Advancing the Regenerative Braking Systems of New Energy Vehicles: A Comprehensive State-of-the-Art Review

Abstract

Regenerative braking systems (RBSs) are a transformative technology in the automotive industry, widely adopted in new energy vehicles (NEVs), especially electric ones. This study comprehensively reviews RBS research, including its origin, working principle, classification, and current status using VOSviewer. This article provides an in-depth analysis and discussion of the latest research progress in key technologies such as RBS mechanical design, logic control and optimization, and technical evaluation. It is found that research on the relationship between regenerative braking and driving safety is relatively limited, and it is suggested to explore the correlation in three aspects: (i) accidents caused by regenerative braking function, (ii) the mechanism of the impact of regenerative braking on driving behavior, and (iii) the scope of safety oriented-regenerative braking level. This study provides a research foundation and direction analysis for the development of safer RBS technology.

1. Introduction

In the past three decades, the global automotive industry has undergone profound upgrades and transformations, witnessing a deep integration between the automotive and energy sectors. Particularly, the development of new energy vehicles (NEVs) and research into technologies to diminish energy consumption and enhance energy efficiency have become imperative. Notably, the energy generated during vehicle braking cannot be entirely recuperated; a portion dissipates as heat into the surrounding air [1]. The recycling and utilization of this energy have emerged as a focal point in the quest to save energy within the realm of NEVs.

The introduction of the regenerative braking system (RBS) offers a solution to these pressing challenges. RBS stands as a pivotal feature of new-energy vehicles, particularly electric vehicles (EVs), allowing them to capture and repurpose a substantial portion of the kinetic energy otherwise lost during braking or deceleration [2–4]. During the braking process of the vehicle, the inertia of the vehicle drives the motor rotor to rotate in the opposite direction to generate braking torque, driving the motor into a power generation state. Through the power generation effect of the motor, a portion of the heat energy lost on the friction brake during the braking process of the car is converted into electrical energy, which is then charged to the dynamic battery. These stored energies can be reused when driven by the motor [2, 5–8]. The implementation of regenerative braking energy recovery for NEVs is usually achieved through the joint action of the brake control system, motor RBS, and hydraulic braking system [5, 6]. This review primarily focuses on RBS technologies implemented in passenger cars and commercial vehicles (e.g., buses and trucks), which represent the dominant application domain for regenerative braking in the automotive industry. While two-wheelers (e.g., electric scooters and motorcycles) and other light EVs also employ regenerative braking, their distinct design constraints (e.g., limited space and lower power requirements) and operational use cases place them outside the scope of this analysis. Future research could explore comparative studies across vehicle classes to address scalability nuances.

RBS can be mainly divided into parallel systems and series systems based on the coordination relationship with hydraulic braking systems [5, 9–13]. In parallel systems, regenerative braking can be directly superimposed on traditional hydraulic braking, and the two types of braking do not affect each other [5]. The design advantage of this structure lies in its simple hardware structure and controllable cost [6]. The disadvantage is that at this time, the regenerative braking energy recovery efficiency of the motor is difficult to fully exert [5, 6]. In a series system, the braking force is first provided by the motor and then supplemented by hydraulic compression force. The motor braking force and hydraulic braking force are coordinated and output according to the total braking demand. The design of this system is costly; however, its advantage lies in the priority provided by the motor for regenerative braking, which greatly improves energy recovery efficiency. Additionally, the coordination of braking forces is safer and more reliable, providing a good braking experience [5, 6].

The rapid adoption of RBS in NEVs is closely tied to stringent government policies aimed at reducing greenhouse gas emissions and fossil fuel dependency. For instance, China’s “New Energy Vehicle Industry Development Plan (2021–2035)” mandates that NEVs constitute 40% of total vehicle sales by 2030, directly incentivizing advancements in energy recovery technologies like RBS [14, 15]. Similarly, the European Union’s CO2 emission standards for vehicles (e.g., 95 g/km by 2021) and the U.S. Corporate Average Fuel Economy (CAFE) regulations have accelerated RBS integration to meet compliance targets [16–18].

The RBS braking energy recovery system has gone through a development process. The initial braking energy recovery systems were all improved from traditional braking systems. Through vacuum source electrification, improved hydraulic adjustment units, and increased decoupling axes, parallel systems, single axis decoupling series braking systems (such as Bosch ESP-hev), and fully decoupled series braking systems (such as Bosch PCA and TRW ESC-R) were successively born. In recent years, simpler vacuum free fully decoupled braking systems have gradually become mainstream, giving rise to electronic hydraulic braking systems (such as Bosch SBC, Bosch HAS hev, Toyota ECB), electric auxiliary cylinder braking systems (such as Honda ESS, Bosch IPB, Continental AG MK C1), and electric power-assisted braking systems (such as Bosch iBooster, Shanghai Huizhong Ebooster) Various fully electric braking systems, including electronic and mechanical braking systems [5, 19–21].

The advent and evolution of RBS underscore the automobile industry’s endeavor to harness the energy expended during braking [22, 23]. This technology bestows economic benefits, such as heightened vehicle energy efficiency [24] and increased driving range [25]. Moreover, the integration of RBS yields substantial environmental advantages [26]. In general, RBS amplifies energy utilization efficiency, lowers emissions, enhances vehicle performance, reduces wear on engines and brakes, requires smaller accessories, and exhibits superior operational versatility compared to conventional braking systems [27]. Nonetheless, as a nascent technology, the implementation of regenerative braking functions presents several challenges [28]. Generally speaking, due to the limitations of RBS in braking force and other vehicle factors [7, 29, 30], RBS must be harmonized with other braking systems [30], and supplementary friction brakes are necessitated to bring the vehicle to a complete halt [5, 7]. Meanwhile, in shaping driving behavior, many studies and incidents have shown that different levels of regenerative braking have a significant impact on driving tasks [28, 31, 32], and regenerative braking is gradually reshaping driving behavior [3, 33, 34]. The safety issues in the development process of these high-tech cannot be ignored.

Therefore, prior to conducting an in-depth analysis and evaluation of regenerative braking technology, a comprehensive review of its developmental and research status is imperative. Section 2 presents a comprehensive statistical analysis of regenerative braking literature, covering publication sources, publication years, geographical distribution of authors, and publication keywords. On this basis, this article provides an in-depth analysis and discussion of the latest research progress in key technologies such as RBS hardware structure, software logic, and technical evaluation. Section 3 discusses RBS mechanical design and its latest research progress. Section 4 analyzes the research progress in RBS logic control and algorithm optimization. Section 5 elaborates on RBS technology evaluation methods and the latest research progress. Section 6 discusses the new challenges and future directions of RBS technology, especially in terms of safety, and a summary of the entire article is provided.

2. Literature Review

2.1. Publication Resources

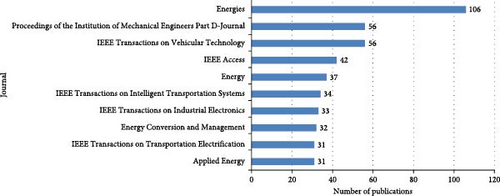

Based on a review of literature pertaining to regenerative braking within the Web of Science Core Collection database, the top 10 journals with relevant publications are as follows: Energies, with 106 articles; Proceedings of the Institution of Mechanical Engineers Part D-Journal, featuring 56 articles; IEEE Transactions on Vehicular Technology, also presenting 56 articles. This information is visually represented in Figure 1.

The above statistics underscore that publications focusing on regenerative braking research tend to exhibit a pronounced degree of specialization, encompassing technical, engineering, and scientific aspects. These publications predominantly find their place in international academic journals specializing in fields such as energy, electronic and electrical engineering, vehicle technology, mechanical engineering, vehicle energy, intelligent transportation, and vehicle electrification. In conjunction with the analysis of keywords and research directions, it becomes evident that the primary application domain of regenerative braking technology lies within the automotive industry. This is primarily manifest in its contributions towards advancing vehicle energy systems, electronic and electrical components, and automotive intelligence.

2.2. Years of Publications

Drawing from a comprehensive statistical analysis of the Web of Science Core Collection database spanning the last 15 years, we present the literature and research trends in the realm of “regenerative braking,” as depicted in Figure 2. The count of studies in this domain surged from 72 in 2009 to 179 in 2023, reflecting an impressive 15-year growth rate of 148.6%. Remarkably, by the year 2019, the tally of studies pertaining to regenerative braking reached its zenith at 264, marking a peak within the last 5 years. Notably, the average annual publication count over the past half-decade has remained robust, hovering around 223, underscoring the sustained popularity and ongoing relevance of this subject matter.

The annual surge in the number of studies related to regenerative braking underscores the ongoing progress in regenerative braking technology, especially in the past 5 years. RBS’s impact on various aspects, including vehicle performance, system integration, and the selection of optimal strategies, has garnered significant attention from both vehicle designers and consumers. With the continuous maturity of regenerative braking technology, the complexity of the technology continues to deepen; it is anticipated that further specialized research will emerge in various domains, maintaining the current level of research enthusiasm. Consequently, the upward trajectory in the number of studies is expected to persist.

2.3. Geographically of Authors

Recent statistical data derived from the Web of Science Core Collection database underscores China’s paramount role as the most active country in “regenerative braking” research, contributing 863 published papers. Following China, the United States follows with 274 papers, India with 219, England with 143, and Japan with 113 (Figure 3).

The research prowess of each country in the realm of scientific and technological literature closely correlates with the level of attention devoted to the corresponding technology. According to statistics from the China Association of Automobile Manufacturers (CAAM), In 2023, China’s production and sales of NEVs reached 9.587 million and 9.495 million, respectively. At this point, China’s production and sales of NEVs have remained the world’s top for 9 consecutive years. In the midst of this meteoric rise in NEVs, Chinese enterprises have adeptly seized technological opportunities, positioning themselves at the forefront of industrial development. Research on regenerative braking, a pivotal technology in the EV domain, necessitates close collaboration among enterprises, research institutions, and consumers, fostering a high level of research enthusiasm. China’s leadership in RBS research aligns with its aggressive policy framework, including subsidies for NEV manufacturers, tax exemptions for consumers, and infrastructure investments in charging networks. These measures have fostered a robust ecosystem for RBS innovation [35]. Conversely, Japan’s “Green Growth Strategy” prioritizes hybrid technologies, while India’s faster adoption and manufacturing of hybrid and electric (FAME) vehicles scheme emphasizes localized RBS development to address urban air quality [36, 37].

2.4. Keywords of Publications

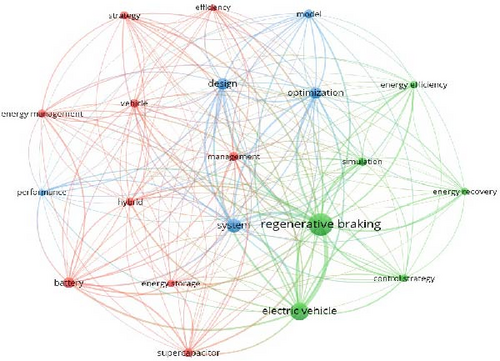

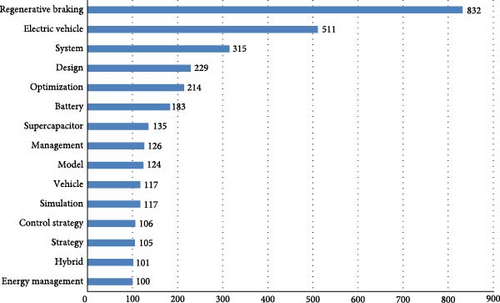

Based on a comprehensive analysis of data from the Web of Science Core Collection database, the search query “regenerative braking” was featured in 2485 primary articles, including papers and editorial materials. The frequency of keyword occurrences is visually presented in Figures 4 and 5, with the top 15 keywords by frequency being regenerative braking, electric vehicle, system, design, optimization, battery, management, supercapacitor, management, model, vehicle, simulation, control strategy, strategy, hybrid, energy management.

As illustrated in Figures 4 and 5, energy management remains a focal point of attention. A closer examination of keyword analyses and research trends reveals an evolution in regenerative braking research. Initially, the focus was predominantly on the system’s fundamental attributes, encompassing aspects such as system design, energy dynamics, and braking mechanisms. However, a notable shift has occurred toward the exploration of strategy selection and collaborative control, involving optimization, management, and control strategies. Consequently, recent research endeavors have delved into specialized subfields like battery technology, torque optimization, voltage control, and the development of mathematical models, reflecting a deepening of research sophistication.

3. RBS Mechanical Design

As mentioned earlier, the main structures of RBS are divided into parallel systems and series systems. In the RBS parallel system, the braking energy recovery module determines the motor braking force based on the pedal opening signal and sends instructions to the motor to generate the corresponding braking force, that is, regenerative braking force. A portion of the braking energy is recovered and converted into electrical energy, which is stored in the power battery. The hydraulic braking system works simultaneously, generating hydraulic braking force on the front and rear axles. This system is equivalent to the parallel operation of hydraulic braking and motor regenerative braking, hence it is called a parallel system [5]. This system does not significantly modify the traditional braking system structure and has a low-cost advantage in production and manufacturing, but the energy recovery efficiency of RBS is relatively low.

To further improve the energy recovery efficiency of RBS, the RBS series system has effectively solved this problem and become a more widely used solution in RBS mechanical design structures. In the RBS series system, first, the motor provides its maximum regenerative braking force, and the insufficient part is compensated by the hydraulic braking system. This system can independently adjust the hydraulic compression force of the front and rear wheels so that the hydraulic compression force and the motor braking force are coordinated and output according to the total braking demand [5].

In the realm of RBS design, extensive research has primarily revolved around vehicle mechanical design, component selection, voltage, and current performance enhancements. Many studies have proposed new design ideas for RBSs [38–42]. For example, Ping et al. [43] introduced an effective method to achieve integrated control of a brushless DC motor drive and regenerative braking aimed at achieving steady-state speed control. The primary objective of these studies is to enhance vehicle braking performance, with some concurrently addressing energy efficiency improvements based on this premise [44–48]. For example, Kumar et al. [49] introduced an adaptive neuro-fuzzy and PID-based regenerative system for e-vehicles to expand the range of EVs.

Certain studies within the realm of RBS design have honed in on the utilization of ultracapacitors, driven by their remarkable capacity to rapidly store electrical energy [50–54]. This avenue of research distinctly prioritizes energy efficiency enhancements. Supercapacitors have been shown to extend battery life and augment the efficiency of EV systems [28, 55]. Yan et al. [56], for instance, merged an energy storage control strategy with an energy optimization scheme, addressing concerns like low braking energy utilization rates and high investment costs associated with regenerative braking energy utilization systems.

The integration of supercapacitors (ultracapacitors) into RBS has garnered significant attention due to their high-power density and rapid charge–discharge capabilities. Unlike batteries, supercapacitors excel in capturing transient braking energy, reducing peak load stress on batteries, and extending their lifespan [57, 58]. For instance, Iannuzzi [59] demonstrated that real-time power tracking using supercapacitors improved energy recovery by 12% under urban driving cycles. However, limitations such as low energy density (~5–10 Wh/kg) restrict their standalone use, necessitating hybrid systems with batteries [60]. Emerging technologies like solid-state batteries and flywheel energy storage are also being explored for RBS. Solid-state batteries offer higher energy density and safety, while flywheels provide mechanical energy storage with minimal degradation [61]. Despite these advancements, challenges remain in cost optimization, thermal management, and system control logic for multistorage configurations.

While RBS offers significant energy-saving benefits, its mechanical components, such as electric motors, hydraulic systems, and energy storage units, are subject to wear and tear. For instance, the frequent switching between regenerative and friction braking can lead to increased stress on brake pads and rotors, necessitating more frequent maintenance [62, 63]. Additionally, the integration of supercapacitors or advanced battery systems introduces challenges related to thermal management and degradation over time [64, 65]. Ensuring the reliability of RBS components, particularly in harsh driving conditions, remains a key area for improvement.

Additionally, several investigations have delved into vehicle transmission and shift strategies, aiming to elevate energy efficiency and driving comfort [66–71]. For instance, Liu et al. [72] crafted a coordinated control strategy for EV braking and shifting delved into optimal shifting schemes for regenerative braking via a multiobjective cuckoo search algorithm, with the aim of maximizing energy recovery and enhancing driving comfort.

4. RBS Logic Control and Optimization

Under the RBS hardware architecture framework discussed in the previous section, this section discusses the RBS software logic system and algorithm optimization [5]. The RBS system software should include functions such as recovery capability calculation, brake intention recognition, brake force distribution, stability coordination control, motor brake force control, and brake pressure control. It is responsible for receiving signals such as pedal displacement, brake pressure, and motor speed, conducting brake force distribution calculations, and outputting target motor brake torque and target wheel cylinder pressure. This multilevel control strategy not only ensures the safety of the RBS but also improves its effectiveness, thereby achieving maximum recovery of braking energy [19].

The exploration of diverse control strategies for regenerative braking function stands out as a prominent focus within the realm of regenerative braking research [73–77]. Through analyzing these studies, it has been found that when it comes to research on regenerative braking strategies oriented towards distinct objectives, the primary goals encompass enhancing energy recovery efficiency to extend the driving range, improving braking performance and braking safety, and ensuring good braking feeling (driving comfort).

4.1. Enhancing Energy Recovery Efficiency (Extending Driving Range)

The primary aim of the regenerative braking function is energy conservation, making research on strategies to enhance energy recovery efficiency a focal point. In recent years, the field of regenerative braking strategy research, which centers on bolstering energy recovery efficiency to extend the driving range, has witnessed significant advancements, as summarized in Table 1.

| Main author | Year | Content | Research methods | Evaluation methods |

|---|---|---|---|---|

| Ji, Pan [78] | 2019 | Proposed a regenerative braking control strategy based on identifying driver intentions | Vehicle model theory, fuzzy recognition | Road test |

| Xu, He [79] | 2019 | Modeled the RBS and its energy management strategy | Theoretical analysis of accumulator and energy recovery rate | Simulation platform, bench test |

| Li, Lin [80] | 2019 | Designed a fuzzy controller with braking strength, speed, and supercapacitor SOC as input and the ratio of front wheel regenerative braking force to total braking force as output, and proposed an improved front and rear wheel braking force distribution scheme | ECE regulations, I curves, fuzzy theory | MATLAB/Advisor cosimulation (UDDS) |

| Heydari, Fajri [81] | 2020 | Defined the boundary of the hybrid of regenerative braking and friction braking and proposed a new method for the effective distribution of braking power between friction and regenerative braking for electric vehicles | Model and performance diagram of TM and its controller | Hardware in ring test bench (UDDS) |

| Wu, Li [82] | 2020 | Derived the calculation method to determine the optimal regenerative braking torque with the maximum energy recovery at a given speed | PMSM loss model | Simulation and bench test |

| Sun, Lei [83] | 2020 | Analysis and establishment of regenerative braking fuzzy controller and fuzzy control strategy model suitable for electric vehicles | Mathematical model and fuzzy control of electric vehicle and motor | MATLAB/Simulink cosimulation (EUDC) |

| Liu [84] | 2021 | Proposed a series regenerative braking control strategy based on PMSM fuzzy logic, which divided 4 braking zones according to braking intensity and comprehensively considered the speed, ECE regulations, battery, motor characteristics, and other influencing factors. Different braking force distribution strategies should be used | PMSM model, fuzzy logic | Simulink/Cruise cosimulation |

| Zhou, Wang [85] | 2022 | Divided the braking modes according to the braking intensity and designed a regenerative braking control strategy combined with the electromechanical braking model | Fuzzy theory | MATLAB/Simulink cosimulation |

| Sandrini, Chindamo [86] | 2022 | Proposed a regenerative braking logic. The priority of the logic is to maximize the recovery of energy under braking, followed by the pursuit of the best braking distribution, which aims to maximize the recovery of energy in the braking process without damaging the stability of the vehicle | Wheel and vehicle dynamics model | MATLAB/Simulink cosimulation (WLTC) |

| Ye, Wu [87] | 2023 | Comprehensively consider the braking dynamics and regenerative braking structure, and optimize the braking energy recovery control strategy | Braking dynamics and regenerative braking structure, fuzzy control | Matlab/Simulink and AMEsim |

| Yin, Ma [88] | 2023 | Adopt a fuzzy control strategy to achieve the distribution of regenerative braking force on the front axle to improve energy efficiency, and conduct experiments under six specific working conditions such as NEDC | Fuzzy control | Simulink platform (NEDC, WLTC, FTP-72, FTP-75, CLTC-P, NYCC) |

| Ning, Wang [89] | 2023 | Proposed an energy recovery efficiency optimization algorithm for hydraulic regenerative braking systems based on fuzzy Q-learning | Fuzzy Q-learning (FQL) | ADVISOR (UDDS) |

| Prasanth, Paul [90] | 2023 | Proposed an efficient method based on machine learning to utilize the maximum braking energy of electric vehicles to provide longer distances | Machine learning | MATLAB/Simulink cosimulation |

| Ruan, Wu [91] | 2023 | Proposed a machine learning-based energy management strategy to optimize the distribution of dual motor driving force in battery electric drive and regenerative braking | Machine learning, deep deterministic policy gradient (DDPG) | Simulation platform |

Numerous scholars have put forth regenerative braking strategies geared toward improving energy recovery efficiency and expanding vehicle range. These strategies often rely on dynamic modeling of vehicles or specific components, such as motors and wheels [78, 81, 83, 86]. Ye et al. [87] comprehensively consider the braking dynamics and regenerative braking structure and optimize the braking energy recovery control strategy. Wu et al. [82] and Liu [84] developed a loss model rooted in a permanent magnet synchronous motor (PMSM) field-oriented control system to determine the optimal regenerative braking torque calculation method that maximizes energy recovery. Xu et al. [79] delved into the factors influencing the energy recovery rate of hydraulic hybrid EV RBS, constructing a model based on theoretical analyses of the energy accumulator and energy recovery rate, ultimately achieving higher energy recovery rates. Park et al. [92] introduced how to extract maximum performance and corresponding optimal control variables to maximize energy recovery.

Regarding vehicle braking force distribution methods, Li et al. [80] and Liu [84] referenced standards like the Economic Commission of Europe (ECE) or the ideal braking force distribution curve (I curve) established by the United Nations Economic Commission for Europe to propose corresponding regenerative braking schemes. Fuzzy theory has found applicability in regenerative braking strategy research, leading several scholars to design regenerative braking control strategies grounded in fuzzy logic [77, 78, 80, 83–85]. Yin et al. [88] adopt a fuzzy control strategy to achieve the distribution of regenerative braking force on the front axle to improve energy efficiency, and conduct experiments under six specific working conditions such as NEDC.

Advanced methods such as machine learning (ML) and deep learning have attracted great attention in multiobjective optimization problems, which is a key challenge in energy management strategies for multipower hybrid systems. Ning et al. [89] proposed an energy recovery efficiency optimization algorithm for hydraulic RBSs based on fuzzy Q-learning. Prasanth et al. [90] proposed an efficient method based on ML to utilize the maximum braking energy of EVs to provide longer distances. Ruan et al. [91] proposed an ML-based energy management strategy to optimize the distribution of dual motor driving force in battery electric drive and regenerative braking.

In addition, there is research that not only considers the energy recovery efficiency of individual vehicles but also considers the energy cost control problem of EV fleets. Li and Wang [93] proposed a two-layer energy efficiency optimization strategy for EV queuing, which solves the problem of how to control EV queuing with minimal energy cost during transient processes.

4.2. Improving Braking Performance and Braking Safety

Within the realm of regenerative braking strategy research, which concentrates on enhancing braking performance and safety, the key recent developments are encapsulated in Table 2. In the domain of strategic optimization for regenerative braking, Gao et al. [96] established a link between contact coupling stiffness and braking force, employing a closed-loop coupling disc brake model. Saxena [101] analyzed the optimal control of speed and regenerative braking in EVs to better achieve the optimal speed and regenerative torque of EVs. Wang et al. [102] proposed a new regenerative braking dynamic model and power system torque compensation control method based on gear backlash and half-axis flexibility considerations. The fluctuation of half-axis torque was effectively suppressed, and the driving performance of the vehicle was improved. Advanced RBS control strategies have been developed to address the challenges posed by varying road conditions. For example, Basrah [106] proposed a compound braking anti-lock braking system (ABS) system that integrates regenerative and hydraulic braking forces to ensure stability on slippery surfaces. Similarly, Wang et al. [107] explored the coordinated control of RBS and ABS in hybrid EVs, demonstrating improved braking performance on wet and icy roads. These systems leverage real-time sensor data, such as wheel speed and road adhesion estimates, to dynamically adjust braking force distribution and maximize energy recovery without compromising safety.

| Main author | Year | Content | Research methods | Evaluation methods |

|---|---|---|---|---|

| Qiu, Wang [94] | 2018 | Proposed the control strategy of a new RBS in the anti-lock braking process of electric vehicles. In the case of safety-critical driving, four kinds of tire-road adhesion conditions were tested on the road | Phase plane theory | Road test |

| Subramaniyam [95] | 2019 | On the basis of considering the instantaneous braking mixing and slope braking mixing characteristics of electric heavy road vehicles, a cooperative braking system composed of regenerative braking and friction braking with different dynamic characteristics was studied to improve the stopping distance and driving comfort in terms of vehicle braking performance | Hardware equipped with TruckMaker software is tested in the ring | Hardware equipped with TruckMaker software is tested in the ring |

| Gao, Ruan [96] | 2019 | Established the relationship between contact coupling stiffness and braking force, proposed two different regenerative braking strategies, and studied the continuous change of front and rear wheel braking force distribution and the influence of two different strategies on the suppression of braking noise tendency | Closed-loop coupled disc brake model | Bench test |

| Subramaniyam and Subramanian [97] | 2019 | Proposed the cooperative braking strategy of optimal braking force sharing between regenerative braking and friction braking to improve the overturning stability and handling performance of electric heavy commercial vehicles during overturning braking | RBS model | IPG TruckMaker simulation, hardware in the loop test |

| Xu, Zhou [98] | 2021 | Established the coordinated control model of regenerative braking and ABS | Predictive control algorithm | Simulink simulation |

| Vignati, Belloni [99] | 2021 | Proposed an optimal distributed control strategy for distributed motors to achieve synergy between regenerative braking and hydraulic braking | Vehicle dynamics model | MATLAB/Simulink cosimulation |

| Wang [100] | 2021 | Introduced the slip rate of automobile wheels as the control target and proposed a compound braking ABS system with regenerative braking force and hydraulic braking force | ECE regulations, I curve | Carsim/Simulink cosimulation |

| Saxena [101] | 2023 | Analyzed the optimal control of speed and regenerative braking in electric vehicles (EVs) to better achieve the optimal speed and regenerative torque of electric vehicles | Vehicle dynamics model, fuzzy logic controller | Simulation platform |

| Wang, Wu [102] | 2023 | Proposed a new regenerative braking dynamic model and power system torque compensation control method based on gear backlash and half-axis flexibility considerations. The fluctuation of half-axis torque was effectively suppressed, and the driving performance of the vehicle was improved | Vehicle dynamics model, RBS model | Simulation platform, REP hardware in the loop test |

| Wang, Wu [103] | 2023 | Proposed a new nonlinear regenerative braking torque compensation control (NL-TCC) strategy aimed at improving the braking stability of plug-in hybrid electric vehicles (PHEVs) with dual motor power systems | Vehicle dynamics model | MATLAB/Simulink cosimulation |

| Wang, Gao [104] | 2023 | Proposed and validated an electro-hydraulic composite stability control method to ensure both braking performance and driving stability | Vehicle dynamics model, model predictive control algorithm | Real vehicle test |

| Wang, Wang [105] | 2023 | Proposed an anti-lock braking system (ABS) using a novel interval type-2 fuzzy neural network (IT2FNN) control scheme, which achieves a balance between braking energy recovery efficiency and braking safety | Type-2 fuzzy sets | Simulation platform |

Some studies have examined the synergy between regenerative braking and other braking systems, focusing on the collaborative optimization of RBSs and associated systems. Subramaniyam [95] and Subramaniyam and Subramanian [97] proposed a collaborative braking strategy aimed at optimizing the distribution of braking force between regenerative and friction braking. Vignati et al. [99] introduced an optimal distributed control strategy for distributed motors, founded on a vehicle dynamics model, to foster synergy between regenerative and hydraulic braking. Wang et al. [103] proposed a new nonlinear regenerative braking torque compensation control (NL-TCC) strategy aimed at improving the braking stability of plug-in hybrid EVs (PHEVs) with dual motor power systems. Wang et al. [104] proposed and validated an electro-hydraulic composite stability control method to ensure both braking performance and driving stability.

The impact of regenerative braking on vehicle stability during high-speed or emergency braking scenarios is a critical area of research, as abrupt deceleration can lead to instability, particularly in terms of yaw rate, lateral acceleration, and wheel slip. Recent studies have highlighted the challenges of maintaining vehicle stability when regenerative braking is integrated with traditional friction braking systems, especially under extreme conditions.

For instance, Zhou et al. [108] proposed an electro-hydraulic composite stability control method to address regenerative braking failure in high-speed scenarios, demonstrating that the integration of regenerative braking with hydraulic braking can significantly improve stability during emergency braking. Similarly, Xu et al. [109] investigated the role of regenerative braking in preventing wheel slip and overturning instability in heavy vehicles, emphasizing the importance of dynamic braking force distribution to maintain stability under varying road conditions. Furthermore, Wu et al. [110] introduced a swarm intelligence-based predictive regenerative braking control strategy, which optimizes stability metrics such as sideslip angle and yaw rate during high-speed braking. Their findings suggest that RBSs must be carefully calibrated to balance energy recovery with stability requirements, particularly in vehicles equipped with in-wheel motors.

These studies underscore the need for advanced control algorithms that integrate regenerative braking with electronic stability control (ESC) systems to ensure safe and stable deceleration in high-speed and emergency scenarios. Future research should focus on developing adaptive control strategies that dynamically adjust regenerative braking torque based on real-time stability metrics, such as wheel slip and lateral acceleration.

Several studies have delved into the synergy between RBS and the ABS. Qiu et al. [94] computed the optimal braking torque for EV ABS control using phase plane theory, introducing a novel control strategy for RBS during the anti-lock braking process. Xu et al. [98] explored the coordinated control of a hybrid EV’s RBS and ABS, employing a composite-structure motor to ensure optimal operational efficiency and brake slip ratio. Adhering to ECE regulations and the I curve, Wang [100] devised a rational conventional braking force distribution strategy and proposed a composite braking ABS system that amalgamates regenerative and hydraulic braking forces. Wang et al. [105] proposed an ABS using a novel interval type-2 fuzzy neural network (IT2FNN) control scheme, which achieves a balance between braking energy recovery efficiency and braking safety.

While RBSs enhance energy efficiency, their integration with traditional braking systems necessitates robust fail-safe mechanisms to address potential failures. Key strategies identified in recent studies include:

Redundant Hydraulic Braking Systems: Parallel or series RBS architectures often incorporate redundant hydraulic circuits to ensure braking force continuity during regenerative system malfunctions [111, 112]. For example, Petrescu [113] validated an electro-hydraulic composite stability control method that activates hydraulic backup during RBS failures, maintaining vehicle deceleration.

Real-Time Diagnostics and Fault Detection: Advanced sensor networks and algorithms enable real-time monitoring of RBS components (e.g., motor torque and battery state of charge [SOC]). Xing et al. [114] proposed hardware-in-loop diagnostics to detect anomalies and seamlessly transition to friction braking.

Integration with Vehicle Stability Controls: Coordination between RBS and ESC systems ensures stability during abrupt regenerative braking deactivation. Zhang et al. [115] demonstrated a predictive control algorithm that adjusts hydraulic braking torque to compensate for sudden RBS torque loss, minimizing wheel slip.

Driver Alert Systems: Auditory or haptic feedback mechanisms warn drivers of RBS malfunctions, prompting manual intervention. Spadoni [116] highlighted the role of pedal-feel compensation in maintaining driver awareness during regenerative braking failures.

These strategies underscore the importance of multilayered safety frameworks to address RBS vulnerabilities, balancing energy recovery with fail-safe reliability.

The research methods for braking safety strategies under the regenerative braking function, as mentioned above, primarily revolve around the analysis of vehicle systems, structures, dynamic mechanisms, and braking performance. This includes the utilization of control theories, such as model predictive control and Lyapunov theory, to construct vehicle dynamics models, motor models, battery models, and more. In recent years, researchers have introduced operational research theories like Markov decision processes, as well as ML methods, including reinforcement learning, value strategy networks, and swarm intelligence algorithms, to tailor power optimization allocation strategies.

4.3. Ensuring Good Braking Feeling (Driving Comfort)

In the domain of regenerative braking strategy, with a focus on ensuring an optimal braking sensation and driving comfort, recent years have witnessed significant developments, as outlined in Table 3. Research in this field is characterized by its unique approach. First, it involves a strategic analysis from a vehicle design perspective. Many scholars have proposed algorithms geared toward preserving the pedal feel, ensuring vehicle safety, and enhancing overall driving comfort, utilizing vehicle dynamics models and related component modeling [118, 121]. Caliskan and Patoglu [123] constructed a brake booster model employing various test equipment, such as an elastic brake pedal and a pedal-feel test platform. Their work investigated the impact of tactile pedal-feel compensation during regenerative braking on driving safety and performance. Qiu [126] proposed an intelligent regenerative braking control strategy for connected vehicles based on the accelerator pedal, which enables energy recovery of different intensities under different driving conditions and modes, which is beneficial for improving energy recovery efficiency.

| Author | Year | Content | Research methods | Evaluation methods |

|---|---|---|---|---|

| Lin, Liu [117] | 2015 | Simulated the reverse engine braking of a traditional internal combustion engine vehicle to provide a driving feeling similar to that of a traditional internal combustion engine vehicle | Fuzzy control | Hardware-in-the-loop simulation control system |

| Zhao, Li [118] | 2018 | Designed a high-performance, low-cost solution for a series RBS consisting of ABS and motor-driven E-booster, a pressure sensorless braking force decoupling control solution | Series regenerative braking model, vacuum booster dynamic model | MATLAB/Simulink cosimulation, test bed |

| Wang, Zhao [119] | 2018 | Explored the optimal distribution method of braking force under multiobjective and multiconstraint conditions to solve the problem that braking torque always changes abruptly when switching braking modes | Dynamic model, multiobjective optimization, compensation control of electro-hydraulic composite braking system | MATLAB/Simulink cosimulation |

| Wang, Zhao [120] | 2019 | Optimized the parameters of electro-hydraulic composite braking system with braking sensation and braking energy as the optimization goals and ECE regulations as the constraint conditions | Model of electro-hydraulic composite braking system decomposed multiobjective evolutionary algorithm (MOEA/D) | Simulation |

| Chen [121] | 2020 | Proposed an algorithm to maintain the feeling of the pedal to ensure the safety and comfort of the car | Design and dynamics model of electric power-assisted braking system | Test bench and vehicle test |

| Zhu, Cui [122] | 2020 | Adjusted the curve of the driver’s braking intention parameter preset in the software to match the curve of the braking fluid volume and pressure of the real vehicle and proposed a new energy-coordinated RBS using software SPD self-learning | Physical model of coordinated RBS | Software SPD self-learning algorithm |

| Caliskan and Patoglu [123] | 2020 | Constructed a brake booster model to study the impact of tactile pedal sensation compensation on driving safety and performance in regenerative braking and to evaluate the effectiveness of maintaining the natural brake pedal sensation in two-pedal collaborative braking and single-pedal driving scenarios | Series of elastic brake pedal and pedal feeling test platform and other test devices | Series of elastic brake pedal and pedal feeling test platform and other test devices |

| Chen [124] | 2021 | Proposed an analytical evaluation method of electric vehicle braking sensation based on human–vehicle integrated model | Driver model, vehicle model | Simulink-CarSim simulation |

| Zhou and Niu [125] | 2021 | A braking intention classification and recognition method has been proposed to more accurately identify the driver’s braking intention and achieve a stable regenerative braking function | Braking intent recognition algorithm based on BP neural network | Bench test |

| Qiu, Yu [126] | 2023 | Proposed an intelligent regenerative braking control strategy for connected vehicles based on the accelerator pedal, which enables energy recovery of different intensities under different driving conditions and modes | Modified method of driving style characteristic parameters | Vehicle simulation model and hardware-in-the-loop experiment platform |

| Qui, Wan [127] | 2023 | Proposed a new regenerative braking energy recovery strategy for electric vehicles based on IDP (Iterative dynamic programing)–BLSTM (bidirectional long short-term memory) to meet the personalized needs of various drivers, improve driving experience and safety | IDP (iterative dynamic programing), BLSTM (bidirectional long short-term memory) | Real vehicle test |

| Hwang, Lee [128] | 2023 | Proposed a comfort regenerative braking system (CRBS) based on AI algorithm, which uses artificial neural networks as the vehicle control strategy under braking conditions | Artificial neural networks | Car Sim and MATLAB/Simulink simulations |

This research also delves into understanding the driver experience. Chen [124] introduced an analytical evaluation method for EV braking sensation, rooted in the comprehensive man-vehicle model, to explore the relationship between key parameters of the driver model and the driving sensation. Lin et al. [117] harnessed fuzzy control theory and a regenerative braking control strategy based on accelerator pedal input to simulate and provide a driving sensation akin to that of traditional internal combustion engine vehicles. Wang et al. [119] and Wang et al. [120] explored optimal methods for distributing braking force using a multiobjective optimization algorithm to enhance the driver’s braking experience. Zhu et al. [122], from the Pan-Asian Automobile Technology Center, proposed an algorithm founded on software SPD self-learning, aiming to adjust brake pedal feel during regenerative braking conditions to ensure consistency with the brake pedal feel during nonbrake energy recovery scenarios. Zhou and Niu [125] employed a braking intention recognition algorithm based on a BP neural network to more accurately and real-time identify the driver’s braking intention and achieve a comfortable driving experience. Qiu et al. [127] proposed a new regenerative braking energy recovery strategy for EVs based on iterative dynamic programing (IDP)–bidirectional long short-term memory (BLSTM) to meet the personalized needs of various drivers, improve the driving experience and safety. Hwang et al. [128] proposed a comfort RBS (CRBS) based on AI algorithm, which uses artificial neural networks as the vehicle control strategy under braking conditions.

Recent human–machine interaction studies reveal that driver perception of braking comfort is closely tied to the intuitiveness of RBS feedback mechanisms. For instance, haptic feedback in accelerator pedals—simulating resistance proportional to regenerative braking force—has been shown to improve driver confidence and reduce unintended acceleration errors [128, 129]. Conversely, abrupt transitions between regenerative and hydraulic braking modes can disrupt driving rhythm, leading to discomfort [22]. Single-pedal systems, while popular for energy efficiency, require significant behavioral adaptation; surveys indicate that 30%–40% of drivers initially report discomfort with reduced brake pedal usage, though acclimatization occurs within weeks [130, 131].

The research methods employed to ensure a superior driving experience and comfort primarily revolve around the braking sensation and the driver’s intentions. Researchers frequently employ a combination of vehicle system models and driver models to conduct their investigations. Leveraging techniques such as BP neural networks and fuzzy logic, researchers undertake driver braking intention recognition and compare and analyze driver braking intention parameter curves with vehicle braking curves. Through methods like simulation testing and others, they closely follow the driver’s intention, striving to align vehicle braking with the driver’s braking intention to deliver an optimal pedal feel and braking experience.

4.4. Multiobjective Strategies

Research findings have demonstrated that achieving high regenerative braking efficiency is crucial for ensuring a significant energy return to the battery. However, it may compromise driver comfort due to rapid deceleration. It is evident that when considering energy recovery efficiency, braking safety, and driving comfort, striking a balance and finding an optimal solution becomes imperative without blindly pursuing the maximization of a single goal [28]. There are several research areas within regenerative braking strategies that take into account these goals, including the energy recovery rate, braking performance, pedal feel, and battery performance.

First, there is no doubt that improving both energy recovery efficiency and braking performance is the most concerning goal for researchers in this field [132–139]. For instance, Li et al. [140] addressed the challenge of balancing braking stability and energy recovery by estimating the road slope angle and devising a regenerative braking force control strategy based on vehicle stability requirements. Xu et al. [141], Zhu et al. [142], and Jiang et al. [143] optimized the braking force distribution between front and rear wheels to enhance braking energy recovery efficiency and vehicle driving range while ensuring braking safety and stability. Yin et al. [144] proposed a deep Q-learning network (DQN) regenerative braking control strategy based on adaptive weight coefficients to improve braking energy recovery efficiency and braking stability coefficient.

Second, braking sensation and driving comfort are the most common daily experiences for drivers. Many studies focus on improving driving sensation in conjunction with energy recovery and braking performance [145–148]. For example, Li et al. [149], He et al. [24], and [150] took driver and vehicle factors into account, focusing on driving intention and different stages of driver braking to recover energy while maintaining braking stability and aligning with driver expectations. Driver behavior significantly influences RBS performance. Aggressive driving patterns, characterized by abrupt deceleration, often necessitate greater reliance on hydraulic braking, thereby reducing energy recovery efficiency. Conversely, anticipatory driving—gradual deceleration enabled by regenerative braking—maximizes energy recuperation. For instance, Ning et al. [151] observed that drivers who adapted to single-pedal braking reduced hydraulic brake usage by 90%, enhancing energy recovery. However, untrained drivers may exhibit suboptimal braking strategies, underscoring the need for targeted training programs to harmonize driving behavior with RBS capabilities.

Third, there are also some studies that focus on battery performance and health issues and consider them in sync with the improvement of other goals [152, 153]. Regenerative braking control strategies outlined in studies [154–157] played a constructive role in extending battery service life, ensuring braking safety, and optimizing energy recovery. For instance, Mei et al. [158] and Mei et al. [159] introduced a novel fuzzy sliding mode control scheme under an adaptive control strategy to optimize battery state and energy recovery efficiency while respecting real-world constraints. In light of these considerations, some studies have taken into account the energy recovery rate, battery performance, and pedal sensation [160]. For instance, Sun et al. [161] introduced a dual-mode regenerative braking control strategy, which is particularly advantageous when the battery is in a high charging state or experiencing extreme temperatures, ensuring charging safety, regeneration efficiency, and ride comfort.

Lastly, comprehensively enhancing the energy recovery rate, braking performance, pedal feel, battery performance, and other objectives poses a significant challenge. Typically, the quest for the optimal regenerative braking control strategy considers safety, economy, and comfort. Zhang et al. [129] established fuzzy logic rules governing braking force concerning braking requirements, vehicle speed, and battery SOC. These rules effectively realize driving safety, comfort, stability, and battery safety in EVs. Zhang et al. [162] introduced a predictive regenerative braking control strategy based on swarm intelligence to achieve high-efficiency characteristics and battery longevity in RBSs.

The comprehensive analysis of regenerative braking strategies is presented in Table 4. Considering the objectives of these strategies, energy recovery emerged as the predominant focus, accounting for 97% of the cases examined in the 32 scenarios. Following closely were braking performance (78.1%), vehicle battery performance (37.5%), and driver pedal feeling (34.4%). Notably, the bulk of research on regenerative braking strategies has centered on their effects on vehicle and component performance, with limited consideration of their impact on drivers.

| Main author | Year | Energy recovery | Braking performance | Pedal feeling | Battery performance |

|---|---|---|---|---|---|

| Zhao, Chu [132] | 2018 | √ | √ | — | — |

| Li, Chengkun [133] | 2018 | √ | √ | — | — |

| Li, Zhang [140] | 2019 | √ | √ | — | — |

| Xu, Chen [141] | 2019 | √ | √ | — | — |

| Zhang [134] | 2019 | √ | √ | — | — |

| Zhao and Guo [154] | 2019 | √ | √ | — | √ |

| Zhang, Dong [129] | 2019 | √ | √ | √ | √ |

| Zhu, Chen [142] | 2020 | √ | √ | — | — |

| Favilli, Pugi [152] | 2020 | √ | — | — | √ |

| Zhu, Wu [160] | 2020 | √ | — | √ | √ |

| Liu, Lei [155] | 2020 | √ | √ | — | √ |

| Gao [145] | 2020 | √ | √ | √ | — |

| Zhang, Wang [162] | 2020 | √ | √ | √ | √ |

| Jiang, Zhang [143] | 2021 | √ | √ | — | — |

| He, Wang [24] | 2021 | √ | √ | √ | — |

| Wu [153] | 2021 | √ | — | — | √ |

| Mei, Karimi [158] | 2021 | √ | — | — | √ |

| Mei, Yang [159] | 2021 | √ | — | — | √ |

| Zhu, Wu [156] | 2021 | √ | √ | — | √ |

| Sun, Zhang [161] | 2021 | √ | — | √ | √ |

| Li, Du [149] | 2022 | √ | √ | √ | — |

| Yin, Zhang [144] | 2023 | √ | √ | — | — |

| Zhou, Liu [135] | 2023 | √ | √ | — | — |

| Liu, Bu [136] | 2023 | √ | √ | — | — |

| Huang, Wu [137] | 2023 | √ | √ | — | — |

| Xing, Zhu [138] | 2023 | √ | √ | — | — |

| Xu, Li [139] | 2023 | √ | √ | — | — |

| Zhang, Zhao [146] | 2023 | √ | — | √ | — |

| Zhang, Zhao [148] | 2023 | — | √ | √ | — |

| Ziadia, Kelouwani [147] | 2023 | √ | √ | √ | — |

| Li, Ma [150] | 2023 | √ | √ | √ | — |

| Ghazali, Hassan [157] | 2023 | √ | √ | — | √ |

5. RBS Evaluation

RBS evaluation is an indispensable and important link in the process of technology research and development, it is beneficial for forming closed-loop feedback in the research and development and production process, optimizing and improving product design and manufacturing. The commonly used methods for RBS evaluation include hardware in the loop simulation testing and actual vehicle testing [5, 19]. Based on domestic and international research and practical work, the evaluation objectives of RBS mainly include energy-saving effects, braking performance, and braking sensation, as well as research on some influencing factors. The following section will elaborate on them separately.

5.1. Evaluation of Energy-Saving and Emission Reduction Effects

The evaluation of energy-saving effects is mainly characterized by two indicators: braking energy recovery rate and contribution to the driving range [163–167]. In terms of energy conservation and emissions reduction, research of Spichartz and Sourkounis [168] revealed that regenerative braking excels in reducing emissions and curbing energy consumption, a cornerstone of its development and primary function. Hicks et al. [169] showed that RBS would reduce brake wear by 64%–95%, and the average PM emission coefficient would decrease by 68%. Altomonte et al. [170] conducted experimental tests, and the results indicate that energy recovery can significantly reduce the propulsion energy required to execute the duty cycle.

Furthermore, the assessment of single-pedal mode, which epitomizes high-level regenerative braking capability, has emerged as a prominent research focal point. For instance, Ma et al. [171] evaluated single-pedal mode under EV regenerative braking, affirming its significant role in improving economic performance. Similarly, Liu et al. [172] demonstrated that a single-pedal control strategy effectively boosts energy recovery rates and extends driving range while ensuring braking safety. Xie [173] examined the impact of a single-pedal characteristic control strategy on the performance of pure EVs.

5.2. Evaluation of Braking Performance

The prerequisite for evaluating braking performance is to first comply with relevant standards for the braking performance of domestic and foreign vehicles, such as China’s GB 21670 Technical Requirements and Test Methods for Passenger Car Braking Systems, GB 12676 Technical Requirements and Test Methods for Commercial Vehicle and Trailer Braking Systems, FMVSS135 Passenger Car Braking Systems in the United States, and ECE R13-H Unified Regulations for Approval of Passenger Car Braking Systems in Form in the European Union. On this basis, the evaluation of RBS braking performance mainly considers whether the vehicle performs better in braking performance with the addition of RBS braking technology, which can provide greater deceleration or stronger braking force.

Compliance with international standards such as ECE R13-H and FMVSS135 is not merely technical but reflects adherence to regional safety and environmental mandates. For example, the European Commission’s evolving safety protocols for regenerative braking under UN Regulation No. 13-H directly influence RBS design priorities, balancing energy recovery with fail-safe hydraulic backup requirements [174].

Regarding braking performance, the incorporation of regenerative braking functionality generally augments overall braking capabilities when combined with traditional braking systems. Research by Mosadegh et al. [164], Mitropoulos-Rundus et al. [175], Subramaniyam and Subramanian [176] showed that RBS indeed confers braking advantages to drivers. However, it is acknowledged that in certain hazardous scenarios, achieving the required level of braking with regenerative braking alone may be challenging, as noted by Hamada and Orhan [29], where the force generated by RBS may be insufficient, necessitating reliance on the traditional brake pedal for greater braking force.

Simultaneously, it is crucial to consider the strength range of the regenerative braking function. Dimitrov and Pavlov [31] investigated EV deceleration under regenerative braking across four distinct driving modes: standard, Eco, Eco+, and emergency. This underscores that different regenerative braking force levels result in varied driving experiences, necessitating further research and demonstration to determine the optimal range suitable for diverse driving styles. Berjoza et al. [28] conducted experiments and recommended setting regenerative braking within the range of 70%–80% as, under a 100% regenerative braking setting, EVs braked rapidly through the motor, making brake pedal control challenging. This underscores that the strength range of the regenerative braking function does not necessarily follow the “higher is better” principle, and the release of regenerative braking force is intricately linked to pedal force and pedal travel. Precise pedal operation is a challenging aspect, especially at higher regenerative braking intensities, where driver control requirements are more demanding.

In addition, during the research and development process, it should also be noted that braking performance is reflected in whether the vehicle has a braking backup function in the event of motor braking failure or hydraulic pipeline failure and whether the system can ensure that traditional hydraulic pipelines can still play a partial role in the event of RBS failure, ensuring that the vehicle does not lose all braking capabilities [5].

5.3. Evaluation of Driver’s Braking Perception

Braking sensation mainly refers to braking comfort, which is reflected in the smoothness of vehicle braking [163]. In the realm of developing new automotive technologies, it is paramount not to disregard human emotions and experiences. Current research findings suggest an overwhelmingly positive reception of the driving experience facilitated by regenerative braking functionality. On one hand, this driving experience tends to be highly satisfactory [33, 34, 172, 177–179]. On the other hand, this technology is relatively easy to grasp [33, 34]. Nevertheless, some drivers may encounter challenges in adapting to the system, as observed by Cocron et al. [33]. This can be addressed by providing varying levels of regeneration to accommodate individual preferences.

Emerging evidence suggests that structured driver training can amplify RBS benefits. For example, simulation-based training programs teaching “pulse-and-glide” techniques—alternating acceleration and coasting—have shown promise in improving energy recovery rates by 10%–15% [180, 181]. However, current research on training interventions remains sparse. Future studies should explore standardized curricula to educate drivers on maximizing regenerative braking efficiency while maintaining safety, particularly in scenarios like downhill braking or low-friction conditions. Field studies leveraging driver feedback highlight critical factors influencing braking comfort. For example, Patoine et al. [182] utilized electroencephalography (EEG) to demonstrate that inconsistent regenerative braking force profiles increase cognitive workload, particularly in elderly drivers. Similarly, Marrone [183] conducted longitudinal surveys showing that drivers prioritize predictable deceleration curves over maximal energy recovery. These findings underscore the need for adaptive RBS interfaces that balance efficiency with user-centric design. Spadoni [116] further validated that tactile pedal-feel compensation systems improve perceived safety and satisfaction during regenerative braking, especially in low-speed urban environments.

It is also worth noting that the regenerative braking function is gradually affecting driving behavior. From a positive perspective, driving habits may become gentler and more energy-efficient [34]. Nonetheless, there are also potential downsides. First, deceleration can be more abrupt. Research by Krems et al. [184] highlighted that certain participants noted the more noticeable or abrupt deceleration associated with RBS, which requires some adaptation and may potentially affect both the EV driver and other road users. Second, there is a shift in braking operation. Cocron et al. [33] discovered that, as most deceleration events are performed solely through regenerative braking, traditional braking operations are significantly reduced. In the experiment conducted by Labeye et al. [34], participants employed regenerative braking instead of the brake pedal in 89.9% of braking situations. Third, excessive dependence may lead to accidents. Witzlack et al. [3] found that experienced drivers, who are familiar with and trust the RBS system, frequently use it and reach its limits, thereby exceeding the parking line more frequently, which may lead to critical issues in specific situations, including accidents. In the case of emergency braking, whether the regenerative braking function genuinely enhances or diminishes safety is a pivotal issue requiring further investigation.

5.4. Analysis of Influencing Factors

Understanding the factors that influence the level of energy recovery in braking energy recovery systems is crucial due to their diverse operating strategies. When analyzing the factors affecting regenerative braking, existing studies have revealed that, on the one hand, external environment factors significantly impact the extent of regenerative braking. For instance, Bian and Qiu [185], Zhang and Cai [186], and Chen et al. [187] noted that road slopes have a notable effect on fuel economy and vehicle control. Chen et al. [188] considered the influence of road adhesion coefficient on the regenerative braking process. Zhao and Wu [12] and Szumska and Jurecki [189] revealed that different road types are also one of the influencing factors. As noted by Zhang et al. [190], environmental temperature indirectly affects the RBS feedback energy process by altering total braking energy, battery charging power and loss, and braking energy distribution ratio. Lower temperatures result in reduced regenerative braking energy. Road conditions play a critical role in the effectiveness of RBS. On wet or icy surfaces, the reduced tire-road adhesion coefficient limits the maximum regenerative braking force that can be applied without compromising vehicle stability. Studies have shown that RBS must dynamically adjust braking torque distribution to prevent wheel lock-up or skidding under such conditions [191, 192]. Uneven surfaces, such as gravel or potholed roads, further complicate RBS operation by introducing unpredictable variations in braking demand and energy recovery efficiency. For instance, Zuo and Zhang [193] demonstrated that road roughness can lead to fluctuations in regenerative braking energy recovery, necessitating advanced control strategies to maintain optimal performance.

On the other hand, the level of regenerative braking is influenced by key parameters inherent to the vehicle itself. Heydari et al. [194] and Heydari et al. [195] emphasized that the low-speed cutout point (LSCP) is the primary determinant for assessing regenerative braking performance across various operating conditions. Mohammadi et al. [196] compared two methods using fixed and dynamic low-speed boundaries (LSBs) to solve RSB limitations at low speeds and studied the impact of each method on the ecological driving control problem of autonomous EVs (AEVs). Lee et al. [197] evaluated and analyzed the energy consumption characteristics of an electric SUV equipped with RBS during each regenerative braking stage through actual driving tests. Supercapacitor performance is notably affected by ambient temperature, with efficiency dropping by 15%–20% at sub-zero conditions due to increased internal resistance [198, 199]. Similarly, battery SOC thresholds limit regenerative braking energy absorption, as highlighted by Itani et al. [200], who proposed dynamic low-speed cutoffs to mitigate this issue. These factors underscore the need for adaptive energy storage management in RBS.

Furthermore, Heydari et al. [201] pointed out that regenerative braking performance and system losses in EVs hinge on various factors, including battery voltage levels. Some studies have integrated these influencing factors. Valladolid et al. [202], for example, analyzed regenerative braking efficiency under actual driving conditions and across diverse geographical locations, identifying factors that either facilitate or hinder energy recovery. These factors include vehicle weight, torque, speed, road inclination, and braking duration. Variables such as SOC, speed, torque, and road terrain play pivotal roles in shaping the efficiency of RBSs. In addition to energy-saving and braking performance, the long-term reliability and maintenance requirements of RBS are critical for its widespread adoption. Studies have shown that the complexity of RBS integration can lead to higher maintenance costs, particularly in systems with dual braking mechanisms (regenerative and hydraulic) [160, 203]. For example, the need for periodic calibration of motor controllers and hydraulic systems to ensure seamless coordination adds to operational overheads. Furthermore, the durability of energy storage systems, such as batteries and supercapacitors, under repeated charge–discharge cycles must be carefully monitored to prevent performance degradation [88, 204].

5.5. Limitations of Current Evaluation Methods and Emerging Alternatives

RBS relies heavily on hardware-in-the-loop (HIL) simulations, controlled road tests, and standardized driving cycles. However, these methods exhibit significant limitations. HIL setups often fail to replicate real-world environmental variables such as temperature fluctuations, road surface irregularities, and stochastic driver behavior, potentially overestimating system reliability [205, 206]. Standardized driving cycles (e.g., NEDC and WLTC) lack the unpredictability of real-world driving, limiting their ability to assess RBS performance under edge cases like emergency braking on icy roads [207, 208]. Actual vehicle testing, though valuable, is constrained by high costs, safety risks, and the inability to systematically evaluate long-term durability across diverse conditions [209, 210]. To address these gaps, researchers are exploring advanced methodologies:

Digital Twin Technology: Integrating real-time telematics data with dynamic simulations enables adaptive testing environments that mirror real-world conditions. For example, Birnie [211] demonstrated a digital twin framework for RBS that accounts for battery aging and road friction variability.

AI-Driven Scenario Generation: ML algorithms can synthesize diverse driving scenarios, including rare but critical events (e.g., hydroplaning), to stress-test RBS logic beyond conventional cycles [212, 213].

Edge Computing in Real-World Testing: Onboard edge devices equipped with IoT sensors allow continuous, unobtrusive data collection during normal vehicle operation, facilitating large-scale validation of RBS under naturalistic conditions [214, 215].

These emerging methodologies offer promising avenues to overcome the limitations of traditional evaluation methods, enabling more holistic assessments of RBS performance, durability, and safety.

6. Conclusions and Future Directions

This study focuses on the research of RBS for NEVs, providing an overview of the origin, working principle, advantages, and disadvantages of regenerative braking technology. It systematically reviews and sorts out relevant research in recent years and applies VOSviewer to conduct statistical analysis of literature in the Web of Science database. Analysis shows that with the development of regenerative braking technology, scientific research related to is also more active, with obvious engineering characteristics.

Furthermore, by analyzing the keywords of regenerative braking research in recent years, the focus has shifted from basic attributes such as system design, energy efficiency, and braking mechanisms to strategy optimization and collaborative control, delving deeper into subareas such as battery technology and torque distribution optimization. With a large number of mathematical methods, research has shown a trend of complexity, refinement, and deepening. Overall, energy management remains the focus of attention.

First, future research should focus on improving the reliability and reducing the maintenance burden of RBS. This includes developing more robust materials for braking components, optimizing thermal management systems, and advancing predictive maintenance algorithms using ML. Second, future research should prioritize the development of RBS control strategies tailored to diverse road conditions. This includes enhancing real-time road adhesion estimation algorithms, optimizing torque distribution for low-friction surfaces, and integrating environmental sensors (e.g., rain or ice detection) into RBS control logic. After that, future research could prioritize the development of hybrid evaluation frameworks that combine the controlled rigor of HIL simulations with the ecological validity of real-world data. Adopting digital twins and AI-enhanced testing protocols will enable more comprehensive assessments of RBS performance.

From the above, we can see that achieving an optimal balance between high-energy recovery and braking performance, driving experience, battery safety, and other objectives remains a formidable challenge in devising regenerative braking function strategies [28]. Among them, the safety impact brought by the regenerative braking function is particularly noteworthy. In recent years, sudden acceleration accidents of NEVs have attracted high social attention. Accident investigations have shown that a considerable number of accidents are caused by drivers accidentally stepping on the accelerator pedal, and the reasons for this phenomenon are related to the changes in driving behavior caused by RBS. On the one hand, research has shown that different levels of regenerative braking have a significant impact on driving tasks [28, 31, 32]; on the other hand, regenerative braking is gradually reshaping driving behavior [3, 33, 34], this reduces traditional braking operations. How to effectively reduce the risks brought by these issues will have a significant impact on the sustainable development of RBS technology’s health and safety.

In order to better compensate for the lack of research on the relationship between regenerative braking and driving safety, more in-depth research can be focused on the following five key aspects in the future:

(i) Research on accidents caused by regenerative braking function. Currently, mainstream research mainly focuses on the forward development and design of RBSs, which can also provide technical support and reference for the development and design of RBSs. However, there is limited attention to driving accidents caused by regenerative braking function. This type of accident usually does not refer to the failure of the regenerative braking function but is precisely caused by the reasons mentioned earlier, that is, regenerative braking changes driving habits. If such accident data can be deeply excavated, it can provide key factual data analysis and safety measures research foundation for the study of regenerative braking function and driving safety.

(ii) Research on the mechanism of the impact of regenerative braking on driving behavior. As mentioned earlier, research has focused on the changes in driving behavior caused by regenerative braking function but has not yet formed a more formal mechanism research. The specific how regenerative braking function affects driving behavior, how driving behavior has changed, and to what extent, these issues are waiting to be demonstrated, and there is still a lot of research work to be done in this regard. At present, research on the relationship between regenerative braking and braking safety, as well as driver perception, is relatively small compared to research related to energy recovery. Therefore, there are limited methods available for reference. However, overall, the research approach should consider the coupling modeling of vehicle and driver models.

(iii) Research on the scope of safety-oriented regenerative braking level. Based on some traffic accidents that have occurred and some experimental studies, some scholars propose that the range of regenerative braking level should be controlled within a certain range to better ensure driving safety. At present, there are few studies and conclusions in this area, and they are all relatively rough. Future research can be carried out in conjunction with the above-mentioned accident research and impact mechanism research, with a driving safety-oriented approach to study the range of regenerative braking level control. Drivers can not only experience the pleasure brought by new technologies but also have the smallest impact on driving behavior.

(iv) Investigating dynamic stability control algorithms for RBSs in high-speed (>100 km/h) and emergency braking scenarios, particularly focusing on yaw stability and wheel slip mitigation. Future research should explore the integration of regenerative braking with advanced stability control systems, such as ESC, to ensure safe and stable deceleration under extreme conditions. Standardized testing protocols, such as ISO 26262, should be developed to evaluate RBS stability in high-speed and emergency braking scenarios.

(v) RBS technology scalability gaps across different types of vehicles. While this review emphasizes RBS in passenger and commercial vehicles, scalability challenges for lightweight or specialized vehicles (e.g., two-wheelers and drones) remain underexplored. Future studies should investigate adaptive RBS designs tailored to diverse vehicle architectures, addressing unique power, weight, and safety requirements.

In addressing safety concerns, foundational risk mitigation strategies—such as redundant braking architectures, real-time diagnostics, and ESC integration—have emerged as critical safeguards against RBS failures. Future research should explore adaptive fail-safe algorithms and standardized safety protocols to further enhance system resilience.

Regenerative braking technology, as a key new technology for NEVs, has achieved commendable results in areas such as energy conservation, emission reduction, and improved braking performance. However, at the same time, regenerative braking technology has brought a new driving mode, and the limitations of regenerative braking force and changes in driving behavior caused by regenerative braking function can bring worrying risks. At the current stage of RBS technology development, the driver’s acceptance, adaptation, and mastery of new technologies are key to ensuring safety. This is also what this study hopes to call for, and we hope that professional technicians and academic researchers will pay more attention to the correlation between regenerative braking and driving safety. This will provide important research data for reducing personal injury, promoting technological progress, and ensuring the healthy development of the industry.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This study was supported by the National Key Research and Development Program of China (No. 2024YFC3307800), the SAMR Science and Technology Innovation Talent Program (Leading Talents) (No. KJLJ202308), and the National Natural Science Foundation of China (No. 52372422).

Acknowledgments

This study was supported by the National Key Research and Development Program of China (No. 2024YFC3307800), the SAMR Science and Technology Innovation Talent Program (Leading Talents) (No. KJLJ202308), and the National Natural Science Foundation of China (No. 52372422).

Open Research

Data Availability Statement

The data that support the findings of this study were derived from the following resources available in the public domain: the Web of Science Core Collection database.