Impact of Molecular Weight Variation Among Rubber Clones on the Properties of Vulcanized Latex Films

Abstract

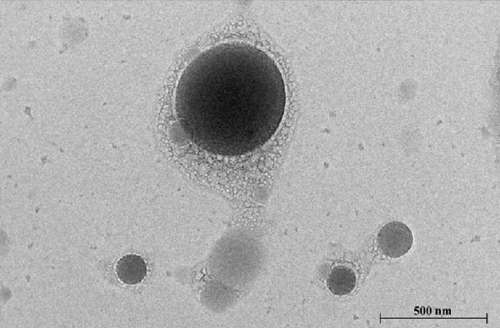

Vulcanized latex films from different Hevea brasiliensis natural rubber clones, including RRIM600, RRIT251, and PB235, were prepared using the creaming process of concentrated latex. The protein content, morphology, molecular weight distribution (MWD), mechanical properties, dynamic mechanical analysis, and thermo-mechanical properties were studied. The morphological characteristics of the Hevea brasiliensis natural rubber clones were analyzed using transmission electron microscopy (TEM). The results indicated that the particle sizes of the three clones ranged from 1.0 to 2.5 µm. Moreover, the MWD exhibited a bimodal pattern in the RRIM600 and RRIT251 clones, leading to a high polydispersity index (PDI) that correlates with protein content. Additionally, the PB235 clone showed higher molecular weight (Mw) than the other clones, which affected the properties of the vulcanized latex films. The mechanical properties, dynamic mechanical properties, thermal properties from temperature scanning stress relaxation (TSSR) analysis, and swelling resistance were also studied. The results indicated that the crosslinked density of the vulcanized latex films is related to the bimodal MWD. This leads to increased physical interactions between the end chains of short and long rubber molecules. Moreover, the crosslinked density is associated with protein content. This study confirms that the MWD and non-rubber components in different natural rubber clones affect the properties of vulcanized rubber.

1. Introduction

Hevea brasiliensis is a species of rubber tree native to the Amazon rainforest in South America, particularly Brazil, but it is now cultivated in various tropical regions around the world, including Southeast Asia, particularly in Thailand. In Thailand, the cultivation of rubber trees is widespread, with extensive plantations across various regions. However, the southern part of Thailand, particularly provinces like Songkhla, Surat Thani, and Trang, is especially known for its extensive rubber plantations. These regions offer favorable climatic conditions for rubber tree cultivation, including consistent rainfall and warm temperatures. The clone RRIM600 is grown in 75% of the rubber production areas in Thailand and other rubber-producing regions [1]. Following RRIM600, the RRIT251 and PB235 clones are also widely cultivated. These specific varieties of rubber tree clones have been developed for their desirable characteristics, particularly in terms of latex yield, disease resistance, wood quality, and latex properties. These clones have been created through selective breeding and research efforts to improve rubber tree cultivation and latex production.

The latex produced by Hevea brasiliensis contains about 60% water, 35% cis-1,4-polyisoprene (the primary component of natural rubber), and 5% non-rubber molecules [2]. The quantitative estimation of these components mainly depends on various parameters, including rubber clone, climate, soil quality, tapping methodology, and the geological location of the plantation [3]. These non-rubber components are biochemical compounds, primarily including proteins, lipids, and carbohydrates [4]. Their distribution within the latex fractions is not homogeneous and the non-rubber content varies among different rubber clones. Additionally, molecular weight (Mw) is an important parameter in different natural rubber clones as it affects their bulk properties. The Mw and molecular weight distribution (MWD) can significantly influence the mechanical properties of rubber [5, 6]. Generally, the mechanical properties of natural rubber, such as strength, elasticity, and resilience are influenced by various factors, including the Mw of the polymer chains in the rubber material. As the Mw of the polymer chains increases, the mechanical properties of the rubber tend to improve. This is because longer polymer chains provide more entanglements and cross-linking points, which enhance the material’s strength and elasticity [7]. The great variation in their Mw and MWD depends on clones, the age of the rubber trees, as well as soil and climate conditions of the plantation. It has been found that rubber from young trees has a unimodal MWD with a lower Mw than that of mature trees [5]. Tarachiwin, Sakdapipanich, and Tanaka [6] observed that the size of rubber particles is an important parameter affecting latex Mw in Hevea rubber trees. Wisunthorn et al. [8] characterized the mesostructure of two Hevea brasiliensis clones (RRIM600 and PB235). It was found that the macromolecular structure, especially the Mn and gel content, dramatically increased after fast structuring for both clones [8]. These results indicate that the dynamic structuring of natural rubber is dependent on genotype. Additionally, Thepchalerm et al. [9] studied the mesostructure of fresh natural rubber latex and creamed latex. They detected that the macromolecules in both latexes had bimodal elution profiles of long and short polyisoprene chains [9]. The MWD of rubber found in cultivated Hevea brasiliensis confirmed that the distribution of natural rubber was generally bimodal [10, 11].

This research work aimed to study the effect of three different natural rubber clones: RRIM600, RRIT251, and PB235 chosen for their differences in Mw and MWD. Fresh natural rubber latex from these three different clones were used to prepare concentrated natural rubber latex by creaming processes. In addition, the physical, mechanical, dynamic mechanical, thermo-mechanical properties, and crosslink density were investigated.

2. Materials and Methods

Hevea brasiliensis clones RRIM 600, RRIT251, and PB235 were used in this study. The samples were collected from a rubber plantation in Sadao, Songkhla, Thailand, approximately during the late part of the tapping season (May–June). The total solid content (TSC) of the collected latex samples were all in the range of 40%–45%. The fresh natural rubber latex was filtered through gauze to remove impurities and preserved by adding 0.25% v/v ammonia, which was purchased from RCI Lab-Scan Limited (Bangkok, Thailand).

Concentrated latex was prepared through a creaming process. The chemicals used for the creaming process included 1% (w/w in water) hydroxyethyl cellulose (HEC) from Ashland Industries Nederland B.V. (Zwijndrecht, Netherlands). The stability of the creamed system was improved by adding 20% (w/w) potassium laurate from Guangdong Kiyu New Material Co., Ltd. (Guangdong, China). Specifically, potassium laurate was added to the treated latex with continuous mechanical stirring for 5 min. Then, the creaming agent was thoroughly mixed into the latex and stirred at 120 rpm for 30 min. The mixture was then incubated at room temperature for 7 days to separate the cream and serum fractions, following the method used in our previous work [11]. The resulting cream fraction was used to prepare the latex compound for pre-vulcanization. The specifications of the creamed concentrated latex from the three Hevea brasiliensis clones (RRIM600, RRIT251, and PB235) are provided in Table 1.

| Properties | Hevea brasiliensis clones | ||

|---|---|---|---|

| RRIM600 | RRIT251 | PB235 | |

| Total solid content (TSC) (%) | 56.00 ± 0.020 | 54.00 ± 0.049 | 66.00 ± 0.054 |

| Dry rubber content (DRC) (%) | 55.00 ± 0.058 | 52.00 ± 1.266 | 65.00 ± 0.021 |

| Protein content (%w/w) | 2.20 ± 0.002 | 2.93 ± 0.009 | 1.64 ± 0.004 |

| Viscosity (cps) (spin no.1/speed 60 rpm) | 46.00 | 41.00 | 75.50 |

- Note: These properties followed from our previous work.

The chemical agents used for the latex compound were potassium laurate and potassium hydroxide (KOH, stabilizer) purchased from Loba Chemie Pvt. Ltd., (Mumbai, India); zinc oxide (ZnO, activator); zinc N-diethyl dithiocarbamate (ZDEC, accelerator); Wingstay L (antioxidant); and sulfur (vulcanizing agent), all of which were obtained from Siam Chemical Industry Co., Ltd. (Samudprakarn, Thailand).

2.1. Preparation of Pre-vulcanized Latex Films

The creamed latex compound was prepared by compounding the ingredients as shown in Table 2. Sulfur and other ingredients for curing were added to creamed latex in the form of dispersions under slow stirring around at 90 rpm for 24 h at room temperature for maturation. After attaining proper maturation, latex films from three Hevea brasiliensis clones, namely RRIM600, RRT251, and PB235 were prepared from sulfur pre-vulcanized compounded by casting methods. Latex films were cast onto a glass plate and dried in the oven at 100°C for 30 min. The dried latex films were then stripped from a glass plate and stored in the desiccators before further tests. The process of pre-vulcanized latex films is illustrated schematically in Figure 1.

| Total solid content (TSC) | Ingredient | Parts by weight (phra) |

|---|---|---|

|

Creamed latex from three Hevea brasiliensis clones | 100 |

| 50% | ZnO dispersion | 1.0 |

| 50% | ZDEC dispersion | 1.0 |

| 50% | Wing stay-L dispersion | 1.0 |

| 20% | Potassium laurate | 1.0 |

| 10% | Potassium hydroxide | 0.5 |

| 50% | Sulfur dispersion | 2.0 |

- aphr = part per hundred of rubber by mass.

3. Characterization

3.1. Determination of Protein Contents

Regarding to our previous work [12], the protein content was determined using the Kjeldahl method, which involves nitrogen quantification, following the protocols outlined in the Association of Official Analytical Chemists (AOAC) and Official Methods of Analysis of Fertilizers (OMAF). Briefly, 0.1 g of latex was mixed with a 0.65 g catalyst and digested in concentrated sulfuric acid (H2SO4) until fully dissolved. An alkaline solution (67% w/v NaOH) was then added and the mixture was distilled. The distillate was collected in boric acid and titrated with 0.01 N H2SO4 to determine ammonia content. Protein content was estimated by multiplying nitrogen mass by 6.25.

3.2. Gel Permeation Chromatography (GPC)

The Mw values, including number-average molecular weight (Mn), weight-average molecular weight (Mw), Z-average molecular weight (Mz), and polydispersity index (PDI), of the fresh natural rubber latex were investigated using GPC (1260 Infinity II GPC/SEC MDS, Agilent Technologies, Germany) with a refractive index detector. Tetrahydrofuran (THF) was used as the mobile phase at a flow rate of 1.0 mL/min at 40°C. Approximately 10 g of fresh natural rubber latex was weighed into Petri dishes and dried at 60°C for 4 h. The dried samples were then dissolved in THF at a concentration of 0.10% w/v. The dissolved samples were subsequently filtered through a 0.45 µm nylon membrane filter before analysis.

3.3. Transmission Electron Microscopy (TEM) Analysis

The morphology of fresh natural rubber latex and creamed concentrated latex surface were analyzed using a transmission electron microscope, model Jem 2010, Japan with 160 kV with a magnification of 6000x and 25,000x. Before analysis, both types of latex were diluted with deionized water to a concentration of 0.025 wt%. An aqueous solution of OsO4 (2 wt%) was then added into the diluted latex and allowed to stain the rubber molecule overnight. After that, one drop of the latex suspension was put on copper grid and allowed to dry before observation [12].

3.4. Mechanical Properties

The mechanical properties like tensile strength, elongation at break, modulus, and tear strength were measured with an Instron machine (Model 3365) with a load cell of 1000 N at a cross-head speed of 500 mm/min. The tensile experiments were prepared dumbbell shape test specimens in accordance with ASTM D 412 standard. The tear strengths were estimated following ASTM D 624 using unnicked 90° angle test pieces. The hardness was measured according to ASTM 2240 using a Shore A durometer (Frank GmbH, Hamburg, Germany).

3.5. Dynamic Mechanical Analysis

Dynamic mechanical properties of vulcanized latex film were analyzed using a dynamic mechanical analyzer, DMA 1 Mettler Toledo, Switzerland. The test was measured in tension mode at heating rate of 5°C/min and frequency of 5 Hz. The storage (E’) and loss (E”) modulus together with tan δ were determined from the DMA thermograms.

3.6. Temperature Scanning Stress Relaxation (TSSR) Measurement

In TSSR measurement, the thermo-mechanical behavior of natural rubber was investigated by a TSSR Meter (Brabender, Germany). The TSSR test had two stages: isothermal and non-isothermal conditions. In the isothermal stage, the rubber samples were placed in the TSSR chamber and elongated to approximately 75% strain at 23°C for 2 h to allow for short-time relaxations. After that, the non-isothermal test was performed by raising the temperature at 23–220°C with a constant heating rate of 2°C/min until the stress relaxation was completed or the sample break. The TSSR results in terms of initial force (σ0), T10, T50, T90, and crosslink density were obtained from each relaxation spectrum. It is noted that the T10, T50, and T90 represent the stress declines by 10%, 50%, and 90% from the initial stress. Furthermore, T90 could be used to determine the level of thermo-oxidative degradation of polymer chains [13].

3.7. Determination of Crosslink Density

4. Results and Discussion

4.1. Molar Mass Distribution (MMD)

The MMDs of fresh natural rubber latex from three different Hevea brasiliensis clones, namely, RRIM600, RRIT251, and PB235 are shown in Figure 2. The MMD of fresh natural rubber latex confirmed that the RRIM600 and RRIT251 clones exhibited a bimodal distribution, whereas the PB235 clone showed a quasi-unimodal distribution. The PB235 clone contained a smaller quantity of short chains. In terms of macromolecular structure, the main difference between bimodal and quasi-unimodal MMD lies in the Mn, as shown in Table 3. The RRIM600 and RRIT251 clones, with bimodal MMD, had Mn values ranging from 370–385 kg/mol, while PB235 had a higher Mn of 434 kg/mol. This is because the PB235 clone has fewer short chains or a higher proportion of long chains in its rubber molecules, resulting in the highest Mn.

| Parameters | Hevea brasiliensis clones | ||

|---|---|---|---|

| RRIM600 | RRIT251 | PB235 | |

| Number-average molar mass (kg/mol) | 381 | 372 | 434 |

| Weight-average molar mass (kg/mol) | 1961 | 1683 | 2022 |

| Z-average molar mass (kg/mol) | 4012 | 3306 | 3864 |

| Polydispersity index | 5.14 | 4.53 | 4.66 |

The PB235 clone also had the largest Mw of 2022 kg/mol and the narrowest molecular mass distribution, while the RRIT251 and RRIM600 clones had lower Mw values of about 1683 and 1961 kg/mol, respectively, with the broadest MWD. The Mz of the RRIM600 clone (4012 kg/mol) was higher than that of the PB235 clone (3864 kg/mol). The higher Mz in RRIM600 may be due to increased interactions or linkages between rubber chains in bimodal clones [15]. Mz is sensitive to larger molecules and influences viscoelasticity and melt flow behavior. The large quantity of short chains in the bimodal distribution of the RRIM600 clone likely resulted in many chain ends or terminals in natural rubber molecules. The PDI was relatively narrow, ranging from 4 to 5, across all the rubber clones studied. The RRIM600 clone had a PDI of 5.14, higher than the other clones, indicating a wider MWD. However, the low Mw fraction of natural rubber consists of linear polymers, while the high Mw fraction consists of branched molecules [7, 16].

Generally, natural rubber contains a very high Mw fraction with a wide range of MWD. This suggests that the local environment, especially the ecosystem of the native trees, can strongly influence the Mw of rubber [5].

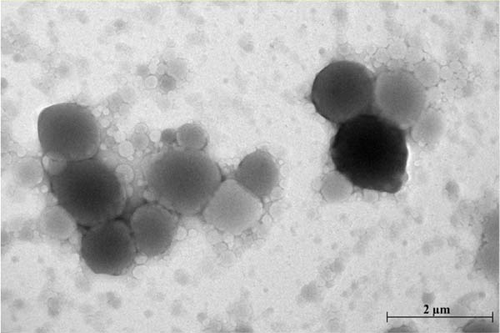

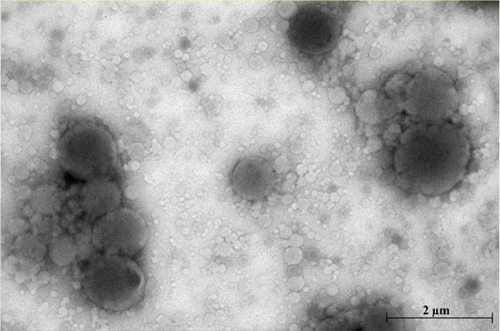

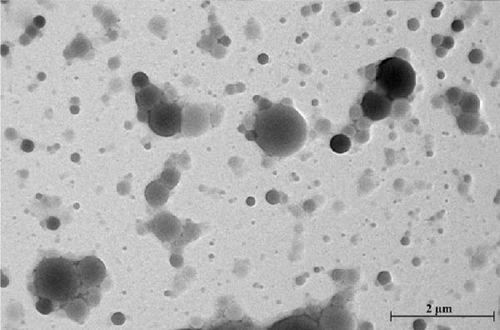

4.2. Morphological and Structural Characterization

Transmission electron micrographs revealed the microstructure of rubber particles in fresh natural rubber latex from all three clones, as shown in Figure 3. The results indicated that rubber particles in all clones were predominantly spherical in shape and were surrounded by non-rubber components, including lutoids and Frey–Wyssling particles on their surfaces. Each clone exhibited both large and small rubber particles. However, the PB235 clone had the smallest particles with no significant agglomeration (heavy clustering) of rubber particles [12]. To better visualize the rubber particles, PB235 latex was examined at 25,000x magnification (Figure 3d), revealing rubber particles surrounded by non-rubber components. The relationship between Mw and the size of rubber particles varied among the clones.

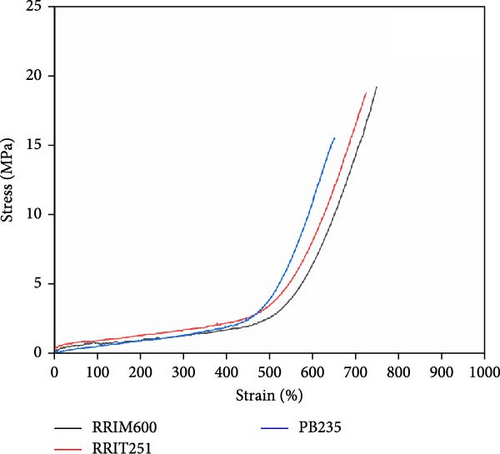

4.3. Mechanical Properties

The mechanical properties of vulcanized latex films from various rubber clones are shown in Table 4. The results indicate that the RRIM600 clone exhibits the highest tensile strength (21.77 MPa) and the highest elongation at break (737%). This could be attributed to its high PDI (PDI = 5.14), suggesting a wide distribution of Mws which might be influent to the crosslink density of rubber. This broad distribution may be due to the presence of both short and long rubber molecular chains, which facilitate chain entanglement at the ends of these molecular chains.

| Properties | Hevea brasiliensis clones | ||

|---|---|---|---|

| RRIM600 | RRIT251 | PB235 | |

| 100% modulus (MPa) | 0.63 ± 0.03 | 0.93 ± 0.01 | 0.61 ± 0.01 |

| Tensile strength (MPa) | 21.77 ± 1.39 | 18.47 ± 0.29 | 15.56 ± 0.04 |

| Elongation at break (%) | 737 ± 9.40 | 726 ± 2.02 | 685 ± 3.13 |

| Tear strength (N/mm) | 77.17 ± 0.95 | 75.23 ± 0.16 | 89.33 ± 0.45 |

| Hardness (Shore A) | 42.80 ± 0.8 | 42.50 ± 0.7 | 44.50 ± 0.5 |

In contrast, the PB235 clone has the highest tear resistance (89.33 N/mm). This behavior is likely due to the higher Mw of the PB235 clone, In general, a higher Mw of rubber leads to a greater tear strength, meaning that a rubber with a higher Mw provides more resistant to tearing; essentially, longer polymer chains create more entanglement points, making it harder for a tear to propagate through the rubber, thereby improving tear resistance [5]. The hardness properties for all three clones fall within a similar range, specifically between 42 and 44 Shore A. The detailed mechanical properties of the vulcanized latex films from the three clones are presented in Table 4.

Additionally, the stress–strain curves of vulcanized latex films from the different clones are depicted in Figure 4. These curves reveal that the stress behavior of the vulcanized latex films from each clone follows a similar trend. Below 400% strain, the stress gradually increases due to the chain entanglement of rubber molecular chains. Beyond 400% strain, the stress increases markedly and continues to rise significantly until the point of fracture. This behavior can be attributed to strain-induced crystallization (SIC) during the elongation of the vulcanized latex films. During this phase, the RRIT251 clone, which has the highest protein content (2.93 wt%), shows the greatest initial increase in stress compared to the other two clones. These characteristics suggest that the presence of non-rubber components in the rubber molecules directly influences the occurrence of SIC.

Latex clones with a bimodal MWD exhibit higher tensile strength and elongation at break. A bimodal MWD indicates the presence of more short chains in the rubber molecules. This behavior leads to physical crosslinking between the end groups of short chains or between short and long chains. Moreover, latex clones with higher protein content also show higher tensile strength and elongation at break, as the end groups of rubber molecular chains more easily contribute to physical crosslinking or entanglement in the rubber molecular chains.

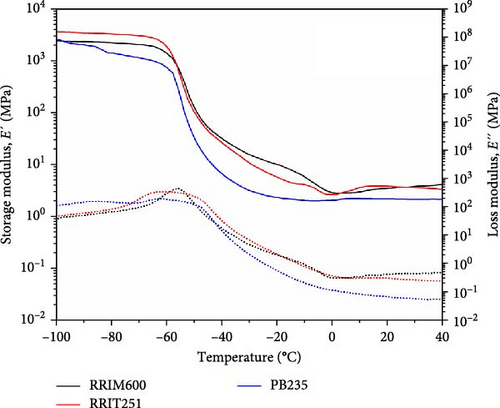

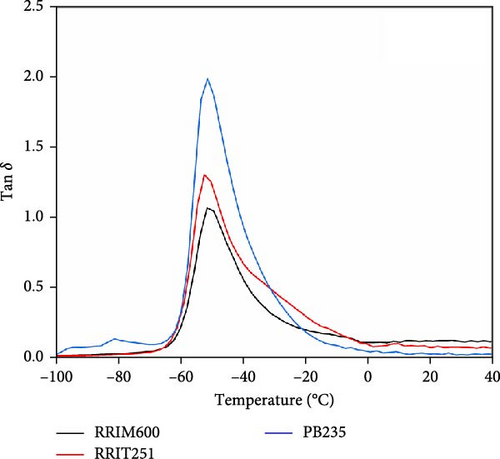

4.4. Dynamic Mechanical Analysis

Dynamic mechanical properties evaluate the viscoelastic behavior of polymers or rubber, typically using a dynamic mechanical thermal analyzer (DMTA) in temperature mode. This analysis aims to investigate the viscoelastic behavior of vulcanized latex films, focusing on parameters such as storage modulus (E′), loss modulus (E″), and tan delta (tan δ). The experimental results are shown in Figures 5 and 6. Generally, the storage modulus indicates the energy absorbed or the stiffness of the material, while the loss modulus indicates the energy dissipated.

Figure 5 illustrates the relationship between storage modulus and temperature for various natural rubber clones, revealing three distinct phases:

State I (glassy state): In the temperature range of −100 to −60°C, the vulcanized latex film from the RRIT251 clone exhibits the highest storage modulus compared to the other clones. This is attributed to the presence of a bimodal MWD and higher protein content, which may increase interactions between non-rubber components (proteins) and the rubber molecular chains. These results align with the findings of Nun-anan et al. [11], which also indicated that the RRIM600 clone has a higher storage modulus than the PB235 clone, likely due to higher gel content and greater molecular chain entanglement. In contrast, the PB235 clone exhibits the highest loss modulus and tan δ values, which may result from its high Mw and unimodal MWD, suggesting a significant number of long molecular chains. These long chains hinder molecular mobility, requiring more energy for movement and state transition.

State II (glass transition state): In the temperature range of −60°C to −20°C, this phase represents the transition of rubber from a glassy state to a rubber-like state, indicating elastic properties [17, 18]. During this phase, both storage modulus and loss modulus gradually decrease as temperature increases. Tan δ indicates the glass transition temperature (Tg), as summarized in Table 5, which reflects the ease of state transition and molecular chain mobility. The Tg of the vulcanized latex films from the RRIM600 and RRIT251 clones is approximately −54°C, while the Tg for the PB235 clone is slightly higher at −53°C. The higher Tg of the PB235 clone is due to its high Mw, leading to greater molecular chain entanglement and restricted molecular mobility. This result is consistent with the Mw data in Table 3, which shows that PB235 has a higher Mw compared to the other two clones.

| Hevea brasiliensis clones | Tg (°C) |

|---|---|

| RRIM600 | −54.28 |

| RRIT251 | −54.18 |

| PB235 | −53.08 |

State III (rubber-like state): At temperatures above −20°C [17, 18], this phase represents the flow characteristics of rubber molecules. It can be observed that both the storage modulus and loss modulus correlate with PDI. The RRIM600 and RRIT251 clones exhibit higher values compared to the PB235 clone.

4.5. TSSR

TSSR is a crucial property for predicting the long-term performance and durability of rubber-containing components under various loading conditions [19]. Therefore, the TSSR technique was characterized in this study. TSSR can indicate the thermo-elastic properties and stress relaxation behaviors of rubber.

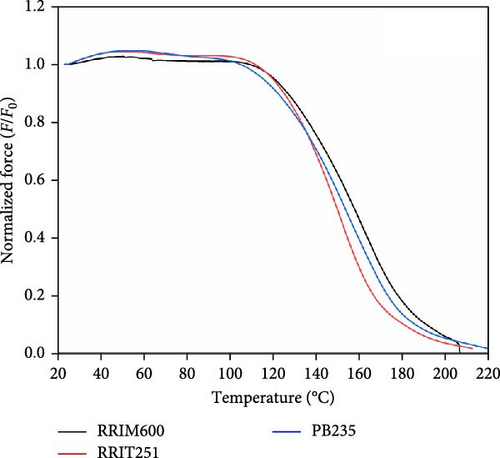

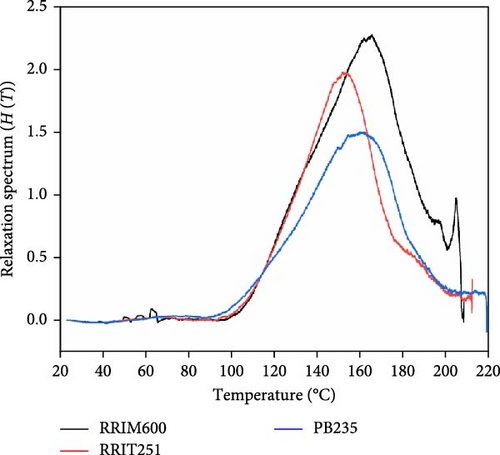

Figure 7 presents the normalized force as a function of temperature in non-isothermal relaxation mode. It is noted that the normalized force was calculated by using the stress values from the TSSR measurement. It was observed that the initial stress in each of the natural rubber clones decreases over time under constant strain. This decrease is attributed to the rearrangement of rubber molecular chains, leading to shape changes due to applied stress and increased energy dissipation between the molecular chains. This process results in the formation of microaggregates and macroaggregates of molecules [19]. These characteristics demonstrate the viscoelastic behavior of rubber. Additionally, the interaction of proteins inhibits the movement of rubber molecular chains, reducing the stress relaxation of these chains [19]. Figure 8 displays the relaxation spectrum as a function of temperature of the vulcanized latex. The intensity peaks observed at 100–200°C indicated the cleavage of crosslink bridges and/or scission of the rubber main chain due to the thermo-oxidative decomposition of the NR molecules under stress.

Furthermore, the heat resistance of vulcanized latex films from the three different clones was evaluated using the TSSR technique. The parameters T10, T50, and T90 are presented in Table 6. The initial stress values, T10, T50, and T90, are highest in the clones with the greatest MWD and highest PDI. The RRIM600 has the highest PDI, indicating more short chains and chain-ends of natural rubber which could delay chain scission during thermo-oxidative degradation, resulting in the higher thermal stability. The crosslink density of the RRIT251 and RRIM600 clones is higher than that of the PB235 clone, indicating that a higher protein content leads to increased chain entanglement in the rubber molecules.

| Properties | Hevea brasiliensis clones | ||

|---|---|---|---|

| RRIM600 | RRIT251 | PB235 | |

| σ0 (MPa) | 0.72 | 0.55 | 0.50 |

| T10 (°C) | 126.90 | 125.20 | 122.30 |

| T50 (°C) | 157.90 | 149.80 | 153.60 |

| T90 (°C) | 191.20 | 180.70 | 186.10 |

| υ ((mol/m3) | 102.83 | 103.96 | 96.96 |

4.6. Crosslink Density Analysis

The solvent resistance tests on vulcanized latex films from the three rubber clones are shown in Table 7. The results indicate that the vulcanized latex films from the PB235 clone exhibited the highest swelling ratio at 365%. This may be attributed to the natural rubber molecules, which contain hydrocarbon compounds in their structure, making them more soluble in nonpolar solvents. Additionally, the PB235 clone, with its high Mw and a significant number of dispersed molecular chains, allows solvents to penetrate and interact with the molecular chains more easily, leading to greater swelling. Furthermore, incomplete vulcanization might result in fewer crosslinks between natural rubber chains, contributing to a lower crosslink density, as shown in Table 7.

| Hevea brasiliensis clones | Swelling ratio (%) | Crosslink density (× 10−5) (mol/cm3) |

|---|---|---|

| RRIM600 | 350.23 ± 1.60 | 1.01 ± 0.01 |

| RRIT251 | 340.67 ± 1.51 | 1.36 ± 0.02 |

| PB235 | 365.38 ± 1.90 | 0.79 ± 0.01 |

In contrast, the RRIT251 rubber film demonstrates the highest crosslink density. This is due to the vulcanization process, where sulfur facilitates cross-linking between rubber molecules at reactive sites upon heating. As a result, the rubber molecules become larger and stronger, reducing their solubility in solvents. Therefore, the RRIT251 rubber film exhibits the lowest swelling ratio at 341%, indicating the best resistance to swelling. Despite having the highest cross-linking density, the RRIT251 clone exhibited the lower tensile strength and thermal stability (T90) than RRIM600. This might be due to its lower Mw and PDI, resulting in reduced tensile strength and thermal stability compared to RRIM600 clone.

5. Conclusion

The latex films from fresh latex of three clones, including RRIM600, RRIT251, and PB235, were successfully prepared using HEC as the creaming agent. Each rubber clone exhibits different values for DRC, TSC, protein content, and rubber particle size. The Mw of the latex from the three clones revealed the highest value in the PB235 clone with 2022 kg/mol. The pre-vulcanized latex was prepared by incubating the latex for 24 h. The mechanical properties, dynamic properties, TSSR, and crosslink density of the vulcanized latex films from the three clones indicate that the properties of each vulcanized latex film are largely correlated with the non-rubber components, particularly the differing protein content, and the varying Mws of each clone. The crosslink density of the vulcanized latex films is related to the bimodal MWD and protein content. This leads to increased physical interactions between the end chains of short and long rubber molecules, enhancing the mechanical properties in term of modulus, tensile strength, elongation at break as well as solvent resistance, and thermal stability. In contrast, the PB235 clone exhibited superior tear resistance caused by high Mw of rubber led to the higher chain entanglement.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This research was supported by National Science, Research and Innovation Fund (NSRF) and Prince of Songkla University (Grant no. SCI6601162S).

Acknowledgments

This research was supported by National Science, Research and Innovation Fund (NSRF) and Prince of Songkla University (Grant no. SCI6601162S). The authors would like to express their gratitude to the Faculty of Science, Prince of Songkla University, Hat Yai Campus.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.