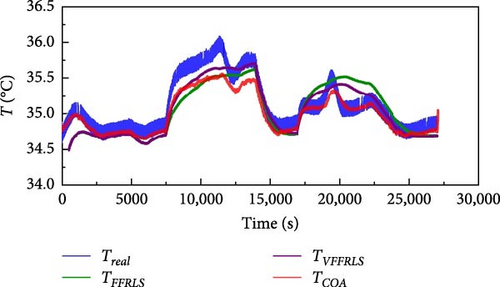

Similar to the identification process of the first-order thermal model, the offline identification parameters of the second-order thermal model are set as follows: The iteration range for thermal resistance is set as (0, 100), and the iteration range for heat capacity is specified as (0, 2000). The second-order TECM part is identified and iterated by the COA algorithm, and the heat capacity of the core Cc and the heat capacity of the surface Cs in the thermal model are obtained to be 64.973 J/K−1 and 4.649 J/K−1, respectively, whereas the conduction thermal resistance Rc and the convection thermal resistance Ru are obtained to be 2.989 K/W−1 and 3.4817 K/W−1, respectively. At the same time, the obtained battery data are identified online by FFRLS and VWF-VFFRLS, respectively.

The simulated temperatures of the second-order thermal model and the actual measured surface temperatures of the cell obtained by different algorithmic identification are shown in Figure 17. It is found that the error by online identification approach is larger than that by offline identification method. In order to assess the accuracy of temperature prediction from different identification methods, the RMSE is used as an evaluation metric. RMSE is denoted as follows:

After obtaining the parameters of the thermal model of the battery, the TEM developed in Section 3 can be verified. Based on the internal resistance Re of the battery obtained from the identification, the heat generation of the battery can also be derived from Equation (3). Therefore, the corresponding model is built in MATLAB/Simulink, and the voltage following and temperature following of the two batteries are compared to verify the accuracy of the model. The RMSE calculations of the two batteries and their results are shown in Table 3. The RMSE of the TEM is expressed as the average value of the RMSE of the voltage verification results in the electrical model part and the temperature verification results in the thermal model part.

| Battery number | RMSE |

|---|---|

| Bat1 | 0.2198 |

| Bat2 | 0.2759 |

- Abbreviations: RMSE, root mean square error; TEM, thermoelectric equivalent model.

From the validation results of the thermoelectric model, it can be seen that the accuracy of the model can already track the actual accuracy well. However, in practical applications, it is impossible to eliminate the ineliminable oscillations brought about by VWF-VFFRLS at the beginning of the partial identification process of the electrical model, which largely affects the accuracy of the model. Therefore, based on the thermal model, combined with the data-driven algorithm, real-time prediction of the temperature of the thermal model can be realized, thus greatly avoiding this error.

5.3. Validation of KF-BiGRU-Transformer to Predict Battery Temperature

For temperature prediction, two batteries with different SOH were selected for the study. The charging and discharging processes of the first brand new battery Bat1 and the second battery with SOH value of 0.6578 Bat2 are exactly the same. Initially, voltage, current, and ambient temperature data from the two cells, as well as computationally acquired heat generation and internal resistance, were used as inputs, and the surface temperature of each cell was used as an output. Bat1 is the training set when Bat2 is the prediction set at this point.

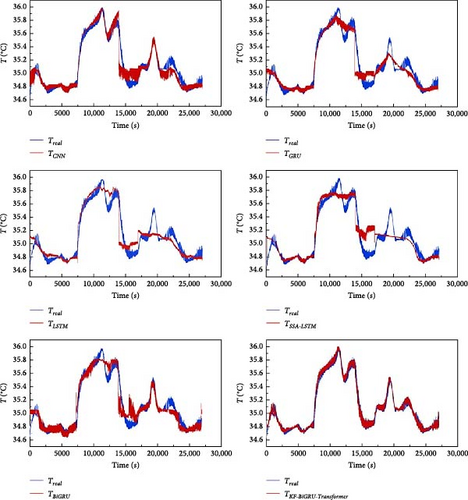

In the experiments, CNN, GRU, LSTM, BiGRU, and SSA-LSTM are set as control groups, where the hyperparameters of CNN, GRU, LSTM, and BiGRU models are the same as those of KF-BiGRU-Transformer. And the hyperparameters of SSA-LSTM model are optimized by SSA. Based on the RMSE comparison, the training effect of KF-BiGRU-Transformer is significantly better than other neural networks. Therefore, the data of Bat1 are firstly trained as the training set, and the obtained training results are shown in Figure 18 and Table 4. It can be seen that the RMSE of KF-BiGRU-Transformer on Bat1 data is only 0.0570, which is much smaller than the remaining four control sets. This indicates that the KF-BiGRU-Transformer is trained with extremely high accuracy under the same training conditions and can have better results in the subsequent tests.

| Method | Average error (%) | Maximum error (°C) | RMSE (°C) |

|---|---|---|---|

| Training set | |||

| CNN | 0.18361 | 0.68139 | 0.0945 |

| GRU | 0.20813 | 0.75062 | 0.1113 |

| LSTM | 0.25172 | 0.76128 | 0.1290 |

| BiGRU | 0.20888 | 0.50976 | 0.1066 |

| SSA-LSTM | 0.26767 | 0.65737 | 0.1437 |

| KF-BiGRU-Transformer | 0.1194 | 0.28054 | 0.0570 |

| Test set | |||

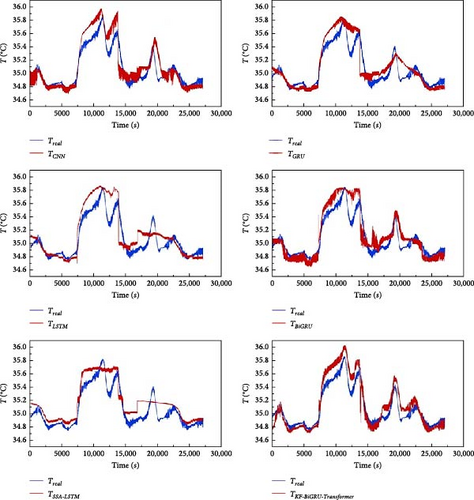

| CNN | 0.10733 | 0.5247 | 0.14758 |

| GRU | 0.1056 | 0.68429 | 0.14845 |

| LSTM | 0.12364 | 0.63383 | 0.16458 |

| BiGRU | 0.1140 | 0.4396 | 0.1494 |

| SSA-LSTM | 0.12427 | 0.44457 | 0.14095 |

| KF-BiGRU-Transformer | 0.10418 | 0.3423 | 0.1266 |

- Abbreviations: GRU, gated recurrent unit; KF, Kalman filter; LSTM, long short-term memory; RMSE, root mean square error; SSA, sparrow search algorithm.

The results with Bat2 used for testing are shown in Figure 19 and Table 4, and the KF-BiGRU-Transformer proposed in this paper predicts the temperature results of Bat2 with an RMSE of 0.1266, which is better than the other five sets of neural networks. However, it can be observed that there is still a relative error in the fitting of the test results on the battery peak, which is mainly caused by the influence of the training data. However, the maximum prediction error of the model in Bat2 is 0.3423°C. This peak error is acceptable for temperature prediction, and the prediction accuracy will be further improved if there exist more training results under more working conditions. In addition, the average prediction error of the model in Bat2 is 0.10418°C, which indicates that the KF-BiGRU-Transformer model is more effective in predicting the battery temperature process under the complete working conditions and also indicates that the model can also predict the temperature well under different SOH conditions.

6. Conclusions

This paper presents a modeling and data-driven fusion approach to predict battery temperature. The method first analyzes the first-order and second-order TECM of the battery, aiming to help related research to select the most suitable TECM for battery temperature prediction. For the first-order TECM, no significant differences were found between the online method (VWF-VFFRLS) and the offline identification (COA). For the second-order TECM, the offline identification method using COA is significantly more accurate. Subsequently, a TEM combining EECM and TECM was proposed. However, it was found that the model-based approach required higher computational resources during computation, and parameter oscillations interfered with the identification results during the initial stage of identifying certain parameters. Therefore, in this study, a combined modeling and data-driven temperature prediction method is proposed for batteries under different SOH conditions. KF-BiGRU-Transformer is utilized as the data-driven part, firstly, KF is utilized to perform noise reduction on the collected data, then BiGRU is utilized to extract the characteristics of temporal relationship between the data with respect to sensitivities in the time series, and finally, Transformer is utilized to extract the characteristics of the data at different locations for temperature prediction. Validation of the proposed hybrid model reveals that its average temperature error can be controlled at 0.29%, and the prediction errors RMSE are 0.0570 and 0.1266 for two types of batteries under different SOH, respectively. The results show that the estimation method is not only highly accurate, but also has a good generalization to batteries under different SOH conditions

Theoretically, the modeling approach in this paper is general, and the TECM in the TEM can be substituted for the first- and second-orders according to the actual situation. Similarly, the EECM can be replaced according to the specific working conditions. This makes the model suitable for temperature estimation studies of different models of Li-ion batteries under different operating conditions, and only the model parameters need to be adjusted according to the specific battery. In order to improve the generality and temperature estimation accuracy of the fusion model, in the subsequent research, on the one hand, the data-driven part is optimized, and the network structure is improved, so that the data-driven model can be trained to modify the model parameters by obtaining a small amount of new battery data to improve the training efficiency; moreover, the applicability of changing the prediction model under different room temperatures will be considered in the subsequent research work, and the corresponding corrections will be made, and on the other hand, the balance between the computational complexity of the thermoelectric model and the simulation accuracy needs to be addressed.

Nomenclature

-

- :

-

- Heat generation rate

-

- Vol:

-

- Volume of the battery (m3)

-

- Vbatt:

-

- Voltage of the battery (V)

-

- Voc:

-

- Open-circuit voltage (V)

-

- dVoc/dT:

-

- Entropy change coefficient

-

- T:

-

- Battery temperature (°C)

-

- Ibatt:

-

- Current of the battery (A)

-

- Rp:

-

- Polarization resistance (Ω)

-

- Ro:

-

- Ohmic internal resistance (Ω)

-

- Re:

-

- Internal resistance (Ω)

-

- Tamb:

-

- Current ambient temperature (°C)

-

- RT:

-

- Thermal resistance (K/W−1)

-

- CT:

-

- Heat capacity (J/K−1)

-

- Tc:

-

- Core temperature (°C)

-

- Ts:

-

- Surface temperature (°C)

-

- Cc:

-

- Heat capacity of the core (J/K−1)

-

- Cs:

-

- Heat capacity of the surface (J/K−1)

-

- Ru:

-

- Convection thermal resistance (K/W−1)

-

- Rc:

-

- Conduction thermal resistance (K/W−1)

-

- λ:

-

- Forgetting factor

-

- Ɐ:

-

- Weighting factor

-

- Np:

-

- Population size

-

- Nc:

-

- Number of individuals

-

- :

-

- Social condition of a coyote individual

-

- :

-

- Coyote’s adaptation

-

- leadp,t:

-

- Alpha coyote of the pack

-

- :

-

- Social tendency of the pack

-

- :

-

- New individual parents

-

- ω:

-

- Worse adapted pack

-

- ϕ:

-

- Number of coyotes

-

- Pc:

-

- Transition between packs

-

- RtranS, RtranL:

-

- Polarization resistances (Ω).

Glossary

-

- BMSs:

-

- Battery management systems

-

- DCFC:

-

- DC fast charging

-

- EECM:

-

- Electrical equivalent circuit model

-

- EKF:

-

- Extended Kalman filter

-

- ETNN:

-

- Electrochemical–thermal neural network

-

- EV(s):

-

- Electric vehicle(s)

-

- FRA:

-

- Fast recursive algorithm

-

- GRU:

-

- Gated recurrent unit

-

- LSTM:

-

- Long short-term memory

-

- OCV:

-

- Open-circuit voltage

-

- PINN:

-

- Physically informed neural network

-

- RNN:

-

- Recurrent neural network

-

- SOC:

-

- State of charge

-

- SOH:

-

- State of health

-

- SOT:

-

- State of temperature

-

- SSA:

-

- Sparrow search algorithm

-

- TECM:

-

- Thermal equivalent circuit modeling

-

- TEM:

-

- Thermoelectric equivalent model

-

- TSM:

-

- Two-state thermal model

-

- UKF:

-

- Untraceable Kalman filtering.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This work was supported by the Ministry of Education (MoE) Academic Research Fund (AcRF) Tier-1 Seed Fund RS12/23 and the Major Science and Technology Projects in Zhejiang Province – Key R&D Projects (2023C01SA301767).

Acknowledgments

This work was supported by the Ministry of Education (MoE) Academic Research Fund (AcRF) Tier-1 Seed Fund RS12/23 and the Major Science and Technology Projects in Zhejiang Province – Key R&D Projects (2023C01SA301767).

Open Research

Data Availability Statement

The data supporting this study’s findings are available from the corresponding author upon reasonable request.