Influence of the Recyclate Content on the Process Stability and Part Quality of Injection Moulded Post-Consumer Polyolefins

Abstract

In recent years, the drive to adopt sustainable practices and develop eco-friendly processes and products has gained significant momentum in the global polymer industry. A key component of this shift is the increased use of recycled materials, which not only align with environmental goals, but also offer considerable economic advantages. Integrating post-consumer recyclates (PCRs) into manufacturing processes, particularly in injection moulding, holds great potential for reducing CO2 emissions, decreasing reliance on virgin materials, mitigating waste and promoting a circular economy. Nevertheless, a switch to 100% recyclate has not yet been effective or economical in many areas of application, so mixtures of virgin and recyclate material represent a promising approach and must be analysed further. Therefore, this study examines the impact of different virgin/recyclate-mixture ratios on both injection moulding process stability and resulting part quality, focusing on high-density polyethylene (HDPE) and polypropylene (PP) blends. For this purpose, virgin/PCR mixtures are compounded, rheologically analysed using high-pressure capillary rheometry and processed via injection moulding. The process data are analysed, and the produced parts are mechanically and geometrically evaluated. The findings show that for PP, an increasing recyclate content results in a nearly linear improvement in tensile strength and modulus of elasticity without significantly affecting material viscosity, ensuring stable processing conditions. However, part warpage increases with higher recyclate content. In contrast, for HDPE, a higher recyclate content decreases the mixture viscosity, leading to decreased injection pressure and dosing torque during processing. Despite this, the tensile strength and modulus of elasticity improve, while part warpage decreases for HDPE. For both materials, though tensile strength and elasticity increase, higher recyclate contents negatively affect fracture behaviour, as evidenced by breakage patterns and strain at break. The study also demonstrates that the linear mixing rule can be applied to process parameters and part geometry characteristics for virgin/recyclate mixtures, facilitating the integration of recyclate content into product development.

1. Introduction

By diverting waste from landfills and reducing energy consumption and greenhouse gas emissions inherent in virgin material production, recyclates and especially post-consumer recyclates (PCRs) offer a compelling avenue toward achieving sustainability targets in the plastics industry [1, 2]. As of 2022, European processors incorporated PCR in their operations, amounting to 12.9% of the total plastics processing volume [3]. However, the current utilisation of recyclates remains below 20% across various industries, predominantly due to limited availability and insufficient experience in processing recyclate materials [4]. Nonetheless, a proposed legislation within the EU aims to enforce a minimum 35% inclusion of PCR in all plastic packaging by 2030 [5, 6], incentivising increased adoption and processing of recycled materials. Adaptations in recyclate utilisation rates are anticipated for more specialised applications such as vehicles and electronic devices as well, aligning with heightened product specifications and therefore, preliminary, lower recyclate contents [7, 8]. This means that soon, regulations about mandatory usage of recyclate materials will influence the product development and processing for large parts of the plastics industry.

High-density polyethylene (HDPE) and polypropylene (PP) make up about 40% of the different produced plastics, particularly within the packaging sector, which itself contributes to 59% of the total generated waste [3, 9]. Given their above-average presence, polyethylene (PE) and PP collectively represent a significant portion of PCR. These materials find primary application in the injection moulding and extrusion process [10]. Consequently, this study is directed toward evaluating the recyclate behaviour specifically for HDPE and PP.

Unlike virgin materials, recyclates often exhibit variations in composition, quality and physical properties, complicating stable processing [11–14]. Contaminants, outgassing, thermal degradation and inconsistent melt flow characteristics are among the primary challenges that demand innovative solutions to ensure process stability and part quality [15–18]. For many polymers, remelting of the material leads to a deterioration in quality due to thermally induced chain degradation. However, the effects of reprocessing can vary from polymer to polymer [19]. Additional crystallisation effects can occur during the recycling of polyolefins such as HDPE and PP, which influence the mechanical properties [20]. As a result, the mechanical properties can be maintained or even improved despite recycling [19]. The mechanisms of chain degradation as well as cross-linking and side chain branching can occur during the recycling process of HDPE, which can have a positive effect on many mechanical properties, but also influence the crystallisation [20]. With a low number of recycling repetitions of up to 10 cycles, the cross-linking mechanism dominates [19]. Kealy [21] investigated the recycling process of HDPE (six times) and found an increase in the molecular weight. Oblak et al. [22] even found a slight increase in the number average and mass average molecular weight during the first 30 melting cycles. Only then does the molecular weight drop significantly, which can lead to a drop in mechanical properties. The degree of crystallisation, which influences the mechanical properties, also did not change significantly during the first 20 extrusion cycles, whereas it drops sharply between the 20th and 30th cycle. Thermal degradation of PP during recycling can lead to a reduction in molecular weight, but favours crystallisation behaviour [23, 24]. Due to the increased chain mobility with lower molecular weight, the polymers can crystallise easier. To this end, Huang and Peng [24] investigated the influence of recycling on PP by reprocessing it five times through injection moulding and then shredding it. Aurrekoetxea et al. [23] simulated the recycling process of PP with 10 melting cycles. Both were able to determine an increase in the degree of crystallisation with the number of cycles. From the sixth cycle onward, the degree of crystallisation no longer changed significantly. Due to the higher crystallinity, the modulus of elasticity and tensile strength also increased [23]. The development weakened from the sixth cycle onward. In the investigations by Huang and Peng [24], the tensile strength even fell again in the fourth and fifth cycle. The elongation at break is almost constant during the first four cycles, while it drops significantly thereafter. Aurrekoetxea et al. [23] relate the lower elongation at break to the decrease in molecular weight.

In contrast to the molecular weight and the degree of crystallisation, Oblak et al. [22] found that extrusion had an immediate effect on the melt flow rate (MFR). Already after the first extrusion, the MFR dropped from 7.53 g/10 min to 7.02 g/10 min. After 10 cycles, the MFR was 1.453 g/10 min and after 30 cycles, it approached 0 g/10 min, so that no decrease could be observed with a further increase in the number of cycles. Kealy [21] observed a drop in the MFR for each cycle during the first six extrusion cycles. Aurrekoetxea et al. [23] found no changes in the MFR during the first four cycles. It increased from the fifth cycle onward. Aurrekoetxea et al. [23] attribute the delayed changes in the MFR to the absence of stabilisers. As a result, the MFR of PCR could increase at different times and strong batch fluctuations could occur. The investigations by Huang and Peng [24] also found that the MFR increases with the number of reprocessing cycles. The changes started directly with the first recycling cycle. A change in the MFR is also accompanied by a change in processability. The improved flow behaviour of the recyclates or mixtures of recyclates and virgin material can lead to problems in the quality characteristic of dimensional accuracy during injection moulding [10]. The low viscosity can lead to improved pressure transfer and therefore more material in the cavity [25]. For this reason, the frequently large batch fluctuations of recycled materials can lead to errors in the moulded part dimensions.

Since the material behaviour changes due to reprocessing, the idea of mixing PCR material with virgin material with known properties is very prominent. Therefore, the influence of different recyclate contents on some materials has already been analysed with regard to the flow behaviour and mechanical properties like the tensile strength, stiffness, and impact strength [26–29]. Altan, Yurci, and Nugay [30] found that the higher the proportion of recycled material, the higher the residual stresses after injection moulding. Pattanakul et al. [31] also found an increasing modulus of elasticity and an increasing tensile strength after recycling. However, the mechanical parameter that was most affected in Pattanakul et al. [31] was the elongation at break, which fell from 69.7% to 36.9%. Zhang, Hirschberg, and Rodrigue [26] on the other hand used virgin material to improve low-quality PCR HDPE and measured an increase in mechanical properties with increasing virgin material. The different studies show that the effects of reprocessing and the different properties and qualities of PCR materials as for example the content of foreign polymers or contaminations can greatly vary and influence the resulting part and material characteristics depending on the chosen material.

Traxler, Kaineder, and Fischer [32] showed that an improved prediction of virgin/recyclate PP mixtures can be reached by adapting and combing different mixture rules, which are not further analysed in this study.

This research aims to determine the influence of an increased recyclate content on the processing stability and the part geometry. Additionally, the results are analysed with regard to the transferability of the linear mixing rule onto the modelling of the part geometry and injection pressure for different virgin/recyclate ratios. The research is conducted for PP and HDPE PCR. The rheological material properties are first determined in laboratory tests to be able to comprehensively evaluate the influences of the recyclate content. The materials are then processed to produce two different components through injection moulding, with the resulting process data being recorded and analysed. Finally, the components are assessed geometrically and mechanically.

2. Materials and Methods

Since, according to the existing guidelines, recyclate proportions of less than 50% will be predominantly required in the coming years, it is particularly relevant to understand the mixing and processing behaviour between virgin material and recyclate with a high content of virgin material. Recyclate contents between 0% and 40% are, therefore, analysed in 10% increments for this study. For higher recyclate contents, 20% steps are selected.

2.1. Material Compounding and Mixture Characterisation

The material mixtures are created out of virgin material from LyondellBasell Industries Basell Polyolefine GmbH, Wesseling, Germany, and recyclate material from pre-sorted municipal waste (post-consumer fractions 324 and 329). The used recyclate materials are commercially available grades. Since the input source of PCR often fluctuates seasonally, it is ensured that in each case only recyclate from one PP, respectively. PE batch is used to produce the mixtures. Further material specifications are shown in Table 1. The material combinations are chosen with regard to similar flow behaviours (MFRs) to achieve a homogeneous mixture during the compounding process. Due to the high-value range of the MFR given by the supplier of the recyclate material, an exact match cannot be guaranteed from the datasheet.

| Material | HDPE | PP | |||

|---|---|---|---|---|---|

| Virgin | Recyclate | Virgin | Recyclate | ||

| Density (g/cm3) | 0.95 | 0.95 ± 0.02 | 0.90 | 0.95 ± 0.05 | |

| MFR measurement conditions | 190°C; 5 kg | 230°C; 2.16 kg | |||

| MFR (g/10 min) | 3.1 | 1.7 ± 0.7 | 16.0 | 15.0 ± 3.0 | |

- Abbreviations: HDPE, high-density polyethylene; MFR, melt flow rate; PP, polypropylene.

The material mixtures for both plastics are compounded separately with recyclate proportions of 0, 10, 20, 30, 40, 60, 80 and 100 wt% using an extruder and a granulator A ZSK 26K 10.5 twin-screw extruder from Coperion GmbH, Stuttgart, Germany (screw diameters: 26 mm). An integrated cooling section is installed downstream of the extruder. The PELL-TEC SP 50 pure strand pelletiser (also Coperion) is used to produce cylindrical pellets. To reduce shear-induced material degradation, the resulting torque is minimised by adjusting the processing temperature and speed. The temperatures are chosen according to the processing recommendations. A front cylinder temperature of 180°C is selected for HDPE and 190°C for PP. The screw speed for processing both materials is 300 rpm. The 0 wt% (solely virgin material) and 100 wt% (solely recyclate material) mixtures are also extruded to ensure comparability.

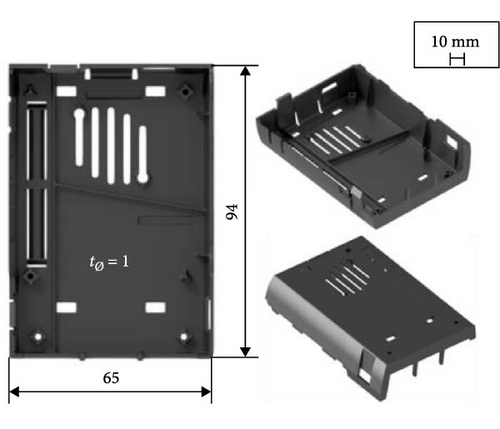

To assess the rheological behaviour comparable to the injection moulding process, high-pressure capillary rheometry (HCR) analysis is carried out using a Rheograph 2002 from GÖTTFERT Werkstoff-Prüfmaschinen GmbH, Buchen, Germany.

Due to the measurement duration, the HCR measurements are carried out for selected recyclate percentages (0, 40, 60 and 100 wt%) at five stamp speed levels (2.78, 1.39, 0.56, 0.28 and 0.14 mm/s). The measurements are taken with three different capillaries with lengths of 30, 20 and 10 mm and a capillary diameter of 1.0 mm at a temperature of 240°C (PP), respectively, 230°C (HDPE).

2.2. Processing Through Injection Moulding

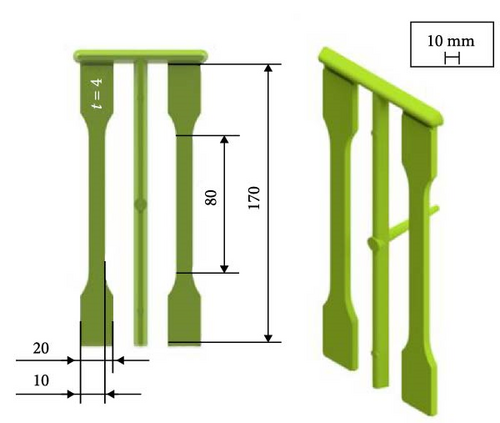

For the injection moulding process, a Sumitomo SHI Demag IntElect2 100/470-250 machine from Sumitomo (SHI) Demag Plastics Machinery GmbH, Schwaig, Germany, is used. To analyse the mechanical properties and also validate the processing effects and influence on the part quality, two part geometries are chosen. A cold runner two-cavity injection mould is used to produce tension rods type 1A [36] (Figure 1a) as well as a hot runner mould to produce a more complex casing part (Figure 1b).

The moulds are temperature-controlled to a cavity surface temperature of 40°C via two water temperature control units type Thermo-6 from HB-Therm AG, St. Gallen, Switzerland. The melt temperature settings for both geometries are equal and chosen based on the processing recommendations and comparable to the measurement temperatures (HCR). The relevant parameter settings for the production of both geometries and materials are shown in Table 2. The settings and temperatures are kept constant over the variation of the different recyclate contents to determine the influence of the mixtures but vary for PP and HDPE (240°C, respectively, 230°C).

| Material | HDPE | PP | ||

|---|---|---|---|---|

| Setting/geometry | Casing | Tension rod | Casing | Tension rod |

| Nozzle temperature (°C) | 230 | 240 | ||

| Injection time (s) | 0.54 | 0.75 | 0.38 | 0.71 |

| Holding pressure (bar) | 800 | 550 | 350 | 350 |

| Screw velocity dosing (mm/s) | 400 | |||

| Back pressure (bar) | 100 | |||

- Abbreviations: HDPE, high-density polyethylene; PP, polypropylene.

The resulting process data are monitored during injection moulding to assess process stability. The control system of the used injection moulding machine allows access to Open Platform Communication Unified Architecture (OPC UA) interfaces. These enable the injection moulding process to be monitored via OPC UA clients and provide cyclical data on, for example, the maximum injection pressure, maximum torque, melt cushion or dosing time.

In addition to the obtained cyclical data, continuous process data can be collected and extracted via a machine-specific data acquisition system (DAS) light. This enables the process data of individual production cycles to be visualised in curves (e.g., the injection pressure, screw position, rotational speed or torque), downloaded and analysed through VIPRA by SHS plus GmbH, Dinslaken, Germany.

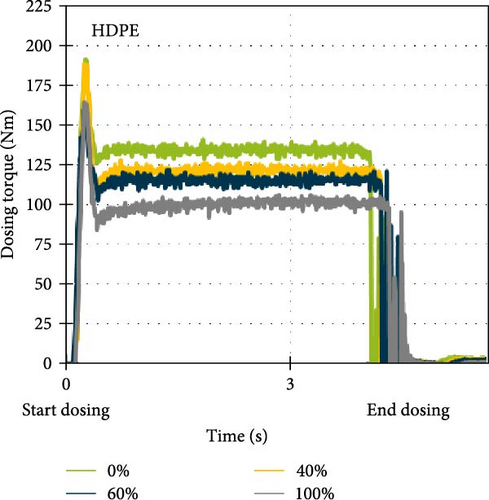

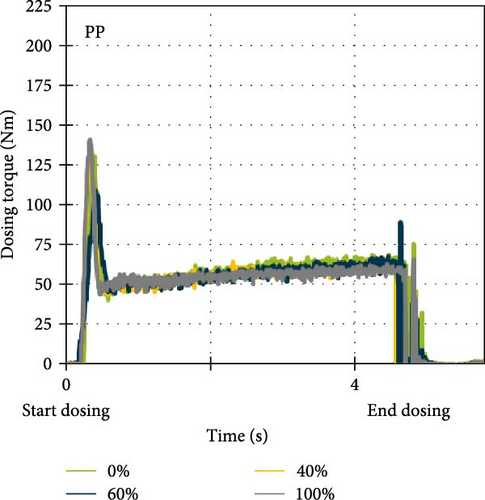

An example of the injection pressure and dosing torque over one cycle is shown in Figure 2.

The different phases of the injection moulding cycle can be deducted over the course of both parameters. The maximum injection pressure occurs directly after the start of the injection phase, while the maximum torque most likely occurs at the beginning or end of the dosing phase due to acceleration and deceleration processes, which are not representable for the mean torque during dosing. Therefore, also the curve progression is analysed.

2.3. Analysis of the Part Quality

To assess the influence of the recyclate percentage on the part quality, the mechanical properties, part weight and part warpage are analysed and correlated to the machine data during processing.

The tensile tests are carried out on a ZwickRoell type Z100 from ZwickRoell, Ulm, Germany, with a MultiXtens extensometer also from ZwickRoell and a U3 load cell from HBM Machines B.V., Moordrecht, Netherlands. The modulus of elasticity is first determined at a speed of 1 mm/min. The test is then continued at a speed of 50 mm/min until break or until the maximum elongation or minimum force measurable by the machine is reached.

Additionally, the part geometry consistency of the complex part is evaluated. Therefore, two distances are measured to assess the part warpage with a GOM ScanCobot through an optical 3D-scanner type ATOS Q from Carl Zeiss GOM Metrology GmbH, Braunschweig, Germany, in reference to the optimal 3D geometry.

3. Results and Discussion

The results of the material analysis are presented first followed by the results of the process data and part properties. Five parts or data sets are analysed for all test results (except for HCR). The average values and standard deviations are shown. If no error indicators are recognisable, the standard deviations are presented, but minimal and therefore not visible. The presented recyclate contents are given in wt%.

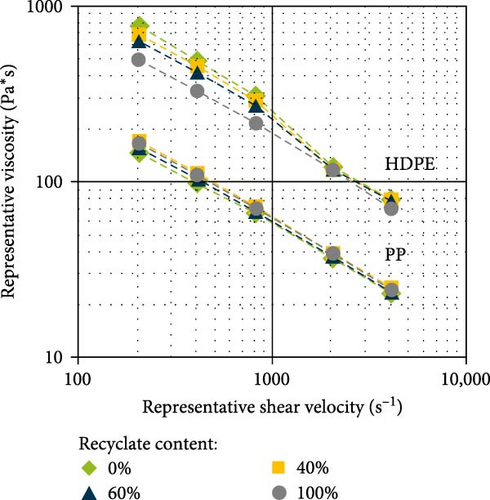

3.1. Mixture Viscosity

The analysed PP and HDPE mixtures show varying rheological properties. Overall, the analysed PP mixtures have a lower viscosity level for all measured shear viscosities. For HDPE, the viscosity decreases with a decreased recyclate content. Furthermore, with higher shear rates, the percentage difference in shear viscosity decreases significantly (Figure 3). While the viscosities differ by up to 42% at the lowest shear rate of 204 1/s, they only differ by 12% at the highest shear rate of 4075 1/s. Comparable to viscosity measurements for different temperatures or mixtures containing materials with varying flow characteristics, the influence of the recyclate content on the viscosity is significantly greater at low shear than at high shear velocity [37, 38].

As for HDPE, the percentage difference in shear viscosity among the PP mixtures decreases as the shear rate increases. However, the differences are significantly smaller at 17% at the lowest shear rate and 11% at the highest shear rate. For the 0% (virgin), 60% and 100% mixtures, the viscosity tends to increase with increasing recyclate content, but the 40% mixture behaves abnormally and shows a higher viscosity than the 100% recyclate. Overall, the PP measurements only show slight viscosity differences over the changing recyclate content, which complicates clear interpretations.

Since the material viscosity influences the flow behaviour and therefore the processing in injection moulding, the processability is analysed further. Viscosity fluctuations of the processed polymer can have a direct effect on the torque during dosing [39]. Furthermore, with increased viscosity, the required pressure to fill the cavity during injection increases, resulting in an increased (injection) pressure [10].

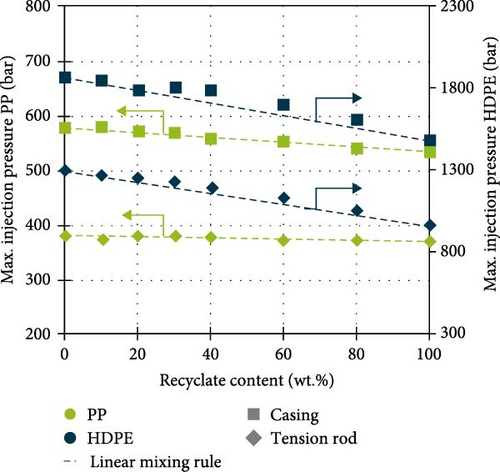

3.2. Influence of the Recyclate Content on the Process Stability During Injection Moulding

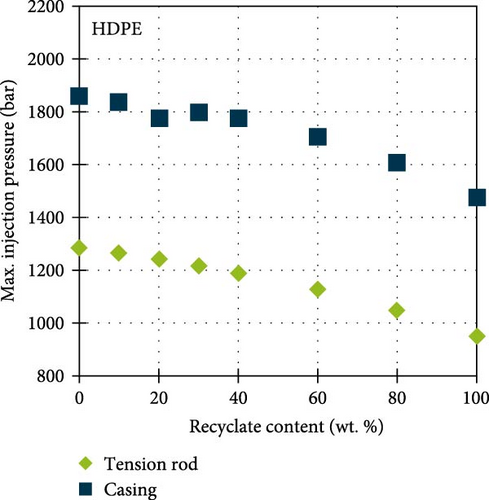

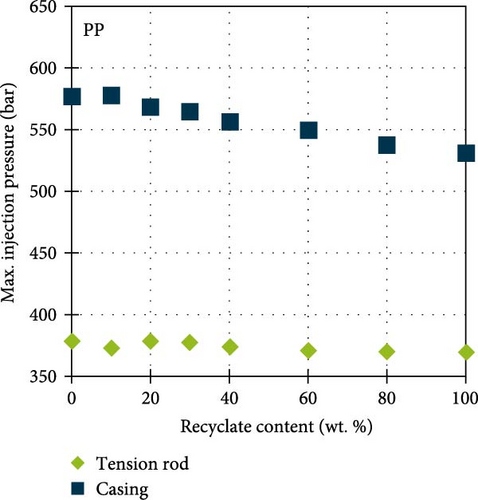

In speed-controlled processes, the injection pressure is a resulting process variable, which acts on the melt in front of the screw due to the set injection velocity and the temperature-dependent viscosity [40, 41]. During filling, the melt must overcome the flow resistance in the nozzle and in the gating system, which is defined by the material viscosity [10]. The maximum injection pressure is therefore a significant process key figure to determine process stability and accordingly process fluctuations. Figure 4 shows the maximum injection pressure for the production of both part geometries for the HDPE and PP mixtures. The maximum injection pressure is overall higher for the casing geometry because of the reduced wall thickness (average: 1 mm) in contrast to the thicker tension rods (4 mm) which results in a flow path to wall thickness ratio of over 110 for the casing and about 70 for the tension rod. In Figure 4a, the results for both HDPE part geometries show that the pressure falls from 1287 bar (0%) to 950 bar (100%) for the tension rod. The injection pressure during production of the complex component also drops from 1857 bar (0%) to 1474 bar (100%). The decrease is initially slower but increases as the percentage of recycled material increases. This applies to both analysed components. For the tension rods, the maximum pressure decreases by 8% over the first 40% of increased recyclate content and for the complex geometry by 4%. During the increase from 60% to 100% recyclate content, the injection pressure of the tension rods decreases by 20% and 17% for the complex part.

During the production of the PP parts, an almost linear but slow decrease in maximum injection pressure can be observed with increasing recyclate content. The maximum injection pressures of both components averaged over all test points for each recyclate content are shown in Figure 4b. The maximum injection pressure of the complex geometry falls from 577 bar (0%) to 532 bar (100%), while the injection pressure of the tension rods falls from 378 bar (0%) to 369 bar (100%). This means that the maximum injection pressure falls by 8% and 2%, which is less significant than the decrease during processing of HDPE and suggests a more stable process regardless of the recyclate content.

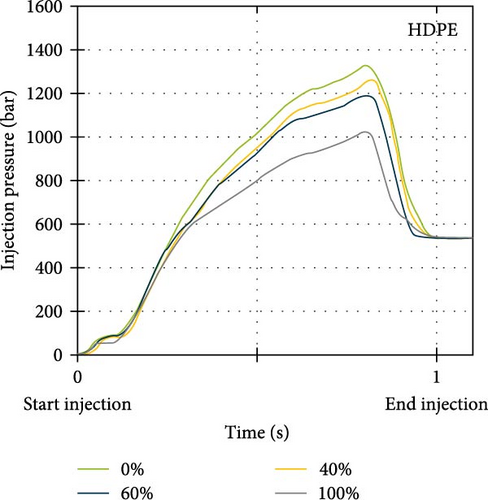

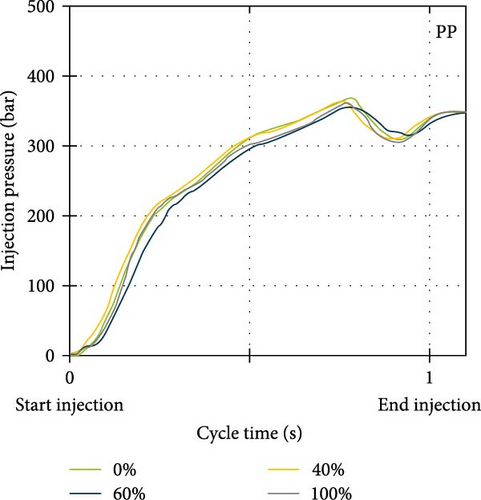

In addition to the evaluation of the maximum injection pressure (cyclic), the course of the injection pressure is analysed individually by continuously recording the data for each part. To allow differentiability between the different data curves only the courses for 0%, 40%, 60% and 100% recyclate for the tension rod specimen are presented. Figure 5 shows the injection pressure curves during the injection phase for the different HDPE (Figure 5a) and PP (Figure 5b) material mixtures. The curves of the HDPE mixtures have few intersections, which means that the material with the maximum injection pressure also has a higher injection pressure over most of the injection phase. Correlating with the recorded cyclic machine data, the highest injection pressure is reached during processing of the virgin material, followed by the HDPE mixture with 40%, 60% and 100% recyclate content. Similar to the maximum injection pressure, the difference between 0% and 40% recyclate content is smaller than the difference between 60% and 100%, which confirms the cyclical key figures. It can be deduced that the maximum injection pressure as a cyclic key figure can be a suitable characteristic value for comparing the overall injection pressure behaviour for HDPE. This trend matches the viscosity development over the recyclate content, which was determined through the HCR measurement. The increasing level of the injection pressure curves correlate with increasing material viscosity.

As for HDPE, the maximum injection pressure when processing PP also appears to be a suiting indicator for the course of the injection pressure (Figures 4 and 5). Figure 5b shows that the pressure of PP at low recyclate content is higher than the pressure at high recyclate content for the majority of the injection phase. However, for the maximum injection pressure as well as for the viscosity, the difference between the virgin material and the different recyclate contents is negligible.

Besides the injection pressure, an important key value of injection moulding and especially of the dosing phase is the resulting screw torque. According to Bichler [39], the material has the greatest influence on the torque, followed by the barrel temperature and the screw speed. By increasing those parameters, the viscosity of the material decreases which decreases the resistance to rotation. An increased torque in the dosing process indicates that a large amount of frictional heat is generated, which carries the risk of mechanical and thermal damage to the melt.

As shown in Figure 2, the maximum torque only provides a limited indication of the torque curve and can therefore lead to incorrect interpretation since it is mostly generated during start-up or as an outlier value at the end of the dosing phase. In contrast to the maximum injection pressure, it is therefore useful to consider the torque over a constant duration within the dosing phase. Regarding the maximum torque, no trends and correlations can be detected for both materials between the cyclic value and the varying recyclate percentage. In contrast, regarding the constant torque levels during dosing, clear differences occur for HDPE (Figure 6a). The lowest torque is measured for the 100% recyclate material (~100 Nm) and the highest for the virgin material (~135 Nm). The increase of 35% correlates with the increasing viscosity of the HDPE mixtures with a lower recyclate content (compare with Figure 3). Due to the higher viscosity of the virgin material measured in the HCR measurements, the material exerts a greater resistance to flow. To overcome this resistance to screw rotation, a greater torque is required.

As for the injection pressure, there is no significant influence of the recyclate content on the torque during dosing of the different PP mixtures for the chosen machine settings (Figure 6b). Overall, the process data suggest a high process stability during processing of different PP recyclate contents, which could also suggest a high part quality reproducibility. In comparison, the trends in the process data for processing HDPE suggest a change in part characteristics with varying recyclate content.

3.3. Part Properties and Resulting Correlations

In the following, the results of the part quality analyses are discussed. First the mechanical properties are presented, followed by the part weight and resulting part warpage.

3.3.1. Mechanical Properties

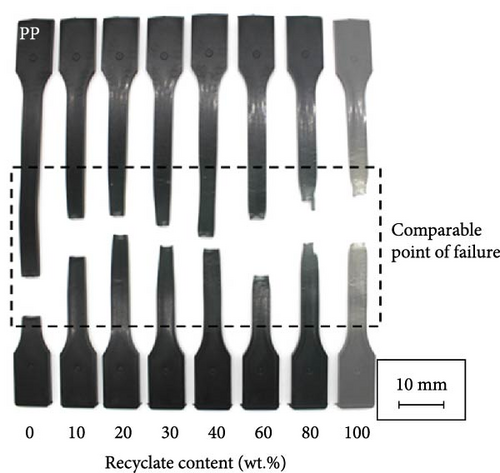

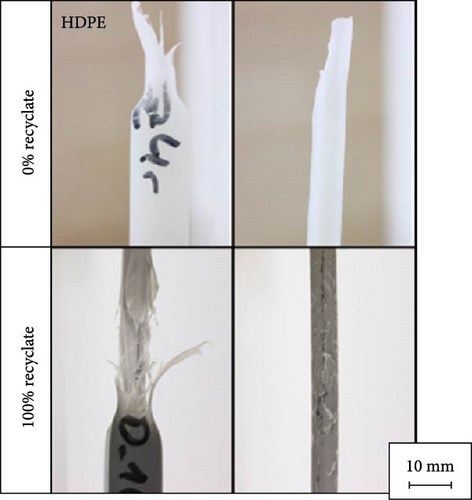

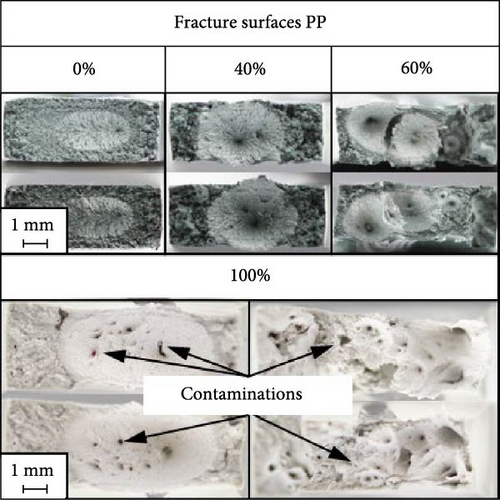

The mechanical properties of the material mixtures are evaluated using tension rods. Since recyclate materials often show inhomogeneities due to contaminations, the point of failure of the specimens with different recyclate contents is analysed first to ensure comparability of the results. Therefore, Figure 7 shows representative tension rods of the different materials and for the different recyclate contents after testing. Since the PP test specimens exhibit a brittle fracture behaviour, the specimens of all recyclate contents are presented (Figure 7a).

The failure point of the PP specimens differs slightly for the samples with 0% and 100% recyclate content but is generally constant across the virgin/recyclate mixtures and thus allows the comparability of the results. Due to its material characteristics, the HDPE specimens on the other hand break ductile and show considerable deformation and flaking at long elongations during testing (Figure 7b). However, this aspect can be neglected for the evaluation of the tensile strength and modulus of elasticity, as these are measured and reached reproducibly at low elongations. The influence of the recyclate content on the elongation at break is discussed in more detail later on.

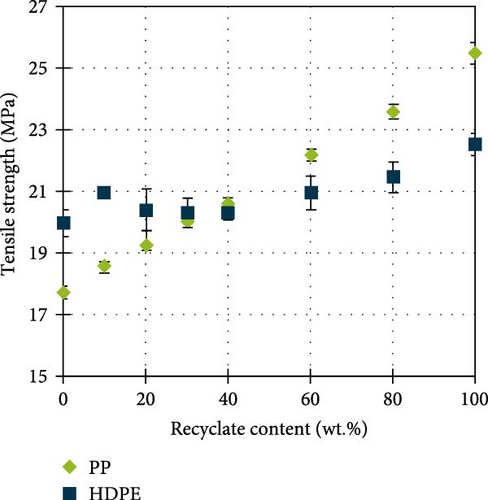

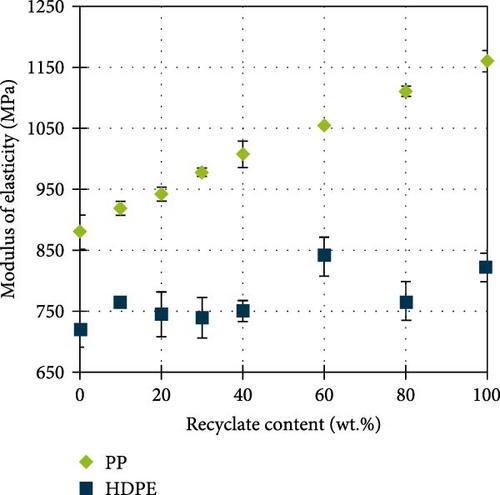

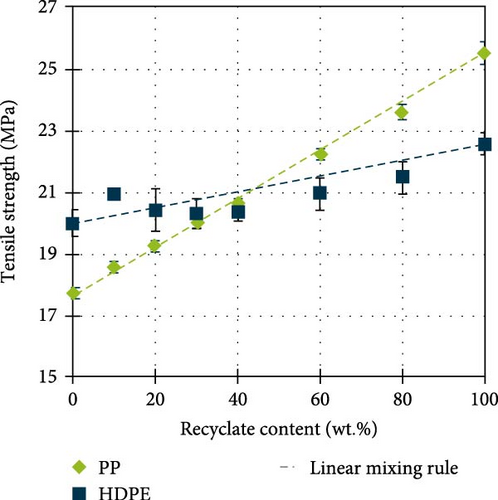

The results of the tensile tests are presented in Figure 8. The tensile strength and modulus of elasticity of the HDPE mixtures increase with increasing recyclate content. By adding 10% of recyclate the tensile strength slightly increases but falls again at 20% and stays almost equal until 40% (20.49–20.63 MPa). The increase from 40% to 100% is greater with 11% as depicted in Figure 8a. The modulus of elasticity of the tested HDPE also increases with increasing recyclate content but shows a less explicit development (Figure 8b). The modulus differs from 719.58 MPa (0%) to 840.05 (60%), respectively, 821.49 MPa (100%). The outlier behaviour at 60% could be explained by the overall more discontinuous fracture behaviour with increasing recyclate content, which is discussed in detail below.

In contrast to the HDPE, the mechanical properties of the PP increase almost linearly. With an increased recyclate content the tensile strength increases form 17.73 to 25.52 MPa (+44%), whereas the modulus of elasticity increases significantly from 880.58 to 1160.55 MPa (+32%). As stated before, the usage of recyclate HDPE and PP material does not generally reduce mechanical properties, since the recyclate processes strongly influence the thermally induced chain degradation, the resisting cross-linking, the molecular weight and the degree of crystallisation, which can also benefit the mechanics [19, 23, 24].

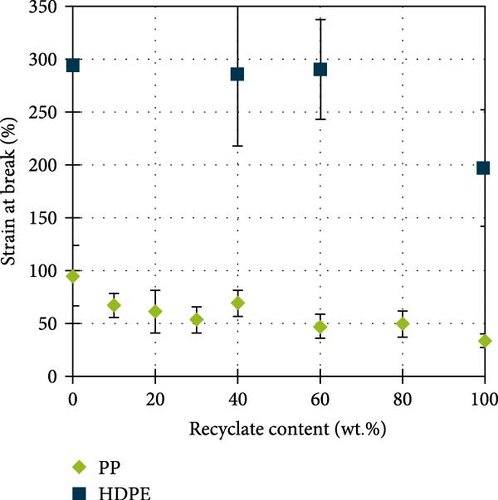

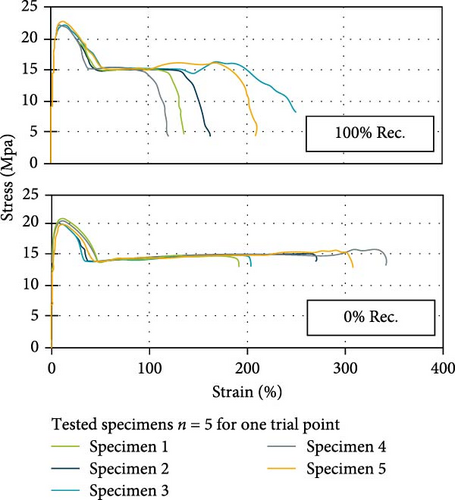

Even though the tensile strength and modulus of elasticity of the HDPE and PP mixtures show a tendency to increase with an increasing recyclate content the related breakage behaviour has to be analysed further, since it is vulnerable to the influence of contaminations and foreign polymers inside the matrix. Therefore, the strain at break for the different mixtures is depicted in Figure 9a.

For HDPE, only four measurements are presented since the maximum elongation or minimum measurable force is often reached during testing, which stops the procedure. Due to the high deviations, caused by the inconsistent breakage behaviour and high elasticity, the strain at break is difficult to interpret. With increasing recyclate content, the strain at break for HDPE seems to be stable up until 60% recyclate content but drops overall from about 290% to about 190% (−34.5%). It also decreases for the analysed PP mixtures by 64.3%. The high decrease over an increase in recyclate content can be explained when analysing the fracture surfaces in Figure 9b. The virgin material shows a relatively clean break that is initiated in one point and spreads almost radially. In contrast, the fractures of the material mixtures with an increased recyclate content show increasingly more fracture sources mostly due to contaminations, which cannot bond with the matrix material. The fractures are therefore more random, and the breakage behaviour is harder to predict. Even though the fracture pictures show a consistent increase in contaminations (Figure 9b), the fracture position was reproducible (Figure 7a) and the small deviations of the test results (Figure 8) allow the conclusion that the properties of the mixed-matrix material determine the modulus of elasticity and the tensile strengths while the contaminations are responsible for the final breakage behaviour.

To interpret the results further, the course of the fracture behaviour (stress over strain) for 0% and 100% recyclate content is presented in Figure 10. With a low proportion of recyclate, the samples break abruptly after pronounced plastic deformation. Whereas the samples of the recyclate at low strains of approximately 80%–120% initially exhibit flaking behaviour, but do not break. The recyclate samples continue to flake off as a result of the continuous stress (Figure 7b). At a recyclate content of 100%, the tests partially stopped before the samples broke due to insufficient residual stress.

The flaking of the material can also be seen in the stress–strain diagrams by a slow and specimen-dependent drop in stress as a comparison to the abruptly breaking samples of the virgin material processed with the same process parameters.

3.3.2. Part Quality Stability

Since the tensions rods are produced using a cold runner mould and two rods result from one process cycle, the part weight analysis is only presented for the casing geometry. The weight for both materials is examined and shown in Figure 11 relative to the recyclate content.

The shot weights for both materials slightly increase with the percentage of recycled material (PP: 12.17–12.22 g, HDPE: 12.86–12.93 g). Since the weight only differs by about 1%, application-specific tolerances could most likely still be fulfilled.

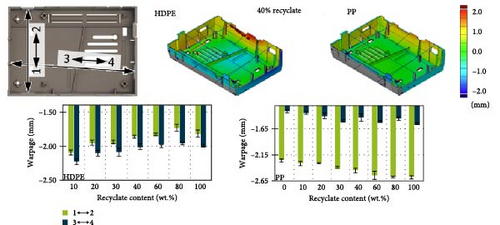

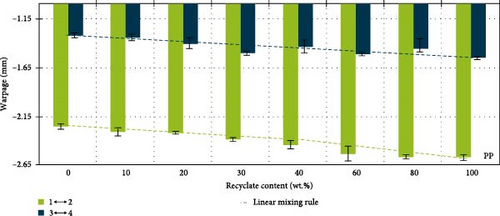

To further analyse the part quality stability, the part warpage due to material-specific shrinking is additionally analysed. Semicrystalline materials such as PP and PE have a higher shrinkage tendency than amorphous materials, which explains the overall high warpage of the casing geometries [42]. Due to the light colour of the virgin HDPE material, the laser system cannot measure the warpage of the 0% (virgin) HDPE recyclate parts. The resulting part warpage in relation to the optimal geometry is shown in Figure 12. For HDPE, the warpage in length and width decreases by 10.2 (1–2)%, respectively, 11.5 (3–4)% with an increase in recyclate content.

Figure 3 shows that the viscosity of the HDPE mixtures decreases as the percentage of recycled material increases. This improves the pressure transfer into the mould and is accompanied by a slight increase in weight (Figure 11) which could result in the improved dimensional tolerance.

The same trends cannot be determined for the PP warpage, as it increases with an increase in recyclate content. For PP, the viscosity and resulting pressure effects are not as significant, which leads to the conclusion that the material composition is the dominant factor for the warpage increase. The used virgin PP is a compound for technical applications and has a lower shrinkage potential than the recyclate material. The mineral contaminations, which are also present in PP recyclates, most likely still reduce the shrinkage in comparison to unfilled material, but the material properties of the virgin material are more prominent. Furthermore, the difference between the width and length warpage is greater than for HDPE.

To summarise the generated results and trends, Table 3 shows a comparison of the influence of the increasing recyclate content on the material and process properties as well as the mechanical characteristics discussed before for HDPE and PP.

| Material | HDPE | PP |

|---|---|---|

| Viscosity | Decrease | Stable |

| Maximum injection pressure | Decrease | Stable |

| Dosing torque | Decrease | Stable |

| Tensile strength | Increase | Increase |

| Modulus of elasticity | Increase | Increase |

| Strain at break | Decrease | Decrease |

| Part weight complex part | Stable | Stable |

| Warpage complex part | Decrease | Increase |

- Abbreviations: HDPE, high-density polyethylene; PP, polypropylene.

To interpret the results further, it should be taken into account that the miscibility behaviour is always a result of the respective properties of the blending partners. The application of mixing rules is therefore considered in more detail below.

3.4. Transfer of Mixing Rules Onto Process Key Figures and Geometric Properties

The use of mixing rules for virgin/virgin and partially virgin/recyclate materials has already been established for the resulting flow behaviour, tensile strength, and impact strength for selected material combinations [29, 33, 43, 44]. Figure 13 shows that the linear mixing rule can also be applied for the analysed virgin/recyclate PP mixtures regarding tensile strength, injection process key figures, and part warpage. Since no single value is obtained for the dosing torque, it is not included.

For HDPE, the linear approach also gives a close approximation for the tensile strength and maximum injection pressure, but due to the unsteady processing, the deviations are more significant than for PP. Since the warpage of the virgin HDPE component could not be measured, the mixing rule cannot be applied for the part geometry estimation of the HDPE mixtures. The differences in accuracy of the linear mixing rule for the two materials and different properties can be described through calculating the Pearson correlation as seen in Table 4.

| Material/geometry | Pearson correlation r [−] | |||

|---|---|---|---|---|

| PP | HDPE | |||

| Tension rod | Casing | Tension rod | Casing | |

| Tensile strength | 0.999 | — | 0.864 | — |

| Maximum injection pressure | 0.843 | 0.991 | 0.991 | 0.967 |

| Warpage 1–2 | — | 0.967 | — | — |

| Warpage 3–4 | — | 0.823 | — | — |

- Abbreviations: HDPE, high-density polyethylene; PP, polypropylene.

Overall, the Pearson correlation coefficient is >0.8, which shows a high correlation between the measured values and the approximate values according to the linear mixing rule. For some characteristics, the correlation is even greater than 0.99 and therefore applicable for the product development phase. The accurate prediction of the resulting mechanical properties as well as the part geometry is particularly relevant when considering the future increased use of recyclates in products with narrow tolerance specifications. Additionally, the transfer of mixing rules onto process parameters allows processors to decide whether a product can be produced in a specified virgin/recyclate ratio since for example, the maximal injection pressure (which can be a limiting parameter due to machine limits) can be estimated for a PCR material mixture.

4. Conclusion and Outlook

The aim of this work was to analyse the influence of different recyclate contents on the process stability and component quality in injection moulding. For this purpose, 16 material mixtures with different ratios were compounded from PP and HDPE virgin and post-consumer material. The mixtures were rheologically analysed and used to produce two different injection moulded geometries. Based on the data recording of the injection moulding tests, the process parameters were evaluated, and the manufactured components were mechanically and optically analysed. For the PP mixtures, no significant effect of the recyclate content on the rheological behaviour could be detected through viscosity measurements. The additional analysis of the process parameters injection pressure and torque confirmed this since the data showed a stable process over the different PP mixtures. Nevertheless, an influence on the mechanical and geometrical part properties was detected. An increased recyclate content led to an almost linear increase of tensile strength and modulus of elasticity, but a decrease in strain at break and less predictable breakage behaviour in general. Additionally, the warpage increased with an increase of PCR. The linear changes in maximum injection pressure, tensile strength and warpage, which were confirmed using the linear mixing rule, allow processors to draw simple conclusions about material mixtures with different recyclate proportions by means of extrapolation or interpolation.

In contrast, HDPE showed stronger effects of the recyclate content on the viscosity, which decreased with increasing recyclate content and led to an increase in injection pressure and torque during processing. The tensile strength and modulus of elasticity also increased with increasing recyclate content, whereas the strain at break and the warpage decreased. The progression over the increasing recyclate content is overall more irregular for HDPE. The linear mixing rule can also be applied to HDPE for the process key figures and tensile strength; however, the deviations from the approximation are higher.

The study shows that the influence of the recyclate content can be significant during processing and for the resulting part qualities. It is relevant to determine the material-specific effects since a stable process can still result in varying mechanical or geometrical part characteristics over a changing recyclate content.

Further material analyses should be carried out in the future to verify the hypotheses put forward in this research with regard to the material-specific and partially varying effects of the recyclate, since the analyses were only conducted for two specific recyclate materials. One step to generalise the results would be the analysis of the influence of different PCR qualities on the mixing behaviour with virgin material. Furthermore, the positive impact of the recyclate on the mechanical properties could be analysed in more detail using gel permeation chromatography to characterise the material. Since the properties of PCR material itself are strongly influenced by foreign polymers and impurities, an approach could also be developed that enables the determination of the crystallisation behaviour of foreign polymer mixtures with varying recyclate contents. Finally, the influence of the recyclate on shrinkage and warpage should be further investigated, for example by analysing the specific cooling behaviour of virgin/recyclate mixtures.

Disclosure

The responsibility for the content of this publication lies with the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Pia Wagner: formal analysis (lead), investigation (lead), methodology (lead), validation (lead), visualisation (lead), data curation (lead), writing–original draft (lead). Jan Kleinsorge: formal analysis (supporting), investigation (supporting), methodology (supporting), data curation (supporting), validation (supporting), writing–original draft (supporting). Christian Hopmann: conceptualisation (supporting), funding acquisition (lead), supervision (lead), writing–review and editing (lead), project administration (lead). All authors have read and agreed to the published version of the article.

Funding

The shown research is funded by the Federal Ministry of Education and Research (BMBF) (02J20E540). Open Access funding enabled and organized by Projekt DEAL.

Acknowledgments

The authors would like to thank the BMBF, the project management organisation in Karlsruhe (PTKA) and our project partners.

Open Research

Data Availability Statement

The datasets presented in this article are not readily available because they are part of an ongoing study. Requests to access the datasets should be directed to [email protected].